Abstract

Phosphines are an important class of ligands in the field of metal-catalysis. This has spurred the development of new routes toward functionalized phosphines. Some of the most important C–P bond formation strategies were reviewed and organized according to the hybridization of carbon in the newly formed C–P bond.

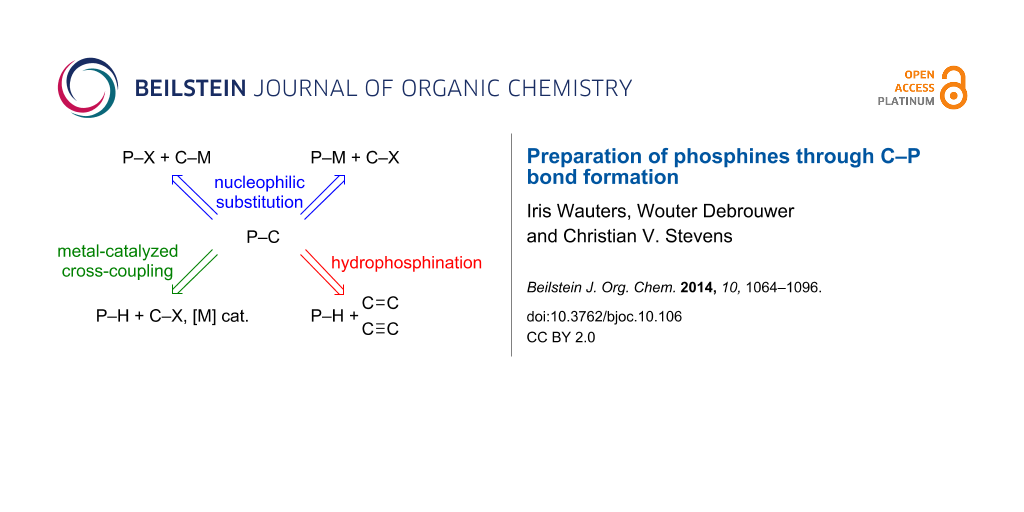

Graphical Abstract

Introduction

Phosphines are an important class of organophosphorus compounds. They are often used as ligands in metal complex catalysis and they have become a popular reagent for organocatalysis [1]. The methods most widely used for the synthesis of phosphines include the reaction of organometallic compounds with halophosphines, the reaction of metal phosphides with alkyl halides, the reduction of other phosphorus compounds and the hydrophosphination [2]. Research in the past years has focused on the catalytic synthesis of phosphines [3,4]. The asymmetric catalytic synthesis of chiral phosphines has only recently emerged and is under full development. Chiral phosphines are interesting ligands for the preparation of transition metal complex catalysts for asymmetric synthesis [5,6]. Only a minor part of the chiral phosphines are chiral at the phosphorus atom (P-stereogenic) [7-9].

A major drawback of phosphines is their highly oxidizable nature. They are easily converted to the corresponding phosphine oxide which makes the isolation difficult. To prevent losses during purification, the phosphines are sometimes deliberately transformed into the corresponding oxides (or sulfides). However, this requires an additional reduction step afterwards to get the phosphine back [10-15]. Therefore phosphines are sometimes protected by generation of the corresponding phosphine–borane complex [16,17]. The phosphine–borane complex is a stable intermediate toward the free phosphine. If necessary the boranato group can be removed by treatment with an excess of amine [18]. However, not all phosphines are prone to oxidation and show good air-stability [19].

This review will provide a general overview on phosphine synthesis over the last 10 to 15 years. Only reactions establishing a C–P bond will be discussed. The synthesis of phosphine-based polymers was not included [20]. Reactions involving pentavalent phosphorus derivatives (phosphine oxides, phosphonates, phosphinates and phosphate derivatives, etc.) are out of the scope of this review.

Review

Preparation of alkylphosphines via formation of a C(sp3)–P bond

Reaction of organometallic reagents with halophosphines

One of the main approaches to synthesize a carbon–phosphorus bond involves the displacement of a halogen atom from phosphorus by an organometallic reagent. This method has proven its usefulness for many years. A variety of organometallic compounds have been described. Most frequently used are the Grignard [21,22] and lithium species. But also organozinc [23,24], organolead [25], organomercury [26] or aluminum-based [27] reagents have been used. However, nowadays it is recommended to avoid the use of certain reagents such as organomercury or organolead compounds as they pose a serious toxicological hazard [28,29].

Despite the fact that the methodology is historically useful it also has major drawbacks. The presence of an anionic carbon reagent in the reaction restricts the scope of the methodology. The aspired phosphines cannot contain certain functional groups that are able to react with the organometallic compound. Further, stoichiometric amounts of reagents are required. Also, attention should be paid to the handling of halophosphines as some of the simple alkyldichlorophosphines are extremely corrosive and flammable in air.

Asymmetric phosphines are difficult to access via a nucleophilic substitution at a halophosphine due to the limited availability of unsymmetrical halophosphines and their weak configurational stability. P-stereogenic chlorophosphines racemize easily even at room temperature [30].

Enantiopure P-stereogenic compounds can be synthesized via a diastereoselective nucleophilic substitution at phosphorus utilizing chiral auxiliaries. Diastereomeric intermediates are formed that are separable by chromatography or recrystallization. The protocol has proven to be effective and has become the preferred approach for the synthesis of chiral phosphines. Commonly used chiral auxiliaries are chiral secondary alcohols (for example (−)-menthol (3), endo-borneol, etc.) or thiols that are reacted with halophosphines [31-34].

The diastereoisomers of menthylphosphinite boranes are popular synthetic intermediates for this approach (Scheme 1) [35]. The diastereomeric phosphinites 2, that were prepared from an alkyldichlorophosphine 1, were separated by preparative HPLC or recrystallization. Nucleophilic substitution of pure diastereomer (RP)-2a with methyllithium afforded the phosphine–borane (S)-4 with 94% enantiomeric excess. The substitution resulted in inversion of the configuration at the phosphorus center. Deboranation of the air stable borane adduct (S)-4 to obtain 5, was achieved by treatment with N-methylpyrrolidine.

Scheme 1: Synthesis of P-stereogenic phosphines 5 using menthylphosphinite borane diastereomers 2.

Scheme 1: Synthesis of P-stereogenic phosphines 5 using menthylphosphinite borane diastereomers 2.

An alternative method is based on ephedrine as a chiral auxiliary and was developed by Genêt and Jugé [36,37]. The key synthetic intermediates in this approach are 1,3,2-oxazaphospholidine boranes 7. These compounds are the result of the reaction between bis(diethylamino)alkylphosphine 6 and ephedrine, followed by protection with borane. The subsequent stereoselective ring opening of compound 7 with an organolithium reagent gives way to acyclic products 8 with retention of configuration at the phosphorus center. These phosphamide boranes 8 undergo methanolysis with inversion of configuration to produce intermediate phosphinite boranes 9 that are subsequently substituted with a second nucleophile. A following deprotection of the boranato group gives the chiral phosphines 10. Both enantiomers can be obtained by preparation of different starting oxazaphospholidine borane complexes 7 from (−)-ephedrine or (+)-ephedrine [38] or by starting from the same oxazaphospholidine borane adduct 7 and then changing the order of addition of the organolithium reagents (Scheme 2).

Scheme 2: Enantioselective synthesis of chiral phosphines 10 with ephedrine as a chiral auxiliary.

Scheme 2: Enantioselective synthesis of chiral phosphines 10 with ephedrine as a chiral auxiliary.

Acidolysis with HCl of compounds 8a results in the stereoselective synthesis of chiral chlorophosphine boranes 11a [39]. The borane complex has a good configurational stability with borane as a protecting group, in contrast to chlorophosphines that can undergo inversion at the phosphorus center [30]. They allow the synthesis of a variety of P-chiral tertiary phosphine boranes 12a via substitution of the chlorine atom with organometallic nucleophiles. This substitution causes an inversion of configuration at the phosphorus center (Scheme 3). Schuman et al. have prepared several dialkenylphosphines using this methodology [40].

Scheme 3: Chlorophosphine boranes 11a as P-chirogenic electrophilic building blocks.

Scheme 3: Chlorophosphine boranes 11a as P-chirogenic electrophilic building blocks.

Nucleophilic substitution with metallated organophosphines

Another classical method for the preparation of phosphines is the nucleophilic substitution of alkyl halides with phosphide anions derived from secondary phosphines or phosphine–borane complexes [41]. This approach requires stoichiometric amounts of base. Numerous examples of this approach are available [22,42-48].

In recent years methodologies were developed for the asymmetric alkylation. Livinghouse and Wolfe have reported an enantioselective method for the preparation of chiral tertiary phosphine–boranes starting from a racemic secondary phosphine borane precursor such as 13a (Table 1) [49]. A nucleophilic phosphide reagent was prepared by deprotonation of 13a in the presence of (−)-sparteine. The subsequent alkylation of the lithium phosphide with an electrophile proceeded with good enantiocontrol via dynamic resolution. One enantiomer is thermodynamically favored by the spartein auxiliary. The enantioselectivity was found to be time and temperature dependent. Simple stirring of the intermediate (−)-sparteine–lithium complex of 13a for 1 h at 25 °C prior to alkylation resulted in an increase in enantiomeric excess of 14a.

The organocatalyst 16 has also been used to carry out an asymmetric alkylation reaction (Scheme 4). The monoalkylation of phosphine–borane complex 15 was performed in the presence of the Cinchona alkaloid ammonium salt 16 [50]. However, the enantioselectivity of the reaction was low.

Scheme 4: Monoalkylation of phenylphosphine borane 15 with methyl iodide in the presence of Cinchona alkaloid-derived catalyst 16.

Scheme 4: Monoalkylation of phenylphosphine borane 15 with methyl iodide in the presence of Cinchona alkaloid...

Imamoto et al. prepared a new tetraphosphine ligand 19 by deprotonation of enantiopure secondary diphosphine borane 17 at low temperature (Scheme 5) [51]. The configuration was retained during the nucleophilic attack at 18. This approach provides a very straightforward access to P-stereogenic tertiary phosphines but requires the availability of P-chiral substrates.

Scheme 5: Preparation of tetraphosphine borane 19.

Scheme 5: Preparation of tetraphosphine borane 19.

