Abstract

Photoredox catalysis (PRC) is a cutting-edge frontier for single electron-transfer (SET) reactions, enabling the generation of reactive intermediates for both oxidative and reductive processes via photon activation of a catalyst. Although this represents a significant step towards chemoselective and, more generally, sustainable chemistry, its efficacy is limited by the energy of visible light photons. Nowadays, excellent alternative conditions are available to overcome these limitations, harvesting two different but correlated concepts: the use of multi-photon processes such as consecutive photoinduced electron transfer (conPET) and the combination of photo- and electrochemistry in synthetic photoelectrochemistry (PEC). Herein, we review the most recent contributions to these fields in both oxidative and reductive activations of organic functional groups. New opportunities for organic chemists are captured, such as selective reactions employing super-oxidants and super-reductants to engage unactivated chemical feedstocks, and scalability up to gram scales in continuous flow. This review provides comparisons between the two techniques (multi-photon photoredox catalysis and PEC) to help the reader to fully understand their similarities, differences and potential applications and to therefore choose which method is the most appropriate for a given reaction, scale and purpose of a project.

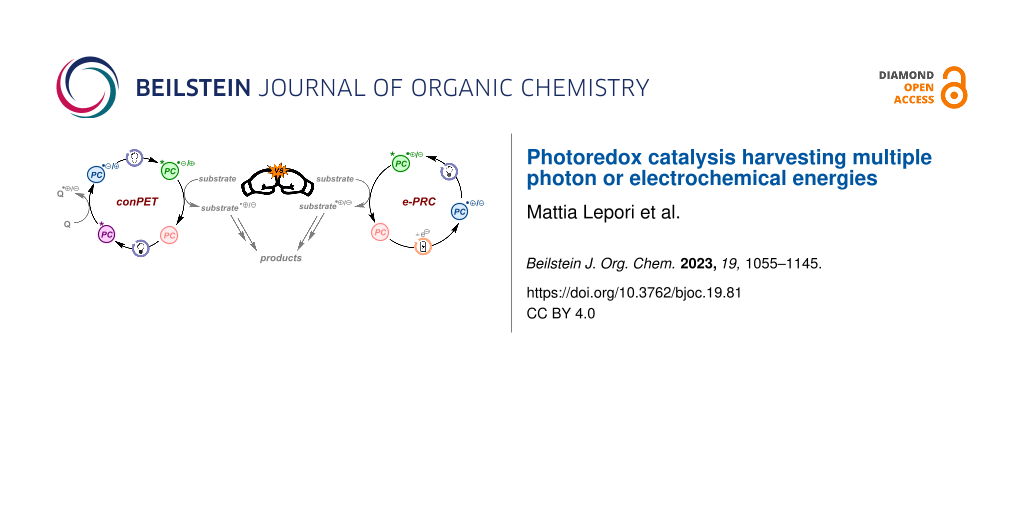

Graphical Abstract

Review

1 Introduction

Owing to the unique reactivity patterns of free radicals that often provide access to new dimensions of synthetic chemical space, the field of single electron transfer (SET) in organic synthesis has expanded considerably in the past two decades. Among this area, photoredox catalysis (PRC) is highly attractive due to its abilities i) to generate reactive intermediates under mild conditions for both oxidative and reductive reactions and ii) to use photons as traceless reagents to drive reactions in a “greener” manner [1-6]. As depicted in Figure 1, for an oxidative PRC cycle, the excited photocatalyst (*PC) firstly undergoes oxidative quenching by SET with an electron acceptor (A), leading to PC•+ and A•−. The ground state photocatalyst is then regenerated by an SET reaction with an electron donor (D), affording also D•+. Both species described can be further involved in various organic transformations to form the target products (or byproducts). In a complementary manner, *PC generates A•− and D•+ within a reductive quenching cycle via SET reactions. The milder conditions that PRC enjoys to access potent redox agents guarantees sustainable and safer processes when compared to classical methods of equivalent redox power. For example, in the context of deeply reductive reactions, dissolving alkali metal conditions have remained the most commonly employed both in academia and industry for over a century and even to date continue to be used despite their hazards, poor selectivity and chemical waste [7-10]. Nowadays, excellent alternative conditions are available via PRC (vide infra).

Figure 1: Oxidative and reductive activations of organic compounds harvesting photoredox catalysis.

Figure 1: Oxidative and reductive activations of organic compounds harvesting photoredox catalysis.

