Abstract

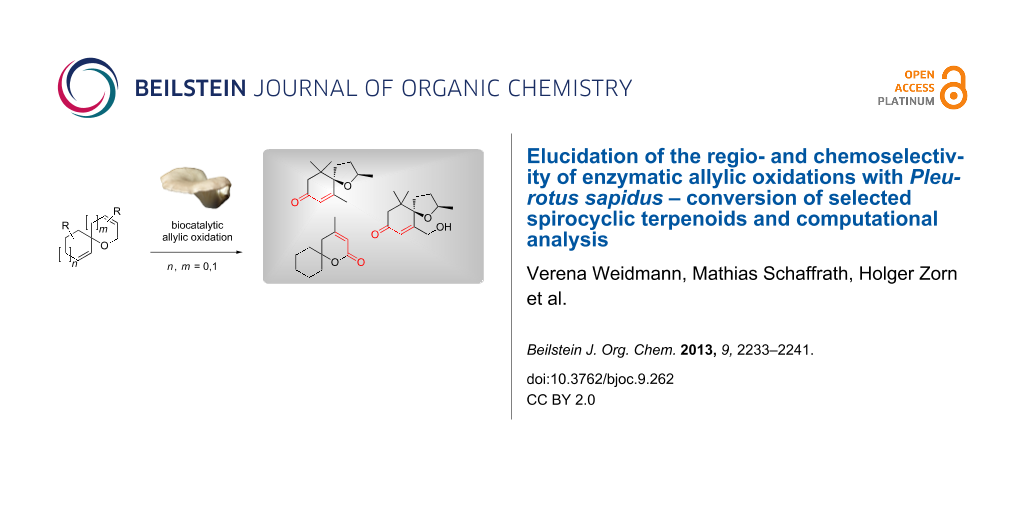

Allylic oxidations of olefins to enones allow the efficient synthesis of value-added products from simple olefinic precursors like terpenes or terpenoids. Biocatalytic variants have a large potential for industrial applications, particularly in the pharmaceutical and food industry. Herein we report efficient biocatalytic allylic oxidations of spirocyclic terpenoids by a lyophilisate of the edible fungus Pleurotus sapidus. This ‘’mushroom catalysis’’ is operationally simple and allows the conversion of various unsaturated spirocyclic terpenoids. A number of new spirocyclic enones have thus been obtained with good regio- and chemoselectivity and chiral separation protocols for enantiomeric mixtures have been developed. The oxidations follow a radical mechanism and the regioselectivity of the reaction is mainly determined by bond-dissociation energies of the available allylic CH-bonds and steric accessibility of the oxidation site.

Graphical Abstract

Introduction

Selective oxidations of CH-bonds are attractive synthetic transformations with a broad spectrum of applications in academia and a high impact on the industrial chemical value chain as they convert relatively cheap precursors into value-added products [1,2]. Among these transformations, allylic oxidations are of high interest because the olefinic starting materials are readily available as cheap bulk chemicals and many interesting derivatives such as terpenes are available from renewable sources [3-5]. In addition, the resulting allyl alcohols [6-10] or α,β-unsaturated carbonyl compounds are attractive synthetic targets of high economic and scientific interest [11-17]. Allylic oxidations of olefins to enones have classically been performed with strong oxidants such as chromium or other metal-based reagents [18,19]. In addition, metal-free and biocatalytic methods have been reported [5]. Several of these biocatalytic protocols have been applied to the synthesis of fine chemicals [20-22], drugs [23], and food ingredients [24-26]. A particularly interesting biocatalytic system for allylic oxidation is the edible fungus Pleurotus sapidus (PSA), which is able to oxidize selected terpenes and fatty acids [27-31]. We have recently shown that the lyophilisate of PSA is able to affect allylic and benzylic oxidations in a broad range of olefinic substrates including simple cyclohexene derivatives and several functionalized terpenoids (Figure 1) [32].

Figure 1: Selected biocatalytic allylic and benzylic oxidations with the lyophilisate of Pleurotus sapidus (PSA).

Figure 1: Selected biocatalytic allylic and benzylic oxidations with the lyophilisate of Pleurotus sapidus (P...

Biocatalytic allylic oxidations with PSA may be performed with the lyophilisate from submerged cultures. Cyclic alkenes and particularly cyclohexene derivatives are the preferred substrates of PSA. A PSA-derived dioxygenase has been shown to be responsible for the allylic oxidation of valencene to nootkatone, and the same enzyme oxidizes unsaturated fatty acids [29,31]. It is thus likely that this dioxygenase is the major oxidant in other allylic oxidations with PSA-lyophilisate, too. However, since the lyophilisate is a mixture of enzymes, alternative oxidation pathways cannot be ruled out for other substrates. Reviewing the available examples for PSA-mediated conversions in the literature, the regio- and chemoselectivity of these oxidations seems to be determined by the radical mechanism of the reactions and would thus follow well-established rules for other radical-type allylic oxidations [33-36].

A notable example of an allylic oxidation with PSA is the conversion of theaspirane (1), a spirocyclic flavor compound of tea, vanilla and different fruits [37] to the corresponding theaspirone (2) (Scheme 1) [32].

Scheme 1: Biocatalytic allylic oxidation of theaspirane (1) with lyophilisates of PSA. Only one enantiomer of racemic compounds is shown.

