Abstract

A solution-phase automated synthesis of the versatile synthetic intermediate, Garner’s aldehyde, was demonstrated. tert-Butoxycarbonyl (Boc) protection, acetal formation, and reduction of the ester to the corresponding aldehyde were performed utilizing our originally developed automated synthesizer, ChemKonzert. The developed procedure was also useful for the synthesis of Garner’s aldehyde analogues possessing fluorenylmethyloxycarbonyl (Fmoc) or benzyloxycarbonyl (Cbz) protection.

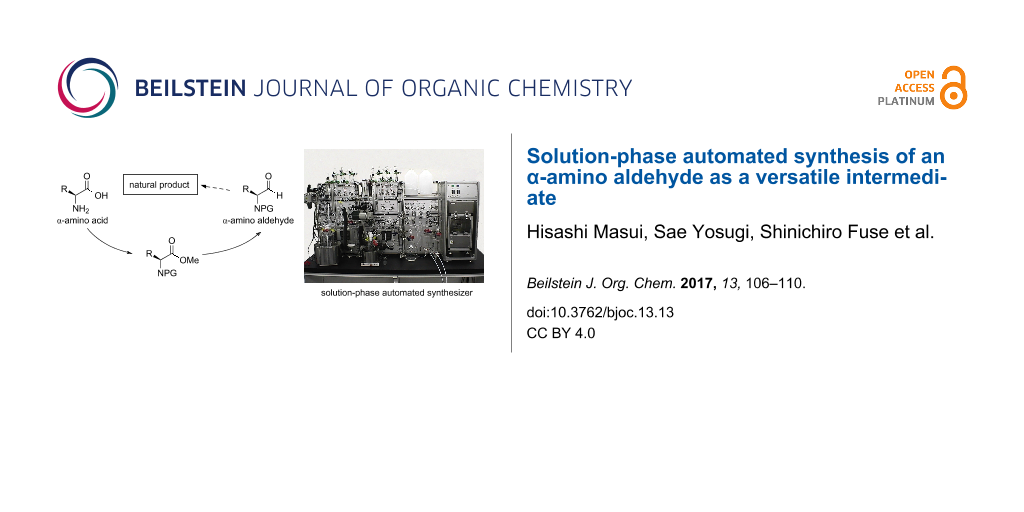

Graphical Abstract

Introduction

Automated synthesis has attracted a great deal of attention in recent years because the automation of synthetic operations improves both the reproducibility and reliability of syntheses [1-4]. Synthetic chemists frequently perform repetitive processes such as the optimization of reaction conditions, construction of compound libraries, and preparation of synthetic intermediates. These operations are very time-consuming, and do not require expert knowledge and skills. Development of automated synthetic procedures and storage of relevant digital data allow anyone to reproduce the same results anytime and anywhere using the same apparatus and reagents. As a result, synthetic chemists can spend more time on advanced and challenging problems. We previously reported automated syntheses of various bioactive compounds [5-8], including taxol, using our originally developed solution-phase automated synthesizer, ChemKonzert [9].

Protected α-amino aldehydes are versatile intermediates for the synthesis of vicinal amino alcohols and important building blocks for various bioactive natural products [10-12]. In particular, Garner’s aldehyde (4a) is very useful as a chiral building block [13-18]. It is sufficiently stable and its configurational rigidity allows stereoselective addition of nucleophiles to the aldehyde [19].

The most conventional synthesis of 4a involves the protection of the amine, the carboxylic acid, and the alcohol moiety of serine, and the subsequent reduction of carboxylic acid derivatives such as ester [20-27], thioester [28], or Weinreb amide [29,30] to the aldehyde. In addition, Burke and co-workers reported an asymmetric hydroformylation of 2,2-dimethyl-2,3-dihydrooxazole for the synthesis of 4a [31]. Although various syntheses of 4a have been established, an automated synthesis has never been demonstrated. The automated synthesis of a versatile intermediate such as 4a will improve the overall research efficiency of synthetic chemists. Herein, we report the first solution-phase automated synthesis of Garner’s aldehyde (4a) and its analogues.

Results and Discussion

Our synthetic route is shown in Scheme 1. We planned to synthesize 4a with various protecting groups from a commercially available amino ester through a three-step procedure utilizing the automated synthesizer, ChemKonzert (Figure 1).