However, even if PRC provides elegant methods to circumvent these issues, it comes with its own set of limitations. In particular, the accessible energy for photocatalytically-driven transformations is generally limited by the energy of a single visible light photon (400–700 nm; 1.8–3.1 eV). In addition, this energy is also diminished by as much as ≈25% through vibrational relaxation, internal conversion and intersystem crossing [11] and hence, many highly stabilized molecules including important feedstock molecules such as arenes, haloarenes or olefins remain inert to direct photoredox activation powered by visible light [12]. Irradiation with UV photons that intrinsically possess higher energy, however, is generally unfavorable due to the high expense and thermal footprint of the reactors. Although most organic molecules directly absorb photons in the UV region, side reactions and selectivity issues arise upon direct excitation of organic molecules. In recent years, two conceptually distinct but mechanistically related strategies have emerged that enable access to excited state catalysts wielding i) higher redox power than standard monophotonic photoredox catalysts and ii) energy that parallels the energy of UV-driven transformations, but under cheaper, safer conditions and in a more selective manner by indirect substrate activation via a catalyst. These are: a) multi-photon processes that accumulate visible light photon energies for electron transfer processes and b) photoelectrochemistry (PEC) in which electronic and photonic energies are either compiled or productively utilized. This Review summarizes key examples of both strategies, presents their respective advantages and drawbacks and aims to draw comparisons that can help readers decide which strategy is a more suitable fit for a given purpose. In order to do so, the scope of our Review is thus restricted to electron transfer redox processes and does not include energy transfer or atom/group transfer processes. Particularly interesting are instances where the same active catalytic intermediate is proposed in conPET and PEC reactions (e.g., a photoexcited radical anion), yet different reactivity outcomes arise; the underlying reasons for such are discussed. Finally, we provide our perspective on current challenges and target areas for future exploration.

1.1 Multi-photon processes

As mentioned, the energy accessible for a PRC reaction relying on a single visible photon is limited and does not suffice for many desirable target organic substrates. Direct cumulative absorption of visible light photons by a given molecule is extremely challenging, since the short lifetimes of excited states generally do not allow their accumulation in appreciable concentrations to absorb a subsequent photon and be further photoexcited. In biological photosynthesis – nature’s omnipresent example of light-driven reactions – this limitation is overcome by transferring the energy of an initial photoexcitation process at photosystem II (PSII) via an electron transfer chain to photosystem I (PSI) where a second photoexcitation occurs [13,14]. Mimicry of this “Z-scheme” led to a seminal disclosure the concept of consecutive photoinduced electron transfer (conPET) by König and co-workers in 2014 for the generation of super-reductants [15] and by Wagenknecht in 2018 for the generation of super-oxidants [16]. Herein, initial excitation of the photocatalyst by a single photon is followed by reduction or oxidation by a sacrificial SET donor (e.g., Et3N [15]) or acceptor (e.g., SF6 [16]) to yield the catalyst radical anion or radical cation. As a semi-stable, higher energy ground-state entity, this can accumulate in sufficient concentration under the reaction conditions to absorb another photon and thereby generate a super-reducing or super-oxidizing excited state (Figure 2 left). In addition to ‘radical ion’ conPET, this Review will also cover deviating variants such as neutral (acridine) radical conPET as well as polysulfide or ‘tandem’ photoredox catalysis that similarly rely on the absorption of two photons to access activated catalyst states that engage redox-inert substrates.

Other two-photon processes where the photoredox-active species is generated by an initial energy transfer process – such as triplet-triplet annihilation (TTA) upconversion – are excluded from this Review as i) they are comprehensively and elegantly reviewed elsewhere [17], and ii) comparisons are not straightforward to make with PEC, a main theme of this Review. Protocols for sensitization-initiated electron transfer (SenI-ET) relying on a dual catalytic system of transition-metal based photocatalysts and pyrenes to generate highly reductive species are also excluded as such reported transformations are now equally achievable by a single catalyst entity [18-21].

1.2 Photoelectrochemistry (PEC)

Another important vehicle for SET is synthetic organic electrochemistry (SOE) [22,23]. While undoubtedly powerful, electrochemistry can suffer limitations in reaction selectivity because the constant application of high magnitude potentials can lead to uncontrolled reactions due to the accumulation of reactive intermediates within proximity of the electrode surface. Compared to homogeneous photocatalytic processes that lend themselves to high selectivity for taming radical intermediates by taking place in bulk solution, direct electrolytic reactions taking place at the heterogeneous interface presents an additional layer of complexity to mechanistic understanding and conferring selectivity. Nonetheless, SOE has enjoyed a dramatic rise in popularity in the last decade [24-27], partly driven by reactor standardization but also thanks to developments in technology (flow, alternating polarity) and understanding that fundamentally improve selectivity. Among these is its innovative merger with PRC (synthetic PEC) in a fashion that tackles the issues of both parent techniques and has risen to the forefront of methods for SET chemistry.

In the context of synthetic molecular photoelectrochemistry, there are various sub-fields classified depending on how the electrochemical and photochemical steps interplay in the mechanism. This Review’s main focus is on electrochemically mediated photoredox catalysis (e-PRC), where the electrochemical and photochemical steps are intimately involved within the same catalytic cycle, as subsequent steps. This broadly separates into two subcategories, “radical ion e-PRC” (Figure 2, right) and “recycling e-PRC”. Radical ion e-PRC typically implicates electrogenerated radical ion doublet states which are photoexcited to yield super-oxidants or super-reductants while recycling e-PRC involves the turnover of a ‘standard’ (typically closed-shell) photoredox catalyst (PC) by means of anodic oxidation or cathodic reduction [28,29]. Furthermore, a series of new protocols using decoupled photoelectrochemistry (dPEC), where electrochemical and photochemical components have separate, discrete roles will be presented. This review excludes interfacial photoelectrochemistry (iPEC) processes, where reactions occur at photoelectrode surfaces. These are reviewed exhaustively elsewhere [28].

