Abstract

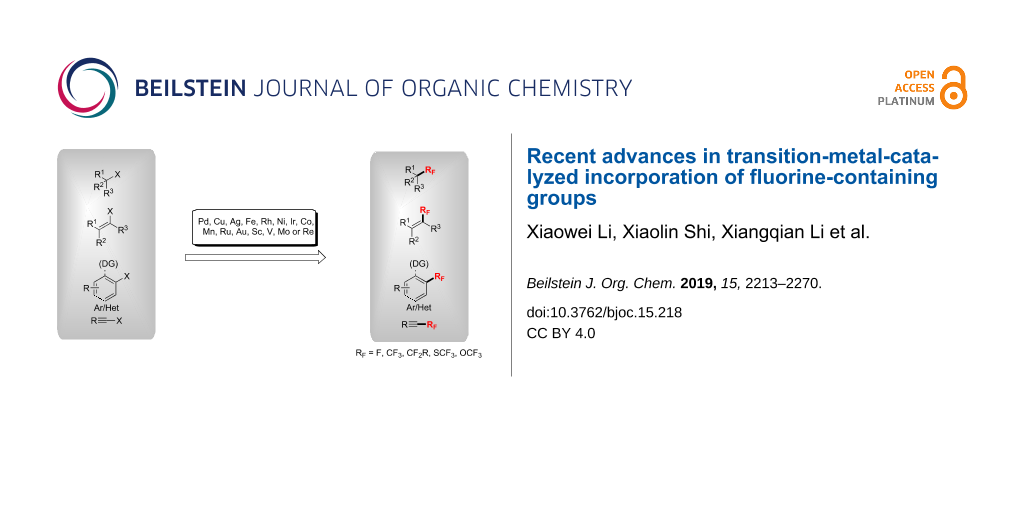

Fluorine chemistry plays an increasingly important role in pharmaceutical, agricultural, and materials industries. The incorporation of fluorine-containing groups into organic molecules can improve their chemical and physical properties, which attracts continuous interest in organic synthesis. Among various reported methods, transition-metal-catalyzed fluorination/fluoroalkylation has emerged as a powerful method for the construction of these compounds. This review attempts to describe the major advances in the transition-metal-catalyzed incorporation of fluorine, trifluoromethyl, difluoromethyl, trifluoromethylthio, and trifluoromethoxy groups reported between 2011 and 2019.

Graphical Abstract

Introduction

Compared with other halogens (Cl, Br, I), fluorine (F) has completely different physical and chemical properties, such as a unique electronic structure, strongest electronegativity, and small atomic radius similar to that of hydrogen atoms. Due to these unique properties, the introduction of fluorine into a molecule can cause dramatic changes, such as the acidity or basicity of neighboring groups, dipole moment, and properties such as lipophilicity, metabolic stability, and bioavailability [1]. Consequently, carbon–fluorine bonds have become an integral part of pharmaceutical [2,3], agricultural [4], materials industries [5], and tracers for positron emission tomography [6]. According to statistics, about 35% of agrochemicals and 20% of pharmaceuticals contain fluorine [7].

Although the content of fluorine in the Earth’s crust is relatively abundant (13th most abundant element), scientists have identified only 21 kinds of fluorine-containing natural molecules [8,9]. Therefore, it is highly desirable to introduce a fluorine-containing substituent into a molecule artificially. However, traditional fluorination methods to these building blocks, such as Friedel–Crafts-type electrophilic halogenation [10,11], Sandmeyer-type reactions of diazonium salts [12], and halogenations of preformed organometallic reagents [13], commonly involve multiple steps, harsh reaction conditions, and the use of stoichiometric amounts and/or toxic reagents [14]. Also, low functional group tolerance, being limited to activated arenes, the production of metal salts as stoichiometric byproducts, and poor levels of regioselectivity would always be observed, limiting the progress of fluorine chemistry to some extent. In this regard, the use of various transition metals to catalyze the synthesis of organic fluorides has become a mature field, and the application of these methodologies has allowed decreasing the need of pre-functionalized substrates, less consumption of reaction time and costs, and enabled to produce enantioenriched target compounds [15-20]. Furthermore, transition metals have the unique advantage of possessing multiple mechanistic features, which translates into the ability to apply new substrate classes and provide hitherto novel and inaccessible structures. Therefore, transition-metal-catalyzed fluorination/fluoroalkylation reactions represent an important and hot topic in fluorine chemistry. In addition, among the various metals developed, palladium is the most commonly employed transition metal, followed by copper owing to its high efficiency and cheapness. Meanwhile, other transition metals, such as Fe, Ni, Rh, Ag, Co, etc., have received considerable attention and are widely applied due to their respective characteristics.

Over the past few years, several reviews on fluorination/fluoroalkylation have disclosed. Kamlet [17] mainly discussed progresses in catalyzed fluorination and trifluoromethylation before 2011, and Besset [21] focused on the direct introduction of fluorinated groups into alkenes and alkynes. Then, Toste [1] covered advances in catalytic enantioselective fluorination, mono‑, di‑, and trifluoromethylation, and trifluoromethylthiolation reactions. Recently, Zhang [14] offered a brief summary of the recent achievements in the ever-growing field of green fluoroalkylation. However, until now, no comprehensive survey of the literature has been reported on this topic. In this review, we highlight the recent progress of transition-metal-catalyzed fluorination and trifluoromethylation reported between 2011 and 2019. Meanwhile, we also present the incorporation of difluoromethyl, trifluoromethylthiol and trifluoromethoxy groups. Some sections of this review are structured around the synthesis of alkyl-, aryl- and vinyl- as well as alkynyl organofluorides. Notably, the current review covers mainly two types of transition-metal-catalyzed reactions: 1) cross-couplings with a fluorinated organometallic species or a halogenated fluorinated species and 2) the direct introduction of fluorinated moieties into nonfunctionalized substrates with a fluorinated reagent. We hope that this review will provide a comprehensive overview of this topic and attract significant attention.

Review

Fluorination

For many years, specialists in the field of fluorine chemistry have been actively studying ways to introduce fluorine into organic molecules by aid of transition-metal catalysis. Depending on the transfer form of fluorine, there are three general strategies for constructing C–F bonds: nucleophilic, electrophilic and radical fluorination (Scheme 1) [22].

Scheme 1: The main three strategies of fluorination: nucleophilic, electrophilic and radical fluorination.

Scheme 1: The main three strategies of fluorination: nucleophilic, electrophilic and radical fluorination.

In nucleophilic fluorination reactions, the fluoride anion (F−) or a derivative thereof, such as tetrafluoroborate (BF4−), is the fluorine source and behaves as a nucleophile. The electrophile, such as an alkyl chain or an aryl ring with halides or sulfonates, reacts with the fluoride source (Scheme 1a). On the other hand, in the electrophilic fluorination, the nucleophile may be a carbon anion (e.g., Grignard reagent), a compound with electron-rich unsaturated bonds (arene, alkene, or alkyne), or a substrate having a nucleophilic and labile bond (e.g., C−Si, C−Sn, and C−B), while the electrophile is the fluorination reagent (Scheme 1b). As shown in Scheme 1d, many nucleophilic and electrophilic fluorination reagents have been developed by chemists. In the radical fluorination, C–F bonds are produced by carbon-based radicals (generated in situ by various methods) with "atomic fluorine" sources, such as XeF2, hypofluorite, or molecular fluorine (Scheme 1c). Notably, transition metals are not biased to one reaction class, and the same metal may be successfully applied to all three kinds of fluorination.

Several reviews of fluorination have been published within the past few years, Buchwald [23], Weng [24], Gouverneur [25], Reiser [26], and etc. [22,27-33] discussed progresses of fluorination, such as Weng who focused on the recent advances in the transition-metal-assisted synthesis of alkyl fluorides, and Buchwald introduced the discovery and development of Pd(0)/Pd(II)-catalyzed aromatic fluorination reactions. Herein, we focus on the developments towards the construction of C(sp3)–F and C(sp2)–F bonds with different catalysts, such as palladium, copper, silver, iron, nickel, ruthenium, cobalt, etc.

Palladium catalysis

Palladium is a member of the nickel triad in the periodic table, and palladium complexes exist in three oxidation states, Pd(0), Pd(II), and Pd(IV). Straightforward interconversion between different oxidation states, tolerance to various guiding groups, easy electroplating of C–H bonds, and the compatibility of many Pd(II) catalysts with oxidants make them act as ideal catalysts for C–H activations [34]. Over the last decade, a number of Pd-catalyzed methods have been developed to synthesize aryl fluorides [23,32].

Allylic fluorination: In 2010, Doyle and co-worker [35] developed a strategy for C–F bond formation of readily available cyclic allylic chlorides and AgF using a Pd(0) catalyst in combination with Trost’s bisphosphine ligand at room temperature (Scheme 2a). They also proved that the allylic fluorination was achieved by an SN2-type attack of fluoride on an electrophilic Pd(II)-allyl intermediate. One year later, the same author extended this method to a highly regio- and enantioselective fluorination of acyclic allylic chlorides. Compared to the previous process, this reaction used a different chiral bisphosphine ligand resulting in larger bite angles and afforded the products in good yields (Scheme 2b) [36].

Scheme 2: Doyle’s Pd-catalyzed fluorination of allylic chlorides.

Scheme 2: Doyle’s Pd-catalyzed fluorination of allylic chlorides.

A palladium-catalyzed method for the formation of allylic C–F bonds from allyl p-nitrobenzoate using TBAF(t-BuOH)4 as the fluoride source was explored by Gouverneur et al. in the same year (Scheme 3) [37]. The 2- and 3-arylpropenyl fluorides can be quickly synthesized under mild conditions in moderate to good yields.

Scheme 3: Allylic fluorination of 2- and 3-substituted propenyl esters.

Scheme 3: Allylic fluorination of 2- and 3-substituted propenyl esters.