Jugé and co-workers synthesized chiral tertiary phosphine–borane complexes 12b starting from P-stereogenic chlorophosphine–borane complexes 11b (Scheme 6) [52]. These complexes are accessible with the ephedrine methodology (vide supra). Treatment of 11b with t-butyllithium leads to metal–halogen exchange. After reaction of the phosphide anion 20 with an electrophile, the chiral tertiary phosphine boranes 12b are formed with retention of configuration at the phosphorus atom.

Scheme 6: Using chiral chlorophosphine-boranes 11b as phosphide borane 20 precursors.

Scheme 6: Using chiral chlorophosphine-boranes 11b as phosphide borane 20 precursors.

Catalytic C(sp3)–P bond formation

Only a few examples of a metal catalyzed C(sp3)–P cross-coupling exist and they are mostly restricted to benzylic and allylic coupling partners.

Ager and Laneman have synthesized tertiary phosphine oxide 23 through the nickel-catalyzed coupling of benzyl bromide (21a) with diphenylphosphine chloride (22a) (Scheme 7) [53]. However oxidation occurred during work-up.

Scheme 7: Nickel-catalyzed cross-coupling (dppe = 1,2-bis(diphenylphosphino)ethane).

Scheme 7: Nickel-catalyzed cross-coupling (dppe = 1,2-bis(diphenylphosphino)ethane).

The group of Togni has investigated a palladium-catalyzed enantioselective coupling reaction between allylic substrates 24 and several secondary phosphines 25a as nucleophiles [54]. The scope of the reaction was limited to 1,3-diphenylallyl acetate 24. The reaction produced not only 26, but gave several side products 27–29 (Table 2).

Another example of a C(sp3)–P cross-coupling was reported by Lanteri et al. [55]. A palladium catalyst effectuated the coupling of n-Bu3SnPPh2 (30) with several perfluoroalkyl iodides 31 (Scheme 8). The stannane 30 was in situ generated by the reaction of the diphenylphosphide anion with n-Bu3SnCl. After oxidation, the perfluoroalkyl-substituted phosphine oxides 32 were obtained in low to moderate yields (15–51%) although full conversion was observed. The byproduct formed was reduced perfluoroalkane HCnF2n+1.

Scheme 8: Pd-catalyzed cross-coupling reaction with organophosphorus stannanes 30.

Scheme 8: Pd-catalyzed cross-coupling reaction with organophosphorus stannanes 30.

Ethyl diazoacetate (33) was reacted with the secondary phosphine borane 13a in the presence of a copper catalyst [56]. The product 14b was obtained in good yield with retention of configuration at the phosphorus center (Scheme 9). Other chiral phosphine boranes 13 were reacted similarly. This protocol is limited to the availability of these chiral substrates.

Scheme 9: Copper iodide catalyzed carbon–phosphorus bond formation.

Scheme 9: Copper iodide catalyzed carbon–phosphorus bond formation.

Protocols for the enantioselective cross-coupling of benzyl or alkyl halides with racemic secondary phosphines have been developed. These reactions were catalyzed by chiral platinum or ruthenium complexes. The enantioselectivity is based on a dynamic kinetic resolution. Upon reaction with the catalyst precursor containing a chiral ligand (L*), a diastereomeric metal–phosphido complex 34 is formed. Rapid pyramidal inversion of this key catalytic intermediate 34 occurs. This complex performs a nucleophilic attack on the electrophile resulting in tertiary phosphines 10, in which the substituent ‘E’ comes from the electrophile. If the inversion of the diastereomers 34 is much faster than their reactions with an electrophile, P-stereogenic phosphines 10 are formed enantioselectively. The ratio of phosphine end products 10 is determined by the equilibrium (Keq) between the complexes 34 and the rate of nucleophilic attack (kS and kR) on the electrophile. The enantioselectivity of the end products 10 is related to the ratio of the diastereomeric phosphido complexes 34. The major phosphine product is derived from the major diastereomeric phosphido complex. The dynamic kinetic resolution approach has been reviewed in more detail by Glueck [57,58]. Scheme 10 relates to reactions of secondary phosphines with several electrophiles, including alkyl halides (alkylation), alkenes (hydrophosphination) and aryl iodides (arylation).

Scheme 10: Thermodynamic kinetic resolution as the origin of enantioselectivity in metal-catalyzed asymmetric synthesis of P-stereogenic phosphines.

Scheme 10: Thermodynamic kinetic resolution as the origin of enantioselectivity in metal-catalyzed asymmetric ...

Chan et al. synthesized P-stereogenic phosphine boranes using a ruthenium catalyst. The secondary phosphine 36a underwent an enantioselective alkylation to 12c (Scheme 11). The mechanism of the reaction is based on the formation of an electron-rich ruthenium–phosphido complex that enhances the nucleophilicity at the phosphorus atom. This permitted the reaction to proceed with the less electrophilic benzylic chlorides 35 instead of bromides. The metal-catalyzed reaction was faster than the achiral base-mediated alkylation of 36a. Bisphosphines 37 were also reported with high enantiomeric excesses. The procedure is mainly restricted to benzylic halides but also allowed for the asymmetric alkylation with ethyl bromide. All the phosphines were isolated as their air-stable phosphine–borane complexes 12c, 37 [59,60].

Scheme 11: Ru-catalyzed asymmetric phosphination of benzyl and alkyl chlorides 35 with HPPhMe (36a, PHOX = phosphinooxazoline).

Scheme 11: Ru-catalyzed asymmetric phosphination of benzyl and alkyl chlorides 35 with HPPhMe (36a, PHOX = pho...

The group of Glueck has reported a method for the asymmetric alkylation of racemic secondary phosphines 36b by means of a chiral platinum-based catalyst 39 (Scheme 12) [61]. The enhanced nucleophilicity at phosphorus of the platinum–phosphido intermediate was beneficial for the alkylation. The scope of the reaction was investigated using diverse benzylic bromides 22b and secondary phosphines 36b. Bidentate ligands 40 and 41 were also synthesized [61,62]. This procedure was also restricted to benzylic halides. High enantiomeric excesses were reported. As expected, a mechanistic study suggested that the major enantiomer of product was formed from the major diastereomer of the platinum–phosphido intermediate [63]. Glueck and co-workers also developed an analogous method for the tandem alkylation/arylation of primary phosphines on the basis of a platinum catalyst resulting in several enantio-enriched phosphaacenaphtalenes [64].

Scheme 12: Pt-catalyzed asymmetric alkylation of secondary phosphines 36b.

Scheme 12: Pt-catalyzed asymmetric alkylation of secondary phosphines 36b.

Hydrophosphination

Hydrophosphination involves the addition of P–H to an unsaturated C–C bond. In this reaction phosphines, silylphosphines [65,66] or phosphine–borane complexes are used as phosphinating agents to react with unactivated or activated alkenes, dienes and alkynes. Hydrophosphination has gained much interest as an alternative to the classical phosphine syntheses involving a substitution that is incompatible with certain functional groups. Moreover the addition of P–H to an unsaturated C–C bond is more efficient than substitution reactions when considering atom efficiency, what makes it not only greener but also more economical. Other phosphination reactions of unsaturated bonds, such as diphosphination, thiophosphination or selenophosphination, were not included [67].

Depending on the regioselectivity of the reaction, the addition of P–H to the unsaturated bond results in the formation of different products 43 (Scheme 13). The product that results from the Markovnikov addition of P–H corresponds to the α-adduct and the anti-Markovnikov addition is referred to as the β-adduct. The stereoselectivity of the method determines the conformation at the newly formed chiral centers.

Scheme 13: Different adducts 43 can result from hydrophosphination.

Scheme 13: Different adducts 43 can result from hydrophosphination.

The hydrophosphination typically proceeds via thermal [68,69], radical, acidic [70-72] or basic [73,74] initiation. Radical addition of secondary phosphines to alkenes can be accomplished by thermal activation [75,76], through the use of radical initiators (AIBN) [77-82] or photochemically by irradiation with UV or visible light [22,83-85]. Most of these reactions give anti-Markovnikov products. The hydrophosphination of activated alkenes (e.g., Michael acceptors) has also been shown to take place at room temperature in the absence of a catalyst [86,87] and even under solvent-free conditions [88]. More recently also metal complex-assisted or organocatalyzed hydrophosphinations have been reported. Several reviews focusing on hydrophosphination have been pusblished [89-91].

In recent years a lot of progress has been made in the metal complex-catalyzed hydrophosphination. It was shown that several metals can function as catalysts for the inter- and intramolecular addition of PH3 and R2PH to alkenes. Most research has focused on the use of platinum [92-96], palladium [97-99] or nickel [100-104] complexes. Other catalysts that have been less investigated are iron [105-107], rhodium [108-110], lanthanides [111-114], copper [115] and alkaline-earth metals [114,116]. The catalyst activates either the P-nucleophile or the C-electrophile.

Chiral phosphines have attracted more and more interest since they are employed as ligands in transition metal complexes to perform asymmetric catalysis [117]. Enantiopure phosphines have mostly been prepared by starting from enantiopure products or by resolution. The methodologies for catalytic asymmetric hydrophosphination of olefins are limited. Chiral metal complexes have been used to promote and control the asymmetric P–H addition reaction. Recent reviews covering the asymmetric hydrophosphination reaction catalyzed by metal catalysts have been published by Glueck [118,119] and Pullarkat and Leung [120]. Some recent developments in the asymmetric catalytic hydrophosphination will be discussed.

The group of Glueck reported on an approach to chiral phosphines by the addition of secondary phosphines 36c to Michael acceptor alkenes (acrylonitrile or derivatives and acrylate esters 44) in the presence of Pt((R,R)-Me-DuPhos) complexes (Scheme 14). However, the products 45 suffered from low enantioselectivities [121]. The mode of action is based on the activation of the P-nucleophile. The proposed mechanism includes the P–H oxidative addition to platinum giving a platinum–phosphido complex. Subsequent nucleophilic attack on a Michael acceptor alkene was suggested to lead to a zwitterion intermediate. Addition of a protic additive was beneficial for the selectivity and reaction rate [95].

Scheme 14: Pt-catalyzed asymmetric hydrophosphination.

Scheme 14: Pt-catalyzed asymmetric hydrophosphination.

