Abstract

The aim of this review is to give an update on current progress in the synthesis, properties and applications of thiophene-based conjugated systems bearing tetrathiafulvalene (TTF) units. We focus mostly on the synthesis of poly- and oligothiophenes with TTF moieties fused to the thiophene units of the conjugated backbone either directly or via a dithiin ring. The electrochemical behaviour of these materials and structure–property relationships are discussed. The study is directed towards the development of a new type of organic semiconductors based on these hybrid materials for application in organic field effect transistors and solar cells.

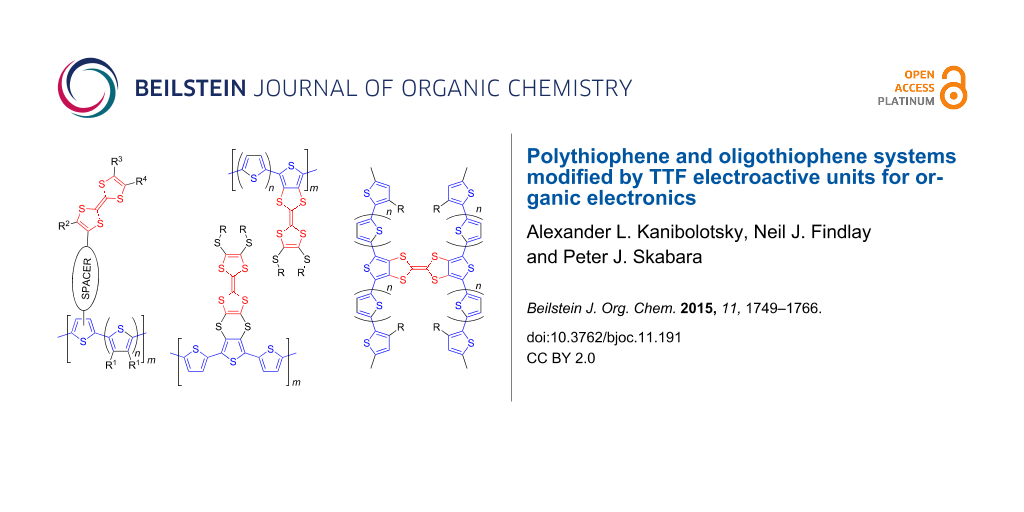

Graphical Abstract

Introduction

Sulfur-rich π-functional systems are important building blocks in materials chemistry. Among them, tetrathiafulvalene (TTF) electron donor and polythiophene (PT) conjugated systems are highly popular classes of organic compounds which have shown fascinating conducting and electronic properties. The advantages of PT-based materials are their synthetic versatility, excellent film-forming properties and potential to increase the dimensionality of charge carrier transport [1] by involving π–π stacking interactions. Varying the substituents of the conjugated backbone allows control over the polymer’s effective conjugation length and electronic properties, whilst also influencing the extent of inter-chain interactions. Two of the most studied polythiophene materials for organic electronics are regioregular poly(3-hexylthiophene) (P3HT) [2,3] and poly(3,4-ethylenedioxythiophene) (PEDOT) [4], which is highly conductive in its doped state. P3HT has become a benchmark polymer semiconductor for both bulk hetero-junction solar cells (BHJSCs) [5] and organic field effect transistors (OFETs) [6,7], whereas the PEDOT:poly(styrene sulfonate) salt (PEDOT:PSS) was originally investigated for antistatic applications but is now commercially available for its use as a hole-injecting/collecting material for organic light emitting diodes (OLEDs) and BHJSCs. So far, various electroactive units have been anchored aside the polythiophene backbone, including ferrocene [8], porphyrin [9], 2-carboxyanthraquinone [10], 1,3-dithiole-2-ylidenefluorene [11,12], dithiinoquinoxaline [13,14] and fullerene C60 [15,16]. The incorporation of acceptor units into a conjugated network is a standard way to narrow the HOMO/LUMO band gap and examples of such units include dioxopyrrolopyrrole (DPP) [17-19], benzodifuranone [20] and boron-dipyrromethene (BODIPY) [21,22].

As a different class of electroactive materials, TTF derivatives are well-known as reversible redox systems with low potentials of oxidation to cation radical and dication species. The high level of stability observed for the oxidised TTF π-electron system arises from the aromatic nature of the oxidised 1,3-dithiolium rings and this has triggered tremendous efforts directed toward the synthesis of compounds with TTF donor units and subsequent investigation of their properties. Since the first discovery of the semiconducting properties of TTF and its cation radical [23], and the metallic behaviour of the TTF-TCNQ charge transfer complex [24], great attention was focused on the preparation of TTF mixed valance state materials, which showed superconducting properties [25]. Fusing the TTF unit with dithiin rings in bis(ethylenedithio)tetrathiafulvalene (BEDT-TTF) led to the extension of 1D π–π stacking intermolecular interactions in a donor sheet of a mixed valance state system to 2D with a significant contribution from S···S non-covalent interactions [26]. This gave a record transition temperature among TTF mixed valence ambient pressure superconductors in the salt κ-(BEDT-TTF)2Cu[N(CN)2]Br [27]. In an attempt to create macromolecular compounds with multi-electron redox activity and to further increase the dimensionality of their intermolecular interactions in the solid phase, the TTF units were incorporated into dendritic structures [28-32]. The extraordinary propensity of TTF and its doped species to aggregate was the reason for using this unit in the design of gelators [33,34].

Combining the exceptional donor strength of TTF and excellent film-forming properties of a conjugated polymer (CP) opens up the possibility to create promising materials with interesting redox behaviour. So far the TTF unit has been used for redox modification of various CP systems [35] including incorporation within the conjugated backbone [36,37], as a pendant unit [38-40] and direct fusion to the π-conjugated system of the polymer [41,42]. Incorporation of a TTF unit into a PT architecture allows the creation of interesting hybrid redox systems with a wide range of electro-activities. The goal of this review is to provide an update on the synthesis of TTF-PT hybrid conjugated systems, their properties and their application to organic electronics. Both electrodeposition and chemical polymerisation will be considered as methods of producing the PT conjugated backbone. In some cases poly(ethynylene/vinylene) homologues will be considered for comparison. Additionally, monodispersed tetrathiafulvalene-oligothiophene (TTF-OT) conjugated systems will be discussed as their well-defined structures provide a stronger insight into structure–property relationships.

Review

PT conjugated systems with TTF units within the polymer backbone or as pendant units

The most straightforward way to modify PT conjugated systems is to incorporate the TTF unit into the polymer backbone or attach it as a pendant unit, as only minor modifications to the synthesis of the TTF/thiophene monomer are required. Both chemical [43] and electrochemical polymerisation [44] have been used to incorporate a TTF moiety within the polythiophene backbone. Yamamoto coupling of diiodo monomers 1a and 1b provided polymer 1c, albeit with a modest molecular weight (Mw = 5800 Da) compared to that of the polymer 1d, which was obtained by Sonogashira coupling of 1b with 1e and exhibited a partial solubility in THF with Mw = 610000 Da (THF soluble fraction) [43] (Scheme 1).

Scheme 1: The synthesis of PT based conjugated systems with the TTF unit incorporated within the polymer backbone.

Scheme 1: The synthesis of PT based conjugated systems with the TTF unit incorporated within the polymer back...

Polymer properties in the solid state are hugely important for organic electronics applications, with the electronic properties of materials being greatly affected by film morphology. The electropolymerisation technique creates a simple test for the viability of a certain structural motif in the PT chain and is considered both as a potential route for the synthesis of a new functional CP and also as a method for the modification of an electrode surface [45]. The electrodeposition of a polymer has a number of advantages over any chemical protocol: 1) it is cheap and can be performed on a very small scale; 2) it requires no reagent or catalyst and is very clean; 3) due to the interfacial nature of a polymer growth the spectro-electrochemical investigation of the polymer film is straightforward; 4) it provides control over the morphology through the choice of solvent, electrolyte and/or the method of electrodeposition. TTF has been incorporated into a CP backbone by electropolymerisation of its bis(EDOT) derivative to afford polymer 2 [44] (Scheme 1). All the polymers (1c,d and 2) exhibited electro-activity of the TTF units. Due to a break in conjugation of the polymers in their neutral state there is no electrochemical signature of the PT backbone. As such, the aforementioned systems cannot be considered as true TTF-PT systems.

The first example of the electrochemical preparation of PT with a pendant TTF-carboxylic unit (3) was reported by the Bryce group [46] (Scheme 2). The mixture of CH2Cl2 with PhNO2, to supress the electrochemical activity of TTF during electropolymerisation, was used as a solvent. Another example of a TTF-PT hybrid polymer (4), now with an ester linkage between the tetrathio-TTF derivative and the PEDOT polymer backbone, has also been reported [47]. The TTF-functionalised EDOT monomer unit allowed the authors to manage the electropolymerisation in an acetonitrile:CH2Cl2 mixture using both potentiodynamic and potentiostatic electrodeposition. Nevertheless, the labile ester bond and its potential cleavage remain an issue due to formation of acid upon electropolymerisation.

Scheme 2: PT with pendant TTF units, prepared by electropolymerisation.

Scheme 2: PT with pendant TTF units, prepared by electropolymerisation.

Roncali and co-workers used more reliable ether bonds to anchor a TTF moiety to a thiophene monomer via a long aliphatic spacer group, avoiding the effect of steric interactions between pendant TTF units and increasing the conjugation length of the PT backbone (Scheme 2). They successfully electropolymerised TTF-modified thiophene monomer 5a to polymer 6a from a nitrobenzene monomer solution [48]. Cyclic voltammetry of the polymer thin film revealed the splitting of the first oxidation wave during the cathodic run, which the authors attributed to a stepwise reduction from the aggregated radical cation to an intermediate mixed valence state, then further reduction to the neutral species. To decrease the difference in the oxidation potential of TTF and that of the thiophene backbone of the monomer, the TTF-modified bithiophene compounds 5b–d were used as monomers for electropolymerisation to 6b–d [49]. The appearance of an additional, well-defined oxidation wave in the CV, as the first oxidation wave was split in both anodic and cathodic runs, was evident for all polymers, but clearest for 6c. This was assigned to the formation of a mixed valence state and aggregated cation radical [50]. The relative increase in the peak current during oxidation to the dication, compared to that of cation radical formation, was explained by an additional contribution to charge transport from the doped PT backbone [49]. The oxidation of the latter did not contribute significantly to the CV of the polymer films due to the much stronger electrochemical response of the TTF. However, from a separate experiment in which the authors electropolymerised monomer 5c (2 × 10−2 M) in the presence of a double excess of a non-modified bithiophene monomer 7 [49], the contribution from the PT backbone oxidation in the CV of the final copolymer was clear. However, it was unresolved from the wave of TTF2+ formation during the anodic run (Figure 1).

![[1860-5397-11-191-1]](/bjoc/content/figures/1860-5397-11-191-1.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 1: Cyclic voltammograms of copolymers electrodeposited from nitrobenzene solutions of TTF modified monomer 6c and nonsubstituted bithiophenes 7. Left: 2 × 10−2 M of 6c; middle: 2 × 10−2 M of 6c + 1 × 10−2 M of 7; right: 2 × 10−2 M of 6c + 4 × 10−2 M of 7; ref. SCE, 0.1 M (TBA)PF6 in acetonitrile as an electrolyte. Reproduced with permission from [49]. Copyright 1998 Wiley-VCH.