In 2012, a Pd(0)-catalyzed allylic fluorination of allylic phosphorothioate esters with AgF was accomplished by Wu’s group (Scheme 4) [38]. The formation of fluorinated products with an overall retention of the stereochemical configuration suggests a mechanism wherein a palladium-π-allyl intermediate undergoes a rapid π-σ-π isomerization.

Scheme 4: Regioselective allylic fluorination of cinnamyl phosphorothioate esters.

Scheme 4: Regioselective allylic fluorination of cinnamyl phosphorothioate esters.

In 2013, the first example of an allylic C–H fluorination reaction of simple alkenes with Et3N·3HF as a nucleophilic fluoride source was reported by Doyle and co-worker (Scheme 5) [39]. Herein, the authors utilized a Pd/Cr cocatalytic system to generate the allylic fluorides with high regioselectivity (branched > linear).

Scheme 5: Palladium-catalyzed aliphatic C–H fluorination reported by Doyle.

Scheme 5: Palladium-catalyzed aliphatic C–H fluorination reported by Doyle.

Alkyl fluorination of acidic carbonyl compounds and other compounds: In 2012, the group of Sodeoka [40] reported the first example of an enantioselective monofluorination of α-keto esters catalyzed by Pd-μ-hydroxo complexes with cyclopentyl methyl ether (CPME) as the best solvent (Scheme 6). Also, they achieved the diastereoselective reduction of the remaining keto group with lithium tri(sec-butyl)borohydride (ʟ-Selectride). The syn-β-fluoro-α-hydroxy esters were obtained finally in good yields with excellent enantioselectivities (83–95% ee).

Scheme 6: Pd-catalyzed enantioselective fluorination of α-ketoesters followed by stereoselective reduction to give β-fluoro-α-hydroxy esters.

Scheme 6: Pd-catalyzed enantioselective fluorination of α-ketoesters followed by stereoselective reduction to...

There are two examples of a Pd-catalyzed fluorination of oxindoles. In 2012, Shi and co-workers [41] described the enantioselective asymmetric fluorination of oxindoles with an axially chiral C2-symmetric N-heterocyclic carbene (NHC) palladium complex as a catalyst (Scheme 7a). The corresponding products were obtained in excellent yields but low to moderate enantioselectivities. Meanwhile, Wu and co-workers [42] developed a similar system using a BINAP-derived palladium complex to perform the similar reaction with 4,4’-diF-NFSI as the fluorinating agent in higher enantioselectivities (Scheme 7b).

Scheme 7: Pd-catalyzed C(sp3)–H fluorination of oxindoles.

Scheme 7: Pd-catalyzed C(sp3)–H fluorination of oxindoles.

In 2012 the group of Sanford [43] achieved the palladium-catalyzed C–H fluorination of 8-methylquinoline derivatives using AgF as the nucleophilic fluoride source and PhI(OPiv)2 as a hypervalent iodine oxidant (Scheme 8). Very recently, they [44] optimized this transformation and achieved the benzylic C–H radiofluorination with no-carrier-added Ag[18F]F. This method was applied to the radiolabeling of diversely substituted 8-methylquinoline derivatives. Notably, in this process, a new method was developed for generating Ag[18F]F by using a sep-pak cartridge.

Scheme 8: C–H fluorination of 8-methylquinoline derivatives with F− reagents.

Scheme 8: C–H fluorination of 8-methylquinoline derivatives with F− reagents.

In 2012, van Leeuwen and co-workers [45] described the synthesis of new enantiopure wide-bite-angle diphosphanes and their application in the asymmetric fluorination of α-cyanoacetates with a palladium catalyst (Scheme 9). Under these conditions, the fluorination of ethyl 2-cyano-2-phenylacetate afforded the product with highest enantiomeric excess (93%).

Scheme 9: Fluorination of α-cyano acetates reported by van Leeuwen.

Scheme 9: Fluorination of α-cyano acetates reported by van Leeuwen.

In 2013, Kim’s group [46] described an enantioselective electrophilic fluorination of α-chloro-β-keto phosphonates with up to 95% ee (Scheme 10). Notably, this reaction used an air and moisture-stable chiral palladium complex as the catalyst, which worked well at low catalyst loading (as low as 0.5 mol %).

Scheme 10: The catalytic enantioselective electrophilic C–H fluorination of α-chloro-β-keto phosphonates.

Scheme 10: The catalytic enantioselective electrophilic C–H fluorination of α-chloro-β-keto phosphonates.

In 2015, Shi et al. [47] introduced a Pd(II)/Pd(IV)-catalyzed fluorination of β-methylene C(sp3)–H bonds of α-amino acid derivatives (Scheme 11a). This process was carried out under the strongly binding bidentate 2-(pyridine-2-yl)isopropylamine (PIP) auxiliary. A range of substrates containing both aliphatic and benzylic C(sp3)–H bonds was finally converted to the corresponding fluorinated products with excellent diastereoselectivities. Based on the PIP auxiliary developed by Shi, Ge’s group [48] developed a similar direct, highly site- and diastereoselective fluorination of aliphatic amides (Scheme 11b). Although the roles of Fe(OAc)2 and Ag2CO3 were unclear, their addition significantly improved the reaction yield. A catalytic cycle of these β-fluorination reactions is proposed in Scheme 11. Initially, coordination of the amide with the palladium species followed by a base-promoted ligand-exchange process yields the palladium complex A. Subsequently, cyclometallation of the palladium complex A occurs to produce the intermediate B through the C–H bond-activation process. Oxidative addition of the intermediate B with Selectfluor affords the palladium(IV) species C, followed by reductive elimination and ligand dissociation to give the final product.

Scheme 11: Fluorination of unactivated C(sp3)–H bonds directed by the bidentate PIP auxiliary.

Scheme 11: Fluorination of unactivated C(sp3)–H bonds directed by the bidentate PIP auxiliary.

Similar to these publications in strategy and products, in the same year, Xu’s group [49] presented the palladium-catalyzed direct fluorination of unactivated C(sp3)–H bonds at the β-position of carboxylic acids with NFSI (Scheme 12). To achieve this transformation, an 8-aminoquinoline-derived auxiliary was developed as an effective directing group for the activation of the C–H bonds. In this transformation the presence of Ag2O and pivalic acid was found to be crucial for the successful synthesis of β-fluorinated carboxylic acids.

Scheme 12: Fluorination of C(sp3)–H bonds at the β-position of carboxylic acids.

Scheme 12: Fluorination of C(sp3)–H bonds at the β-position of carboxylic acids.

Recently, the first example of a Pd-catalyzed protocol for the general enantioselective electrophilic C(sp3)–H fluorination of benzaldehyde substrates was reported by Yu and co-workers (Scheme 13) [50]. Enantioenriched benzyl fluorides were obtained by aid of a chiral α-amino amide transient directing group (TDG). Notably, the condensation of this bulky amino amide with the aldehyde led to control of the stereochemistry of the C–H insertion step, promoting the C–F over C–O bond formation via an inner-sphere pathway.

Scheme 13: Enantioselective benzylic C–H fluorination with a chiral transient directing group.

Scheme 13: Enantioselective benzylic C–H fluorination with a chiral transient directing group.

Fluorination of arenes, aryl bromides, -alcohols, -triflates, and -boronic acid derivatives: In 2013, Larhed and co-workers [51] established a one-pot, two-step fluorination of aryl alcohols via aryl nonafluorobutylsulfonates. This transformation employed Pd2(dba)3/t-BuBrettPhos and CsF to convert aryl alcohols to aryl fluorides at 180 °C under microwave conditions (Scheme 14). The proposed catalytic cycle of this aryl fluorination is also shown. Only reductive elimination was investigated by Larhed, because this reaction step is crucial for product formation and a successful outcome of the reaction.

Scheme 14: Microwave-heated Pd-catalyzed fluorination of aryl alcohols.

Scheme 14: Microwave-heated Pd-catalyzed fluorination of aryl alcohols.

In the same year, the Ritter group [52] reported a Pd-catalyzed fluorination of arylboronic acid derivatives via a Pd(II)/Pd(III) cycle (Scheme 15). A single-electron-transfer (SET) mechanism involving a well-defined Pd(III) intermediate has been proposed. First, a bis(terpyridyl)Pd(II) complex B is oxidized by Selectfluor with turnover-limiting to obtain Pd(III) C and a Selectfluor radical cation. Then, a transfer of a F· radical from the Selectfluor radical cation to an aryl trifluoroborate occurs, forming the C−F bond and producing a delocalized radical. Finally, SET from the radical to C regenerates palladium species B, and affords a delocalized cation which converts to the aryl fluoride with loss of BF3. Notably, the addition of NaF increases the yield of aryl fluoride by reacting with the generated BF3.

Scheme 15: Fluorination of aryl potassium trifluoroborates.

Scheme 15: Fluorination of aryl potassium trifluoroborates.

In 2013, Buchwald et al. [53] introduced an improved catalyst system involving CsF and the stable Pd(0) species [(1,5-cyclooctadiene)(L1·Pd)2] (L1 = AdBrettPhos), which is a precatalyst for the fluorination of aryl triflates and heteroaryl triflates (Scheme 16a). Furthermore, aryl fluorides were provided in good to excellent yields with easy to separate byproducts. A year later, the same catalyst was employed for the nucleophilic fluorination of aryl bromides and iodides with AgF and KF [54]. Meanwhile, with a slight modification of the phosphine ligand, Buchwald developed a similar Pd(0) precatalyst [L2Pd]2(cod), which was used to fluorinate nitrogen-containing heteroaryl bromides (Scheme 16b).

Scheme 16: C(sp2)–F bond formation using precatalyst [L·Pd]2(cod).

Scheme 16: C(sp2)–F bond formation using precatalyst [L·Pd]2(cod).

In 2015, Buchwald and co-workers [55] explored a novel ligand for the Pd-catalyzed fluorination of (hetero)aryl triflates and bromides. The desired aryl fluorides were obtained with higher than 100:1 selectivity (Scheme 17).

Scheme 17: Pd-catalyzed fluorination of (hetero)aryl triflates and bromides.

Scheme 17: Pd-catalyzed fluorination of (hetero)aryl triflates and bromides.

