Abstract

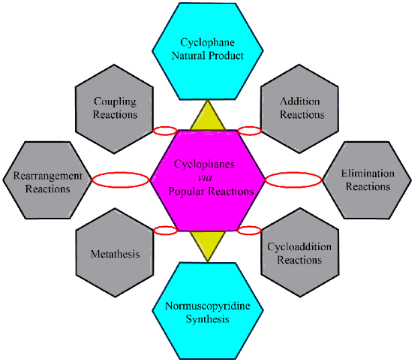

In this review we cover various approaches to meta- and paracyclophanes involving popular reactions. Generally, we have included a strategy where the reaction was used for assembling the cyclophane skeleton for further functionalization. In several instances, after the cyclophane is made several popular reactions are used and these are not covered here. We included various natural products related to cyclophanes. To keep the length of the review at a manageable level the literature related to orthocyclophanes was not included.

Graphical Abstract

Indroduction

Cyclophanes [1-38] are strained organic molecules which contain aromatic ring(s) as well as aliphatic unit(s). The aromatic rings provide rigidity to their structure, whereas the aliphatic unit(s) form bridge(s) between the aromatic rings and also provide flexibility to the overall structure. Cyclophanes play an important role in “host–guest” chemistry [39-43] and supramolecular assembly [44-47]. “Phane”-containing molecules show interactions with π-systems, and they can also bind to a large number of cations, anions, and neutral molecules. Cyclophanes are widely used in materials science and molecular recognition processes [48-52]. A general classification of cyclophanes is as follows: [n]orthocyclophane, [n]metacyclophane, and [n]paracyclophane (1–3) (Figure 1). The prefixes represent the position of the attachment to an aromatic system while [n] represents the number of methylene groups present in the aliphatic bridge. The orthocyclophanes are also known as benzocycloalkanes. Several cyclophanes consisting of two or more aromatic systems and aliphatic bridges have been reported in the literature [53]. The representative [2,2]ortho-, meta-, and paracyclophanes (4–6) are shown in Figure 1. In general, cyclophanes with one aromatic ring and two alkyl bridges are called [n,n]metapara or [n,n]paraparacyclophanes (7, 8) based on the position of the attachment of the alkyl chain to the aromatic system. In this review we are not discussing orthocyclophanes but rather focus on meta- and paracyclophanes only.

Figure 1: General representation of cyclophanes.

Figure 1: General representation of cyclophanes.

The aromatic ring present in the cyclophane system can be either heterocyclic or carbocylic in nature. If there is a heteroatom present in the aromatic ring system then the system is called a heterophane (9) [54-56], whereas if the heteroatom is present in the alkyl chain of the bridge, then it is called a heteraphane (10) [57-60]. Alternatively, if the heteroatom is present in both the aromatic ring and the alkyl chain, it is called a hetero-heteraphane (11, Figure 2).

Figure 2: cyclophanes one or more with heteroatom.

Figure 2: cyclophanes one or more with heteroatom.

A number of cyclophane derivatives have been employed as hosts, and their guest-binding properties have been widely investigated. A variety of reviews related to the cyclophane chemistry has been published. Although monomeric cyclophanes show moderate guest-binding abilities, an improved affinity can be achieved by polytopic hosts [61-63] through multivalency effects in macrocycles. Olefin metathesis has played a key role in the development of cyclophane chemistry. Some of the catalysts used for this purpose are listed in Figure 3. The development of new synthetic methods in this area is considered a useful exercise. To this end, name reactions or popular reactions, and rearrangement reactions are widely used. In connection with the synthesis of cyclophanes, we describe the employment of these reactions for C–C or C–heteroatom-bond formation. The first part of this review focuses on the syntheses of various cyclophanes related to natural products and the subsequent sections describe the use of various popular reactions in cyclophane synthesis.

Figure 3: Metathesis catalysts 12–17 and C–C coupling catalyst 18.

Figure 3: Metathesis catalysts 12–17 and C–C coupling catalyst 18.

Natural products containing a cyclophane skeleton

The cyclophane skeleton is a core structural unit in many biologically active natural products such as macrocidin A (19) and B (20) [64], nostocyclyne A (21) [65], and in the turriane family of natural products 22–24 [66]. Cyclophanes are also applied in research areas such as pharmaceuticals [67,68], catalysis [69,70] and supramolecular chemistry [71].

Figure 4: Natural products containing the cyclophane skeleton.

Figure 4: Natural products containing the cyclophane skeleton.

Macrocidin A (19) and macrocidin B (20) [64] belong to a family of plant pathogens produced by Phoma macrostoma, a microorganism parasitic to Canadian thistle. Macrocidins contain a tetramic acid group in their skeleton and show selective herbicidal activity on broadleaf weeds but do not affect grasses. Nostocyclyne A (21) is an acetylenic cyclophane derivative isolated from a terrestrial Nostoc species, with antimicrobial activity (Figure 4). The turriane family of natural products 22–24 were isolated from the stem wood of the Australian tree Grevillea striata. Turrianes 22–24 are effective DNA-cleaving agents in the presence of Cu(II). Fürstner and co-workers [72] have reported the total synthesis of natural products 22–24 by using a metathesis reaction [73-82] as the key step. The ring-closing metathesis (RCM) has been utilized for the synthesis of the turriane with a saturated alkyl chain (22), whereas the unsaturated turrianes 23, 24 containing a (Z)-alkene moiety have been prepared by alkyne metathesis followed by reduction using Lindlar’s catalyst (Figure 5).

Figure 5: Turriane family of natural products.

Figure 5: Turriane family of natural products.

Muscopyridine and its analogues

Musk is a widly used component in Chinese pharmaceuticals and it has also been used in perfume industry. Muscopyridine was first isolated by a Swiss group [83] from the musk deer (Moschus moschiferus). Muscopyridine and its synthetical analogue normuscopyridine are heterophanes, more precisely metapyridinophanes. There are various routes to these compounds and related compounds which are discussed in detail in this review.

Review

Synthetic routes to cyclophanes

Addition reactions

Mannich reaction: In 2001, Erker and co-workers [84] have reported the synthesis of amino-substituted [3]ferrocenophane through an intramolecular Mannich reaction starting with the ferrocene framework. In the first step, the unsaturated amino-functionalized [3]ferrocenophane 28 was synthesized from 1,1’-diacetylferrocene (25) in the presence of an excess amount of dimethylamine and a stoichiometric amount of a Lewis acid such as TiCl4. These conditions lead to the generation of the bisenamine 26, which was subsequently converted to the cyclophane 28 by a Mannich-type condensation reaction (40%) (Scheme 1).

Scheme 1: Synthesis of [3]ferrocenophanes through Mannich reaction. Reagents and conditions: (i) excess HNMe2; (ii) TiCl4, C5H12, −78 °C, 20 min, 40%.

Scheme 1: Synthesis of [3]ferrocenophanes through Mannich reaction. Reagents and conditions: (i) excess HNMe2...

Michael addition: In 1999, Reißig and co-workers [85] have synthesized a functionalized cyclophane by a cascade reaction, which proceeds with desilylation, ring opening, proton transfer, and finally, an intramolecular Michael addition to provide benzannulated large ring compounds 31 and 33. In this regard, substituted methyl 2-alkenyl-2-siloxycyclopropanecarboxylate 29 was converted into the alkylation product and further react with the ester enolate dibromide to yield vinyl cyclopropane derivatives 30 (62%) and 32 (44%). Later, Michael addition in the presence of caesium fluoride and benzyltriethylammonium chloride in DMF gave the benzannulated cyclodecanone derivatives 31 (11%) and 33 (10%) (Scheme 2).

Scheme 2: Synthesis of cyclophanes through Michael addition. Reagents and conditions: (i) xylylene dibromide, LDA, −70 °C, 18 h; (ii) NaH, CH2(CO2Me)2; (iii) CsF, BnEt3N+Cl−, DMF, 90 °C, 3 h.

Scheme 2: Synthesis of cyclophanes through Michael addition. Reagents and conditions: (i) xylylene dibromide,...

Oxymercuration – Hantzsch pyridine synthesis: Kondo and Miyake [86] have reported the synthesis of [11](2,6)-pyridinophane (37), a normuscopyridine analogue, by an oxymercuration–oxidation strategy. The ketoolefin 34 was converted to the hydroxyketone 35 by treatment with Hg(OAc)2 and NaSH. Oxidation of the keto alcohol 35 gave diketone 36, which reacted with hydroxylamine hydrochloride and afforded [11](2,6)-pyridinophane (37) (Scheme 3).

Scheme 3: Synthesis of normuscopyridine analogue 37 through an oxymercuration–oxidation strategy. Reagents and conditions: (i) Hg(OAc)2, NaSH; (ii) oxidation; (iii) NH2OH·HCl.

Scheme 3: Synthesis of normuscopyridine analogue 37 through an oxymercuration–oxidation strategy. Reagents an...

Coupling reactions

Castro–Stephens coupling: Youngs and co-workers [87] have synthesized p-methoxy-substituted tribenzocyclotriyne 39 using the Castro–Stephens coupling reaction (Scheme 4). Compound 39 is a planar antiaromatic dehydroannulene that forms complexes with Ni(0), Cu(I), Co(0) and also with Ag+ cations.

Scheme 4: Synthesis of tribenzocyclotriyne 39 through Castro–Stephens coupling reaction. Reagents and conditions: (i) CuCl/ NH4OH/EtOH, pyridine, reflux, 24 h, 80%.

Scheme 4: Synthesis of tribenzocyclotriyne 39 through Castro–Stephens coupling reaction. Reagents and conditi...

Glaser–Eglinton coupling: Whitlock and Cloninger [88] have reported the synthesis of cyclophane 43 using the Glaser–Eginton coupling reaction. In this regard, compound 40 was treated with 9,10-bis(chloromethyl)anthracene (41) under basic conditions to generate compound 42 which was further subjected to a Glaser–Eglinton coupling to deliver cyclophane 43 (Scheme 5). A derivative of compound 43 was used as a host for compounds such as 6-nitro-2-naphthol, stilbene derivatives and serotonin mimics. This paper depicts the edge–face interaction between the face of the anthracene bridge present in the cyclophane molecule and the edge of the host molecule.

Scheme 5: Synthesis of cyclophane 43 through Glaser–Eglinton coupling. Reagents and conditions: (i) 9,10-bis(chloromethyl)anthracene (41), Cs2CO3; (ii) Cu(OAc)2·H2O, CH3CN/pyridine.

Scheme 5: Synthesis of cyclophane 43 through Glaser–Eglinton coupling. Reagents and conditions: (i) 9,10-bis(...

Bukownik and Wilcox [89] have synthesized macrocyclic C-glycosyl compounds, and obtained the chiral and water-soluble cyclophane 46. They reported on the use of its sulfonamide derivative in preparing glycophane molecule (Scheme 6).

Scheme 6: Synthesis of the macrocyclic C-glycosyl cyclophane through Glaser coupling. Reagents and conditions: (i) Cu(OAc)2 (10 equiv), pyridine, reflux, 5 h, 54%.