Scheme 1: Biocatalytic allylic oxidation of theaspirane (1) with lyophilisates of PSA. Only one enantiomer of...

The reaction is quite clean and gives the enone 2 in good yield along with minor amounts of the corresponding allyl alcohol 3 and the epoxide 4a. This successful conversion of theaspirane (1) encouraged us to investigate the oxidation of other spirocyclic terpenoids. Many oxidized spiroethers are valuable flavor compounds or have other interesting biological properties such as phytotoxic activity. A few selected examples are depicted in Figure 2.

Figure 2: Selected bioactive terpenoids based on spiroether backbones [38,39].

Figure 2: Selected bioactive terpenoids based on spiroether backbones [38,39].

In this paper, we report biocatalytic allylic oxidations of spirocyclic model compounds and of the natural product vitispirane with the lyophilisate of PSA. A rationalization of the observed selectivity is provided by means of computational determination of bond-dissociation enthalpies and correlation with structural and electronic features. In addition, a short synthesis of vitispirane is presented.

Results and Discussion

Allylic spiroethers, such as theaspirane (1) (Scheme 1) are suitable substrates for allylic oxidations with PSA. Due to their interesting properties as flavor compounds, we focused our attention to the oxidation of terpenoid spiroethers. As model compounds, unsaturated spiroethers 7, 8, 11 and 12 were synthesized by the intramolecular silyl-modified Sakurai reaction of precursors 5 and 10 and alkene 6 (Scheme 2). Two pairs of regioisomeric endocyclic derivatives 7, 8 and 11, 12 were obtained as the major products of cyclization in a 1:1 mixture. The third regioisomer 9 and 13 respectively, with an exocyclic double bond was observed in minor amounts only. Separation of the regioisomeric spiroethers by column chromatography proved to be difficult, and in both cases only the two major isomers with endocyclic double bonds were isolated in pure form. The regioisomeric spiroethers 7, 8, 11 and 12 are interesting model compounds for the allylic oxidation with PSA because they contain allylic positions with different stereoelectronic properties.

Scheme 2: Intramolecular silyl modified Sakurai reaction to spiroethers 7–9 and 11–13.

Scheme 2: Intramolecular silyl modified Sakurai reaction to spiroethers 7–9 and 11–13.

All four spiroethers 7, 8, 11 and 12 were submitted to identical conditions and were treated with PSA lyophilisate in Tris-buffer at room temperature (Scheme 3). The reactions were monitored by GC. The oxidation of allyl ether 7 may follow two alternative pathways either to the α,β-unsaturated lactone 14 or to the enone 15 (allylic oxidations at exocyclic positions are generally less favorable if radical mechanisms are operating) [35]. Due to sterical hindrance at position 5 and the strong activation for hydrogen abstraction in position 2, spiroether 7 was selectively converted to the spirolactone 14. The alternative oxidation product 15 was not found by GC–MS. The regioisomeric spiroether 8 offers only one plausible path for allylic oxidation in position 3. However, this spiroether was not converted at all and the starting material 8 was recovered almost quantitatively from the reaction mixture. This finding may reflect the increased sterical hindrance of the allylic position in 8 compared to the site of oxidation in regioisomer 7 and a less stable radical intermediate.

Scheme 3: Biocatalytic allylic oxidation of spiroethers 7, 8, 11 and 12 with the lyophilisate of PSA. Conversion was measured by GC and yields are given after isolation of the oxidation products and purification by chromatography.

Scheme 3: Biocatalytic allylic oxidation of spiroethers 7, 8, 11 and 12 with the lyophilisate of PSA. Convers...

Similar results were obtained for oxidation of spiroethers 11 and 12 which contain two separated double bonds. The allyl ether 11 allows three plausible oxidation products 17–19. However, due to our experiences with oxidations of 7, 8 and theaspirane (1), position 2 should be activated most strongly for hydrogen abstraction and should thus be privileged for oxidation. As a consequence, the α,β-unsaturated lactone 17 is indeed the major product along with some unidentified more complex oxidation products. Again, oxidation in 5-position of 11 to the enone 18 was not observed. In addition, the allylic hydrogens in 9-position are obviously also of low reactivity and the corresponding oxidation product 19 was also not detectable. In agreement with the oxidation of 8, substrate 12 was not oxidized by PSA at all and the starting material was reisolated almost quantitatively.

Computational analysis (for full computational details see Supporting Information File 1) of relative radical stabilities and bond-dissociation enthalpies (BDH298) based on DFT (B3LYP/6-31+G** and B3LYP/6-31G* + PCM) and composite method (CBS-QB3) calculations enable a quantification and visual rationalization of the observed experimental results. Since PCM and gas phase results do not differ significantly neither in terms of geometry nor energy, we will restrict the discussion to gas phase values only unless otherwise stated (for details of the PCM results see Supporting Information File 1). The CBS-QB3 method has been used to obtain accurate energies and to evaluate the DFT-energies in terms of relative and absolute values. For this comparison CBS-QB3 has been applied to model structures 11A and 11B that contain key structural features of 11 and 12 (Table 1). According to the data summarized in Table 1 and Table 2 B3LYP/6-31+G** gives reasonable results and is a suitable method to predict at least relative BDH-values of C–H bonds of the spiro compounds at hand. In absolute terms, B3LYP underestimates the BDH systematically by 2.9–4.6 kcal/mol.