More recently, Yamamoto and co-workers [56] described a palladium-catalyzed general method for aromatic C–H fluorination with mild electrophilic fluorinating reagents at room temperature (Scheme 18). Notably, in this process, a reactive transition metal fluoride electrophile B is catalytically formed from A with Selectfluor or NFSI instead of an organometallic intermediate as usual. Then, the activated Pd(IV)–F electrophile B would be capable of electrophilic fluorination of weakly nucleophilic arenes. This unusual mechanism of catalysis may provide a new idea to the catalysis of C–H functionalization reactions.

Scheme 18: The Pd-catalyzed C–H fluorination of arenes with Selectfluor/NFSI.

Scheme 18: The Pd-catalyzed C–H fluorination of arenes with Selectfluor/NFSI.

Aryl C–H fluorination with various directing groups: With Pd(OTf)2(MeCN)4 and N-methyl-2-pyrrolidinone (NMP) used as the catalyst system, in 2011 the Yu group [57] described the ortho-fluorination of benzoic acid substrates with a directing group, an electron-deficient removable acidic amide (Scheme 19). With this method, both mono- and difluorinated benzoic acid derivatives can be selectively obtained in high yields.

Scheme 19: Pd(II)-catalyzed ortho-monofluorination protocol for benzoic acids.

Scheme 19: Pd(II)-catalyzed ortho-monofluorination protocol for benzoic acids.

In 2014, Pu and co-workers [58] devised the regioselective Pd(PPh3)4-catalyzed electrophilic ortho-fluorination of 2-arylbenzothiazoles with NFSI and ʟ-proline as the crucial promoter and the benzothiazoles as the directing groups (Scheme 20). This strategy plays an important role in the pharmaceutical and agrochemical industries.

Scheme 20: Pd-catalyzed C(sp2)–H bond fluorination of 2-arylbenzothiazoles.

Scheme 20: Pd-catalyzed C(sp2)–H bond fluorination of 2-arylbenzothiazoles.

Meanwhile, Xu’s group [59] used O-methyl oxime as the directing group for the Pd-catalyzed ortho-fluorination of aromatic and olefinic C(sp2)–H bonds (Scheme 21a). It is worth noting that a cheap and nontoxic nitrate was added as a highly efficient promoter in the presence of NFSI and Pd2(dba)3. In addition, the authors proposed a reaction mechanism that involves a Pd(II)/Pd(IV) catalytic cycle (Scheme 21b). At the early stage of this process, an in situ-generated cationic [Pd(NO3)]+ species facilitates the C–H bond activation to give intermediate A. The Pd(II)(1a)2 complex B is formed via further C–H bond activation of another molecule 1a by the cyclopalladation(II) intermediate A. Then, intermediate B undergoes oxidative addition by NFSI to give the highly reactive species F–Pd(IV)1a)2-N(SO2Ph)2 (C), which produces the product 2a and reductive elimination intermediate 1a-Pd(II)-N(SO2Ph)2 (D). Finally, intermediate A regenerates from intermediate D by aid of the catalytic amount of HNO3 released during the C–H activation step.

Scheme 21: Nitrate-promoted fluorination of aromatic and olefinic C(sp2)–H bonds and proposed mechanism.

Scheme 21: Nitrate-promoted fluorination of aromatic and olefinic C(sp2)–H bonds and proposed mechanism.

In 2015, Zhao et al. [60] discovered a Pd(II)-catalyzed ortho-selective C–H fluorination of oxalyl amide-protected benzylamines (Scheme 22). The yields were up to 95% with NFSI as the [F+] source and tert-amyl alcohol as the solvent.

Scheme 22: Fluorination of oxalyl amide-protected benzylamine derivatives.

Scheme 22: Fluorination of oxalyl amide-protected benzylamine derivatives.

In 2018, the Sorensen group [61] described a direct Pd-catalyzed ortho-C–H fluorination of benzaldehydes. Notably, these transformations were achieved with orthanilic acids as new transient directing groups (TDGs) in DCE in the presence of air (Scheme 23). This approach employed 1-fluoro-2,4,6-trimethylpyridinium salts as a bystanding F+ oxidant or an electrophilic fluorinating reagent. A broad substrate scope and high functional group compatibility were observed.

Scheme 23: C–H fluorination of benzaldehydes with orthanilic acids as transient directing group.

Scheme 23: C–H fluorination of benzaldehydes with orthanilic acids as transient directing group.

In addition to the methods discussed above, there are some other methods for the aromatic C–H fluorination using electrophilic fluorination reagents with various other directing groups [60,62-66]. Additionally, a diverse range of N-heterocycles, amides and motifs commonly encountered in medicinal chemistry were used as handles to direct C–H fluorination for the synthesis of pharmaceutical drugs (Scheme 24) [25].

Scheme 24: Pd(II)-catalyzed aryl C–H fluorination with various directing groups.

Scheme 24: Pd(II)-catalyzed aryl C–H fluorination with various directing groups.

Copper catalysis

Despite the success of Pd-catalyzed fluorinations, the more widespread use of these technologies has been partially hampered by the high cost and toxicity associated with Pd, in addition to the difficulty encountered when attempting to remove this metal from product mixtures. Therefore, cupper as low-cost, earth-abundant and readily available transition metal has emerged as a prevalent catalyst in a huge number of organic transformations. Similar to palladium complexes, copper complexes generally exist in four oxidation states, Cu(0), Cu(I), Cu(II), and Cu(III) and various fluorination reactions could be developed by different catalytic mechanisms.

Fluorination of inert C–H bonds, alkyl bromides and -triflates: In a 2012 study, Lectka’s group [67] disclosed the catalytic fluorination of a series of aliphatic, benzylic, and allylic substrates with moderate yields. In this case, the authors employed a multicomponent catalytic system, involving Selectfluor, the radical precursor N-hydroxyphthalimide (NHPI), an anionic phase-transfer catalyst (KB(C6F5)4), and a Cu(I)-bisimine complex, to give the corresponding monofluorinated product (Scheme 25).

Scheme 25: Cu-catalyzed aliphatic, allylic, and benzylic fluorination.

Scheme 25: Cu-catalyzed aliphatic, allylic, and benzylic fluorination.

One year later, Weng and co-workers [68] synthesized and characterized a new copper(I) fluoride complex ligated by a phenanthroline derivative. This complex was applied to the SN2 fluorination of primary and secondary alkyl bromides, producing the corresponding alkyl fluorides in 40–90% yield (Scheme 26).

Scheme 26: Cu-catalyzed SN2 fluorination of primary and secondary alkyl bromides.

Scheme 26: Cu-catalyzed SN2 fluorination of primary and secondary alkyl bromides.

In 2014, the group of Lalic [69] developed a mild fluorination of alkyl triflates with potassium fluoride catalyzed by a phase-transfer copper catalyst (Scheme 27). Notably, with 10 mol % of (IPr)CuOTf, full conversion can be accomplished in 10 minutes at 45 °C.

Scheme 27: Copper-catalyzed fluorination of alkyl triflates.

Scheme 27: Copper-catalyzed fluorination of alkyl triflates.

Allylic fluorination: In 2013, there is an example of a copper-catalyzed fluorination of internal allylic bromides (Scheme 28). In Liu’s study, this approach was achieved using Et3N·3HF as the fluorine source with a high catalyst loading (20–30 mol %) affording the products in 45–92% yield [70]. The heteroatom-containing functional group (R1) is necessary for good reactivity and regioselectivity.

Scheme 28: Cu-catalyzed fluorination of allylic bromides and chlorides.

Scheme 28: Cu-catalyzed fluorination of allylic bromides and chlorides.

α-Fluorination of acidic carbonyl compounds: In 2011, Shibatomi and co-workers [71] described the one-pot asymmetric gem-chlorofluorination of active methylene compounds by using a copper(II) complex with a chiral spiro 2-pyridyl monooxazoline ligand (SPYMOX). The corresponding α-chloro-α-fluoro-β-keto esters were isolated with up to 92% ee (Scheme 29a). This approach could be extended to asymmetric gem-chlorofluorination of β-ketophosphonates. Two years later, the same authors [72] demonstrated the highly enantioselective fluorination of α-alkyl-β-keto esters and α-alkylmalonates using the same catalyst system (Scheme 29b). Moreover, various cyclic and acyclic substrates were successfully fluorinated with high enantioselectivities.

Scheme 29: Synthetic strategy for the fluorination of active methylene compounds.

Scheme 29: Synthetic strategy for the fluorination of active methylene compounds.

In 2013, the Kesavan group [73] reported the use of tartrate-derived bidentate bisoxazoline-Cu(II) complexes for the enantioselective fluorination of aliphatic cyclic and acyclic β-ketoesters with up to 98% yields (Scheme 30). In this method, (S,S)-Nap-(R,R)-Box as the most suitable diastereomeric ligand forms a 5-membered chelate with copper.

Scheme 30: Fluorination of β-ketoesters using a tartrate-derived bidentate bisoxazoline-Cu(II) complex.

Scheme 30: Fluorination of β-ketoesters using a tartrate-derived bidentate bisoxazoline-Cu(II) complex.

In the same year, an efficient and highly enantioselective fluorination of β-ketoesters catalyzed by diphenylamine-linked bis(thiazoline)-Cu(OTf)2 complexes was reported by Du and co-worker (Scheme 31a) [74]. Che and co-workers [75] achieved a similar α-fluorination of β-ketoesters and N-Boc-oxindoles (Scheme 31b). Compared with Du’s method, Che employed both AgClO4 and chiral iron(III)-salan complexes as the catalyst.

Scheme 31: Highly enantioselective fluorination of β-ketoesters and N-Boc-oxindoles.

Scheme 31: Highly enantioselective fluorination of β-ketoesters and N-Boc-oxindoles.

