Abstract

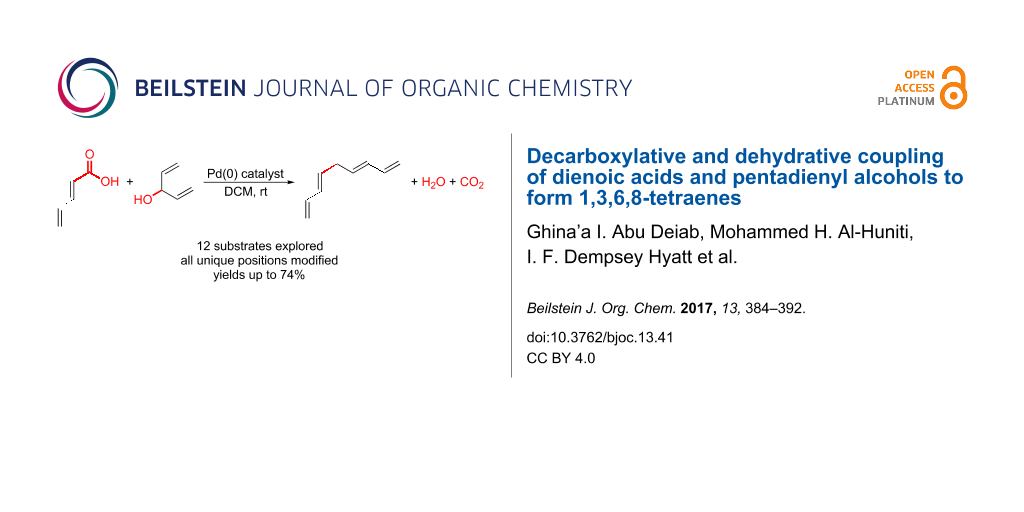

Dienoic acids and pentadienyl alcohols are coupled in a decarboxylative and dehydrative manner at ambient temperature using Pd(0) catalysis to generate 1,3,6,8-tetraenes. Contrary to related decarboxylative coupling reactions, an anion-stabilizing group is not required adjacent to the carboxyl group. Of mechanistic importance, it appears that both the diene of the acid and the diene of the alcohol are required for this reaction. To further understand this reaction, substitutions at every unique position of both coupling partners was examined and two potential mechanisms are presented.

Graphical Abstract

Introduction

The construction of sp2–sp3 carbon–carbon bonds remains a difficult and important problem in organic synthesis. Cross-coupling reactions provide avenues to these otherwise difficult reactions, but often require prefunctionalization of the coupling partners [1-9]. However, recent C–H activation research has enabled the use of further simplified starting materials [10-18]. Another approach to the formation of C–C bonds is through decarboxylative coupling reactions (Scheme 1). This can be arrived in a one-component fashion via the removal of CO2 from an ester or in a two-component manner by removal of CO2 from a carboxylic acid and coupling this to a substrate with a benzylic or allylic leaving group [19,20].

Scheme 1: Prior and current decarboxylative couplings.

Scheme 1: Prior and current decarboxylative couplings.

Typical Pd(0)-catalyzed decarboxylative coupling reactions utilize an allylic or benzylic ester with either an anion-stabilizing group adjacent to the carboxyl group (i.e., carbonyl [19,21,22], nitrile [23-25], nitro [26,27], or alkyne [21,28-32], Scheme 1), or use an aryl carboxylate [33,34] which typically requires the assistance of silver or copper(I) salts for the decarboxylative step. It is rare to use a pentadienyl electrophile [35], or to have a diene or simple alkene adjacent to the carboxyl group [20,36-39]. Despite the absence of this type of reactivity, the decarboxylative coupling of a pentadienyl dienoate (9; Scheme 2) was desirable enough for our group’s synthesis of clinprost that we attempted the reaction [40,41]. Fortunately, this coupling reaction was successfully employed in our reported nine-step synthesis of clinprost [41]. A structurally related compound (11) reacted similarly, however, the sorbate derivative (13) was low yielding with the majority of the material only rearranging to the linear ester. In all three of these cases, we never observed the more stable, fully conjugated tetraene. ”Skipped diene” motifs are found in various natural products and there are few methods available to prepare these dienes [42-52]. Skipped tetraene systems have even fewer methods for their synthesis [53-55], which makes the method described herein even more valuable.

Scheme 2: Esters examined in the decarboxylation reaction.

Scheme 2: Esters examined in the decarboxylation reaction.

It was determined that modifying the dienoate motif yielded only the rearranged product under the reaction conditions, including the dihydro (14), cinnamate (15), benzoate (16), and acrylate (17) analogues (Scheme 2). Moreover, allylic dienoates 18 and 19 gave no reaction with Pd(0) catalysis. These results led us to the determination that there was a unique reactivity imbued to the molecule by having both the dienoate and pentadienyl moieties. Herein, are presented more details for this reaction, including the substrate scope for the intermolecular case.

Results and Discussion

In addition to determining the requisite nature of both the pentadienyl and dienoate groups, it was found that trace amounts of water were required for decarboxylative coupling (Table 1). For example, careful exclusion of water from reagents and solvent and performing the reaction in the glovebox led to formation of rearranged product and no decarboxylative coupling reaction (22, Table 1, entry 1). Less than 1 equivalent of water allowed for a slow reaction and incomplete conversion, 1–2 equivalents was optimal with yields around 70% and more water was not beneficial (Table 1, entries 2–8). The use of equimolar amounts of methanol and water as a proton source allowed for decarboxylation to take place but with a low yield (Table 1, entry 9) and the reaction run in TFE as a solvent did not result in any decarboxylation (Table 1, entry 10).