Figure 1: Cyclic voltammograms of copolymers electrodeposited from nitrobenzene solutions of TTF modified mon...

An alternative way of preparing PT hybrid materials with TTF pendant groups was to modify the pre-polymerised PT containing an appropriate functionality with a TTF derivative. The Roncali group reported electropolymerisation of EDOT monomers 8a,b bearing a ω-iodo-functionalised aliphatic chain to polymers 9a,b, which was followed by the heterogeneous reaction of the polymeric film with TTF thiolates 10a [51] and 10c [52] to produce the polymers 11a–d (Scheme 3). The polymers 11a,c were also prepared by electropolymerisation of the corresponding TTF functionalised monomers 12a,c [52]. The electrochemical response from the polymeric film of 11c, prepared by functionalising prepolymerised PEDOT 9a with thiolatoTTF 10c, and that prepared by direct electropolymerisation of 12c turned out to be very similar, confirming that the heterogeneous derivatisation of 9a with 10c was rapid and quantitative with no significant effect on the integrity of the polymer. The crown ether TTF modified polymers 11c,d were tested for electrochemical recognition of Ba2+ ions. At [Ba2+] saturation concentration of 4 mM the shifts of the first CV peak for 11c and 11d films were +60 and +30 mV with a TTF electrode coverage of 1.4 × 10−9 and 9 × 10−9 mol/cm2, respectively.

Scheme 3: PT with pendant TTF units prepared by electropolymerisation and post-modification of polymerised PT through iodoalkyl functionality.

Scheme 3: PT with pendant TTF units prepared by electropolymerisation and post-modification of polymerised PT...

A recent example of the chemical preparation of PT with pendant TTF-units has been reported [53] (Scheme 4) where direct arylation polymerisation of quaterthiophene 13a and 3-(acetoxymethyl)thiophene (13b), followed by acidic hydrolysis of the ester groups in polymer 13c, provided the polymer 13d with hydroxy groups for further modification by ω-bromooctyloxymethylTTF 13f . The CV of the final PT-TTF compound 13e showed mainly the characteristics of the PT backbone; due to the low content of the TTF unit in the polymer 13e, the two oxidation waves related to formation of TTF cation radical and dication were not apparent in the CV of the film, but were discernible in solution state. Pure 13e, and 13e with a small amount of the parent poly(3,3'''-didodecyl-2,2':5',2'':5'',2'''-quaterthiophene) (PQT12) (5 or 10 wt %), did not exhibit any OFET activity due to hole trapping by the TTF unit. This hole trapping was explained to be the reason for a negative Seebeck coefficient of the non-doped polymer 13e and was used for sensing trinitrotoluene (TNT) using the drain-source current-increase response to TTF-TNT complexation in an OFET fabricated from 13e with 5% of PQT12.

Scheme 4: Synthesis of PT with pendant TTF by post-modification of the polymer prepared by direct arylation.

Scheme 4: Synthesis of PT with pendant TTF by post-modification of the polymer prepared by direct arylation.

Conjugated OT systems with fused TTF units

Synthesis of the monomer units

Incorporation of a TTF unit into a PT architecture via fusion to the polymer backbone allows the realisation of highly diverse electroactive conjugated systems with different contributions to the properties from each of the components. In contrast to polymers where TTF is attached as a pendant unit or incorporated within a PT backbone, the construction of the TTF unit in this case is normally performed through coupling of the corresponding dithiol units, with one or both of them already fused to the monomer thiophene backbone precursor. The retrosynthetic scheme for these monomers with direct fusion of the TTF unit to a thiophene 14a–c is shown in Scheme 5, with the key building block thieno[3,4-d][1,3]dithiole-2-one 15a–c.

Scheme 5: Retrosynthetic scheme for the synthesis of the monomer building block which is required for the preparation of PT with TTF directly fused to the polymer backbone. Bis(bromomethyl) derivative 21 and diketone 22 are starting compounds for synthetic pathways A and B, respectively.

Scheme 5: Retrosynthetic scheme for the synthesis of the monomer building block which is required for the pre...

Where there is no substitution at the α-position of the thiophene monomer, e.g., 14a, triethylphosphite mediated heterocoupling of 15a with 4,5-bis(hexylthio)-1,3-dithiole-2-thione (16) proceeds in low yield (20–30%) [54]. However, the same procedure for the synthesis of dibromo derivative 14b turned out to be more effective, with the monomer 14b being isolated in 70% yield [55]. The starting compound required for this, 4,6-dibromothieno[3,4-d][1,3]dithiole-2-one (15b), can be efficiently obtained by brominating compound 15a, which in turn is synthesised by mercury(II) acetate assisted transchalcogenation reaction from the corresponding thione 17. Unsubstituted thieno[3,4-d][1,3]dithiole-2-thione (17) can be constructed by building up either of its two rings, involving cyclisation of a suitable precursor already containing one existing heterocycle. The construction of the 1,3-dithiole-2-thione unit of 17 can be completed using 3,4-dibromothiophene (18) as a starting material [56], or by oxidation of dihydroderivative 19 obtained from 4,6-dihydrothieno[3,4-d][1,2,3]thiadiazole (20) [57,58]. However, the most reliable method for the synthesis of 4,6-dihydrothieno[3,4-d][1,3]dithiole-2-thione (19) is cyclisation of 4,5-bis(bromomethyl)-1,3-dithiole-2-thione (21) [59] (synthetic pathway A).

For 4,6-diaryl substituted thienodithiole-2-ones, e.g., 4,6-di(thiophen-2-yl)thieno[3,4-d][1,3]dithiol-2-one (15c), construction of the thiophene directly onto the dithiole ring seems to be the only strategy, which can be readily achieved by reductive cyclisation of diketone 22 [60] (synthetic pathway B). Compound 22 is normally synthesised by transchalcogenation from the corresponding 1,3-dithiole-2-thione derivative. One method for the synthesis of 1,3-dithiole-2-thione with electron-acceptor substituents [61] is the reaction of readily accessible ethylene trithiocarbonate (23) [62] with electron-deficient acetylene compounds (Scheme 6). By reacting 23 with 24a this method provides diester 25a in good yield [63]. Compound 25a can be reduced to diol 25d [64] and further converted by either the Appel method [59] or by reaction with PBr3 [65] into dibromomethyl compound 21, which is required for synthetic pathway A.

Scheme 6: Synthesis of bisfunctionalised derivatives of vinylene trithiocarbonate 21 and 25c required for synthetic pathways A and B, respectively.

Scheme 6: Synthesis of bisfunctionalised derivatives of vinylene trithiocarbonate 21 and 25c required for syn...

Even though the reaction of 23 with acetylene compound 24b (containing only one electron-withdrawing group) is efficient, affording 25b with a 60% yield [66], attempts to invoke cycloaddition of 23 and 24c in a similar manner led to a poor yield of 25c (8%) [60]. An efficient method for the synthesis of 25c – a compound required for synthetic pathway B – was found to be repeated sequential lithiation of vinylene trithiocarbonate (26) [67] followed by subsequent trapping of the lithium organic species with thiophenecarboxaldehyde 27 [60]. The diol 25e, formed as a product of this reaction, is unstable and undergoes various rearrangments [68,69] in acidic conditions. Hence, it is preferably oxidised directly to the more stable diketone 25c without delay.

The retrosynthetic scheme for the monomer units 28a,b with thieno-dithiino-dithiole type fusion is shown in Scheme 7. Similar to the aforementioned synthetic pathway B, the strategy for the synthesis of 29 involves construction of the thiophene ring by cyclisation of diketone 30 (synthetic pathway C).

Scheme 7: Retrosynthetic scheme for the synthesis of the building block which is required for the preparation of PT with TTF fused to a polymer backbone via a dithiin ring (synthetic pathway C).

Scheme 7: Retrosynthetic scheme for the synthesis of the building block which is required for the preparation...

The diketone 31 is constructed through the cycloaddition reaction of diacylethene 33 with oligomer 32, readily available by oxidation of bis(tetraethylammonium) bis(2-thioxo-1,3-dithiole-4,5-dithiolato)zincate with iodine [70]. This versatile strategy can be applied where R1 and R2 are either aromatic or aliphatic [71]. The application of the strategy has been utilised for both symmetric 28a [60] and asymmetric 28b systems [72].

Polymers with fused TTF units

The electronic characterisation for monomer units 14a–c and 28a is shown in Table 1.

Table 1: Electrochemical and UV–vis absorption data for the monomer compounds 14a–c, and 28a in CH2Cl2 solution. The oxidation potentials are shown vs Ag/AgCl reference.

| Compound | E1/21ox, V | E1/22ox, V | Ep3ox, V | λmax, nm |

|---|---|---|---|---|

| 14a | 0.74 | 1.10 | 2.18 | 324 |

| 14b | 0.95 | 1.31 | – | 337 |

| 14c | 0.64 | 1.02 | 1.55 | 373 |

| 28a | 0.64 | 0.99 | 1.52 | 344 |

Electropolymerisation of monomer compounds 14a, 14c and 28a [73] was attempted. Due to the high oxidation potential (see Table 1) of the thiophene unit in the fused system 14a (2.18 V vs Ag/AgCl), electropolymerisation for this compound was unsuccessful (Scheme 8). Surprisingly, the other two monomers, both with a similar, low Ep3ox – attributed to oxidation of the terthiophene unit (14c (1.55 V vs Ag/AgCl) and 28a (1.52 V vs Ag/AgCl)) – showed different behaviour upon repetitive voltammetric cycling over the range of 0.0–1.6 V vs Ag/AgCl. Although upon electrodeposition of 14c onto the surface of a working electrode a red film appeared, it was non-polymeric in nature. On the contrary, the electropolymerisation of 28a under the same conditions exhibited a reproducible polymer growth of 34.

Scheme 8: The monomers 14a, 14c and electropolymerisation of 28a.

Scheme 8: The monomers 14a, 14c and electropolymerisation of 28a.

The CV of polymer 34 exhibited the characteristic electrochemical signature of the TTF-unit – two reversible oxidation waves to a cation radical and a dication, with a linear dependence of peak currents upon scan rates. Similar to PT systems with a pendant TTF unit [49], the peak current of the second wave was noticeably higher than that of the first (Figure 2). There are three possible reasons for such behaviour that can be considered: 1) the interaction between the TTF units would cause the partial splitting of the first oxidation wave with poorly resolved components – attributed to oxidation of the neutral TTF into a mixed valence state and further to an aggregated cation radical; 2) contrary to formation of the cation radical, the oxidation to the dication is not limited by charge transport through the film as the conductivity of the latter is ensured by both charged TTF species and the polaron charge carrier route; 3) the oxidation potential of the polymer backbone is likely to be in the same region as the potential for TTF2+ formation, although the contribution to the current from the normally irreversible oxidation of the PT backbone would be small due to the high TTF content in the polymer.

![[1860-5397-11-191-2]](/bjoc/content/figures/1860-5397-11-191-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: Cyclic voltammograms of a thin film of 34 at various scan rates (25 mV, 50 × n mV/s, n = 1–10). Adapted with permission from [73].Copyright 2000 The Royal Society of Chemistry.

Figure 2: Cyclic voltammograms of a thin film of 34 at various scan rates (25 mV, 50 × n mV/s, n = 1–10). Ada...