In 2016, the group of Nishikata [76] described a copper-catalyzed site-selective fluorination of α-bromocarbonyl compounds using a copper/CsF catalyst system (Scheme 32). Tertiary alkyl fluorides could be generated by this fluorination through the assistance of an amide group. From the results, the catalytic cycle of this reaction includes: 1) copper salt induced generation of the alkyl radical species B from substrate A and 2) fluorination of the alkyl radical species B with CuF2, which is in situ-generated from the reaction of CuXBr and CsF with the aid of an amide group, gives the desired product and recyclable CuF.

Scheme 32: Amide group-assisted site-selective fluorination of α-bromocarbonyl compounds.

Scheme 32: Amide group-assisted site-selective fluorination of α-bromocarbonyl compounds.

Csp2–H bond formation catalyzed by Cu catalysts: In 2013, Sanford and co-workers [77] developed a simple and practical process for the nucleophilic fluorination of arylpotassium trifluoroborates. The reaction proceeds in CH3CN at 60 °C in the presence of Cu(OTf)2 as the catalyst and KF as the fluoride source (Scheme 33). A possible mechanism for this transformation is proposed in Scheme 33 below. Notably, Cu acts as both a mediator and an oxidizer in this reaction.

Scheme 33: Cu-mediated aryl fluorination reported by Sanford [77].

Scheme 33: Cu-mediated aryl fluorination reported by Sanford [77].

In the same year, Daugulis et al. [78] presented a Cu-catalyzed selective fluorination of benzoic acid derivatives and benzylamine derivatives assisted by an aminoquinoline auxiliary. With a CuI catalyst, AgF as fluoride source, NMO as oxidant, and DMF as solvent, they achieved the selective mono- or difluorination in high yields (Scheme 34). Notably, pyridine as an additive could prevent the decomposition of an amide substrate in a long-time reaction.

Scheme 34: Mono- or difluorination reactions of benzoic acid derivatives.

Scheme 34: Mono- or difluorination reactions of benzoic acid derivatives.

Meanwhile, the group of Sanford [79] presented the nucleophilic fluorination of diaryliodonium salts with KF through a Cu(I/III) catalytic cycle mechanism. This procedure preferentially fluorinates the smaller aromatic ligand on iodine(III). Also, the addition of Cu(OTf)2 and 18-crown-6 promoted the fluorination effectively. Finally, excellent yields, fast rate, high selectivity, and a broad substrate scope were observed by the authors (Scheme 35). The proposed mechanism is as follows: ligand exchange of the active Cu(I) catalyst A, which is generated via either reduction by the solvent or disproportionation of the precatalyst Cu(II)(OTf)2, provides Cu(I)-F (B). Then, oxidation of Cu(I)-F (B) by the diaryliodonium reagent forms Cu(III)–aryl intermediate C. Subsequently, a reductive elimination of intermediate C provides a putative π-complex D, which then releases the desired aryl–F product and regenerates the CuI catalyst A.

Scheme 35: Cu-catalyzed fluorination of diaryliodonium salts with KF.

Scheme 35: Cu-catalyzed fluorination of diaryliodonium salts with KF.

Subsequently, the Cu-catalyzed fluorination of 2-pyridylaryl bromides was achieved by Liu and co-workers [80] through a Cu(I/III) catalytic cycle as well (Scheme 36). This method is based on the aid of an important pyridyl directing group and the final aryl C–F bond is formed after the reductive elimination of ArCu(III)–F species.

Scheme 36: Copper(I)-catalyzed cross-coupling of 2-pyridylaryl bromides.

Scheme 36: Copper(I)-catalyzed cross-coupling of 2-pyridylaryl bromides.

Other catalysts

Other transition metals, including Co, Ni, Fe, Ag, Ir, Mn, etc., have received more and more attention.

Aliphatic and benzylic C–H fluorination and decarboxylative fluorination: In 2012, a silver-catalyzed radical decarboxylative fluorination of aliphatic carboxylic acids in aqueous solution was provided by Li and co-workers (Scheme 37) [81]. The corresponding alkyl fluorides were produced in 47–95% yield under mild conditions. Additionally, the authors proposed a mechanism involving a Ag(III)-mediated SET followed by a fluorine transfer.

Scheme 37: AgNO3-catalyzed decarboxylative fluorination of aliphatic carboxylic acids.

Scheme 37: AgNO3-catalyzed decarboxylative fluorination of aliphatic carboxylic acids.

Subsequently, the group of Groves [82] developed two manganese catalysts for the fluorination of C(sp3)–H bonds (Scheme 38). On the one hand, they employed a manganese porphyrin to catalyze the oxidative aliphatic C–H fluorination with iodosylbenzene (PhIO) as a stoichiometric oxidant. A variety of substrates, including simple hydrocarbons, substituted cyclic molecules, terpenoids, and steroid derivatives, were selectively fluorinated at some otherwise inaccessible sites, however, in low to moderate yields. On the other hand, the same group [83] developed Mn(salen)Cl as a catalyst for the direct C–H fluorination at benzylic positions with a nucleophilic fluorine source. Notably, Groves adapted the method for the 18F-radiofluorination of benzylic and aliphatic C–H bonds using no-carrier-added [18F]-fluoride with Mn(salen)OTs [84].

Scheme 38: The Mn-catalyzed aliphatic and benzylic C–H fluorination.

Scheme 38: The Mn-catalyzed aliphatic and benzylic C–H fluorination.

In 2013, Lectka’s group [85,86] reported an iron-catalyzed C(sp3)–H fluorination of benzylic substrates with or without an electron-withdrawing group (EWG) in the presence of Selectfluor (Scheme 39). Notably, an EWG beta to the benzylic position is efficient for an excellent selectivity of the benzylic fluorination.

Scheme 39: Iron(II)-promoted C–H fluorination of benzylic substrates.

Scheme 39: Iron(II)-promoted C–H fluorination of benzylic substrates.

Moreover, Gouverneur and co-workers [87] established the decarboxylative fluorination of α,α-difluoro- and α-fluoroarylacetic acids with a wide functional group compatibility in the presence of AgNO3 as catalyst in good yields (Scheme 40). Further, this approach was efficiently applied to the preparation of [18F]-labelled tri- and difluoromethylarenes using [18F]Selectfluor bis(triflate).

Scheme 40: Ag-catalyzed fluorodecarboxylation of carboxylic acids.

Scheme 40: Ag-catalyzed fluorodecarboxylation of carboxylic acids.

In 2014, Chen and co-workers [88] described a selective direct C(sp3)–H fluorination catalyzed by a commercially available vanadium(III) oxide with Selectfluor in good yields (Scheme 41). It is noteworthy that the catalyst and the byproduct H-TEDA could be removed easily by filtration.

Scheme 41: Vanadium-catalyzed C(sp3)–H fluorination.

Scheme 41: Vanadium-catalyzed C(sp3)–H fluorination.

A simple AgNO3-catalyzed synthesis of alkyl fluorides through radical deboronofluorination of alkyl boronates and boronic acids in acidic aqueous solution was also developed by Li and co-workers in 2014 [89]. This method features good yields and a wide functional group compatibility (Scheme 42).

Scheme 42: AgNO3-catalyzed radical deboronofluorination of alkylboronates and boronic acids.

Scheme 42: AgNO3-catalyzed radical deboronofluorination of alkylboronates and boronic acids.

Recently, the group of Van Humbeck [90] reported a selective and mild method for the C–H fluorination of azaheterocycles with Selectfluor at room temperature. In this case, a new radical mechanism was proposed that electron transfer from the heterocyclic substrate to Selectfluor eventually generates a benzylic radical, leading to the desired C–F bond formation. The excellent selectivity of the desired fluorinated product was obtained without additives. In addition, a catalytic amount of iron(III) complex [FeCl4][FeCl2(dmf)3] was found to improve the yields in some cases (Scheme 43).

Scheme 43: Selective heterobenzylic C–H fluorination with Selectfluor reported by Van Humbeck.

Scheme 43: Selective heterobenzylic C–H fluorination with Selectfluor reported by Van Humbeck.

With an Fe(II)-catalyzed orchestrated redox process, an alkoxyl radical-guided strategy for the site-selective fluorination of unactivated methylene and methine C–H bonds was published by Liu and co-workers in 2018 (Scheme 44) [91]. The fluorination of various primary, secondary, and tertiary hydroperoxides was achieved in moderate to excellent yields, with the hydroperoxide functional group acting as a precursor of an alkoxy radical to control site-selective carbon-centered radical formation.

Scheme 44: Fe(II)-catalyzed site-selective fluorination guided by an alkoxyl radical.

Scheme 44: Fe(II)-catalyzed site-selective fluorination guided by an alkoxyl radical.

Allylic fluorination: In 2011, the group of Nguyen [92] developed the nucleophilic fluorination of allylic trichloroacetimidates, as shown in Scheme 45a. Cyclooctadiene iridium chloride dimer, [IrCl(COD)]2, was an effective catalyst to promote this fluorination with Et3N·3HF, forming allylic fluorides in moderate to good yields. This facile method shows a good regioselectivity to gain the branched isomer within 1 h. Later in 2017, they described a similar method for the asymmetric fluorination of racemic allylic trichloroacetimidates utilizing a chiral bicyclo[3.3.0]octadiene-ligated iridium complex (Scheme 45b) [93]. This reaction proceeded under mild conditions with an extremely broad substrate scope, as well as excellent branched-to-linear ratios and enantioselectivities.

Scheme 45: Fluorination of allylic trichloroacetimidates reported by Nguyen et al.

Scheme 45: Fluorination of allylic trichloroacetimidates reported by Nguyen et al.

In 2013, Gouverneur and co-workers [94] demonstrated the regio and stereocontrolled fluorination of allylic carbonates with [Ir(COD)Cl]2 as the catalyst and TBAF(t-BuOH)4 as the fluoride source to produce branched and linear allylic fluorides (Scheme 46). Remarkably, this was the first example to afford (Z)-allyl fluorides (Z:E ratio > 20:1).

Scheme 46: Iridium-catalyzed fluorination of allylic carbonates with TBAF(t-BuOH)4.

Scheme 46: Iridium-catalyzed fluorination of allylic carbonates with TBAF(t-BuOH)4.