Several chiral cyclic phosphines were acquired via the lanthanide catalyzed intramolecular hydrophosphination of phosphinoalkenes. Scheme 15 shows the diastereoselective synthesis of 2,5-dimethylphospholanes 49 from 47 with a lanthanide catalyst 48 [122]. The common mechanism when using lanthanide [113] or alkaline earth metal [123] catalysts is based on the formation of a phosphido–metal complex that undergoes insertion of the olefin. Protonolysis of the metal–alkyl complex via σ-bond metathesis with the phosphine reagent completes the catalytic cycle giving the product and regenerating the phosphido intermediate.

Scheme 15: Intramolecular hydrophosphination of phosphinoalkene 47.

Scheme 15: Intramolecular hydrophosphination of phosphinoalkene 47.

The group of Togni has developed an enantioenriched hydrophosphination of vinyl nitriles catalyzed by a dicationic nickel complex (Table 3). The method is based on the activation of the electrophile. It was suggested that complexation of the nitrile 50 to the chiral nickel Lewis acid activates the double bond towards 1,4-addition of the phosphine 25b. A final proton transfer yields the phosphine product 51 [124,125].

A chiral Pincer-palladium complex 55 has been used for the addition of diarylphosphines 25c to enones 53 (Table 4) [126]. Several enones 53, having electron-donating or -withdrawing groups on the aromatic ring, reacted with a variety of electron-rich and -poor diarylphosphines 25c. The chiral phosphine oxides 54 were obtained in high yield with excellent stereoselectivities. In the proposed mechanism the catalyst 55 acts as a base toward the diarylphosphine 25c. Some other examples of palladium-catalyzed asymmetric hydrophosphination are the addition of diphenylphosphine to α,β-unsaturated ketones [127,128], esters [129], sulfonic esters [130] or to dienones [131]. The proposed mechanism is ubiquitous in metal-catalyzed hydrophosphination involving a P–H oxidative addition, insertion of the olefin into the Pd–H bond and reductive elimination.

Table 4: Palladium-catalyzed asymmetric addition of diarylphosphines 25c to enones 53.

|

|

|||||

| Entry | R1 | R2 | Ar | Yield of 54 (%) | ee of 54 (%) |

|---|---|---|---|---|---|

| 1 | H | H | Ph | 93 | 99 |

| 2 | p-Br- | H | Ph | 89 | 99 |

| 3 | p-MeO- | H | Ph | 75 | 98 |

| 4 | m-Br- | H | Ph | 93 | 97 |

| 5 | p-NO2- | H | Ph | 78 | 95 |

| 6 | H | p-Br- | Ph | 90 | 98 |

| 7 | H | p-NO2- | Ph | 88 | 99 |

| 8 | H | m-Br- | Ph | 90 | 99 |

| 9 | H | o-MeO- | Ph | 69 | 90 |

| 10 | H | p-Me- | Ph | 63 | 90 |

| 11 | H | H | p-MeO-C6H4 | 86 | 94 |

| 12 | H | H | p-Cl-C6H4 | 92 | 96 |

In 2007 several papers appeared reporting on organocatalyzed asymmetric hydrophosphinations. The organocatalytic process has the advantage that in contrast to a metal-catalyzed method, it cannot undergo product inhibition as a result of the coordination ability of phosphorus to a metal catalyst.

The addition of diphenylphosphine to a range of nitroalkenes 56 has been described using a bifuntional Cinchona alkoid/thiourea catalyst 58 [132]. The catalyst 58 is able to simultaneously activate both the electrophilic and nucleophilic reagents. On one hand the thiourea presumably binds the nitro group while on the other hand the tertiary amine enables proton transfer from phosphorus to carbon (Table 5).

The organocatalyzed hydrophosphination of α,β-unsaturated aldehydes has been described by Carlone et al. [133] and Ibrahem et al. [134]. The method is based on activation of the aldehyde 59 via iminium-ion formation by reaction with chiral pyrrolidine 62 derivatives and acid (Scheme 16). Subsequent treatment with sodium borohydride forms the air-stable phosphine–borane product and also reduces the aldehyde. The method gives compounds 61 in high yields and enantioselectivities (ee up to 99%) for α,β-unsaturated aldehydes containing either aliphatic or aromatic groups.

Scheme 16: Organocatalytic asymmetric hydrophosphination of α,β-unsaturated aldehydes 59.

Scheme 16: Organocatalytic asymmetric hydrophosphination of α,β-unsaturated aldehydes 59.

Preparation of alkenylphosphines via formation of a C(sp2)–P bond

The C(sp2)–P bond formation is reviewed for arylic and vinylic phosphines. The group of Gaumont has provided a recent review (2010) on the main synthetic methods to obtain alkenylphosphines [135].

Reaction of organometallic reagents with halophosphines

The reaction of an organometallic reagent with the P-atom of halophosphines is a classical method used for the synthesis of both alkenyl- and arylphosphines. The organometallic reagents are mostly Grignard reagents [136-138] or organolithium [139-142] derivatives. Other organometallic reagents such as aluminum [143] or organomercury [26,144] reagents have been used less frequently.

Grignard or organolithium compounds are highly reactive nucleophiles and do not tolerate the presence of various functional groups. As a consequence, new approaches were developed including zinc, zirconium and copper reagents.

Polyfunctional alkenylphosphine 65 was accessible via the reaction of organozinc derivative 64 with chlorophosphine 22a. The organozinc bromide 64 was prepared from the corresponding alkenyl iodide 63. To prevent oxidation, the phosphines were protected as the corresponding borane adducts 65. The methodology is also applicable for aryl bromide 66 (Scheme 17) [23,24].

Scheme 17: Preparation of phosphines using zinc organometallics.

Scheme 17: Preparation of phosphines using zinc organometallics.

Alkenylphosphines were also synthesized by reacting alkenylzirconocenes 69 with a chlorophosphine 22b. Alkenylzirconocene compounds 69 displaying different substitution patterns were used, giving access to a variety of alkenylphosphines 71a via this method. If a more sterically hindered substrate ((α-substituted alkenyl)zirconocene) or reagent (iPr2PCl) is used, a transmetallation of Zr(IV) to Cu(I) is necessary for the reaction in order to proceed (Scheme 18). An intermediate phosphorus-copper complex 70 is formed. The phosphines 71a were liberated by treatment with Na2(dtc) or Na4(edta) [145].

Scheme 18: Preparation of alkenylphosphines 71a from alkenylzirconocenes 69 (dtc = N,N-diethyldithiocarbamate, edta = ethylenediaminetetraacetate).

Scheme 18: Preparation of alkenylphosphines 71a from alkenylzirconocenes 69 (dtc = N,N-diethyldithiocarbamate,...

Nucleophilic substitution with metallated organophosphines

The method is based on the reaction of phosphorus nucleophiles, derived from secondary phosphines or phosphine–borane complexes, and carbon electrophiles. Nucleophilic substitution with metallated organophosphines is less frequently used for the synthesis of vinylphosphines [42,146] due to possible isomerization to phospha-alkenes under basic conditions [147]. The method is mainly applied for the synthesis of arylphosphines. However, the nucleophilic reagents are incompatible with functional groups susceptible to nucleophilic attack. These sensitive groups have to be protected first to avoid undesired reactions. Despite these limitations this approach is still generally used for the synthesis of simple phosphines [137,138,148,149].

The group of Imamoto reported the SNAr reaction of P-chiral secondary phosphine boranes 13c with halobenzenechromium complexes 72 in the presence of sec-butyllithium [150]. The stereochemistry at the phosphorus atom was retained during the substitution when it was performed in THF at low temperature (Scheme 19). When fluorobenzenechromium complex 72 was used as a substrate, the yields of 73 were high (81–93%), in contrast to the reaction with chloro- and bromobenzenechromium complexes. The former reacted in low yield (7%), the latter did not react. The highly electronegative fluorine atom is needed for the SNAr reaction to take place, even though the arenechromium complexes are already very electron-deficient aromatic compounds.

Scheme 19: SNAr with P-chiral alkylmethylphosphine boranes 13c.

Scheme 19: SNAr with P-chiral alkylmethylphosphine boranes 13c.

The same group also developed a P-chiral ligand, QuinoxP 74, via deprotonation of chiral secondary phosphine borane 13d with n-butyllithium and subsequent nucleophilic substitution with 2,3-dichloroquinoxaline at low temperature (Scheme 20) [151]. After removal of the boranato group, the ligand was obtained in a good yield (80%).

Scheme 20: Synthesis of QuinoxP 74 (TMEDA = tetramethylethylenediamine).

Scheme 20: Synthesis of QuinoxP 74 (TMEDA = tetramethylethylenediamine).

Catalytic C(sp2)–P bond formation

The transition metal typically used for catalytic C–P bond formation is palladium [152] and, in some cases, nickel or copper. The phosphinating agents may comprise primary and secondary phosphines, silylphosphines [153] or phosphine–borane complexes.

The vinylic coupling partner mostly consists of alkenylhalides or alkenyltriflates. Vinyl triflates are used more since they can easily be derived from the corresponding ketone and they are more reactive then the vinyl chloride or bromide during the oxidative addition. More recently also vinyl tosylates and enol phosphates have proven to be suitable reagents.

The catalytic arylic C–P cross-coupling reaction can be a greener approach towards the widely used arylphosphines that are inaccessible by hydrophosphination. Recent advances in this area concern the synthesis of P-stereogenic phosphines through a dynamic kinetic resolution of racemic secondary phosphines in a metal-catalyzed P–H/aryl halide coupling.

C(sp2)–P bond formation of vinylphosphines

Palladium: Beletskaya and co-workers have described the synthesis of secondary and tertiary vinylphosphines by means of palladium catalyzed cross-coupling of vinylhalides and (silyl)phosphines [154-156]. Table 6 shows the protocols (A or B) generally used [157]. The vinylhalide substrates 75a were cross-coupled with diphenylphosphine or diphenyltrimethylsilylphosphine. When diphenylphosphine was used, triethylamine was added for the basic activation of the phosphinating agent. All the tested substrates 75a contained an alkoxy or amino group and depending on their position relative to the halogen, it was necessary to adjust the reaction temperature. The substrates bearing the halogen in the α-position to the alkoxy or amino group proved to be more reactive. With the halogen in β-position the substrate was less activated and the temperature had to be raised. Method B gave lower yields and longer reaction times were required to compensate for the use of the less reactive diphenyltrimethylsilylphosphine.

