Abstract

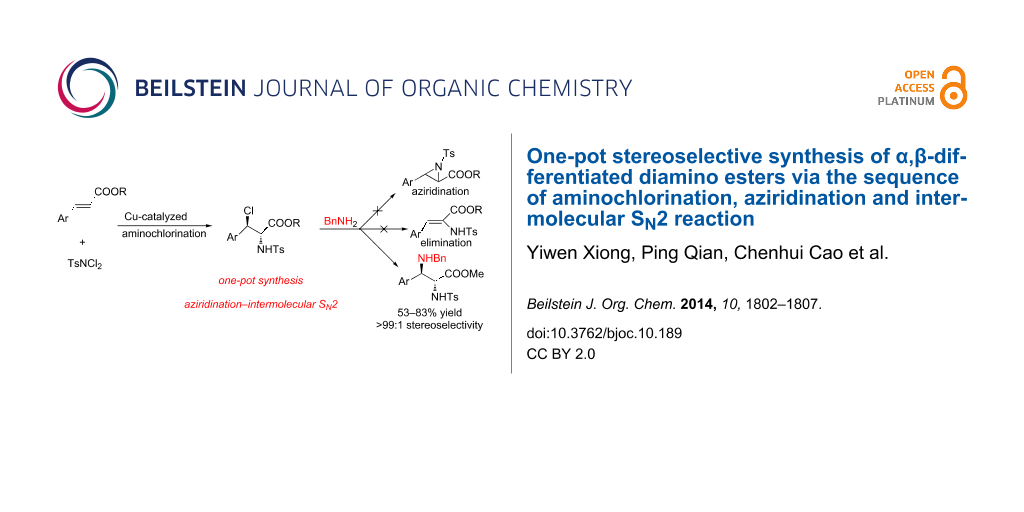

We report here an efficient one-pot method for the synthesis of α,β-differentiated diamino esters directly from cinnamate esters using N,N-dichloro-p-toluenesulfonamide and benzylamine as nitrogen sources. The key transformations include a Cu-catalyzed aminohalogenation and aziridination, followed by an intermolecular SN2 nucleophilic ring opening by benzylamine. The reactions feature a wide scope of substrates and proceed with excellent stereo- and regioselectivity (anti:syn >99:1) .

Graphical Abstract

Introduction

α,β-Diamino acid derivatives are one of the most important classes of nitrogen-containing bioactive compounds [1,2]. Their chemistry has attracted a lot of attention [3-5], leading to discovery and development of numerous useful compounds in the fields of biology, medicine, therapy and food [6-9]. They also belong to useful organic synthetic intermediates as they can be easily converted into the corresponding β,γ-amino alcohols and vicinal diamines. α,β-Diamino acid derivatives have been served as organocatalysts, chiral ligands, chiral auxiliaries for asymmertric synthesis [10-12], as well as synthetic fragments for peptides and natural products [13].

Mannich-type addition reactions of α-amino acid derivatives with imino compounds, or their precursors, is one of the most straightforward synthetic approaches to α,β-diamino acid compounds, in particular in asymmetric mode [14-22]. Direct catalytic oxidative diaminations of functionalized alkenes also present an access for the generation of α,β-diamino esters, which usually employ palladium or osmium as catalysts [23-25]. The electrophilic diamination reaction is an alternative methodology [26-28], which makes use of α,β-unsaturated esters as starting materials to form imidazoline diamine derivatives. However, these methods suffer from the shortcomings, such as need of special starting materials, use of expensive metal catalysts or strict anhydrous and anaerobic conditions.

The aminohalogenation reaction has been well studied in the past decade [29-32], and the corresponding vicinal haloamine product can be easily converted into aziridines [33,34] and α,β-dehydroamino acid derivatives [35] in the presence of an organic amine. Recently, we found that treating haloamine with benzylamine resulted in an unexpected α,β-diamino product, instead of the aziridine or the α,β-dehydroamino product. Herein, we report an anomalous outcome in the one-pot reaction, which provides a highly efficient method for the synthesis of α,β-differentiated diamino esters directly from readily available starting materials, α,β-unsaturated ester, N,N-dichlorotoluenesulfonamide (TsNCl2) and benzylamine. Furthermore, the reaction could be conducted in a one-pot model, under operationally convenient conditions [36-39] through Cu-catalyzed aminohalogenation, aziridination and intermolecular SN2 nucleophilic ring opening without isolation of haloamine intermediate (Scheme 1).