The as grown polymer exhibited two broad absorption peaks at 459 and 833 nm, indicating that the polymer film exists in a doped state. The aforementioned peaks can be assigned to the cation radical of the TTF unit and are very similar to the absorption features of tetraalkylthiotetrathiafulvalene cation radical [31,32]. The doped film exhibited excellent stability and its absorption characteristics did not change despite treatment with hydrazine. However, de-doping was achieved with repetitive scanning of the polymer film over the range of −0.3–0 V vs Ag/AgCl for 2 hours [73]. After de-doping, the polymer 34 exhibited an absorption band with a maximum at ca. 490 nm and extending to ca. 736 nm, with an optical band gap of 1.69 eV (Table 2). For a simple π-conjugated polymer the difference between the oxidation and reduction onsets constitute the electrochemical band gap [74,75]. For polymer 34, if the first oxidation wave was taken into consideration, the electrochemical band gap was found to be 1.39 eV. However, if the second oxidation wave was considered the band gap was calculated to be 1.81 eV, a value slightly higher than the aforementioned optical band gap of the polymer (1.69 eV). This is to be expected considering that upon oxidation of the PT backbone the electron must be removed from a polymer already containing oxidised TTF moieties. The agreement between the optical and electrochemical band gaps in this case infers that the oxidation of the PT backbone in the polymer 34 occurs at the potential close to the second oxidation wave of the TTF unit. A more detailed spectroelectrochemical study [76] of the polymer 34 film deposited on ITO glass revealed an electrochemical signature of both oxidised TTF species (TTF+•, TTF2+) [31,32] and polarons (vide infra).

Table 2: Characterisation of the polymers 34, 35, 37, and 39.

| Polymer | Mn, Da | PDI | Condition | E1/21ox, V | E1/22ox, V | Epc1red, V | λmax, nm (Egopt, eV) | |

|---|---|---|---|---|---|---|---|---|

| CH2Cl2 | Film | |||||||

| 34 | – | – | Film | 0.77 | 1.09 | −1.21 | – | 494 (1.69) |

| 35 | 3437 | 1.32 | CH2Cl2 | 0.81 | 1.10 | −1.15 | 466(1.86) | 487 (1.75) |

| 37 | 4886 | 2.40 | CH2Cl2 | 0.69 | 1.07 | −1.65 | 456 | 496 (1.82) |

| 39 | 3158 | 1.19 | CH2Cl2 | 0.89 | 1.31 | – | 578 | – |

| Film | 0.91a | 1.35a | −0.96 | – | 598 (1.45) | |||

aDue to the irreversible nature of the oxidation waves, the anodic peak values Epaox are shown.

To investigate the properties of PT-TTF systems with the TTF moiety directly fused to a thiophene backbone, chemical polymerisation of suitably functionalised monomers was carried out (Scheme 9). For all chemically synthesised polymers a Soxhlet extraction (with methanol, acetone and CH2Cl2) has been used as a method of purification and to narrow their polydispersity. Using Yamamoto coupling compound 14b was polymerised. Use of DMF alone as solvent led to a polymer that was sparingly soluble in CH2Cl2 [77]. However, a mixture of DMF:toluene (1:1) as a medium for Yamamoto polymerisation afforded polymer 35 as a dark purple solid in 95% yield [55]. Polymer 35 is the analogue of the polymer which could have been obtained had the monomer 14a been suitable for electropolymerisation, while Stille coupling of dibromo monomer 14b with 5,5'-bis(trimethylstannyl)-2,2'-bithiophene (36) [78] was used to circumvent problems with the electropolymerisation of terthiophene 14c, and to chemically synthesise the analogous polymer 37 [76]. By reacting monomer 14b and 1,2-bis(tributylstannyl)ethylene (38) [79], polymer 39 was synthesised using the Stille coupling protocol [76].

Scheme 9: Chemical polymerisation of 14b into polymers 35, 37 and 39.

Scheme 9: Chemical polymerisation of 14b into polymers 35, 37 and 39.

The number average molecular weight (Mn) revealed by GPC analysis (Table 2) corresponds to about 7 thienoTTF monomer units per polymer chain for 35 and 37, and about 6 units for 39. MALDI–TOF MS characterisation was only successful for polymer 39 and showed a series of peaks with a mass difference of 516 Da, corresponding to the mass of the 2-(4,5-bis(hexylthio)-1,3-dithiol-2-ylidene)thieno[3,4-d][1,3]dithiol-4,6-diyl-alt-vinylene repeating unit. The mass spectra confirmed that the polymer was end-capped with a thienoTTF unit, with the terminal bromo substituents still intact. The highest mass peak of 5290 Da registered by MALDI–MS corresponds to 10 thienoTTF units, which is significantly higher than the aforementioned Mn measured by GPC.

Table 2 displays the electrochemical and UV–vis absorption characteristics of the polymers. The peaks corresponding to the absorption maximum occurred in the range 450–500 nm for polymers 34, 35 and 37, with the optical band gap being in the range of 1.7–1.9 eV. When comparing the spectra in CH2Cl2 solutions to those of the solid film, the red shift in absorption is due to the emergence of π–π interactions in the solid state. Compared to the aforementioned polymers, poly(thienylenevinylene) (PTV) 39 exhibited a red-shifted absorption with maxima occurring at 578 and 598 nm in CH2Cl2 and as a thin film, respectively.

The CVs in CH2Cl2 solution of 35 and 37 (Table 2) revealed two quasi-reversible oxidation waves that are shifted to lower potentials compared to the corresponding reversible oxidation waves of monomer 14b (+0.91 and +1.31 V, see Table 1). Monomer 14b has a weaker donating ability due to the strong electron-withdrawing inductive effect of the terminal bromo substituents, while the PTV polymer 39 exhibited almost identical oxidation potentials to monomer 14b. On the other hand, both oxidation waves of the TTF unit in polymers 35, 37, and 39 shifted to significantly higher potentials in comparison to those of the non-brominated monomer compound 14a (+0.46 and +0.83 V, see Table 1) [54]. This can be explained by: 1) the electron-withdrawing effect of the polymer backbone and 2) the electrostatic interaction between the oxidised TTF units within the polymer backbone. The degree to which these polymer oxidation potentials shift is in the order 37 < 35 < 39, which roughly follows the expected charge density of the doped polymer backbone. The chronocoulometry experiment during bulk electrolysis of 35 and 39 revealed that approximately two electrons were released per monomer unit; this is much more than one would expect from a simple PT that normally donates one electron per 3–10 thiophene units [80]. To the best of our knowledge, 35 is the most dopable polythiophene in the literature, with respect to the level of oxidation that is achieved per repeating unit, the excellent electrochemical reversibility observed, and the modest potential window in which the highly doped state is attained. Even for a stable doped system, for example a PEDOT sample heavily doped with polystyrenesulfonic (PSSH) or p-toluenesulfonic (TosH) acid, the doping level is 3–5 units per one positive charge [81,82]. So, the presence of TTF units fused to each thiophene of the PT backbone creates a polymer with a greatly enhanced p-doping ability. The direct fusion in this case of two electroactive units (TTF and PT) inhibits any electrochemical activity from the polymer backbone and the electrochemistry of the material is dominated by the TTF unit.

The inhibition of the polymer backbone’s electrochemical activity was confirmed by spectroelectrochemistry of 39, which indicated no change of the π–π* transition upon applying potentials up to +2.0 V. The CV of 39 shows an irreversible first oxidation wave, and the band gap calculated from the first oxidation onset agreed well with the optical band gap. The former indicates the possibility of significant interchain interactions between the TTF unit and the polymer backbone.

Upon oxidation, the film of polymer 37 exhibited a broad ill-defined band extending from 700 nm into the near infrared range. The intensity of the π–π* transition in this case diminished upon oxidation, but this band still remained the most intense feature of the spectrum across the entire potential range (Figure 3a). The spectoelectrochemistry of polymer 34 revealed more drastic changes in the spectra upon oxidation of the film, where the resolved absorption signature of a cation radical, dication and polaron can be observed (Figure 3b). As the applied potential is increased, two peaks appear: one at 460 nm that overlaps with the backbone π–π* transition, and a second centred at 800 nm. Those peaks were observed in the spectrum of the doped polymer film (Figure 3b) and could be assigned to the absorption of the cation radical of the TTF unit. With further increase in the applied potential the TTF cation radical UV–vis signature diminishes and a strong absorption band at 700 nm, along with a broad absorption in the NIR region, appear. The former can be assigned to the absorption of the dication of the TTF unit and both bands to a polaron formation. Therefore, for 34 the spectroelectrochemistry unequivocally confirms the electrochemical activity of the polymer backbone, which is involved in the formation of polarons at potentials close to the second oxidation potential of the TTF unit.

![[1860-5397-11-191-3]](/bjoc/content/figures/1860-5397-11-191-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: Spectroelectrochemistry of polymers 37 (a) and 34 (b) as thin films deposited on the working electrode. Adapted with permission from [76]. Copyright 2006 The American Chemical Society.

Figure 3: Spectroelectrochemistry of polymers 37 (a) and 34 (b) as thin films deposited on the working electr...

The polymer 39, which has the lowest band gap, was tested as a donor material for BHJSCs with PC61BM as the acceptor. The OPV performance is shown in Table 3. The estimation of HOMO and LUMO levels by electrochemical analysis gave values of −5.24 and −3.78 eV, respectively, indicating a small offset between the LUMO of 39 and PC61BM (ca. −3.8 eV) [83,84]. This is the main reason for the small short circuit current density (Jsc) and low efficiency of the cell. Due to the possible presence of efficient interchain interactions between the TTF units and the PTV backbone (vide supra) in the film of polymer 39, another important factor that should be considered is photoinduced charge transfer. Photoexcitation of 39 can lead to an increase in the donor ability of the TTF unit due to a greater contribution of the quinoidal structure to the excited polymer backbone, and foster electron transfer from the TTF moiety to PC61BM (Scheme 10). However, further hole transfer from the TTF unit to the PTV backbone may still limit dissociation of the (TTF+•)(PC61BM−•) bound pair.

Table 3: Performance of BHJSCs fabricated from the thiophene-TTF hybrid systems.

| Compound | Acceptor | Solvent | Pinc, mW cm−2 | Jsc, mA cm−2 | Voc, V | FF | PCE, % |

|---|---|---|---|---|---|---|---|

| 39 | PC61BM | CB | 80 | 0.68 | 0.52 | 0.30 | 0.13 |

| 48 | none | o-DCB | 100 | 1.8 | 0.61 | 0.28 | 0.31 |

| 48 | PC71BM | CHCl3 | 100 | 4.9 | 0.66 | 0.31 | 1.0 |

| 48 | PC71BM | o-DCB | 100 | 8.0 | 0.71 | 0.32 | 1.8 |

| 54 (n = 1) | PC71BM | CHCl3 | 100 | 7.44 | 0.70 | 0.33 | 1.7 |

| 54 (n = 1) | PC71BM | o-DCB | 100 | 9.81 | 0.78 | 0.33 | 2.5 |

Scheme 10: Photoinduced charge transfer from the TTF of polymer 39 to PC61BM.

Scheme 10: Photoinduced charge transfer from the TTF of polymer 39 to PC61BM.