Table 2: Optimized geometries and BDH298 values of radicals derived from 11 and 12 for gas phase and PCM calculations.

|

|

|||||||

| entry | compd | B3LYP/6-31+G** | B3LYP/6-31G* + PCM | ||||

|---|---|---|---|---|---|---|---|

|

ΔHa

[kcal/mol] |

ΔGa

[kcal/mol] |

BDH298

[kcal/mol] |

ΔHa

[kcal/mol] |

ΔGa

[kcal/mol] |

BDH298

[kcal/mol] |

||

| 1 | 11 | 1.2 | 1.3 | — | 1.0 | 1.2 | — |

| 2 | 11-R1 | −1.5 | −0.2 | 80.9 | −1.9 | −0.3 | 81.6 |

| 3 | 11-R2 | 0.5 | 0.7 | 82.9 | 0.3 | 0.7 | 83.7 |

| 4 | 11-R3 | −7.5 | −6.4 | 74.9 | −7.8 | 0.0 | 74.6 |

| 5 | 12 | 0.0 | 0.0 | — | 0.0 | 0.0 | — |

| 6 | 12-R1 | −3.3 | −2.1 | 80.3 | 3.4 | 2.0 | 80.1 |

| 7 | 12-R2 | 0.0 | 0.0 | 83.6 | 0.0 | 0.0 | 83.4 |

aReferring to 12 for closed-shell species and 12-R2 for radicals.

The experimental observation as summarized in Scheme 3, e.g., the selective oxidation in 2-position of an allyl ether subunit may be rationalized by the particularly low BDH298 for the corresponding C–H bond compared to the other allylic C–H bonds (Table 2). Carbon-centered radicals adjacent to an oxygen atom are commonly known to be stabilized as they benefit from inductive effects as well as from orbital interactions of the p-type lone pair of the oxygen atom with the half-filled p-orbital of the mainly sp2 hybridized radical [40]. The picture of the SOMO and the mapped out spin density of 11-R3 illustrate the latter effect (Figure 3). In addition, the methyl group in 3-position of the allylic system in 11-R3 as well as in the model system 11B-R3 helps to stabilize the radical further, mainly by hyperconjugation. In total, both substituent effects result in a rather low C–H bond-dissociation enthalpy of 79.5 kcal/mol at CBS-QB3 level of theory (74.9 kcal/mol B3LYP/6-31+G**, Table 2).

![[1860-5397-9-262-3]](/bjoc/content/figures/1860-5397-9-262-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: Bond-dissociation enthalpies for three allylic C–H bonds in 11. Double stabilization of the radical in 11-R3 by the adjacent oxygen and hyperconjugation lead to a rather low BDH of 74.9 kcal/mol (B3LYP/6-31+G**).

Figure 3: Bond-dissociation enthalpies for three allylic C–H bonds in 11. Double stabilization of the radical...

Compared to the other potential allylic radicals like 11-R1 and 11-R2, 11-R3 is up to 8 kcal/mol more stable. Within the subset of allylic radicals that differ only by their alkyl substitution pattern (11-R1, 11-R2, 12-R1 and 12-R2) the energetic differences are less pronounced. Equally, the reasons for the small variations in BDH298 values are more subtle and might be referred to additional steric strain imposed by a change in hybridization of the carbon atom from sp3 to sp2 upon radical formation and hyperconjugation effects (Table 2). Correlating the experimental observations with the computational results, one can deduce that a BHD298 of around 80 kcal/mol (CBS-QB3) seems to be a threshold that might be used as a guideline to decide whether an allylic oxidation of spiro compounds related to 11 and 12 with PSA takes places or not.

As a further test on the substrate scope of the reaction, we were interested in the biocatalytic oxidation of vitispirane as a terpenoid with a conjugated double bond and a sterically hindered allylic position (Figure 2). Vitispirane is a flavor compound of vanilla and quince fruit and was identified in grape juice and wine [41,42]. Various syntheses of vitispirane have been reported in the literature [43-45]. To get sufficient quantity of the oxidation precursor, we focused on a strategy reported by Ohloff starting from commercially available theaspirane (1) [46]. As described by Ohloff and coworkers, the separation of vitispirane diastereoisomers is quite difficult. Therefore we decided to start with diastereomerically pure theaspirane (trans-1) that was obtained by chromatographic separation of the commercial diastereomeric mixture of cis- and trans-theaspirane (1). As depicted in Scheme 4, trans-theaspirane (trans-1) was converted to the corresponding epoxides 4a and 4b following the literature protocol using m-chloroperbenzoic acid. The major epoxide 4a was obtained in good yield and a diastereoselectivity of 11:1.

Scheme 4: Improved 3-step synthesis of vitispirane (23) from theaspirane (1). Only one enantiomer of racemic compounds is shown.

Scheme 4: Improved 3-step synthesis of vitispirane (23) from theaspirane (1). Only one enantiomer of racemic ...