Table 1: Optimization of the one-component decarboxylation reaction.a

|

|

||||

| Entry | Catalyst | Solvent | Additives |

Yield of 10

(Yield of 22)b |

|---|---|---|---|---|

| 1 | Pd(PPh3)4 | CH2Cl2 | anhydrous | 0% (99%) |

| 2 | Pd(PPh3)4 | CH2Cl2 | 0.5 equiv H2O | 27% |

| 3 | Pd(PPh3)4 | CH2Cl2 | 1.1 equiv H2O | 77% |

| 4 | Pd(PPh3)4 | CH2Cl2 | 1.3 equiv H2O | 72% |

| 5 | Pd(PPh3)4 | CH2Cl2 | silylated glass, 1 equiv H2O | 55% (15%) |

| 6 | Pd(PPh3)4 | CH2Cl2 | dry glass balls | 37% (24%) |

| 7 | Pd(PPh3)4 | CH2Cl2 | wet glass balls | 51% |

| 8 | Pd(PPh3)4 | CH2Cl2/H2O | biphasic | 49% |

| 9 | Pd(PPh3)4 | CH2Cl2 | 1 equiv MeOH, 1 equiv H2O | 33% (26%) |

| 10 | Pd(PPh3)4 | TFE | trace CH2Cl2 | 0% |

| 11 | Pd2(dba)3 | CH2Cl2 | 0 mol % PPh3, 1 equiv H2O | 0% |

| 12 | Pd2(dba)3 | CH2Cl2 | 10 mol % PPh3, 1 equiv H2O | 64% |

| 13 | Pd2(dba)3 | CH2Cl2 | 20 mol % PPh3, 1 equiv H2O | 61% |

| 14 | Pd2(dba)3 | CH2Cl2 | 30 mol % PPh3, 1 equiv H2O | 12% |

| 15 | Pd2(dba)3 | CH2Cl2 | 10 mol % L1, 1 equiv H2O | 70% |

| 16 | Pd2(dba)3 | CH2Cl2 | 10 mol % L2, 1 equiv H2O | 70% |

| 17 | Pd2(dba)3 | CH2Cl2 | 10 mol % L4, 1 equiv H2O | 18% |

| 18 | Pd2(dba)3 | CH2Cl2 | 10 mol % L5, 1 equiv H2O | 10% |

| 19 | Pd(OAc)2 | CH2Cl2 | 1 equiv H2O | 0% |

| 20 | Pd(OAc)2 | CH2Cl2 | 40 mol % PPh3, 1 equiv H2O | 10% |

| 21 | none | CH2Cl2 | 1 equiv PPh3, 1 equiv H2O | 0% |

aReaction Conditions: Pd metal (10 mol %) and the indicated solvent and additives for 24 hours. bIsolated yields.

In addition to the requirement for water, it was determined that phosphine ligands were necessary (Table 1, entry 11), either as ligands or as participants in the reaction as discussed later. The typical catalyst used, Pd(PPh3)4, worked well, however, it was found that a more ideal ratio of palladium metal to ligand was 1:1 or 1:2, with greater amounts of triphenylphosphine lowering the reaction yield when using the Pd2dba3 catalyst (Table 1, entries 12–14). It was determined that reactions performed in the presence of electron-rich ligands had both quicker kinetics and more efficient yields compared to electron-deficient ligands (Table 1, entries 15–18 and Supporting Information File 1 for kinetic information). Although not as efficient, it was found that a palladium(II) catalyst functioned in this reaction, presumably functioning as a pre-catalyst and being reduced in situ to the palladium(0) catalyst (Table 1, entries 19 and 20). As a control reaction, it was found that no reaction occurred in the absence of palladium catalyst (Table 1, entry 21).

As shown earlier, bis-allylic sorbate 13 (Scheme 2) was found to be low yielding for the decarboxylative coupling reaction. Reactions of sorbate 13 monitored by 1H NMR showed nearly quantitative isomerization of the bis-allylic group into a linear pentadienyl system. Increasing the reaction time did not result in greater conversion to tetraene 8a, which indicates that the products may be competitively ligating and poisoning the Pd(0) catalyst (see Supporting Information File 1 for additional evidence of product inhibition). The isomerization reaction to form 22 was presumably occurring via ionization of the allylic system using Pd(0), followed by recombination of the carboxylate at the terminal position of the pentadienyl system. Based on these data, we hypothesized that a two-component reaction using a dienoic acid and bis-allylic acetate might be possible, however, the presence of both water and a carboxylic acid would increase the possibility for isomerization of the 1,3,6,8-tetraenes into the fully conjugated 1,3,5,7-tetraenes, or possibly polymerization.