Scheme 1: An anomalous outcome with benzylamine as organic base.

Scheme 1: An anomalous outcome with benzylamine as organic base.

Results and Discussion

According to the previous reports on the derivatization of aminohalogenation reactions, the vicinal haloamines usually underwent elimination or aziridination reactions when they were treated with organic bases (Scheme 2) [33-35]. However, when benzylamine was added to haloamine 1a in acetonitrile, the reaction could also proceed smoothly giving a sole product. Quite unexpectedly, the 1H NMR data showed the presence of a benzyl group. This result clearly indicated that the benzylamine substituted product was formed.

Scheme 2: Transformation of vicinal haloamines by the use of organic amines.

Scheme 2: Transformation of vicinal haloamines by the use of organic amines.

Encouraged by this result, we then focused on the optimization of the reaction conditions with 1a as a model substrate to fully explore this new synthetic method (Table 1). Diamine product 5a was obtained in 83% yield when 1a reacted with benzylamine in acetonitrile at room temperature for 0.5 h (Table 1, entry 1). Increasing the temperature to 50 °C, gave no improvement on the yield (Table 1, entry 2). A higher yield was obtained when the reaction time was prolonged to 1 h (Table 1, entry 3). Further optimization efforts showed that the base loading amount could be lowered to 2 mL without any drop in yield (Table 1, entries 4 and 5). When 0.1 mL of benzylamine was used for this transformation in the presence of 2 mL triethylamine, the yield decreased dramatically even the reaction time was prolonged to 6 h (Table 1, entries 6–8). The solvent was also proved to be crucial for this transformation (Table 1, entries 4, 9 and 10). As shown by these experiments, acetonitrile and dichloromethane were the best choices. With the aim of developing a one-pot method, we chose acetonitrile as solvent for the following experiments because the previous reports indicated acetonitrile was the best solvent for the aminohalogenation of methyl cinnamate (4a).

Table 1: Optimization of typical reaction conditions.a

|

|

|||||

| entry | amount (mL)b | solvent | T (°C) | time (h) | yield (%)c |

|---|---|---|---|---|---|

| 1 | 4 | CH3CN | rt | 0.5 | 83 |

| 2 | 4 | CH3CN | 50 | 0.5 | 75 |

| 3 | 4 | CH3CN | rt | 1 | 91 |

| 4 | 2 | CH3CN | rt | 1 | 93 |

| 5 | 0.5 | CH3CN | rt | 1 | 63 |

| 6 | 0.1 | CH3CN | rt | 1 | 28d |

| 7 | 0.1 | CH3CN | rt | 3 | 59d |

| 8 | 0.1 | CH3CN | rt | 6 | 60d |

| 9 | 2 | CH2Cl2 | rt | 1 | 89 |

| 10 | 2 | CHCl3 | rt | 1 | 80 |

aReaction conditions: 1a (0.5 mmol), solvent (3 mL). bAmount of benzylamine. c Isolated yields. d2 mL triethylamine was added.

To prove the synthetic value of the methodology, other common primary or secondary amines, were tested in the reaction under optimized conditions (Table 2). The use of aliphatic amines, such as methylamine (Table 2, entry 2), dimethylamine (Table 2, entry 3) and ammonia solution (Table 2, entry 4), lead to the formation of the aziridine as the sole product in 88%, 83%, 91% yield, respectively. Notably, a complex mixture was obtained when 1,2-ethanediamine was used in this reaction (Table 2, entry 1).

Table 2: Examination of other organic bases.a

|

|

|||||

| entry | base (mL) | T (°C) | time (min) | product (%)b | |

|---|---|---|---|---|---|

| 3a | 5a | ||||

| 1 | 1,2-ethanediamine (2) | rt | 30 | complex mixture | |

| 2 | methylamine (2) | rt | 30 | 88 | |

| 3 | dimethylamine (2) | rt | 30 | 83 | |

| 4 | ammonia solution (2) | rt | 30 | 91 | |

aReaction conditions: 1a (0.5 mmol), acetonitrile (3 mL), base. bIsolated yields.