Isomerisation of epoxide 4a to allyl alcohol 22 was reported with aluminium triisopropoxide at 140 °C [46]. However, in our hands this procedure gave only complex reaction mixtures containing minor amounts of the target allyl alcohol 22. In an alternative protocol, we used Yamamoto´s conditions [47] for the isomerization of epoxides (TMP, n-BuLi, Et2AlCl) and obtained allyl alcohol 22 in excellent 93% yield. The conversion of allyl alcohol 22 to vitispirane (23) has been reported with POCl3 in pyridine. Again, this known protocol did not work satisfactory for us resulting in only minor amounts of the desired vitispirane (23). As a consequence, we decided to use an alternative method via acetylation and Pd-catalyzed elimination. This conversion gave vitispirane (23) in good yield [48]. Overall, this improved protocol gave racemic vitispirane (23) in three steps from theaspirane (trans-1) in excellent 72% overall yield. It should be noted that the gas chromatographic separation of racemic vitispirane (23) has been reported by Schreier [45]. In addition, we have been able to separate racemic vitispirane by HPLC on a chiral stationary phase (see Supporting Information File 1).

Vitispirane (23) is a challenging substrate for allylic oxidation with PSA. As outlined above, the oxidation with PSA is quite sensitive to steric and electronic factors and the allylic position 9 in vitispirane (23) is sterically hindered (Scheme 5).

Scheme 5: Oxidation of vitispirane (23) with PSA gave enone 24 and two diastereomeric allyl alcohols 26a and 26b. A putative intermediate is epoxide 25, which upon hydrolysis would give allyl alcohols 26a and 26b. Oxidation of the latter might provide enone 24. Only one enantiomer of racemic compounds is shown.

Scheme 5: Oxidation of vitispirane (23) with PSA gave enone 24 and two diastereomeric allyl alcohols 26a and ...

Treatment of vitispirane (23) with PSA was indeed not a clean conversion giving a number of different oxidation products. From this mixture, however, three main products 24, 26a and 26b were identified unambiguously. So far, we have never detected similar oxidation products with PSA and rationalize their formation by an initial epoxidation of the endocyclic double bond to give the allyl epoxide 25, which might then be hydrolyzed to two diastereomeric alcohols 26a and 26b. The latter reaction is known for similar allyl epoxides under slightly acidic conditions [49]. However, participation of hydrolases from the PSA lyophilisate is also possible. A fraction of the resulting alcohols 26 would then finally be oxidized to give enone 24. Support for an epoxide intermediate comes from oxidations of substrates containing similarly hindered allylic CH-bonds. For β-ionone, for example, we have previously observed epoxidation to be the major oxidation pathway.

It should be noted, that all three compounds 24, 26a and 26b are new derivatives of vitispirane 24 with potentially interesting properties as flavors. The relative stereochemistry of 26a and 26b was evaluated after HPLC separation of the two diastereoisomers by 2D-NOESY NMR.

The compounds 24, 26a and 26b were obtained as racemic mixtures. However, we found HPLC protocols for the separation of these terpenoids with commercial chiral stationary phases (see Supporting Information File 1). This allows the isolation of large quantities of the enantiomerically pure derivatives and their detailed olfactory analysis.

Conclusion

The edible fungus PSA allows efficient allylic oxidations of terpenoid olefins. The oxidation protocols are quite simple, because the lyophilisate of PSA can be used as a catalyst. In this paper we have investigated the substrate scope of these biocatalytic oxidations with a special focus on spiroether derivatives due to their high relevance as flavor compounds. Several new spirocyclic model compounds and the natural product vitispirane (23) were synthesized and submitted to oxidation with PSA. The outcome of these oxidations was found to be dependent on steric and electronic factors of the substrate. The reactivity of most terpenoids towards allylic oxidation with PSA can thus be estimated using the same rules established for conventional radical oxidations: The reactivity is determined by bond-dissociation energies of the allylic CH-bonds. Correlating the experimental observations of this study with computational results we deduced a threshold BHD298 of around 80 kcal/mol as a guideline to decide whether an allylic oxidation with PSA takes places or not.

Allyl spiroethers 7 and 11 were oxidized to the corresponding α,β-unsaturated lactone derivatives 14 and 17, whereas the close derivatives 8 and 12 containing slightly less reactive allylic C–H bonds were not converted by PSA at all. The natural product vitispirane (23) was oxidized by PSA, and three new vitispirane derivatives 24, 26a and 26b were isolated. In this case, the oxidation pathway is not favoring products of allylic oxidation but most likely those of epoxidation with subsequent hydrolysis of the epoxide. HPLC protocols with chiral stationary phases allow the separation of racemic mixtures of oxidized vitispirane derivatives.

Supporting Information

| Supporting Information File 1: Computational details, experimental procedures, analytical data, NMR spectra and chromatograms of new compounds. | ||

| Format: PDF | Size: 2.7 MB | Download |

Acknowledgements

H. Zorn would like to thank the DFG and the State of Hesse for funding the GC system (INST 162/381-1 FUGG) and the excellence initiative of the Hessian Ministry of Science and Art for the generous grant for the LOEWE research focus “integrative fungal research”. M. Schaffrath would like to thank Peter Hamley and Martin Will from Sanofi for their support.