In 2015, Nguyen et al. [95] explored the asymmetric fluorination of racemic, secondary allylic trichloroacetimidates with Et3N·3HF using a chiral-diene-ligated Ir complex (Scheme 47). This process proceeded under mild conditions with excellent enantioselectivity and yields, a broad substrate scope, as well as a wide range of functional group compatibility. Notably, this strategy overcomes the challenges associated with the formation of secondary allylic fluorides bearing α-linear substituents, providing complete regio and stereocontrolled acrylic allylic fluorides.

Scheme 47: Iridium-catalyzed asymmetric fluorination of allylic trichloroacetimidates.

Scheme 47: Iridium-catalyzed asymmetric fluorination of allylic trichloroacetimidates.

Fluorination of acidic carbonyl compounds: In 2010, Itoh and co-workers [96] demonstrated the asymmetric fluorination of cyclic and acyclic β-ketoesters by using a catalytic amount of Co(acac)2 with (R,R)-Jacobsen’s salen ligand (Scheme 48). The α-fluorinated products were thus obtained with good enantioselectivity.

Scheme 48: Cobalt-catalyzed α-fluorination of β-ketoesters.

Scheme 48: Cobalt-catalyzed α-fluorination of β-ketoesters.

In the same year, Kim’s group [97] accomplished an efficient enantioselective electrophilic α-fluorination of various α-chloro-β-ketoesters catalyzed by chiral nickel complexes with good enantioselectivity (up to 99% ee). Notably, the chiral nickel-diamine complexes are air and moisture-stable (Scheme 49).

Scheme 49: Nickel-catalyzed α-fluorination of various α-chloro-β-ketoesters.

Scheme 49: Nickel-catalyzed α-fluorination of various α-chloro-β-ketoesters.

In 2011, two nickel-catalyzed protocols for the enantioselective α-fluorination of β-ketoesters were reported separately. In van Leeuwen’s reaction, SPANamine derivatives were synthesized and applied as chiral ligands in the asymmetric α-fluorination of β-ketoesters (Scheme 50a) [98]. Meanwhile, to achieve this transformation, Gade and co-workers [99] developed a new class of chiral tridentate N-donor pincer ligands, bis(oxazolinylmethylidene)isoindolines. They obtained the desired products under mild conditions with excellent enantioselectivities (up to >99% ee) and good yields (Scheme 50b).

Scheme 50: Ni(II)-catalyzed enantioselective fluorination of oxindoles and β-ketoesters.

Scheme 50: Ni(II)-catalyzed enantioselective fluorination of oxindoles and β-ketoesters.

Also, Feng et al. [100] developed a new method for the highly enantioselective fluorination of N–H-free 3-substituted oxindoles catalyzed by a Sc(III)/N,N’-dioxide complex. A series of 3-aryl- and 3-alkyl-3-fluoro-2-oxindoles were obtained in excellent yields and enantioselectivities (89–99% ee) with NFSI under basic conditions (Scheme 51).

Scheme 51: Scandium(III)-catalyzed asymmetric C–H fluorination of unprotected 3-substituted oxindoles.

Scheme 51: Scandium(III)-catalyzed asymmetric C–H fluorination of unprotected 3-substituted oxindoles.

In 2016, a mild, amide-directed fluorination of benzylic, allylic, and unactivated C–H bonds was described by the Cook group [101]. By the use of the iron(II) triflate (Fe(OTf)2) as catalyst, the desired fluorides were finally obtained through a F-transfer of a short-lived radical intermediate (N-fluoro-2-methylbenzamides) in up to 93% yield (Scheme 52).

Scheme 52: Iron-catalyzed directed C–H fluorination.

Scheme 52: Iron-catalyzed directed C–H fluorination.

Csp2–H bond formation catalyzed by Ag catalysts: In 2010, the Ritter group [102] firstly reported a Ag-catalyzed fluorination of arylstannane derivatives with the electrophilic fluorination reagent F-TEDA-PF6 (Scheme 53). Also, the reaction was applied to late-stage fluorination of small molecules. However, this method uses toxic arylstannanes as starting materials and requires an additional synthetic step from the triflate or halide to the stannanes.

Scheme 53: Electrophilic silver-catalyzed Ar–F bond-forming reaction from arylstannanes.

Scheme 53: Electrophilic silver-catalyzed Ar–F bond-forming reaction from arylstannanes.

Trifluoromethylation

Transition-metal-catalyzed trifluoromethylation reactions have made great progress in the joint efforts of organic fluorination scientists and metalorganic chemists over the past decade. Introducing trifluoromethyl groups into organic molecules can significantly alter their properties, such as their metabolic stability, lipophilicity, and the ability to penetrate the blood–brain barrier. Similar to fluorination, trifluoromethylation can also be achieved by three reaction types: nucleophilic, electrophilic and radical trifluoromethylation.

In recent years, many novel trifluoromethylation reagents, such as cationic, anionic and radical CF3 sources have been discovered and offer manifold choices to effect electrophilic, nucleophilic and radical trifluoromethylation [103] (Figure 1). The selection of the trifluoromethylation reagent has become the main factor in the optimization of these reactions. With a suitable trifluoromethylation reagent, a wide range of substrates are directly converted to the desired trifluoromethylated products. Several reviews [104-110] have been published on this subject, while this part mainly discusses trifluoromethylation reactions catalyzed by metals. However, there are only a few methods available for the C(sp3)–CF3 bond formation and this transformation still needs further examination.

Figure 1: Nucleophilic, electrophilic and radical CF3 sources.

Figure 1: Nucleophilic, electrophilic and radical CF3 sources.

C(sp3)–CF3 bond formation

Copper catalysis: In 2011, two Cu(I)-catalyzed allylic trifluoromethylation reactions of terminal olefins have been developed independently by the groups of Buchwald [111] and Wang [112] (Scheme 54). Under similar mild conditions using Togni's reagent II, the desired allyl–CF3 products were obtained and the methods well tolerated a variety of functional groups (e.g., esters, epoxides, amides, alcohols, or aldehydes). Moreover, the thermodynamically favored E-olefin was generated with high stereoselectivity in good yields.

Scheme 54: Cu(I)-catalyzed allylic trifluoromethylation of unactivated terminal olefins.

Scheme 54: Cu(I)-catalyzed allylic trifluoromethylation of unactivated terminal olefins.

In 2012, two different groups [113,114] individually reported the direct trifluoromethylation of allylsilanes under very similar conditions. These processes furnished various branched cyclic and acyclic allylic CF3 products using copper as the catalyst (Scheme 55).

Scheme 55: Direct copper-catalyzed trifluoromethylation of allylsilanes.

Scheme 55: Direct copper-catalyzed trifluoromethylation of allylsilanes.

Subsequently, an enantioselective trifluoromethylation of cyclic β-ketoesters with commercially available trifluoromethylating reagents was reported by Gade and co-workers using a Cu-boxmi catalyst [115]. Under mild conditions, both five and six-membered ring β-ketoesters were converted to the corresponding products in high yields and enantioselectivities (Scheme 56).

Scheme 56: Cupper-catalyzed enantioselective trifluoromethylation of five and six-membered ring β-ketoesters.

Scheme 56: Cupper-catalyzed enantioselective trifluoromethylation of five and six-membered ring β-ketoesters.

In 2018, the first example for the copper-catalyzed stereospecific trifluoromethylation of secondary propargyl sulfonates was described by the group of Zhang [116]. The resulting chiral trifluoromethylated alkynes were acquired with high regioselectivity and stereospecificity (ees up to >99%). Furthermore, this reaction showed a broad substrate scope, as well as excellent functional-group compatibility (Scheme 57). A possible mechanism was proposed: firstly, trifluoromethylcopper complex A, generated from CuCN with TMSCF3, undergoes oxidative addition with a secondary propargyl sulfonate to give a configuration-inversed propargyl-Cu(III) species B. Then, the reductive elimination of B affords the final product with overall inversion of the configuration.

Scheme 57: Cu-catalyzed highly stereoselective trifluoromethylation of secondary propargyl sulfonates.

Scheme 57: Cu-catalyzed highly stereoselective trifluoromethylation of secondary propargyl sulfonates.

Recently, Li and co-workers [117] explored a simple and facile method to access δ-trifluoromethylated carboxamides and sulfonamides through a copper-catalyzed 1,5-hydrogen atom transfer (Scheme 58).

Scheme 58: Remote C(sp3)–H trifluoromethylation of carboxamides and sulfonamides.

Scheme 58: Remote C(sp3)–H trifluoromethylation of carboxamides and sulfonamides.

Other catalysts: In 2013, Gouverneur and co-workers [118] described a photoredox-based catalytic approach to afford enantioenriched branched allylic CF3 products from allylsilanes using [Ru(bpy)3]Cl2 (Scheme 59). Herein, the silyl group in the substrate plays an important role in controlling the regioselectivity of the trifluoromethylation reaction.

Scheme 59: Trifluoromethylation of allylsilanes with photoredox catalysis.

Scheme 59: Trifluoromethylation of allylsilanes with photoredox catalysis.

Later in 2017, Li’s group [119] described a practical protocol for the decarboxylative trifluoromethylation of various primary and secondary aliphatic carboxylic acids. With AgNO3 as a catalyst, (bpy)Cu(CF3)3 (bpy = 2,2’-bipyridine) as a CF3 source and K2S2O8 as an oxidant, aliphatic carboxylic acids were converted to the corresponding trifluoromethylated products in good yields (Scheme 60). Also, mechanistic studies, a radical clock experiment, revealed the intermediacy of −Cu(CF3)3Me, which undergoes reductive elimination and subsequent oxidation to give the active species Cu(CF3)2. Meanwhile, aliphatic carboxylic acids give the corresponding alkyl radicals via Ag(II)-mediated oxidative decarboxylation. Then, Cu(CF3)2 provides a CF3 group to alkyl radicals to obtain the final product.

Scheme 60: Ag-catalyzed decarboxylative trifluoromethylation of aliphatic carboxylic acids in aqueous CH3CN.