![[1860-5397-13-13-1]](/bjoc/content/figures/1860-5397-13-13-1.jpg?scale=2.0&max-width=1024&background=FFFFFF)

Figure 1: Full picture of ChemKonzert, showing two reaction vessels (RF1 and RF2), a centrifugal separator (SF, 700 mL), two receivers (SF1 and SF2, 500 mL), two glass filters (FF1 and FF2, 500 and 100 mL), 12 substrate and reagent reservoirs (RR1–RR12, 100–200 mL), six solvent and wash-solution bottles (RS1–RS6, 500 mL), three drying pads (DT1–DT3), a round-bottom flask (CF), two solvent tanks (WT1 and WT2), and a computer controller. Transfer of compounds from a server flask to a receiver flask through a Teflon tube is performed as shown below. The receiver flask is vacuumed by a diaphragm pump and N2 flow pushes the compound into the server flask. The flow of liquid in the tube is monitored by a photosensor that detects the difference in reflective index between gas and liquid. All the gas/liquid flows are controlled by solenoid valves and/or rotary valves. This transfer system avoids direct contacts of pumps with compounds that frequently cause mechanical troubles of pumps. Formation of emulsions during phase separation is one of the common problems for liquid-phase automated synthesizers that can perform aqueous work-up. ChemKonzert uses a centrifuge instrument to solve this problem: the emulsified mixture is transferred to the separating flask and the phases are separated by centrifugation. The separated mixture is then transferred to a receiver flask from the lower layer by passing through a flow-type electro-conductivity sensor, which detects the difference in conductivity between the organic phase and aqueous phase. When the sensor detects the boundary of the phases, the solenoid valve is changed to send the upper layer to a different receiver.

Figure 1: Full picture of ChemKonzert, showing two reaction vessels (RF1 and RF2), a centrifugal separator (S...

Figure 1 shows the automated synthesizer ChemKonzert and its various components. An automated synthesis of 4a was examined utilizing ChemKonzert (Scheme 1). It is important to examine and check the reaction conditions manually before performing the automated synthesis. Therefore, we optimized the reaction time and the work-up method was modified. We started with the Boc protection of methyl L-serinate hydrochloride (1). The computer controlling the automated synthesizer was programmed with a specific procedure. The substrate, reagents, solvents, and wash solutions were added to the reaction vessel (RF1), reagent reservoir (RR1), solvent bottles (RS1–3), and wash solution bottles (RS4–6), respectively. A solution of methyl L-serinate hydrochloride in THF was stirred at 25 °C in RF1, to which a solution of triethylamine in THF and Boc2O in THF was added. Originally, the respective solutions were loaded in the reagent reservoirs (RR1 and RR3). After stirring at 25 °C for 5 h, the reaction mixture was diluted with ethyl acetate from RS1 and was quenched by adding 1 M HCl from RR2. The reaction mixture was then transferred to the centrifugal separator (SF). After centrifugation, the two resulting phases were separated; their electroconductivities measured with a sensor and transferred to two receivers (SF1 and SF2). The aqueous phase in SF1 was returned to RF1. Ethyl acetate, from RS1, was added, and the mixture was stirred for 3 min and then transferred to SF. After performing the extraction, the combined organic mixture in the receiver (SF2) was washed with 10% aqueous NaCl solution from RS3. The organic layer was separated in SF, transferred to SF2, subsequently passed through a plug of anhydrous Na2SO4 (DT1) and collected in a round-bottom flask (CF1). The collected solution was manually concentrated in vacuo. The obtained residue was purified manually using silica gel column chromatography. Carbamate 2a was obtained in 82% yield.

Acetal formation was also demonstrated using ChemKonzert. A solution of substrate 2a in dichloromethane was stirred at 25 °C in the reaction vessel (RF1), to which a solution of 2,2-dimethoxypropane in dichloromethane and a solution of boron trifluoride·ethyl ether complex in dichloromethane were added. Originally, the respective solutions were loaded into the reagent reservoirs (RR1 and RR3). After stirring at 25 °C for 3 h, the reaction was quenched by adding 50% aqueous NaOH solution. When the NaOH solution was added to RF1, the yield of the target compound decreased because of the undesired hydrolysis of the acetonide. Therefore, the reaction mixture was transferred to the centrifugal separator (SF), NaOH solution was added to RF1 and the reaction mixture in SF was added to the NaOH solution in RF1. This reverse addition improved the yield. The subsequent automated aqueous work-up, manual concentration, and silica gel column chromatography afforded acetonide 3a in 99% yield.