Scheme 6: Synthesis of the macrocyclic C-glycosyl cyclophane through Glaser coupling. Reagents and conditions...

Haley and Langsdorf [90] have reported the synthesis of a cyclophane-containing octacobalt complex 49 using the Glaser–Eglinton coupling reaction [91] as a key step (Scheme 7). In this regard, palladium-catalyzed alkynylation of 1,4-diiodobenzene with an excess amount of triisopropylsilylbutadiyne (47) followed by complexation with Co2(CO)8 furnished a pale yellow diyne 48. Exchange of the ligand with bis(diphenylphosphino)methane (dppm) afforded a bridged complex which is stable to fluoride ions. Subsequent desilylation, followed by Glaser–Eglinton coupling of the terminal acetylene groups provided complex 49 in 47% yield as fine, deep maroon crystals.

Scheme 7: Synthesis of cyclophane-containing complex 49 through Glaser–Eglinton coupling reaction. Reagents and conditions: (i) 1,4-diiodobenzene, Pd(PPh3)2Cl2, CuI, Et3N, 25 °C, 24 h, 73%; (ii) Co2(CO)8, Et2O, reflux, 6 h, 66%; (iii) dppm, PhMe, 85%; (iv) Bu4NF, THF, >95%; (v) Cu(OAc)2·H2O, pyridine, reflux, 12 h, 47%.

Scheme 7: Synthesis of cyclophane-containing complex 49 through Glaser–Eglinton coupling reaction. Reagents a...

In connection with the cyclophane synthesis, Kotha and Waghule [92] demonstrated the use of the Glaser–Eglinton coupling as a key step. The dipropargylated compound 51 was subjected to a Glaser–Eglinton coupling to generate the macrocyclic bisacetylene derivative 52 in 94% yield. Finally, diyne 52 was subjected to a hydrogenation sequence with 10% Pd/C under 1 atm pressure of H2 to generate cyclophane derivative 53 (92%). Alternatively, cyclophane 53 was also obtained by treatment of the bisphenol derivative 50 with 1,6-dibromohexane in the presence of K2CO3 in acetonitrile under reflux conditions (56%, Scheme 8).

Scheme 8: Synthesis of cyclophane 53 through Glaser–Eglinton coupling. Reagents and conditions: (i) K2CO3, acetone, reflux, 12 h, 86%; (ii) Cu(OAc)2·H2O, pyridine, CH3CN, 60 °C, 2 h, 94%; (iii) H2, Pd/C, EtOAc, 12 h, rt, 92%; (iv) 1,6-dibromohexane, K2CO3, reflux, CH3CN, 56%.

Scheme 8: Synthesis of cyclophane 53 through Glaser–Eglinton coupling. Reagents and conditions: (i) K2CO3, ac...

Another interesting example of a Glaser–Eglinton coupling reaction reported by Rajakumar and Visalakshi [93] is the synthesis of cyclophane 54. Whitlock and co-workers have synthesized donut-shaped cyclophanes 55 and 56 by using the Glaser–Eglinton coupling as a key step (Figure 6) [94].

Figure 6: Cyclophanes 54–56 that have been synthesized through Glaser–Eglinton coupling.

Figure 6: Cyclophanes 54–56 that have been synthesized through Glaser–Eglinton coupling.

Morisaki and co-workers [95] have synthesized 4,7,12,15-tetrasubstituted [2.2]paracyclophane 57 and further studies were carried out to find out the properties of these macrocycles. These molecules show excellent chiroptical properties such as high fluorescence quantum efficiency and a large circularly polarized luminescence dissymmetry factor. Cyclophanes are carbon-rich materials containing extensive alkyne moieties with a persistent molecular architecture. Orita and co-workers have reported the synthesis of chiral cyclophyne 58 through the Eglinton coupling reaction [95]. A tandem inter- and intramolecular Eglinton coupling reaction affords the enantiopure three-dimensional cyclophyne 58 with a large cavity size (Figure 7).

Figure 7: Synthesis of tetrasubstituted [2.2]paracyclophane 57 and chiral cyclophyne 58 through Eglinton coupling.

Figure 7: Synthesis of tetrasubstituted [2.2]paracyclophane 57 and chiral cyclophyne 58 through Eglinton coup...

Glaser–Hay coupling: In 2010, Collins and co-workers [96] demonstrated a macrocylization, with an inbuilt conformation control element to form rigid cyclophanes through the Glaser–Hay coupling. In this regard, diynes 59a–c were treated with CuCl2 and TMEDA in the presence of oxygen to afford the cyclized products 61a–c (Scheme 9).

Scheme 9: Synthesis of cyclophane through Glaser–Hay coupling reaction. Reagents and conditions: (i) CuCl2 (12 equiv), TMEDA (12 equiv), O2, PhMe, 18 h, 80 °C.

Scheme 9: Synthesis of cyclophane through Glaser–Hay coupling reaction. Reagents and conditions: (i) CuCl2 (1...

Intramolecular Heck coupling: In 2003, Snieckus and co-workers [97] have synthesized the seco-C/D ring analogues of ergot alkaloids through the intramolecular Heck reaction as a key step. The coupling precursors 63 and 68 were prepared from 4-bromoindoles by a sequential Vilsmeier–Haack, Henry nitroaldol condensation, reduction with LiAlH4, reductive amination and allylation that afforded the indole derivatives 63 (18%) and N-Boc protected compound 68 (23%). The reaction of 63 with Pd(OAc)2 (25 mol %) and tri(o-tolyl)phosphine (55 mol %) at reflux gave 9-endo-64a (24%) and 8-exo-65b (21%). However, the compound 68 under similar reaction conditions gave the cyclized product 8-exo-69 (30%) as the only isolable compound (Scheme 10).

Scheme 10: Synthesis of seco-C/D ring analogs of ergot alkaloids through intramolecular Heck reaction. Reagents and conditions: (i) (a) POCl3, DMF, 0–40 °C, 1 h, 78%; (b) MeNO2, cat. NH4OAc, reflux, 3 h, 80%; (c) LiAlH4, THF, reflux, 4 h, 88%; (d) PhCHO, NaBH(OAc)3, CH2Cl2/THF, rt, 46%; (e) allyl bromide, MeCN, rt, 24 h, 69–72%; (ii) 25 mol % Pd(OAc)2, 55 mol % P(o-Tol)3, NEt3, MeCN, reflux, 12 h; (iii) DIBAL-H, 0 °C, 15 min, rt, 2 h, CH2Cl2, then allylNHMe, NaBH(OAc)3, CH2Cl2, rt, 12 h, 38%.

Scheme 10: Synthesis of seco-C/D ring analogs of ergot alkaloids through intramolecular Heck reaction. Reagent...

Kumada coupling: Weber and co-workers [98] have synthesized muscopyridine 73 starting from 2,6-disubstituted pyridine. The Kumada cross-coupling reaction of 2,6-dichloropyridine (70) with the Grignard reagent 71 in the presence of a nickel phosphine complex 72 gave muscopyridine 73 in a single step (Scheme 11). This strategy has been applied to generate a variety of pyridinophanes by varying the chain length of the Grignard reagent.

Scheme 11: Synthesis of muscopyridine 73 via Kumada coupling. Reagents and conditions: (i) 72, THF, ether, 20 h, rt, 5–10%.

Scheme 11: Synthesis of muscopyridine 73 via Kumada coupling. Reagents and conditions: (i) 72, THF, ether, 20 ...

McMurry coupling: Kuroda and co-workers [99] have reported the synthesis of polyunsaturated [10]paracyclophane annulated by two azulene rings by using the McMurry reaction [100,101]. The bis(trimethylsilyl)enol ether 74 was reacted with 3-methoxycarbonyl-2H-cyclohepta[b]furan-2-one (75) in refluxing decaline to generate the 1,4-diazulenobenzene derivative 76. Double chain elongation of the bis-azulene derivative 76 with a four-carbon unit has been accomplished by electrophilic substitution with 4,4'-dimethoxybutan-2-one (77) under acidic conditions and subsequent elimination of methanol under basic conditions gave the advanced precursor 78 (28%). The stereochemistry of the newly generated C–C double bonds in 78 was confirmed as trans with the aid of the NMR vicinal coupling constant. Finally, intramolecular McMurry coupling of 78 using titanium trichloride and lithium aluminum hydride (LAH) heated under reflux in THF provided the cyclophane derivative 79 (20%, Scheme 12).

Scheme 12: Synthesis of the cyclophane 79 via McMurry coupling. Reagents and conditions: (i) 75, decaline, reflux, 4 h, 10%; (ii) 77, NaHCO3/HBF4, 28%; (iii) TiCl3/LiAlH4, THF, reflux, 20%.

Scheme 12: Synthesis of the cyclophane 79 via McMurry coupling. Reagents and conditions: (i) 75, decaline, ref...

In another occasion, Rajakumar and co-workers [102] have synthesized a series of stilbenophanes (e.g., 81) involving N-arylated carbazole moieties possessing small and large cavities. The precursor 80 required for the McMurry reaction was synthesized by the N-arylation of carbazole with the corresponding dibromide followed by formylation (Scheme 13).

Scheme 13: Synthesis of stilbenophane 81 via McMurry coupling. Reagents and conditions: (i) TiCl4, Zn, pyridine, THF, reflux, 12 h, 12%.

Scheme 13: Synthesis of stilbenophane 81 via McMurry coupling. Reagents and conditions: (i) TiCl4, Zn, pyridin...

In 2006, Rajkumar and co-workers [103] have published the synthesis of stilbenophane 85 via McMurry coupling as a key step (Scheme 14). Terphenyl derivative 82 was subjected to benzylic bromination in the presence of NBS to generate compound 83. Later, dibromide 83 was converted to bis-aldehyde 84. Finally, McMurry coupling of dialdehyde 84 provided the cyclophane derivative 85 (28%).

Scheme 14: Synthesis of stilbenophane 85 via McMurry coupling. Reagents and conditions: (i) NBS (2 equiv), benzoyl peroxide, CCl4, reflux, 40 h, 80%; (ii) tetrabutylammonium dichromate (TBADC), CHCl3, reflux, 6 h, 69%; (iii) TiCl4 (20 equiv), Zn (40 equiv), pyridine, THF, reflux, 6 h, 28%.

Scheme 14: Synthesis of stilbenophane 85 via McMurry coupling. Reagents and conditions: (i) NBS (2 equiv), ben...