After getting the optimized conditions, we then combined the aminohalogenation and the treatment of benyzlamine to develop a one-pot procedure with α,β-unsaturated esters as starting materials. On the initial reaction step the cinnamic ester underwent a copper(II) trifluoromethanesulfonate-catalyzed aminohalogenation reaction with TsNCl2 as nitrogen source. After being quenched by saturated sodium sulfite, the resulting mixture was stirred with benzylamine. Various α,β-unsaturated esters were studied to evaluate the yield and stereochemical outcome of these reactions (Table 3). As shown in Table 3, almost all of the tested substrates worked well under the optimized conditions giving rise to the corresponding α,β-diamino ester products, even though the aromatic ring was substituted by strong electron-withdrawing groups (fluoro, Table 3, entries 6, 10 and 12; trifluoromethyl, entry 15) or an electron-donating group (methoxy, Table 3, entry 8). In the case of ethyl ester, the reaction showed lower reactivity (Table 3, entry 2), and 70% chemical yield was obtained comparing to 79% yield from methyl ester (Table 3, entry 1). A cinnamic ester with double-substituted aromatic ring 4m was also tolerated in this reaction along with a moderate chemical yield (53%, Table 3, entry 13). Notably, when the phenyl was replaced by 1-naphthyl 4n (Table 3, entry 14), it was also well performing in this reaction giving rise to the target product in 64% yield. For the substrates with ortho-substituents (Table 3, entries 13 and 16), the yields were a little bit lower than the yields of the meta- and para-substituted substrates, which indicates that the steric hindrance affects the formation of the product. Furthermore, excellent stereoselectivity was obtained for all of the examined cinnamic ester substrates, and only the anti-isomers were observed.

Table 3: One-pot reaction for the synthesis of α,β-diamino ester.a

|

|

|||||

| entry | Ar | R | product | yield (%)b | anti:syn c |

|---|---|---|---|---|---|

| 1 | C6H5 | Me | 5a | 79 | >99:1 |

| 2 | C6H5 | Et | 5b | 70 | >99:1 |

| 3 | 4-CH3-C6H4 | Me | 5c | 67 | >99:1 |

| 4 | 4-Br-C6H4 | Me | 5d | 72 | >99:1 |

| 5 | 4-Cl-C6H4 | Me | 5e | 68 | >99:1 |

| 6 | 4-F-C6H4 | Me | 5f | 78 | >99:1 |

| 7 | 4-CF3O-C6H4 | Me | 5g | 80 | >99:1 |

| 8 | 3-CH3O-C6H4 | Me | 5h | 70 | >99:1 |

| 9 | 3-Cl-C6H4 | Me | 5i | 67 | >99:1 |

| 10 | 3-F-C6H4 | Me | 5j | 75 | >99:1 |

| 11 | 2-Cl-C6H4 | Me | 5k | 63 | >99:1 |

| 12 | 2-F-C6H4 | Me | 5l | 83 | >99:1 |

| 13 | 2,6-di-Cl-C6H3 | Me | 5m | 53 | >99:1 |

| 14 | 1-naphthyl | Me | 5n | 64 | >99:1 |

| 15 | 3-CF3-C6H4 | Me | 5o | 74 | >99:1 |

| 16 | 2-Br-C6H4 | Me | 5p | 58 | >99:1 |

aReaction conditions: 1) 10 mol % Cu(OTf)2, 0.5 mmol cinnamic ester 4, 1.0 mmol TsNCl2, 250 mg 4 Å molecular sieves in 3.0 mL acetonitrile at room temperature for 24 h; 2) Quenched by 3 mL saturated Na2SO3 for 30 min; 3) Benzylamine 2.0 mL at room temperature for 1 h. bIsolated yield. cDetermined by 1H NMR.

To determine the structure of product 5, single crystals were prepared. Fortunately, the crystals of product 5o had a good crystallinity and were suitable for single crystal X-ray analysis (Figure 1). Crystallographic analysis has revealed that the anti-vicinal diamino ester was obtained. As a result, the stereochemistry of the other products was assigned (anti-isomer) based on the similarity of their properties.

Finally, some reactions were additionally conducted to gain insight into the reaction mechanism. First, we prepared the aziridine 6 according to the reported method with cinnamic ethyl ester as starting material [33]. Then, we used the aziridine 6 as starting material to react with benzylamine under similar reaction conditions of the third step of this one-pot reaction (Scheme 3). To our delight, aziridine 6 was converted into the corresponding diamino acid ester 5b with 73% chemical yield. Thus, aziridine most likely might be the intermediate in this reaction.