Table 6: Pd-catalyzed cross-coupling reactions of diphenylphosphine with alkenylhalides 75a.

|

|

||||||||

| Entry | R1 | R2 | R3 | X | Method | Temp (°C) | Time (h) | Yield of 71b (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | H | H | OEt | Br |

A

B |

20

20 |

1

1.5 |

97

92 |

| 2 | Me | Me | NEt2 | Cl |

A

B |

20

20 |

6

12 |

84

80 |

| 3 | H | OBu | Br | Br |

A

B |

120

120 |

36

40 |

94

90 |

| 4 | Ph | N-morpholine | H | Br |

A

B |

70

70 |

24

50 |

92

60 |

| 5 | Ph | N-piperidine | H | Br |

A

B |

70

70 |

24

45 |

90

55 |

Lipshutz et al. used a Pd(0) catalyst to synthesize triarylphosphine boranes by coupling secondary diphenylphosphine borane 13e with aryl nonaflates or triflates [158]. The article included one example with vinyl triflate 76 as a substrate (Scheme 21). The vinyl electrophile 76 was activated by the presence of the carbonyl group so the reaction also took place without a palladium catalyst albeit in lower yield (60%) and with formation of byproducts.

Scheme 21: Pd-Mediated couplings of a vinyl triflate 76 with diphenylphosphine borane 13e.

Scheme 21: Pd-Mediated couplings of a vinyl triflate 76 with diphenylphosphine borane 13e.

Julienne et al. have reported the coupling of secondary phosphine boranes with unactivated vinyl triflates (Table 7 and Table 8) [159]. Cyclic and acyclic vinyl triflates (78 and 80a) were reacted with diaryl-, dialkyl- and alkylarylphosphine–borane complexes, 13f and 13g respectively. The reactions were performed with a palladium catalyst in the presence of a weak base. Sometimes microwave irradiation was used to shorten the reaction time.

Table 8: Palladium-catalyzed C–P coupling between cyclic vinyl triflates and phosphine boranes (dppp = 1,3-bis(diphenylphosphino)propane).

|

|

||||||

| Entry | R1 | R2 | R3 | R4 | Heating | Yield of 81a (%) |

|---|---|---|---|---|---|---|

| 1 | H | H | Ph | Ph | Oil bath | 68 |

| 2 | H | H | Ph | Ph | MWI | 71 |

| 3 | H | H | Me | Ph | Oil bath | 71 |

| 4 | H | H | t-Bu | Ph | Oil bath | 70 |

| 5 | H | H | t-Bu | Ph | MWI | 77 |

| 6 | H | H | Et | Et | Oil bath | 50 |

| 7 | H | H | Cy | Cy | MWI | 67 |

| 8 | Me | H | Ph | Ph | Oil bath | 70 |

| 9 | H | Me | Ph | Ph | Oil bath | 65 |

Gilbertson et al. have converted a series of vinyl triflates 80b into the corresponding vinyl phosphine boranes 81b through palladium catalysis with HPPh2 (Table 9) [160]. The reaction proceeded under mild conditions (40 °C). These vinyltriflates 80b were obtained from the corresponding ketone 82 opening access to a range of other structures. The chiral phosphines 83 and 84 were prepared from the natural products menthone and camphor in the same manner (Figure 1). All products were converted to the corresponding borane complex to facilitate further handling. However, when the same conditions were applied with diphenylphosphine borane and cyclohexenyltriflate no reaction was observed. A similar methodology has been applied for the synthesis of several ligands [161-163].

Figure 1: Menthone (83) and camphor (84) derived chiral phosphines.

Figure 1: Menthone (83) and camphor (84) derived chiral phosphines.

Julienne et al. succeeded in coupling vinyl tosylates 85 and 87 with diphenylphosphine borane 13e despite the fact that alkenyl tosylates are poor reagents for cross-coupling [164]. The products 86 and 79b were formed in the presence of a palladium catalyst. The reaction proceeded at lower temperature when the vinyl tosylate was substituted with an electron-withdrawing group like in 85 (Scheme 22).

Scheme 22: Palladium-catalyzed cross-coupling reaction of vinyl tosylates 85 and 87 with diphenylphosphine borane 13e (dppp = 1,3-bis(diphenylphosphino)propane).

Scheme 22: Palladium-catalyzed cross-coupling reaction of vinyl tosylates 85 and 87 with diphenylphosphine bor...

The group of Gaumont has also reported their preliminary results for the enantioselective palladium-catalyzed C–P cross-coupling reaction between an achiral vinyl triflate 80c and a racemic secondary phosphine–borane complex 13b (Scheme 23) [165]. Chiral phosphines with a C-stereogenic center have been studied but this was the first attempt for the asymmetric synthesis of a P-stereogenic compound. After evaluating several conditions the best catalyst was (S,S)-Me-DuPhos (46). An enantioenriched alkenylphosphine 81c was formed. The highest enantiomeric excess measured by chiral HPLC was 56%. No reaction was observed without the palladium catalyst [165].

Scheme 23: Attempt for the enantioselective palladium-catalyzed C–P cross-coupling reaction between an alkenyltriflate 80c and a phosphine borane 13b.

Scheme 23: Attempt for the enantioselective palladium-catalyzed C–P cross-coupling reaction between an alkenyl...

Gillaizeau and co-workers have demonstrated the use of α-amido enol phosphates 88 as vinylic coupling partners in the palladium-catalyzed C–P cross-coupling reaction (Scheme 24) [166]. The enol phosphates 88 were prepared from the corresponding amides. The phosphane function was introduced in the α-position of the nitrogen. Several chiral and achiral secondary phosphine borane complexes 13 were used. The coupling was achieved under mild conditions. Most reactions gave 89 in low to good yields but in some cases the product could not be isolated, probably due to instability of the product. During the coupling reaction with 13h partial inversion of the phosphorus atom occurred, resulting in racemization.

Scheme 24: Enol phosphates 88 as vinylic coupling partners in the palladium-catalyzed C–P cross-coupling reaction (dppf = 1,1'-bis(diphenylphosphino)ferrocene).

Scheme 24: Enol phosphates 88 as vinylic coupling partners in the palladium-catalyzed C–P cross-coupling react...

Nickel: Most research has focused on the use of a palladium catalyst to perform the C–P cross-coupling between secondary phosphines and vinylic electrophiles. A few reports are available concerning the nickel-catalyzed cross-coupling. Ager and Laneman have prepared phosphines 91 and 93 from vinyl triflate 90 and vinyl bromide 92, respectively, under similar conditions (Scheme 25) [53]. The reaction was catalyzed by NiCl2(dppe) in the presence of zinc. The role of zinc was to reduce Ni(II) to Ni(0) and to form Ph2PZnCl for the transmetallation step.

Scheme 25: Nickel-catalyzed cross-coupling in the presence of zinc (dppe = 1,2-bis(diphenylphosphino)ethane).

Scheme 25: Nickel-catalyzed cross-coupling in the presence of zinc (dppe = 1,2-bis(diphenylphosphino)ethane).

Kazankova and co-workers have explored the catalysts (Ph3P)2NiCl2 and Ni(acac)2 for the coupling of several vinyl bromides 75b and chlorides with 25d (Table 10). These reactions proceeded without the addition of zinc [167].

Copper: The group of Buchwald has reported one example of a copper catalyst to accomplish the phosphination of the vinyl halide 94 (Scheme 26) [168]. The protocol uses CuI as catalyst in combination with N,N’-dimethylethylenediamine (96) as ligand and a weak base Cs2CO3.The desired phosphine 95 is isolated in good yield.

Scheme 26: Copper-catalyzed coupling of secondary phosphines with vinyl halide 94.

Scheme 26: Copper-catalyzed coupling of secondary phosphines with vinyl halide 94.

C(sp2)–P bond formation of arylphosphines

The C–P bond formation of aryl phosphines is typically catalyzed by palladium, nickel and less frequently copper. The phosphorus coupling partners used are primary, secondary and tertiary phosphines, secondary phosphine–borane complexes, silyl- and stannylphosphines and phosphine chlorides. These phosphinating agents are coupled with aryl halides and triflates. Several general protocols are available.

Palladium: In 1987, Tunney and Stille reported on the palladium-catalyzed synthesis of several aryldiphenylphosphines by cross-coupling aryl halides with (trimethylsilyl)diphenylphosphine or (trimethylstannyl)diphenylphosphine [169]. No base is required for this method. Trimethylsilyl compounds are preferred over tristannyl derivatives since they are less toxic. However, in recent years the group of Rossi has reported a one-pot procedure for the palladium-catalyzed coupling of aryl iodides 97 with in situ generated Ph2SnBu3 (30, Scheme 27) [170]. When naphthyl triflate was used as a substrate, CuI was added as a co-catalyst [171].

Scheme 27: Palladium-catalyzed cross-coupling of aryl iodides 97 with organoheteroatom stannanes 30.

Scheme 27: Palladium-catalyzed cross-coupling of aryl iodides 97 with organoheteroatom stannanes 30.

Imamoto et al. have developed a method for the palladium-catalyzed C–P bond formation using secondary phosphine boranes [41]. The authors also discovered how the choice of the solvent influences the stereochemistry of 100. When the coupling between aryl iodide 99 and asymmetric secondary phosphine borane 13b was performed in acetonitrile or DMF, the stereochemistry at the phosphorus atom was almost completely retained while the reaction performed in THF or toluene resulted mainly in inversion (Scheme 28) [172,173]. The stereochemistry also depended on the base used. The presence of K2CO3 or KOAc favored a good stereoselectivity in contrast to K3PO4 or DBU. Sodium hydride or Ag2CO3 promoted retention of configuration. The mechanism of the reaction was studied by Gaumont et al. through isolation of the reactive intermediate [174]. Lipshutz et al. reported the palladium-catalyzed phosphination of aryl triflates and nonaflates instead of aryl iodides with phosphine boranes [158]. The first examination towards an enantioselective C–P cross-coupling starting from racemic secondary phosphine boranes was performed by Gaumont and Pican [175]. The highest enantiomeric excess obtained was 45%. The same group has shown that imidazolium based ionic liquids can be used as a medium to perform the C–P cross-coupling reactions. This method allows an easy separation of the product from the catalyst and the recycling of the palladium catalyst [176].