The surprising inertness of 14c towards electropolymerisation can be circumvented by replacing the thiophene units in the monomer terthiophene backbone with more electron-rich moieties, such as pyrrole and EDOT. Bisthienylpyrrolo-TTF monomer compounds 40 and 41, which were synthesised by Stille coupling of diiodopyrrolo-TTF 42 with trimethylstannyl derivatives of EDOT 43 and hexylthiophene 44, were efficiently electropolymerised (Scheme 11) into polymers 45 and 46, respectively [85]. Note that these latter two polymers are analogues of polymer 37. Polymer 47, synthesised by Stille polymerisation of 42 and 38, is an analogue of the polymer 39. A direct comparison between the obtained polymers with pyrroloTTF and thienoTTF units showed that the incorporation of an electron-rich pyrrole unit into the conjugated backbone leads to materials with a wider band gap as they are less stable to n-doping. The pyrrole unit lowers the oxidation potentials of the TTF moieties but the electrochemical dominance of the TTF is lost in the pyrrolo-TTF polymers.

Scheme 11: Electropolymerisation of 40 and 41 into polymers 45 and 46, respectively, and Stille polymerisation of 42 into polymer 47.

Scheme 11: Electropolymerisation of 40 and 41 into polymers 45 and 46, respectively, and Stille polymerisation...

Another analogue of polymer 37 includes the 2,5-bis(2-octyldodecyl)-1,4-dioxopyrrolo[3,4-c]pyrrole (DPP) unit incorporated within the PT backbone [86]. The polymer 48 was prepared by Suzuki coupling polymerisation of diboronic ester 49 and dibromothieno-TTF 50 (Scheme 12). The latter was synthesised following the aforementioned synthetic pathway A. The incorporation of the DPP π-acceptor into the conjugated backbone led to a polymer with a narrow optical band gap (Egopt = 1.32 eV in CH2Cl2 solution), with the expected lower value of Egopt = 1.26 eV in the film due to π–π stacking interactions. The value of the HOMO/LUMO levels (−5.13/−3.49 eV) in the film were noticeably different from those in solution (−4.95/−3.55 eV), which suggested significant donor–acceptor interactions in the solid phase between the DPP and TTF units.

OFET device fabrication employing polymer 48 exhibited p-type semiconductor behaviour, with the best performance from devices using the bottom contact top gate configuration [87]. The hole mobility values calculated in the saturated region were found to be 3.8 × 10−2 and 5.3 × 10−2 cm2 V−1 s−1 for OFETs fabricated via spincoating the semiconductor from solution in chlorobenzene and chloroform, respectively. The strong propensity of 48 to aggregation led to the tightly packed grain morphology of the film cast from chlorobenzene with small sized crystalline domains (Figure 4). On the contrary, using chloroform the high solvation energy of the TTF unit and the carbonyl groups of the DPP moieties made the rate of nucleation lower compared to the rate of grain growth, so the size of the crystalline domain in the film was higher in this case. These larger crystalline domains in films spin-coated from chloroform were beneficial for field effect mobility.

![[1860-5397-11-191-4]](/bjoc/content/figures/1860-5397-11-191-4.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 4: Tapping mode AFM height images of polymer 48 film spin-coated from chlorobenzene (left) and chloroform (right) solutions on ODTS treated SiO2 substrate. Reproduced with permission from [87]. Copyright 2015 The American Chemical Society.

Figure 4: Tapping mode AFM height images of polymer 48 film spin-coated from chlorobenzene (left) and chlorof...

None of the OFETs showed any n-type mobility. The extended character of the HOMO residing on the dithienyl-thieno-TTF unit and the localised nature of the LUMO led to donor–acceptor interactions in the solid phase, making it impossible for efficient overlap between LUMOs, which would normally be required for an efficient n-type semiconductor.

BHJSCs were fabricated from 48 as the electron donor and PC71BM as the electron acceptor using ortho-diclorobenzene (o-DCB) and chloroform as solvents (Table 3). The devices prepared with o-DCB showed up to a two-fold increase in power conversion efficiency (PCE) compared to those obtained by spincoating the blend from chloroform, which is due to a more homogeneous blend morphology leading to improved charge carrier transport and increased Jsc. Since the use of o-DCB as the solvent for spincoating provided better performance for BHJSCs than chloroform, it was used for the fabrication of a single material organic solar cell (SMOSC) (Table 3). The SMOSC performance is modest compared to that of similar devices fabricated using donor–acceptor block copolymers [88-90]. Nevertheless, the value of the PCE (0.31%) is higher than one would expect from a SMOSC fabricated from polymer 48 as a semiconductor, since it has no obvious donor–acceptor phase separation and is lacking efficient electron mobility.

TTF-oligothiophene systems with well-defined structures

The monodisperse analogue of polymer 34, bearing two TTF units and capped with dodecyl chains at the terminal positions, was synthesised using chemical coupling protocols, or alternatively via electrochemical oxidation of terthiophene 28b (Scheme 13) [72]. The latter was synthesised by the aforementioned synthetic pathway C.

Scheme 13: The synthesis of TTF-sexithiophene system 51 and the structure of the parent sexithiophene 53.

Scheme 13: The synthesis of TTF-sexithiophene system 51 and the structure of the parent sexithiophene 53.

The electrochemical method for the preparation of sexithiophene 51 was achieved by potentiostatic oxidative electrodimerization of 28b in a mixture of 2:1 CH2Cl2/hexane, with 0.1 M tetrabutylammonium hexafluorophosphate as the supporting electrolyte. On a larger scale, chemical oxidation by FeCl3 in nitrobenzene was used which after purification, afforded 51 in a 24% yield. Lithiation of compound 28b with LDA and successive trapping of the aryllithium compound with perfluorohexyl iodide afforded iodoterthiophene 52 in a 74% yield. Compound 52 was used to explore other possibilities for synthesising sexithiophene 51, including Ullmann and Yamamoto coupling, which provided 51 in 43 and 10% yield, respectively. Sexithiophene 51 exhibited a strong propensity to aggregate even in chloroform solution, hence an interpretable 1H NMR spectrum was only obtained in a mixture of CDCl3 with CS2.

In CH2Cl2 solution, the chemically synthesised product showed a π–π* transition peak at 443 nm, with a HOMO–LUMO gap of 2.32 eV, a value very similar to that of the parent sexithiophene 53 [91]. For the electrochemically prepared film of 51, there were two broad bands with maxima centred at 449 and 735 nm, confirming the doped state of the film and the presence of a cation radical centred on the TTF unit. After de-doping, a single broad band remained with its maximum red-shifted compared to that of the solution state spectrum of the chemically synthesised sexithiophene 51; this is evidence of a strong π–π stacking interaction upon aggregation in the solid state. The electrochemistry of compound 51 is similar for both solution and solid state samples, with the main feature being the overlap between the second oxidation peak of the TTF and the oxidation of the sexithiophene backbone.

A series of hybrid electroactive compounds 54 (n = 0–2) with two oligothiophenes directly fused to one TTF unit was recently reported [92,93]. Here, triethylphosphite mediated homo-coupling of the corresponding oligothiophenes 55 (n = 0–2) containing a central thieno[3,4-d][1,3]dithiole-2-one unit proceeded smoothly, with yields of 77% for n = 0, 82% for n = 1 and 39% for n = 2 (Scheme 14).

Scheme 14: The synthesis of TTF-oligothiophene H-shaped systems 54 (n = 0–2).

Scheme 14: The synthesis of TTF-oligothiophene H-shaped systems 54 (n = 0–2).

The oligothiophene half-unit precursors, 55 (n = 0–2), were synthesised following synthetic pathway B. The electrochemical and optical properties of 54 (n = 0–2) are shown in Table 4.

Table 4: The properties of monodisperse oligothiophene-TTF systems in dichloromethane solution.

| 51 | 54 (n = 0) | 54 (n = 1) | 54 (n = 2) | |

|---|---|---|---|---|

| E1ox, Va | +0.29/0.21 | +0.39/+0.32 | +0.27/+0.21 | +0.26/+0.23 |

| E2ox, Va | +0.53/0.45 | +0.86/+0.75 | +0.54/+0.48 | +0.66/+0.49 |

| E3ox, Va | – | +1.13 | +0.76/+0.71 | +0.97/+0.94 |

| E4ox, Va | – | – | +0.97/+0.89 | – |

| Ered, Va | – | –2.12 | –2.19 | −1.98 |

| HOMOb, eV | −4.93 | –5.06 | –4.96 | −4.95 |

| LUMOb, eV | – | –2.92 | –2.81 | −3.00 |

| HOMO–LUMO gap, eV | – | 2.14 | 2.15 | 1.95 |

| λmax, nm | 443 | 351 | 431 | 461 |

| Absorption onset, eV | 2.32 | 2.92 | 2.45 | 2.20 |

aThe electrochemical data are referenced against the Fc/Fc+ couple. Both Epa and Epc or anodic peak value (Epa, if the wave is irreversible) for the oxidation waves and cathodic peak values (Epc) for the reduction waves are quoted. bHOMO/LUMO values were calculated using the formula HOMO/LUMO = −Eonsetox/Eonsetred − 4.80.

The optical properties of 54 (n = 0–2) in solution (Table 4) follow a general trend of decreasing the absorption onset, while increasing the conjugation length. The electrochemistry of each H-shaped system 54 (n = 0–2) on the other hand is not so straightforward. While the first and the second oxidation waves are easily identified and assigned for 51 (vide supra), for 54 (n = 0–2) it is only the first oxidation wave which can be unequivocally assigned to the first oxidation potential of the TTF unit. It is interesting to note that the terthiophene-TTF H-shaped system 54 (n = 0) exhibits a significantly higher potential for the formation of TTF+• than that of the quinqui- and septithiophene systems 54 (n = 1–2). This can be explained by the increased π-donating ability of the oligothiophene with a higher conjugation length due to a more pronounced contribution of the quinoidal resonance structure. This effect is only possible for hybrid systems with a TTF unit directly fused to the PT backbone (Scheme 15).

Scheme 15: The oxidation of a fused TTF-oligothiophene system.

Scheme 15: The oxidation of a fused TTF-oligothiophene system.

Quinqui- and septithiophene TTF bridge systems 54 (n = 1–2) are prone to strong aggregation in solution and, as with 51, a mixture of chloroform with CS2 was used for NMR spectroscopy in these cases. For compound 54 (n = 2) the absorption spectrum as a thin film exhibits a maximum at 496 nm and is red-shifted by 35 nm compared to the solution state spectrum, suggesting strong intermolecular interactions in the solid phase.

Single crystal X-ray diffraction of 54 (n = 2) (Figure 5) revealed that the molecules in the solid state are essentially planar, apart from a significant torsion angle of 33° between the terminal thiophene A and the thiophene B.

![[1860-5397-11-191-5]](/bjoc/content/figures/1860-5397-11-191-5.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 5: Molecular structure and packing arrangement of compound 54 (n = 2). Adapted by permission from [92]. Copyright 2011 The Royal Society of Chemistry.

Figure 5: Molecular structure and packing arrangement of compound 54 (n = 2). Adapted by permission from [92]. Co...

The angle between planes D and F is 5.79°, with the inter-ring distance being 3.74 Å. The angle between thiophenes C and G is higher (18.36°) but the two S-atoms are involved in a weak non-covalent interaction with a distance of 3.81 Å between them. The strong π–π stacking interaction and the presence of multiple S–S non-covalent interactions in the H-shaped TTF-oligothiophene system 54 (n = 2) made this compound a promising p-type organic semiconductor material. The time of flight mobility for this compound was found to increase from 1.4 × 10−6 to 1.1 × 10−5 cm2 V−1 s−1, as the electric field increases from 1 × 105 to 4 × 105 V cm−1 [92].