Based on the above results, a proposed reaction mechanism for this one-pot reaction is illustrated in Scheme 4, which contains the sequence of aminochlorination, aziridination and followed by the SN2 nucleophilic ring-opening. The first step is the Cu-catalyzed aminochlorination reaction of methyl cinnamate 1a resulting in anti-chloroamine intermediate A. The second step involves a typical intramolecular SN2 substitution reaction of intermediate A with the aid of benzylamine, to give the aziridine intermediate B. The intermediate B undergoes a SN2 nucleophilic process attacked by benzylamine, leading to the formation of the final product 5a. The excellent stereoselectivity and formation of only anti-isomer can be explained by the formation of aziridine intermediate and complete geometry control of the following SN2 nucleophilic attack. The formation of the unexpected diamino ester, instead of aziridine, may be due to the relative strong nucleophilicity of benzylamine. Considering the fact that the final product 5a is anti and the aminohalogenation product intermediate A is also anti, the only way to explain the stereochemistry of product 5 is the double inversion via aziridine formation. The direct substitution of the Cl atom is possible, but it will lead to the syn product 5. Therefore we believe that the interpretation of the observed stereochemical outcome must involve the intermediate aziridine formation.

Conclusion

In conclusion, a new one-pot method for the synthesis of α,β-differentiated diamino esters directly from α,β-unsaturated esters has been developed. The reaction sequence includes copper-catalyzed aminochlorination, aziridination and SN2 nucleophilic ring-opening reaction. This one-pot reaction is operationally convenient and can tolerate a variety of substrates affording the target products in good-to-excellent chemical yields. Furthermore, this reaction gives virtually complete stereochemical outcomes, and only the anti-isomer is found for all the cases, which provides an easy access to α,β-diamino acid derivatives.

Experimental

General procedure for the one-pot synthesis of α,β-diamino esters: Into a dry vial was added cinnamic ester 4 (0.50 mmol) and freshly distilled acetonitrile (3.0 mL). The reaction vial was loaded with freshly activated 4 Å molecular sieves (250 mg), TsNCl2 (1.0 mmol) and Cu(OTf)2 (10 mol %). The solution in the capped vial was stirred at room temperature for 24 h without argon protection. The reaction was finally quenched by dropwise addition of saturated aqueous Na2SO3 solution (3.0 mL). After quench for 30 min, benzylamine (2.0 mL) was added to the mixture exposed to air. Another one hour was needed until conversion was complete. Then the phases were separated, and the aqueous phase was extracted with ethyl acetate (3 × 10 mL). The combined organic layers were washed with brine, dried over anhydrous sodium sulfate, and concentrated to dryness. Purification by flash chromatography (EtOAc/hexane, from 1:20 to 1:3, v/v) provided final products 5.

Supporting Information

| Supporting Information File 1: Experimental details and spectral data. | ||

| Format: PDF | Size: 1.4 MB | Download |

Acknowledgements

We gratefully acknowledge the financial support from the National Natural Science Foundation of China (No. 21102071) and the Fundamental Research Funds for the Central Universities (No. 1107020522 and No. 1082020502). The Jiangsu 333 program (for Pan) and Changzhou Jin-Feng-Huang program (for Han) are also acknowledged.

References

-

Viso, A.; Fernández de la Pradilla, R.; García, A.; Flores, A. Chem. Rev. 2005, 105, 3167–3196. doi:10.1021/cr0406561

Return to citation in text: [1] -

Viso, A.; Fernández de la Pradilla, R.; García, A.; Flores, A. Chem. Rev. 2011, 111, PR1–PR42. doi:10.1021/cr100127y

Return to citation in text: [1] -

Shi, S.-H.; Huang, F.-P.; Zhu, P.; Dong, Z.-W.; Hui, X.-P. Org. Lett. 2012, 14, 2010–2013. doi:10.1021/ol300510b

Return to citation in text: [1] -

Bandar, J. S.; Lambert, T. H. J. Am. Chem. Soc. 2013, 135, 11799–11802. doi:10.1021/ja407277a

Return to citation in text: [1] -

Valle, M. S.; Saraiva, M. F.; Retailleau, P.; de Almeida, M. V.; Dodd, R. H. J. Org. Chem. 2012, 77, 5592–5599. doi:10.1021/jo300468j

Return to citation in text: [1] -

Meierhenrich, U. J.; Muñoz Caro, G. M.; Bredehöft, J. H.; Jessberger, E. K.; Thiemann, W. H.-P. Proc. Natl. Acad. Sci. U. S. A. 2004, 101, 9182–9186. doi:10.1073/pnas.0403043101