Scheme 28: Synthesis of optically active phosphine boranes 100 by cross-coupling with a chiral phosphine borane 13b.

Scheme 28: Synthesis of optically active phosphine boranes 100 by cross-coupling with a chiral phosphine boran...

Stelzer and co-workers have developed a general method for the coupling of primary or secondary phosphines instead of their silyl derivatives or borane complexes with functional aryliodides 101 [177-179]. It should be noted, however, that the reactions were again limited to (di)phenylphosphine (Scheme 29). The protocols use palladium as a catalyst in the presence of tertiary amines as base. A variety of hydrophilic phosphines (102, 103) was synthesized. Since no protective groups were introduced, the method proves to be compatible with several functionalities. This methodology or in a slightly modified form has been used by several authors for the phosphination of a large variety of compounds [180-188]. Microwave-assisted procedures have also been developed [189-191].

Scheme 29: Palladium-catalyzed P–C cross-coupling reactions between primary or secondary phosphines and functional aryliodides 101 (dba = dibenzylideneacetone, dppp = 1,3-bis(diphenylphosphino)propane).

Scheme 29: Palladium-catalyzed P–C cross-coupling reactions between primary or secondary phosphines and functi...

Kwong et al. implemented a palladium-catalyzed phosphination of aryl bromides and triflates 104 with triarylphosphines 105a as phosphinating agents. This aryl–aryl exchange reaction was compatible with several functional groups such as ketones, aldehydes, esters, nitriles, ethers (Table 11) [192-195]. Products 106a were isolated in only moderate yields. Several P,N-biaryl ligands were prepared from the corresponding triflate under similar conditions [196,197]. The reaction also proceeded under solvent-free conditions with slightly higher yields [198]. A heterogeneous Pd/C catalyst has been applied as well [199,200].

The group of Glueck has reported the first asymmetric palladium-catalyzed C–P bond formation for the synthesis of P-stereogenic phosphines by adding a catalytic amount of a chiral auxiliary. The enantioenriched phosphine 108 was obtained through coupling of racemic bulky secondary phosphine 107 with PhI in the presence of the base NaOSiMe3 and the Pd-catalyst (Scheme 30) [201]. In the following years, the scope and mechanism were elaborated [202-204]. In accordance with the mechanism given in Scheme 10, it was concluded that the major enantiomer of the product 108 was derived from the major diastereomer of the Pd-phosphido intermediate. Korff and Helmchen have prepared several triarylphosphines with this methodology. However, a modified catalyst system [Pd(Et-FerroTANE)] containing a ferrocene-based ligand was used [205]. This catalyst had the advantage that it was easily prepared in situ while the unstable catalyst used by Glueck et al., required storage at −25 °C in the dark.

Scheme 30: Enantioselective synthesis of a P-chirogenic phosphine 108.

Scheme 30: Enantioselective synthesis of a P-chirogenic phosphine 108.

The protocol of Tunney and Stille starting from silylphosphines has been modified by Chan, Bergman and Toste to be enantioselective by using a [Pd(Et-FerroTANE)] catalyst. P-stereogenic phosphine boranes 111 and 112 were synthesized by arylation of racemic silylphosphines 110 under dynamic kinetic control (Scheme 31). The best enantiomeric excess was obtained when an ortho-amide substituent was present in the substrate 109 [206].

Scheme 31: Enantioselective arylation of silylphosphine 110 ((R,R)-Et-FerroTANE = 1,1'-bis((2R,4R)-2,4-diethylphosphotano)ferrocene).

Scheme 31: Enantioselective arylation of silylphosphine 110 ((R,R)-Et-FerroTANE = 1,1'-bis((2R,4R)-2,4-diethyl...

Nickel: Cristau et al. were the first which achieved the nickel-catalyzed arylation of diphenylphosphine [207]. Upon reaction of bromobenzene (113) with 25d in the presence of NiBr2 a mixture of triphenylphosphine 105b and tetraphenylphosphonium bromide salt 114 was obtained (Scheme 32).

Scheme 32: Nickel-catalyzed arylation of diphenylphosphine 25d.

Scheme 32: Nickel-catalyzed arylation of diphenylphosphine 25d.

The first conversion of an aryltriflate to an arylphosphine using diphenylphosphine was reported by Cai et al. (Scheme 33) [208,209]. The method was developed for the synthesis of chiral (R)-BINAP 116; a successful chiral ligand. Nickel was chosen as catalyst instead of palladium to minimize catalyst poisoning by binding of the metal with the phosphines present. After optimization, the desired chiral BINAP 116 was obtained in 77% yield. This protocol has been adopted by other research groups for the synthesis of a range of phosphines [138,210-216]. Analogous palladium-catalyzed reactions coupling aryl triflates with diphenylphosphine have been reported [217,218].

Scheme 33: Nickel-catalyzed synthesis of (R)-BINAP 116 (dppe = 1,2-bis(diphenylphosphino)ethane, DABCO = 1,4-diazabicyclo[2.2.2]octane).

Scheme 33: Nickel-catalyzed synthesis of (R)-BINAP 116 (dppe = 1,2-bis(diphenylphosphino)ethane, DABCO = 1,4-d...

Laneman et al. later developed a modified version of Cai’s method and synthesized several tertiary phosphines 118 via the cross-coupling of aryl triflates and halides 117 with chlorodiphenylphosphine (22a) instead of diphenylphosphine (Table 12) [53]. The reaction was catalyzed by NiCl2(dppe) in the presence of zinc. A hydrodehalogenation side reaction resulted in lower yields of aryl halide substrates compared to aryl triflates.

Zhao and co-workers disclosed a method for the cross coupling of various aryl bromides 119 with diphenylphosphine (25d) in the absence of external reductants and supporting ligands [219]. The reaction gave mixtures of phosphines 120 and phosphine oxides 121 (Scheme 34). Several functional groups (ester, ether, ketone and cyano groups) remained intact under the conditions. The reaction was also performed with diphenylphosphine–borane complex but this resulted in only small amounts of products due to decomposition of the phosphinating reagent at 100 °C.

Scheme 34: Nickel-catalyzed cross-coupling between aryl bromides 119 and diphenylphosphine (25d) (dppp = 1,3-bis(diphenylphosphino)propane).

Scheme 34: Nickel-catalyzed cross-coupling between aryl bromides 119 and diphenylphosphine (25d) (dppp = 1,3-b...

Copper: Copper was first used as a co-catalyst in palladium-catalyzed phosphorylation reactions, Livinghouse et al. demonstrated that the aromatic phosphorylation proceeded even at low temperatures of ≤0 °C when copper was added [220]. The method also allows for the stereocontrolled Pd(0)−Cu(I) co-catalyzed coupling of enantiopure secondary phosphine borane 13b with aryl iodides 122 (Scheme 35) [221].

Scheme 35: Stereocontrolled Pd(0)−Cu(I) cocatalyzed aromatic phosphorylation.

Scheme 35: Stereocontrolled Pd(0)−Cu(I) cocatalyzed aromatic phosphorylation.

In 2003, copper-catalyzed palladium free phosphorylation methods were developed by Venkataraman and Van Allen [222] and Buchwald et al. [168]. Both methodologies use catalytic amounts of copper(I) salts in the presence of K2CO3 or Cs2CO3 as a base. Buchwald et al. also added N,N’-dimethylethylenediamine 96 as a ligand to enhance the efficiency of the coupling. A secondary phosphine 25e was coupled with a variety of aryl halides 124 with electron-withdrawing or -donating substituents. The method tolerated the presence of functional groups such as esters or amines (Table 13). This approach was also used for the synthesis of phosphinoxazolines [223].

Hydrophosphination of alkynes

The addition of P–H to a triple bond is a highly desirable method when taking atom economy principles into account. Activated [224,225] or unactivated alkynes were investigated as substrates. Phosphines as well as silylphosphines [65,66,226,227] or phosphine–borane complexes can be used as phosphinating agents. The addition reaction has been initiated in several ways including base [228-233], radical (thermal radical [234] or AIBN radical [77,78,83,235,236]) or transition metal activation.

Depending on the regioselectivity of the procedure, the addition of P–H to the triple bond results in the formation of two regioisomers (Scheme 36). The product that results from the Markovnikov addition of P–H corresponds to the α-adduct 126 and the anti-Markovnikov addition results in the β-adduct 127. The stereoselectivity of the reaction determines the formation of E- or Z-127.

Scheme 36: Preparation of alkenylphosphines by hydrophosphination of alkynes.

Scheme 36: Preparation of alkenylphosphines by hydrophosphination of alkynes.

Despite the great appeal of this method for the preparation of vinylphosphines it does not allow the syntheses of the widely used arylphosphines or alkenes bearing no hydrogen on the double bond. Additionally, due to the absence of small rings containing a triple bond, no cyclic alkenylphosphines are accessible. Until now, the protocols lack sufficient control over selectivity and mostly give mixtures. Most addition products (radical, base, metal) are anti-Markovnikov 127, only a few palladium catalyzed reactions give the Markovnikov products 126.

Several reviews on hydrophosphination of alkynes have been published [90,91,237]. Some recent developments will be discussed. In recent years research has mainly focused on metal-catalyzed hydrophosphinations.

Metal complex-catalyzed hydrophosphinations

Hydrophosphination catalysts are mainly based on transition metals. However, it has been shown that lanthanides and alkaline earth metals can offer a valid alternative.

Palladium and nickel complexes were used to catalyze the addition of the P–H bond to alkynes 125a (Scheme 37). The regioselectivity was strongly dependent on the catalytic precursor. In the presence of palladium(0) and nickel(0) complexes the β-adduct 127a was formed as the major product. By contrast palladium(II) and nickel(II) complexes mainly gave rise to the α-adduct 126a [98,238]. The nickel based catalyst was more effective than the palladium so the reaction proceeded at lower temperature.

Scheme 37: Palladium and nickel-catalyzed addition of P–H to alkynes 125a.

Scheme 37: Palladium and nickel-catalyzed addition of P–H to alkynes 125a.

Join et al. had the objective to enantioselectively create P-stereogenic vinylphosphine boranes [239]. To achieve this goal some asymmetric hydrophosphination reactions were performed using a palladium catalyst in combination with a chiral ligand. After optimizing the conditions, the addition of methylphenylphosphine borane (13b) to 1-ethynylcyclohexene (128) with the Pd-catalyst afforded tertiary phosphine borane 129 with a conversion of 70% and only 42% ee (Scheme 38).

