Search results

Search for "wetting" in Full Text gives 168 result(s) in Beilstein Journal of Nanotechnology.

Hybridization vs decoupling: influence of an h-BN interlayer on the physical properties of a lander-type molecule on Ni(111)

Beilstein J. Nanotechnol. 2020, 11, 1168–1177, doi:10.3762/bjnano.11.101

- large-area STM images (Supporting Information File 1, Figure S2), which confirm a close-packed DBP wetting layer as well as DBP clusters on top for a nominal film thickness of about 1.6 MLE. Hence, there is little discrepancy between 1 MLE, defined via DRS, and a fully covered substrate surface

A 3D-polyphenylalanine network inside porous alumina: Synthesis and characterization of an inorganic–organic composite membrane

Beilstein J. Nanotechnol. 2020, 11, 938–951, doi:10.3762/bjnano.11.78

- rearrangement of the secondary, tertiary, or quaternary structure of the polypeptides. The reduction of the measured water contact angle can be explained by the established model of Cassie and Baxter, in which the wetting properties are affected by heterogeneous surfaces (inner surface is not wetted) and the

Templating effect of single-layer graphene supported by an insulating substrate on the molecular orientation of lead phthalocyanine

Beilstein J. Nanotechnol. 2020, 11, 814–820, doi:10.3762/bjnano.11.66

- consider any influence of the underlying substrate on the MPc orientation. It has been shown that a monolayer of graphene, due to its extremely thin nature, exhibits transparency to the wetting behavior on substrates where van der Waals forces are the dominant surface–water interactions [14]. The wetting

- polymer residues via thermal treatment [30]. Recently, Rafiee et al. found, in the context of wetting, that the van der Waals forces are not disrupted by the graphene sheet as it is extremely thin (ca. 0.3 nm) [14]. Hence, we consider that the edge-on configurations are formed under the influence of the

Electromigration-induced directional steps towards the formation of single atomic Ag contacts

Beilstein J. Nanotechnol. 2020, 11, 680–687, doi:10.3762/bjnano.11.55

- was employed in order to obtain nanostructures of bow-tie shape that were 100 to 200 nm wide at the smallest constriction. After HF dip, in order to get a hydrogen-terminated surface, 1 nm of Ti served as wetting layer before we evaporated 5 nm of Ag onto the substrate at room temperature. Thirdly

Exfoliation in a low boiling point solvent and electrochemical applications of MoO3

Beilstein J. Nanotechnol. 2020, 11, 662–670, doi:10.3762/bjnano.11.52

- supercapacitors [30][31]. The composite with 5 wt % CB was tested for about 500 cycles (Figure 3e). Initially the specific capacitance was found to increase, which can be attributed to the wetting of the active material in the initial cycles [26]. Electrochemical impedance spectroscopy was used to study the

- response with a small iR drop. This can be attributed to the better conductivity after adding CB. To study the stability of the composite, cyclic voltammetry was carried out up to 2000 cycles. Initially, the capacitance increases, which may be attributed to the wetting of the electrode with the electrolyte

Preparation, characterization and photocatalytic performance of heterostructured CuO–ZnO-loaded composite nanofiber membranes

Beilstein J. Nanotechnol. 2020, 11, 631–650, doi:10.3762/bjnano.11.50

- account the nanofiber diameters of the CNFMs presented in Table 1, it can be found that the pore sizes of the CNFMs are mainly determined by the nanofiber diameters. Larger nanofiber diameters lead to larger pore sizes. Wetting properties: The measured contact angle (CA) values of the CNFMs with different

- -treatment temperature. Wetting properties: The CA values of the CNFMs obtained without and with heat treatment are illustrated in Figure 14. The hydrophobicity of the heat-treated CNFMs is smaller than that of the CNFMs without heat treatment, due to the formation of hydrophilic CuO and ZnO nanoparticles

- a hydrothermal method. The effects of growth solution concentration as well as temperature and time of the hydrothermal synthesis on the morphology of the heterostructured CuO–ZnO-loaded CNFMs were investigated by SEM. Also, structure and wetting properties of the CNFMs were studied. Effect of the