Return to citation in text: [1] -

Cox, P. A.; Banack, S. A.; Murch, S. J. Proc. Natl. Acad. Sci. U. S. A. 2003, 100, 13380–13383. doi:10.1073/pnas.2235808100

Return to citation in text: [1] -

Boer, J.; Blount, K. F.; Luedtke, N. W.; Elson-Schwab, L.; Tor, Y. Angew. Chem., Int. Ed. 2005, 44, 927–932. doi:10.1002/anie.200461182

Return to citation in text: [1] -

Ferreira, P. M. T.; Maia, H. L. S.; Monteiro, L. S. Tetrahedron Lett. 1999, 40, 4099–4102. doi:10.1016/S0040-4039(99)00691-7

Return to citation in text: [1] -

Dobbin, P. S.; Hider, R. C.; Hall, A. D.; Taylor, P. D.; Sarpong, P.; Porter, J. B.; Xiao, G.; van der Helm, D. J. Med. Chem. 1993, 36, 2448–2458. doi:10.1021/jm00069a002

Return to citation in text: [1] -

Chiang, M.; Li, Y.; Krishnan, D.; Sumod, P.; Ng, K. H.; Leung, P.-H. Eur. J. Inorg. Chem. 2010, 9, 1413–1418. doi:10.1002/ejic.200901142

Return to citation in text: [1] -

Robinson, A. J.; Stanislawski, P.; Mulholland, D.; He, L.; Li, H.-Y. J. Org. Chem. 2001, 66, 4148–4152. doi:10.1021/jo001152f

Return to citation in text: [1] -

Roviello, G. N.; Di Gaetano, S.; Capasso, D.; Franco, S.; Crescenzo, C.; Bucci, E. M.; Pedone, C. J. Med. Chem. 2011, 54, 2095–2101. doi:10.1021/jm1012769

Return to citation in text: [1] -

Arrayás, R. G.; Carretero, J. C. Chem. Soc. Rev. 2009, 38, 1940–1948. doi:10.1039/b820303b

Return to citation in text: [1] -

Cutting, G. A.; Stainforth, N. E.; John, M. P.; Kociok-Köhn, G.; Willis, M. C. J. Am. Chem. Soc. 2007, 129, 10632–10633. doi:10.1021/ja073473f

Return to citation in text: [1] -

Li, L.; Ganesh, M.; Seidel, D. J. Am. Chem. Soc. 2009, 131, 11648–11649. doi:10.1021/ja9034494

Return to citation in text: [1] -

Xie, C.; Mei, H.; Wu, L.; Soloshonok, V. A.; Han, J.; Pan, Y. Eur. J. Org. Chem. 2014, 1445–1451. doi:10.1002/ejoc.201301377

Return to citation in text: [1] -

Soloshonok, V. A.; Avilov, D. V.; Kukhar', V. P.; Meervelt, L. V.; Mischenko, N. Tetrahedron Lett. 1997, 38, 4671–4674. doi:10.1016/S0040-4039(97)00963-5

Return to citation in text: [1] -

Qiu, W.; Gu, X.; Soloshonok, V. A.; Carducci, M. D.; Hruby, V. J. Tetrahedron Lett. 2001, 42, 145–148. doi:10.1016/S0040-4039(00)01864-5

Return to citation in text: [1] -

Shibata, N.; Nishimine, T.; Shibata, N.; Tokunaga, E.; Kawada, K.; Kagawa, T.; Aceña, J. L.; Sorochinsky, A. E.; Soloshonok, V. A. Org. Biomol. Chem. 2014, 12, 1454–1462. doi:10.1039/c3ob42425a

Return to citation in text: [1] -

Shibata, N.; Nishimine, T.; Tokunaga, E.; Kawada, K.; Kagawa, T.; Sorochinsky, A. E.; Soloshonok, V. A. Chem. Commun. 2012, 48, 4124–4126. doi:10.1039/c2cc30627a

Return to citation in text: [1] -

Soloshonok, V. A.; Ohkura, H.; Sorochinsky, A.; Voloshin, N.; Markovsky, A.; Belik, M.; Yamazaki, T. Tetrahedron Lett. 2002, 43, 5445–5448. doi:10.1016/S0040-4039(02)01103-6

Return to citation in text: [1] -

de Figueiredo, R. M. Angew. Chem., Int. Ed. 2009, 48, 1190–1193. doi:10.1002/anie.200804362

