Abstract

Pyridine is a crucial heterocyclic scaffold that is widely found in organic chemistry, medicines, natural products, and functional materials. In spite of the discovery of several methods for the synthesis of functionalized pyridines or their integration into an organic molecule, new methodologies for the direct functionalization of pyridine scaffolds have been developed during the past two decades. In addition, transition-metal-catalyzed C–H functionalization and rare earth metal-catalyzed reactions have flourished over the past two decades in the development of functionalized organic molecules of concern. In this review, we discuss recent achievements in the transition-metal and rare earth metal-catalyzed C–H bond functionalization of pyridine and look into the mechanisms involved.

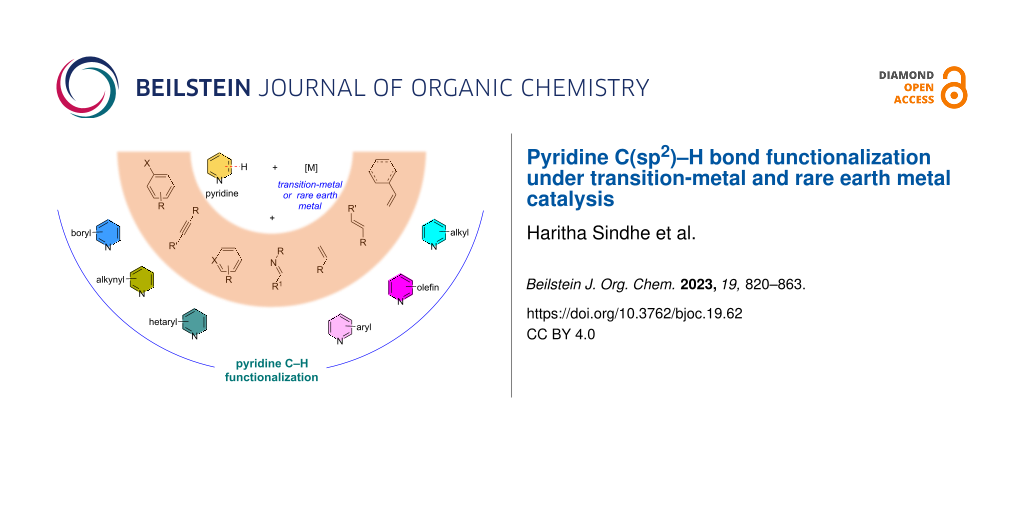

Graphical Abstract

Introduction

Pyridine, one of the most important azaheterocyclic scaffolds, is found in a diverse range of bioactive natural products, pharmaceuticals, and functional materials [1-10]. Due to its different characteristics such as basicity, stability, water solubility, small molecular size, and ability to form hydrogen bonds, pyridine continues to be a suitable moiety in organic synthesis. In addition, it has been observed that pyridine rings serve as bioisostere for aromatic rings, amines, amides, and N-containing heterocycles. Due to the aforementioned qualities, numerous U.S. FDA-approved medications have pyridine scaffolds in their molecules (Figure 1).

Figure 1: Representative examples of bioactive natural products and FDA-approved drugs containing a pyridine moiety.

Figure 1: Representative examples of bioactive natural products and FDA-approved drugs containing a pyridine ...

In this context, the synthesis of the pyridine motif is always there in trend. Many pyridine syntheses have relied on the condensation of carbonyl compounds and amines for a very long time [11]. The classical methods for the synthesis of functionalized pyridine include the Hantzsch pyridine synthesis and the Bohlmann–Rahtz synthesis (Scheme 1a and b). Furthermore, alternative methodologies are being developed for the synthesis of functionalized pyridines or its integration into an organic molecule [12-20]. Although classical organic synthesis is incredibly effective, it frequently requires the prefunctionalization of substrates and involves stoichiometric waste.

Scheme 1: Classical and traditional methods for the synthesis of functionalized pyridines.

Scheme 1: Classical and traditional methods for the synthesis of functionalized pyridines.

The challenges associated with the functionalization of pyridine are based on the low reactivity of the pyridine ring system for undergoing substitution reactions. This is attributed to the electron-deficient nature of the ring system due to the presence of the sp2-hybridized nitrogen atom. In addition, the lone pair electrons of the nitrogen atom interact with Lewis acids instead of the π-electrons of the ring system thus resulting to its reduced reactivity for electrophilic aromatic substitution reactions, such as a Friedel–Crafts reaction [21-23]. Hence, it is challenging to functionalize a C–H bond in pyridine with traditional chemical transformations. On the other hand, intriguing developments have been made for the functionalization of inert C–H bonds in organic synthesis during the past two decades. In this regard, the transition-metal-catalyzed C–H functionalization has made its way towards the synthesis and functionalization of various complex organic molecules [24-31]. In addition, rare earth metal-catalyzed C–H functionalization reactions have been known for a few decades, however, they received growing interest only recently [32-34]. Thus, diversely functionalized pyridines have been synthesized via C–H activation under transition-metal and rare earth metal catalysis, including C–H alkylation, alkenylation, arylation, heteroarylation, borylation, etc. Recently, metal-free approaches have also been developed for the C–H functionalization of N-heterocycles [35-39]. However, due to the vastness of reports on C–H functionalizations of N-heterocycles, in this review we have summarized recent progress (from year 2010 to 2023) in the C–H functionalization of the pyridine ring only. Herein, we discuss transition-metal as well as rare earth metal-catalyzed directed and undirected, proximal as well as distal pyridine C(sp2)–H bond functionalizations in detail under different types of reactions. Further, this review excludes the use of pyridine as a directing group for C–H functionalizations and the C–H functionalization of fused pyridines.

Review

C–H Alkylation of pyridine

The C–H bond is the backbone of an organic molecule and the conversion of a C–H bond to a C–X bond (X = carbon or heteroatom) forms the basis in organic synthesis. The functionalization of C–H bonds is challenging due to a large kinetic barrier for C–H bond cleavage and also achieving selectivity is difficult due to its ubiquitous nature [40]. The metal-catalyzed C–H bond functionalization is a good strategy for synthesizing highly functionalized organic frameworks. In this context, the C–H alkylation is one of the most important C–C bond-formation reactions [41-45]. On the other hand, a metal-catalyzed functionalization of arene/heteroarene C–H bonds to the corresponding C–C bonds is an area of great interest and has been well studied [46,47]. Pyridine, being an important heterocyclic scaffold, various studies have been conducted for the C(sp2)–H alkylation of the pyridine ring. In this part, we describe pyridine C–H alkylation reactions sub-sectioning based on the position of the alkylation reported.

ortho-C–H Alkylation

Inspired by the pioneering work of Jordan and co-workers [48] on the ortho-selective C–H alkylation of 2-picoline with propene using a cationic zirconium complex under a H2 atmosphere in 1989 and the work done by Bergman and Ellmann [49] in 2010 for the ortho-C–H alkylation of pyridines under Rh(I) catalysis at high temperature, in 2011 Hou and Guan reported an atom economical method for the selective ortho-alkylation of pyridines by C–H addition to olefins under cationic half-sandwich rare-earth catalysis [50]. They carried out the reaction in the presence of dialkyl complexes of scandium (Sc) or yttrium (Y) such as (C5Me5)Ln(CH2C6H4NMe2-o)2 (Ln = Sc, Y) in combination with B(C6F5)3 as an activator. The method demonstrated a wide substrate scope of both pyridines and olefins including α-olefins, styrenes, and conjugated dienes. The yttrium complex was found to be superior as compared to the scandium complex for the alkylation reaction of bulkier 2-tert-butylpyridine with ethylene. In addition, the yttrium catalyst was also found to have a higher catalytic activity for the ortho-alkylation of pyridines with styrenes to give the linear alkylated products (5b,c, Scheme 2). Further, the authors proposed that the C–H bond activation could be the rate limiting step based on kinetic isotope experiments (KIE). The proposed mechanism involves the coordination of pyridine to the metal center of the cationic catalyst and B(C6F5)3 promotes the ortho-C–H activation (deprotonation) of pyridine to afford pyridyl species 6. Next, the 2,1-migratory insertion of alkene 2 into the metal–pyridyl bond in 6 gives the intermediate 7, which on subsequent deprotonation gives the branched alkylated product 4. Whereas, in case of styrene 3 a 1,2-insertion takes place possibly due to the formation of the stable benzallylic species 8, which on deprotonation gives the linear alkylated product 5.

Scheme 2: Rare earth metal (Ln)-catalyzed pyridine C–H alkylation.

Scheme 2: Rare earth metal (Ln)-catalyzed pyridine C–H alkylation.

The C–H activation/C–C cross-coupling reaction with 1° alkyl electrophiles has been known in the past, however, the C–H alkylation with nonactivated secondary (2°) alkyl electrophiles and tertiary alkyl electrophiles was little known. In this context, in 2013, Fu and co-workers came across an unexpected finding with Pd-catalyzed C–H activation/C–C cross-coupling of pyridine N-oxides with nonactivated secondary (2°) alkyl bromides [51]. The cross-coupling is difficult to achieve as the Pd-catalyzed SN2 process is sensitive towards the steric bulk of the secondary or tertiary alkyl electrophiles. The optimized conditions for the ortho-alkylation of pyridine N-oxides 9 with nonactivated secondary (2°) alkyl bromides 10 required 5 mol % of the Pd(OAc)2dppf catalyst, Cs2CO3 (2.0 equiv) as base in toluene at 100 °C as shown in Scheme 3. Under these conditions, the reaction provided diverse 2-alkylpyridine derivatives 11 in moderate to good yields starting from both cyclic and acyclic alkyl bromides. The findings of the reaction’s stereochemistry and observations made during some cyclization or ring-opening reactions indicated that the C–H alkylation may proceed through a radical-type mechanism. Next, in 2013, Wang and co-workers [52] reported a protocol using CuI (10 mol %) as inexpensive catalyst and LiOt-Bu (3.5 equiv) as the base for the C–H alkylation of N-iminopyridinium ylides 12 with N-tosylhydrazones 13 showing good substrate scope for both coupling partners (Scheme 4). A substituent on the aromatic ring of the tosylhydrazones did not significantly affect the C–H alkylation reaction and the reaction also proceeded well with hydrazones 13 obtained from aliphatic aldehydes or ketones. Based on mechanistic experiments and DFT calculations, the reaction presumably proceeds via a Cu–carbene migratory insertion (Scheme 4b). In the presence of CuI and the base the initial direct C–H activation of the ylide 12 gives the copper pyridinium ylide 15. The latter reacts with the diazo compound formed through reaction of hydrazone 13 with the base to give the copper–carbene species 16. Then, the intermediate 16 undergoes a Cu–carbene migratory insertion giving intermediate 16’, which upon protonation gives the desired alkylated product 14.