Figure 2: General catalytic cycles of radical ion conPET (left) and radical ion e-PRC (right).

Figure 2: General catalytic cycles of radical ion conPET (left) and radical ion e-PRC (right).

In recent years, both multi-photon processes and PEC developed from conceptually interesting techniques into widely applicable and well-developed methods capable of efficiently mediating and enabling difficult chemical transformations. Following a temporal order of discoveries, the reader will find the first section dedicated to reductive substrate activations via conPET and other multi-photon processes followed by more recently developed protocols for oxidative conPET. Hereafter, to provide continuity and highlight differences and comparisons between the two techniques, the Review will then focus attention on oxidative substrate activations in PEC before reductive activation examples of this field. Before plunging into the details of the two techniques, Figure 3 offers some advice for newcomers, a “Beginner’s guide” flowchart, to understand which of the two techniques might be more appropriate in certain contexts of application. Broadly speaking, it can be concluded that carrying out reactions with conPET, both in academia and industry, has a lower barrier of accessibility due to more intuitive/standardized reactor setups. Essentially, the reactor setup can be identical to standard photoredox catalysis reaction setups, although it should be noted that since there are two photoactive species with often different absorption bands or different extinction coefficients at any given wavelength, it is necessary to use i) polychromatic wavelength which is less well-defined or ii) dual(/multi) wavelength LEDs that complicate the setup. The simpler reaction setups and lack of a heterogeneous surface (electrodes) can make the mechanistic investigation more accessible. While quantum parameters (quantum yield, quadratic relationships with light intensity, etc) have been touched upon for a monochromatic light source, the impact of relative intensities of different wavelengths (λmax,ex of PC and PC•−/+) has never been investigated.

Figure 3: “Beginner’s guide”: comparison between advantages, capacities, and prospectives of conPET and PEC.

Figure 3: “Beginner’s guide”: comparison between advantages, capacities, and prospectives of conPET and PEC.

Notwithstanding the above, for longer-term industrial purposes, PEC is ultimately more suitable because only one species need be photoactive, and in purely economic terms generating one photon is cheaper than two (or more). Electrons (/holes, in the form of applied potential) are cheaper than photons as well. Regarding the additives necessary for the processes, even if electrolytes needed to reduce the Ohmic drop in PEC reactions are more expensive or more abundant than sacrificial reductants/oxidants employed in conPET (e.g., tetraalkylammonium salts vs trialkylamines), it is worth emphasizing that electrolytes, generally, are chemically innocent to undesired reactions, whereas the byproducts of sacrificed amines may be involved in processes that lower the efficiency and selectivity of the reactions (vide infra, conPET section).

Electrolytes have the potential to be i) aqueous-separated and recovered in batch, or ii) decreased, even ultimately eliminated by flow reactors as an engineering control.

Regarding purely the chemical reactivity and scope of applications, the most marked difference between the two types of processes, however, is that conPET is more appropriate for redox-neutral reactions, whereas PEC is more appropriate for net oxidations or reductions due to the radical polar crossover nature of its reactivity [30,31]. In the former, the neutral photoexcited catalyst must be able to engage substrates/intermediates in PET to achieve a redox neutral process. In the latter, following the first photoinduced electron transfer (PET) step a subsequent electrochemical SET occurs in the same redox direction and this subsequent SET is user-tunable by the applied cell potential. These divergent reactivity features make the two techniques totally complementary, allowing the exploration of a large portion of SET-driven organic transformations using at least one of them at a time. Since ‘radical ion’ conPET/e-PRC are proposed to involve the same radical ion catalyst intermediate, the same catalyst can in principle be repurposed for either technique, and mechanistic learnings will thus be highly transferrable between the fields.

Although asymmetric transformations are yet to be achieved using conPET, the PEC section of this Review will also describe pioneering first efforts in this direction [32,33]. Finally, both techniques are amenable to large-scale synthesis and ideally integrated with state-of-the-art reactor technology platforms, such as continuous flow reactors and high throughput screening plates. Various examples of scalability will be highlighted in this Review, with a particular emphasis on the challenges and areas for improvement, such as the standardization of reactors capable to conjugate applied potential and light irradiation either in different modules or within the same flow path.

2 conPET in organic synthesis

2.1 Reductive activation

2.1.1 C(sp2)–X activation: In the rise of visible light-mediated PRC, the generation of aryl radicals for C(sp2)–C(sp2/3) couplings under mild conditions (room temperature, visible light activation of a catalyst) was heavily investigated [34-36]. However, initially the procedures were generally limited to electron-poor arenes like diazonium/iodonium salts or aryl iodides with electron-withdrawing substituents as aryl radical precursors, due to the limited accessible reducing power of photocatalysts that relied on a monophotonic excitation event. However, the vast majority of inexpensive, commercially available aryl halides are chlorides [37,38], with potentials for reduction that almost exclusively lie beyond the threshold of monophotonically-excited photoredox catalysts (i.e., more deeply negative than E1/2 = −2.0 V vs SCE). Considering this, state-of-the-art developments have focused on the generation of super-reductants (*E1/2 > −2.0 V vs SCE) that accumulate the energy of multiple photons. Case studies will now be presented.