Yamoto and co-workers have reported the synthesis of medium-sized cyclophanes, [2.n]metacyclophane-1,2-diols 86 and 87 by using the McMurry coupling as a key step (Figure 8) [104-106]. Among the π-conjugated systems stilbene derivatives found a unique place in materials science due to their optical and charge conducting properties. Tsuge and co-workers [107] reported the synthesis of stilbene 88 by using the McMurry coupling and studies on the transmission of the electronic effect through transannular interactions. Rajakumar and Selvam [108] also synthesized chiral stilbenophane 89 with small to large cavity sizes. These chiral stilbenophanes forms a complex with tetracyanoethylene (TCNE) and tetracyanoquinodimethane (TCNQ). The same group also reported on the synthesis of indolophanes 90a–c by using the McMurry coupling [109]. Furthermore, they synthesized dioxastilbenophanes 91 and carried out charge transfer complexation studies which showed that these molecules form a complex with TCNE and TCNQ [110]. Due to the presence of nitrogen and sulfur atoms benzene rings in phenothiaziophanes exhibit a butterfly conformation and thus have shown an enhanced bending character. When the benzene rings are bent, the reactivity of these cyclophanes is altered. Considering this aspect, Müller and co-workers [111] have devised different routes to these molecules. They have reported the synthesis of ethylene-bridged phenothiazinophane 92 using the McMurry coupling reaction. Also cyclic voltammetry experiments indicated the intramolecular electronic communication between the phenothiazinyl subunits. Calixarene-based macrocycles bind with various metal ions. Lee and Park [112] have synthesized various orthocyclophanes 93 which were further converted into spirobicyclic polyketals with a 2n-crown-n-moiety. Lee and co-workers [113] also reported the synthesis of bicyclic bis-cyclophane 94 by using the McMurry reaction as a key step. Oda and co-workers [114] have reported the first time synthesis of a fully conjugated ionic cyclophane by using the McMurry reaction. The McMurry coupling was carried out with tris(5-formyl-2-thienyl)methane to give an unsubstituted, etheno-bridged trithienylmethanophane 95. Later, it was converted into the novel cage-molecular monocation, dication, and dianion of substantial stability. Riccardin C (96) is a macrocyclic bis-bibenzyl entity with pharmacological properties, including antimycotic and antibacterial effects, and cytotoxicity against P-388 mouse leukaemia and KB cell lines from nasopharyngeal carcinoma. In view of these useful medicinal properties Harrowven and co-workers [115] have reported the synthesis of this molecule by using the McMurry reaction. Kawase and co-workers [116] have reported double-helically twisted macrocycles 97 exhibiting chiral sensor properties. Kasahara and co-workers [117] have reported the synthesis of ferrocenophane derivative 98 by McMurry reaction as a key step. Oda and co-workers [118] have reported the synthesis of cyclic paraphenylacetylene in which their spectral properties vary mainly with decrease of ring size of the molecule. They have synthesized intermediate 99 using the McMurry coupling which is required for the synthesis of the paraphenylacetylene compound. Tolanophanes are a new class of cyclophanes possessing a diphenylacetylene moiety which possess interesting structural, electronic, nonlinear optical and luminescent properties. Darabi and co-workers [119] have reported the syntheses of 100 molecules by using the McMurry reaction followed by hydrogenation. Pei and co-workers [120] have synthesized anthracene-based π-conjugated strained cyclophane 101 by using an intramolecular McMurry reaction. The combination of unsaturated linkages in these molecules might create a twisted conformation that imparts helical chirality. Double helically twisted chiral cyclophanes are important macrocycles due to their potential applications in optics and electronics. Kawase and co-workers [121] have reported the synthesis of 8,14,30,36-tetramethoxy[2.0.2.0](1,6)naphthalenophane-1,19-diyne (102) using the McMurry coupling (Figure 8).

Figure 8: List of cyclophanes prepared via McMurry coupling reaction as a key step.

Figure 8: List of cyclophanes prepared via McMurry coupling reaction as a key step.

Pd(0)-catalyzed cross-coupling reaction: In 1997, Yamamoto and co-workers [122] have synthesized the exomethylene paracyclophane 108 via intramolecular benzannulation of conjugated enynes in the presence of palladium(0). In this regard, dibromoalkane 103 was treated with dilithiated 2-methyl-1-butene-3-yne (104) to generate the corresponding bis-enyne 105. Treatment with Pd(PPh3)4 in dry toluene under high dilution conditions at 100 °C afforded the exomethylene paracyclophane 106. The paracyclophane 106 was converted to oxocyclophane 107 by ozonolysis followed by deoxygenation which finally gave the paracyclophane 108 (85%, Scheme 15).

Scheme 15: Synthesis of paracyclophane by cross coupling involving Pd(0) catalyst. Reagents and conditions: (i) THF, rt, 72%; (ii) Pd(PPh3)4, PhMe, high dilution, ∆, 15 min, 32%; (iii) O3, −78 °C, Pd/C (10 mol %), H2, rt, 55%; (iv) Pd/C (10 mol %), H2, 50 °C, rt, 85%.

Scheme 15: Synthesis of paracyclophane by cross coupling involving Pd(0) catalyst. Reagents and conditions: (i...

Pinacol coupling: Kanomata and co-workers [123] have reported the synthesis of the cyclophane 112 by using pinacol coupling [124] mediated by SmI2. A double Sonogashira reaction of 1,4-diiodobenzene (109) with 4-pentyn-1-ol (110) generates the diyne product in quantitative yield. Next, the in situ prepared diyne was subjected to hydrogenation followed by oxidation with PCC which gave the dialdehyde 111 (85%). The pinacol coupling of the dialdehyde 111 in the presence of Sm2+ and HMPA generated the cyclophane 112 in a moderate yield. RCM of the diene derived from the dialdehyde 111 afforded the macrocyclic cyclophane 113 as a less strained product (Scheme 16).

Scheme 16: Synthesis of the cyclophane 112 via the pinacol coupling and 113 by RCM. Reagents and conditions: (i) (a) 4-pentyne-1-ol (110), CuI, Pd(PPh3)4, CH2Cl2/Et3N 1:3, 50 °C, 1 d; (b) H2, Pd/C, MeOH, rt, 12 h, (two steps 96%); (c) PCC, MS 4 Å, CH2Cl2, rt, 2 h, 85%; (ii) SmI2, HMPA, Mg, TMSCl, rt, 3d, 64%; (iii) (a) H2C=PPh3, THF, −78 °C to rt, 1 h, 95%; (b) Grubbs first generation catalyst (G-I, 12), CH2Cl2, 50 °C, 14 h, 76%.

Scheme 16: Synthesis of the cyclophane 112 via the pinacol coupling and 113 by RCM. Reagents and conditions: (...

Sonogashira coupling: Wegner and co-workers [125] have reported the synthesis of cyclophanes 122a–c via Sonogoshira coupling [126] (Scheme 17). To this end, the 1,4-diiodobenzene (109) was reacted with the cyclohexane-1,4-dione (114) in the presence of CeCl3/LiCl/n-BuLi to generate the diol 115. Then, the hydroxy groups were protected as MOM groups to generate the key synthone 116. The other building blocks 119a–c were obtained by protection of dialkynes 117a–c with (3-cyanopropyl)dimethylsilyl chloride (CPDMSCl) (118). This protecting group was chosen to facilitate the separation of the mono- and diprotected products generated in this reaction. The two building blocks 116 and 119a–c were subsequently assembled via the Sonogashira reaction producing differently substituted diynes 120a–c. Deprotection of silyl groups in 120a–c using TBAF furnished the key intermediates 121a–c in moderate to good yields. Treatment of 121a–c with Pd(PPh3)4 and copper iodide in THF in the presence of diisopropylamine gave the desired macrocycles 122a–c (Scheme 17).

Scheme 17: Synthesis of cyclophane derivatives 122a–c via Sonogoshira coupling. Reagents and conditions: (i) CeCl3, LiCl, n-BuLi, THF, −78 °C to rt, 2 h, 48%; (ii) MOMCl, iPrNEt3, 19 h, rt, 98%; (iii) 118, EtMgBr, Et2O, 30 min, 0 °C then 1 h, rt, further 24 h stirring; (iv) CuI, Pd(PPh3)4, diisopropylamine, THF, rt; (v) TBAF, THF, 30 min, rt; (vi) CuI (20 mol %), Pd(PPh3)4 (10 mol %), diisopropylamine, THF, 12 h, rt.

Scheme 17: Synthesis of cyclophane derivatives 122a–c via Sonogoshira coupling. Reagents and conditions: (i) C...

Suzuki–Miyaura coupling: Bodwell and Li [127] have reported the synthesis of the cyclophane 130 involving hydroboration and the Suzuki–Miyaura (SM) coupling [128-135] as key steps. 1,3-Diallylindole (127) was first synthesized in two steps from indole (123) by successive allylation at the 3 position to give 126 (66%) and later, N-allylation was carried out to afford the diallylindole 127 (69%, Scheme 18). A three-step (123→124→125→127) sequence was found to give a higher yield of the 1,3-diallylindole (127). Iodination of 123 gave the 3-iodoindole (124) quantitatively, which on N-allylation afforded 125 (98%). The treatment of compound 125 with n-BuLi followed by alkylation with allyl bromide gave diallylindole 127 (77%), which on further treatment with 9-BBN (6 equiv) gave the doubly hydroborated species 128. Then, it was directly subjected to the Suzuki–Miyaura coupling reaction with 3,6-diiodopyridazine (129) and the desired cyclophane 130 was obtained (30%) as an oil (Scheme 18).

Scheme 18: Synthesis of cyclophane 130 via Suzuki–Miyaura reaction as a key step. Reagents and conditions: (i) MeMgBr, allyl bromide, ether, 20 °C, overnight, 66%; (ii) KOH, allyl bromide, TBAB, rt, 6 h, 69%; (iii) KOH, I2, DMF, 20 °C, 0.45 h, 100%; (iv) KOH, allyl bromide, rt, 6 h, 98%; (v) n-BuLi, allyl bromide, 77%; (vi) 9-BBN, THF; (vii) 129, Pd(PPh3)2Cl2, PPh3, Cs2CO3, dioxane, 65 °C, 5 h, 30%.

Scheme 18: Synthesis of cyclophane 130 via Suzuki–Miyaura reaction as a key step. Reagents and conditions: (i)...

In 2012, Hutton and co-workers [136] have synthesized a highly strained bicyclic framework of mycocyclosin (135) by utilizing the intramolecular Suzuki–Miyaura [137] cross-coupling reaction as a key step. The L,L-cyclodi(iodotryrosin) (131) was subjected to a benzylation reaction to give the protected compound 132 (76%). A one-pot Pd-catalyzed borylation and Suzuki–Miyaura coupling was employed to generate the cross-coupling product 134 (42%). Finally, deprotection of 134 was carried out with trifluoroacetic acid (TFA) in the presence of pentamethylbenzene to generate mycocyclosin (135, 74%) (Scheme 19).

Scheme 19: Synthesis of the mycocyclosin via Suzuki–Miyaura cross coupling. Reagents and conditions: (i) benzyl bromide (1.7 mmol), K2CO3 (1.7 mmol), DMF, 16 h, 76%; (ii) Pd(dppf)Cl2, 133 (1 equiv), DMSO, K2CO3, 90 °C for 16 h, 42%; (iii) pentamethylbenzene (1.1 mmol), TFA, 1 h, 74%.

Scheme 19: Synthesis of the mycocyclosin via Suzuki–Miyaura cross coupling. Reagents and conditions: (i) benzy...

Wurtz coupling: The Wurtz reaction is one of the oldest methods to form a C–C bond in organic synthesis. Baker and co-workers [138] have reported the synthesis of cyclophanes 137 and 139 by using the Wurtz coupling as a key step (Scheme 20).