Despite the low yield for decarboxylation with sorbate 13, the initial attempt used inexpensive sorbic acid as the dienoic acid. Gratifyingly, this reaction was successful and it was again determined that no isomerization to the fully conjugated system was observed (Table 2, entry 1). Other bis-allylic leaving groups were studied and, unexpectedly, it was determined that divinylcarbinol was superior (Table 2, entries 1–6). In fact, the better leaving groups were either slow or ineffective. This could be due to the less basic leaving groups not sufficiently deprotonating sorbic acid, which may be required for this reaction as is discussed mechanistically later (Scheme 3). Similar to the single component reaction, more than two equivalents of phosphine, relative to palladium metal, was detrimental (compare entries 12–14 of Table 1 with entries 6–8 of Table 2), however, the reaction was successful using Pd(PPh3)4 (Table 1, entry 9).

Table 2: Optimization of the two-component decarboxylation reaction.a

|

|

|||

| Entry | Pentadienyl group | Additive | Yieldb |

|---|---|---|---|

| 1 | 6a, X = OAc | PPh3 (20 mol %) | 12% |

| 2 | 6b, X = OCO2Me | PPh3 (20 mol %) | 35% |

| 3 | 6c, X = OBz | PPh3 (20 mol %) | 11% |

| 4 | 6d, X = O2C(4-CF3Ph) | PPh3 (20 mol %) | 6% |

| 5 | 7a, X = Br | PPh3 (20 mol %) | 0% |

| 6 | 6e, X = OH | PPh3 (20 mol %) | 40% |

| 7 | 6e, X = OH | PPh3 (10 mol %) | 18% |

| 8 | 6e, X = OH | PPh3 (30 mol %) | 24% |

| 9c | 6e, X = OH | NA | 28% |

aReaction conditions: Sorbic acid (5a, 1 equiv), pentadienyl group (6 or 7, 1 equiv), Pd2(dba)3·CHCl3 (5 mol %) unless indicated otherwise, H2O (1 equiv), in CDCl3 for 48 hours. bNMR yields. cPd(PPh3)4 (10 mol %).

To further understand this interesting decarboxylative coupling reaction, a handful of different pentadienyl electrophiles and dienoic acids were examined (Table 3). Typically, the pentadienyl alcohol was used; however, in some cases the acetate was superior. It was found that both a methyl or phenyl substituent on the alcohol derivative would result in branched product 8b or 8d as a major product with a product ratio of 6:1 or 4:1, respectively (Table 3, entries 2–4). The yields for these reactions were low, but the remaining material was typically starting material and the ester where the acid and alcohol are coupled together. There was no effect on the yields upon leaving the reactions longer than 48 hours and it was found that the addition of tetraene product inhibited the reaction (see Supporting Information File 1 for details). With these highly unsubstituted tetraene products, it is hypothesized that the product may be sequestering the palladium catalyst. Two cyclic dienyl acetates were also studied (Table 3, entries 5 and 6) and they yielded tetraenes 8f and 8g. The dienes of entries 5 and 6 could have formed additional isomers by coupling to the other end of the pentadienyl group, but only one regioisomer was observed.

Table 3: Substrate scope for the two-component decarboxylation reaction.a

|

|

|||

| Entry | Dienoic acid | Pentadienyl group | Yield (product)b |

|---|---|---|---|

| 1 |

5a |

6e |

40%b (8a) |

| 2 |

5a |

7b |

8%c (8b/8c) |

| 3 |

5a |

6f |

21%b, 17%c (8d/8e) |

| 4 |

5a |

6g |

13%b, 6%c (8d/8e) |

| 5 |

5a |

7c |

16%c (8f) |

| 6 |

5a |

7d |

18%c (8g) |

| 7 |

5b |

6e |

14%b (8h/8i/8j) |

| 8 |

5c |

6e |

24%c (8k) |

| 9 |

5d |

6e |

36%b (8l) |

| 10 |

5e |

6e |

decomposition |

| 11 |

5f |

6e |

decomposition |

| 12 |

5g |

6e |

74%c (8m) |

aReaction conditions: Dienoic acid (5, 1 equiv), pentadienyl group (6 or 7, 1 equiv), H2O (1 equiv), Pd2(dba)3·CHCl3 (5 mol %), PPh3 (20 mol %), in CDCl3 for 48 h. bNMR yields due to volatility of product. cIsolated yields.

With respect to the dienoic acid, it was determined that the unsubstituted compound, pentadienoic acid, underwent decarboxylative coupling, although as a mixture of E/E, E/Z, and Z/Z isomers (Table 3, entry 7). Alkyl and aryl substituents were possible on the dienoate with the exception of an aryl group at the gamma position (Table 3, entries 8–10). Two cyclic dienoic acids were synthesized [56,57] and while the cyclohexadienoic acid did not decarboxylate (Table 3, entry 11), the vinylcyclopentenoic acid had a good yield of a complex tetraene (Table 3, entry 12).

Based on the information obtained during optimization and screening of compounds, two potential mechanisms are proposed (Scheme 3). Both options allow for the one (13) or two (5 and 6) component process to be used while also allowing for the reversible formation of linear ester 23. Pathway B involves a Morita–Baylis–Hillman type process. The role of water would be to hydrogen bond to the carboxylate to make the system more electrophilic (B). This would accelerate the addition of the phosphine to generate zwitterion C [58]. Preliminary modeling for this ion indicates that both the electrophilic terminal vinyl group of the pentadienyl ligand and the nucleophilic α-carbon are in close proximity to one another. Formation of the carbon–carbon bond would then regenerate the Pd(0) catalyst and phosphonium carboxylate D. Decarboxylative elimination of the phosphine results in formation the 1,3,6,8-tetraene. It is proposed for pathway B that the dienoate is required so that the α-carbon is not blocked by the bulky phosphine group since it can add in a 1,6- or 1,4-manner, both reversibly.