Scheme 3: Pd-catalyzed C–H alkylation of pyridine N-oxide.

Scheme 3: Pd-catalyzed C–H alkylation of pyridine N-oxide.

Scheme 4: CuI-catalyzed C–H alkylation of N-iminopyridinium ylides with tosylhydrazones (A) and a plausible reaction mechanism (B).

Scheme 4: CuI-catalyzed C–H alkylation of N-iminopyridinium ylides with tosylhydrazones (A) and a plausible r...

Later, in the year 2018, Yao and co-workers [53] developed the first example of a group 4 metal-based catalyst protocol for the C–H alkylation of pyridine 1 with alkenes 18 and 20 as coupling partners. They demonstrated that the reaction in the presence of cationic zirconium complexes derived from zirconium dibenzyl complexes bearing tridentate [ONO]-type amine-bridged bis(phenolato) ligands and [Ph3C][B(C6F5)4] (Scheme 5), gave rise to ortho-selective C–H alkylated pyridines 19 and 21. It was observed that the cationic Zr complexes provided good transformations, probably due to good accessibility of the coordination site and an increased Lewis acidity of the metal center. The authors also demonstrated that this catalytic system also catalyzes the alkylation of benzylic C–H bonds (C(sp3)–H) of various dialkylpyridines with alkenes. It is to be noted that the ligands’ backbones were found to be crucial for the regioselectivity of the addition to benzylic C(sp3)–H bonds, as N-arylamine-bridged bis(phenolato) Zr complexes provided branched products whereas N-alkylamine-bridged bis(phenolato) Zr complexes provided the linear addition products. The proposed mechanism (Scheme 5b) involves the initial formation of Zr complex 22 through the reaction of neutral Zr complex 17 with [Ph3C][B(C6F5)4], which on coordination with the pyridine resulted in the formation of the 3-membered zirconacyclic intermediate 23. The migratory insertion of the alkene into the metal–C bond of 23 gives the intermediate 24a on reaction with styrene 18 and intermediate 24b in the presence of alkene 20. The intermediates 24a and 24b then undergo further hydrolysis to give the desired linear products 19 and branched products 21, respectively.

Scheme 5: Zirconium complex-catalyzed pyridine C–H alkylation.

Scheme 5: Zirconium complex-catalyzed pyridine C–H alkylation.

In the same year, Tsurugi and Mashima reported the use of rare earth metal complexes for the insertion of nonpolar unsaturated substrates (C=N) into the ortho-C–H bond of pyridine derivatives [54]. They carried out the C–H aminoalkylation of pyridines 1 using yttrium complex 26 with nonactivated imines 25 (Scheme 6). The authors also demonstrated the enantioselective aminoalkylation, using chiral diamines as ligands. The introduction of chiral diamines in the metal complex produced the aminoalkylated products enantioselectivity with good ratio of enantiomeric excess. The plausible mechanism involves the formation of (dibenzylamido)yttrium complex 28 by the reaction of yttrium complex 26 with HNBn2. Then σ-bond metathesis between the Y–N bond of 28 and the ortho-C–H bond of pyridine gives η2-pyridyl species 29 which on imine insertion produces species 30. Subsequent protonation then provides the aminoalkylated product 27 (Scheme 6b).

Scheme 6: Rare earth metal-catalyzed pyridine C–H alkylation with nonpolar unsaturated substrates.

Scheme 6: Rare earth metal-catalyzed pyridine C–H alkylation with nonpolar unsaturated substrates.

The selective C–H monoalkylation of pyridines with alkenes is a challenging task. Most ortho-C–H alkylation reactions have been achieved starting from C2-substituted pyridines. There are a few studies reported for the selective C–H monoalkylation of unsubstituted pyridines, which, however, displayed limited substrate scope [55,56]. In this regard, in 2021, Nakao and co-workers [57] reported a selective C2-monoalkylation of 2,6-unsubstituted pyridines with alkenes 31 using a heterobimetallic Rh–Al catalyst. The reaction provided the linear product 32 with aliphatic alkenes 31, whereas vinylarenes produced the branched product 33 and also alkenylated products 34. The reaction gave excellent yields of the ortho-alkylated products with good functional group tolerance (Scheme 7).

Scheme 7: Heterobimetallic Rh–Al complex-catalyzed ortho-C–H monoalkylation of pyridines.

Scheme 7: Heterobimetallic Rh–Al complex-catalyzed ortho-C–H monoalkylation of pyridines.

The C–H functionalization of pyridines through action of different catalyst systems including transition metals and rare earth metals has been described and some other organometallic systems also were shown to have catalytic reactivity. Adopting this catalytic reactivity of organometallics and also the special bidentate nature of phosphinoamide ligands, in 2021, Chen and group [58] described the catalytic ortho-C(sp2)–H functionalization of pyridines with polar imines 35 and nonpolar alkenes 37 by using mono(phosphinoamido)-ligated rare earth complexes (NP2-Gd and NP1-Sc) as shown in Scheme 8. Complex NP2-Gd was found to be effective in the functionalization of pyridines with imines providing various ortho-aminoalkylated products 36 whereas ortho-alkylated pyridine derivatives 38 were obtained when using NP1-Sc as the catalyst (Scheme 8).

Scheme 8: Mono(phosphinoamido)-rare earth complex-catalyzed pyridine C–H alkylation.

Scheme 8: Mono(phosphinoamido)-rare earth complex-catalyzed pyridine C–H alkylation.

Attributing to the strong coordination of unsubstituted pyridine with Rh(I) catalysts, C–H alkylations of pyridine lacking ortho-blocking groups is a challenge. In this context, a regioselective alkylation of ortho-unsubstituted or substituted unactivated pyridines with acrylates and acrylamides under Rh(I) catalysis has been demonstrated by Ellman and co-workers [59]. The authors observed that in the presence of [Rh(cod)Cl]2 as catalyst, dppe as ligand, and potassium pivalate (KOPiv) as base, linear C–H-alkylated products 40 were obtained from both acrylates and acrylamides in moderate to high yields (Scheme 9, reaction conditions a). However, when K3PO4 was employed as the base under otherwise identical conditions, the authors observed a switch in regioselectivity and branched products 41 were obtained with acrylamides as coupling partners (Scheme 9, reaction conditions b). Thus, the authors demonstrated a switch in regioselectivity (linear/branched) which was controlled exclusively by the base used. During further investigations the authors found that the use of ligand dArFpe at reduced reaction temperature resulted in a significant increase in the yield of the branched alkylated product 41 (Scheme 9, reaction conditions c) compared to using the ligand dppe (Scheme 9, reaction conditions b). Moreover, when ethyl methacrylate was used as the coupling partner under the reaction conditions c, branched alkylated products 41’ were obtained selectively in high yields (Scheme 9). A high functional group tolerance was observed in both linear and branched alkylated products.

Scheme 9: Rhodium-catalyzed pyridine C–H alkylation with acrylates and acrylamides.

Scheme 9: Rhodium-catalyzed pyridine C–H alkylation with acrylates and acrylamides.

It is known that the strong coordination of the nitrogen atom in pyridine rings with metals inhibits the metal–chiral ligand coordination, thus making the C–H alkylation of pyridine substrates challenging. In addition, transition-metal-catalyzed enantioselective C–H alkylation reactions of pyridine still remain a great challenge. In this regard, in 2022, Ye and co-workers [60] reported for the first time an enantioselective C-2 alkylation of pyridine using a chiral phosphine oxide-ligated Ni–Al bimetallic catalyst system and the protocol was found effective for a wide range of pyridines including unsubstituted pyridines, C2, C3 and C4-substituted pyridines and complex pyridines containing bioactive molecules (Scheme 10). To attain enantioselectivity a chiral phosphine oxide (43)-ligated Ni–Al bimetallic catalyst was used that was critical in improving the reactivity and controlling the selectivity of the reaction. Further, based on deuterium labelling experiments, KIE studies, and DFT calculation, a plausible mechanism (Scheme 10b) has been proposed. Initially, a reversible ligand-to-ligand H-transfer process occurs for C–H activation between the intermediates 46 and 47. Next, isomerization of the η1-allyl complex 47 forms the η3-allylic nickel complex 48, which on reductive elimination delivers the desired product 44 via the intermediate 49 (Scheme 10b). It was proposed that the enantioselectivity was mainly due to the C–C reductive elimination of the R-pathway, which is lower in energy than the S-pathway.

Scheme 10: Ni–Al bimetallic system-catalyzed pyridine C–H alkylation.

Scheme 10: Ni–Al bimetallic system-catalyzed pyridine C–H alkylation.

Remote C–H alkylation

Several remarkable studies have been reported for proximal C–H functionalizations in pyridine substrates under different catalytic systems. However, the intermolecular undirected distal C–H functionalization in pyridine remained unstudied. In these circumstances, the distal C–H alkylation by addition of the pyridine C–H bond to an aldehyde 50 under iridium catalysis was achieved by Shi [61] in 2010 through an unusual meta-selectivity for the first time (Scheme 11a). To achieve meta-selectivity, the group has screened various transition metals and revealed that a silyl-iridium complex promoted the addition of meta-pyridyl C–H bonds to aldehydes 50 which resulted in C3-alkylated pyridines 51. Based on the reactions performed for the catalytic activity of the silyl-iridium complex, the authors proposed a catalytic mechanism (Scheme 11b). The mechanism involves the initial formation of the active silyl-iridium catalyst A which through oxidative addition of 1 gives the silyl-iridium complex 52. The insertion of aldehyde 50 into the Ir–Si bond of 52 provides the pyridyl alkyl iridium species 53 that finally by C–C formation via reductive elimination furnishes the desired products 51 along with the formation of an iridium hydride species (Scheme 11b).

Scheme 11: Iridium-catalyzed pyridine C–H alkylation.

Scheme 11: Iridium-catalyzed pyridine C–H alkylation.