Compound 54 (n = 1) was tested as a solution processable p-type semiconductor in OFETs using two solvents for spin-coating – chloroform and chlorobenzene [93]. A bottom contact, bottom gate device configuration was used with an n-doped silicon gate and a SiO2 dielectric layer. After annealing at 120 °C, AFM imaging indicated a closely packed grain-like surface morphology of the film cast from chlorobenzene as a result of the strong propensity of H-shaped TTF-quinquithiophene 54 (n = 1) to aggregate in this solvent (Figure 6, left). Upon spin-coating and further annealing, the rate of nucleation exceeded the rate of grain growth, leading to the small size of the crystalline domain. An OFET mobility of 1.41 × 10−4 cm2 V−1 s−1 calculated in the saturation region was observed. An increase in the field effect mobility (to µ = 1.17 × 10−3 cm2 V−1 s−1) by almost an order of magnitude was observed in devices cast from chloroform. As with polymer 48, tapping mode AFM of the organic semiconductor film spin-coated from this solvent revealed that, after annealing, the surface morphology consisted of large crystalline domains with a smooth grain boundary (Figure 6, centre). Such a striking difference in morphology of the films cast from chlorobenzene and CHCl3 is explained by the high energy of solvation of 54 (n = 1) in chloroform, which leads to a higher crystallisation rate compared to the rate of nucleation during spin-coating and subsequent annealing. When substrates with a pre-treated n-octadecyltrichlorosilane (ODTS) SiO2 surface were used for spin-coating from a CHCl3 solution, the surface morphology remained essentially the same (Figure 6, right), with a further increase in mobility (µ = 8.61 × 10−3 cm2 V−1 s−1) observed due to the beneficial effects of large crystalline domains on the field effect mobility.

![[1860-5397-11-191-6]](/bjoc/content/figures/1860-5397-11-191-6.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 6: AFM tapping mode images of the compound 54 (n = 1) film cast on an untreated SiO2 substrate surface from solutions in chlorobenzene (left), CHCl3 (centre) and on an ODTS treated SiO2 substrate from CHCl3 (right). Reproduced with permission from [93]. Copyright 2014 The Royal Society of Chemistry.

Figure 6: AFM tapping mode images of the compound 54 (n = 1) film cast on an untreated SiO2 substrate surface...

Compound 54 (n = 1) was tested as a donor material in BHJSCs. The results are presented in Table 3. Similar to polymer 48, the device prepared by spin-coating the blend of 54 (n = 1) and PC71BM from solution in o-DCB showed a higher performance than that fabricated with CHCl3, with a short circuit current density (increased up to 9.81 mA cm−2) being more affected by the solvent than the open circuit voltage (0.78 V). AFM revealed a smoother surface morphology of the donor–acceptor blend film cast from o-DCB than that when chloroform was used as solvent.

Conclusion

The series of poly- and oligothiophene based compounds bearing TTF units reported so far in the literature have been discussed. The most interesting properties were exhibited by polymers where TTF units were incorporated alongside the conjugated backbone, allowing for the different charge transport mechanisms on the basis of TTF mixed valence states and polarons to be observed. Upon positioning the TTF unit in the vicinity of the polymer backbone, a variation of electrochemical behaviour is observed, including complete dominance by the TTF units and, at times, independent activity of both electroactive entities.

The initial idea of creating materials with hybrid charge transport on the basis of the polaron mechanism and the mixed valence state of doped TTF units has developed now into efforts to use the TTF unit as a handle for controlling the morphology of organic semiconductors in the solid state. The great challenge in this field is to design hybrid materials where the position of the TTFs relative to the polymer backbone and the choice of optimised processing conditions allow tuning of the energy levels and the intrinsic charge carrier mobility in order to achieve maximum device performance.

References

-

Skabara, P. J.; Arlin, J.-B.; Geerts, Y. H. Adv. Mater. 2013, 25, 1948–1954. doi:10.1002/adma.201200862

Return to citation in text: [1] -

Chen, T. A.; Rieke, R. D. J. Am. Chem. Soc. 1992, 114, 10087–10088. doi:10.1021/ja00051a066

Return to citation in text: [1] -

McCullough, R. D.; Tristram-Nagle, S.; Williams, S. P.; Lowe, R. D.; Jayaraman, M. J. Am. Chem. Soc. 1993, 115, 4910–4911. doi:10.1021/ja00064a070

Return to citation in text: [1] -

Groenendaal, L.; Jonas, F.; Freitag, D.; Pielartzik, H.; Reynolds, J. R. Adv. Mater. 2000, 12, 481–494. doi:10.1002/(SICI)1521-4095(200004)12:7<481::AID-ADMA481>3.0.CO;2-C

Return to citation in text: [1] -

Dang, M. T.; Hirsch, L.; Wantz, G.; Wuest, J. D. Chem. Rev. 2013, 113, 3734–3765. doi:10.1021/cr300005u

Return to citation in text: [1] -

Sirringhaus, H.; Tessler, N.; Friend, R. H. Science 1998, 280, 1741–1744. doi:10.1126/science.280.5370.1741

Return to citation in text: [1] -

Cho, S.; Lee, K.; Yuen, J.; Wang, G.; Moses, D.; Heeger, A. J.; Surin, M.; Lazzaroni, R. J. Appl. Phys. 2006, 100, 114503. doi:10.1063/1.2400796

Return to citation in text: [1] -

Zotti, G.; Zecchin, S.; Schiavon, G.; Berlin, A.; Pagani, G.; Canavesi, A. Chem. Mater. 1995, 7, 2309–2315. doi:10.1021/cm00060a019

Return to citation in text: [1] -

Schäferling, M.; Bäuerle, P. J. Mater. Chem. 2004, 14, 1132–1141. doi:10.1039/b313296j

Return to citation in text: [1] -

Iraqi, A.; Crayston, J. A.; Walton, J. C. J. Mater. Chem. 1998, 8, 31–36. doi:10.1039/a703397d

Return to citation in text: [1] -

Skabara, P. J.; Serebryakov, I. M.; Perepichka, I. F.; Sariciftci, N. S.; Neugebauer, H.; Cravino, A. Macromolecules 2001, 34, 2232–2241. doi:10.1021/ma0015931

Return to citation in text: [1] -

Skabara, P. J.; Berridge, R.; Serebryakov, I. M.; Kanibolotsky, A. L.; Kanibolotskaya, L.; Gordeyev, S.; Perepichka, I. F.; Sariciftci, N. S.; Winder, C. J. Mater. Chem. 2007, 17, 1055–1062. doi:10.1039/B609858D

Return to citation in text: [1] -

Goldenberg, L. M.; Skabara, P. J.; Roberts, D. M.; Berridge, R.; Ortí, E.; Viruela, P. M.; Pou-Amérigo, R. J. Mater. Chem. 2000, 10, 2458–2465. doi:10.1039/b003914o

Return to citation in text: [1] -

Berridge, R.; Wright, S. P.; Skabara, P. J.; Dyer, A.; Steckler, T.; Argun, A. A.; Reynolds, J. R.; Harrington, R. W.; Clegg, W. J. Mater. Chem. 2007, 17, 225–231. doi:10.1039/B613879A

Return to citation in text: [1] -

Palermo, E. F.; Darling, S. B.; McNeil, A. J. J. Mater. Chem. C 2014, 2, 3401–3406. doi:10.1039/c3tc32512a

Return to citation in text: [1] -

Chan, S.-H.; Lai, C.-S.; Chen, H.-L.; Ting, C.; Chen, C.-P. Macromolecules 2011, 44, 8886–8891. doi:10.1021/ma201425d

Return to citation in text: [1] -

Bijleveld, J. C.; Zoombelt, A. P.; Mathijssen, S. G. J.; Wienk, M. M.; Turbiez, M.; de Leeuw, D. M.; Janssen, R. A. J. J. Am. Chem. Soc. 2009, 131, 16616–16617. doi:10.1021/ja907506r

Return to citation in text: [1] -

Zhang, K.; Tieke, B.; Forgie, J. C.; Skabara, P. J. Macromol. Rapid Commun. 2009, 30, 1834–1840. doi:10.1002/marc.200900442

Return to citation in text: [1] -

Zhang, K.; Tieke, B.; Forgie, J. C.; Vilela, F.; Parkinson, J. A.; Skabara, P. J. Polymer 2010, 51, 6107–6114. doi:10.1016/j.polymer.2010.10.054

Return to citation in text: [1] -

Zhang, K.; Tieke, B.; Forgie, J. C.; Vilela, F.; Skabara, P. J. Macromolecules 2012, 45, 743–750. doi:10.1021/ma202387t

Return to citation in text: [1] -

Cortizo-Lacalle, D.; Howells, C. T.; Gambino, S.; Vilela, F.; Vobecka, Z.; Findlay, N. J.; Inigo, A. R.; Thomson, S. A. J.; Skabara, P. J.; Samuel, I. D. W. J. Mater. Chem. 2012, 22, 14119–14126. doi:10.1039/c2jm32374e

Return to citation in text: [1] -

Forgie, J. C.; Skabara, P. J.; Stibor, I.; Vilela, F.; Vobecka, Z. Chem. Mater. 2009, 21, 1784–1786. doi:10.1021/cm9004823

Return to citation in text: [1] -

Wudl, F.; Wobschall, D.; Hufnagel, E. J. J. Am. Chem. Soc. 1972, 94, 670–672. doi:10.1021/ja00757a079

Return to citation in text: [1] -

Ferraris, J.; Cowan, D. O.; Walatka, V.; Perlstein, J. H. J. Am. Chem. Soc. 1973, 95, 948–949. doi:10.1021/ja00784a066

Return to citation in text: [1] -

Jérome, D. Chem. Rev. 2004, 104, 5565–5592. doi:10.1021/cr030652g

Return to citation in text: [1] -

Seo, H.; Hotta, C.; Fukuyama, H. Chem. Rev. 2004, 104, 5005–5036. doi:10.1021/cr030646k

Return to citation in text: [1] -

Kini, A. M.; Geiser, U.; Wang, H. H.; Carlson, K. D.; Williams, J. M.; Kwok, W. K.; Vandervoort, K. G.; Thompson, J. E.; Stupka, D. L. Inorg. Chem. 1990, 29, 2555–2557. doi:10.1021/ic00339a004

Return to citation in text: [1] -

Bryce, M. R.; Devonport, W.; Goldenberg, L. M.; Wang, C. Chem. Commun. 1998, 945–951. doi:10.1039/a800536b

Return to citation in text: [1] -

Christensen, C. A.; Becher, J.; Goldenberg, L. M.; Bryce, M. R. Chem. Commun. 1998, 509–510. doi:10.1039/A707504I

Return to citation in text: [1] -

Beeby, A.; Bryce, M. R.; Christensen, C. A.; Cooke, G.; Duclairoir, F. M. A.; Rotello, V. M. Chem. Commun. 2002, 2950–2951. doi:10.1039/b209765f

Return to citation in text: [1] -

Kanibolotsky, A.; Roquet, S.; Cariou, M.; Leriche, P.; Turrin, C.-O.; de Bettignies, R.; Caminade, A.-M.; Majoral, J.-P.; Khodorkovsky, V.; Gorgues, A. Org. Lett. 2004, 6, 2109–2112. doi:10.1021/ol049648x