DIBAL reduction was also achieved using ChemKonzert. The amount of Rochelle salt required to diminish the aluminum salt generated from DIBAL was optimized in manual operation preliminarily. A solution of the substrate in toluene was stirred at −80 °C in the reaction vessel (RF1). A solution of DIBAL in toluene, originally loaded into the reagent reservoir (RR1), was added to RF1. After further stirring at −80 °C for 4 h, the reaction was quenched by adding saturated aqueous Rochelle salt solution at 25 °C from the solvent bottle RS2. The subsequent automated aqueous work-up, manual concentration, and silica gel column chromatography afforded 4a in 71% yield. The observed yields of the automated syntheses were similar to those obtained from the corresponding reported manual syntheses (see Scheme 1).

Garner’s aldehyde analogues containing a Fmoc [32] or Cbz [33-35] group were synthesized using the established procedure. Protection of the amino group in methyl serinate using Fmoc–OSu or CbzCl afforded the corresponding carbamates in good yields (Table 1, experimental details, see Supporting Information File 1). Acetal formation and reduction were performed by the developed procedure in ChemKonzert (Table 1).

The Garner’s aldehydes containing an Fmoc or Cbz protecting group (PG) could be synthesized from the corresponding methyl ester; however, lower yields were obtained for the DIBAL reduction, probably due to the DIBAL-mediated removal of the carbamates [32].

Conclusion

In conclusion, the first solution-phase automated synthesis of 4a (Boc protection) was demonstrated utilizing our originally developed automated synthesizer, ChemKonzert. The observed yields were comparable to those of the corresponding reported manual syntheses. In addition, 4b and 4c (Fmoc and Cbz protection) were also synthesized automatically according to the established procedure. Garner’s aldehyde (4a) and its analogues are very important versatile intermediates. The automated synthesis of 4a can be applied to the synthesis of various useful compounds containing a vicinal amino alcohol moiety.

Supporting Information

| Supporting Information File 1: Synthetic procedures and 1H NMR spectral data of compounds 2a–c, 3a–c, and 4a–c. | ||

| Format: PDF | Size: 318.8 KB | Download |

References

-

Cork, D. G.; Sugawara, T., Eds. Laboratory Automation in the Chemical Industries; Marcel Dekker Inc.: New York, 2002. doi:10.1201/9780203908945

Return to citation in text: [1] -

Li, J.; Ballmer, S. G.; Gillis, E. P.; Fujii, S.; Schmidt, M. J.; Palazzolo, A. M. E.; Lehmann, J. W.; Morehouse, G. F.; Burke, M. D. Science 2015, 347, 1221–1226. doi:10.1126/science.aaa5414

Return to citation in text: [1] -

Adamo, A.; Beingessner, R. L.; Behnam, M.; Chen, J.; Jamison, T. F.; Jensen, K. F.; Monbaliu, J.-C. M.; Myerson, A. S.; Revalor, E. M.; Snead, D. R.; Stelzer, T.; Weeranoppanant, N.; Wong, S. Y.; Zhang, P. Science 2016, 352, 61–67. doi:10.1126/science.aaf1337

Return to citation in text: [1] -

Seeberger, P. H.; Werz, D. B. Nat. Rev. Drug Discovery 2005, 4, 751–763. doi:10.1038/nrd1823

Return to citation in text: [1] -

Doi, T.; Fuse, S.; Miyamoto, S.; Nakai, K.; Sasuga, D.; Takahashi, T. Chem. – Asian J. 2006, 1, 370–383. doi:10.1002/asia.200600156

Return to citation in text: [1] -

Fuse, S.; Ikebe, A.; Oosumi, K.; Karasawa, T.; Matsumura, K.; Izumikawa, M.; Johmoto, K.; Uekusa, H.; Shin-ya, K.; Doi, T.; Takahashi, T. Chem. – Eur. J. 2015, 21, 9454–9460. doi:10.1002/chem.201500703

Return to citation in text: [1] -

Fuse, S.; Okada, K.; Iijima, Y.; Munakata, A.; Machida, K.; Takahashi, T.; Takagi, M.; Shin-ya, K.; Doi, T. Org. Biomol. Chem. 2011, 9, 3825–3833. doi:10.1039/c0ob01169j

Return to citation in text: [1] -

Tanaka, Y.; Fuse, S.; Tanaka, H.; Doi, T.; Takahashi, T. Org. Process Res. Dev. 2009, 13, 1111–1121. doi:10.1021/op9002455

Return to citation in text: [1] -

Machida, K.; Hirose, Y.; Fuse, S.; Sugawara, T.; Takahashi, T. Chem. Pharm. Bull. 2010, 58, 87–93. doi:10.1248/cpb.58.87