A direct selective C4-alkylation of pyridine has been reported by the groups of Hiyama [62] (Scheme 12a) and Zhang [63] (Scheme 12c) in 2010 and 2020, respectively. The Hiyama group developed a C-4-selective alkylation of pyridines using a Ni/Lewis acid cooperative catalytic system in combination with a bulky N-heterocyclic carbene ligand and (2,6-t-Bu2-4-Me-C6H2O)2AlMe (MAD) as the Lewis acid which allowed the direct C-4 alkylation of pyridines 1 (Scheme 12a). With the optimized reaction conditions in hand the group also screened the alkene and pyridine substrate scope which resulted C4-alkylated products 55 in moderate to high yields. A possible mechanistic cycle (Scheme 12b) was also proposed, comprising an initial formation of η2-arenenickel species 56A, which undergoes oxidative addition to the C(4)–H bond of pyridine to form intermediate 56B. Next, coordination and migratory insertion of the alkene provides the intermediate 57 which on subsequent reductive elimination furnishes the C4-alkylated products 55. Based on the deuterium exchange experiment, the author suggested that the steps involved in the catalytic cycle from 56A to 57 are reversible in nature, which may activate the C2 or C3 position as well. However, the reductive elimination at the C4-position was suggested to be irreversible in nature and does not takes place at the C2 and C3 position. On the other hand, the Zhang group reported the C4 alkylation of pyridines using alkenes 58 catalyzed by an organoborohydride (NaBEt3H) and aided by organoboranes (Scheme 12c). The proposed mechanism (Scheme 12d) involves the formation of the organoborate intermediate 60 from alkene 58 in the presence of the NaBEt3H catalyst and the organoborane. Next, the organoborane-activated pyridine species 61 undergoes an addition reaction regioselectively at the C4 position of the organoborate intermediate 60 delivering the σH-adduct intermediates 62 and 63. Subsequently, hydride elimination with the help of the organoborane gave the desired alkylated product 59 and regenerates the hydride catalyst.

Scheme 12: para-C(sp2)–H Alkylation of pyridines with alkenes.

Scheme 12: para-C(sp2)–H Alkylation of pyridines with alkenes.

Further enantioselective pyridine C–H alkylation reactions are very scarcely reported which specifically include the intramolecular C–H alkylation of pyridine with alkenes at the C3 or C4 positions. Hence, very recently in 2022, Shi and co-workers [64] adopted an intermolecular process and reported the enantioselective para-alkylation of pyridines with styrenes 64 using a Ni–Al bimetallic system and NHC ligand 65 through intermolecular hydroarylation with high levels of enantio- and regioselectivity in the alkylated products 66 (Scheme 13). Also, the authors performed DFT studies revealing the reaction mechanism and supported that the interaction of the NHC aryl part with trans-styrene was highly important for the reaction to proceed and for the enantiocontrolled formation of the products.

Scheme 13: Enantioselective pyridine C–H alkylation.

Scheme 13: Enantioselective pyridine C–H alkylation.

Alkenylation

The C–H alkenylation is another important C–C bond-forming reaction. Olefinated organic molecules like vinylarenes play a significant role as key intermediates in organic synthesis and are also present in various natural products as well as drug molecules [65-68]. Though there are traditional methods available for C–H olefinations they suffer from some disadvantages such as for example requiring prefunctionalized substrates as in case of the Heck cross-coupling [69,70]. However, researchers have developed various methods for the transition-metal-catalyzed C(sp2)–H olefination using various types of alkenes as coupling partners [71-73]. This part of the review covers reports for the alkenylation of pyridine with terminal alkynes, acrylates, allenes, and alkynes as coupling partners achieving the functionalized C(sp2)–H-olefinated pyridine frameworks via metal catalysis.

ortho-C–H Alkenylation

In 2012, Huang and co-workers [74] disclosed a ligand-free oxidative cross-coupling reaction of pyridine with acrylates, acrylamides, and styrenes (Scheme 14). Their preliminary investigation provided both C2 and C3-olefinated products, with the C2-selective product 69 as the major product (Scheme 14a). With the optimized conditions of Pd(OAc)2 (10 mol %), AgOAc (3 equiv), PivOH (2.5 equiv) in DMF, the method showed wide substrate scope and good yields. Based on the experimental findings the authors proposed a catalytic cycle (Scheme 14b) which commences with the coordination of Pd(II) with the pyridine nitrogen to provide intermediate 70. A strong trans-effect results in the C–H cleavage for the formation of Pd(II) species 71. Subsequently, insertion of alkene 68 provides the cyclic Pd(II) intermediate 72 which undergoes β-hydride elimination to produce the desired product 69.

Scheme 14: Pd-catalyzed C2-olefination of pyridines.

Scheme 14: Pd-catalyzed C2-olefination of pyridines.

In the same year, Ramana and Goriya [75] proposed an unexpected C-6 (C-2)-propenylation reaction of pyridine in the presence of allyl bromide (73) and a Ru catalyst using 2-arylpyridines (Scheme 15). Earlier reports described the propenylation took place on the ortho-position of the phenyl ring [76,77], whereas this group achieved the propenylation of the pyridine moiety. The authors screened different allyl halides and Ru complexes as catalysts. With the optimized conditions in hand, diverse 2-arylated pyridines were screened resulting in the corresponding products 74 in good yields.

Scheme 15: Ru-catalyzed C-6 (C-2)-propenylation of 2-arylated pyridines.

Scheme 15: Ru-catalyzed C-6 (C-2)-propenylation of 2-arylated pyridines.

Allene, a cumulated diene and an important building block in organic synthesis has versatile biological properties and is also an important subunit in various natural products and pharmaceutical compounds [78]. Allenes have been applied as useful substrates for the alkenylation of organic molecules [79]. There are various reports for the C–H alkenylation of aromatic C–H bonds using allenes [80]. To this end, Hou and group in 2015 [81] demonstrated the C–H allenylation of pyridines with excellent substrate scope using a scandium catalyst (Scheme 16). A vast number of pyridines and allenes were studied as substrates to provide the C2-alkenylated pyridines in good to high yields. Based on the mechanistic experiments a possible catalytic cycle has been proposed (Scheme 16b). The half-sandwich scandium complex 76 along with the tetrakis(pentafluorophenyl)borate and pyridine forms a cationic Sc-pyridyl complex 78, which after addition of allene 75, forms a transient pentacyclic intermediate 80 via intermediate 79. Next, another molecule of pyridine adds to intermediate 80 to furnish the transient complex 81 which undergoes σ-bond metathesis to give the product 77 and regenerating 78 (Scheme 16b).

Scheme 16: C–H addition of allenes to pyridines catalyzed by half-sandwich Sc metal complex.

Scheme 16: C–H addition of allenes to pyridines catalyzed by half-sandwich Sc metal complex.

While speaking regarding the alkenylation, the geometrical isomerism, i.e., the stereoselectivity between the cis- and trans-alkenylation, has not been considered so far. Except lately, in 2020, Chen and group [82] reported a Pd/Cu-catalyzed regio- and stereoselective synthesis of C2-alkenylated pyridines starting from internal alkynes 84 and pyridinium salts in a stereodivergent manner (Scheme 17a). The interesting part of this work was the switching of the alkene configuration of the products by modifying the substituents on the nitrogen of the pyridinium salts. Further, the method showed a wide substrate scope for both the Z- and E-alkenylated products in which Z-selectivity was achieved when N-methylpyridinium salts were used and E-selectivity when N-benzylpyridinium salts were used.

Scheme 17: Pd-catalyzed stereodivergent synthesis of alkenylated pyridines.

Scheme 17: Pd-catalyzed stereodivergent synthesis of alkenylated pyridines.

In the proposed mechanism (Scheme 17b) the E- and Z-isomers can be assessed through point at which dealkylation occurs, i.e., if it occurs as last step the Z-isomer 85 is obtained and if it takes place at an early stage, E-isomer 86 predominates (Scheme 17b). The proposed mechanism involves the initial formation of π-complex A via activation of the alkyne by Pd. Then, in case of N-methylpyridinium salt 82, in presence of CuBr the pyridine–Cu(I) complex 87 is formed through C–H activation that further undergoes nucleophilic attack to the coordinated alkyne in a trans-manner to give Pd(II)–alkenyl intermediate 88. Then, the intermediate 88 undergoes protio-depalladation and demethylation to yield the Z-isomer 85 (Scheme 17b). In case of N-benzylpyridinium salts 83, first debenzylation occurs to form 2-pyridyl–Cu(I) species 89 in the presence of CuBr which then coordinates to the Pd center of π-complex A via the lone electron pair of the pyridine nitrogen to give 90 which further attacks the π-bond in a cis-manner to give intermediate 91. After protio-depalladation the E-isomer 86 is obtained as major product (Scheme 17b).

Remote alkenylation

In 2011, a study for weakening the strong coordination of the pyridyl N-atom with Pd in the presence of a bidentate ligand was reported by Yu and co-workers [83]. They showcased the C3-selective olefination of pyridines using 1,10-phenanthroline, a bis-dentate ligand that weakens the coordination of the Pd catalyst with the pyridyl N-atom through the trans-effect (Scheme 18). The trans-effect is the switching of the metal coordination between the π-ring system and the hetero-(nitrogen) atom of pyridine [84,85]. In comparison to coordination with nitrogen, which is strong in nature, the coordination with the ring is weaker and cleavable. The usage of a bidentate ligand will enhance the trans-effect and shift the coordination towards the ring (Scheme 18b).

Scheme 18: Pd-catalyzed ligand-promoted selective C3-olefination of pyridines.

Scheme 18: Pd-catalyzed ligand-promoted selective C3-olefination of pyridines.

There are numerous studies reported for directing group or chelate-assisted metal-catalyzed C–H functionalization reactions. However, non-chelate-assisted or undirected C–H functionalizations under ligand-controlled conditions are underexplored. Hence, differentiating from this co-coordinative model, in 2013, Zeng and co-workers [86] reported the MPAA (mono-N-protected amino acids) ligand-promoted non-chelate-assisted C–H activation via Pd-catalyzed dehydrogenative Heck reactions on pyridines with simple alkenes 96, leading to the C3-alkenylated products 97 (Scheme 19). The reaction was based on the previous reports of using of the MPAA ligands in the Pd-catalyzed oxidative cross-coupling reactions discovered by Yu et al. [87]. When 2-methoxypyridine was screened, the reaction resulted in a mixture of C3- and C5-selective C–H-functionalized products 97f and 97f' in a regioisomeric ratio of nearly 1:1. Further, during the substrate scope study, when 1,1′-disubstituted butyl methacrylate was used as coupling partner a mixture of 97g and the isomeric product 97g' was observed in 42% yield.