Scheme 38: Palladium-catalyzed asymmetric hydrophosphination of an alkyne 128.

Scheme 38: Palladium-catalyzed asymmetric hydrophosphination of an alkyne 128.

Nagata et al. performed the palladium-catalyzed hydrophosphination of alkynes by using tetraphenyldiphospine (130) (Table 14) [240]. Since there is no P–H bond in this phosphinating agent, a bisphosphination was expected but a hydrophosphination took place. However, an excess (3–5 equiv) of alkyne was used. The reaction proceeded regioselectively and the α-adducts 126b of several terminal alkynes 125b were formed. Air-oxidation during work-up resulted in the formation of the corresponding phosphine oxides 131. The products 131 were isolated in moderate yields with respect to the diphosphine 130 as limiting reagent. It was suggested that the alkynyl hydrogen acts as the hydrogen source for the hydrophosphination. This can also explain why the method was not applicable to internal alkynes. Silanes have also been added as the source for hydrogen [241].

Ruthenium complexes are the first catalysts reported for the direct hydrophosphination of propargyl alcohols [242]. Several catalytic systems were tested and the reaction with 5 mol % RuCl(cod)(C5Me5) in the presence of Na2CO3 provided the best results (Scheme 39). The reaction gave two stereoisomeric adducts (Z)-133 and (E)-133. The hydrophosphination of 132 proceeded with excellent regioselectivity and good stereoselectivity as the Z-isomers, (Z)-133, were preferentially formed with Z/E ratios around 80/20. This method could not be performed on alkynes with an internal triple bond, only terminal alkynes were accessible.

Scheme 39: Ruthenium catalyzed hydrophosphination of propargyl alcohols 132 (cod = 1,5-cyclooctadiene).

Scheme 39: Ruthenium catalyzed hydrophosphination of propargyl alcohols 132 (cod = 1,5-cyclooctadiene).

A catalytic amount of Co(acac)2 in combination with butyllithium can mediate the hydrophosphination of internal alkynes [243]. Various alkynes 134a were subjected to these conditions to provide the corresponding syn-adducts exclusively (Scheme 40). The regioselectivity is mostly influenced by steric hindrance. To avoid loss of product by oxidation, the adducts were isolated as their thiophosphine analogues 135 and 136.

Scheme 40: Cobalt-catalyzed hydrophosphination of alkynes 134a (acac = acetylacetone).

Scheme 40: Cobalt-catalyzed hydrophosphination of alkynes 134a (acac = acetylacetone).

Hayashi and co-workers have reported a rhodium-catalyzed phosphination of alkynes 134b using silylphosphines 137 as phosphinating agents (Table 15) [108]. The cationic rhodium catalyst was generated in situ by adding silver triflate to a chlororhodium complex. The silylgroup was not incorporated in the vinylphosphine product 138a and methanol was added as a proton source for completing the reaction. The adducts 138a were formed with good to high syn-selectivity.

Table 15: Rhodium-catalyzed hydrophosphination of alkynes 134b with a silylphosphine 137 (cod = 1,5-cyclooctadiene).

|

|

||||

| Entry | R1 | R2 | Yield of 138a (%) | E/Z |

|---|---|---|---|---|

| 1 | Ph | H | 89 | 96/4 |

| 2 | MeO-C6H4 | H | 53 | 92/8 |

| 3 | n-C5H11 | H | 78 | 95/5 |

| 4 | HOCH2 | H | 66 | 80/20 |

| 5 | Ph | Me | 68 | 92/8 |

| 6 | Ph | n-Bu | 72 | 95/5 |

| 7 | n-C5H11 | n-C5H11 | 67 | >99/1 |

| 8 | EtO2C | n-Bu | 81 | >99/1 |

| 9 | EtO2C | Ph | 76 | 80/20 |

Kondoh et al. demonstrated the P–H addition to 1-alkynylphosphines under copper catalysis (Table 16) [244]. Besides copper(I) iodide several other copper salts effectuated the reaction albeit in lower yields as did silver(I) iodide, palladium(II) chloride and platinum(II) chloride. Other transition metal catalysts such as gold(I) chloride, nickel(II) chloride and cobalt(II) chloride gave no reaction. In the presence of copper(I) iodide and cesium carbonate diphenylphospine (25d) added to the triple bond in an anti-fashion. A diverse set of alkynylphosphines 139 was subjected to the protocol proving the compatibility of the method with certain functional groups. The Z-adducts were formed exclusively and isolated as the phosphine sulfides 140 to prevent lower yields by oxidation to the corresponding oxides. The phosphines 141 were obtained by radical reduction of 140 with tris(trimethylsilyl)silane (TTMSS).

However, when Kumaraswamy et al. explored the copper-catalyzed hydrophosphination on substituted phenylacetylenes 125c further oxidation of the double bond led to the corresponding phenacyl tertiary phosphine boranes 142 in moderate to good yields (Scheme 41). The products 142 were obtained when the reactions were performed under inert atmosphere and in open air. Since the latter gave slightly better yields, it was argued that the dissolved air contributed to the product formation. A Cu(II)–TMEDA catalyzed tandem phosphorus–carbon bond formation–oxyfunctionalization was developed [245]. When methyl propiolate was subjected to the same reaction conditions only the β-adducts were isolated.

Scheme 41: Tandem phosphorus–carbon bond formation–oxyfunctionalization of substituted phenylacetylenes 125c (TMEDA = tetramethylethylenediamine).

Scheme 41: Tandem phosphorus–carbon bond formation–oxyfunctionalization of substituted phenylacetylenes 125c (...

The intramolecular hydrophosphination and cyclization of primary alkynyl phosphines 143 has been accomplished using organolanthanide precatalysts of the type Cp’2LnCH(SiMe3)2 (Cp’ = η5-C5Me5) and Me2Si(Me4C5)(t-BuN)SmN(SiMe3)2 [111,112]. The reaction succeeded also using homoleptic lanthanocenes of the form Ln[CH(SiMe3)2]3 (Ln = La, Nd, Sm, Y, Lu) or Ln[N(SiMe3)2]3 (Ln = La, Nd, Sm, Y) [246]. The reaction was performed in NMR tubes until full conversion to the phospholane 144 (n = 1) or phosphorinane 144 (n = 2) was obtained (Scheme 42). The reaction is regioselective as only one adduct was obtained. Several butadiene derivatives were synthesized by hydrophosphination of the triple bond in enynes in the presence of yttriumcomplexes [247].

Scheme 42: Organolanthanide-catalyzed intramolecular hydrophosphination/cyclization of phosphinoalkynes 143.

Scheme 42: Organolanthanide-catalyzed intramolecular hydrophosphination/cyclization of phosphinoalkynes 143.

An ytterbium–imine complex 145 [Yb(η2-Ph2CNPh)(hmpa)3] has also been applied for the synthesis of alkenylphosphines [245,248-251]. The products were isolated as their corresponding phosphine oxides (146 and 147) after oxidative work-up (Scheme 43). The reaction proceeded under mild conditions (rt, 5 min to 4 h), except for the less reactive aliphatic internal alkynes (80 °C, 6 h). The regio- and stereoselectivity was mainly affected by the nature of the substrate and not so much by the reaction conditions. An active ytterbium phosphide species is generated in situ and therefore the imine complex could be categorized as a basic catalyst.

Scheme 43: Hydrophosphination of alkynes 134c catalyzed by ytterbium-imine complexes 145 (hmpa = hexamethylphosphoramide).

Scheme 43: Hydrophosphination of alkynes 134c catalyzed by ytterbium-imine complexes 145 (hmpa = hexamethylpho...

The only catalysts based on heavy alkaline earth metals for the hydrophosphination of alkynes are derived from calcium [123,252,253]. A similar behavior of calcium(II) and ytterbium(II) compounds seems possible as the oxidation state of Yb(II) does not change during the ytterbium(II)-catalyzed hydrophosphination of alkynes. The reaction of alkyne 134d in the presence of the calcium catalyst resulted in diphenyl-vinylphosphine 138b in good yield (Scheme 44). A set of butadiynes was reacted in a similar way [254]. Mixtures of butadienyldiphosphine isomers were obtained depending on the bulkiness of the end groups at the butadiyne moieties.

Scheme 44: Calcium-mediated hydrophosphanylation of alkyne 134d.

Scheme 44: Calcium-mediated hydrophosphanylation of alkyne 134d.

Other hydrophosphinations

A relatively recent example for the thermal activated hydrophosphination was from Mimeau and Gaumont and described the use of a microwave reactor [254]. This reaction is performed with secondary phosphine–borane complexes 13j and terminal alkynes 125d. Mimeau and Gaumont demonstrated that the regioselectivity of the hydrophosphination reaction can be controlled by adjusting the activation method. Thermal activation with the microwave reactor gave the β-adducts 148 (anti-Markovnikov addition) (Table 17). In the same article the α-adducts 149 (Markovnikov addition) were formed by using a palladium catalyst (Table 18). In both cases the regioselectivity was excellent, the stereochemistry in the case of the β-adduct 148 favoured the Z-product. The conditions are compatible with aliphatic and oxygen-functionalized alkynes.

Table 18: Hydrophosphination reactions of terminal alkynes 125e with phosphine boranes 13f using a Pd catalyst (dba = dibenzylideneacetone, dppp = 1,3-bis(diphenylphosphino)propane).

|

|

|||

| Entry | R1 | R2 | Yield of 149 (%) |

|---|---|---|---|

| 1 | n-Hex | Ph | 84 |

| 2 | Ph | Ph | 49 |

| 3 | -(CH2)2OH | Ph | 71 |

| 4 | -CH2OCH3 | Ph | 73 |

| 5 | Cy | Ph | 60 |

| 6 | n-Hex | Me | 85 |

| 7 | Ph | Me | 53 |

Busacca et al. have described the hydrophosphination of internal alkynes with phosphine–borane complexes under basic conditions [255,256]. Several diaryl- and alkylarylalkynes 134e were reacted with a variety of phosphine boranes 25f, some examples are shown in Table 19. Mixtures of E and Z-isomers of 150 were formed, with the E-isomer as the major product.