Return to citation in text: [1] [2] [3] -

Kimura, H.; Konishi, K.; Muraoka, S.-y.; Shirahata, T.; Misaki, Y. Chem. Lett. 2014, 43, 843–845. doi:10.1246/cl.140092

Return to citation in text: [1] [2] [3] -

Yang, X.; Zhang, D.; Zhang, G.; Zhu, D. Sci. China: Chem. 2011, 54, 596–602. doi:10.1007/s11426-011-4225-y

Return to citation in text: [1] -

Nalluri, S. K. M.; Shivarova, N.; Kanibolotsky, A. L.; Zelzer, M.; Gupta, S.; Frederix, P. W. J. M.; Skabara, P. J.; Gleskova, H.; Ulijn, R. V. Langmuir 2014, 30, 12429–12437. doi:10.1021/la503459y

Return to citation in text: [1] -

Inagi, S.; Naka, K.; Chujo, Y. J. Mater. Chem. 2007, 17, 4122–4135. doi:10.1039/b708640g

Return to citation in text: [1] -

Kashimura, Y.; Goto, T.; Nakashima, H.; Furukawa, K.; Wang, E.; Li, H.; Hu, W.; Torimitsu, K. Jpn. J. Appl. Phys. 2010, 49, 01AB08. doi:10.1143/JJAP.49.01AB08

Return to citation in text: [1] -

Jia, H.-P.; Forgie, J. C.; Liu, S.-X.; Sanguinet, L.; Levillain, E.; Le Derf, F.; Sallé, M.; Neels, A.; Skabara, P. J.; Decurtins, S. Tetrahedron 2012, 68, 1590–1594. doi:10.1016/j.tet.2011.11.087

Return to citation in text: [1] -

Zhang, X.; Wang, C.; Lai, G.; Zhang, L.; Shen, Y. New J. Chem. 2010, 34, 318–324. doi:10.1039/B9NJ00520J

Return to citation in text: [1] -

Zhang, X.-C.; Wang, C.-Y.; Lai, G.-Q.; Zhang, L.; Shen, Y.-J. Polym. Bull. 2011, 66, 893–903. doi:10.1007/s00289-010-0322-x

Return to citation in text: [1] -

Zhang, L.; Li, M.; Wang, C.; Lai, G.; Shen, Y. Polym. Bull. 2013, 70, 353–369. doi:10.1007/s00289-012-0841-8

Return to citation in text: [1] -

Hou, Y.; Wan, X.; Yang, M.; Ma, Y.; Huang, Y.; Chen, Y. Macromol. Rapid Commun. 2008, 29, 719–723. doi:10.1002/marc.200800023

Return to citation in text: [1] -

Hou, Y.; Chen, Y.; Liu, Q.; Yang, M.; Wan, X.; Yin, S.; Yu, A. Macromolecules 2008, 41, 3114–3119. doi:10.1021/ma702864c

Return to citation in text: [1] -

Yamamoto, T.; Shimizu, T. J. Mater. Chem. 1997, 7, 1967–1968. doi:10.1039/a704753c

Return to citation in text: [1] [2] -

Zotti, G.; Zecchin, S.; Schiavon, G.; Berlin, A.; Huchet, L.; Roncali, J. J. Electroanal. Chem. 2001, 504, 64–70. doi:10.1016/S0022-0728(01)00429-6

Return to citation in text: [1] [2] -

Roncali, J. J. Mater. Chem. 1999, 9, 1875–1893. doi:10.1039/a902747e

Return to citation in text: [1] -

Bryce, M. R.; Chissel, A. D.; Gopal, J.; Kathirgamanathan, P.; Parker, D. Synth. Met. 1991, 39, 397–400. doi:10.1016/0379-6779(91)91766-4

Return to citation in text: [1] -

Zhang, L.; Li, M.; Wang, C.; Wang, Y.; Shen, Y. J. Appl. Polym. Sci. 2013, 127, 3356–3364. doi:10.1002/app.37803

Return to citation in text: [1] -

Thobie-Gautier, C.; Gorgues, A.; Jubault, M.; Roncali, J. Macromolecules 1993, 26, 4094–4099. doi:10.1021/ma00068a004

Return to citation in text: [1] -

Huchet, L.; Akoudad, S.; Roncali, J. Adv. Mater. 1998, 10, 541–545. doi:10.1002/(SICI)1521-4095(199805)10:7<541::AID-ADMA541>3.0.CO;2-1

Return to citation in text: [1] [2] [3] [4] [5] -

Huchet, L.; Akoudad, S.; Levillain, E.; Roncali, J.; Emge, A.; Bäuerle, P. J. Phys. Chem. B 1998, 102, 7776–7781. doi:10.1021/jp982593u

Return to citation in text: [1] -

Besbes, M.; Trippé, G.; Levillain, E.; Mazari, M.; Le Derf, F.; Perepichka, I. F.; Derdour, A.; Gorgues, A.; Sallé, M.; Roncali, J. Adv. Mater. 2001, 13, 1249–1252. doi:10.1002/1521-4095(200108)13:16<1249::AID-ADMA1249>3.0.CO;2-W

Return to citation in text: [1] -

Trippé, G.; Le Derf, F.; Lyskawa, J.; Mazari, M.; Roncali, J.; Gorgues, A.; Levillain, E.; Sallé, M. Chem. – Eur. J. 2004, 10, 6497–6509. doi:10.1002/chem.200400303

Return to citation in text: [1] [2] -

Sinha, J.; Lee, S. J.; Kong, H.; Swift, T. W.; Katz, H. E. Macromolecules 2013, 46, 708–717. doi:10.1021/ma3019365

Return to citation in text: [1] -

Skabara, P. J.; Müllen, K. Synth. Met. 1997, 84, 345–346. doi:10.1016/S0379-6779(97)80774-6

Return to citation in text: [1] [2] -

Skabara, P. J.; Berridge, R.; McInnes, E. J. L.; West, D. P.; Coles, S. J.; Hursthouse, M. B.; Müllen, K. J. Mater. Chem. 2004, 14, 1964–1969. doi:10.1039/b400809j

Return to citation in text: [1] [2] -

Shu, P.; Chiang, L.; Emge, T.; Holt, D.; Kistenmacher, T.; Lee, M.; Stokes, J.; Poehler, T.; Bloch, A.; Cowan, D. J. Chem. Soc., Chem. Commun. 1981, 920–921. doi:10.1039/c39810000920

Return to citation in text: [1] -

Rovira, C.; Santalō, N.; Veciana, J. Tetrahedron Lett. 1989, 30, 7249–7252. doi:10.1016/S0040-4039(01)93950-4

Return to citation in text: [1] -

Rovira, C.; Veciana, J.; Santalo, N.; Tarres, J.; Cirujeda, J.; Molins, E.; Llorca, J.; Espinosa, E. J. Org. Chem. 1994, 59, 3307–3313. doi:10.1021/jo00091a017

Return to citation in text: [1] -

Skabara, P. J.; Müllen, K.; Bryce, M. R.; Howard, J. A. K.; Batsanov, A. S. J. Mater. Chem. 1998, 8, 1719–1724. doi:10.1039/a803027h

Return to citation in text: [1] [2] -

Skabara, P. J.; Serebryakov, I. M.; Roberts, D. M.; Perepichka, I. F.; Coles, S. J.; Hursthouse, M. B. J. Org. Chem. 1999, 64, 6418–6424. doi:10.1021/jo990198+

Return to citation in text: [1] [2] [3] [4] -

O'Connor, B. R.; Jones, F. N. J. Org. Chem. 1970, 35, 2002–2005. doi:10.1021/jo00831a062

Return to citation in text: [1] -

Lee, A. W. M.; Chan, W. H.; Wong, H. C. Synth. Commun. 1988, 18, 1531–1536. doi:10.1080/00397918808081310

Return to citation in text: [1] -

Liu, B.; Wu, B.; Xu, J.; Wu, Z.; Zhao, Y.; Zheng, X.; Wang, H. J. Raman Spectrosc. 2010, 41, 1185–1193. doi:10.1002/jrs.2580

Return to citation in text: [1] -

Fox, M. A.; Pan, H.-l. J. Org. Chem. 1994, 59, 6519–6527. doi:10.1021/jo00101a009

Return to citation in text: [1] -

Jeppesen, J. O.; Takimiya, K.; Jensen, F.; Brimert, T.; Nielsen, K.; Thorup, N.; Becher, J. J. Org. Chem. 2000, 65, 5794–5805. doi:10.1021/jo000742a

Return to citation in text: [1] -

Salle, M.; Gorgues, A.; Jubault, M.; Boubekeur, K.; Batail, P. Tetrahedron 1992, 48, 3081–3090. doi:10.1016/S0040-4020(01)92250-1

Return to citation in text: [1] -

Guziec, F. S., Jr.; Russo, J. M.; Torres, F. F.; Long, G. C.; Tellez, M. R. J. Chem. Soc., Perkin Trans. 1 1989, 1068–1070. doi:10.1039/p19890001068

Return to citation in text: [1] -

Serebryakov, I. M.; Skabara, P. J.; Perepichka, I. F. J. Chem. Soc., Perkin Trans. 2 1999, 1405–1410. doi:10.1039/a901178a

Return to citation in text: [1] -

Vilela, F.; Skabara, P. J.; Mason, C. R.; Westgate, T. D. J.; Luquin, A.; Coles, S. J.; Hursthouse, M. B. Beilstein J. Org. Chem. 2010, 6, 1002–1014. doi:10.3762/bjoc.6.113

Return to citation in text: [1] -

Svenstrup, N.; Becher, J. Synthesis 1995, 215–235. doi:10.1055/s-1995-3910

Return to citation in text: [1] -

Berridge, R.; Serebryakov, I. M.; Skabara, P. J.; Ortí, E.; Viruela, R.; Pou-Amérigo, R.; Coles, S. J.; Hursthouse, M. B. J. Mater. Chem. 2004, 14, 2822–2830. doi:10.1039/b404545a

Return to citation in text: [1] -

Kanibolotsky, A. L.; Kanibolotskaya, L.; Gordeyev, S.; Skabara, P. J.; McCulloch, I.; Berridge, R.; Lohr, J. E.; Marchioni, F.; Wudl, F. Org. Lett. 2007, 9, 1601–1604. doi:10.1021/ol070366h

Return to citation in text: [1] [2] -

Skabara, P. J.; Roberts, D. M.; Serebryakov, I. M.; Pozo-Gonzalo, C. Chem. Commun. 2000, 1005–1006. doi:10.1039/b001943g

Return to citation in text: [1] [2] [3] -

Roncali, J. Chem. Rev. 1997, 97, 173–206. doi:10.1021/cr950257t

Return to citation in text: [1] -

Bredas, J.-L. Mater. Horiz. 2014, 1, 17–19. doi:10.1039/C3MH00098B

Return to citation in text: [1] -

Berridge, R.; Skabara, P. J.; Pozo-Gonzalo, C.; Kanibolotsky, A.; Lohr, J.; McDouall, J. J. W.; McInnes, E. J. L.; Wolowska, J.; Winder, C.; Sariciftci, N. S.; Harrington, R. W.; Clegg, W. J. Phys. Chem. B 2006, 110, 3140–3152. doi:10.1021/jp057256h

Return to citation in text: [1] [2] [3] [4] -

Skabara, P. J.; Roberts, D. M.; Ray, A. K.; Umare, S. S.; Hassan, A. K.; Nabok, A. V.; Müllen, K. Tetrathiafulvalene Units. In Electronic, Optical and Optoelectronic Polymers and Oligomers; Jabbour, G. E.; Sariciftci, N. S., Eds.; Materials Research Society: Michigan, 2002; Vol. 665, pp 45–52.