Scheme 19: Mono-N-protected amino acids in Pd-catalyzed C3-alkenylation of pyridines.

Scheme 19: Mono-N-protected amino acids in Pd-catalyzed C3-alkenylation of pyridines.

Further, Shi and co-workers reported the rhodium-catalyzed directed C–H olefination of pyridines using different directing groups in 2013 [88] (Scheme 20a) and 2014 [89] (Scheme 20c), respectively. In the former study, under optimized conditions of [RhCp*Cl2]2 (5 mol %), AgSbF6 (20 mol %) in DCE at 120 °C, Cu(OAc)2 was found crucial for the transformation in comparison to other additives and showed good substrate scope while unactivated alkenes like styrene resulted in no reaction. Also, the authors successfully applied the developed protocol to a multigram-scale synthesis of compound 101, a tricyclic imidazonaphthyridinone derivative having antibacterial properties, with low catalyst loading (0.1 mol %) (Scheme 20b). Later, in 2014, the same authors, using an amide as directing group (DG), developed a protocol for the regioselective C3-alkenylation of pyridines through syn-addition of alkynes, displaying broad substrate scope and high yields (Scheme 20c). Based on literature reports and experimental studies, a possible mechanism (Scheme 20d) was proposed in which coordination of the DG 102 to the rhodium cationic species followed by ortho-metalation and migratory insertion of 103 into the Rh–C bond of 105 provides a seven-membered rhodacyclic intermediate 106. The protonation at the Rh–C bond of intermediate 106 in the presence of RCOOH furnishes hydroarylation product 104.

Scheme 20: Amide-directed and rhodium-catalyzed C3-alkenylation of pyridines.

Scheme 20: Amide-directed and rhodium-catalyzed C3-alkenylation of pyridines.

Nitrogen heterocyclic carbenes (NHCs) are of central importance in organometallic chemistry and in organic synthesis. Also, metal–NHC complexes have wide application in catalysis and various organic transformations and a range of metal–NHCs served as catalysts. In 2010, using NHC ligands, Yap and co-workers [90] developed a method for the direct para and meta-C–H alkenylation of pyridines with 4-octyne (107) using a nickel Lewis acid catalyst with amino pendant linked NHC complex (Scheme 21). In addition, the authors were able to isolate the bimetallic intermediate structure η2,η1-pyridine–Ni(0)–Al(III) complex 112, as a support for their mechanism for the para-C–H functionalization. They further investigated the scope and limitations of the dual catalyst Ni–AlMe3 and also the sensitivity of the reaction towards the steric environment on the pyridine ring. The complex 112 undergoes oxidative addition followed by an alkyne insertion reaction to give intermediate 113, which after reductive elimination provides the alkenylated product 109 (Scheme 21b).

Scheme 21: Bimetallic Ni–Al-catalyzed para-selective alkenylation of pyridine.

Scheme 21: Bimetallic Ni–Al-catalyzed para-selective alkenylation of pyridine.

Arylation

C-2 Arylation

Owing to the remarkable role of aromatic C–H arylation reactions in organic synthesis abundant methods have been reported for aromatic C–H arylations using different arylating coupling partners, such as for instance, aryl halides. In 2014, using organoboron coupling partners, Wu and co-workers [91] reported a protocol for the Cu-catalyzed C–H arylation of pyridine N-oxides 9 with arylboronic esters 114 and prepared C2-arylated pyridines 115 in moderate to good yields (Scheme 22). By using an inexpensive Cu catalyst, the method allows for the simple and practical synthesis of 2-arylpyridines. The reaction starts with the formation of arylated pyridine N-oxide 116 by reaction of pyridine N-oxide 9 with the arylboronic ester 114 in the presence of Cu catalyst and base which is followed by deoxygenation to furnish the desired product 115 (Scheme 22b).

Scheme 22: Arylboronic ester-assisted pyridine direct C–H arylation.

Scheme 22: Arylboronic ester-assisted pyridine direct C–H arylation.

In 2015, a palladium-catalyzed cross dehydrogenative coupling of pyridine N-oxides with toluene for the regioselective arylation and benzylation of pyridine N-oxide was reported by Khan and co-workers [92] (Scheme 23). The authors have shown toluene 117 when used as benzyl and aryl source remained intact under the reaction conditions without any further oxidation. Different oxidants resulted in different products such as the monoarylated product 118 formed in the presence of TBHP as oxidant and the benzylated product 119 was obtained when potassium persulfate was used. Interestingly, aza-fluorene N-oxide 119b was formed during benzylation of 2-ethylpyridine N-oxide. A possible mechanism has also been reported (Scheme 23b). Electrophilic palladation at the C2-position of pyridine N-oxide 9 provides intermediate 120. The radical intermediate 121 is generated in situ by H-atom abstraction from toluene 117 by sulfate radical anion. Coordination of intermediate 120 and 121 leads to complex 122 which undergoes reductive elimination to provide product 119. 2-Ethyl-substituted pyridine N-oxides may undergo a dual C–H activation due to the buttressing effect of the ethyl group to produce azafluorene N-oxide 119b.

Scheme 23: Pd-catalyzed C–H arylation/benzylation with toluene.

Scheme 23: Pd-catalyzed C–H arylation/benzylation with toluene.

In 2016, Wei and co-workers [93] reported the arylation of pyridine N-oxides 9 employing potassium (hetero)aryltrifluoroborates 126 as coupling partner using palladium acetate and TBAI (Scheme 24). Electron-withdrawing and donating groups on the pyridine N-oxide 9 resulted in the corresponding C2-arylated products 127 in good to excellent yields with high site selectivity. A catalytic mechanism was proposed in which the electrophilic C–H palladation of pyridine N-oxide 9 occurs preferentially at the C-2 position leading to heterocoupling intermediate 128. Subsequent transmetalation provides the arylpalladium intermediate 129 which after reductive elimination furnishes the desired product 127.

Scheme 24: Pd-catalyzed pyridine C–H arylation with potassium aryl- and heteroaryltrifluoroborates.

Scheme 24: Pd-catalyzed pyridine C–H arylation with potassium aryl- and heteroaryltrifluoroborates.

In 2017, Chen and group [94] developed a protocol for the C2,C6-arylation of pyridine under Pd catalysis (Scheme 25). In their study, N-alkylpyridinium salts were used as a directing group, facilitating the C–H arylation of pyridine. Dimethyl sulfate was used as a good N-methylating agent, which acts as transient activator. The group performed HRMS and KIE studies and proposed a catalytic cycle (Scheme 25b). The oxidative addition of ArBr 130 to the in situ-formed Pd(0) species gives species 132 followed by transmetalation with CuI pyridyl species 133 generated from the reaction of Cu2O with the methylated pyridine to afford intermediate 134 that on reductive elimination results in salt 135. Subsequent demethylation of 135 gives monoarylated product 136 or the intermediate 135 reenters the catalytic cycle to produce the diarylated N-methylpyridinium species, which again undergoes demethylation to produce product 131.

Scheme 25: Transient activator strategy in pyridine C–H biarylation.

Scheme 25: Transient activator strategy in pyridine C–H biarylation.

C-3 Arylation

In 2011 and 2013, the groups Yu [95] and Tan [96], reported a ligand-assisted distal arylation selectively taking place at the meta-position in pyridine. Both groups used Pd(OAc)2 as catalyst with 1,10-phenanthroline as ligand. The group of Yu used aryl halides 137 as coupling partner, whereas the group of Tan utilized aryl tosylates 142 as coupling partner (Scheme 26). The Yu group also applied the developed protocol for the synthesis of the drug molecule preclamol (139, Scheme 26b). The presumed catalytic cycle (Scheme 26c) involved the coordination of Pd(II) to the pyridine nitrogen to give N-bound pyridine substrate A followed by the formation of Pd(II) intermediate (B) involving the π-system of pyridine, which initiates the activation of the C(3)–H of pyridine to form aryl–Pd(II) species 140 via intermediate C. Subsequently, oxidative addition takes place in the presence of the aryl halide to give the Pd(IV) complex 141 followed by reductive elimination furnishing 3-arylpyridines 138.

Scheme 26: Ligand-promoted C3-arylation of pyridine.

Scheme 26: Ligand-promoted C3-arylation of pyridine.

Almost at the same time, Yu and co-workers reported the selective Pd(0)/PR3-catalyzed C3 or C4-arylation of nicotinic and isonicotinic acids using amide as a directing group (Scheme 27) [97]. This method provides a way for arylated nicotinic acid derivatives which serve as building blocks for biologically important molecules. This was the first report for a directing group-assisted C3/C4-arylation of pyridines. The authors screened various N-arylamide directing groups 144 out of which N-phenylamide was found to be the better directing group. Then, the authors screened various nicotinic and isonicotinic acids which afforded the desired products 145 and 146 in good yields generating a library of isonicotinic and nicotinic acid derivatives.

Scheme 27: Pd-catalyzed arylation of nicotinic and isonicotinic acids.

Scheme 27: Pd-catalyzed arylation of nicotinic and isonicotinic acids.

Another inexpensive and non-toxic iron-catalyzed C–H arylation of pyridines has been reported by DeBeof and co-workers [98]. Using the imine in 147 as directing group, afforded the arylated pyridine products 150 in good to high yields (Scheme 28). In this reaction, Grignard reagent 148 was used as arylation source in excess amount as the reagent underwent homocoupling leading to the formation of biaryl systems under the reaction conditions. 1,2-Dichloro-2-methylpropane (149) was found to be an effective oxidant under the reaction conditions. Also, the additive KF was employed in order to minimize the oxidative iron-catalyzed homocoupling of 148. An imine directing group at the para-position in pyridine 147 lead to activated ortho-position products 150 within 15 minutes. The imine group of the products can further be hydrolyzed to get the corresponding ketones.

Scheme 28: Iron-catalyzed and imine-directed C–H arylation of pyridines.

Scheme 28: Iron-catalyzed and imine-directed C–H arylation of pyridines.