References

-

Roduner, E.; Kaim, W.; Sarkar, B.; Urlacher, V. B.; Pleiss, J.; Gläser, R.; Einicke, W.-D.; Sprenger, G. A.; Beifuß, U.; Klemm, E.; Liebner, C.; Hieronymus, H.; Hsu, S.-F.; Plietker, B.; Laschat, S. ChemCatChem 2013, 5, 82–112. doi:10.1002/cctc.201200266

Return to citation in text: [1] -

Newhouse, T.; Baran, P. S. Angew. Chem., Int. Ed. 2011, 50, 3362–3374. doi:10.1002/anie.201006368

Return to citation in text: [1] -

Page, P. C. B.; McCarthy, T. J. 2.1 - Oxidation Adjacent to C=C Bonds. In Comprehensive Organic Synthesis; Trost, B. M.; Fleming, I., Eds.; Pergamon: Oxford, 1991; Vol. 7, pp 83–117. doi:10.1016/B978-0-08-052349-1.00184-0

Return to citation in text: [1] -

Nakamura, A.; Nakada, M. Synthesis 2013, 45, 1421–1451. doi:10.1055/s-0033-1338426

Return to citation in text: [1] -

Weidmann, V.; Maison, W. Synthesis 2013, 45, 2201–2221. doi:10.1055/s-0033-1338491

Return to citation in text: [1] [2] -

Kharasch, M. S.; Sosnovsky, G. J. Am. Chem. Soc. 1958, 80, 756. doi:10.1021/ja01536a062

Return to citation in text: [1] -

Andrus, M. B.; Lashley, J. C. Tetrahedron 2002, 58, 845–866. doi:10.1016/S0040-4020(01)01172-3

Return to citation in text: [1] -

Rispens, M. T.; Zondervan, C.; Feringa, B. L. Tetrahedron: Asymmetry 1995, 6, 661–664. doi:10.1016/0957-4166(95)00054-S

Return to citation in text: [1] -

Moiseev, I. I.; Vargaftik, M. N. Coord. Chem. Rev. 2004, 248, 2381–2391. doi:10.1016/j.ccr.2004.05.020

Return to citation in text: [1] -

Christie, S. D. R.; Warrington, A. D. Synthesis 2008, 1325–1341. doi:10.1055/s-2008-1067031

Return to citation in text: [1] -

Joseph, T.; Sawant, D. P.; Gopinath, C. S.; Halligudi, S. B. J. Mol. Catal. A: Chem. 2002, 184, 289–299. doi:10.1016/S1381-1169(02)00010-9

Return to citation in text: [1] -

Smith, A. B., III; Konopelski, J. P. J. Org. Chem. 1984, 49, 4094–4095. doi:10.1021/jo00195a055

Return to citation in text: [1] -

Berger, R. G. Biotechnol. Lett. 2009, 31, 1651–1659. doi:10.1007/s10529-009-0083-5

Return to citation in text: [1] -

Hanson, J. R. Nat. Prod. Rep. 2007, 24, 1342–1349. doi:10.1039/b705948p

Return to citation in text: [1] -

Fraatz, M. A.; Berger, R. G.; Zorn, H. Appl. Microbiol. Biotechnol. 2009, 83, 35–41. doi:10.1007/s00253-009-1968-x

Return to citation in text: [1] -

Salvador, J. A. R.; Silvestre, S. M.; Moreira, V. M. Curr. Org. Chem. 2012, 16, 1243–1276. doi:10.2174/138527212800564204

Return to citation in text: [1] -

Salvador, J. A. R.; Silvestre, S. M.; Moreira, V. M. Curr. Org. Chem. 2006, 10, 2227–2257. doi:10.2174/138527206778742641

Return to citation in text: [1] -

Muzart, J. Chem. Rev. 1992, 92, 113–140. doi:10.1021/cr00009a005

Return to citation in text: [1] -

Muzart, J. Mini-Rev. Org. Chem. 2009, 6, 9–20. doi:10.2174/157019309787316120

Return to citation in text: [1] -

Çelik, A.; Flitsch, S. L.; Turner, N. J. Org. Biomol. Chem. 2005, 3, 2930–2934. doi:10.1039/b506159h

Return to citation in text: [1] -

Bellucci, G.; Chiappe, C.; Pucci, L.; Gervasi, P. G. Chem. Res. Toxicol. 1996, 9, 871–874. doi:10.1021/tx9600053

Return to citation in text: [1] -

Straathof, A. J. J.; Panke, S.; Schmid, A. Curr. Opin. Biotechnol. 2002, 13, 548–556. doi:10.1016/S0958-1669(02)00360-9

Return to citation in text: [1] -

Tao, J.; Xu, J.-H. Curr. Opin. Chem. Biol. 2009, 13, 43–50. doi:10.1016/j.cbpa.2009.01.018

Return to citation in text: [1] -

Fraatz, M. A.; Riemer, S. J. L.; Stöber, R.; Kaspera, R.; Nimtz, M.; Berger, R. G.; Zorn, H. J. Mol. Catal. B: Enzym. 2009, 61, 202–207. doi:10.1016/j.molcatb.2009.07.001

Return to citation in text: [1] -

Janssens, L.; De Pooter, H. L.; Schamp, N. M.; Vandamme, E. J. Process Biochem. 1992, 27, 195–215. doi:10.1016/0032-9592(92)80020-4

Return to citation in text: [1] -

Kirk, O.; Borchert, T. V.; Fuglsang, C. C. Curr. Opin. Biotechnol. 2002, 13, 345–351. doi:10.1016/S0958-1669(02)00328-2

Return to citation in text: [1] -

Onken, J.; Berger, R. G. J. Biotechnol. 1999, 69, 163–168. doi:10.1016/S0168-1656(99)00040-1

Return to citation in text: [1] -

Krings, U.; Lehnert, N.; Fraatz, M. A.; Hardebusch, B.; Zorn, H.; Berger, R. G. J. Agric. Food Chem. 2009, 57, 9944–9950. doi:10.1021/jf901442q