Design of a nanostructured mucoadhesive system containing curcumin for buccal application: from physicochemical to biological aspects

Beilstein J. Nanotechnol. 2019, 10, 2304–2328, doi:10.3762/bjnano.10.222

Ultrathin Ni1−xCoxS2 nanoflakes as high energy density electrode materials for asymmetric supercapacitors

Beilstein J. Nanotechnol. 2019, 10, 2207–2216, doi:10.3762/bjnano.10.213

- higher conductivity of the sulfide material [39]. Another critical parameter of supercapacitor electrodes is cycling stability. It can be seen from Figure 3d that the capacity increased in the first 50 cycles, which can be due to the wetting process of the electrode in the electrolyte [40]. After a total

Nanostructured and oriented metal–organic framework films enabling extreme surface wetting properties

Beilstein J. Nanotechnol. 2019, 10, 1994–2003, doi:10.3762/bjnano.10.196

- report on the synthesis of highly oriented and nanostructured metal–organic framework (MOF) films featuring extreme surface wetting properties. The Ni- and Co- derivatives of the metal–catecholate series (M-CAT-1) were synthesized as highly crystalline bulk materials and thin films. Oriented pillar-like

- nanostructured M-CAT-1 films exhibiting pronounced needle-like morphology on gold substrates were established by incorporating a crystallization promoter into the film synthesis. These nanostructured M-CAT-1 MOF films feature extreme wetting phenomena, specifically superhydrophilic and underwater superoleophobic

- . Keywords: antifog; antifouling; biomimetic coatings; metal–organic frameworks (MOFs); superhydrophilic; superoleophobic; thin films; vapor-assisted conversion; Introduction Over millions of years, plants and animals have evolved a spectrum of surface designs enabling specific wetting properties tailored

Fabrication and characterization of Si1−xGex nanocrystals in as-grown and annealed structures: a comparative study

Beilstein J. Nanotechnol. 2019, 10, 1873–1882, doi:10.3762/bjnano.10.182

- crystals upon annealing. A similar phenomenon may have occurred in our structures, as depicted in Figure 4 and Figure 5. Thus, we can anticipate heterogeneous nucleation to be a dominant process during crystallization rather than conventional homogenous nucleation. This can be due to a better wetting of

Upcycling of polyurethane waste by mechanochemistry: synthesis of N-doped porous carbon materials for supercapacitor applications

Beilstein J. Nanotechnol. 2019, 10, 1618–1627, doi:10.3762/bjnano.10.157

- vapor adsorption was performed exemplarily for the samples PUPC-800-3, PUUPC-800-1, and PUUPC-800-2 to demonstrate the effect of the porosity and the generated nitrogen functionalities on sorption, phase and wetting behavior. The water isotherms of all measured samples are assigned to a type V isotherm

Pure and mixed ordered monolayers of tetracyano-2,6-naphthoquinodimethane and hexathiapentacene on the Ag(100) surface

Beilstein J. Nanotechnol. 2019, 10, 1188–1199, doi:10.3762/bjnano.10.118

- that no de-wetting from the Ag(100) surface by formation of small three-dimensional clusters occurred over time. HTPEN forms two different structures on Ag(100) depending on the coverage. The predominantly observed phase has a slightly larger unit cell (ca. 10%) than the second phase with a more

Porous N- and S-doped carbon–carbon composite electrodes by soft-templating for redox flow batteries

Beilstein J. Nanotechnol. 2019, 10, 1131–1139, doi:10.3762/bjnano.10.113

- (H2SO4, for analysis, 96%) was utilized from Acros Organics. Prior to each measurement the electrolyte was purged with nitrogen for at least 15 min to make sure that there was no remaining dissolved oxygen in the solution. The homogeneous wetting of the felts was ensured by dipping them into the

CuInSe2 quantum dots grown by molecular beam epitaxy on amorphous SiO2 surfaces

Beilstein J. Nanotechnol. 2019, 10, 1103–1111, doi:10.3762/bjnano.10.110

- called Cu-poor CIS composition, CIS is capable of maintaining its crystalline structure as well as its optoelectronic properties [39]. We interpret this thin layer as a 2D wetting layer (WL) formed during the first steps of growth that transits to 3D nanodots as the growth continues. This WL also appears