In 2018, Albéniz and group [99] reported the direct C3-arylation of pyridines with the help of bipy-6-OH as coordinating ligand under palladium catalysis (Scheme 29). In most of the cases the arylated pyridines 152 were obtained as mixtures of ortho-/meta-/para-substitution, however, the authors found that the yield of the meta (C-3)-arylated pyridines were drastically higher, thereby showcasing the regioselectivity of the reaction. The chelating anionic ligand acted as base in the catalytic cycle, allowing for the oxidative addition of the arene to the Pd complex. The proposed mechanism (Scheme 29b) involves the oxidative addition of the aryl halide to the Pd(0) complex in the presence of base ligand to afford 153. Subsequently, the substitution of the halide by pyridine 1 provides the intermediate 154 which undergoes C–H activation followed by reductive elimination to furnish the C3-arylated product 152.

Scheme 29: Pd–(bipy-6-OH) cooperative system-mediated direct pyridine C3-arylation.

Scheme 29: Pd–(bipy-6-OH) cooperative system-mediated direct pyridine C3-arylation.

Heteroarylation

C-2 Heteroarylation

Heteroaryl groups are a common core in natural products and pharmaceuticals. In addition, the heterodiaryl systems widely occur in biologically important organic molecules, dyes, fragrances, advanced materials, and agrochemicals as well. Thus, the functionalization of the pyridine core with a heterocycle is a desirable transformation in organic synthesis. Manickam and co-workers [100] carried out a palladium-catalyzed decarboxylative ortho-(hetero)arylation of pyridine N-oxides 9 with heteroarylcarboxylic acids 156 (Scheme 30). The reaction showed good compatibility with various functional groups. The proposed mechanism (Scheme 30b) involves the silver-catalyzed decarboxylation of heteroaryl acid 156 followed by transmetalation providing palladium intermediate 160. Further, C–H activation of pyridine N-oxide 9 provides intermediate 161 which upon reductive elimination furnishes the desired product 157 and regeneration of Pd(0) (Scheme 30b).

Scheme 30: Pd-catalyzed pyridine N-oxide C–H arylation with heteroarylcarboxylic acids.

Scheme 30: Pd-catalyzed pyridine N-oxide C–H arylation with heteroarylcarboxylic acids.

Later in 2014, Kuang and co-workers [101] developed a highly efficient and regioselective oxidative cross-coupling of pyridine N-oxides 9 with five-membered heterocycles 162 and 163 through a two-fold C–H activation under palladium catalysis. Silver carbonate and 2,6-lutidine were found to be an effective base and ligand, respectively, for providing the desired products 164 and 165 in good yields (Scheme 31).

Scheme 31: Pd-catalyzed C–H cross-coupling of pyridine N-oxides with five-membered heterocycles.

Scheme 31: Pd-catalyzed C–H cross-coupling of pyridine N-oxides with five-membered heterocycles.

In 2015, an economic route for copper-catalyzed biaryl coupling of azine(pyridine)-N-oxides 9 with oxazoles 166 was reported by Miura and group [102]. Although their work majorly covered quinoline N-oxide substrates, they also investigated three pyridine substrates in the reaction leading to the corresponding products in moderate yields (Scheme 32). The N-oxide plays a role as an activator and is subsequently eliminated via deoxygenative elimination furnishing the C-2-functionalized pyridines 167. The reaction mechanism (Scheme 32b) involves the initial C–H-cupration of 166 producing an oxazolyl–copper intermediate 168. Nucleophilic addition followed by C–H activation of 9 provides the hydroxy copper species 169, which on deoxygenative elimination furnishes the desired product 167.

Scheme 32: Cu-catalyzed dehydrative biaryl coupling of azine(pyridine) N-oxides and oxazoles.

Scheme 32: Cu-catalyzed dehydrative biaryl coupling of azine(pyridine) N-oxides and oxazoles.

C-3 Heteroarylation

In 2013, Su and co-workers [103] developed a catalytic methodology for the distal heteroarylation of pyridines 170 via Rh(III)-catalyzed dehydrogenative cross-coupling showcasing a good substrate scope (Scheme 33). Initially, their investigation involved evaluating the reaction between N-phenylisonicotinamide 170 and 2-methylthiophene 171 which resulted in the desired product 172. The plausible mechanism (Scheme 33b) starts with the initial coordination of the pyridine directing group 170 with rhodium providing a five-membered rhodacyclic intermediate I which further forms the aryl–rhodium(III) complex II by reaction with 171. Subsequently, this intermediate undergoes reductive elimination from the rhodium(III) center to furnish the desired ortho-C–H-arylated product 172 releasing a Rh(I) species. The Rh(III) species is regenerated in the presence of the copper salt.

Scheme 33: Rh(III)-catalyzed cross dehydrogenative C3-heteroarylation of pyridines.

Scheme 33: Rh(III)-catalyzed cross dehydrogenative C3-heteroarylation of pyridines.

In another case of C3-(hetero)arylation, Yu and group [104] using palladium for C–H activation of pyridine with phenanthroline as a ligand developed a method in 2016 (Scheme 34). The authors achieved both arylation and heteroarylation at the C-3-position in pyridine and showcased the formation of bipyridines 174. The mechanism is depicted in Scheme 34b, where the complex A undergoes C3–H activation to provide intermediate 176 which similarly undergoes one more step of C–H activation to provide the bi(hetero)arene–Pd(II) species 177 which undergoes reductive elimination furnishing the desired products 174/175.

Scheme 34: Pd-catalyzed C3-selective arylation of pyridines.

Scheme 34: Pd-catalyzed C3-selective arylation of pyridines.

C–H Annulation of pyridine to fused heterocycles

Annulation reactions in organic synthesis have achieved great attention toward the construction of various carbocycles and heterocycles. These annulations can be either intermolecular or intramolecular and various substrates have been studied resulting in diverse products. Pyridine has been also reported for the construction of pyridine-fused heterocycles via C(sp2)–H functionalization and further annulation. In this aspect, considering the use of pyridines for the formation of quinolines and isoquinolines, an oxidant-dependent rhodium-catalyzed C–H annulation of pyridines with alkynes was reported by Li and co-workers [105] in 2011 for the direct synthesis of quinolines 180 and isoquinolines 181 involving a two-fold C–H activation of pyridine at the C2 and C3 position (Scheme 35a). Further, during optimization when silver additives like Ag2CO3, Ag2O, and AgOAc were used the reaction resulted in the formation of isoquinoline derivative 181. In addition, the reaction showed high regioselectivity in the presence of unsymmetrical alkynes 179. Different directing groups 178 were employed resulting in diversified products 180. The proposed mechanism (Scheme 35b) involves coordination of rhodium with isonicotinamide 178 and subsequent ortho-C–H activation generating the five-membered rhodacycle 183. Next, first alkyne 179 insertion results in the five-membered rhodacycle 184 which is followed by a second regioselective insertion of alkyne 179 into the Rh–C bond of 184 providing the seven-membered cyclic intermediate 185. Further reductive elimination furnishes the quinoline product 180 and a Rh(I) species, with the latter being oxidized by Cu(II) to complete the catalytic cycle.

Scheme 35: Rhodium-catalyzed oxidative C–H annulation of pyridines to quinolines.

Scheme 35: Rhodium-catalyzed oxidative C–H annulation of pyridines to quinolines.

Next, considering the role of N-heterocyclic carbene (NHC) ligands acting as directing group as well as functionalizing unit in arene C–H functionalization reactions with alkynes, Choudhury and group [106] in 2015 developed a protocol for the intermolecular C–H annulation of NHC-substituted pyridines with a variety of internal alkynes 187 under rhodium catalysis for the synthesis of annulated and highly decorated pyridines 188 (Scheme 36). The authors used the N-heterocyclic carbene ligand as directing group to prepare imidazo[1,2-a][1,6]naphthyridine motifs 188 as desired products. Based on the experimental results and annulation chemistry a catalytic mechanism has been proposed (Scheme 36b) that involves the C3 hydrogen of pyridine undergoing a cyclorhodation with the catalyst in the presence of NaOAc, directed by in-built NHC ligand coordination to provide intermediate 189. The further coordination of 189 with the alkyne 187 results in intermediate 190 and subsequent insertion provides rhodacycle intermediate 191 which undergoes reductive elimination to furnish the product 188 via dissociation of intermediate 192 along with oxidative regeneration of 189 (Scheme 36b).

Scheme 36: Rhodium-catalyzed and NHC-directed C–H annulation of pyridine.

Scheme 36: Rhodium-catalyzed and NHC-directed C–H annulation of pyridine.

In 2019, using NHC ligands, a protocol for the regio- and enantioselective C–H cyclization of pyridines was reported by Shi and co-workers [107] toward the direct asymmetric pyridine C–H alkylation (Scheme 37). The authors found that alkene-tethered C2 pyridine 193, C3 pyridine 195 and C4 pyridine 197 can undergo endo-cyclization reactions in the presence of Ni(cod)2, a chiral NHC ligand, and MAD as Lewis acid to afford optically active 5,6,7,8-tetrahydroquinolines 194 and 5,6,7,8-tetrahydroisoquinolines 196 and 198. The endo-selective annulation approach was compatible with various tethered alkenes, such as 1,1-disubstituted alkenes, styrene, diene, trisubstituted alkene and enamines. To get insights into the mechanism the authors conducted additional experiments including deuterium labelling reactions and proposed the mechanism depicted in Scheme 37b. Initially, the sterically bulky additive MAD coordinates to the pyridine nitrogen, which pushes the tethered alkene close to the nickel center subsequently providing the intermediate 201. Then, the C–D bond on cleavage via oxidative addition of Ni(0) forms the Ni–D species 202 which after anti-Markovnikov hydronickelation of the alkene provides the seven-membered cyclic intermediate 203. Subsequent reductive elimination furnishes the endo-annulated product 194 (Scheme 37b).

Scheme 37: Ni/NHC-catalyzed regio- and enantioselective C–H cyclization of pyridines.

Scheme 37: Ni/NHC-catalyzed regio- and enantioselective C–H cyclization of pyridines.