Return to citation in text: [1] -

Kher, S. S.; Penzo, M.; Fulle, S.; Finn, P. W.; Blackman, M. J.; Jirgensons, A. Bioorg. Med. Chem. Lett. 2014, 24, 4486–4489. doi:10.1016/j.bmcl.2014.07.086

Return to citation in text: [1] -

Segade, Y.; Montaos, M. A.; Rodríguez, J.; Jiménez, C. Org. Lett. 2014, 16, 5820–5823. doi:10.1021/ol502958u

Return to citation in text: [1] -

Vasudevan, N.; Kashinath, K.; Reddy, D. S. Org. Lett. 2014, 16, 6148–6151. doi:10.1021/ol503011g

Return to citation in text: [1] -

Singh, P.; Manna, S. K.; Panda, G. Tetrahedron 2014, 70, 1363–1374. doi:10.1016/j.tet.2013.11.074

Return to citation in text: [1] -

Takahata, H.; Banba, Y.; Ouchi, H.; Nemoto, H. Org. Lett. 2003, 5, 2527–2529. doi:10.1021/ol034886y

Return to citation in text: [1] -

Sa-ei, K.; Montgomery, J. Tetrahedron 2009, 65, 6707–6711. doi:10.1016/j.tet.2009.05.029

Return to citation in text: [1] -

Bhabak, K. P.; Proksch, D.; Redmer, S.; Arenz, C. Bioorg. Med. Chem. 2012, 20, 6154–6161. doi:10.1016/j.bmc.2012.08.035

Return to citation in text: [1] -

Sudhakar, N.; Kumar, A. R.; Prabhakar, A.; Jagadeesh, B.; Rao, B. V. Tetrahedron Lett. 2005, 46, 325–327. doi:10.1016/j.tetlet.2004.11.035

Return to citation in text: [1] -

Chen, J.; Chen, X.; Bois-Choussy, M.; Zhu, J. J. Am. Chem. Soc. 2006, 128, 87–89. doi:10.1021/ja0571794

Return to citation in text: [1] -

Passiniemi, M.; Koskinen, A. M. P. Beilstein J. Org. Chem. 2013, 9, 2641–2659. doi:10.3762/bjoc.9.300

Return to citation in text: [1] -

Karjalainen, O. K.; Koskinen, A. M. P. Tetrahedron 2014, 70, 2444–2448. doi:10.1016/j.tet.2014.02.020

Return to citation in text: [1] -

Upadhyay, P. K.; Kumar, P. Synthesis 2010, 3063–3066. doi:10.1055/s-0030-1258185

Return to citation in text: [1] -

Garner, P.; Park, J. M. Org. Synth. 1992, 70, 18–28. doi:10.15227/orgsyn.070.0018

Return to citation in text: [1] -

Foss, F. W., Jr.; Snyder, A. H.; Davis, M. D.; Rouse, M.; Okusa, M. D.; Lynch, K. R.; Macdonald, T. L. Bioorg. Med. Chem. 2007, 15, 663–677. doi:10.1016/j.bmc.2006.10.060

Return to citation in text: [1] -

Ocejo, M.; Vicario, J. L.; Badía, D.; Carrillo, L.; Reyes, E. Synlett 2005, 2110–2112. doi:10.1055/s-2005-871947

Return to citation in text: [1] -

Dondoni, A.; Perroni, D. Org. Synth. 2000, 77, 64–77. doi:10.15227/orgsyn.077.0064

Return to citation in text: [1] -

Jurczak, J.; Gryko, D.; Kobrzycka, E.; Gruza, H.; Prokopowicz, P. Tetrahedron 1998, 54, 6051–6064. doi:10.1016/S0040-4020(98)00299-3

Return to citation in text: [1] -

Roush, W. R.; Hunt, J. A. J. Org. Chem. 1995, 60, 798–806. doi:10.1021/jo00109a008

Return to citation in text: [1] -

Trajkovic, M.; Ferjancic, Z.; Saicic, R. N. Tetrahedron: Asymmetry 2012, 23, 602–604. doi:10.1016/j.tetasy.2012.03.019

Return to citation in text: [1] -

Hoffman, T. J.; Kolleth, A.; Rigby, J. H.; Arseniyadis, S.; Cossy, J. Org. Lett. 2010, 12, 3348–3351. doi:10.1021/ol101145t