Hereafter, while we quote the excited state redox potentials from the report in question, it should be noted that these are estimates associated with uncertainties especially in the case of excited radical ions which oftentimes exhibit unusual wavelength dependencies on catalytic efficiency. Light source wavelengths/input powers (radiant flux is rarely reported) are quoted if available, readers are directed to the report in question for details. When not available, the qualitative description is used as per the report in question (e.g., ‘blue LEDs’).

The König group first reported a photocatalytic approach to C(sp2)–X activation harnessing multiple photon energies in their seminal work on perylene diimide (PDI) catalysts [15]. In their proposed consecutive photoinduced electron transfer (conPET) mechanism (Figure 4C), PDI is photoexcited and reductively quenched by Et3N to form its stable, colored radical anion PDI•− that can be photoexcited again to generate an even stronger reductant; *PDI•− (*E1/2 = −1.87 V vs SCE) [34]. A SET process to the aryl halide regenerates neutral PDI and forms the aryl halide’s radical anion, which then undergoes C(sp2)–X bond fission to afford the aryl radical as a reactive intermediate. The aryl radical then either reacts via hydrogen atom transfer (HAT) with solvent molecules or Et3N•+ in an overall dehalogenation to furnish product 2, or it is trapped with pyrrole derivatives 3 in a C–C bond formation to afford arylated products 4. Based on the ultrashort lifetime of *PDI•− (τ = 145 ps), the notion of its photochemistry has attracted skepticism and it has been suggested decomposition products of *PDI•− may instead serve as reductants as a theme of ongoing debate [39]. Nonetheless, this protocol enabled the reduction of various electron-poor aryl iodides and aryl bromides and, for the first time, the reduction of aryl chlorides (albeit electron-poor ones) via visible light PRC in good to excellent yields (35–98%) (Figure 4A). Notably, the protocol was also applicable to 4-iodotoluene as a moderately deactivated aryl iodide and the C(sp2)–I bond cleavage occurred chemoselectively in the presence of a C(sp2)–Br bond. N-Methylpyrrole and various other substituted pyrroles could be applied as trapping agents for electron-poor aryl halides and the coupling products were obtained in good yields (52–74%) (Figure 4B). To suppress the rapid HAT with solvent DMF that yields the dehalogenated product, DMSO was chosen as solvent for the C–H arylation. When applying the catalytic protocol to 2-allyloxy-1,3,5-tribromobenzene, the 5-exo-trig cyclized product 5a was obtained – albeit only in 28% yield – corroborating a radical mechanism. PDI catalysts have since found applications in other chemical transformations, their photophysical properties have been investigated further [40], and new variants [41] including heterogeneous versions have been introduced [42-44].

Figure 4: A) conPET reductive dehalogenation of aryl halides with PDI. B) Reductive C–H arylation with pyrroles (top) and selected examples from the substrate scope (bottom). C) Proposed mechanism.

Figure 4: A) conPET reductive dehalogenation of aryl halides with PDI. B) Reductive C–H arylation with pyrrol...

Since radical ion conPET chemistry gives access to different reducing species of the same catalyst and both are photoactive, König and co-workers developed a synthetic protocol that allows the chromoselective (wavelength-dependent) regulation of catalytic behavior and thus enabling controlled bond activations [45]. Regarding the reductive C–C arylation, the application of the xanthene dye rhodamine 6G (Rh-6G) as a catalyst for the reduction of heteroarenes bearing two or three bromine atoms (e.g., 6) under irradiation with green light (λ = 530 nm) gave monosubstituted products (e.g., 7) whereas irradiation with blue light (λ = 455 nm) provided disubstituted products 8 (Figure 5A). Additionally, adding a different trapping reagent before switching from green to blue light allows for a sequential and controlled substitution in a one-pot reaction (Figure 5B). 2,4,6-Tribromopyrimidine (6a), whose core pyrimidine structure can be found in many biologically active compounds, could be sequentially substituted with 1,3,5-trimethoxybenzene and N-methylpyrrole to give 8a. The protocol also enabled the selective reductive dehalogenation at the benzylic position of 9a with green light while the C(sp2)–Br bond remained untouched. Subsequent irradiation with blue light gave the sequentially substituted products 9c and 9d. As with PDI, the xanthene dye rhodamine 6G (Rh-6G) can undergo reductive quenching upon excitation with green or blue light (Figure 5C). Considering that Rh-6G describes a chloride salt, the photocatalyst itself is a monocationic species (Rh-6G+) that forms a neutral radical (Rh-6G•) upon reductive quenching. The radical Rh-6G• itself (E1/2 = −1.0 V vs SCE) can directly reduce certain aryl bromides or other substrates with sufficiently accessible reduction potentials whereas a second excitation with blue light yields the excited state *Rh-6G• that can reduce substrates with much more negative reduction potentials (Epred < −2.4 V vs SCE). The authors also demonstrated the applicability of Rh-6G for reductive arylation reactions (Figure 5D). While the use of PDI was mostly limited to electron-poor aryl halides, *Rh-6G• could reach a step further and reductively activate electron-rich aryl bromides such as 4-bromotoluene and 4-bromoanisole, albeit providing low (27% and 25%) yields of the coupled products 4d and 4e, respectively.