Out of various pyridine-fused heterocyclic hybrids, azaindolines are important scaffolds in natural products and pharmaceuticals serving different biological activities. Hence, looking at the importance of azaindolines in drug discovery a protocol of rare earth metal-catalyzed intramolecular insertion of the pyridine C–H bond into unactivated vinyl C–H bonds has been developed by Chen and co-workers [108] (Scheme 38). Using this protocol azaindolines 205 were accessed in moderate to excellent yields and also naphthyridine derivatives (205k and 205l) were synthesized. In the proposed mechanism, the initial deprotonation of HNBn2 by Ln[N(TMS)2]3 provided the lanthanide amide. Activation of the vinyl-substituted pyridin-3-amine 204 by the lanthanide amide gives a lanthanide–pyridine complex 206. Then, coordination and sequential insertion of C=C into the Ln–pyridine bond of 206 provided intermediate 207, which undergoes intermolecular protonation with 204 to afford the desired product 205 and regenerating the lanthanide species (Scheme 38b).

Scheme 38: Rare earth metal-catalyzed intramolecular C–H cyclization of pyridine to azaindolines.

Scheme 38: Rare earth metal-catalyzed intramolecular C–H cyclization of pyridine to azaindolines.

C(sp2)–H Functionalization of pyridine rings in bipyridine systems

The functionalization and synthesis of bipyridine derivatives is of great interest and importance in synthetic chemistry. These compounds are well-studied for their roles as chelating ligands in transition-metal-catalyzed reactions, coordination chemistry including materials science [109,110]. The challenge associated with the C–H functionalization of bidentate molecules is the finding strategy in the subduing the high activation barrier of rollover cyclometallation pathway. In this section we discuss the C(sp2)–H functionalization of the pyridine ring in bipyridine ring systems. In early 2009 Miura and co-workers [111] reported the rhodium-catalyzed regioselective reaction of aryl-N-heterocycles and aromatic imines with terminal silylacetylenes 209 to synthesize C–H-alkenylated products 210. The terminal silylacetylenes were employed as effective substrates for catalytic cross-dimerization reactions. The reaction was performed in the presence of [RhCl(cod)]2 (3 mol %), taking PPh3 or (4-ClC3H4)3P as the ligand at 160 °C, for about 48 h (Scheme 39). This work provides an effective way for preparing C–H-alkenylated bipyridines 210.

Scheme 39: Rh-catalyzed alkenylation of bipyridine with terminal silylacetylenes.

Scheme 39: Rh-catalyzed alkenylation of bipyridine with terminal silylacetylenes.

In 2012, a hydroarylation of alkenes 211 and alkynes 212 with 2,2′-bipyridines 208 and 2,2′-biquinolines was reported by Chang and co-workers [112] in the presence of Rh(acac)3 as catalyst, IMes·HCl (3 mol %) as ligand and t-BuONa (30 mol %) in toluene for 2 h (Scheme 40). The authors demonstrated theoretically and mechanistically the important role of the NHC ligand in the resultant catalyst Rh(NHC) for the hydroarylation of alkenes and alkynes with chelating 2,2-bipyridine and 2,2-biquinoline molecules. The experimental studies revealed that the trans-effect of the NHC ligand in the complex assisting in the reduced energy barrier of a rollover cyclometallation pathway and results in selective and efficient hydroarylation of the alkenes and alkynes. This was the first report for the role of a “rollover” cyclometallation pathway catalytically leading to double C–H bond functionalization of chelating molecules under action of a Rh(NHC) system. Based on the computational studies and experimental data, the proposed mechanism (Scheme 40b) describes that the Rh(I) complex ligated to tert-butoxide and NHC (IMes·HCl) 215 is a catalytically active species. The Rh–hydride species 217 is formed after oxidative addition via C–H-bond cleavage followed by olefin insertion to form intermediate 218, which on subsequent reductive elimination results in the formation of monoalkylated bipyridine 219. This intermediate reenters into another cycle of hydroarylation by starting as bidentate complex 220 and finally furnishing the desired bishydroarylated product 213 (Scheme 40b).

Scheme 40: Rollover cyclometallation in Rh-catalyzed pyridine C–H functionalization.

Scheme 40: Rollover cyclometallation in Rh-catalyzed pyridine C–H functionalization.

Next, a protocol for the selective and catalytic C–H functionalization of N,N,N-tridentate chelating compounds using a rollover cyclometallation strategy was reported by the same group in 2016 [113]. The reaction involves the Rh-catalyzed alkylation of 2,2’:6’,2”-terpyridine 221 with 3,3-dimethyl-1-butene coupled in the presence of a catalytic amount of t-BuONa providing the mono- and dialkylated products in low combined yields. The alkylation of terpyridines with aliphatic olefins 222 afforded only anti-Markonikov linear products 223 (Scheme 41). The authors also expanded their study to tridentate heteroarenes. Delightfully, they observed the dialkylated products 223 in good yields. The plausible reaction mechanism (Scheme 41b) was explained by the formation of a cationic Rh–terpyridine complex 224 generated from terpyridine 221 and a Rh(NHC) species formed from the Rh(I) precursor and the NHC in the presence of an external base and successive decomplexation of 224 provides complex 225. The latter undergoes an initial key rollover cyclometallation followed by oxidative addition leading to the metal–hydride intermediate 226 which on olefin insertion and subsequent reductive elimination resulted in the monoalkylated rhoda complex 227. Complex 227 then undergoes recomplexation to form 228 and enters the subsequent catalytic cycle furnishing the bisalkylated product 223.

Scheme 41: Rollover pathway in Rh-catalyzed C–H functionalization of N,N,N-tridentate chelating compounds.

Scheme 41: Rollover pathway in Rh-catalyzed C–H functionalization of N,N,N-tridentate chelating compounds.

In 2018, Cheng and co-workers [114] reported a straight forward approach to 3’-aryl-2,2’-bipyridine-6-carboxamide derivatives 231 with exclusive selectivity starting from 2,2’-bipyridine-6-carboxamides 229 under Pd catalysis (Scheme 42). The arylation reaction of N-butyl-2,2’-bipyridine-6-carboxamide with iodobenzene 230 in the presence of Pd(OAc)2 as catalyst, Cs2CO3 as a base in DMSO at 160 °C furnished the desired products 231 (Scheme 42). It was found that non-polar solvents resulted in good yields of the products 231. It is reported that 2,2’-bipyridine-6-carboxamides 229 can bind to the transition metal, such as Pd(II), to form stable N,N,N-chelates I (Scheme 42b). The amide moiety of the N,N,N-chelates I exerts a strong trans-effect which weakens the Pd(II)–pyridyl bond trans to the amide anion, thus, allowing the decomplexation to afford complex II which is key intermediate for furnishing the desired C–H functionalization product (Scheme 42b).

Scheme 42: Pd-catalyzed rollover pathway in bipyridine-6-carboxamides C–H arylation.

Scheme 42: Pd-catalyzed rollover pathway in bipyridine-6-carboxamides C–H arylation.

In 2019, Cheng and co-workers reported an approach for the C3-selective acylmethylation of [2,2”-bipyridine]-6-carboxamides 232 with sulfoxonium ylides 233 in the presence of a Rh(III) catalyst (Scheme 43) [115]. Sterically hindered amide directing groups were also well tolerated under the optimal conditions. A H/D exchange reaction exclusively at the C3-position suggested C–H-bond cleavage is reversible. The catalytic cycle involves the coordination of the carboxamide 232 with the Rh(III) species affording Rh(III) complex 235, which on rollover cyclometalation gives the complex 236. The addition of sulfoxonium ylide 233 to the intermediate complex 236 generates the Rh–carbene complex 237 with the release of DMSO and further migratory insertion of complex 237 and subsequent protonolysis furnishes the acylmethylated product 234 (Scheme 43b).

Scheme 43: Rh-catalyzed C3-acylmethylation of bipyridine-6-carboxamides with sulfoxonium ylides.

Scheme 43: Rh-catalyzed C3-acylmethylation of bipyridine-6-carboxamides with sulfoxonium ylides.

Recently, in 2020, Zhu and co-workers [116], developed a novel annulation reaction of bipyridine systems 211 with alkynes 239 via a Rh(III)-catalyzed dual C–H functionalization. The authors have initiated their studies with 6-bromo-2,2’-bipyridine as their model substrate and with diphenylacetylene as coupling partner. The optimized conditions included [RhCp*Cl2]2 (5 mol %), AgOAc (2.5 equiv), NaOAc (5 equiv) in DCE, at 110 °C for 24 h to obtain the annulated product 240 (Scheme 44). The proposed mechanism (Scheme 44b) involves the formation of Rh(III) complex 241 by coordination of the bipyridine with rhodium and complex 241 via a rollover cyclometallation process gives the intermediate 242. It was suggested that the substitution at the 6 position of the bipyridine ring system facilitates the rollover cyclometallation process by weakening the Rh–N bond. Next, intermediate 242 coordinates with alkyne 239 to give the seven-membered rhodacycle 243. The excess Ag+ help in the dissociation of the N–Rh bond in complex 243 and give the five-membered rhodacyclic intermediate 244 which again coordinates with the alkyne 239 furnishing another seven-membered rhodacyclic intermediate 245 or 246. Finally, reductive elimination delivers the desired product 240.

Scheme 44: Rh-catalyzed C–H functionalization of bipyridines with alkynes.

Scheme 44: Rh-catalyzed C–H functionalization of bipyridines with alkynes.

In the subsequent year, the same group reported a method for the rhodium-catalyzed acylmethylation of bipyridines [117]. The group has demonstrated a switchable reaction, wherein changing the additive can deliver the acylmethylated product 248 or the annulation product pyrido[2,3-a]indolizine 249 (Scheme 45). Under action of the Rh(III) catalyst, zinc acetate and PivOH as additives, the acylmethylation of bipyridines takes place at the C-2 position to furnish acylmethylated products 248 and the reaction was found suitable for various substrates. On the other hand, the usage of silver acetate as an additive provided the annulated (intramolecular cyclization of bipyridine) product 249.

Scheme 45: Rh-catalyzed C–H acylmethylation and annulation of bipyridine with sulfoxonium ylides.

Scheme 45: Rh-catalyzed C–H acylmethylation and annulation of bipyridine with sulfoxonium ylides.