Table 19: Hydrophosphination of alkynes 134e with phosphine–borane complexes 25f (DMAc = dimethylacetamide).

|

|

|||||

| Entry | R1 | R2 | R3 | Yield of 150 (%) | E/Z ratio |

|---|---|---|---|---|---|

| 1 | Ph | Me | Cy | 85 | >20/1 |

| 2 | Ph | Ph | t-Bu | 88 | >20/1 |

| 3 | Ph | Me | p-(iPrO)-C6H4 | 78 | >20/1 |

| 4 | Ph | Ph | iBu | 79 | 4/1 |

| 5 | p-CF3-C6H4 | p-CF3-C6H4 | Ph | 98 | >20/1 |

| 6 | o-Tol | o-Tol | Cy | 99 | >20/1 |

Preparation of alkynylphosphines via formation of a C(sp)–P bond

An extensive review concerning the stoichiometric and catalytic synthesis of alkynylphosphines and their borane complexes has been published in 2012 by Gaumont et al. [257].

Reaction of organometallic reagents with halophosphines

Alkynylphosphines are commonly synthesized by the nucleophilic displacement of the halogen at the phosphorus atom of a halophosphine with a metal acetylide. Grignard [258,259] and organolithium [244,260-262] reagents have frequently been used since many years. The main disadvantage is the incompatability of lithium and magnesium reagents with alkynylphosphines having labile functional groups susceptible to nucleophilic attack.

This approach is mainly used for the synthesis of tertiary phosphines. It is difficult to synthesize secondary alkynylphosphines since they easily convert into their phosphaallene tautomer. They can only be obtained when they have sterically hindering substituents [263,264].

The asymmetric synthesis of alkynylphosphines also suffers from limited availability of unsymmetrical halophosphines and their weak configurational stability. Stereospecific substitution at chiral phosphorus atoms by alkynyl nucleophiles has been reported by Imamoto et al. (Scheme 45) [265]. Firstly, a bromo(tert-butyl)methylphosphanyl borane 151 was formed in situ by treating the enantiomerically pure (S)-(tert-butyl)methylphosphine borane 13d with n-BuLi and 1,2-dibromoethane. An alkynyl lithium reagent was directly added to intermediate 151. The expected substitution products 152 were obtained in high yield and almost exclusively with inversion of configuration, resulting in excellent stereospecificities.

Scheme 45: Formation and substitution of bromophosphine borane 151.

Scheme 45: Formation and substitution of bromophosphine borane 151.

Catalytic C(sp)–P bond formation

This type of carbon–phosphorus bond formation relies on the cross-coupling reaction in the presence of a catalyst. The cross-coupling reaction is in general performed between a terminal alkyne 125 and an electrophilic phosphorus reagent in the form of a halophoshine 153, mostly chlorophosphine, in the presence of a catalyst such as nickel (Ni(acac)2) [244,266,267] or copper (CuI) [268-270] (Scheme 46). The nickel based catalyst was not suitable for the cross-coupling of alkynes containing a sensitive alkoxy or amino functional group. Therefore, another catalytic method was developed using copper(I) salts.

Scheme 46: General scheme for a nickel or copper catalyzed cross-coupling reaction.

Scheme 46: General scheme for a nickel or copper catalyzed cross-coupling reaction.

Alkynylphosphines were synthesized through the use of a copper-catalyzed reaction between a secondary phosphine borane 13k and various 1-bromoalkynes 155 in the presence of 1,10-phenanthroline as a ligand and K2CO3 or K3PO4 as a base (Scheme 47). This was the first method involving a nucleophilic phosphorus reagent in the synthesis of alkynylphosphines and was presented by the group of Gaumont [271,272]. The method was applicable for dialkyl, diaryl or alkylaryl phosphine boranes 13k and required only mild conditions.

Scheme 47: Copper-catalyzed synthesis of alkynylphosphines 156.

Scheme 47: Copper-catalyzed synthesis of alkynylphosphines 156.

Conclusion

The developments over the past years in the field were reviewed. The use of phosphines as ligands in metal complex catalysis has been a major driving force for the synthesis of functionalized phosphines. In recent years many catalytic procedures have emerged. In general these catalytic protocols proceed under milder conditions that tolerate the presence of functional groups. Gradually a broader variety of phosphines is accessible. Due to the growing importance of asymmetric catalysis, a lot of attention has been paid to the asymmetric synthesis of chiral phosphines. The challenge to find a general protocol that permits simple access to chiral phosphines, is still ongoing and further developments are required.

References

-

Methot, J. L.; Roush, W. R. Adv. Synth. Catal. 2004, 346, 1035–1050. doi:10.1002/adsc.200404087

Return to citation in text: [1] -

Gilheany, D. G.; Mitchell, C. M. Preparation of Phosphines. In Organophosphorus Compounds; Hartley, F. R., Ed.; John Wiley and Sons: Chichester, U.K., 1990; Vol. 1, pp 151–190. doi:10.1002/9780470034439.ch7

Return to citation in text: [1] -

Beletskaya, I. P.; Kazankova, M. A. Russ. J. Org. Chem. 2002, 38, 1391–1430. doi:10.1023/A:1022685801622

Return to citation in text: [1] -

Tappe, F. M. J.; Trepohl, V. T.; Oestreich, M. Synthesis 2010, 3037–3062. doi:10.1055/s-0030-1257960

Return to citation in text: [1] -

Zhou, Q.-L. Privileged Chiral Ligands and Catalysts; Wiley-VCH: Weinheim, Germany, 2011.

Return to citation in text: [1] -

Busacca, C. A.; Senanayake, C. H. The use of New Phosphines as Powerful Tools in Asymmetric Synthesis of Biologically Active Compounds. In Comprehensive Chirality; Carreira, E. M.; Yamamoto, H., Eds.; Elsevier: Amsterdam, 2012; pp 167–216. doi:10.1016/B978-0-08-095167-6.00110-5

Return to citation in text: [1] -

Grabulosa, A.; Granell, J.; Muller, G. Coord. Chem. Rev. 2007, 251, 25–90. doi:10.1016/j.ccr.2006.05.009

Return to citation in text: [1] -

Harvey, J. S.; Gouverneur, V. Chem. Commun. 2010, 46, 7477–7485. doi:10.1039/c0cc01939a

Return to citation in text: [1] -

Kolodiazhnyi, O. Tetrahedron: Asymmetry 2012, 23, 1–46. doi:10.1016/j.tetasy.2012.01.007

Return to citation in text: [1] -

Horner, L.; Balzer, W. D. Tetrahedron Lett. 1965, 6, 1157–1162. doi:10.1016/S0040-4039(01)83990-3

Return to citation in text: [1] -

Naumann, K.; Zon, G.; Mislow, K. J. Am. Chem. Soc. 1969, 91, 7012–7023. doi:10.1021/ja01053a021

Return to citation in text: [1] -

Imamoto, T.; Kikuchi, S.-i.; Miura, T.; Wada, Y. Org. Lett. 2001, 3, 87–90. doi:10.1021/ol0068041

Return to citation in text: [1] -

Kondoh, A.; Yorimitsu, H.; Oshima, K. J. Am. Chem. Soc. 2007, 129, 6996–6997. doi:10.1021/ja071622o

Return to citation in text: [1] -

Petit, C.; Favre-Réguillon, A.; Albela, B.; Bonneviot, L.; Mignani, G.; Lemaire, M. Organometallics 2009, 28, 6379–6382. doi:10.1021/om900747b

Return to citation in text: [1] -

Li, Y.; Das, S.; Zhou, S.; Junge, K.; Beller, M. J. Am. Chem. Soc. 2012, 134, 9727–9732. doi:10.1021/ja301764m

Return to citation in text: [1] -

Carboni, B.; Monnier, L. Tetrahedron 1999, 55, 1197–1248. doi:10.1016/S0040-4020(98)01103-X

Return to citation in text: [1] -

Staubitz, A.; Robertson, A. P. M.; Sloan, M. E.; Manners, I. Chem. Rev. 2010, 110, 4023–4078. doi:10.1021/cr100105a

Return to citation in text: [1] -

Brunel, J. M.; Faure, B.; Maffei, M. Coord. Chem. Rev. 1998, 178–180, 665–698. doi:10.1016/S0010-8545(98)00072-1

Return to citation in text: [1] -

Hiney, R. M.; Ficks, A.; Müller-Bunz, H.; Gilheany, D. G.; Higham, L. J. Air-stable chiral primary phosphines part (i) synthesis, stability and applications. Organometallic Chemistry; The Royal Society of Chemistry, 2011; Vol. 37, pp 27–45. doi:10.1039/9781849732802-00027

Return to citation in text: [1] -

Kanbara, T.; Takase, S.; Hayashi, R.; Kagaya, S.; Hasegawa, K.; Yamamoto, T. J. Polym. Sci., Part A: Polym. Chem. 2002, 40, 2637–2647. doi:10.1002/pola.10343

Return to citation in text: [1] -

Casey, C. P.; Paulsen, E. L.; Beuttenmueller, E. W.; Proft, B. R.; Petrovich, L. M.; Matter, B. A.; Powell, D. R. J. Am. Chem. Soc. 1997, 119, 11817–11825. doi:10.1021/ja9719440

Return to citation in text: [1] -

Jiménez, M. V.; Pérez-Torrente, J. J.; Bartolomé, M. I.; Oro, L. A. Synthesis 2009, 1916–1922. doi:10.1055/s-0028-1088060

Return to citation in text: [1] [2] [3] -

Langer, F.; Knochel, P. Tetrahedron Lett. 1995, 36, 4591–4594. doi:10.1016/0040-4039(95)00813-R

Return to citation in text: [1] [2] -

Langer, F.; Püntener, K.; Stürmer, R.; Knochel, P. Tetrahedron: Asymmetry 1997, 8, 715–738. doi:10.1016/S0957-4166(97)00027-X

Return to citation in text: [1] [2] -

Kharasch, M. S.; Jensen, E. V.; Weinhouse, S. J. Org. Chem. 1949, 14, 429–432. doi:10.1021/jo01155a014

Return to citation in text: [1] -

Larock, R. C. Tetrahedron 1982, 38, 1713–1754. doi:10.1016/0040-4020(82)80245-7

Return to citation in text: [1] [2] -

Soroka, M. Synthesis 1977, 450. doi:10.1055/s-1977-24435

Return to citation in text: [1] -

Dopp, E.; Hartmann, L. M.; Florea, A.-M.; Rettenmeier, A. W.; Hirner, A. V. Crit. Rev. Toxicol. 2004, 34, 301–333. doi:10.1080/10408440490270160