Scheme 20: Synthesis of cyclophanes via Wurtz coupling reaction Reagents and conditions: (i) PhLi, Et2O, C6H6, reflux, 39%; (ii) Na, NaI (cat), PhBr (cat), Et2O, 12%; (iii) PhLi, Et2O, C6H6, 60 °C, 30 min, 20%.

Scheme 20: Synthesis of cyclophanes via Wurtz coupling reaction Reagents and conditions: (i) PhLi, Et2O, C6H6,...

Metathesis

Alkyne metathesis reaction: In 2010, Murphy and Jarikote [139] have developed a useful protocol for assembling non-natural macrocyclic compounds containing carbohydrates. Compound 140 was prepared in several steps and was further subjected to the RCM with G-I (12) as a catalyst in CH2Cl2. Later, catalytic hydrogenation followed by deacetylation gave compound 141 (48%). Similarly, alkyne metathesis of compound 142 was carried out in the presence of Mo(CO)6 and 2-fluorophenol in chlorobenzene and heated under reflux to yield the cyclized product. The cleavage of the acetate groups with sodium methoxide in methanol gave the glycophane (a glycophane is a hybrid of carbohydrate and cyclophane) 143 (27%, Scheme 21).

Scheme 21: Synthesis of non-natural glycophanes using alkyne metathesis. Reagents and conditions: (i) G-I (12), CH2Cl2, 8 h; (ii) Pd/C (5 mol %), NaOMe/MeOH, 48%; (iii) Mo(CO)6, 2-fluorophenol, chlorobenzene, ∆; (iv) NaOMe/MeOH, 27%.

Scheme 21: Synthesis of non-natural glycophanes using alkyne metathesis. Reagents and conditions: (i) G-I (12)...

The synthesis of fullerene-related molecules with high binding affinity and/or high selectivity is an active research area due to the cost and energy demanding purification process and the poor processibility of the fullerenes. To this end, Zhang and co-workers [140] reported the synthesis of the bisporphyrin macrocycle 144 with an adaptable cavity by using alkyne metathesis with high efficiency. Tamm and co-workers [141] reported the synthesis of meta-cyclophane 145 at room temperature by ring-closing alkyne metathesis of 1,3-bis(3-pentynyloxymethyl)benzenes (Figure 9). This strategy has also been extended to ortho and para-derivatives.

Figure 9: Synthesis of cyclophanes via ring-closing alkyne metathesis.

Figure 9: Synthesis of cyclophanes via ring-closing alkyne metathesis.

Cross-enyne metathesis: Recently, Kotha and Waghule [142] have synthesized diverse crownophanes by using a cross-enyne metathesis and Diels–Alder (DA) reaction as key steps. Here, the macrocycles 146 and 149 were subjected to a cross-enyne metathesis protocol with ethylene to generate the dienes 147 and 150, respectively. These dienes were subjected to a DA reaction with different dienophiles followed by aromatization which gave the crownophanes (e.g., 148 and 151) (Scheme 22).

Scheme 22: Synthesis of crownophanes by cross-enyne metathesis. Reagents and conditions: (i) G-II (13), 5 mol %, CH2Cl2, 24 h, rt, (147, 78%), (150, 82%); (ii) DMAD, PhMe, reflux, 24 h, DDQ, reflux, 30 h, (148, 78%), (151, 83%).

Scheme 22: Synthesis of crownophanes by cross-enyne metathesis. Reagents and conditions: (i) G-II (13), 5 mol ...

Cross metathesis: In 1992, (−)-cylindrocyclophane A (156) and (−)-cylindrocyclophane F (155) were isolated by Moore and co-workers [143] from a blue-green algae belonging to Cylindrospermum licheniforme. These paracyclophane derivatives exhibit potent cytotoxicity against the KB and LoVo tumor cell lines (IC50 = 2–10 μg/mL). On another occasion, Smith and co-workers have reported the synthesis of (−)-cylindrocyclophane A (156) and (−)-cylindrocyclophane F (155) [144]. The dialkenyl derivative 152 was subjected to dimerization involving cross-metathesis with G-I/G-II/Schrock catalysts which generated the cyclized product 154. Subsequently, hydrogenation of the cyclophane 154 followed by minor functional group modification gave the natural products 155 and 156 (Scheme 23). Furthermore, the same group has reported the syntheses of (−)-cylindrocyclophanes A and F (156, 155) by a RCM approach using different strategies.

Scheme 23: Synthesis of (−)-cylindrocyclophanes A (156) and (−)-cylindrocyclophanes F (155). Reagents and conditions: (i) G-I/G-II/Schrock catalyst, 50–80%; (ii) (a) H2, Pd/C; (b) BBr3 (84% over 2 steps); (iii) (a) TBAF, THF; (b) H2, PtO2; (c) PhSH, K2CO3, NMP (60% over 3 steps).

Scheme 23: Synthesis of (−)-cylindrocyclophanes A (156) and (−)-cylindrocyclophanes F (155). Reagents and cond...

Kotha and co-workers [145] have synthesized cyclophanes by using 1,3-indanedione using freshly prepared KF-Celite followed by SM cross-coupling reaction with an excess amount of allylboronic acid pinacol ester and afforded the required diallyl derivative 157 in good yield. Surprisingly, when the dialkyl compound 157 was subjected to RCM, instead of the monomer, the dimeric cyclophane 158 was obtained which was further subjected to hydrogenation to deliver the saturated cyclophane derivative 159 (Scheme 24).

Scheme 24: Synthesis of cyclophane 159 derivatives via SM cross-coupling and RCM. Reagents and conditions: (i) G-II (13), CH2Cl2 (0.002 M), 50 °C; (ii) H2, 10% Pd/C, CH2Cl2/MeOH, rt.

Scheme 24: Synthesis of cyclophane 159 derivatives via SM cross-coupling and RCM. Reagents and conditions: (i)...

To prepare π-conjugated three-dimensional molecules with potential isoelectronic properties and facile processibility, Kurata and co-workers [146] reported sexithiophene 163, a bridged cage shaped compound (Scheme 25). Its synthesis involves a Suzuki–Miyaura coupling reaction followed by cross metathesis. The molecule shows a hypsochromic shift which indicates rigidity in the molecule compared with the other linear molecules.

Scheme 25: Sexithiophene synthesis via cross metathesis. Reagents and conditions: (i) 161, Pd(PPh3)4, K2CO3, THF/PhMe/H2O; (ii) G-II (13), CH2Cl2, 27%.

Scheme 25: Sexithiophene synthesis via cross metathesis. Reagents and conditions: (i) 161, Pd(PPh3)4, K2CO3, T...

Enyne metathesis: In 1998, Fürstner and co-workers [147] have employed platinum(II)-catalyzed enyne metathesis as a key step to form cyclophane ring systems which are found in streptorubin B and metacycloprodigiosin [148-150]. In this context, the cyclooctene 164 was reacted with the intermediate formed in situ from chloramine-T and elemental selenium [151] and yielded the allylic amine derivative 165 (75%). An N-alkylation with propargyl bromide gave the enyne product 166 (92%), which on further acylation of terminal alkyne with butanoyl chloride delivered compound 167 (82%). Then, it was subjected to an enyne metathesis with simple platinum salts such as PtCl2 and PtCl4 to give product 168 (79%). A subsequent reduction of the α,β-unsaturated ketone delivered the compound 169 (64%). Finally, aromatization of compound 169 by using potassium 3-aminopropylamide (KAPA) gave compound 170 (75%) (Scheme 26).

Scheme 26: Synthesis of pyrrole-based cyclophane using enyne metathesis. Reagents and conditions: (i) Se, chloramine-T, 75%; (ii) NaH, THF, propargyl bromide, 92%; (iii) n-BuLi, −78 °C, ZnCl2, −30 °C, butanoyl chloride, rt, 82%; (iv) PtCl2 (5 mol %), 66 h, 20 °C, 79%; (v) (a) Bu3SnH, Pd(0), HBF4, 94%; (b) LiAlH4, 96%; (c) PhOC(S)Cl, 95%; (d) Bu3SnH, AlBN, 64%; (vi) (CH2)3(NH2)2, KH, 3 h, KAPA, 75%.

Scheme 26: Synthesis of pyrrole-based cyclophane using enyne metathesis. Reagents and conditions: (i) Se, chlo...

Ring-closing metathesis (RCM): In 2003, Tae and Yang [152] have reported an efficient macrocyclization of various alkenyl derivatives 171 via RCM/CM using G-I (12) or G-II (13) under high dilution conditions to obtain the [n], [n,n] and [n,n,n]paracyclophanes 172–174. Compounds with a short alkenyl chain gave mainly [n,n] and [n,n,n]paracyclophanes (173 and 174) by a dimerization or trimerization sequence. When the compound has a alkenyl chain of sufficient length the [n]paracyclophane 172 was obtained by an intramolecular cyclization (Scheme 27).

Scheme 27: Synthesis of macrocyclic derivatives by RCM. Reagents and conditions: (i) G-I/G-II, CH2Cl2, 0.005 M, 45 °C, 14–22 h, 60–76%.

Scheme 27: Synthesis of macrocyclic derivatives by RCM. Reagents and conditions: (i) G-I/G-II, CH2Cl2, 0.005 M...

Alcaide and co-workers [153] have reported the synthesis of different bis(dihydrofuryl)cyclophane scaffolds 179 from carbonyl compounds. 1,4-Bis(3-bromoprop-1-ynyl)benzene (175) was reacted with azetidine-2,3-diones 176 under eco-friendly reaction conditions to generate bis(allene) 177. Compound 177 was then converted into bis(dihydrofuran) 178 by using AuCl3. Macrocyclization of 178 was carried out by using a Ru(II) or Ru(III) catalyst to generate 179 as a mixture of E/Z isomers (Scheme 28).

Scheme 28: Synthesis of enantiopure β-lactam-based dienyl bis(dihydrofuran) 179. Reagents and conditions: (i) indium, THF/saturated aq NH4Cl 1:5, 24 h; (ii) 5 mol % AuCl3, CH2Cl2, rt, 3 h; (iii) 10 mol % Ru(II) or Ru(III) catalyst, CH2Cl2 (high dilution conditions).

Scheme 28: Synthesis of enantiopure β-lactam-based dienyl bis(dihydrofuran) 179. Reagents and conditions: (i) ...

In the literature, there are limited reports on the preparation of cyclophane derivatives by a combination of the Suzuki–Miyaura (SM) coupling and an RCM as key steps. Kotha and Mandal [135] reported a new approach to assemble [1.1.6]metaparacyclophane derivative 183 via the SM cross coupling and an RCM as key steps. In this regard, the α,α'-dibromo-m-xylene (136) was treated with arylboronic acid 180, to give the dialdehyde 181 which on reaction with indium-mediated Grignard addition reaction gave diolefin 182. Later RCM of diolefin 182 delivered cyclophane 183. Subsequent oxidation of diol 183 gave [1.1.6]metaparacyclophane derivative 184 (Scheme 29).