Miscellaneous reactions

C–H Borylation

Due to the broad utilities of arylboronic esters in organic synthesis, various protocols have been reported till date for their incorporation into an organic molecule. In 2017, Nakao and group reported a method for the iridium-catalyzed para-C–H borylation of pyridines using bis(pinacolato)diboron (250) for the synthesis of borylated pyridines 251, which are important intermediates for various derivatization reactions (Scheme 46) [118]. In common, site-selective borylations have been in less focus, due to the lack of suitable strategies, however, this group achieved the para-selective borylation of pyridines using a cooperative catalyst strategy. The authors used [Ir(cod)(OMe)]2 as a metal catalyst, along with a sterically bulky Lewis acid such as methylaluminum bis(2,6-di-tert-butyl-4-methylphenoxide) as a cooperative catalyst.

Scheme 46: Iridium-catalyzed C4-borylation of pyridines.

Scheme 46: Iridium-catalyzed C4-borylation of pyridines.

Later, in 2019, the same group reported a protocol for the selective C5(C3)-borylation of pyridines under iridium–Lewis acid bifunctional catalysis (Scheme 47) [119]. With the optimized conditions in hands, the authors screened for the substrate scope of substituted pyridines. Also, they employed the reported protocol for the late-stage functionalization of brompheniramine (252d), an antihistaminic drug.

C–H Silaboration

In 2011, a protocol for the synthesis of highly functionalized dihydropyridines via palladium-catalyzed silaboration providing silylated dihydropyridines 255 and 256 (Scheme 48) was developed by Suginome and co-workers [120]. This reaction involved a dearomatizing conversion of pyridines to dihydropyridines under mild conditions with the introduction of a silyl group on a carbon atom of pyridine ring. Various pyridines were subjected to this silaboration using the Pd/PCy3 catalytic system providing the corresponding products in good yields. The proposed mechanism (Scheme 48b) involves the oxidative addition of silylboronic ester 254 to Pd(0) and coordination of pyridine 1 providing the intermediate 257 which on further regioselective insertion of pyridine into the Pd–B bond resulted in the π-allyl palladium complex 258. Subsequent reductive elimination furnishes the silaboration products 255 and 256 with the regeneration of Pd(0).

Scheme 48: Pd-catalyzed regioselective synthesis of silylated dihydropyridines.

Scheme 48: Pd-catalyzed regioselective synthesis of silylated dihydropyridines.

Conclusion

Significant progress has been made in the area of ortho- and distal C–H-functionalization of pyridines, as evidenced by the reactions outlined in this review. The previous research and their mechanistic insight provided us with more information to approach the new avenue of catalytic C−H functionalization of the pyridine nucleus. The challenges still remain for the distal C–H functionalization, particularly at the C4 position. Even the directing group on pyridine ring system has been less explored for ortho- or distal C–H functionalization. Although the C–H functionalization with transition-metal catalysis and rare earth metal catalysis has advanced, the functionalization of the pyridine ring system can further be explored by employing new catalytic systems and merging of different strategies. Taking this into account, we hope that the efforts for the development of novel protocols for the preparation and incorporation of functionalized pyridine scaffolds will continue and could be applicable for applications in industry.

References

-

Attla, A. M.; Mansour, H. A.; Almehdi, A. A.; Abbasi, M. M. Nucleosides Nucleotides 1999, 18, 2301–2306. doi:10.1080/07328319908044882

Return to citation in text: [1] -

Zav’yalova, V. K.; Zubarev, A. A.; Shestopalov, A. M. Russ. Chem. Bull. 2009, 58, 1939–1944. doi:10.1007/s11172-009-0265-2

Return to citation in text: [1] -

Vitaku, E.; Smith, D. T.; Njardarson, J. T. J. Med. Chem. 2014, 57, 10257–10274. doi:10.1021/jm501100b

Return to citation in text: [1] -

El-Naggar, M.; Almahli, H.; Ibrahim, H. S.; Eldehna, W. M.; Abdel-Aziz, H. A. Molecules 2018, 23, 1459. doi:10.3390/molecules23061459

Return to citation in text: [1] -

Chen, Z.; Li, P.; Hu, D.; Dong, L.; Pan, J.; Luo, L.; Zhang, W.; Xue, W.; Jin, L.; Song, B. Arabian J. Chem. 2019, 12, 2685–2696. doi:10.1016/j.arabjc.2015.05.003

Return to citation in text: [1] -

Khalaf, H. S.; Tolan, H. E. M.; El-Bayaa, M. N.; Radwan, M. A. A.; El-Manawaty, M.; El-Sayed, W. A. Russ. J. Gen. Chem. 2020, 90, 1706–1715. doi:10.1134/s1070363220090182

Return to citation in text: [1] -

Bhutani, P.; Joshi, G.; Raja, N.; Bachhav, N.; Rajanna, P. K.; Bhutani, H.; Paul, A. T.; Kumar, R. J. Med. Chem. 2021, 64, 2339–2381. doi:10.1021/acs.jmedchem.0c01786

Return to citation in text: [1] -

Ling, Y.; Hao, Z.-Y.; Liang, D.; Zhang, C.-L.; Liu, Y.-F.; Wang, Y. Drug Des., Dev. Ther. 2021, 15, 4289–4338. doi:10.2147/dddt.s329547

Return to citation in text: [1] -

Yin, P.; Zhang, Q.; Shreeve, J. N. M. Acc. Chem. Res. 2016, 49, 4–16. doi:10.1021/acs.accounts.5b00477

Return to citation in text: [1] -

Wang, Q.; Lei, C.-j.; Yang, H.-w.; Cheng, G.-b. Energ. Mater. Front. 2022, 3, 68–73. doi:10.1016/j.enmf.2022.05.003

Return to citation in text: [1] -

Movassaghi, M.; Hill, M. D.; Ahmad, O. K. J. Am. Chem. Soc. 2007, 129, 10096–10097. doi:10.1021/ja073912a

Return to citation in text: [1] -

Hill, M. D. Chem. – Eur. J. 2010, 16, 12052–12062. doi:10.1002/chem.201001100

Return to citation in text: [1] -

Nakao, Y. Synthesis 2011, 3209–3219. doi:10.1055/s-0030-1260212

Return to citation in text: [1] -

Hilton, M. C.; Dolewski, R. D.; McNally, A. J. Am. Chem. Soc. 2016, 138, 13806–13809. doi:10.1021/jacs.6b08662

Return to citation in text: [1] -

Murakami, K.; Yamada, S.; Kaneda, T.; Itami, K. Chem. Rev. 2017, 117, 9302–9332. doi:10.1021/acs.chemrev.7b00021

Return to citation in text: [1] -

Proctor, R. S. J.; Phipps, R. J. Angew. Chem., Int. Ed. 2019, 58, 13666–13699. doi:10.1002/anie.201900977

Return to citation in text: [1] -

Duan, J.; Zhang, L.; Xu, G.; Chen, H.; Ding, X.; Mao, Y.; Rong, B.; Zhu, N.; Guo, K. J. Org. Chem. 2020, 85, 8157–8165. doi:10.1021/acs.joc.0c01081

Return to citation in text: [1] -

Xie, D.; Wang, Y.; Zhang, X.; Fu, Z.; Niu, D. Angew. Chem., Int. Ed. 2022, 61, e202204922. doi:10.1002/anie.202204922

Return to citation in text: [1] -

Cen, K.; Usman, M.; Shen, W.; Liu, M.; Yang, R.; Cai, J. Org. Biomol. Chem. 2022, 20, 7391–7404. doi:10.1039/d2ob01344d

Return to citation in text: [1] -

Hamada, Y. Role of Pyridines in Medicinal Chemistry and Design of BACE1 Inhibitors Possessing a Pyridine Scaffold. In Pyridine; Pandey, P. P., Ed.; IntechOpen: Rijeka, 2018; pp 9–26. doi:10.5772/intechopen.74719

Return to citation in text: [1] -

Mąkosza, M. Chem. Soc. Rev. 2010, 39, 2855–2868. doi:10.1039/b822559c

Return to citation in text: [1] -

Haag, B.; Mosrin, M.; Ila, H.; Malakhov, V.; Knochel, P. Angew. Chem., Int. Ed. 2011, 50, 9794–9824. doi:10.1002/anie.201101960

Return to citation in text: [1] -

Chinchilla, R.; Nájera, C.; Yus, M. Chem. Rev. 2004, 104, 2667–2722. doi:10.1021/cr020101a

Return to citation in text: [1] -

Wang, H.; Huang, H. Chem. Rec. 2016, 16, 1807–1818. doi:10.1002/tcr.201500274

Return to citation in text: [1] -

Gandeepan, P.; Müller, T.; Zell, D.; Cera, G.; Warratz, S.; Ackermann, L. Chem. Rev. 2019, 119, 2192–2452. doi:10.1021/acs.chemrev.8b00507

Return to citation in text: [1] -

Dalton, T.; Faber, T.; Glorius, F. ACS Cent. Sci. 2021, 7, 245–261. doi:10.1021/acscentsci.0c01413

Return to citation in text: [1] -

Sinha, S. K.; Guin, S.; Maiti, S.; Biswas, J. P.; Porey, S.; Maiti, D. Chem. Rev. 2022, 122, 5682–5841. doi:10.1021/acs.chemrev.1c00220

Return to citation in text: [1] -

Rogge, T.; Kaplaneris, N.; Chatani, N.; Kim, J.; Chang, S.; Punji, B.; Schafer, L. L.; Musaev, D. G.; Wencel-Delord, J.; Roberts, C. A.; Sarpong, R.; Wilson, Z. E.; Brimble, M. A.; Johansson, M. J.; Ackermann, L. Nat. Rev. Methods Primers 2021, 1, 43. doi:10.1038/s43586-021-00041-2

Return to citation in text: [1] -

Guillemard, L.; Kaplaneris, N.; Ackermann, L.; Johansson, M. J. Nat. Rev. Chem. 2021, 5, 522–545. doi:10.1038/s41570-021-00300-6

Return to citation in text: [1] -

Sambiagio, C.; Schönbauer, D.; Blieck, R.; Dao-Huy, T.; Pototschnig, G.; Schaaf, P.; Wiesinger, T.; Zia, M. F.; Wencel-Delord, J.; Besset, T.; Maes, B. U. W.; Schnürch, M. Chem. Soc. Rev. 2018, 47, 6603–6743. doi:10.1039/c8cs00201k