Figure 5: A) Chromoselective mono- and disubstitution or polybrominated pyrimidines with pyrroles. B) Sequential substitution with distinct trapping reagents. C) Proposed mechanism. D) Selected examples from the substrate scope of the C–H arylation via monosubstitution of aryl halides.

Figure 5: A) Chromoselective mono- and disubstitution or polybrominated pyrimidines with pyrroles. B) Sequent...

Building on this work, König and co-workers also demonstrated the synthesis of pyrrolo[1,2-a]quinolines (12) and ullazines (13) from N-arylpyrroles (10) with arylalkynes (11) using Rh-6G (Figure 6) [46]. Additionally, the König group also used Rh-6G as a catalyst for a photo-Arbuzov reaction to generate arylphosphonates (15) from aryl halides and trialkylphosphites (14) via a similar conPET mechanism (Figure 7) [47]. Notably, even 4-bromoanisole could be reductively activated and phosphorylated in 58% yield (15b).

Figure 6: A) Synthesis of pyrrolo[1,2-a]quinolines. B) Synthesis of ullazines.

Figure 6: A) Synthesis of pyrrolo[1,2-a]quinolines. B) Synthesis of ullazines.

Figure 7: A) Reductive phosphorylation of aryl halides via conPET. B) Selected examples from the substrate scope.

Figure 7: A) Reductive phosphorylation of aryl halides via conPET. B) Selected examples from the substrate sc...

Reports from Eggins [48], Lund and Eriksen [49] have shown that upon excitation, the radical anions of anthraquinones – a class of organic dyes widely applied as catalysts in organic PRC [50] – are capable of reducing aryl halides with deeply negative reduction potentials. Starting from these premises, the König group in 2017 demonstrated the use of 1,8-dihydroxyanthraquinone (AQN) as a suitable conPET catalyst for reductive dehalogenations (Figure 8A), C–H arylations and olefinations of aryl halides (Figure 8B) [51]. In addition to the classical conPET mechanism involving the formation of *AQN•−, the authors also confirmed formation of the semiquinone anion AQN-H− via formal addition of a hydrogen atom (e.g., through protonation and successive reduction or HAT) that upon excitation also acts as a super-reductant (Figure 8C).

Figure 8: A) Reductive dehalogenation of aryl halides via conPET and selected examples from the substrate scope. B) Reductive C–H arylation and olefination (top) and selected examples from the substrate scope (bottom). C) Photo- and redox-active species of AQN.

Figure 8: A) Reductive dehalogenation of aryl halides via conPET and selected examples from the substrate sco...

Simultaneously, Jacobi von Wangelin, Pérez-Ruiz and co-workers introduced the structurally related 9,10-dicyanoanthracene (DCA) as a conPET catalyst. Excitation of PET-generated radical anion DCA•− generates *DCA•− as a super-reductant capable of reducing aryl bromides and chlorides [52]. Due to minimal overlap in the absorption spectral bands of DCA and DCA•−, a cold-white LED (λ = 410–700 nm) was used for polychromatic irradiation. The protocol for reductive C–H arylations with pyrroles was applicable to electron-poor aryl halides including various heterocyclic halides, affording their products in poor to excellent yields (4–92%) (Figure 9A). Regarding the unsatisfactory results, the coupled products of the strongly deactivated 4-bromoanisole (Epred = −2.75 V vs SCE) and 4-chloroanisole (Epred = −2.88 V vs SCE) were only obtained in yields of 6% and 4%, respectively, which the authors attributed to insufficient redox power of *DCA•− in its D1 state (*E1/2 = −2.60 V vs SCE) [53]. These results strongly contrast to the work of Lambert and Lin on e-PRC reductions with DCA (vide infra) where these exact electron-rich aryl halides could be engaged successfully.

Figure 9: A) Reductive C–H arylation of aryl halides via conPET (top) and selected examples from the substrate scope (bottom). B) Methodology extension to C(sp2)–Het(Arene) couplings (top) and selected examples from the substrate scope (bottom).

Figure 9: A) Reductive C–H arylation of aryl halides via conPET (top) and selected examples from the substrat...