Alternatively, pathway A has the palladium catalyst coordinate to one of the alkenes of the dienoate instead of the carboxylate (E). It is proposed that a water cluster around the carboxylate would enable this process by hydrogen bonding to the carboxylate. The conversion of E to F would form the C–C bond by having the palladium catalyst convert from one type of η3-allyl and π-complex (E) to a different allyl/π-complex (F). Finally, decarboxylative reduction of the palladium would release the product while regenerating the catalyst. Preliminary computational calculations using NEB [59] support pathway A and the HOMO of the transition state between E and F (Figure 1) calculated using the Gaussian 09 implementation of DFT with a B3LYP functional, 6-31g* basis, and polarized continuum model of solvation for DCM, shows close proximity of two in-phase orbitals for the requisite C–C bond, whereas removal of any one of the alkenes from this structure would lead to anti-bonding relationships to bond to the alpha carbon.

Figure 1: Calculated HOMO of transition state between E and F.

Figure 1: Calculated HOMO of transition state between E and F.

Conclusion

In summary, we present information that is of value to advancing the area of metal-catalyzed decarboxylative coupling reactions, specifically those of pentadienyl dienoates that do not require an anion-stabilizing group, are run at ambient temperature, and can utilize the more accessible alcohol for a leaving group. This reaction was advanced to be possible in a two-component fashion, allowing for the conversion of dienoic acids and pentadienyl alcohols into 1,3,6,8-tetraenes with the only stoichiometric byproducts being water and carbon dioxide. These reactions currently require a diene motif with each coupling partner, but the product maintains the independent reactivity opportunities of these isolated dienes as opposed to forming the fully conjugated 1,3,5,7-tetraene. A variety of substrates were explored where each of the unique positions on the coupling partners was modified and two different mechanistic pathways are presented. A more in-depth mechanistic analysis to improve the yields and to explore other reactivity possibilities based on this process are currently being studied and will be published in due time.

Supporting Information

| Supporting Information File 1: Experimental procedures and analytical data for all substrates and products, product inhibition study, computational calculation information, and relevant energies and Cartesian coordinates. | ||

| Format: PDF | Size: 6.2 MB | Download |

Acknowledgements

Funding for this project from the North Carolina Biotechnology Center (BRG-1205) and University of North Carolina at Greensboro is gratefully acknowledged. The authors thank Dr. Franklin J. Moy for assisting with analysis of NMR data and Dr. Daniel A. Todd for acquisition of the high resolution mass spectrometry data at the Triad Mass Spectrometry Laboratory at the University of North Carolina at Greensboro.

References

-

Torborg, C.; Beller, M. Adv. Synth. Catal. 2009, 351, 3027. doi:10.1002/adsc.200900587

Return to citation in text: [1] -

McGlacken, G. P.; Fairlamb, I. J. S. Eur. J. Org. Chem. 2009, 4011. doi:10.1002/ejoc.200900139

Return to citation in text: [1] -

Nicolaou, K. C.; Bulger, P. G.; Sarlah, D. Angew. Chem., Int. Ed. 2005, 44, 4442. doi:10.1002/anie.200500368

Return to citation in text: [1] -

Terao, J.; Kambe, N. Acc. Chem. Res. 2008, 41, 1545. doi:10.1021/ar800138a

Return to citation in text: [1] -

Martin, R.; Buchwald, S. L. Acc. Chem. Res. 2008, 41, 1461. doi:10.1021/ar800036s

Return to citation in text: [1] -

Marion, N.; Nolan, S. P. Acc. Chem. Res. 2008, 41, 1440. doi:10.1021/ar800020y

Return to citation in text: [1] -

Denmark, S. E.; Regens, C. S. Acc. Chem. Res. 2008, 41, 1486. doi:10.1021/ar800037p

Return to citation in text: [1] -

Kantchev, E. A. B.; O'Brien, C. J.; Organ, M. G. Angew. Chem., Int. Ed. 2007, 46, 2768. doi:10.1002/anie.200601663

Return to citation in text: [1] -

Corbet, J.-P.; Mignani, G. Chem. Rev. 2006, 106, 2651. doi:10.1021/cr0505268

Return to citation in text: [1] -

Schaub, T. A.; Kivala, M. Cross-Coupling Reactions to sp Carbon Atoms. Metal-Catalyzed Cross-Coupling Reactions and More; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, 2014; pp 665 ff.

Return to citation in text: [1] -

Davies, H. M. L.; Morton, D. J. Org. Chem. 2016, 81, 343. doi:10.1021/acs.joc.5b02818

Return to citation in text: [1] -

Brückl, T.; Baxter, R. D.; Ishihara, Y.; Baran, P. S. Acc. Chem. Res. 2012, 45, 826. doi:10.1021/ar200194b

Return to citation in text: [1] -

Stuart, D. R.; Fagnou, K. The Discovery and Development of a Palladium(II)-Catalyzed Oxidative Cross-Coupling of Two Unactivated Arenes. In Inventing Reactions; Gooßen, L. J., Ed.; Springer: Berlin, Heidelberg, 2013; pp 91 ff.