- could also be expected from the Cu-poor CIS wetting layer. We would expect the WL to behave as a thin (ca. 1.3 nm) quantum well with a narrow PL emission. However, the TEM analysis is highly localized, and the thickness of the layer could vary in other regions of the sample. To analyse the PL emissions

- in more detail, simple quantum confinement calculations were carried out considering a hard wall spherical QD of radius R and the wetting layer as a hard wall quantum well (QW) of thickness L. The calculations consider the free exciton emission for the QD and QW, respectively. The first transition

Concurrent nanoscale surface etching and SnO2 loading of carbon fibers for vanadium ion redox enhancement

Beilstein J. Nanotechnol. 2019, 10, 985–992, doi:10.3762/bjnano.10.99

- , 100B/W (BAS). An Au wire as a lead was connected to the upper side of the 1 cm2 sample to form the working electrode. The electrode was immersed in ethanol and then rinsed with high-purity water to fully wet the electrode and to minimize the influence of wetting [7][30]. The counter electrode was

Novel reversibly switchable wettability of superhydrophobic–superhydrophilic surfaces induced by charge injection and heating

Beilstein J. Nanotechnol. 2019, 10, 840–847, doi:10.3762/bjnano.10.84

- termed electrowetting [19]. The equilibrium morphology under electrical wetting conditions is determined by the equilibrium of Maxwell stress and Laplace pressure [20][21]. Verplanck et al. [22] reported the reversible electrical wetting of droplets on superhydrophobic silicon nanowires in air and oil

- environments. At 150 V, the maximum contact angle could be reduced by 23° by electrical wetting in a reversible manner. Li et al. [23] studied the diffusion of droplets of ionic liquids on an insulating electrode subjected to an external voltage. The catalytic effect of a vertical electric field on the

- different sizes using a voltage of 3 V and a 25 V electrical wetting. The maximum contact angle decreased from 150 ± 0.1° to 20° and the contact-angle saturation conditions changed with droplet size. Zahiri et al. [27] reported the reversible active control of surface wettability of copper electrodeposition

Features and advantages of flexible silicon nanowires for SERS applications

Beilstein J. Nanotechnol. 2019, 10, 725–734, doi:10.3762/bjnano.10.72

- strong enough to overcome the stiffening caused by sputtering. Another significant substrate feature is surface wetting. Unlike vertical SiNWs [38], horizontal SiNWs are hydrophilic, as freshly prepared SiNW substrate as well as after Ag sputtering (Supporting Information File 1, Figure S12). The reasons

Self-assembly and wetting properties of gold nanorod–CTAB molecules on HOPG

Beilstein J. Nanotechnol. 2019, 10, 696–705, doi:10.3762/bjnano.10.69

- such studies could be relevant especially in those areas where conversion of a nonwetting surface (or some particular regions of a surface) to a wetting ones is desired. Also, the presence of such CTAB layers (which cannot be observed using scanning electron microscopy (SEM)) between the substrate and

Topochemical engineering of composite hybrid fibers using layered double hydroxides and abietic acid

Beilstein J. Nanotechnol. 2019, 10, 589–605, doi:10.3762/bjnano.10.60

- beginning and subsequently at 1 s and 2 s intervals until either the water droplet was absorbed or no changes during wetting occurred. The results were analyzed and interpreted with Attention Theta software (Biolin Scientific, Sweden) based on the Young-Laplace function for iterative CA calculation. Oil

Biological and biomimetic surfaces: adhesion, friction and wetting phenomena

Beilstein J. Nanotechnol. 2019, 10, 481–482, doi:10.3762/bjnano.10.48

- Keywords: adhesion; air retention; contact mechanics; fluid transport; friction; functional gradients; wetting; This Thematic Series is the continuation of the previous series on the broad topic of biological and bioinspired materials and surfaces [1][2][3]. This collection of articles displays a current