This contrast suggests either i) a different active species was involved in the latter report (vide infra: Figure 60 in PEC reductive activations) or ii) that the higher steady-state concentrations of DCA•− available by electrogeneration favor a preassembly with Ar−X that i) upon photoexcitation accesses excited states higher than the first (D1) to bolster reactivity and/or ii) following PET assists in the Ar−X•− fragmentation step. The scope was expanded using triethylphosphite (P(OEt)3), dimethyl disulfide (MeSSMe) and bis(pinacolato)diboron (B2pin2) as trapping agents for C(sp2)–Het(Arene) couplings (Figure 9B).

The successful activation of electron-neutral and electron-rich aryl halides via conPET mostly remained an unsolved challenge until the Nicewicz group in 2020 disclosed a modified acridinium (Fukuzumi) salt Mes-Acr-BF4 as a suitable conPET catalyst. Following the conPET catalytic cycle, the Mes-Acr+ cation is excited and reductively quenched by DIPEA to yield the acridine radical Mes-Acr• (Figure 10C) [54]. Upon excitation to its twisted intramolecular charge-transfer (TICT) state, Mes-Acr• has an excited-state half potential (*E1/2 = −3.36 V vs SCE) even more negative than alkali metals including lithium, making it one of the most potent chemical reductants ever reported.

Figure 10: A) Reductive hydrodehalogenation of aryl halides with Mes-Acr-BF4. B) Selected examples from the substrate scope. C) Photo- and redox-active species of Mes-Acr-BF4.

Figure 10: A) Reductive hydrodehalogenation of aryl halides with Mes-Acr-BF4. B) Selected examples from the su...

Owing to this exceptional reductive redox power, hydrodehalogenation of various electron-poor and electron-rich aryl bromides and chlorides including 4-bromoanisole and 4-chloroanisole (2e), 1-bromo-2,4- dimethoxybenzene (2f) and 4-ethylchlorobenzene (2h) occurred in good to excellent yields (58–99%) (Figure 10B).

Based on their exciting success with isophthalonitrile derived compounds as electron-primed photocatalysts in e-PRC (vide infra, Figure 69), the Wickens group developed a conPET protocol using 2,4,5,6-tetrakis(diphenylamino)isophthalonitrile (4-DPAIPN) for the reduction of electron-rich aryl chlorides [55]. With 4-DPAIPN as an electron-primed photocatalyst, substrates with reduction potentials as deep as Epred = −3.4 V vs SCE (1c) were readily reduced and dehalogenated products obtained in excellent yields (70–92%) (Figure 11A). Sodium formate was found to be a more efficient terminal reductant than trialkylamines which the authors attributed to the formation of a carbon dioxide radical anion (CO2•−) upon oxidation of the formate via SET to 4-DPAIPN and successive deprotonation by a second formate anion (Figure 11B). Due to its reducing nature, CO2•− (E0 = −2.2 V vs SCE) may promote the photoreductant activity either by reducing another equivalent of photocatalyst or the direct reduction of sufficiently electron-poor aryl halide substrates (Figure 11C). While trialkylamines like Et3N or DIPEA have been proven to be suitable terminal reductants in conPET chemistry [15,45,46,51,54], they may still decrease photoreductant activity via back electron transfer [56], in contrast to CO2•− which has an entropic driving force (evolution of CO2). Triethylphosphite P(OEt)3 and bis(pinacolato)diboron B2pin2 were successfully applied as trapping reagents for redox-neutral photo-Arbuzov and borylation reactions with good to excellent yields (Figure 11D). Additionally, the authors were able to perform the net-reductive hydroarylation of tert-butyl vinylcarbamate and unactivated alkenes like 1-octene and 3-buten-1-ol although the vinyl carbamate substrate (Epred = −2.2 V vs SCE) is significantly easier to reduce than most aryl chlorides. This selectivity, especially considering the need for an excess of the vinyl carbamate, might indicate a preassembly between 4-DPAIPN•− and the aryl chloride.

Figure 11: A) Reductive hydrodechlorination of aryl chlorides with 4-DPAIPN. B) Proposed formation of CO2•−. C) Potential reductive modes involving CO2•−. D) Extension to phosphorylation, borylation and hydroarylation of olefins.

Figure 11: A) Reductive hydrodechlorination of aryl chlorides with 4-DPAIPN. B) Proposed formation of CO2•−. C...

Simultaneously, Zhou, Wu and co-workers demonstrated 2,4,5-tri(9H-carbazol-9-yl)-6-(ethyl(phenyl)amino)isophthalonitrile (3CzEPAIPN) as yet another isophthalonitrile derived photocatalyst suitable for conPET chemistry [57]. Similar to 4-DPAIPN, both electron-poor and electron-rich aryl chlorides with reduction potentials up to Epred = −2.94 V vs SCE were readily reduced by *3CzEPAIPN•−. The authors demonstrated an impressive scope of borylation reactions with B2pin2 as well as other boronate esters (17h) and several examples of late-stage functionalization (17i and 17j) (Figure 12A). Interestingly, sodium oxalate could be used as the electron donor provided a catalytic loading of 4-cyanopyridine was added. Although the role of the latter species was not proposed by authors, it is more facile to reduce than an aryl chloride so could act as an electron shuttle (potentially via a π-stacking assembly).