Scheme 60: Ag-catalyzed decarboxylative trifluoromethylation of aliphatic carboxylic acids in aqueous CH3CN.

Very recently, MacMillan et al. [120] discovered an efficient approach to the decarboxylative trifluoromethylation of aliphatic carboxylic acids via the combination of photoredox and copper catalysis (Scheme 61). The method tolerates a myriad of primary, secondary and tertiary carboxylic acids and provides the corresponding CF3 analogue in good to excellent yields. Details of the proposed dual copper–photoredox cycle are shown in Scheme 61. The Ir(III) photocatalyst Ir[dF(CF3)ppy]2(4,4’-dCF3bpy)PF6 (1) undergoes photoexcitation with visible light to form the highly oxidizing excited state ·Ir(III) 2. Then, SET from copper carboxylate 4, derived from carboxylic acid 3 with the Cu(II) catalyst to ·Ir(III) 2 provides Cu(III) carboxylate 5, or in the dissociated form, a carboxyl radical and Cu(II) complex 6, along with reduced Ir(II) photocatalyst 7. The resulting carboxyl radical extrudes CO2 and sequentially recombines to generate Cu(III) species 9. At this stage, SET from 7 to 9 closes the photoredox catalytic cycle and produces an alkylcopper(II) species 10. Under the addition of Togni’s reagent I (11), species 10 affords the final alkyl−CF3 product and complex 13, which is used for ligand exchange with 3.

Scheme 61: Decarboxylative trifluoromethylation of aliphatic carboxylic acids via combined photoredox and copper catalysis.

Scheme 61: Decarboxylative trifluoromethylation of aliphatic carboxylic acids via combined photoredox and copp...

C(sp2)–CF3 bond formation

Palladium-catalyzed trifluoromethylation of aryl and vinyl compounds: In 2010, Watson and co-workers [121] developed the first Pd-catalyzed trifluoromethylation of aryl/heterocyclic chlorides with the CF3 source TESCF3 (TES, triethylsilyl), which proceeded following a classical Pd(0)/Pd(II) catalytic cycle (Scheme 62). Also, the reaction tolerates a variety of functional groups, such as esters, amides, ethers, nitriles, etc., and therefore provides a new way for late-stage modifications.

Scheme 62: Palladium-catalyzed Ar–CF3 bond-forming reaction.

Scheme 62: Palladium-catalyzed Ar–CF3 bond-forming reaction.

In the same year, Yu’s group [122] reported a Pd(II)-catalyzed C–H trifluoromethylation of arenes with an electrophilic trifluoromethylation reagent using diverse heterocyclic directing groups. Notably, the presence of trifluoroacetic acid (TFA) is crucial for the Ar–CF3 bond formation and Cu(OAc)2 can increase the catalytic turnover (Scheme 63). Based on three different modes of the ArPd(II) species reaction with nucleophiles, electrophiles and highly oxidizing reagents, three possible reaction pathways (A, B and C, respectively) are envisaged, that can follow the C–H activation event to the trifluoromethylated products, as described in Scheme 63. In this case, the specific catalytic mechanism remains to be studied.

Scheme 63: Palladium-catalyzed trifluoromethylation of arenes with diverse heterocyclic directing groups.

Scheme 63: Palladium-catalyzed trifluoromethylation of arenes with diverse heterocyclic directing groups.

In 2011, the group of Liu [123] accomplished a Pd(II)-catalyzed oxidative trifluoromethylation of indoles with TMSCF3 and PhI(OAc)2 at room temperature (Scheme 64). Through reductive elimination from the (Ar)Pd(IV)-CF3 intermediate, the aryl C–CF3 bond is generated. Notably, the bidentate nitrogen-containing ligand is crucial to the achievement of this process.

Scheme 64: Pd-catalyzed trifluoromethylation of indoles as reported by Liu.

Scheme 64: Pd-catalyzed trifluoromethylation of indoles as reported by Liu.

In the same year, Buchwald et al. [124] discovered a palladium-catalyzed trifluoromethylation of vinyl triflates and nonaflates (Scheme 65). A variety of trifluoromethylated cyclohexenes were obtained using a catalyst system, which was composed of Pd(dba)2 or [(allyl)PdCl]2 and the monodentate biaryl phosphine ligand t-BuXPhos. Also, TMSCF3 and KF were more suitable to the trifluoromethylation of triflate electrophiles, while the use of TESCF3 and RbF gave better results for nonaflate electrophiles.

Scheme 65: Pd-catalyzed trifluoromethylation of vinyl triflates and vinyl nonaflates.

Scheme 65: Pd-catalyzed trifluoromethylation of vinyl triflates and vinyl nonaflates.

Subsequently, the Yu [15,125] and Shi group [126] independently reported the palladium-catalyzed ortho-trifluoromethylation of an aromatic C–H bond with Umemoto’s trifluoromethylation reagent. Notably, Cu(II) salts were crucial for forming the aryl–CF3 bonds. In Yu’s study, benzamides and benzylamines were well trifluoromethylated via a Pd(II)/Pd(IV) catalytic cycle with the addition of TFA (and Ag2O) (Scheme 66a). With an acetamido group as a directing group, Shi developed an efficient method to access ortho-CF3 acetanilides and anilines (Scheme 66b).

Scheme 66: Pd(II)-catalyzed ortho-trifluoromethylation of aromatic C–H bonds.

Scheme 66: Pd(II)-catalyzed ortho-trifluoromethylation of aromatic C–H bonds.

Recently, Wang and co-workers [127] reported a visible-light-induced Pd-catalyzed ortho-trifluoromethylation of acetanilides. Without the need of an external photocatalyst and additive, various N-substituted anilides and acetanilides were obtained efficiently at room temperature in air. The strategy features good yields, broad functional group tolerance and high regioselectivity (Scheme 67).

Scheme 67: Visible-light-induced Pd(OAc)2-catalyzed ortho-trifluoromethylation of acetanilides with CF3SO2Na.

Scheme 67: Visible-light-induced Pd(OAc)2-catalyzed ortho-trifluoromethylation of acetanilides with CF3SO2Na.

Copper-catalyzed trifluoromethylation of aryl- and alkenylboronic acids: In 2011, Liu and Shen [128] developed a CuI-catalyzed method for the trifluoromethylation of aryl- and alkenylboronic acids with Togni’s reagent (Scheme 68). A range of different substrates gave the corresponding trifluoromethylated (hetero)arenes in good to excellent yields.

Scheme 68: CuI-catalyzed trifluoromethylation of aryl- and alkenylboronic acids.

Scheme 68: CuI-catalyzed trifluoromethylation of aryl- and alkenylboronic acids.

Also, in 2012, Beller and co-workers [129] described a copper-catalyzed trifluoromethylation of aryl- and vinylboronic acids with the generation of CF3-radicals at room temperature. The mild reaction conditions allowed a wide variety of functional groups to be tolerated, though a large quantity of TBHP was required (Scheme 69). Notably, the authors proposed two mechanistic pathways for this trifluoromethylation reaction. The difference between path A and path B is that the sequence of CF3 radicals and aryl- and vinylboronic acids is reversed. In addition, the CF3 radical is generated from the reaction of TBHP with NaSO2CF3.

Scheme 69: Cu-catalyzed trifluoromethylation of aryl- and vinylboronic acids.

Scheme 69: Cu-catalyzed trifluoromethylation of aryl- and vinylboronic acids.

Copper-catalyzed trifluoromethylation of alkenes: The method described by Hu [130] was applied to the trifluoromethylation of a wide range of α,β-unsaturated carboxylic acids through CuF2-catalyzed decarboxylative fluoroalkylation with high yields and excellent E/Z ratio (Scheme 70).

Scheme 70: Copper-catalyzed trifluoromethylation of α,β-unsaturated carboxylic acids.

Scheme 70: Copper-catalyzed trifluoromethylation of α,β-unsaturated carboxylic acids.

Additionally, a copper(I)-catalyzed trifluoromethylation of alkenes was disclosed by Sodeoka and co-workers in 2012 [131]. The reaction was carried out with Togni’s reagent as the CF3 source and TsOH as a Brønsted acid in CH2Cl2 at 40 °C (Scheme 71). Notably, trifluoromethylstyrenes were formed through further transformations of the oxytrifluoromethylated products with high efficiency.

Scheme 71: Formation of C(sp2)–CF3 bond catalyzed by copper(I) complex.

Scheme 71: Formation of C(sp2)–CF3 bond catalyzed by copper(I) complex.

In the same year, Loh’s group [132] used the same copper catalyst and Togni’s reagent to achieve the trifluoromethylation of enamides in good yields at room temperature (Scheme 72a). Meanwhile, this reaction exhibited excellent stereoselectivity towards the E-isomer. One year later, the same group [133] extended this approach to the directing-group-assisted copper-catalyzed trifluoromethylation of electron-deficient alkenes (Scheme 72b). Moreover, α-aryl and α-alkyl-substituted acrylate derivatives could be used as substrates to form the C(sp2)–CF3 bond with a complete Z-selectivity. A radical species participated in the reaction’s catalytic cycle.

Scheme 72: Loh’s Cu(I)-catalyzed trifluoromethylation of enamides and electron-deficient alkenes.

Scheme 72: Loh’s Cu(I)-catalyzed trifluoromethylation of enamides and electron-deficient alkenes.

In 2013, the group of Liu [134] described a copper-catalyzed decarboxylative trifluoromethylation of α,β-unsaturated carboxylic acids with CF3SO2Na. This method was applied to a wide range of α,β-unsaturated carboxylic acids. Meanwhile, a similar radical process for the difluoromethylation of aryl-substituted acrylic acids was also achieved by Liu and co-workers. The HCF2-substituted E-alkenes were finally obtained with iron catalysis and zinc difluoromethanesulfinate ((CF2HSO2)2Zn, Baran reagent). Also, the authors proved that the formation of the Cvinyl–CF3/Cvinyl–CF2H bonds followed a radical addition–elimination process (Scheme 73).

Scheme 73: Copper and iron-catalyzed decarboxylative tri- and difluoromethylation.