Return to citation in text: [1] -

Krügener, S.; Krings, U.; Zorn, H.; Berger, R. G. Bioresour. Technol. 2010, 101, 457–462. doi:10.1016/j.biortech.2009.08.087

Return to citation in text: [1] [2] -

Zelena, K.; Krings, U.; Berger, R. G. Bioresour. Technol. 2012, 108, 231–239. doi:10.1016/j.biortech.2011.12.097

Return to citation in text: [1] -

Plagemann, I.; Zelena, K.; Arendt, P.; Ringel, P. D.; Krings, U.; Berger, R. G. J. Mol. Catal. B: Enzym. 2013, 87, 99–104. doi:10.1016/j.molcatb.2012.11.004

Return to citation in text: [1] [2] -

Rickert, A.; Krombach, V.; Hamers, O.; Zorn, H.; Maison, W. Green Chem. 2012, 14, 639–644. doi:10.1039/c2gc16317a

Return to citation in text: [1] [2] -

Wiberg, K. B.; Nielsen, S. D. J. Org. Chem. 1964, 29, 3353–3361. doi:10.1021/jo01034a055

Return to citation in text: [1] -

Dauben, W. G.; Lorber, M. E.; Fullerton, D. S. J. Org. Chem. 1969, 34, 3587–3592. doi:10.1021/jo01263a079

Return to citation in text: [1] -

Rothenberg, G.; Sasson, Y. Tetrahedron 1998, 54, 5417–5422. doi:10.1016/S0040-4020(98)00215-4

Return to citation in text: [1] [2] -

Howard, J. A.; Ingold, K. U. Can. J. Chem. 1967, 45, 793–802. doi:10.1139/v67-132

Return to citation in text: [1] -

Kaiser, R.; Kappeler, A.; Lamparsky, D. Helv. Chim. Acta 1978, 61, 387–400. doi:10.1002/hlca.19780610136

Return to citation in text: [1] -

Macías, F. A.; Galindo, J. L. G.; Varela, R. M.; Torres, A.; Molinillo, J. M. G.; Fronczek, F. R. Org. Lett. 2006, 8, 4513–4516. doi:10.1021/ol061673a

Return to citation in text: [1] -

Huang, C.; Liu, B. Chem. Commun. 2010, 46, 5280–5282. doi:10.1039/c0cc00481b

Return to citation in text: [1] -

Laarhoven, L. J. J.; Mulder, P.; Wayner, D. D. M. Acc. Chem. Res. 1999, 32, 342–349. doi:10.1021/ar9703443

Return to citation in text: [1] -

Humpf, H. U.; Wintoch, H.; Schreier, P. J. Agric. Food Chem. 1992, 40, 2060–2062. doi:10.1021/jf00023a006

Return to citation in text: [1] -

Kato, T.; Kondo, H. Bull. Chem. Soc. Jpn. 1981, 54, 1573–1574. doi:10.1246/bcsj.54.1573

Return to citation in text: [1] -

Marschall, H.; Penninger, J.; Weyerstahl, P. Liebigs Ann. Chem. 1982, 68–72. doi:10.1002/jlac.198219820107

Return to citation in text: [1] -

Nilsson, Y. I. M.; Aranyos, A.; Andersson, P. G.; Bäckvall, J.-E.; Parrain, J.-L.; Ploteau, C.; Quintard, J.-P. J. Org. Chem. 1996, 61, 1825–1829. doi:10.1021/jo9505031

Return to citation in text: [1] -

Herion, P.; Full, G.; Winterhalter, P.; Schreier, P.; Bicchi, C. Phytochem. Anal. 1993, 4, 235–239. doi:10.1002/pca.2800040509

Return to citation in text: [1] [2] -

Schulte-Elte, K. H.; Gautschi, F.; Renold, W.; Hauser, A.; Frankhauser, P.; Limacher, J.; Ohloff, G. Helv. Chim. Acta 1978, 61, 1125–1133. doi:10.1002/hlca.19780610326

Return to citation in text: [1] [2] -

Yasuda, A.; Yamamoto, H.; Nozaki, H. Bull. Chem. Soc. Jpn. 1979, 52, 1705–1708. doi:10.1246/bcsj.52.1705

Return to citation in text: [1] -

Hauser, F. M.; Tommasi, R.; Hewawasam, P.; Rho, Y. S. J. Org. Chem. 1988, 53, 4886–4887. doi:10.1021/jo00255a047

Return to citation in text: [1] -

Valverde, S.; Lopez, J. C.; Rabanal, R. M.; Escudero, J. Tetrahedron 1986, 42, 573–582. doi:10.1016/S0040-4020(01)87456-1