Scheme 29: Synthesis of a [1.1.6]metaparacyclophane derivative 183 via SM cross coupling. Reagents and conditions: (i) Pd(PPh3)4, Na2CO3, THF/water, reflux, 12 h, 80%; (ii) indium, allyl bromide, DMF; (iii) G-I (12), CH2Cl2; (iv) PCC, CH2Cl2.

Scheme 29: Synthesis of a [1.1.6]metaparacyclophane derivative 183 via SM cross coupling. Reagents and conditi...

Using the same approach, a butenyl Grignard reagent was added to compound 181 to generate diol 185. Surprisingly, after the addition of G-II catalyst 13, the two RCM products 186 and 189 were obtained [135]. The outcome of product 189 was explained on the basis of a tandem isomerization of a terminal double bond followed by the macrocyclization with G-II (13). Finally, the oxidation of diols 186 and 189 generated cyclophanes 187 and 190, respectively (Scheme 30).

Scheme 30: Synthesis of a [1.1.6]metaparacyclophane derivative 190 via SM cross coupling. Reagents and conditions: (i) Mg, Et2O, 4-bromobut-1-ene; (ii) G-II (13, 10 mol %), CH2Cl2; (iii) PCC, CH2Cl2, rt.

Scheme 30: Synthesis of a [1.1.6]metaparacyclophane derivative 190 via SM cross coupling. Reagents and conditi...

Guan and coworkers [154] have reported a novel synthetic approach to cyclophanes by using a template-promoted cyclization involving the RCM as a key step. This approach proceeded via the condensation of compound 191 with acenaphthenequinone in the presence of p-TSA to deliver the RCM precursor 192, which facilitate the cyclization protocol with G-II (13) as a catalyst to generate cyclophane derivative 193 containing an α-diimine functionality. Subsequently, the hydrogenation of 193 gave cyclophane 195. The removal of the template under hydrogenolytic conditions gave the macrocyclic compound 194 (Scheme 31).

Scheme 31: Template-promoted synthesis of cyclophanes involving RCM. Reagents and conditions: (i) acenaphthenequinone, p-TSA, C6H6; (ii) G-II (13), CH2Cl2 (0.002 M), 50 °C; (iii) Pd/C (10 mol %), H2, CH2Cl2/MeOH, rt.

Scheme 31: Template-promoted synthesis of cyclophanes involving RCM. Reagents and conditions: (i) acenaphthene...

In continuation of earlier work [145], Kotha and co-workers have demonstrated an interesting strategy to assemble [3.4]cyclophane derivative 197 by using the SM cross coupling and an RCM as key steps. The commercially available active methylene compound diethyl malonate was alkylated with a benzyl bromide derivative followed by the SM cross coupling to give dialkyl 196. Subsequently, an olefin metathesis with G-II (13) as a catalyst delivered dimeric 197 and monomeric 198 cyclophane derivatives. Later, the hydrogenation of 197 and 198 gave the corresponding saturated [3.4]cyclophane derivatives 199 and 200, respectively (Scheme 32).

Scheme 32: Synthesis of [3.4]cyclophane derivatives 200 via SM cross coupling and RCM. Reagents and conditions: (i) G-II (13), CH2Cl2 (0.002 M), 50 °C; (ii) H2, 10% Pd/C, CH2Cl2/MeOH, rt.

Scheme 32: Synthesis of [3.4]cyclophane derivatives 200 via SM cross coupling and RCM. Reagents and conditions...

Müllen and co-workers [155] have synthesized hexa-peri-hexabenzocoronene cyclophane 201a–c. They studied their properties by carrying out differential scanning calorimetry (DSC), optical microscopy, wide-angle X-ray scattering (WAXD), and scanning tunneling microscopy (STM). Tunneling spectroscopy reveals a diode-like behavior which introduces a high caliber of these molecular complexes. The RCM protocol has been successfully employed to generate a series of dicyanobiphenylcyclophanes 202 which are useful as n-type semiconductors [156]. Winkelmann and co-workers [157] have synthesized chiral concave imidazolinium salts 203 as precursors to chiral concave N-heterocyclic carbenes. Molecular encapsulation was achieved by using double RCM to generate insulated oligoynes 204. Here, the masked hexayne plays an important role to lock the flanking chains [158]. The synthesis of planer chiral cyclophanes is a difficult task owing to the flipping of the ansa-chain present in these molecules. Suzuki and co-workers [159] have reported the synthesis of enantiomerically pure planar-chiral [10]- and [12]paracyclophanes 205, which will serve as useful intermediates for the synthesis of various other cyclophane derivatives. Literature reports demonstrate the extensive use of RCM in the synthesis of different metallophanes involving ferrocenophane (e.g., 206) [160] and other metallophanes [161-164]. The synthesis of mechanically interlocked molecules such as catenanes and rotaxanes which are used to assemble molecular machines, sensors and nanomaterials is a challenging task. Huang and co-workers [165] have reported a taco complex template method to synthesize a cryptand/paraquat [2]rotaxane and [2]catenane (e.g., 207) by using RCM as a key step. Structural features and interesting bioactivity of the hirsutellones have grabbed the attention of synthetic chemists. Liu and co-workers [166] have constructed the [10]paracyclophane 208 (skeleton of hirsutellones) via RCM. The 2,2’-bipyridine unit is an interesting building block due to its use in chelating ligands, as a binding agent and also a useful template in supramolecular chemistry, Rykowski and co-workers [167] have synthesized azathiamacrocycle 209 using RCM (Figure 10).

Figure 10: Examples for cyclophanes synthesized by RCM.

Figure 10: Examples for cyclophanes synthesized by RCM.

Collins and co-workers [168] have reported the application of auxiliaries that engage in quadrupolar interactions in a total synthesis of a macrocyclic portion of longithorone C. To investigate the macrocyclization with the pentafluorobenzyl ester auxiliary, ester 210 was synthesized in a multistep process and then subjected to olefin metathesis to deliver the macrocycle using the Blechert catalyst 17. The treatment of the pentafluorophenyl benzyl ester 210 with catalyst 17 in toluene afforded the rigid macrocycle 211 (39%, Scheme 33).

Scheme 33: Synthesis of the longithorone C framework assisted by fluorinated auxiliaries. Reagents and conditions: (i) Blechert catalyst (17, 10 mol %), Ti(iOPr)4, CH2Cl2, 4 h, 39%.

Scheme 33: Synthesis of the longithorone C framework assisted by fluorinated auxiliaries. Reagents and conditi...

Kotha and Shirbhate [169] have reported the longithorone framework by using RCM as a key step. Dibromo compound 212 was reacted with monoalkylated ethyl acetoacetate 213 in the presence of NaH to deliver bis-alkyated product 214, followed by an oxidation the quinone derivative 215 (67%) was obtained. Next, the quinone 215 was subjected to RCM to generate the cyclized product 216 (71%, Scheme 34).

Scheme 34: Synthesis of the longithorone framework via RCM. Reagents and conditions: (i) 213, NaH, THF, rt, 10–15 h; (ii) CAN/SiO2, H2O, CH2Cl2, 5 min, rt, 67%; (iii) 13, (5 mol %), PhMe, reflux, 10 h, 71%.

Scheme 34: Synthesis of the longithorone framework via RCM. Reagents and conditions: (i) 213, NaH, THF, rt, 10...

Nicolaou and Xu [170] assembled the floresolide B 219 via RCM as a key step. Compound 217 underwent cyclization in the presence of G-II (13) in DCM heated under reflux to generate the two isomers of 218 (89%). Subsequently, the cleavage of the nitrobenzoate group with K2CO3 in MeOH gave the floresolide B 219 (Scheme 35).

Scheme 35: Synthesis of floresolide B via RCM as a key step. Reagents and conditions: (i) G-II (13, 0.1 equiv), 0.5 mM in CH2Cl2, 40 °C, 15 min; (ii) K2CO3 (10.0 equiv), MeOH/H2O 1:1, 25 °C, 2 h, 90%.

Scheme 35: Synthesis of floresolide B via RCM as a key step. Reagents and conditions: (i) G-II (13, 0.1 equiv)...

Fürstner and Leitner [171] have reported the synthesis of the normuscopyridine (223) by a cross-coupling reaction and an RCM as key steps. The treatment of the pyridine derivative 220 with an excess amount of the 5-hexenylmagnesium bromide in the presence of a catalytic amount of iron complex 18 as the precatalyst provides the dialkylation product 221 (75%). The treatment of the hydrochloride solution of 221 with Ru catalyst 17 in a dilute CH2Cl2 solution gave the cycloalkene 222 which on subsequent hydrogenation yielded the targeted normuscopyridine (223, 68%, Scheme 36).

Scheme 36: Synthesis of normuscopyridine (223) by the RCM strategy. Reagents and condition: (i) Mg, THF, hexenylmagnesium bromide, Fe complex 18 (10 mol %), THF/NMP, 0 °C, 75%; (ii) (a) HCl, Et2O; (b) Ru catalyst 17 (10 mol %), CH2Cl2, reflux, 14 h; (iii) (a) H2 (50 atm.), 70 °C; (b) aq sat. NaHCO3, 68%.

Scheme 36: Synthesis of normuscopyridine (223) by the RCM strategy. Reagents and condition: (i) Mg, THF, hexen...

Donohoe and coworkers [172] have reported the synthesis of muscopyridine (73) by RCM as a key step. The Wadsworth–Emmons olefination of the commercially available undecenal 224 provided acrylate 226, which was subjected to enantioselective copper-catalyzed conjugate addition with a methyl Grignard reagent involving (R)-tol-BINAP ligand to generate ester 227 in good yield and high enantiopurity. This intermediate was then converted to the key metathesis precursor involving a three step sequence of a Weinreb amide formation 228, epoxidation, and double addition of the vinyl Grignard 229 to generate the advanced intermediate 230. Finally, RCM of diolefin 230 under high dilution conditions afforded muscopyridine (73) (Scheme 37).

Scheme 37: Synthesis of muscopyridine (73) via RCM. Reagents and conditions: (i) 225, NaH, THF, 0 °C to rt, 1.5 h, 95%; (ii) CuI (5 mol %) (R)-tol-BINAP (7.5 mol %), t-Bu2O, MeMgBr, −20 °C, 1 h, rt, 15 h, 77%; (iii) (a) iPrMgCl, THF, −10 °C to rt, 20 min, 89%; (b) NHMeOMe, CH2Cl2, m-CPBA, rt, 19 h, 96%; (iv) 229, cat. CuI, DMP, −10 °C, 1 h, 68%; (v) (a) G-H-II (10 mol %), CH2Cl2, 55 °C, (b) NH4OAc, AcOH, EtOH, 96 h, 42%.

Scheme 37: Synthesis of muscopyridine (73) via RCM. Reagents and conditions: (i) 225, NaH, THF, 0 °C to rt, 1....