Figure 12: A) Reductive conPET borylation with 3CzEPAIPN (top) and selected examples from the substrate scope (bottom). B) Phosphonylation scope. C) Intramolecular dearomative hydroarylation scope.

Figure 12: A) Reductive conPET borylation with 3CzEPAIPN (top) and selected examples from the substrate scope ...

The synthetic scope was extended to C(sp2)–P bond formations by trapping with phosphines or phosphites (Figure 12B), and in all these cases DIPEA was used as the electron donor (0.5–5 equiv). Arylphosphonium chlorides 20 that are widely used as reagents, organocatalysts, or phase transfer reagents [58-61] were synthesized from aryl chlorides in various yields (20–87%) under mild photocatalytic conditions whereas previously reported protocols typically relied on transition metal catalysis or high temperature processes [62-64]. Arylphosphonates 15 were obtained in a photo-Arbuzov reaction by trapping with trimethylphosphite in good to excellent yields (62–88%) (Figure 12B). Additionally, intramolecular trapping via dearomative hydroarylation gave access to spirocyclic cyclohexadienes bearing dihydrobenzofuran and indoline scaffolds (22a,b) via a radical-polar crossover mechanism (Figure 12C) [65], showcasing the power of conPET in dearomatization reactions. Finally, the synthesis of tetraphenylphosphonium chloride (20a) could be scaled up efficiently in an operationally very simple continuous-flow setup with only 2.5 mol % of photocatalyst and a productivity of 13.1 g/day (Figure 13). Of note, only 0.5 equiv of DIPEA was required for all reactions of aryl chlorides with triarylphosphines, suggesting the intermediate tetraarylphosphine radical reduces DIPEA•+ to regenerating DIPEA.

Figure 13: Scale-up of conPET phosphorylation with 3CzEPAIPN.

Figure 13: Scale-up of conPET phosphorylation with 3CzEPAIPN.

Even though various organic compounds have been successfully implemented as radical (anion) photocatalysts for Ar–X bond activation in the reports of König, Jacobi von Wangelin and Pérez-Ruiz, Nicewicz, Wickens, Zhou and Wu above [15,45,46,51,54-57,66], the underlying mechanism has largely remained elusive. While Kasha’s rule is classically applied only for photophysical phenomena stating that emission events generally occur only from the lowest excited state of a certain multiplicity due to very fast relaxation via internal conversion (IC) and vibronic relaxation [67-69], it can also be adapted to photochemical reactions stating that outer sphere ET events generally occur only from the lowest excited state due to the same relaxation pathways [69]. It has been largely proven that this limitation is circumvented by the involvement of excited radical anions and two excitation processes; to access molecular orbitals beyond the frontier orbitals of the neutral photocatalyst and thus, higher redox potentials. However, the identity of the key intermediate has remained a matter of debate [40,70,71]. Full elucidations of the mechanism toward confirming the key(/main) active catalyst species and possible deactivation pathways are incredibly important for the development of new radical ion catalysts with improved photon economies and novel applications. Lee, Cho, You, and co-workers recently disclosed a fully elucidated mechanism of the reductive borylation of aryl halides using three newly developed photocatalysts bearing indolocarbazole electron donor and benzothienopyrimidine electron acceptor moieties (Figure 14A and B) [72].

Figure 14: A) Borylation of 1d. B) Characteristics and structure of PC1 with green and red parts showing the localization of HOMO and LUMO, respectively. C) Full mechanism for the conPET borylation of 1d with blue and red arrows indicating activating and deactivating pathways, respectively.

Figure 14: A) Borylation of 1d. B) Characteristics and structure of PC1 with green and red parts showing the l...

In general, three possible pathways can lead to catalyst deactivation and thus, kinetically limit the overall photon economy (Figure 14C, red arrows). Firstly, both photoinduced electron transfer steps are competing with the intrinsic relaxation of the excited states *PC and *PC•−. In particular, the latter is commonly a very short-lived species (e.g., τobs(*PC1•−) = 64 ps vs τobs(*PC1) = 2.2 µs). Secondly, even if the initial PET generation of PC•− succeeds, it can be quickly reversed by charge recombination via unproductive back electron transfer (PC•− + D•+ → PC + D), preventing the second excitation. The prevalence of this charge recombination process in conPET effectively regulates a lower steady-state concentration of active photocatalyst compared to PEC where the electrochemical reduction to PC•− ensures higher concentrations that are directly user-influenced. Upon activation, PC1 could successfully reduce various aryl halides generating borylated products in modest to excellent (30–99%) yields. Control experiments confirmed that light, catalyst and DBU as a sacrificial electron donor were all essential for product formation. A diminished yield of 19% under aerobic conditions indicates the involvement of a triplet excited state. Addition of i) 2,2,6,6-tetramethylpiperidine-N-oxide (TEMPO) as a free-radical quencher or ii) 1,4-dinitrobenzene as an electron trap inhibited product formation which corroborates the involvement of free radicals. The authors argued against radical chain propagation on the basis of lack of reactivity in the dark during the light ON-OFF cycle experiments (we note that this does not rule out chain propagation with an efficient chain death). Investigations of the photon stoichiometry by elucidation of the relation between product yield and light intensity, as well as the insufficient reductive power of both *PC1 (*E1/2 = −1.56 V vs SCE) and PC1•− (E1/2 = −1.49 V vs SCE) for the reduction of 1d (Epred = −1.66 V vs SCE) confirmed the borylation is indeed a two-photon process. DBU was found to quench the steady-state fluorescence of *PC1 with a quenching rate constant two orders of magnitude smaller than the diffusion rate constant in DMSO at 298 K and one order of magnitude greater under the borylation reaction conditions (i.e., 0.20 M DBU) than the intrinsic decay rate of *PC1. Since no quenching by 1d or B2pin2 could be observed, the formation of PC1•− can be attributed exclusively to the thermodynamically favored reductive quenching of *PC1 by DBU. Nanosecond laser flash photolysis techniques were employed to directly monitor the back electron transfer. Second-order kinetics analyses revealed that rapid charge recombination (e.g., kCR (PC1•−) = 2.6 × 108 M−1 s−1) is a significant deactivation pathway in the generation of the key intermediate. This deactivation by back electron transfer taking place in the Marcus-inverted region of electron transfer can be significantly suppressed by using photocatalysts with a more negative reduction half potential E1/2 (PC/PC•−) [73,74].