Return to citation in text: [1] -

Du, H.; Zhao, B.; Shi, Y. J. Am. Chem. Soc. 2007, 129, 762–763. doi:10.1021/ja0680562

Return to citation in text: [1] -

Muñiz, K.; Nieger, M. Chem. Commun. 2005, 2729–2731. doi:10.1039/B502150B

Return to citation in text: [1] -

Li, G.; Kim, S. H.; Wei, H.-X. Tetrahedron Lett. 2000, 41, 8699–8703. doi:10.1016/S0040-4039(00)01579-3

Return to citation in text: [1] -

Li, G.; Wei, H.-X.; Kim, S. H.; Carducci, M. D. Angew. Chem., Int. Ed. 2001, 40, 4277–4280. doi:10.1002/1521-3773(20011119)40:22<4277::AID-ANIE4277>3.0.CO;2-I

Return to citation in text: [1] -

Wu, H.; Ji, X.; Sun, H.; An, G.; Han, J.; Li, G.; Pan, Y. Tetrahedron 2010, 66, 4555–4559. doi:10.1016/j.tet.2010.04.054

Return to citation in text: [1] -

Li, G.; Saibabu Kotti, S. R. S.; Timmons, C. Eur. J. Org. Chem. 2007, 2745–2758. doi:10.1002/ejoc.200600990

See for a review on aminohalogenation.

Return to citation in text: [1] -

Han, J.-L.; Zhi, S.-J.; Wang, L.-Y.; Pan, Y.; Li, G. Eur. J. Org. Chem. 2007, 1332–1337. doi:10.1002/ejoc.200600902

Return to citation in text: [1] -

Mei, H.; Han, J.; Li, G.; Pan, Y. RSC Adv. 2011, 1, 429–433. doi:10.1039/c1ra00174d

Return to citation in text: [1] -

Li, G.; Wei, H.-X.; Kim, S. H.; Neighbors, M. Org. Lett. 1999, 1, 395–398. doi:10.1021/ol990059e

Return to citation in text: [1] -

Chen, D.; Timmons, C.; Guo, L.; Xu, X.; Li, G. Synthesis 2004, 2479–2484. doi:10.1055/s-2004-831203

Return to citation in text: [1] [2] [3] -

Mei, H.; Yan, L.; Han, J.; Li, G.; Pan, Y. Chem. Biol. Drug Des. 2010, 76, 392–396. doi:10.1111/j.1747-0285.2010.01023.x

Return to citation in text: [1] [2] -

Chen, D.; Guo, L.; Liu, J.; Kirtane, S.; Cannon, J. F.; Li, G. Org. Lett. 2005, 7, 921–924. doi:10.1021/ol050002u

Return to citation in text: [1] [2] -

Park, N. H.; Teverovskiy, G.; Buchwald, S. L. Org. Lett. 2014, 16, 220–223. doi:10.1021/ol403209k

Return to citation in text: [1] -

Boyall, D.; Frantz, D. E.; Carreira, E. M. Org. Lett. 2002, 4, 2605–2606. doi:10.1021/ol026282k

Return to citation in text: [1] -

Soloshonok, V. A.; Ohkura, H.; Yasumoto, M. J. Fluorine Chem. 2006, 127, 924–929. doi:10.1016/j.jfluchem.2006.04.003

Return to citation in text: [1] -

Soloshonok, V. A.; Ohkura, H.; Yasumoto, M. J. Fluorine Chem. 2006, 127, 930–935. doi:10.1016/j.jfluchem.2006.04.004

Return to citation in text: [1]

| 1. | Viso, A.; Fernández de la Pradilla, R.; García, A.; Flores, A. Chem. Rev. 2005, 105, 3167–3196. doi:10.1021/cr0406561 |

| 2. | Viso, A.; Fernández de la Pradilla, R.; García, A.; Flores, A. Chem. Rev. 2011, 111, PR1–PR42. doi:10.1021/cr100127y |

| 13. | Roviello, G. N.; Di Gaetano, S.; Capasso, D.; Franco, S.; Crescenzo, C.; Bucci, E. M.; Pedone, C. J. Med. Chem. 2011, 54, 2095–2101. doi:10.1021/jm1012769 |

| 10. | Dobbin, P. S.; Hider, R. C.; Hall, A. D.; Taylor, P. D.; Sarpong, P.; Porter, J. B.; Xiao, G.; van der Helm, D. J. Med. Chem. 1993, 36, 2448–2458. doi:10.1021/jm00069a002 |