Scheme 73: Copper and iron-catalyzed decarboxylative tri- and difluoromethylation.

Subsequently, Bouyssi and co-workers [135-137] used Togni’s reagent to conduct the trifluoromethylation of (hetero)aromatic aldehydes or corresponding N,N-dialkylhydrazones with CuCl as the catalyst at room temperature (Scheme 74). These reactions showed a broad substrate scope and good functional group compatibility with up to 99% yield.

Scheme 74: Cu-catalyzed trifluoromethylation of hydrazones developed by Bouyssi.

Scheme 74: Cu-catalyzed trifluoromethylation of hydrazones developed by Bouyssi.

In 2013, a simple and effective copper-catalyzed approach for the construction of Cvinyl–CF3 bonds without using pre-functionalized substrates was reported by Xiao et al. (Scheme 75) [138]. The process proceeded smoothly to give the trifluoromethylated alkenes in good to excellent yields via a radical mechanism.

Scheme 75: Cu(I)-catalyzed trifluoromethylation of terminal alkenes.

Scheme 75: Cu(I)-catalyzed trifluoromethylation of terminal alkenes.

Additionally, Duan and co-workers [139] discovered a copper/silver-catalyzed decarboxylative trifluoromethylation of α,β-unsaturated carboxylic acids with CF3SO2Na. This reaction proceeded efficiently for a wide range of alkyl and aryl-substituted α,β-unsaturated carboxylic acids derivatives with excellent E/Z selectivity (Scheme 76). It's worth mentioning that the addition of Ag2CO3 additives was crucial for promoting the decarboxylation of α,β-unsaturated carboxylic acids.

Scheme 76: Cu/Ag-catalyzed decarboxylative trifluoromethylation of cinnamic acids.

Scheme 76: Cu/Ag-catalyzed decarboxylative trifluoromethylation of cinnamic acids.

In 2014, a Cu(I/II)-catalyzed α-trifluoromethylation of α,β-unsaturated carbonyl compounds were unfolded by the Bi group (Scheme 77) [140]. The reaction was applied to a broad range of carbonyl compounds, including enones, α,β-unsaturated esters, thioesters, and amides. Notably, the authors obtained products with stable E-configuration through a SET process.

Scheme 77: Copper-catalyzed direct alkenyl C–H trifluoromethylation.

Scheme 77: Copper-catalyzed direct alkenyl C–H trifluoromethylation.

In 2017, Loh and co-workers [141] introduced a Cu(I/II)-catalyzed Cvinyl–H trifluoromethylation of a variety of styrene derivatives. This process was achieved by using 1-methylimidazole (NMI) as ligand and tetrabutylammonium iodide (TBAI) as an additive (Scheme 78). Mechanistic studies revealed that this reaction probably proceeds through a radical pathway.

Scheme 78: Copper(I/II)-catalyzed direct trifluoromethylation of styrene derivatives.

Scheme 78: Copper(I/II)-catalyzed direct trifluoromethylation of styrene derivatives.

Copper-catalyzed trifluoromethylation of arenes and heteroarenes: In 2013, Xi et al. [142] reported a CuCl-catalyzed direct trifluoromethylation of sp2 C–H bonds with Togni reagent (Scheme 79). Also, phenyl, thiophene, and pyridine derivatives achieved regioselectively trifluoromethylation with N-pivalamide as a directing group. The authors also proposed a possible radical pathway for this reaction. The final trifluoromethylated compounds were generated from pivalamido arenes and heteroarenes with the CF3 radical through a Cu(I/II) catalytic cycle.

Scheme 79: Regioselective trifluoromethylation of pivalamido arenes and heteroarenes.

Scheme 79: Regioselective trifluoromethylation of pivalamido arenes and heteroarenes.

In 2013, the Szabó [143] and Wang group [144] described the copper-mediated C–H trifluoromethylation of quinones with Togni’s reagent. Szabó utilized a stoichiometric amount of CuCN combined with catalytic bis(pinacolato)diboron, whereas Wang applied a stoichiometric amount of CuI. Notably, both groups proved a mechanism involving the formation of a CF3 radical with copper(I) acting as a one-electron reducing agent (Scheme 80).

Scheme 80: Synthesis of trifluoromethylquinones in the presence of copper(I).

Scheme 80: Synthesis of trifluoromethylquinones in the presence of copper(I).

With catalytic cupric acetate and TBHP, the group of Tang [145] developed a green strategy for the trifluoromethylation of imidazoheterocycles with a recyclable mixed medium of 1-butyl-3-methylimidazolium tetrafluoroborate ([Bmim]BF4) and water (Scheme 81). By following this method, diverse trifluoromethylated imidazoheterocycles were obtained in up to 80% yield. The method features a green and recyclable solvent, mild reaction conditions (room temperature) and excellent functional group tolerance. In this instance, the copper catalyst may only promote the generation of the tert-butoxyl radical from TBHP. The oxidation of the intermediate A with t-BuOOH produces a carbocation B, followed by an oxidative dehydrogenation process to afford the target product.

Scheme 81: Oxidative trifluoromethylation of imidazoheterocycles in ionic liquid/water.

Scheme 81: Oxidative trifluoromethylation of imidazoheterocycles in ionic liquid/water.

Also in 2015, Li and co-workers [146] developed a mild and fast Cu(I/II)-catalyzed trifluoromethylation procedure to obtain 3-trifluoromethylcoumarins. The reaction was carried out with a CuCl/CF3SO2Na/TBHP system under continuous-flow conditions, affording the corresponding products with wide substrate tolerance in moderate to good yields (Scheme 82).

Scheme 82: A mild and fast continuous-flow trifluoromethylation of coumarins using a CuI/CF3SO2Na/TBHP system.

Scheme 82: A mild and fast continuous-flow trifluoromethylation of coumarins using a CuI/CF3SO2Na/TBHP system.

After one year, the group of Cai [147] presented a Cu(II)-catalyzed 8-amido chelation-induced regioselective C5-trifluoromethylation of quinolines (Scheme 83a). With CuBr2 as a catalyst and azobisisobutyronitrile (AIBN) as an oxidant, a wide range of functional groups were well tolerated to provide the products in moderate to excellent yields. Simultaneously, Zhang and co-workers [148] described a similar, milder regioselective C–H trifluoromethylation of 8-aminoquinolines by using a chitosan-based heterogeneous copper catalyst (CS@Cu(OAc)2, CS = chitosan) (Scheme 83b).

Scheme 83: Copper-catalyzed oxidative trifluoromethylation of various 8-aminoquinolines.

Scheme 83: Copper-catalyzed oxidative trifluoromethylation of various 8-aminoquinolines.

Recently, a picolinamide (PA)-directed method for the Cu-catalyzed trifluoromethylation of anilines was described by the group of Zhang [149]. The trifluoromethyl group was installed at the ortho position of the substrate, yielding 2-(trifluoromethyl)aniline derivatives in moderate to good yields (Scheme 84). Notably, the directing group could be recovered in excellent yields and this approach provided a new way for the efficient synthesis of floctafenine via a single-electron-transfer mechanism.

Scheme 84: PA-directed copper-catalyzed trifluoromethylation of anilines.

Scheme 84: PA-directed copper-catalyzed trifluoromethylation of anilines.

Vinyl C–CF3 bond formation using Fe, Ir, Ru, and Ag catalysts: In 2012, Buchwald and co-workers [150] unfolded an iron(II)-catalyzed trifluoromethylation of potassium vinyltrifluoroborates at room temperature (Scheme 85). With this approach, 2-arylvinyl substrates, in particular, furnished the products in good yields and excellent E/Z ratios (E/Z > 95.5%).

Scheme 85: Trifluoromethylation of potassium vinyltrifluoroborates catalyzed by Fe(II).

Scheme 85: Trifluoromethylation of potassium vinyltrifluoroborates catalyzed by Fe(II).

Also, Cho and co-workers [151] reported a direct method for an alkenyl trifluoromethylation employing a Ru photocatalyst. The method used CF3I as a CF3 radical source and 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) as the base (Scheme 86). Under these mild reaction conditions, the trifluoromethylation of a wide range of alkenes shows high functional-group tolerance with a low catalyst loading. Moreover, compared with other alkenes, this process works especially well for terminal alkenes.

Scheme 86: Alkenyl trifluoromethylation catalyzed by Ru(phen)3Cl2 as photocatalyst.

Scheme 86: Alkenyl trifluoromethylation catalyzed by Ru(phen)3Cl2 as photocatalyst.

In 2013, Akita’s group [152] developed a radical-mediated trifluoromethylation of vinyltrifluoroborates promoted by the photoredox catalyst [Ru(bpy)3](PF6)2 under visible light irradiation (Scheme 87a). The trifluoromethylated alkenes were obtained in up to 95% yield. One year later, the same group [153] presented a procedure for trifluoromethylation of multisubstituted alkenes with a different CF3 source, Umemoto’s reagent (Scheme 87b). Additionally, this reaction could be extended to double trifluoromethylation.

Scheme 87: Ru-catalyzed trifluoromethylation of alkenes by Akita’s group.

Scheme 87: Ru-catalyzed trifluoromethylation of alkenes by Akita’s group.

In 2014, a visible-light-induced decarboxylative trifluoromethylation of α,β-unsaturated carboxylic acids by using [Ir(ppy)3] as a photoredox catalyst was explored by Zhu and co-workers (Scheme 88) [154]. Notably, this procedure employed only 1 mol % catalyst loading to achieve an excellent reactivity and E/Z stereoselectivity at room temperature.

Scheme 88: Ir-catalyzed Cvinyl–CF3 bond formation of α,β-unsaturated carboxylic acids.

Scheme 88: Ir-catalyzed Cvinyl–CF3 bond formation of α,β-unsaturated carboxylic acids.

In 2016, Duan and co-workers [155] disclosed a Ag(I)-catalyzed denitration/trifluoromethylation of β-nitrostyrenes with CF3SO2Na, which employed a large excess of di-tert-butyl peroxide (DTBP) as the oxidant and tetrabutylammonium iodide (TBAI) as phase-transfer catalyst (Scheme 89). Notably, only (E)-isomers of the products were obtained in moderate to high yields.