Return to citation in text: [1]

| 1. | Roduner, E.; Kaim, W.; Sarkar, B.; Urlacher, V. B.; Pleiss, J.; Gläser, R.; Einicke, W.-D.; Sprenger, G. A.; Beifuß, U.; Klemm, E.; Liebner, C.; Hieronymus, H.; Hsu, S.-F.; Plietker, B.; Laschat, S. ChemCatChem 2013, 5, 82–112. doi:10.1002/cctc.201200266 |

| 2. | Newhouse, T.; Baran, P. S. Angew. Chem., Int. Ed. 2011, 50, 3362–3374. doi:10.1002/anie.201006368 |

| 18. | Muzart, J. Chem. Rev. 1992, 92, 113–140. doi:10.1021/cr00009a005 |

| 19. | Muzart, J. Mini-Rev. Org. Chem. 2009, 6, 9–20. doi:10.2174/157019309787316120 |

| 32. | Rickert, A.; Krombach, V.; Hamers, O.; Zorn, H.; Maison, W. Green Chem. 2012, 14, 639–644. doi:10.1039/c2gc16317a |

| 11. | Joseph, T.; Sawant, D. P.; Gopinath, C. S.; Halligudi, S. B. J. Mol. Catal. A: Chem. 2002, 184, 289–299. doi:10.1016/S1381-1169(02)00010-9 |

| 12. | Smith, A. B., III; Konopelski, J. P. J. Org. Chem. 1984, 49, 4094–4095. doi:10.1021/jo00195a055 |

| 13. | Berger, R. G. Biotechnol. Lett. 2009, 31, 1651–1659. doi:10.1007/s10529-009-0083-5 |

| 14. | Hanson, J. R. Nat. Prod. Rep. 2007, 24, 1342–1349. doi:10.1039/b705948p |

| 15. | Fraatz, M. A.; Berger, R. G.; Zorn, H. Appl. Microbiol. Biotechnol. 2009, 83, 35–41. doi:10.1007/s00253-009-1968-x |

| 16. | Salvador, J. A. R.; Silvestre, S. M.; Moreira, V. M. Curr. Org. Chem. 2012, 16, 1243–1276. doi:10.2174/138527212800564204 |

| 17. | Salvador, J. A. R.; Silvestre, S. M.; Moreira, V. M. Curr. Org. Chem. 2006, 10, 2227–2257. doi:10.2174/138527206778742641 |

| 38. | Macías, F. A.; Galindo, J. L. G.; Varela, R. M.; Torres, A.; Molinillo, J. M. G.; Fronczek, F. R. Org. Lett. 2006, 8, 4513–4516. doi:10.1021/ol061673a |

| 39. | Huang, C.; Liu, B. Chem. Commun. 2010, 46, 5280–5282. doi:10.1039/c0cc00481b |

| 6. | Kharasch, M. S.; Sosnovsky, G. J. Am. Chem. Soc. 1958, 80, 756. doi:10.1021/ja01536a062 |

| 7. | Andrus, M. B.; Lashley, J. C. Tetrahedron 2002, 58, 845–866. doi:10.1016/S0040-4020(01)01172-3 |

| 8. | Rispens, M. T.; Zondervan, C.; Feringa, B. L. Tetrahedron: Asymmetry 1995, 6, 661–664. doi:10.1016/0957-4166(95)00054-S |

| 9. | Moiseev, I. I.; Vargaftik, M. N. Coord. Chem. Rev. 2004, 248, 2381–2391. doi:10.1016/j.ccr.2004.05.020 |

| 10. | Christie, S. D. R.; Warrington, A. D. Synthesis 2008, 1325–1341. doi:10.1055/s-2008-1067031 |

| 33. | Wiberg, K. B.; Nielsen, S. D. J. Org. Chem. 1964, 29, 3353–3361. doi:10.1021/jo01034a055 |

| 34. | Dauben, W. G.; Lorber, M. E.; Fullerton, D. S. J. Org. Chem. 1969, 34, 3587–3592. doi:10.1021/jo01263a079 |

| 35. | Rothenberg, G.; Sasson, Y. Tetrahedron 1998, 54, 5417–5422. doi:10.1016/S0040-4020(98)00215-4 |

| 36. | Howard, J. A.; Ingold, K. U. Can. J. Chem. 1967, 45, 793–802. doi:10.1139/v67-132 |

| 3. | Page, P. C. B.; McCarthy, T. J. 2.1 - Oxidation Adjacent to C=C Bonds. In Comprehensive Organic Synthesis; Trost, B. M.; Fleming, I., Eds.; Pergamon: Oxford, 1991; Vol. 7, pp 83–117. doi:10.1016/B978-0-08-052349-1.00184-0 |

| 4. | Nakamura, A.; Nakada, M. Synthesis 2013, 45, 1421–1451. doi:10.1055/s-0033-1338426 |

| 5. | Weidmann, V.; Maison, W. Synthesis 2013, 45, 2201–2221. doi:10.1055/s-0033-1338491 |

| 37. | Kaiser, R.; Kappeler, A.; Lamparsky, D. Helv. Chim. Acta 1978, 61, 387–400. doi:10.1002/hlca.19780610136 |

| 24. | Fraatz, M. A.; Riemer, S. J. L.; Stöber, R.; Kaspera, R.; Nimtz, M.; Berger, R. G.; Zorn, H. J. Mol. Catal. B: Enzym. 2009, 61, 202–207. doi:10.1016/j.molcatb.2009.07.001 |

| 25. | Janssens, L.; De Pooter, H. L.; Schamp, N. M.; Vandamme, E. J. Process Biochem. 1992, 27, 195–215. doi:10.1016/0032-9592(92)80020-4 |

| 26. | Kirk, O.; Borchert, T. V.; Fuglsang, C. C. Curr. Opin. Biotechnol. 2002, 13, 345–351. doi:10.1016/S0958-1669(02)00328-2 |

| 32. | Rickert, A.; Krombach, V.; Hamers, O.; Zorn, H.; Maison, W. Green Chem. 2012, 14, 639–644. doi:10.1039/c2gc16317a |