Return to citation in text: [1] -

Colby, D. A.; Bergman, R. G.; Ellman, J. A. Chem. Rev. 2010, 110, 624. doi:10.1021/cr900005n

Return to citation in text: [1] -

Campeau, L.-C.; Rousseaux, S.; Fagnou, K. J. Am. Chem. Soc. 2005, 127, 18020. doi:10.1021/ja056800x

Return to citation in text: [1] -

Stuart, D. R.; Alsabeh, P.; Kuhn, M.; Fagnou, K. J. Am. Chem. Soc. 2010, 132, 18326. doi:10.1021/ja1082624

Return to citation in text: [1] -

Gorelsky, S. I.; Lapointe, D.; Fagnou, K. J. Org. Chem. 2012, 77, 658. doi:10.1021/jo202342q

Return to citation in text: [1] -

Lafrance, M.; Fagnou, K. J. Am. Chem. Soc. 2006, 128, 16496. doi:10.1021/ja067144j

Return to citation in text: [1] -

Jana, R.; Trivedi, R.; Tunge, J. A. Org. Lett. 2009, 11, 3434. doi:10.1021/ol901288r

Return to citation in text: [1] [2] -

Tokoroyama, T.; Nakamura, M. Chem. Lett. 1977, 6, 659. doi:10.1246/cl.1977.659

Return to citation in text: [1] [2] -

Tsuda, T.; Chujo, Y.; Nishi, S.; Tawara, K.; Saegusa, T. J. Am. Chem. Soc. 1980, 102, 6381. doi:10.1021/ja00540a053

Return to citation in text: [1] [2] -

Tsuda, T.; Okada, M.; Nishi, S.; Saegusa, T. J. Org. Chem. 1986, 51, 421. doi:10.1021/jo00354a001

Return to citation in text: [1] -

Trost, B. M.; Bunt, R. C. J. Am. Chem. Soc. 1998, 120, 70. doi:10.1021/ja9726522

Return to citation in text: [1] -

Corey, E. J.; Fraenkel, G. J. Am. Chem. Soc. 1953, 75, 1168. doi:10.1021/ja01101a047

Return to citation in text: [1] -

Waetzig, S. R.; Rayabarapu, D. K.; Weaver, J. D.; Tunge, J. A. Angew. Chem., Int. Ed. 2006, 45, 4977. doi:10.1002/anie.200600721

Return to citation in text: [1] -

Waetzig, S. R.; Tunge, J. A. J. Am. Chem. Soc. 2007, 129, 14860. doi:10.1021/ja077070r

Return to citation in text: [1] -

Grenning, A. J.; Tunge, J. A. Org. Lett. 2010, 12, 740. doi:10.1021/ol902828p

Return to citation in text: [1] -

Rayabarapu, D. K.; Tunge, J. A. J. Am. Chem. Soc. 2005, 127, 13510. doi:10.1021/ja0542688

Return to citation in text: [1] -

Sim, S. H.; Park, H.-J.; Lee, S. I.; Chung, Y. K. Org. Lett. 2008, 10, 433. doi:10.1021/ol702577g

Return to citation in text: [1] -

Pi, S.-F.; Tang, B.-X.; Li, J.-H.; Liu, Y.-L.; Liang, Y. Org. Lett. 2009, 11, 2309. doi:10.1021/ol900643r

Return to citation in text: [1] -

Torregrosa, R. R. P.; Ariyarathna, Y.; Chattopadhyay, K.; Tunge, J. A. J. Am. Chem. Soc. 2010, 132, 9280. doi:10.1021/ja1035557

Return to citation in text: [1] -

Zhang, W.-W.; Zhang, X.-G.; Li, J.-H. J. Org. Chem. 2010, 75, 5259. doi:10.1021/jo1010284

Return to citation in text: [1] -

Rodriguez, N.; Goossen, L. J. Chem. Soc. Rev. 2011, 40, 5030. doi:10.1039/c1cs15093f

Return to citation in text: [1] -

Gooßen, L. J.; Deng, G.; Levy, L. M. Science 2006, 313, 662. doi:10.1126/science.1128684

Return to citation in text: [1] -

Gruber, S.; Zaitsev, A. B.; Wörle, M.; Pregosin, P. S.; Veiros, L. F. Organometallics 2008, 27, 3796. doi:10.1021/om800295z

Return to citation in text: [1] -

Yamashita, M.; Hirano, K.; Satoh, T.; Miura, M. Org. Lett. 2010, 12, 592. doi:10.1021/ol9027896

Return to citation in text: [1] -

Patel, B. A.; Dickerson, J. E.; Heck, R. F. J. Org. Chem. 1978, 43, 5018. doi:10.1021/jo00420a029

Return to citation in text: [1] -

Yamashita, M.; Hirano, K.; Satoh, T.; Miura, M. Adv. Synth. Catal. 2011, 353, 631. doi:10.1002/adsc.201000897

Return to citation in text: [1] -

Yamashita, M.; Hirano, K.; Satoh, T.; Miura, M. Chem. Lett. 2010, 39, 68. doi:10.1246/cl.2010.68

Return to citation in text: [1] -

Abu Deiab, G. I.; Croatt, M. P. Chapter 3 - Step-Economical Synthesis of Clinprost and Analogs Utilizing a Novel Decarboxylation Reaction. In Strategies and Tactics in Organic Synthesis; Michael, H., Ed.; Academic Press, 2017; Vol. 12, pp 95 ff.