Hagiwara and co-workers [173] have synthesized muscopyridine starting with methyl acetoacetate (231). They treated 231 with 5-bromo-1-pentene to generate keto ester 232 (60%). The coupling of keto ester 232 with vinyl ketone 233 under phase-transfer catalysis conditions generated the new keto ester 234 (93%), which on treatment with lithium chloride at 120 °C in dimethyl propylene urea (DMPU) gave dione 235 (72%). An RCM sequence of compound 235 in the presence of G-I (12) catalyst gave the RCM product 236. A subsequent catalytic hydrogenation generated the saturated dione 237. Finally, the pyridine ring has been introduced by reacting dione 237 with hydroxylamine hydrochloride in a sealed tube to furnish muscopyridine (73, 61%, Scheme 38).

Scheme 38: Synthesis of muscopyridine (73) via RCM strategy. Reagents and conditions: (i) NaH, n-BuLi, 5-bromo-1-pentene, rt, 2.5 h, 60%; (ii) 233, K2CO3, (n-Bu)4NI, rt, 1 h, 93%; (iii) LiCl, DMPU, 120 °C, 7 h, 72%; (iv) G-I (12), CH2Cl2, 40 °C, 16.5 h, 90%; (v) Pd/C, H2, EtOH, rt, 5 h, 98%; (vi) NH2OH·HCl, 150–160 °C, 16 h, 61%.

Scheme 38: Synthesis of muscopyridine (73) via RCM strategy. Reagents and conditions: (i) NaH, n-BuLi, 5-bromo...

Normuscopyridine has been also obtained by an RCM approach. To this end, commercially available 2,6-lutidine dibromide 238 was reacted with sodium benzenesulfinate to deliver 2,6-bis(benzenesulfonylmethyl)pyridine (239) in quantitative yield. Next, bis-sulfone 239 was reacted with 5-bromo-1-pentene (240) in the presence of NaH to give an inseparable mixture of cis and trans-sulfones 241a and 241b, respectively. An RCM sequence of these sulfones in the presence of the G-I (12) catalyst gave cyclophane 243 (51%) and dimeric cyclophane 242 (20%, Scheme 39) [174]. The reduction of the sulfonyl group with Mg/ethanol in the presence of 1,2-dibromoethane aided by TMSCl afforded cyclophane derivative 244 (80%). Subsequently, the hydrogenation of the double bond with Pd/C under a H2 atmosphere gave normuscopyridine (223, 84%). Similar reaction conditions were employed with the dimeric product 242, to generate the macrocyclic pyridinophane 245 (64%).

Scheme 39: Synthesis of pyridinophane derivatives 223 and 245. Reagents and conditions: (i) PhSO2Na, TBAB, CH3CN, reflux, 12 h, 87%; (ii) 240, NaH, THF, rt, 24 h, 65%; (iii) G-I (12) (5 mol %), CH2Cl2, rt, 48 h, 243 (51%), 242 (20%); (iv) Mg/TMSCl, 1,2-dibromoethane, EtOH, 12 h, 80%; (v) H2, EtOAc, Pd/C, rt, 12 h, 84%; (vi) Mg/TMSCl, 1,2-dibromoethane, EtOH, 12 h; (vii) H2, EtOAc, Pd/C, rt, 12 h, (two steps 64%).

Scheme 39: Synthesis of pyridinophane derivatives 223 and 245. Reagents and conditions: (i) PhSO2Na, TBAB, CH3...

It is interesting to note that when the same strategy was applied with a benzene analogue, dipentenylation of bis-sulfone 246 gave compounds 247 and 248, which were easily separable by column chromatography [174]. Moreover, it was observed that cis-sulfone generates the monomeric cyclophane 249 during the metathesis as confirmed by single crystal X-ray diffraction data while the trans-sulfone gave the dimer 252. Finally, the desulfonylation followed by the hydrogenation sequence of 249 and 252 generate the cyclophanes 251 and 253, respectively (Scheme 40).

Scheme 40: Synthesis of metacyclophane derivatives 251 and 253. Reagents and conditions: (i) 240, NaH, THF, rt, 24 h; (ii) G-I (12, 5 mol %), CH2Cl2, rt, 48 h, 247 (29%), 248 (30%); (iii) Mg/TMSCl, 1,2-dibromoethane, EtOH, 12 h; (iv) H2, EtOAc, Pd/C, rt, 12 h.

Scheme 40: Synthesis of metacyclophane derivatives 251 and 253. Reagents and conditions: (i) 240, NaH, THF, rt...

With regard to the synthesis of cyclophane, Kotha and co-workers [174] have demonstrated another synthetic route to normuscopyridine (223) involving a short synthetic sequence. This route involves the reaction of dicyanopyridine 254 with alkenylmagnesium bromide to generate 255 and 256. Further, these compounds were cyclized with the aid of the G-II catalyst 13 to generate the corresponding RCM products 257 and 258 , respectively. The removal of the two carbonyl groups and the hydrogenation of the double bond was accomplished in a one-pot reaction under Wolff–Kishner reaction conditions to generate 223 and 259, respectively (Scheme 41).

Scheme 41: Synthesis of normuscopyridine and its higher analogues. Reagents and conditions: (i) alkenyl bromide, Mg, ether, H2O/H+; (ii) G-II (13, 5 mol %), PhMe, reflux; (iii) N2H4, K2CO3, ethylene glycol, 180 °C.

Scheme 41: Synthesis of normuscopyridine and its higher analogues. Reagents and conditions: (i) alkenyl bromid...

Cycloaddition reactions

[2 + 2] Cycloaddition: Roemer and Lentz [175] have reported the synthesis of fluorinated ferrocenophanes from 1,10-bis(trifluorovinyl)ferrocene and 1,4-(1,10-ferrocenediyl)-1,1,2,2,3,3,4-heptafluorobutane. The authors have reported a [2 + 2] cycloaddition reaction under thermal conditions. 1,10-Bis(trifluorovinyl)ferrocene (261) was synthesized starting with diiodoferrocene 260 by Negishi-type coupling. Compound 261 was subjected to a [2 + 2] cycloaddition sequence to generate cyclobutane derivative 262. Finally, the ring opening occurs with catalytic amounts of potassium hexacyanoferrate(III) in the presence of KF to deliver the fluorinated ferrocenophane 263 (Scheme 42).

Scheme 42: Synthesis of fluorinated ferrocenophane 263 via a [2 + 2] cycloaddition. Reagents and conditions: (i) Pd(OAc)2, PPh3, CF2CFZnCl, THF, 5 h, reflux, 95%; (ii) PhMe, 110 °C, 2 h , 5%; (iii) K3Fe(CN)6, KF, H2O, t-BuOH, rt, 1 h, 67%.

Scheme 42: Synthesis of fluorinated ferrocenophane 263 via a [2 + 2] cycloaddition. Reagents and conditions: (...

Okada and Nishimura [6] have reported the synthesis of syn-[2.n]metacyclophane 270 as a key building block for the synthesis of calix[4]arene. Here, α,ω-bis(p-methoxyphenyl)alkanes 264 were used as starting materials. Compound 264 was treated with acetic anhydride and AlCl3 in nitrobenzene and 1,1,2,2-tetrachloroethane to generate diketone 265 in 58–93% yield. Diketone 265 was then treated with LAH to generate diol 266 (72–92%). The dehydration of diol 266 with pyridinium p-toluenesulfonate in benzene gave diolefin 267. [2 + 2] Photocycloaddition of diolefin 267 was carried out by irradiation with a 400 W high-pressure Hg lamp (Pyrex filter) in benzene for 26–92 h. After evaporation, 268 and [2.n]metacyclophane 269 were isolated (61–87%). Finally, demethylation of compound 269 with BBr3 in CH2Cl2 gave cyclophane 270 (Scheme 43).

Scheme 43: Synthesis of [2.n]metacyclophanes 270 via a [2 + 2] cycloaddition. Reagents and conditions: (i) Ac2O, AlCl3, PhNO2, Cl2CHCHCl2, rt, 12 h, 58–93%; (ii) LiAlH4, THF, rt, 1 h, ~100%; (iii) PyHOTs, C6H6, reflux, 5 d, 72–92%; (iv) hv, C6H6, rt, 26–92 h, 61–87%; (v) BBr3, CH2Cl2, rt, 12 h, 70–80%.

Scheme 43: Synthesis of [2.n]metacyclophanes 270 via a [2 + 2] cycloaddition. Reagents and conditions: (i) Ac2...

[2 + 2 + 2] Co-trimerization: In 2003, Tanaka and Shirasaka [176] have reported a one-step synthesis of [6]metacyclophane 273 by a [2 + 2 + 2] co-trimerization of two different alkynes with a high chemo- and regioselectivity. The Rh(I)/H8-BINAP complex catalyzed the partially intermolecular cyclotrimerization of 1,9-decadiyne (271) and diethyl acetylenedicarboxylate (272) to give [6]metacyclophane derivative 273 (Scheme 44) [177]. This approach is also applicable to synthesize various polyether-based cyclophanes. In this report, they have synthesized various polyether containing cyclophanes by a cross-cyclotrimerization catalyzed by a cationic rhodium(I)/H8-BINAP complex as a key step. The ether linked α,ω-diynes and dimethyl acetylenedicarboxylate were treated with the Ru catalyst to deliver the metacyclophane in a regioselective manner. The ratio of para, meta, and orthocyclophane formation depends on the chain length of the diynes employed (Scheme 44).

Scheme 44: Synthesis of metacyclophane 273 by a [2 + 2 + 2] co-trimerization. Reagents and conditions: (i) [Rh(cod)2]BF4/H8-BINAP, CH2Cl2, 1 h, rt, 50%.

Scheme 44: Synthesis of metacyclophane 273 by a [2 + 2 + 2] co-trimerization. Reagents and conditions: (i) [Rh...

Tanaka and co-workers [178] demonstrated a useful approach to strained dioxa[7]paracyclophane 276 by the application of a [2 + 2 + 2] cycloaddition sequence (Scheme 45). To this end, [2 + 2 + 2] cycloaddition of 1,10-diyne 274 was carried out with methyl propiolate (275) in the presence of a cationic rhodium(I)-(S)-BINAP complex (10 mol %) as a catalyst. The desired [2 + 2 + 2] cycloaddition was carried out at room temperature to generate dioxa[7]paracyclophane 276 with a moderate ee value. The effect of biaryl bis(phosphine) ligands was examined, and it revealed the use of (S)-H8-BINAP afforded the cyclophane 276 with a good yield and optimum ee value.

Scheme 45: Synthesis of paracyclophane 276 via a [2 + 2 + 2] cycloaddition reaction. Reagents and conditions: (i) [Rh(cod)2]BF4/H8-BINAP, (5–10 mol %), CH2Cl2, rt, 1 h, (18% yield, 75% ee).

Scheme 45: Synthesis of paracyclophane 276 via a [2 + 2 + 2] cycloaddition reaction. Reagents and conditions: ...

Similarly, they also reported the synthesis of the planar-chiral carba-paracyclophane 278 by using the cationic rhodium(I)/(S,S)-bdpp-catalyzed [2 + 2 + 2] cycloaddition of cyclic diyne 277 with terminal methyl propiolate (275) under high substrate concentration conditions (Scheme 46) [179].