Return to citation in text: [1] -

Cortes-Clerget, M.; Gager, O.; Monteil, M.; Pirat, J.-L.; Migianu-Griffoni, E.; Deschamp, J.; Lecouvey, M. Adv. Synth. Catal. 2016, 358, 34–40. doi:10.1002/adsc.201500794

Return to citation in text: [1] -

Clemens, A. J. L.; Burke, S. D. J. Org. Chem. 2012, 77, 2983–2985. doi:10.1021/jo300025t

Return to citation in text: [1] -

Rush, J.; Bertozzi, C. R. Org. Lett. 2006, 8, 131–134. doi:10.1021/ol052623t

Return to citation in text: [1] [2] -

Jiang, S.; Li, P.; Lai, C. C.; Kelley, J. A.; Roller, P. P. J. Org. Chem. 2006, 71, 7307–7314. doi:10.1021/jo061037q

Return to citation in text: [1] -

Martin, N. I.; Woodward, J. J.; Winter, M. B.; Marletta, M. A. Bioorg. Med. Chem. Lett. 2009, 19, 1758–1762. doi:10.1016/j.bmcl.2009.01.076

Return to citation in text: [1] -

Lingamurthy, M.; Jagadeesh, Y.; Ramakrishna, K.; Rao, B. V. J. Org. Chem. 2016, 81, 1367–1377. doi:10.1021/acs.joc.5b02275

Return to citation in text: [1]

| 1. | Cork, D. G.; Sugawara, T., Eds. Laboratory Automation in the Chemical Industries; Marcel Dekker Inc.: New York, 2002. doi:10.1201/9780203908945 |

| 2. | Li, J.; Ballmer, S. G.; Gillis, E. P.; Fujii, S.; Schmidt, M. J.; Palazzolo, A. M. E.; Lehmann, J. W.; Morehouse, G. F.; Burke, M. D. Science 2015, 347, 1221–1226. doi:10.1126/science.aaa5414 |

| 3. | Adamo, A.; Beingessner, R. L.; Behnam, M.; Chen, J.; Jamison, T. F.; Jensen, K. F.; Monbaliu, J.-C. M.; Myerson, A. S.; Revalor, E. M.; Snead, D. R.; Stelzer, T.; Weeranoppanant, N.; Wong, S. Y.; Zhang, P. Science 2016, 352, 61–67. doi:10.1126/science.aaf1337 |

| 4. | Seeberger, P. H.; Werz, D. B. Nat. Rev. Drug Discovery 2005, 4, 751–763. doi:10.1038/nrd1823 |

| 13. | Singh, P.; Manna, S. K.; Panda, G. Tetrahedron 2014, 70, 1363–1374. doi:10.1016/j.tet.2013.11.074 |

| 14. | Takahata, H.; Banba, Y.; Ouchi, H.; Nemoto, H. Org. Lett. 2003, 5, 2527–2529. doi:10.1021/ol034886y |

| 15. | Sa-ei, K.; Montgomery, J. Tetrahedron 2009, 65, 6707–6711. doi:10.1016/j.tet.2009.05.029 |

| 16. | Bhabak, K. P.; Proksch, D.; Redmer, S.; Arenz, C. Bioorg. Med. Chem. 2012, 20, 6154–6161. doi:10.1016/j.bmc.2012.08.035 |

| 17. | Sudhakar, N.; Kumar, A. R.; Prabhakar, A.; Jagadeesh, B.; Rao, B. V. Tetrahedron Lett. 2005, 46, 325–327. doi:10.1016/j.tetlet.2004.11.035 |

| 18. | Chen, J.; Chen, X.; Bois-Choussy, M.; Zhu, J. J. Am. Chem. Soc. 2006, 128, 87–89. doi:10.1021/ja0571794 |

| 10. | Kher, S. S.; Penzo, M.; Fulle, S.; Finn, P. W.; Blackman, M. J.; Jirgensons, A. Bioorg. Med. Chem. Lett. 2014, 24, 4486–4489. doi:10.1016/j.bmcl.2014.07.086 |

| 11. | Segade, Y.; Montaos, M. A.; Rodríguez, J.; Jiménez, C. Org. Lett. 2014, 16, 5820–5823. doi:10.1021/ol502958u |

| 12. | Vasudevan, N.; Kashinath, K.; Reddy, D. S. Org. Lett. 2014, 16, 6148–6151. doi:10.1021/ol503011g |

| 9. | Machida, K.; Hirose, Y.; Fuse, S.; Sugawara, T.; Takahashi, T. Chem. Pharm. Bull. 2010, 58, 87–93. doi:10.1248/cpb.58.87 |