| 23. | Tao, J.; Xu, J.-H. Curr. Opin. Chem. Biol. 2009, 13, 43–50. doi:10.1016/j.cbpa.2009.01.018 |

| 29. | Krügener, S.; Krings, U.; Zorn, H.; Berger, R. G. Bioresour. Technol. 2010, 101, 457–462. doi:10.1016/j.biortech.2009.08.087 |

| 31. | Plagemann, I.; Zelena, K.; Arendt, P.; Ringel, P. D.; Krings, U.; Berger, R. G. J. Mol. Catal. B: Enzym. 2013, 87, 99–104. doi:10.1016/j.molcatb.2012.11.004 |

| 20. | Çelik, A.; Flitsch, S. L.; Turner, N. J. Org. Biomol. Chem. 2005, 3, 2930–2934. doi:10.1039/b506159h |

| 21. | Bellucci, G.; Chiappe, C.; Pucci, L.; Gervasi, P. G. Chem. Res. Toxicol. 1996, 9, 871–874. doi:10.1021/tx9600053 |

| 22. | Straathof, A. J. J.; Panke, S.; Schmid, A. Curr. Opin. Biotechnol. 2002, 13, 548–556. doi:10.1016/S0958-1669(02)00360-9 |

| 5. | Weidmann, V.; Maison, W. Synthesis 2013, 45, 2201–2221. doi:10.1055/s-0033-1338491 |

| 27. | Onken, J.; Berger, R. G. J. Biotechnol. 1999, 69, 163–168. doi:10.1016/S0168-1656(99)00040-1 |

| 28. | Krings, U.; Lehnert, N.; Fraatz, M. A.; Hardebusch, B.; Zorn, H.; Berger, R. G. J. Agric. Food Chem. 2009, 57, 9944–9950. doi:10.1021/jf901442q |

| 29. | Krügener, S.; Krings, U.; Zorn, H.; Berger, R. G. Bioresour. Technol. 2010, 101, 457–462. doi:10.1016/j.biortech.2009.08.087 |

| 30. | Zelena, K.; Krings, U.; Berger, R. G. Bioresour. Technol. 2012, 108, 231–239. doi:10.1016/j.biortech.2011.12.097 |

| 31. | Plagemann, I.; Zelena, K.; Arendt, P.; Ringel, P. D.; Krings, U.; Berger, R. G. J. Mol. Catal. B: Enzym. 2013, 87, 99–104. doi:10.1016/j.molcatb.2012.11.004 |

| 41. | Humpf, H. U.; Wintoch, H.; Schreier, P. J. Agric. Food Chem. 1992, 40, 2060–2062. doi:10.1021/jf00023a006 |

| 42. | Kato, T.; Kondo, H. Bull. Chem. Soc. Jpn. 1981, 54, 1573–1574. doi:10.1246/bcsj.54.1573 |

| 35. | Rothenberg, G.; Sasson, Y. Tetrahedron 1998, 54, 5417–5422. doi:10.1016/S0040-4020(98)00215-4 |

| 40. | Laarhoven, L. J. J.; Mulder, P.; Wayner, D. D. M. Acc. Chem. Res. 1999, 32, 342–349. doi:10.1021/ar9703443 |

| 49. | Valverde, S.; Lopez, J. C.; Rabanal, R. M.; Escudero, J. Tetrahedron 1986, 42, 573–582. doi:10.1016/S0040-4020(01)87456-1 |

| 48. | Hauser, F. M.; Tommasi, R.; Hewawasam, P.; Rho, Y. S. J. Org. Chem. 1988, 53, 4886–4887. doi:10.1021/jo00255a047 |

| 45. | Herion, P.; Full, G.; Winterhalter, P.; Schreier, P.; Bicchi, C. Phytochem. Anal. 1993, 4, 235–239. doi:10.1002/pca.2800040509 |

| 46. | Schulte-Elte, K. H.; Gautschi, F.; Renold, W.; Hauser, A.; Frankhauser, P.; Limacher, J.; Ohloff, G. Helv. Chim. Acta 1978, 61, 1125–1133. doi:10.1002/hlca.19780610326 |

| 47. | Yasuda, A.; Yamamoto, H.; Nozaki, H. Bull. Chem. Soc. Jpn. 1979, 52, 1705–1708. doi:10.1246/bcsj.52.1705 |

| 43. | Marschall, H.; Penninger, J.; Weyerstahl, P. Liebigs Ann. Chem. 1982, 68–72. doi:10.1002/jlac.198219820107 |

| 44. | Nilsson, Y. I. M.; Aranyos, A.; Andersson, P. G.; Bäckvall, J.-E.; Parrain, J.-L.; Ploteau, C.; Quintard, J.-P. J. Org. Chem. 1996, 61, 1825–1829. doi:10.1021/jo9505031 |

| 45. | Herion, P.; Full, G.; Winterhalter, P.; Schreier, P.; Bicchi, C. Phytochem. Anal. 1993, 4, 235–239. doi:10.1002/pca.2800040509 |

| 46. | Schulte-Elte, K. H.; Gautschi, F.; Renold, W.; Hauser, A.; Frankhauser, P.; Limacher, J.; Ohloff, G. Helv. Chim. Acta 1978, 61, 1125–1133. doi:10.1002/hlca.19780610326 |

© 2013 Weidmann et al; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)