Return to citation in text: [1] -

Murali, K.; Machado, L. A.; Carvalho, R. L.; Pedrosa, L. F.; Mukherjee, R.; Da Silva Júnior, E. N.; Maiti, D. Chem. – Eur. J. 2021, 27, 12453–12508. doi:10.1002/chem.202101004

Return to citation in text: [1] -

Seth, K. Org. Chem. Front. 2022, 9, 3102–3141. doi:10.1039/d1qo01859k

Return to citation in text: [1] -

Sun, Q.; Xu, X.; Xu, X. ChemCatChem 2022, 14, e202201083. doi:10.1002/cctc.202201083

Return to citation in text: [1] -

Wu, P.; Cao, F.; Zhou, Y.; Xue, Z.; Zhang, N.; Shi, L.; Luo, G. Inorg. Chem. 2022, 61, 17330–17341. doi:10.1021/acs.inorgchem.2c02953

Return to citation in text: [1] -

Jo, W.; Kim, J.; Choi, S.; Cho, S. H. Angew. Chem., Int. Ed. 2016, 55, 9690–9694. doi:10.1002/anie.201603329

Return to citation in text: [1] -

Lee, S. H.; Kwon, N. Y.; Lee, J. Y.; An, W.; Jung, Y. H.; Mishra, N. K.; Ghosh, P.; Park, J. S.; Kim, I. S. Eur. J. Org. Chem. 2020, 4886–4892. doi:10.1002/ejoc.202000610

Return to citation in text: [1] -

Han, S.; Chakrasali, P.; Park, J.; Oh, H.; Kim, S.; Kim, K.; Pandey, A. K.; Han, S. H.; Han, S. B.; Kim, I. S. Angew. Chem., Int. Ed. 2018, 57, 12737–12740. doi:10.1002/anie.201807159

Return to citation in text: [1] -

Kim, M.; Koo, Y.; Hong, S. Acc. Chem. Res. 2022, 55, 3043–3056. doi:10.1021/acs.accounts.2c00530

Return to citation in text: [1] -

Chakraborty, S.; Biju, A. T. Angew. Chem., Int. Ed. 2023, 62, e202300049. doi:10.1002/anie.202300049

Return to citation in text: [1] -

Luo, Y.-R. Handbook of Bond Dissociation Energies in Organic Compounds; CRC Press: Boca Raton, FL, U.S.A., 2002. doi:10.1201/9781420039863

Return to citation in text: [1] -

Dong, Z.; Ren, Z.; Thompson, S. J.; Xu, Y.; Dong, G. Chem. Rev. 2017, 117, 9333–9403. doi:10.1021/acs.chemrev.6b00574

Return to citation in text: [1] -

Evano, G.; Theunissen, C. Angew. Chem., Int. Ed. 2019, 58, 7202–7236. doi:10.1002/anie.201806629

Return to citation in text: [1] -

Sun, A. C.; McAtee, R. C.; McClain, E. J.; Stephenson, C. R. Synthesis 2019, 51, 1063–1072. doi:10.1055/s-0037-1611658

Return to citation in text: [1] -

Mandal, D.; Roychowdhury, S.; Biswas, J. P.; Maiti, S.; Maiti, D. Chem. Soc. Rev. 2022, 51, 7358–7426. doi:10.1039/d1cs00923k

Return to citation in text: [1] -

Wang, H.-H.; Wang, X.-D.; Yin, G.-F.; Zeng, Y.-F.; Chen, J.; Wang, Z. ACS Catal. 2022, 12, 2330–2347. doi:10.1021/acscatal.1c05266

Return to citation in text: [1] -

Bera, A.; Kabadwal, L. M.; Bera, S.; Banerjee, D. Chem. Commun. 2022, 58, 10–28. doi:10.1039/d1cc05899a

Return to citation in text: [1] -

Liu, X.-L.; Jiang, L.-B.; Luo, M.-P.; Ren, Z.; Wang, S.-G. Org. Chem. Front. 2022, 9, 265–280. doi:10.1039/d1qo01223a

Return to citation in text: [1] -

Jordan, R. F.; Taylor, D. F. J. Am. Chem. Soc. 1989, 111, 778–779. doi:10.1021/ja00184a081

Return to citation in text: [1] -

Yotphan, S.; Bergman, R. G.; Ellman, J. A. Org. Lett. 2010, 12, 2978–2981. doi:10.1021/ol101002b

Return to citation in text: [1] -

Guan, B.-T.; Hou, Z. J. Am. Chem. Soc. 2011, 133, 18086–18089. doi:10.1021/ja208129t

Return to citation in text: [1] -

Xiao, B.; Liu, Z.-J.; Liu, L.; Fu, Y. J. Am. Chem. Soc. 2013, 135, 616–619. doi:10.1021/ja3113752

Return to citation in text: [1] -

Xiao, Q.; Ling, L.; Ye, F.; Tan, R.; Tian, L.; Zhang, Y.; Li, Y.; Wang, J. J. Org. Chem. 2013, 78, 3879–3885. doi:10.1021/jo4002883

Return to citation in text: [1] -

Sun, Q.; Chen, P.; Wang, Y.; Luo, Y.; Yuan, D.; Yao, Y. Inorg. Chem. 2018, 57, 11788–11800. doi:10.1021/acs.inorgchem.8b01959

Return to citation in text: [1] -

Kundu, A.; Inoue, M.; Nagae, H.; Tsurugi, H.; Mashima, K. J. Am. Chem. Soc. 2018, 140, 7332–7342. doi:10.1021/jacs.8b03998

Return to citation in text: [1] -

Hara, N.; Saito, T.; Semba, K.; Kuriakose, N.; Zheng, H.; Sakaki, S.; Nakao, Y. J. Am. Chem. Soc. 2018, 140, 7070–7073. doi:10.1021/jacs.8b04199

Return to citation in text: [1] -

Kuriakose, N.; Zheng, J.-J.; Saito, T.; Hara, N.; Nakao, Y.; Sakaki, S. Inorg. Chem. 2019, 58, 4894–4906. doi:10.1021/acs.inorgchem.8b03493

Return to citation in text: [1] -

Hara, N.; Aso, K.; Li, Q.-Z.; Sakaki, S.; Nakao, Y. Tetrahedron 2021, 95, 132339. doi:10.1016/j.tet.2021.132339

Return to citation in text: [1] -

Lin, H.; Li, Y.; Wang, J.; Zhang, M.; Jiang, T.; Li, J.; Chen, Y. Appl. Organomet. Chem. 2021, 35, e6345. doi:10.1002/aoc.6345

Return to citation in text: [1] -

Tran, G.; Hesp, K. D.; Mascitti, V.; Ellman, J. A. Angew. Chem., Int. Ed. 2017, 56, 5899–5903. doi:10.1002/anie.201702409

Return to citation in text: [1] -

Li, J.-F.; Pan, D.; Wang, H.-R.; Zhang, T.; Li, Y.; Huang, G.; Ye, M. J. Am. Chem. Soc. 2022, 144, 18810–18816. doi:10.1021/jacs.2c09306

Return to citation in text: [1] -

Li, B.-J.; Shi, Z.-J. Chem. Sci. 2011, 2, 488–493. doi:10.1039/c0sc00419g

Return to citation in text: [1] -

Nakao, Y.; Yamada, Y.; Kashihara, N.; Hiyama, T. J. Am. Chem. Soc. 2010, 132, 13666–13668. doi:10.1021/ja106514b

Return to citation in text: [1] -

Wang, Y.; Li, R.; Guan, W.; Li, Y.; Li, X.; Yin, J.; Zhang, G.; Zhang, Q.; Xiong, T.; Zhang, Q. Chem. Sci. 2020, 11, 11554–11561. doi:10.1039/d0sc04808a

Return to citation in text: [1] -

Ma, J.-B.; Zhao, X.; Zhang, D.; Shi, S.-L. J. Am. Chem. Soc. 2022, 144, 13643–13651. doi:10.1021/jacs.2c04043

Return to citation in text: [1] -

Cheel, J.; Theoduloz, C.; Rodríguez, J.; Saud, G.; Caligari, P. D. S.; Schmeda-Hirschmann, G. J. Agric. Food Chem. 2005, 53, 8512–8518. doi:10.1021/jf051294g

Return to citation in text: [1] -

Grimsdale, A. C.; Leok Chan, K.; Martin, R. E.; Jokisz, P. G.; Holmes, A. B. Chem. Rev. 2009, 109, 897–1091. doi:10.1021/cr000013v

Return to citation in text: [1] -

Nguyen, P.-H.; Yang, J.-L.; Uddin, M. N.; Park, S.-L.; Lim, S.-I.; Jung, D.-W.; Williams, D. R.; Oh, W.-K. J. Nat. Prod. 2013, 76, 2080–2087. doi:10.1021/np400533h

Return to citation in text: [1] -

Singh, R. S. P.; Michel, D.; Das, U.; Dimmock, J. R.; Alcorn, J. Bioorg. Med. Chem. Lett. 2014, 24, 5199–5202. doi:10.1016/j.bmcl.2014.09.074

Return to citation in text: [1] -

Heck, R. F. Acc. Chem. Res. 1979, 12, 146–151. doi:10.1021/ar50136a006

Return to citation in text: [1] -

Mc Cartney, D.; Guiry, P. J. Chem. Soc. Rev. 2011, 40, 5122–5150. doi:10.1039/c1cs15101k

Return to citation in text: [1] -

Ali, W.; Prakash, G.; Maiti, D. Chem. Sci. 2021, 12, 2735–2759. doi:10.1039/d0sc05555g

Return to citation in text: [1] -

Logeswaran, R.; Jeganmohan, M. Adv. Synth. Catal. 2022, 364, 2113–2139. doi:10.1002/adsc.202200193

Return to citation in text: [1] -

Carral-Menoyo, A.; Sotomayor, N.; Lete, E. Trends Chem. 2022, 4, 495–511. doi:10.1016/j.trechm.2022.03.007

Return to citation in text: [1] -

Wen, P.; Li, Y.; Zhou, K.; Ma, C.; Lan, X.; Ma, C.; Huang, G. Adv. Synth. Catal. 2012, 354, 2135–2140. doi:10.1002/adsc.201200195

Return to citation in text: [1] -

Goriya, Y.; Ramana, C. V. Chem. – Eur. J. 2012, 18, 13288–13292. doi:10.1002/chem.201202379

Return to citation in text: [1] -