Scheme 46: Synthesis of cyclophane 278 via a [2 + 2 + 2] cycloaddition reaction. Reagents and conditions: (i) 5–20 mol % [Rh(cod)2]BF4/(S,S)-bdpp, CH2Cl2, rt, 16 h, (91% ee).

Scheme 46: Synthesis of cyclophane 278 via a [2 + 2 + 2] cycloaddition reaction. Reagents and conditions: (i) ...

Shibata and co-workers [180] have synthesized chiral tripodal cage compounds (e.g., 280) by using a [2 + 2 + 2] cycloaddition reaction of branched triynes (Scheme 47). The best results for a cycloaddition were observed when triyne 279 was added dropwise over a period of 10 min to a solution of a chiral catalyst at elevated temperature (120 °C). Also, highly enantioselective intramolecular reactions of different nitrogen-branched triynes were carried out to obtain diverse cyclophanes (Scheme 47).

Scheme 47: Synthesis of cyclophane 280 via a [2 + 2 + 2] cycloaddition. Reagents and conditions: (i) [(Rh(cod)(S,S)-Me-duphos)]OTf (10 mol %), DCE, 120 °C, (77% yield, 98 ee).

Scheme 47: Synthesis of cyclophane 280 via a [2 + 2 + 2] cycloaddition. Reagents and conditions: (i) [(Rh(cod)(...

Malacria and co-workers [181] have demonstrated an efficient use of a [2 + 2 + 2] cycloaddition reaction to generate the tetracyclic structure 282 related to taxane skeleton (Scheme 48).

Scheme 48: Synthesis of taxane framework by a [2 + 2 + 2] cycloaddition. Reagents and conditions: (i) Cp(CO)2 (5 mol %), xylene, hv, reflux.

Scheme 48: Synthesis of taxane framework by a [2 + 2 + 2] cycloaddition. Reagents and conditions: (i) Cp(CO)2 ...

Ohsima and co-workers [182] have reported a rhodium-catalyzed [2 + 2 + 2] cyclotrimerization of triynes 283 in a water-organic biphasic system. The biphasic system provides dilute reaction conditions suitable for macrocyclization. Selective cross-annulation between hydrophobic diynes and hydrophilic alkynes was achieved to generate ortho- and metacyclophane 284 and 285 (Scheme 49).

Scheme 49: Synthesis of cyclophane 284 and 285 via a [2 + 2 + 2] cycloaddition reaction. Reagents and conditions: (i) RhCl(cod)2tppts (2.5 mol %), H2O/Et2O, 20 h.

Scheme 49: Synthesis of cyclophane 284 and 285 via a [2 + 2 + 2] cycloaddition reaction. Reagents and conditio...

Maryanoff and co-workers [183] have synthesized the bis(indolyl)maleimido pyridinophanes via a [2 + 2 + 2] cycloaddition reaction as a key step. In this regard, indole-3-acetamide (286) was treated with 5-chloro-1-pentyne and NaH in DMF to deliver compound 287. Then, indole-3-glyoxylate 288 was converted to N-alkylated derivative 289 by the treatment with 5-chloro-1-pentyne in the presence of cesium carbonate. The maleimide condensation of 287 and 289 was carried out in the presence of KOt-Bu at 0–23 °C to give the α,α'-diyne substrate 290 (63%, Scheme 50). Next, the diyne 290 was reacted with N,N'-dimethylcyanamide (291) or 292 and CpCo(CO)2 under argon to afford 17-membered m-pyridinophanes 293a,b and 18-membered parapyridinophanes 294a,b in 10–15% isolated yield (Scheme 50).

Scheme 50: Synthesis of pyridinophanes 293a,b and 294a,b via a [2 + 2 + 2] cycloaddition. Reagents and conditions: (i) 5-chloro-1-pentyne, NaH, DMF, 0–55 °C, 12 h, 90%; (ii) 5-chloro-1-pentyne, Cs2CO3, DMF, 10 h, 59%; (iii) KOt-Bu, THF, 0–23 °C, 6 h, 63%; (iv) CpCo(CO)2, 1,4-dioxane, 105–110 °C, 24 h.

Scheme 50: Synthesis of pyridinophanes 293a,b and 294a,b via a [2 + 2 + 2] cycloaddition. Reagents and conditi...

Maryanoff and co-workers [184] have reported the synthesis of various pyridinophanes by a [2 + 2 + 2] cycloaddition reaction mediated by a cobalt catalyst (Scheme 51). To this end, different bisalkynes 271 were reacted with p-toluenenitrile (295, 1 mol equiv) in 1:1 ratio to obtain [2,4]pyridinophane 296 and [2,5]pyridinophane 297 (Scheme 51).

Scheme 51: Synthesis of pyridinophanes 296 and 297 via a [2 + 2 + 2] cycloaddition. Reagents and conditions: (i) 15 mol % CpCo(CO)2, o-xylene (0.001 M), 140 °C, 100 h, 50–61%.

Scheme 51: Synthesis of pyridinophanes 296 and 297 via a [2 + 2 + 2] cycloaddition. Reagents and conditions: (...

[3 + 2] Cycloaddition (1,3-dipolar cycloaddition/click reaction): In 2010, Raghunathan and co-workers [185] have synthesized a C2-symmetric triazolophane by a copper(I)-catalyzed azide-alkyne cycloaddition, involving a click reaction. The dipropargyl fluorenyl derivative 299 was prepared from 9H-fluorene (298) and propargyl bromide, which on further treatment with 1,4-diazidobutane (300) and xylyl azides 302a–c in the presence of CuSO4·5H2O and sodium ascorbate in THF/water (1:1) gave the corresponding macrocycles (301, 42%) and (303a–c, 60–70% yield, Scheme 52).

Scheme 52: Synthesis of triazolophane by a 1,3-dipolar cycloaddition. Reagents and conditions: (i) propargyl bromide, NaOH, PhCH2N+Et3Cl, PhMe, 4 h, reflux 50%; (ii) 300, CuSO4·5H2O/Na ascorbate, THF/H2O 1:1, 60 °C, 12 h, 42%; (iii) 302a–c, CuSO4·5H2O/Na ascorbate, THF/H2O 1:1, 60 °C, 12 h, 60%.

Scheme 52: Synthesis of triazolophane by a 1,3-dipolar cycloaddition. Reagents and conditions: (i) propargyl b...

Murphy and Leyden [186] have reported the synthesis of a glycotriazolophane 309 (carbohydrate–triazole–cyclophane hybrid) from a sugar amino acid via a copper-catalyzed azide-alkyne cycloaddition sequence. An aminosugar acid was identified as a useful building block to generate cyclophanes. Thus, the treatment of 304 with oxalyl chloride in the presence of DMF generated the acid chloride, which on further reaction with p-xylylenediamine (306) in the presence of N,N’-diisopropylethylamine (DIPEA) in dichloromethane followed by de-O-acetylation gave the bisazide 307 (37%). The latter compound was reacted with the dialkyne 308 in the presence of CuSO4 and sodium ascorbate in acetonitrile/water to deliver the desired cyclophane derivative 309 (56%, Scheme 53).

Scheme 53: Synthesis of glycotriazolophane 309 by a click reaction. Reagents and conditions: (i) LiOH, H2O, MeOH, THF, 16 h, rt, 93%; (ii) ClCOCOCl, DMF (cat), CH2Cl2, rt, 0.5 h; (iii) 306, DIPEA, 4 Å MS, CH2Cl2, 0 °C, 2 h; (iv) NaOMe, MeOH/CH2Cl2, rt, 3 h, (three steps 37%); (v) 308, CuSO4, sodium ascorbate, MeCN/H2O, rt, 13 h, 56%.

Scheme 53: Synthesis of glycotriazolophane 309 by a click reaction. Reagents and conditions: (i) LiOH, H2O, Me...

Similarly, a novel BINOL-based cyclophane 310 has been synthesized via click chemistry by incorporating two triazole moieties in the macrocycle [187]. Li and co-workers [188] have reported the synthesis of the naphthalene-diimide-based cyclophane 311 for understanding supramolecular interactions by metal ions (Figure 11).

Figure 11: Cyclophanes 310 and 311 prepared via click chemistry.

Figure 11: Cyclophanes 310 and 311 prepared via click chemistry.

[3 + 2 + 1] Cycloaddition (Dötz benzannulation): In 2003, Wulff and co-workers [189] synthesized cyclophane derivatives using the Dötz benzannulation as a key step. They found that the Fischer carbene complex 314 in a coordinating solvent such as THF lead to the products 312 (15%) and 313 (42%) whereas a non-coordinating solvent like benzene delivered products 315 (40%) and 316 (21%, Scheme 54).

Scheme 54: Synthesis of cyclophane via the Dötz benzannulation. Reagents and conditions: (i) THF, 100 °C, 12 h, (312, 15%), (313, 42%); (ii) benzene, 12 h, 100 °C, (315, 40%), (316, 21%).

Scheme 54: Synthesis of cyclophane via the Dötz benzannulation. Reagents and conditions: (i) THF, 100 °C, 12 h...

Wulff and Wang [190] have synthesized [6,6]metacyclophane via an intermolecular benzannulation reaction of Fischer carbene complexes with a residual alkyne to generate the 18-membered ring. Two molecules of the Fischer carbene complex 317 reacted by an intermolecular fashion to generate the [6,6]metacyclophane 318 (39%). Alternatively, a double benzannulation of a biscarbene complex 319 with 1,9-decadiyne (271) delivered [6,6]metacyclophane 318 (31%) (Scheme 55).

Scheme 55: Synthesis of [6,6]metacyclophane by a Dötz benzannulation. Reagents and conditions: (i) THF, 100 °C, 14 h, (318, 39%); (ii) THF, 100 °C, 14 h, (318, 31%).

Scheme 55: Synthesis of [6,6]metacyclophane by a Dötz benzannulation. Reagents and conditions: (i) THF, 100 °C...

Dötz and Gerhardt [191] have synthesized the [2,2]metacyclophane via chromium-mediated intermolecular benzannulation. In this connection, methoxy(alkynyl)carbene complex undergo an intramolecular benzannulation reaction in the presence of a polar solvent such as THF to deliver [6,6]metacyclophane (321a, 25%, 321b, 20% and 321c, 38%). Similarly metabenzoquinonophane 322 has been synthesized starting with 320 by an in situ oxidation of the benzannulated product by using cerium(IV) ammonium nitrate (40%, Scheme 56).

Scheme 56: Synthesis of cyclophanes by a Dötz benzannulation. Reagents and conditions: (i) THF, 65 °C, 3 h; (ii) (n-Bu)2O, 90 °C, 2 h, CAN, (321, 40%).

Scheme 56: Synthesis of cyclophanes by a Dötz benzannulation. Reagents and conditions: (i) THF, 65 °C, 3 h; (i...