Return to citation in text: [1] -

Gerber, G. B.; Léonard, A.; Jacquet, P. Mutat. Res., Rev. Genet. Toxicol. 1980, 76, 115–141. doi:10.1016/0165-1110(80)90006-8

Return to citation in text: [1] -

Humbel, S.; Bertrand, C.; Darcel, C.; Bauduin, C.; Jugé, S. Inorg. Chem. 2003, 42, 420–427. doi:10.1021/ic026128u

Return to citation in text: [1] [2] -

Miura, T.; Yamada, H.; Kikuchi, S.-i.; Imamoto, T. J. Org. Chem. 2000, 65, 1877–1880. doi:10.1021/jo991460h

Return to citation in text: [1] -

Watanabe, T.; Gridnev, I. D.; Imamoto, T. Chirality 2000, 12, 346–351. doi:10.1002/(SICI)1520-636X(2000)12:5/6<346::AID-CHIR8>3.0.CO;2-R

Return to citation in text: [1] -

Hoge, G. J. Am. Chem. Soc. 2003, 125, 10219–10227. doi:10.1021/ja034715o

Return to citation in text: [1] -

Takahashi, Y.; Yamamoto, Y.; Katagiri, K.; Danjo, H.; Yamaguchi, K.; Imamoto, T. J. Org. Chem. 2005, 70, 9009–9012. doi:10.1021/jo051034y

Return to citation in text: [1] -

Tsuruta, H.; Imamoto, T. Synlett 2001, 999–1002. doi:10.1055/s-2001-14645

Return to citation in text: [1] -

Jugé, S.; Stephan, M.; Laffitte, J. A.; Genet, J. P. Tetrahedron Lett. 1990, 31, 6357–6360. doi:10.1016/S0040-4039(00)97063-1

Return to citation in text: [1] -

Jugé, S. Phosphorus, Sulfur Silicon Relat. Elem. 2008, 183, 233–248. doi:10.1080/10426500701734125

Return to citation in text: [1] -

Rippert, A. J.; Linden, A.; Hansen, H.-J. Helv. Chim. Acta 2000, 83, 311–321. doi:10.1002/(SICI)1522-2675(20000216)83:2<311::AID-HLCA311>3.3.CO;2-9

Return to citation in text: [1] -

Bauduin, C.; Moulin, D.; Kaloun, E. B.; Darcel, C.; Jugé, S. J. Org. Chem. 2003, 68, 4293–4301. doi:10.1021/jo026355d

Return to citation in text: [1] -

Schuman, M.; Trevitt, M.; Redd, A.; Gouverneur, V. Angew. Chem., Int. Ed. 2000, 39, 2491–2493. doi:10.1002/1521-3773(20000717)39:14<2491::AID-ANIE2491>3.3.CO;2-8

Return to citation in text: [1] -

Imamoto, T.; Oshiki, T.; Onozawa, T.; Kusumoto, T.; Sato, K. J. Am. Chem. Soc. 1990, 112, 5244–5252. doi:10.1021/ja00169a036

Return to citation in text: [1] [2] -

King, R. B. Acc. Chem. Res. 1972, 5, 177–185. doi:10.1021/ar50053a003

Return to citation in text: [1] [2] -

Gaumont, A. C.; Morise, X.; Denis, J. M. J. Org. Chem. 1992, 57, 4292–4295. doi:10.1021/jo00041a043

Return to citation in text: [1] -

Ohashi, A.; Imamoto, T. Tetrahedron Lett. 2001, 42, 1099–1101. doi:10.1016/S0040-4039(00)02192-4

Return to citation in text: [1] -

Honaker, M. T.; Salvatore, R. N. Phosphorus, Sulfur Silicon Relat. Elem. 2004, 179, 277–283. doi:10.1080/10426500490262261

Return to citation in text: [1] -

de Quadras, L.; Stahl, J.; Zhuravlev, F.; Gladysz, J. A. J. Organomet. Chem. 2007, 692, 1859–1870. doi:10.1016/j.jorganchem.2006.12.023

Return to citation in text: [1] -

Schrems, M. G.; Pfaltz, A. Chem. Commun. 2009, 6210–6212. doi:10.1039/b912680e

Return to citation in text: [1] -

Nandi, P.; Dye, J. L.; Bentley, P.; Jackson, J. E. Org. Lett. 2009, 11, 1689–1692. doi:10.1021/ol900222v

Return to citation in text: [1] -

Wolfe, B.; Livinghouse, T. J. Am. Chem. Soc. 1998, 120, 5116–5117. doi:10.1021/ja973685k

Return to citation in text: [1] -

Lebel, H.; Morin, S.; Paquet, V. Org. Lett. 2003, 5, 2347–2349. doi:10.1021/ol0347139

Return to citation in text: [1] -

Imamoto, T.; Yashio, K.; Crépy, K. V. L.; Katagiri, K.; Takahashi, H.; Kouchi, M.; Gridnev, I. D. Organometallics 2006, 25, 908–914. doi:10.1021/om050759p

Return to citation in text: [1] -

Chaux, F.; Frynas, S.; Laureano, H.; Salomon, C.; Morata, G.; Auclair, M.-L.; Stephan, M.; Merdès, R.; Richard, P.; Ondel-Eymin, M.-J.; Henry, J.-C.; Bayardon, J.; Darcel, C.; Jugé, S. C. R. Chim. 2010, 13, 1213–1226. doi:10.1016/j.crci.2010.06.001

Return to citation in text: [1] -

Ager, D. J.; Laneman, S. A. Chem. Commun. 1997, 2359–2360. doi:10.1039/a705106i

Return to citation in text: [1] [2] [3] -

Butti, P.; Rochat, R.; Sadow, A.; Togni, A. Angew. Chem., Int. Ed. 2008, 47, 4878–4881. doi:10.1002/anie.200801287

Return to citation in text: [1] -

Lanteri, M. N.; Rossi, R. A.; Martín, S. E. J. Organomet. Chem. 2009, 694, 3425–3430. doi:10.1016/j.jorganchem.2009.06.035

Return to citation in text: [1] -

Kumaraswamy, G.; Venkata Rao, G.; RamaKrishna, G. Synlett 2006, 1122–1124. doi:10.1055/s-2006-939696

Return to citation in text: [1] -

Glueck, D. S. Synlett 2007, 2627–2634. doi:10.1055/s-2007-991077

Return to citation in text: [1] -

Glueck, D. S. Coord. Chem. Rev. 2008, 252, 2171–2179. doi:10.1016/j.ccr.2007.12.023

Return to citation in text: [1] -

Chan, V. S.; Stewart, I. C.; Bergman, R. G.; Toste, F. D. J. Am. Chem. Soc. 2006, 128, 2786–2787. doi:10.1021/ja058100y

Return to citation in text: [1] -

Chan, V. S.; Chiu, M.; Bergman, R. G.; Toste, F. D. J. Am. Chem. Soc. 2009, 131, 6021–6032. doi:10.1021/ja9014887

Return to citation in text: [1] -

Scriban, C.; Glueck, D. S. J. Am. Chem. Soc. 2006, 128, 2788–2789. doi:10.1021/ja058096q

Return to citation in text: [1] [2] -

Anderson, B. J.; Glueck, D. S.; DiPasquale, A. G.; Rheingold, A. L. Organometallics 2008, 27, 4992–5001. doi:10.1021/om800534k

Return to citation in text: [1] -

Scriban, C.; Glueck, D. S.; Golen, J. A.; Rheingold, A. L. Organometallics 2007, 26, 1788–1800. doi:10.1021/om061116s

Return to citation in text: [1] -

Anderson, B. J.; Guino-o, M. A.; Glueck, D. S.; Golen, J. A.; DiPasquale, A. G.; Liable-Sands, L. M.; Rheingold, A. L. Org. Lett. 2008, 10, 4425–4428. doi:10.1021/ol801616s

Return to citation in text: [1] -

Hayashi, M.; Matsuura, Y.; Watanabe, Y. Tetrahedron Lett. 2004, 45, 9167–9169. doi:10.1016/j.tetlet.2004.10.098

Return to citation in text: [1] [2] -

Hayashi, M.; Matsuura, Y.; Watanabe, Y. Tetrahedron Lett. 2005, 46, 5135–5138. doi:10.1016/j.tetlet.2005.05.128

Return to citation in text: [1] [2] -

Yorimitsu, H. Beilstein J. Org. Chem. 2013, 9, 1269–1277. doi:10.3762/bjoc.9.143

Return to citation in text: [1] -

Mann, F. G.; Millar, I. T. J. Chem. Soc. 1952, 4453–4457. doi:10.1039/jr9520004453

Return to citation in text: [1] -

Hinton, R. C.; Mann, F. G.; Todd, D. J. Chem. Soc. 1961, 5454–5470. doi:10.1039/jr9610005454

Return to citation in text: [1] -

Hoff, M. C.; Hill, P. J. Org. Chem. 1959, 24, 356–359. doi:10.1021/jo01085a019

Return to citation in text: [1] -

Dombek, B. D. J. Org. Chem. 1978, 43, 3408–3409. doi:10.1021/jo00411a038

Return to citation in text: [1] -

Wolfsberger, W. Chem.–Ztg. 1988, 112, 53–68.

Return to citation in text: [1] -

Rauhut, M. M.; Hechenbleikner, I.; Currier, H. A.; Schaefer, F. C.; Wystrach, V. P. J. Am. Chem. Soc. 1959, 81, 1103–1107. doi:10.1021/ja01514a022

Return to citation in text: [1] -

Bunlaksananusorn, T.; Knochel, P. Tetrahedron Lett. 2002, 43, 5817–5819. doi:10.1016/S0040-4039(02)01177-2

Return to citation in text: [1] -

Mimeau, D.; Delacroix, O.; Gaumont, A.-C. Chem. Commun. 2003, 2928–2929. doi:10.1039/b311892d

Return to citation in text: [1] -

Mimeau, D.; Delacroix, O.; Join, B.; Gaumont, A.-C. C. R. Chim. 2004, 7, 845–854. doi:10.1016/j.crci.2004.02.016

Return to citation in text: [1] -