| 11. | Chiang, M.; Li, Y.; Krishnan, D.; Sumod, P.; Ng, K. H.; Leung, P.-H. Eur. J. Inorg. Chem. 2010, 9, 1413–1418. doi:10.1002/ejic.200901142 |

| 12. | Robinson, A. J.; Stanislawski, P.; Mulholland, D.; He, L.; Li, H.-Y. J. Org. Chem. 2001, 66, 4148–4152. doi:10.1021/jo001152f |

| 6. | Meierhenrich, U. J.; Muñoz Caro, G. M.; Bredehöft, J. H.; Jessberger, E. K.; Thiemann, W. H.-P. Proc. Natl. Acad. Sci. U. S. A. 2004, 101, 9182–9186. doi:10.1073/pnas.0403043101 |

| 7. | Cox, P. A.; Banack, S. A.; Murch, S. J. Proc. Natl. Acad. Sci. U. S. A. 2003, 100, 13380–13383. doi:10.1073/pnas.2235808100 |

| 8. | Boer, J.; Blount, K. F.; Luedtke, N. W.; Elson-Schwab, L.; Tor, Y. Angew. Chem., Int. Ed. 2005, 44, 927–932. doi:10.1002/anie.200461182 |

| 9. | Ferreira, P. M. T.; Maia, H. L. S.; Monteiro, L. S. Tetrahedron Lett. 1999, 40, 4099–4102. doi:10.1016/S0040-4039(99)00691-7 |

| 33. | Chen, D.; Timmons, C.; Guo, L.; Xu, X.; Li, G. Synthesis 2004, 2479–2484. doi:10.1055/s-2004-831203 |

| 34. | Mei, H.; Yan, L.; Han, J.; Li, G.; Pan, Y. Chem. Biol. Drug Des. 2010, 76, 392–396. doi:10.1111/j.1747-0285.2010.01023.x |

| 35. | Chen, D.; Guo, L.; Liu, J.; Kirtane, S.; Cannon, J. F.; Li, G. Org. Lett. 2005, 7, 921–924. doi:10.1021/ol050002u |

| 3. | Shi, S.-H.; Huang, F.-P.; Zhu, P.; Dong, Z.-W.; Hui, X.-P. Org. Lett. 2012, 14, 2010–2013. doi:10.1021/ol300510b |

| 4. | Bandar, J. S.; Lambert, T. H. J. Am. Chem. Soc. 2013, 135, 11799–11802. doi:10.1021/ja407277a |

| 5. | Valle, M. S.; Saraiva, M. F.; Retailleau, P.; de Almeida, M. V.; Dodd, R. H. J. Org. Chem. 2012, 77, 5592–5599. doi:10.1021/jo300468j |

| 33. | Chen, D.; Timmons, C.; Guo, L.; Xu, X.; Li, G. Synthesis 2004, 2479–2484. doi:10.1055/s-2004-831203 |

| 29. |

Li, G.; Saibabu Kotti, S. R. S.; Timmons, C. Eur. J. Org. Chem. 2007, 2745–2758. doi:10.1002/ejoc.200600990

See for a review on aminohalogenation. |

| 30. | Han, J.-L.; Zhi, S.-J.; Wang, L.-Y.; Pan, Y.; Li, G. Eur. J. Org. Chem. 2007, 1332–1337. doi:10.1002/ejoc.200600902 |

| 31. | Mei, H.; Han, J.; Li, G.; Pan, Y. RSC Adv. 2011, 1, 429–433. doi:10.1039/c1ra00174d |

| 32. | Li, G.; Wei, H.-X.; Kim, S. H.; Neighbors, M. Org. Lett. 1999, 1, 395–398. doi:10.1021/ol990059e |

| 35. | Chen, D.; Guo, L.; Liu, J.; Kirtane, S.; Cannon, J. F.; Li, G. Org. Lett. 2005, 7, 921–924. doi:10.1021/ol050002u |

| 26. | Li, G.; Kim, S. H.; Wei, H.-X. Tetrahedron Lett. 2000, 41, 8699–8703. doi:10.1016/S0040-4039(00)01579-3 |

| 27. | Li, G.; Wei, H.-X.; Kim, S. H.; Carducci, M. D. Angew. Chem., Int. Ed. 2001, 40, 4277–4280. doi:10.1002/1521-3773(20011119)40:22<4277::AID-ANIE4277>3.0.CO;2-I |