Return to citation in text: [1] -

Nagy, E. E.; Hyatt, I. F. D.; Gettys, K. E.; Yeazell, S. T.; Frempong, S. K., Jr.; Croatt, M. P. Org. Lett. 2013, 15, 586. doi:10.1021/ol303402e

Return to citation in text: [1] [2] -

Thadani, A. N.; Rawal, V. H. Org. Lett. 2002, 4, 4317. doi:10.1021/ol0269594

Return to citation in text: [1] -

Wilson, S. R.; Zucker, P. A. J. Org. Chem. 1988, 53, 4682. doi:10.1021/jo00255a007

Return to citation in text: [1] -

Tang, W.; Prusov, E. V. Org. Lett. 2012, 14, 4690. doi:10.1021/ol302219x

Return to citation in text: [1] -

Gagnepain, J.; Moulin, E.; Fürstner, A. Chem. – Eur. J. 2011, 17, 6964. doi:10.1002/chem.201100178

Return to citation in text: [1] -

Jeso, V.; Micalizio, G. C. J. Am. Chem. Soc. 2010, 132, 11422. doi:10.1021/ja104782u

Return to citation in text: [1] -

Schnermann, M. J.; Romero, F. A.; Hwang, I.; Nakamaru-Ogiso, E.; Yagi, T.; Boger, D. L. J. Am. Chem. Soc. 2006, 128, 11799. doi:10.1021/ja0632862

Return to citation in text: [1] -

McCammant, M. S.; Shigeta, T.; Sigman, M. S. Org. Lett. 2016, 18, 1792. doi:10.1021/acs.orglett.6b00517

Return to citation in text: [1] -

Todd, D. P.; Thompson, B. B.; Nett, A. J.; Montgomery, J. J. Am. Chem. Soc. 2015, 137, 12788. doi:10.1021/jacs.5b08448

Return to citation in text: [1] -

Kong, W.; Che, C.; Kong, L.; Zhu, G. Tetrahedron Lett. 2015, 56, 2780. doi:10.1016/j.tetlet.2015.04.036

Return to citation in text: [1] -

Xu, S.; Zhu, S.; Shang, J.; Zhang, J.; Tang, Y.; Dou, J. J. Org. Chem. 2014, 79, 3696. doi:10.1021/jo500375q

Return to citation in text: [1] -

Huang, Y.; Fañanás-Mastral, M.; Minnaard, A. J.; Feringa, B. L. Chem. Commun. 2013, 49, 3309. doi:10.1039/c3cc41021h

Return to citation in text: [1] -

Schmidt, A.; Hilt, G. Org. Lett. 2013, 15, 2708. doi:10.1021/ol401015e

Return to citation in text: [1] -

Lim, H. N.; Parker, K. A. J. Am. Chem. Soc. 2011, 133, 20149. doi:10.1021/ja209459f

Return to citation in text: [1] -

Kennard, O.; Watson, D. G.; Fawcett, J. K.; Kerr, K. A. Tetrahedron 1970, 26, 607. doi:10.1016/S0040-4020(01)97853-6

Return to citation in text: [1] -

Hettrick, C. M.; Kling, J. K.; Scott, W. J. J. Org. Chem. 1991, 56, 1489. doi:10.1021/jo00004a028

Return to citation in text: [1] -

Gradén, H.; Hallberg, J.; Kann, N.; Olsson, T. J. Comb. Chem. 2004, 6, 783. doi:10.1021/cc049929w

Return to citation in text: [1] -

Surovtseva, D. A.; Orlov, D. A.; Morozova, T. A.; Krylov, A. V.; Belov, A. P. Kinet. Catal. 2006, 47, 855. doi:10.1134/s0023158406060073

Return to citation in text: [1] -

Alfonso, D. R.; Jordan, K. D. J. Comput. Chem. 2003, 24, 990. doi:10.1002/jcc.10233

Return to citation in text: [1]

| 59. | Alfonso, D. R.; Jordan, K. D. J. Comput. Chem. 2003, 24, 990. doi:10.1002/jcc.10233 |

| 1. | Torborg, C.; Beller, M. Adv. Synth. Catal. 2009, 351, 3027. doi:10.1002/adsc.200900587 |

| 2. | McGlacken, G. P.; Fairlamb, I. J. S. Eur. J. Org. Chem. 2009, 4011. doi:10.1002/ejoc.200900139 |

| 3. | Nicolaou, K. C.; Bulger, P. G.; Sarlah, D. Angew. Chem., Int. Ed. 2005, 44, 4442. doi:10.1002/anie.200500368 |

| 4. | Terao, J.; Kambe, N. Acc. Chem. Res. 2008, 41, 1545. doi:10.1021/ar800138a |

| 5. | Martin, R.; Buchwald, S. L. Acc. Chem. Res. 2008, 41, 1461. doi:10.1021/ar800036s |

| 6. | Marion, N.; Nolan, S. P. Acc. Chem. Res. 2008, 41, 1440. doi:10.1021/ar800020y |