Return to citation in text: [1] -

Kotani, S.; Shiina, K.; Sonogashira, K. J. Organomet. Chem. 1992, 429, 403–413. doi:10.1016/0022-328X(92)83188-N

Return to citation in text: [1] -

Renaldo, A. F.; Labadie, J. W.; Stille, J. K. Org. Synth. 1989, 67, 86–97. doi:10.15227/orgsyn.067.0086

Return to citation in text: [1] -

Roncali, J. Chem. Rev. 1992, 92, 711–738. doi:10.1021/cr00012a009

Return to citation in text: [1] -

Zotti, G.; Zecchin, S.; Schiavon, G.; Louwet, F.; Groenendaal, L.; Crispin, X.; Osikowicz, W.; Salaneck, W.; Fahlman, M. Macromolecules 2003, 36, 3337–3344. doi:10.1021/ma021715k

Return to citation in text: [1] -

Kim, E.-G.; Brédas, J.-L. J. Am. Chem. Soc. 2008, 130, 16880–16889. doi:10.1021/ja806389b

Return to citation in text: [1] -

Han, G. D.; Collins, W. R.; Andrew, T. L.; Bulović, V.; Swager, T. M. Adv. Funct. Mater. 2013, 23, 3061–3069. doi:10.1002/adfm.201203251

Return to citation in text: [1] -

Holliday, S.; Ashraf, R. S.; Nielsen, C. B.; Kirkus, M.; Röhr, J. A.; Tan, C.-H.; Collado-Fregoso, E.; Knall, A.-C.; Durrant, J. R.; Nelson, J.; McCulloch, I. J. Am. Chem. Soc. 2015, 137, 898–904. doi:10.1021/ja5110602

Return to citation in text: [1] -

Kanibolotsky, A. L.; Forgie, J. C.; Gordeyev, S.; Vilela, F.; Skabara, P. J.; Lohr, J. E.; Petersen, B. M.; Jeppesen, J. O. Macromol. Rapid Commun. 2008, 29, 1226–1230. doi:10.1002/marc.200800154

Return to citation in text: [1] -

Cortizo-Lacalle, D.; Arumugam, S.; Elmasly, S. E. T.; Kanibolotsky, A. L.; Findlay, N. J.; Inigo, A. R.; Skabara, P. J. J. Mater. Chem. 2012, 22, 11310–11315. doi:10.1039/c2jm31502e

Return to citation in text: [1] -

Arumugam, S.; Cortizo-Lacalle, D.; Rossbauer, S.; Hunter, S.; Kanibolotsky, A. L.; Inigo, A. R.; Lane, P. A.; Anthopoulos, T. D.; Skabara, P. J. ACS Appl. Mater. Interfaces 2015. doi:10.1021/am5080562

Return to citation in text: [1] [2] -

Zhang, Q.; Cirpan, A.; Russell, T. P.; Emrick, T. Macromolecules 2009, 42, 1079–1082. doi:10.1021/ma801504e

Return to citation in text: [1] -

Wang, J.; Higashihara, T. Polym. Chem. 2013, 4, 5518–5526. doi:10.1039/c3py00979c

Return to citation in text: [1] -

Sommer, M.; Huettner, S.; Thelakkat, M. J. Mater. Chem. 2010, 20, 10788–10797. doi:10.1039/c0jm00665c

Return to citation in text: [1] -

Mason, C. R.; Skabara, P. J.; Cupertino, D.; Schofield, J.; Meghdadi, F.; Ebner, B.; Sariciftci, N. S. J. Mater. Chem. 2005, 15, 1446–1453. doi:10.1039/b415610b

Return to citation in text: [1] -

Wright, I. A.; Skabara, P. J.; Forgie, J. C.; Kanibolotsky, A. L.; González, B.; Coles, S. J.; Gambino, S.; Samuel, I. D. W. J. Mater. Chem. 2011, 21, 1462–1469. doi:10.1039/C0JM02293D

Return to citation in text: [1] [2] [3] -

Wright, I. A.; Findlay, N. J.; Arumugam, S.; Inigo, A. R.; Kanibolotsky, A. L.; Zassowski, P.; Domagala, W.; Skabara, P. J. J. Mater. Chem. C 2014, 2, 2674–2683. doi:10.1039/c3tc32571g

Return to citation in text: [1] [2] [3]

| 43. | Yamamoto, T.; Shimizu, T. J. Mater. Chem. 1997, 7, 1967–1968. doi:10.1039/a704753c |

| 55. | Skabara, P. J.; Berridge, R.; McInnes, E. J. L.; West, D. P.; Coles, S. J.; Hursthouse, M. B.; Müllen, K. J. Mater. Chem. 2004, 14, 1964–1969. doi:10.1039/b400809j |

| 44. | Zotti, G.; Zecchin, S.; Schiavon, G.; Berlin, A.; Huchet, L.; Roncali, J. J. Electroanal. Chem. 2001, 504, 64–70. doi:10.1016/S0022-0728(01)00429-6 |

| 78. | Kotani, S.; Shiina, K.; Sonogashira, K. J. Organomet. Chem. 1992, 429, 403–413. doi:10.1016/0022-328X(92)83188-N |

| 31. | Kanibolotsky, A.; Roquet, S.; Cariou, M.; Leriche, P.; Turrin, C.-O.; de Bettignies, R.; Caminade, A.-M.; Majoral, J.-P.; Khodorkovsky, V.; Gorgues, A. Org. Lett. 2004, 6, 2109–2112. doi:10.1021/ol049648x |

| 32. | Kimura, H.; Konishi, K.; Muraoka, S.-y.; Shirahata, T.; Misaki, Y. Chem. Lett. 2014, 43, 843–845. doi:10.1246/cl.140092 |

| 77. | Skabara, P. J.; Roberts, D. M.; Ray, A. K.; Umare, S. S.; Hassan, A. K.; Nabok, A. V.; Müllen, K. Tetrathiafulvalene Units. In Electronic, Optical and Optoelectronic Polymers and Oligomers; Jabbour, G. E.; Sariciftci, N. S., Eds.; Materials Research Society: Michigan, 2002; Vol. 665, pp 45–52. |

| 76. | Berridge, R.; Skabara, P. J.; Pozo-Gonzalo, C.; Kanibolotsky, A.; Lohr, J.; McDouall, J. J. W.; McInnes, E. J. L.; Wolowska, J.; Winder, C.; Sariciftci, N. S.; Harrington, R. W.; Clegg, W. J. Phys. Chem. B 2006, 110, 3140–3152. doi:10.1021/jp057256h |

| 49. | Huchet, L.; Akoudad, S.; Roncali, J. Adv. Mater. 1998, 10, 541–545. doi:10.1002/(SICI)1521-4095(199805)10:7<541::AID-ADMA541>3.0.CO;2-1 |

| 49. | Huchet, L.; Akoudad, S.; Roncali, J. Adv. Mater. 1998, 10, 541–545. doi:10.1002/(SICI)1521-4095(199805)10:7<541::AID-ADMA541>3.0.CO;2-1 |

| 50. | Huchet, L.; Akoudad, S.; Levillain, E.; Roncali, J.; Emge, A.; Bäuerle, P. J. Phys. Chem. B 1998, 102, 7776–7781. doi:10.1021/jp982593u |

| 49. | Huchet, L.; Akoudad, S.; Roncali, J. Adv. Mater. 1998, 10, 541–545. doi:10.1002/(SICI)1521-4095(199805)10:7<541::AID-ADMA541>3.0.CO;2-1 |

| 48. | Thobie-Gautier, C.; Gorgues, A.; Jubault, M.; Roncali, J. Macromolecules 1993, 26, 4094–4099. doi:10.1021/ma00068a004 |

| 76. | Berridge, R.; Skabara, P. J.; Pozo-Gonzalo, C.; Kanibolotsky, A.; Lohr, J.; McDouall, J. J. W.; McInnes, E. J. L.; Wolowska, J.; Winder, C.; Sariciftci, N. S.; Harrington, R. W.; Clegg, W. J. Phys. Chem. B 2006, 110, 3140–3152. doi:10.1021/jp057256h |

| 49. | Huchet, L.; Akoudad, S.; Roncali, J. Adv. Mater. 1998, 10, 541–545. doi:10.1002/(SICI)1521-4095(199805)10:7<541::AID-ADMA541>3.0.CO;2-1 |

| 54. | Skabara, P. J.; Müllen, K. Synth. Met. 1997, 84, 345–346. doi:10.1016/S0379-6779(97)80774-6 |

| 46. | Bryce, M. R.; Chissel, A. D.; Gopal, J.; Kathirgamanathan, P.; Parker, D. Synth. Met. 1991, 39, 397–400. doi:10.1016/0379-6779(91)91766-4 |

| 76. | Berridge, R.; Skabara, P. J.; Pozo-Gonzalo, C.; Kanibolotsky, A.; Lohr, J.; McDouall, J. J. W.; McInnes, E. J. L.; Wolowska, J.; Winder, C.; Sariciftci, N. S.; Harrington, R. W.; Clegg, W. J. Phys. Chem. B 2006, 110, 3140–3152. doi:10.1021/jp057256h |

| 47. | Zhang, L.; Li, M.; Wang, C.; Wang, Y.; Shen, Y. J. Appl. Polym. Sci. 2013, 127, 3356–3364. doi:10.1002/app.37803 |

| 79. | Renaldo, A. F.; Labadie, J. W.; Stille, J. K. Org. Synth. 1989, 67, 86–97. doi:10.15227/orgsyn.067.0086 |

| 51. | Besbes, M.; Trippé, G.; Levillain, E.; Mazari, M.; Le Derf, F.; Perepichka, I. F.; Derdour, A.; Gorgues, A.; Sallé, M.; Roncali, J. Adv. Mater. 2001, 13, 1249–1252. doi:10.1002/1521-4095(200108)13:16<1249::AID-ADMA1249>3.0.CO;2-W |

| 52. | Trippé, G.; Le Derf, F.; Lyskawa, J.; Mazari, M.; Roncali, J.; Gorgues, A.; Levillain, E.; Sallé, M. Chem. – Eur. J. 2004, 10, 6497–6509. doi:10.1002/chem.200400303 |

| 86. | Cortizo-Lacalle, D.; Arumugam, S.; Elmasly, S. E. T.; Kanibolotsky, A. L.; Findlay, N. J.; Inigo, A. R.; Skabara, P. J. J. Mater. Chem. 2012, 22, 11310–11315. doi:10.1039/c2jm31502e |

| 52. | Trippé, G.; Le Derf, F.; Lyskawa, J.; Mazari, M.; Roncali, J.; Gorgues, A.; Levillain, E.; Sallé, M. Chem. – Eur. J. 2004, 10, 6497–6509. doi:10.1002/chem.200400303 |

| 87. | Arumugam, S.; Cortizo-Lacalle, D.; Rossbauer, S.; Hunter, S.; Kanibolotsky, A. L.; Inigo, A. R.; Lane, P. A.; Anthopoulos, T. D.; Skabara, P. J. ACS Appl. Mater. Interfaces 2015. doi:10.1021/am5080562 |