| 28. | Wu, H.; Ji, X.; Sun, H.; An, G.; Han, J.; Li, G.; Pan, Y. Tetrahedron 2010, 66, 4555–4559. doi:10.1016/j.tet.2010.04.054 |

| 36. | Park, N. H.; Teverovskiy, G.; Buchwald, S. L. Org. Lett. 2014, 16, 220–223. doi:10.1021/ol403209k |

| 37. | Boyall, D.; Frantz, D. E.; Carreira, E. M. Org. Lett. 2002, 4, 2605–2606. doi:10.1021/ol026282k |

| 38. | Soloshonok, V. A.; Ohkura, H.; Yasumoto, M. J. Fluorine Chem. 2006, 127, 924–929. doi:10.1016/j.jfluchem.2006.04.003 |

| 39. | Soloshonok, V. A.; Ohkura, H.; Yasumoto, M. J. Fluorine Chem. 2006, 127, 930–935. doi:10.1016/j.jfluchem.2006.04.004 |

| 23. | de Figueiredo, R. M. Angew. Chem., Int. Ed. 2009, 48, 1190–1193. doi:10.1002/anie.200804362 |

| 24. | Du, H.; Zhao, B.; Shi, Y. J. Am. Chem. Soc. 2007, 129, 762–763. doi:10.1021/ja0680562 |

| 25. | Muñiz, K.; Nieger, M. Chem. Commun. 2005, 2729–2731. doi:10.1039/B502150B |

| 14. | Arrayás, R. G.; Carretero, J. C. Chem. Soc. Rev. 2009, 38, 1940–1948. doi:10.1039/b820303b |

| 15. | Cutting, G. A.; Stainforth, N. E.; John, M. P.; Kociok-Köhn, G.; Willis, M. C. J. Am. Chem. Soc. 2007, 129, 10632–10633. doi:10.1021/ja073473f |

| 16. | Li, L.; Ganesh, M.; Seidel, D. J. Am. Chem. Soc. 2009, 131, 11648–11649. doi:10.1021/ja9034494 |

| 17. | Xie, C.; Mei, H.; Wu, L.; Soloshonok, V. A.; Han, J.; Pan, Y. Eur. J. Org. Chem. 2014, 1445–1451. doi:10.1002/ejoc.201301377 |

| 18. | Soloshonok, V. A.; Avilov, D. V.; Kukhar', V. P.; Meervelt, L. V.; Mischenko, N. Tetrahedron Lett. 1997, 38, 4671–4674. doi:10.1016/S0040-4039(97)00963-5 |

| 19. | Qiu, W.; Gu, X.; Soloshonok, V. A.; Carducci, M. D.; Hruby, V. J. Tetrahedron Lett. 2001, 42, 145–148. doi:10.1016/S0040-4039(00)01864-5 |

| 20. | Shibata, N.; Nishimine, T.; Shibata, N.; Tokunaga, E.; Kawada, K.; Kagawa, T.; Aceña, J. L.; Sorochinsky, A. E.; Soloshonok, V. A. Org. Biomol. Chem. 2014, 12, 1454–1462. doi:10.1039/c3ob42425a |

| 21. | Shibata, N.; Nishimine, T.; Tokunaga, E.; Kawada, K.; Kagawa, T.; Sorochinsky, A. E.; Soloshonok, V. A. Chem. Commun. 2012, 48, 4124–4126. doi:10.1039/c2cc30627a |

| 22. | Soloshonok, V. A.; Ohkura, H.; Sorochinsky, A.; Voloshin, N.; Markovsky, A.; Belik, M.; Yamazaki, T. Tetrahedron Lett. 2002, 43, 5445–5448. doi:10.1016/S0040-4039(02)01103-6 |

| 33. | Chen, D.; Timmons, C.; Guo, L.; Xu, X.; Li, G. Synthesis 2004, 2479–2484. doi:10.1055/s-2004-831203 |

| 34. | Mei, H.; Yan, L.; Han, J.; Li, G.; Pan, Y. Chem. Biol. Drug Des. 2010, 76, 392–396. doi:10.1111/j.1747-0285.2010.01023.x |

© 2014 Xiong et al; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)

![[1860-5397-10-189-1]](/bjoc/content/figures/1860-5397-10-189-1.png?scale=2.0&max-width=1024&background=FFFFFF)