Scheme 89: Ag(I)-catalyzed denitrative trifluoromethylation of β-nitrostyrenes.

Scheme 89: Ag(I)-catalyzed denitrative trifluoromethylation of β-nitrostyrenes.

Various transition-metal-catalyzed direct C–H bond trifluoromethylation of arenes and heteroarenes: In 2011, the group of MacMillan [156] reported a simple approach for the direct trifluoromethylation of unactivated arenes and heteroarenes through a radical-mediated mechanism (Scheme 90). Under exposure to 26 W fluorescent light, this process proceeded well in the presence of triflyl chloride and different photocatalysts depending on the substrate’s nature, i.e., Ru(phen)3Cl2 for 5-membered heterocycles, Ir(Fppy)3 for 6-membered arenes and heterocycles. It is worth mentioning, that triflyl chloride provides a cheap and easy to handle CF3 source.

Scheme 90: Photocatalyzed direct trifluoromethylation of aryl and heteroaryl C–H bonds.

Scheme 90: Photocatalyzed direct trifluoromethylation of aryl and heteroaryl C–H bonds.

A mild and simple electrophilic trifluoromethylation of various aromatic and heteroaromatic compounds was disclosed by the Togni group [157] in 2012. The authors used methyltrioxorhenium (MTO) as the catalyst (Scheme 91). Notably, the direct aromatic trifluoromethylation tolerates a broad substrate scope, however, is limited to electron-rich substrates.

Scheme 91: Rhenium (MTO)-catalyzed direct trifluoromethylation of aromatic substrates.

Scheme 91: Rhenium (MTO)-catalyzed direct trifluoromethylation of aromatic substrates.

In 2014, Ma et al. [158] developed the first visible-light-promoted radical trifluoromethylation of unprotected anilines. With [Ir(ppy)3] and Togni’s reagent, the method afforded various fluorine-containing molecules and heterocyclic compounds at room temperature (Scheme 92).

Scheme 92: Trifluoromethylation of unprotected anilines under [Ir(ppy)3] catalyst.

Scheme 92: Trifluoromethylation of unprotected anilines under [Ir(ppy)3] catalyst.

In 2015, the group of Hajra [159] described a method for the direct trifluoromethylation of imidazopyridines and other imidazoheterocycles. The CF3SO2Na/t-BuOOH/Ag system enables accomplishing the reaction at room temperature under ambient air (Scheme 93).

Scheme 93: Oxidative trifluoromethylation of imidazopyridines and imidazoheterocycles.

Scheme 93: Oxidative trifluoromethylation of imidazopyridines and imidazoheterocycles.

A direct trifluoromethylation of (hetero)arenes in the presence of only 0.1 mol % [Ru(bpy)3]Cl2 as catalyst was reported by the Stephenson group in 2016 [160]. Notably, the authors utilized pyridine N-oxide derivatives in concert with trifluoroacetic anhydride to facilitate this process (Scheme 94). Moreover, the method has been successfully extended on a kilogram scale.

Scheme 94: Ruthenium-catalyzed trifluoromethylation of (hetero)arenes with trifluoroacetic anhydride.

Scheme 94: Ruthenium-catalyzed trifluoromethylation of (hetero)arenes with trifluoroacetic anhydride.

One year later Mizuno’s group [161] introduced a direct C–H trifluoromethylation of (hetero)arenes with O2 as the terminal oxidant in the presence of catalytic amounts of phosphovanadomolybdic acids (Scheme 95). The reaction tolerated diverse (hetero)arenes to afford the corresponding trifluoromethylated products via a radical pathway in 26–92% yields.

Scheme 95: Phosphovanadomolybdic acid-catalyzed direct C–H trifluoromethylation.

Scheme 95: Phosphovanadomolybdic acid-catalyzed direct C–H trifluoromethylation.

In 2017, Zhang and co-workers [162] were the first who reported a nickel(II)-catalyzed and picolinamide-assisted site-selective C–H bond trifluoromethylation of arylamines in water (Scheme 96a). This strategy displays several advantages: 1) inexpensive nickel catalyst, 2) recyclable catalyst, 3) aqueous phase reaction, and 4) high site selectivity. Only one year later, the group of Xia optimized this approach and established a convenient, oxidant-free protocol for the ortho-trifluoromethylation of arylamine under ultraviolet irradiation (Scheme 96b) [163].

Scheme 96: Picolinamide-assisted ortho-trifluoromethylation of arylamines.

Scheme 96: Picolinamide-assisted ortho-trifluoromethylation of arylamines.

In 2018, Wu and co-workers [164] introduced a one-step strategy for the synthesis of trifluoromethylated free anilines using Togni’s reagent using a nickel-catalyzed C–H trifluoromethylation. Moreover, free anilines with a variety of functional groups were trifluoromethylated under the mild reaction conditions in up to 90% yield (Scheme 97).

Scheme 97: A nickel-catalyzed C–H trifluoromethylation of free anilines.

Scheme 97: A nickel-catalyzed C–H trifluoromethylation of free anilines.

C(sp)–CF3 bond formation

In 2010, Qing’s group [165] reported the first example of a copper-mediated trifluoromethylation of terminal alkynes. Notably, the reaction was carried out with nucleophilic (trifluoromethyl)trimethylsilane (Me3SiCF3) as a CF3 source under air atmosphere (Scheme 98a). Moreover, this protocol was compatible with various terminal alkynes, such as aromatic and aliphatic alkynes, affording the trifluoromethylated alkynes in 47–91% yields. Subsequently, Qing [166] developed an efficient catalytic trifluoromethylation by adding terminal alkynes and Me3SiCF3 slowly with a syringe pump. Two years later, the same group [167] presented an improved Cu-mediated oxidative trifluoromethylation of aryl and heteroaryl terminal alkynes. In the latter case, the trifluoromethylation proceeded at room temperature by using Ag2CO3 as an oxidant with a significantly lower amount of TMSCF3 (Scheme 98b).

Scheme 98: Cu-mediated trifluoromethylation of terminal alkynes reported by Qing.

Scheme 98: Cu-mediated trifluoromethylation of terminal alkynes reported by Qing.

In 2012, Huang et al. [168] reported a process for trifluoromethylation of terminal alkynes with Togni’s reagent in DCM at room temperature (Scheme 99a). The trifluoromethylated acetylenes were obtained with up to 98% yield via a Cu(I/III) catalytic cycle with CF3+. As an extension of their work, this group [169] developed the trifluoromethylation of alkynyltrifluoroborates to form trifluoromethylated acetylenes under similar conditions without the addition of bases (Scheme 99b).

Scheme 99: Huang’s C(sp)–H trifluoromethylation using Togni’s reagent.

Scheme 99: Huang’s C(sp)–H trifluoromethylation using Togni’s reagent.

In the same year, the groups of Guo [170] and Xiao [171] also developed a copper(I)-catalyzed trifluoromethylation of terminal alkynes with Umemoto’s reagent as an electrophilic CF3 source (Scheme 100a). Compared with the reaction conditions reported by Guo, Xiao’s method was carried out at higher temperature, using similar copper(I) catalysts, but with different ligands (Scheme 100b).

Scheme 100: Cu-catalyzed methods for trifluoromethylation with Umemoto’s reagent.

Scheme 100: Cu-catalyzed methods for trifluoromethylation with Umemoto’s reagent.

In 2014, the trifluoromethylation of aromatic alkynes through visible-light photoredox catalysis was described by Cho and co-workers [172]. With fac-[Ir(ppy)3] as photocatalyst and KOt-Bu as a base, the reaction was achieved under blue LED irradiation in moderate yields (Scheme 101). However, this approach was not suitable for aliphatic alkynes.

Scheme 101: The synthesis of alkynyl-CF3 compounds in the presence of fac-[Ir(ppy)3] under visible-light irradiation.

Scheme 101: The synthesis of alkynyl-CF3 compounds in the presence of fac-[Ir(ppy)3] under visible-light irradi...

Compared with the trifluoromethylation and fluorination mentioned above, the methodological research on difluoromethylation, trifluoromethylthiolation and trifluoromethoxylation of organic molecules are quite rare and scattered. Here we summarize the new developments within recent years.

Difluoromethylation

The introduction of a difluoromethylene (CF2) group into organic molecules can significantly improve their metabolic stability and oral bioavailability [3]. Therefore, the difluoroalkylation has become a powerful strategy for regulating the biological activity of organic molecules. It is noteworthy that transition-metal-catalyzed difluoroalkylation is an effective route to obtain these valuable difluoroalkylated backbones. There are four modes of catalytic difluoroalkylation, including nucleophilic difluoroalkylation, electrophilic difluoroalkylation, radical difluoroalkylation, and metal-difluorocarbene coupling (MeDiC) [173]. Finally, a wide range of difluoroalkylated (hetero)arenes [(Het)Ar-CF2R, R = PO(OEt)2, CO2Et, CONR1R2, COR1, (Het)Ar, alkenyl, alkynyl, alkyl, H] and alkenes were obtained with excellent functional group tolerance.

In 2012, the Reutrakul group [174] firstly reported a Pd-catalyzed Heck-type reaction of [(bromodifluoromethyl)sulfonyl]benzene with styrene derivatives (Scheme 102). Notably, the reaction shows a broad substrate scope, including a variety of styrene derivatives, vinyl ethers, vinyl sulfides, and a few heteroaromatic substrates.

Scheme 102: Pd-catalyzed Heck reaction reported by Reutrakul.

Scheme 102: Pd-catalyzed Heck reaction reported by Reutrakul.

In the same year, Yu and co-workers [175] developed an iridium-catalyzed direct C–H functionalization of enamides and ene-carbamates with BrCF2CO2Et under visible-light photoredox conditions (Scheme 103). This method shows excellent yields and a wide substrate scope.

Scheme 103: Difluoromethylation of enamides and ene-carbamates.

Scheme 103: Difluoromethylation of enamides and ene-carbamates.