| 7. | Denmark, S. E.; Regens, C. S. Acc. Chem. Res. 2008, 41, 1486. doi:10.1021/ar800037p |

| 8. | Kantchev, E. A. B.; O'Brien, C. J.; Organ, M. G. Angew. Chem., Int. Ed. 2007, 46, 2768. doi:10.1002/anie.200601663 |

| 9. | Corbet, J.-P.; Mignani, G. Chem. Rev. 2006, 106, 2651. doi:10.1021/cr0505268 |

| 23. | Trost, B. M.; Bunt, R. C. J. Am. Chem. Soc. 1998, 120, 70. doi:10.1021/ja9726522 |

| 24. | Corey, E. J.; Fraenkel, G. J. Am. Chem. Soc. 1953, 75, 1168. doi:10.1021/ja01101a047 |

| 25. | Waetzig, S. R.; Rayabarapu, D. K.; Weaver, J. D.; Tunge, J. A. Angew. Chem., Int. Ed. 2006, 45, 4977. doi:10.1002/anie.200600721 |

| 56. | Hettrick, C. M.; Kling, J. K.; Scott, W. J. J. Org. Chem. 1991, 56, 1489. doi:10.1021/jo00004a028 |

| 57. | Gradén, H.; Hallberg, J.; Kann, N.; Olsson, T. J. Comb. Chem. 2004, 6, 783. doi:10.1021/cc049929w |

| 19. | Jana, R.; Trivedi, R.; Tunge, J. A. Org. Lett. 2009, 11, 3434. doi:10.1021/ol901288r |

| 21. | Tsuda, T.; Chujo, Y.; Nishi, S.; Tawara, K.; Saegusa, T. J. Am. Chem. Soc. 1980, 102, 6381. doi:10.1021/ja00540a053 |

| 22. | Tsuda, T.; Okada, M.; Nishi, S.; Saegusa, T. J. Org. Chem. 1986, 51, 421. doi:10.1021/jo00354a001 |

| 58. | Surovtseva, D. A.; Orlov, D. A.; Morozova, T. A.; Krylov, A. V.; Belov, A. P. Kinet. Catal. 2006, 47, 855. doi:10.1134/s0023158406060073 |

| 19. | Jana, R.; Trivedi, R.; Tunge, J. A. Org. Lett. 2009, 11, 3434. doi:10.1021/ol901288r |

| 20. | Tokoroyama, T.; Nakamura, M. Chem. Lett. 1977, 6, 659. doi:10.1246/cl.1977.659 |

| 42. | Thadani, A. N.; Rawal, V. H. Org. Lett. 2002, 4, 4317. doi:10.1021/ol0269594 |

| 43. | Wilson, S. R.; Zucker, P. A. J. Org. Chem. 1988, 53, 4682. doi:10.1021/jo00255a007 |

| 44. | Tang, W.; Prusov, E. V. Org. Lett. 2012, 14, 4690. doi:10.1021/ol302219x |

| 45. | Gagnepain, J.; Moulin, E.; Fürstner, A. Chem. – Eur. J. 2011, 17, 6964. doi:10.1002/chem.201100178 |

| 46. | Jeso, V.; Micalizio, G. C. J. Am. Chem. Soc. 2010, 132, 11422. doi:10.1021/ja104782u |

| 47. | Schnermann, M. J.; Romero, F. A.; Hwang, I.; Nakamaru-Ogiso, E.; Yagi, T.; Boger, D. L. J. Am. Chem. Soc. 2006, 128, 11799. doi:10.1021/ja0632862 |

| 48. | McCammant, M. S.; Shigeta, T.; Sigman, M. S. Org. Lett. 2016, 18, 1792. doi:10.1021/acs.orglett.6b00517 |

| 49. | Todd, D. P.; Thompson, B. B.; Nett, A. J.; Montgomery, J. J. Am. Chem. Soc. 2015, 137, 12788. doi:10.1021/jacs.5b08448 |

| 50. | Kong, W.; Che, C.; Kong, L.; Zhu, G. Tetrahedron Lett. 2015, 56, 2780. doi:10.1016/j.tetlet.2015.04.036 |

| 51. | Xu, S.; Zhu, S.; Shang, J.; Zhang, J.; Tang, Y.; Dou, J. J. Org. Chem. 2014, 79, 3696. doi:10.1021/jo500375q |

| 52. | Huang, Y.; Fañanás-Mastral, M.; Minnaard, A. J.; Feringa, B. L. Chem. Commun. 2013, 49, 3309. doi:10.1039/c3cc41021h |

| 10. | Schaub, T. A.; Kivala, M. Cross-Coupling Reactions to sp Carbon Atoms. Metal-Catalyzed Cross-Coupling Reactions and More; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, 2014; pp 665 ff. |

| 11. | Davies, H. M. L.; Morton, D. J. Org. Chem. 2016, 81, 343. doi:10.1021/acs.joc.5b02818 |

| 12. | Brückl, T.; Baxter, R. D.; Ishihara, Y.; Baran, P. S. Acc. Chem. Res. 2012, 45, 826. doi:10.1021/ar200194b |

| 13. | Stuart, D. R.; Fagnou, K. The Discovery and Development of a Palladium(II)-Catalyzed Oxidative Cross-Coupling of Two Unactivated Arenes. In Inventing Reactions; Gooßen, L. J., Ed.; Springer: Berlin, Heidelberg, 2013; pp 91 ff. |