| 83. | Han, G. D.; Collins, W. R.; Andrew, T. L.; Bulović, V.; Swager, T. M. Adv. Funct. Mater. 2013, 23, 3061–3069. doi:10.1002/adfm.201203251 |

| 84. | Holliday, S.; Ashraf, R. S.; Nielsen, C. B.; Kirkus, M.; Röhr, J. A.; Tan, C.-H.; Collado-Fregoso, E.; Knall, A.-C.; Durrant, J. R.; Nelson, J.; McCulloch, I. J. Am. Chem. Soc. 2015, 137, 898–904. doi:10.1021/ja5110602 |

| 85. | Kanibolotsky, A. L.; Forgie, J. C.; Gordeyev, S.; Vilela, F.; Skabara, P. J.; Lohr, J. E.; Petersen, B. M.; Jeppesen, J. O. Macromol. Rapid Commun. 2008, 29, 1226–1230. doi:10.1002/marc.200800154 |

| 81. | Zotti, G.; Zecchin, S.; Schiavon, G.; Louwet, F.; Groenendaal, L.; Crispin, X.; Osikowicz, W.; Salaneck, W.; Fahlman, M. Macromolecules 2003, 36, 3337–3344. doi:10.1021/ma021715k |

| 82. | Kim, E.-G.; Brédas, J.-L. J. Am. Chem. Soc. 2008, 130, 16880–16889. doi:10.1021/ja806389b |

| 76. | Berridge, R.; Skabara, P. J.; Pozo-Gonzalo, C.; Kanibolotsky, A.; Lohr, J.; McDouall, J. J. W.; McInnes, E. J. L.; Wolowska, J.; Winder, C.; Sariciftci, N. S.; Harrington, R. W.; Clegg, W. J. Phys. Chem. B 2006, 110, 3140–3152. doi:10.1021/jp057256h |

| 60. | Skabara, P. J.; Serebryakov, I. M.; Roberts, D. M.; Perepichka, I. F.; Coles, S. J.; Hursthouse, M. B. J. Org. Chem. 1999, 64, 6418–6424. doi:10.1021/jo990198+ |

| 61. | O'Connor, B. R.; Jones, F. N. J. Org. Chem. 1970, 35, 2002–2005. doi:10.1021/jo00831a062 |

| 57. | Rovira, C.; Santalō, N.; Veciana, J. Tetrahedron Lett. 1989, 30, 7249–7252. doi:10.1016/S0040-4039(01)93950-4 |

| 58. | Rovira, C.; Veciana, J.; Santalo, N.; Tarres, J.; Cirujeda, J.; Molins, E.; Llorca, J.; Espinosa, E. J. Org. Chem. 1994, 59, 3307–3313. doi:10.1021/jo00091a017 |

| 59. | Skabara, P. J.; Müllen, K.; Bryce, M. R.; Howard, J. A. K.; Batsanov, A. S. J. Mater. Chem. 1998, 8, 1719–1724. doi:10.1039/a803027h |

| 55. | Skabara, P. J.; Berridge, R.; McInnes, E. J. L.; West, D. P.; Coles, S. J.; Hursthouse, M. B.; Müllen, K. J. Mater. Chem. 2004, 14, 1964–1969. doi:10.1039/b400809j |

| 72. | Kanibolotsky, A. L.; Kanibolotskaya, L.; Gordeyev, S.; Skabara, P. J.; McCulloch, I.; Berridge, R.; Lohr, J. E.; Marchioni, F.; Wudl, F. Org. Lett. 2007, 9, 1601–1604. doi:10.1021/ol070366h |

| 56. | Shu, P.; Chiang, L.; Emge, T.; Holt, D.; Kistenmacher, T.; Lee, M.; Stokes, J.; Poehler, T.; Bloch, A.; Cowan, D. J. Chem. Soc., Chem. Commun. 1981, 920–921. doi:10.1039/c39810000920 |

| 91. | Mason, C. R.; Skabara, P. J.; Cupertino, D.; Schofield, J.; Meghdadi, F.; Ebner, B.; Sariciftci, N. S. J. Mater. Chem. 2005, 15, 1446–1453. doi:10.1039/b415610b |

| 53. | Sinha, J.; Lee, S. J.; Kong, H.; Swift, T. W.; Katz, H. E. Macromolecules 2013, 46, 708–717. doi:10.1021/ma3019365 |

| 87. | Arumugam, S.; Cortizo-Lacalle, D.; Rossbauer, S.; Hunter, S.; Kanibolotsky, A. L.; Inigo, A. R.; Lane, P. A.; Anthopoulos, T. D.; Skabara, P. J. ACS Appl. Mater. Interfaces 2015. doi:10.1021/am5080562 |

| 54. | Skabara, P. J.; Müllen, K. Synth. Met. 1997, 84, 345–346. doi:10.1016/S0379-6779(97)80774-6 |

| 88. | Zhang, Q.; Cirpan, A.; Russell, T. P.; Emrick, T. Macromolecules 2009, 42, 1079–1082. doi:10.1021/ma801504e |

| 89. | Wang, J.; Higashihara, T. Polym. Chem. 2013, 4, 5518–5526. doi:10.1039/c3py00979c |

| 90. | Sommer, M.; Huettner, S.; Thelakkat, M. J. Mater. Chem. 2010, 20, 10788–10797. doi:10.1039/c0jm00665c |

| 63. | Liu, B.; Wu, B.; Xu, J.; Wu, Z.; Zhao, Y.; Zheng, X.; Wang, H. J. Raman Spectrosc. 2010, 41, 1185–1193. doi:10.1002/jrs.2580 |

| 64. | Fox, M. A.; Pan, H.-l. J. Org. Chem. 1994, 59, 6519–6527. doi:10.1021/jo00101a009 |

| 93. | Wright, I. A.; Findlay, N. J.; Arumugam, S.; Inigo, A. R.; Kanibolotsky, A. L.; Zassowski, P.; Domagala, W.; Skabara, P. J. J. Mater. Chem. C 2014, 2, 2674–2683. doi:10.1039/c3tc32571g |

| 62. | Lee, A. W. M.; Chan, W. H.; Wong, H. C. Synth. Commun. 1988, 18, 1531–1536. doi:10.1080/00397918808081310 |

| 93. | Wright, I. A.; Findlay, N. J.; Arumugam, S.; Inigo, A. R.; Kanibolotsky, A. L.; Zassowski, P.; Domagala, W.; Skabara, P. J. J. Mater. Chem. C 2014, 2, 2674–2683. doi:10.1039/c3tc32571g |

| 1. | Skabara, P. J.; Arlin, J.-B.; Geerts, Y. H. Adv. Mater. 2013, 25, 1948–1954. doi:10.1002/adma.201200862 |

| 92. | Wright, I. A.; Skabara, P. J.; Forgie, J. C.; Kanibolotsky, A. L.; González, B.; Coles, S. J.; Gambino, S.; Samuel, I. D. W. J. Mater. Chem. 2011, 21, 1462–1469. doi:10.1039/C0JM02293D |

| 92. | Wright, I. A.; Skabara, P. J.; Forgie, J. C.; Kanibolotsky, A. L.; González, B.; Coles, S. J.; Gambino, S.; Samuel, I. D. W. J. Mater. Chem. 2011, 21, 1462–1469. doi:10.1039/C0JM02293D |

| 92. | Wright, I. A.; Skabara, P. J.; Forgie, J. C.; Kanibolotsky, A. L.; González, B.; Coles, S. J.; Gambino, S.; Samuel, I. D. W. J. Mater. Chem. 2011, 21, 1462–1469. doi:10.1039/C0JM02293D |

| 93. | Wright, I. A.; Findlay, N. J.; Arumugam, S.; Inigo, A. R.; Kanibolotsky, A. L.; Zassowski, P.; Domagala, W.; Skabara, P. J. J. Mater. Chem. C 2014, 2, 2674–2683. doi:10.1039/c3tc32571g |

| 6. | Sirringhaus, H.; Tessler, N.; Friend, R. H. Science 1998, 280, 1741–1744. doi:10.1126/science.280.5370.1741 |

| 7. | Cho, S.; Lee, K.; Yuen, J.; Wang, G.; Moses, D.; Heeger, A. J.; Surin, M.; Lazzaroni, R. J. Appl. Phys. 2006, 100, 114503. doi:10.1063/1.2400796 |

| 23. | Wudl, F.; Wobschall, D.; Hufnagel, E. J. J. Am. Chem. Soc. 1972, 94, 670–672. doi:10.1021/ja00757a079 |

| 68. | Serebryakov, I. M.; Skabara, P. J.; Perepichka, I. F. J. Chem. Soc., Perkin Trans. 2 1999, 1405–1410. doi:10.1039/a901178a |

| 69. | Vilela, F.; Skabara, P. J.; Mason, C. R.; Westgate, T. D. J.; Luquin, A.; Coles, S. J.; Hursthouse, M. B. Beilstein J. Org. Chem. 2010, 6, 1002–1014. doi:10.3762/bjoc.6.113 |

| 5. | Dang, M. T.; Hirsch, L.; Wantz, G.; Wuest, J. D. Chem. Rev. 2013, 113, 3734–3765. doi:10.1021/cr300005u |

| 24. | Ferraris, J.; Cowan, D. O.; Walatka, V.; Perlstein, J. H. J. Am. Chem. Soc. 1973, 95, 948–949. doi:10.1021/ja00784a066 |

| 4. | Groenendaal, L.; Jonas, F.; Freitag, D.; Pielartzik, H.; Reynolds, J. R. Adv. Mater. 2000, 12, 481–494. doi:10.1002/(SICI)1521-4095(200004)12:7<481::AID-ADMA481>3.0.CO;2-C |

| 20. | Zhang, K.; Tieke, B.; Forgie, J. C.; Vilela, F.; Skabara, P. J. Macromolecules 2012, 45, 743–750. doi:10.1021/ma202387t |

| 67. | Guziec, F. S., Jr.; Russo, J. M.; Torres, F. F.; Long, G. C.; Tellez, M. R. J. Chem. Soc., Perkin Trans. 1 1989, 1068–1070. doi:10.1039/p19890001068 |

| 2. | Chen, T. A.; Rieke, R. D. J. Am. Chem. Soc. 1992, 114, 10087–10088. doi:10.1021/ja00051a066 |

| 3. | McCullough, R. D.; Tristram-Nagle, S.; Williams, S. P.; Lowe, R. D.; Jayaraman, M. J. Am. Chem. Soc. 1993, 115, 4910–4911. doi:10.1021/ja00064a070 |

| 21. | Cortizo-Lacalle, D.; Howells, C. T.; Gambino, S.; Vilela, F.; Vobecka, Z.; Findlay, N. J.; Inigo, A. R.; Thomson, S. A. J.; Skabara, P. J.; Samuel, I. D. W. J. Mater. Chem. 2012, 22, 14119–14126. doi:10.1039/c2jm32374e |

| 22. | Forgie, J. C.; Skabara, P. J.; Stibor, I.; Vilela, F.; Vobecka, Z. Chem. Mater. 2009, 21, 1784–1786. doi:10.1021/cm9004823 |

| 60. | Skabara, P. J.; Serebryakov, I. M.; Roberts, D. M.; Perepichka, I. F.; Coles, S. J.; Hursthouse, M. B. J. Org. Chem. 1999, 64, 6418–6424. doi:10.1021/jo990198+ |