Intramolecular Diels–Alder (DA) reaction: Suwa and co-workers [192] have synthesized the muscopyridine by a [4 + 2] cycloaddition of the bisketene 325. The condensation of acid dichloride derived from 323 with two molecules of Meldrum’s acid gave 324 which on thermal activation in chlorobenzene yielded bisketenes 325a and 325b. These two ketene derivatives underwent an intramolecular cycloaddition to afford a 1:1 mixture of 326 and 327 (96%, Scheme 57). On heating with concentrated HCl, 326 and 327 were transformed to pyrone derivative 328 (89%). A solution of the compound 328 in ethanol saturated with ammonia was heated in a stainless sealed tube for 3 days to deliver the pyridinone derivative 329 (87%). Further, chlorination of the pyridinone 329 afforded the chloropyridine 330 (93%). Subsequently, hydrogenolysis of the pyridine derivative 330 gave the target muscopyridine (73, 89%).

Scheme 57: Synthesis of muscopyridine (73) via an intramolecular DA reaction of ketene. Reagents and conditions: (i) (a) SOCl2, reflux, 30 min; (b) Meldrum’s acid, DMAP, CH2Cl2, 0 °C, 2 h, then rt, 1 h; (ii) Ph-Cl, reflux, 20 h, 84%; (iii) heating; (iv) conc. HCl, reflux, 12 h, 89%; (v) NH3, EtOH, sealed tube, 140 °C, 72 h, 87%; (vi) POCl3, reflux, 1 h, 93%; (vii) H2, Pd/C, AcONa, rt, 12 h, 89%.

Scheme 57: Synthesis of muscopyridine (73) via an intramolecular DA reaction of ketene. Reagents and condition...

[4 + 2] Cycloaddition (Diels–Alder reaction): In 2003, Tochtermann and co-workers [193] have synthesized a bis[10]paracyclophane with two chiral planes and one chiral axis via the DA reaction as a key step. The bifuran derivative 331 was subjected to a DA sequence with dimethyl acetylenedicarboxylate (DMAD) to deliver compounds 332a,b (77%). These DA adducts were irradiated in diethyl ether/dichloromethane (5:1) to offer the corresponding bioxaquadricyclane 333, subsequent thermolysis gave the bioxepine 334 (81%). Finally, aromatization of bioxepine 334 with trifluoroacetic acid (TFA) delivered ketophenol 335 (37%), which on further treatment with potassium tert-butoxide/methyltriflate mixture, gave the dimethyl ether bis[10]paracyclophane 336 (63%, Scheme 58).

Scheme 58: Synthesis of bis[10]paracyclophane 336 via Diels–Alder reaction. Reagents and conditions: (i) DMAD, PhMe, reflux, 4 h, 77%; (ii) Et2O, hv, 2 h, 78%; (iii) THF, reflux, 2 h, 81%; (iv) CF3OAc, CH2Cl2, rt, 24 h, 37%; (v) CH2Cl2, t-BuOK, methyl triflate, rt, 2 h, 63%.

Scheme 58: Synthesis of bis[10]paracyclophane 336 via Diels–Alder reaction. Reagents and conditions: (i) DMAD,...

In 1980, Gassman and co-workers [194] have synthesized [8]paracyclophane via the DA reaction as a key step. In this connection, 1,3-cyclododecadiene (337) was reacted with maleic anhydride to give the DA product 338 (21%). Later, the DA adduct 338 was heated under reflux in 10% aq tetrahydrofuran to afford the diacid, which on decarboxylation in the presence of lead tetraacetate in a toluene/pyridine mixture delivered compound 339 (22%). Treatment of 339 with 1 equiv of m-chloroperbenzoic acid gave the epoxide 340 (80%), followed by HCl treatment gave [8]paracyclophane 341 (93%) (Scheme 59).

Scheme 59: Synthesis of [8]paracyclophane via DA reaction. Reagents and conditions: (i) maleic anhydride, 3–5 h, 21%; (i) Pb(OAc)4, PhMe/pyridine, 2 h, 21%; (iii) mCPBA, 80%; (iv) HCl, 93%.

Scheme 59: Synthesis of [8]paracyclophane via DA reaction. Reagents and conditions: (i) maleic anhydride, 3–5 ...

Synthesis of the macrocyclic portion of longithorone C (DA reaction): In 1994 longithorone A was first described by Schmitz and co-workers [195]. This unusual heptacyclic marine natural product is a cytotoxic agent. Its synthesis is considered difficult due to the stereocenters present in the ring system of longithorone A and E. Moreover, hindered rotation around the quinone moiety adds even more complexity to its synthesis.

Recently, Shair and co-workers [196] have reported the enantioselective synthesis of (−)-longithorone A by using a conventional synthesis to realize the proposed biosynthesis, which was put forward by Schmitz involving an intermolecular and an intramolecular DA reaction of two [12]paracyclophanequinone [197]. Based on this proposal Shair and co-workers attempted the synthesis of the natural product (−)-longithorone A. Diene 343 and the dienophile 342 were synthesized by several steps and subsequently subjected to the DA sequence to afford the rigid (−)-longithorone A (346, 90%, Scheme 60).

Scheme 60: Biomimetic synthesis of (−)-longithorone A. Reagents and conditions: (i) Me2AlCl, CH2Cl2, −20 °C, 70%, 1:1.4 diastereomers; (ii) TBAF, THF, 0 °C; (iii) PhI(O), MeCN/H2O, 0–25 °C, 90% two steps.

Scheme 60: Biomimetic synthesis of (−)-longithorone A. Reagents and conditions: (i) Me2AlCl, CH2Cl2, −20 °C, 7...

Nicolaou and co-workers [198] have reported the synthesis of sporolide B (349). The synthesis involves a DA reaction between o-quinone as the diene component and indene derivatives as dienophiles. This total synthesis also involves a Ru-catalyzed [4 + 2] cycloaddition reaction to generate a highly substituted indene system containing a chlorine substituent on the aromatic ring (Scheme 61).

Scheme 61: Synthesis of sporolide B (349) via a [4 + 2] cycloaddition reaction. Reagents and conditions: (i) PhMe, 110 °C, 1.5 h, 40% (based on 50% recovered starting material).

Scheme 61: Synthesis of sporolide B (349) via a [4 + 2] cycloaddition reaction. Reagents and conditions: (i) P...

Cavicularin, a natural product containing a cyclophane system was isolated from the liverwort Cavicularia densa. Among several approaches to prepare this natural product, Beaudry and Zhao [199] have reported the synthesis of the basic architecture of (+)-cavicularin (352) by using the DA reaction of pyrone and vinyl sulfone (Scheme 62). They have reported the first intramolecular enantioselective DA reaction of the α-pyrone, also regioselective one-pot three-component Suzuki reaction of a dibromoarene to form a highly substituted terphenyl system (Scheme 62).

Scheme 62: Synthesis of the framework of (+)-cavicularin (352) via a [4 + 2] cycloaddition. Reagents and conditions: (i) cinchona alkaloid derivative, EtOAc, 3 Å MS, 45 °C; (ii) (a) Tf2O, CH2Cl2, 0 °C, 45% (2 steps); (b) NH4CO2H, Pd/C, MeOH, 70 °C, quant.; (c) BBr3, CH2Cl2, 80%.

Scheme 62: Synthesis of the framework of (+)-cavicularin (352) via a [4 + 2] cycloaddition. Reagents and condi...

Rearrangement reactions

Beckmann rearrangement: Uemura and coworkers [200] have synthesized the cyclophane-containing oxazole moiety via a Beckmann rearrangement as a key step. α-Formylketoxime dimethyl acetal 353 was synthesized in several steps and subjected to a Beckmann rearrangement by using polyphosphoric acid in toluene heated under reflux conditions to give oxazole-based cyclophane 354 in 46% (Scheme 63).

Scheme 63: Synthesis of oxazole-containing cyclophane 354 via Beckmann rearrangement. Reagents and conditions: (i) polyphosphoric acid, toluene, reflux, overnight, 46%.

Scheme 63: Synthesis of oxazole-containing cyclophane 354 via Beckmann rearrangement. Reagents and conditions:...

Benzidine rearrangement: Benniston and co-workers [201] have reported the synthesis of cyclophanes 360a–c involving a benzidine rearrangement [202-208]. The m-nitrophenol (355) was reacted with ditosylate 356 to generate m-nitrophenol ether derivative 357, which on a reduction with Zn in MeOH gave azo-derivative 358. It was further converted into the hydrazo compound 359 which underwent a benzidine rearrangement under acidic conditions to deliver cyclophanes 360a–c. The cyclophanes obtained here involve the migration of nitrogen on the aromatic ring (Scheme 64).

Scheme 64: Synthesis of cyclophanes 360a–c via benzidine rearrangement. Reagents and conditions: (i) 356a–d, K2CO3, DMF; (ii) Zn, NaOH; (iii) HCl.

Scheme 64: Synthesis of cyclophanes 360a–c via benzidine rearrangement. Reagents and conditions: (i) 356a–d, K2...

Cho and co-workers [209] have reported the synthesis of 4,4-diaminobiphenyls (benzidine) connected with a polyether unit at the 2,2'-positions using the benzidine rearrangement. The cyclophane synthesis of 365 starts with the preparation of 361a–c starting with m-bromophenol and polyether ditosylates. The Cu(I)-catalyzed coupling reactions of the bis(m-bromophenyl) ethers 361a–c provided the monohydrazides 362a–c (53–57%). Cyclization reactions were carried out by using a Pd catalyst delivering diarylhydrazides 363a–c (46–50%). Later, the hydrazides 363a–c were heated in EtOH with a catalytic amount of aq HCl to generate the corresponding benzidines 364a–c, as indicated by their crude 1H NMR spectra. These products were subjected to an acetylation sequence to generate the cyclophane-based acetamides 365a–c (Scheme 65).

Scheme 65: Synthesis of cyclophanes 365a–c via benzidine rearrangement. Reagents and conditions: (i) BocNHNH2, CuI, Cs2CO3, 1,10-phen, DMF, 80 °C, 24 h; (ii) Pd(OAc)2, P(t-Bu)3, PhMe, 110 °C, 12 h; (iii) aq HCl, EtOH, 80 °C, reflux, 2 h; (iv) AcCl, NaOAc, MeCN, rt, 12 h.

Scheme 65: Synthesis of cyclophanes 365a–c via benzidine rearrangement. Reagents and conditions: (i) BocNHNH2,...

Ciamician–Dennstedt rearrangement: Reese and Dhanak [210] have synthesized a strained cyclophane such as [6](2,4)pyridinophane derivatives 367 by using a ring expansion strategy. Here, pyrrole derivative 366 was treated with dihalocarbene giving the cyclopropane intermediate 366a which was further converted into pyridinophane 367 by a ring expansion (Scheme 66).

Scheme 66: Synthesis of metacyclophane 367 via Ciamician–Dennstedt rearrangement. Reagents and conditions: (i) Cl3CCO2Na (5 equiv), 1,2-dimethoxyethane, reflux, 4 h; (ii) Hg(Ph)(CBr3) (2 equiv), benzene, reflux, 24 h.

Scheme 66: Synthesis of metacyclophane 367 via Ciamician–Dennstedt rearrangement. Reagents and conditions: (i)...