| 14. | Colby, D. A.; Bergman, R. G.; Ellman, J. A. Chem. Rev. 2010, 110, 624. doi:10.1021/cr900005n |

| 15. | Campeau, L.-C.; Rousseaux, S.; Fagnou, K. J. Am. Chem. Soc. 2005, 127, 18020. doi:10.1021/ja056800x |

| 16. | Stuart, D. R.; Alsabeh, P.; Kuhn, M.; Fagnou, K. J. Am. Chem. Soc. 2010, 132, 18326. doi:10.1021/ja1082624 |

| 17. | Gorelsky, S. I.; Lapointe, D.; Fagnou, K. J. Org. Chem. 2012, 77, 658. doi:10.1021/jo202342q |

| 18. | Lafrance, M.; Fagnou, K. J. Am. Chem. Soc. 2006, 128, 16496. doi:10.1021/ja067144j |

| 53. | Schmidt, A.; Hilt, G. Org. Lett. 2013, 15, 2708. doi:10.1021/ol401015e |

| 54. | Lim, H. N.; Parker, K. A. J. Am. Chem. Soc. 2011, 133, 20149. doi:10.1021/ja209459f |

| 55. | Kennard, O.; Watson, D. G.; Fawcett, J. K.; Kerr, K. A. Tetrahedron 1970, 26, 607. doi:10.1016/S0040-4020(01)97853-6 |

| 35. | Gruber, S.; Zaitsev, A. B.; Wörle, M.; Pregosin, P. S.; Veiros, L. F. Organometallics 2008, 27, 3796. doi:10.1021/om800295z |

| 40. | Abu Deiab, G. I.; Croatt, M. P. Chapter 3 - Step-Economical Synthesis of Clinprost and Analogs Utilizing a Novel Decarboxylation Reaction. In Strategies and Tactics in Organic Synthesis; Michael, H., Ed.; Academic Press, 2017; Vol. 12, pp 95 ff. |

| 41. | Nagy, E. E.; Hyatt, I. F. D.; Gettys, K. E.; Yeazell, S. T.; Frempong, S. K., Jr.; Croatt, M. P. Org. Lett. 2013, 15, 586. doi:10.1021/ol303402e |

| 33. | Rodriguez, N.; Goossen, L. J. Chem. Soc. Rev. 2011, 40, 5030. doi:10.1039/c1cs15093f |

| 34. | Gooßen, L. J.; Deng, G.; Levy, L. M. Science 2006, 313, 662. doi:10.1126/science.1128684 |

| 41. | Nagy, E. E.; Hyatt, I. F. D.; Gettys, K. E.; Yeazell, S. T.; Frempong, S. K., Jr.; Croatt, M. P. Org. Lett. 2013, 15, 586. doi:10.1021/ol303402e |

| 21. | Tsuda, T.; Chujo, Y.; Nishi, S.; Tawara, K.; Saegusa, T. J. Am. Chem. Soc. 1980, 102, 6381. doi:10.1021/ja00540a053 |

| 28. | Rayabarapu, D. K.; Tunge, J. A. J. Am. Chem. Soc. 2005, 127, 13510. doi:10.1021/ja0542688 |

| 29. | Sim, S. H.; Park, H.-J.; Lee, S. I.; Chung, Y. K. Org. Lett. 2008, 10, 433. doi:10.1021/ol702577g |

| 30. | Pi, S.-F.; Tang, B.-X.; Li, J.-H.; Liu, Y.-L.; Liang, Y. Org. Lett. 2009, 11, 2309. doi:10.1021/ol900643r |

| 31. | Torregrosa, R. R. P.; Ariyarathna, Y.; Chattopadhyay, K.; Tunge, J. A. J. Am. Chem. Soc. 2010, 132, 9280. doi:10.1021/ja1035557 |

| 32. | Zhang, W.-W.; Zhang, X.-G.; Li, J.-H. J. Org. Chem. 2010, 75, 5259. doi:10.1021/jo1010284 |

| 26. | Waetzig, S. R.; Tunge, J. A. J. Am. Chem. Soc. 2007, 129, 14860. doi:10.1021/ja077070r |

| 27. | Grenning, A. J.; Tunge, J. A. Org. Lett. 2010, 12, 740. doi:10.1021/ol902828p |

| 20. | Tokoroyama, T.; Nakamura, M. Chem. Lett. 1977, 6, 659. doi:10.1246/cl.1977.659 |

| 36. | Yamashita, M.; Hirano, K.; Satoh, T.; Miura, M. Org. Lett. 2010, 12, 592. doi:10.1021/ol9027896 |

| 37. | Patel, B. A.; Dickerson, J. E.; Heck, R. F. J. Org. Chem. 1978, 43, 5018. doi:10.1021/jo00420a029 |

| 38. | Yamashita, M.; Hirano, K.; Satoh, T.; Miura, M. Adv. Synth. Catal. 2011, 353, 631. doi:10.1002/adsc.201000897 |

| 39. | Yamashita, M.; Hirano, K.; Satoh, T.; Miura, M. Chem. Lett. 2010, 39, 68. doi:10.1246/cl.2010.68 |

© 2017 Deiab et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)