| 5. | Doi, T.; Fuse, S.; Miyamoto, S.; Nakai, K.; Sasuga, D.; Takahashi, T. Chem. – Asian J. 2006, 1, 370–383. doi:10.1002/asia.200600156 |

| 6. | Fuse, S.; Ikebe, A.; Oosumi, K.; Karasawa, T.; Matsumura, K.; Izumikawa, M.; Johmoto, K.; Uekusa, H.; Shin-ya, K.; Doi, T.; Takahashi, T. Chem. – Eur. J. 2015, 21, 9454–9460. doi:10.1002/chem.201500703 |

| 7. | Fuse, S.; Okada, K.; Iijima, Y.; Munakata, A.; Machida, K.; Takahashi, T.; Takagi, M.; Shin-ya, K.; Doi, T. Org. Biomol. Chem. 2011, 9, 3825–3833. doi:10.1039/c0ob01169j |

| 8. | Tanaka, Y.; Fuse, S.; Tanaka, H.; Doi, T.; Takahashi, T. Org. Process Res. Dev. 2009, 13, 1111–1121. doi:10.1021/op9002455 |

| 29. | Hoffman, T. J.; Kolleth, A.; Rigby, J. H.; Arseniyadis, S.; Cossy, J. Org. Lett. 2010, 12, 3348–3351. doi:10.1021/ol101145t |

| 30. | Cortes-Clerget, M.; Gager, O.; Monteil, M.; Pirat, J.-L.; Migianu-Griffoni, E.; Deschamp, J.; Lecouvey, M. Adv. Synth. Catal. 2016, 358, 34–40. doi:10.1002/adsc.201500794 |

| 28. | Trajkovic, M.; Ferjancic, Z.; Saicic, R. N. Tetrahedron: Asymmetry 2012, 23, 602–604. doi:10.1016/j.tetasy.2012.03.019 |

| 33. | Jiang, S.; Li, P.; Lai, C. C.; Kelley, J. A.; Roller, P. P. J. Org. Chem. 2006, 71, 7307–7314. doi:10.1021/jo061037q |

| 34. | Martin, N. I.; Woodward, J. J.; Winter, M. B.; Marletta, M. A. Bioorg. Med. Chem. Lett. 2009, 19, 1758–1762. doi:10.1016/j.bmcl.2009.01.076 |

| 35. | Lingamurthy, M.; Jagadeesh, Y.; Ramakrishna, K.; Rao, B. V. J. Org. Chem. 2016, 81, 1367–1377. doi:10.1021/acs.joc.5b02275 |

| 20. | Karjalainen, O. K.; Koskinen, A. M. P. Tetrahedron 2014, 70, 2444–2448. doi:10.1016/j.tet.2014.02.020 |

| 21. | Upadhyay, P. K.; Kumar, P. Synthesis 2010, 3063–3066. doi:10.1055/s-0030-1258185 |

| 22. | Garner, P.; Park, J. M. Org. Synth. 1992, 70, 18–28. doi:10.15227/orgsyn.070.0018 |

| 23. | Foss, F. W., Jr.; Snyder, A. H.; Davis, M. D.; Rouse, M.; Okusa, M. D.; Lynch, K. R.; Macdonald, T. L. Bioorg. Med. Chem. 2007, 15, 663–677. doi:10.1016/j.bmc.2006.10.060 |

| 24. | Ocejo, M.; Vicario, J. L.; Badía, D.; Carrillo, L.; Reyes, E. Synlett 2005, 2110–2112. doi:10.1055/s-2005-871947 |

| 25. | Dondoni, A.; Perroni, D. Org. Synth. 2000, 77, 64–77. doi:10.15227/orgsyn.077.0064 |

| 26. | Jurczak, J.; Gryko, D.; Kobrzycka, E.; Gruza, H.; Prokopowicz, P. Tetrahedron 1998, 54, 6051–6064. doi:10.1016/S0040-4020(98)00299-3 |

| 27. | Roush, W. R.; Hunt, J. A. J. Org. Chem. 1995, 60, 798–806. doi:10.1021/jo00109a008 |

| 19. | Passiniemi, M.; Koskinen, A. M. P. Beilstein J. Org. Chem. 2013, 9, 2641–2659. doi:10.3762/bjoc.9.300 |

| 31. | Clemens, A. J. L.; Burke, S. D. J. Org. Chem. 2012, 77, 2983–2985. doi:10.1021/jo300025t |

© 2017 Masui et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)