- cross section of recent developments in this highly diverse and interdisciplinary field of research. The articles highlight recent achievements in the understanding of animal and plant surfaces in the broadest context of adhesion, friction, and wetting phenomena on one hand. On the other hand, they

Ultraviolet patterns of flowers revealed in polymer replica – caused by surface architecture

Beilstein J. Nanotechnol. 2019, 10, 459–466, doi:10.3762/bjnano.10.45

- also be considered that the cuticle will interact with many different environmental influences, for example, wetting, contamination, and electromagnetic radiation [3][4] as well. Ultraviolet (UV) radiation in the wavelength range 280–380 nm is particularly crucial for plants, for example, when

Interaction of Te and Se interlayers with Ag or Au nanofilms in sandwich structures

Beilstein J. Nanotechnol. 2019, 10, 238–246, doi:10.3762/bjnano.10.22

- the silver towards its surface, which they interpreted as segregation. In 2001, a similar discovery was made for Ag layers grown on Cu [24]. Since then, the effects of this phenomenon have attracted little attention. In 2014, Stefaniuk et al. [14] observed that Ag thin layers on top of Ge wetting

- are good wetting films for silver and gold. Although the plasmonic layers deposited on Te films have their grains size decreased, the XRR extracted layer density profiles show that the density of a layer increases with increasing distance from the SiO2/metal interface, which is the opposite of the

- have segregated to the surface. The poor wetting (or even dewetting) of silver by Se and Te has one more attribute. The intensity of the modified Lorentz band [37] centered at 275–300 nm decreased while the intensity of the bands from 325 to 400 nm increased. The latter are connected to the roughness

A comparison of tarsal morphology and traction force in the two burying beetles Nicrophorus nepalensis and Nicrophorus vespilloides (Coleoptera, Silphidae)

Beilstein J. Nanotechnol. 2019, 10, 47–61, doi:10.3762/bjnano.10.5

- smooth surfaces, possibly being connected to the improved yield stress and slip resistance in this species. On the other hand, under certain conditions, more viscous fluids might also be able to reduce friction (e.g., because of reduced wetting properties). Hence, our conclusion remains a matter of

A new bioinspired method for pressure and flow sensing based on the underwater air-retaining surface of the backswimmer Notonecta

Beilstein J. Nanotechnol. 2018, 9, 3039–3047, doi:10.3762/bjnano.9.282

- high adhesive forces, in turn indicating that the pins became stuck inside the droplet. When the droplet lies on the surface, the clubs support the droplet and prevent surface wetting of the hemelytron (Figure 6b). The results so far suggest that Notonecta uses air layers in combination with

Femtosecond laser-assisted fabrication of chalcopyrite micro-concentrator photovoltaics

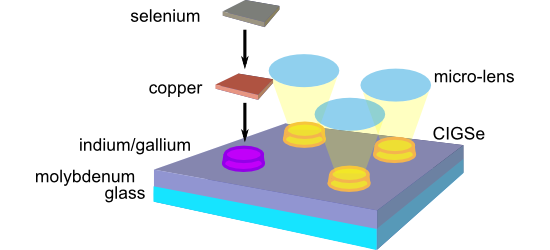

Beilstein J. Nanotechnol. 2018, 9, 3025–3038, doi:10.3762/bjnano.9.281

- deposition conditions, such that a significant wetting layer formed in addition to gallium islands. Due to the different temperature dependence of surface mobility and adsorption–desorption equilibria, a sequential PVD process turned out necessary for the growth of (In,Ga) islands, whereby indium islands

- were grown first, onto which gallium was subsequently deposited. Optimum gallium deposition conditions were found to be a substrate temperature of ca. 400 °C and a deposition rate of 0.15 Å/s. Despite preferential aggregation of gallium at the existing indium islands, an additional gallium wetting

- layer was always observed. In order to avoid the undesired formation of a thin CuGaSe2 layer connecting the separate CIGSe islands after processing, this gallium wetting layer was removed by a mild reactive ion etching step in Ar+ plasma. LIFT approach The second approach presented here for the