The involvement of an excited state radical anion *PC1•− was further supported by analysis of the product quantum yield (QY). The QY exceeded the theoretical limit of a single-photon process when only taking the absorption of PC1 into account but gave a reasonable value (Φprod = 8.2%) for the two-photon process involving excitation of both PC1 and PC1•−. Electron transfer from *PC1•− (*E1/2 = −2.25 V vs SCE) to 1d is thermodynamically favored. While 1d does not quench the distinctive absorption band (λmax = 802 nm) of PC1•− (electrochemically generated) in the absence of light, this absorption band rapidly vanished upon irradiation with red light (λmax = 630 nm), corroborating *PC1•− as the key catalytic species. The rate constants for SET from *PC•− to 1d were obtained by transient absorption spectroscopy with femtosecond pulsed laser excitation and were 2–3 orders of magnitude greater (e.g., keT (*PC1•−) = 6.8 × 1010 s−1) than the diffusion rate in DMSO (kdiff = 4.0 × 108 s−1 of 0.12 M 1d) confirming a preassociation of PC1•− and the substrate prior to PET. This is further supported by the inability of *PC3 (E1/2 = −1.76 V vs SCE) to reduce 1d in the absence of DBU although this is thermodynamically favored. Additionally, the UV–vis–NIR absorption spectrum of a mixture of PC1•− and 1d does not fit the mathematical sum of absorption spectra of both individual compounds but does in fact show additional charge-transfer bands from the preassembly. After electron transfer from *PC1•− to 1d, the C(sp2)–Br bond is cleaved and the aryl radical readily reacts with B2pin2 in a radical substitution reaction yielding the borylated product 17k and a Bpin radical that is subsequently quenched to HBpin by HAT from DBU•+.

As an alternative to organic radical anion conPET, the Chiba group reported the use of homoatomic polysulfide anions as cheap, readily available and potent photocatalysts [75]. Based on the ground state redox potentials and the visible light absorptions of S42− and S3•−, the authors developed a catalytic system that employs these species as photoexcited reductants and oxidants in an elegant redox interplay of the S4•−/S42− and S3•−/S32− redox couples (Figure 15D). Irradiation of S42− with blue light generates the potent reductant *[S42−] enabling the single electron reduction of aryl halides while simultaneously generating S4•−. Upon C(sp2)–X bond cleavage, an aryl radical is formed and trapped by a trapping reagent such as N-methylpyrrole, yielding the open-shell species 4•. Upon irradiation of S3•−, the excited species *[S3•−] oxidizes 4• to the corresponding carbocation 4+ while simultaneously generating S32−. Subsequent deprotonation of 4+ yields the C–H arylated product 4 while SET between S4•− and S32− regenerates the catalytically active polysulfide species S42− and S3•− and closes both catalytic cycles. Showing high versatility, the direct application of commercially available potassium (poly)sulfide (K2Sx) with H2O, the top-down generation from elemental sulfur (S8) with sodium tert-butoxide (NaOt-Bu), and the bottom-up generation from lithium sulfide (Li2S) or triisopropylsilanethiol (iPr3SiSH) were all suitable methods of catalyst generation for the reduction of aryl halides. Compared to conPET chemistry with organic photocatalysts, no terminal reductants like trialkylamines or formates were required for redox-neutral transformations like the C–H arylation, borylation or phosphorylation owing to the interplay between the two polysulfide redox couples. However, K2CO3 was needed to quench liberated protons.

Figure 15: A) Reductive C–H arylation scope with polysulfide conPET (top) and selected examples from the substrate scope (bottom). B) Reductive dehaloborylation. C) Reductive hydrodehalogenation. B) Polysulfide conPET mechanism.

Figure 15: A) Reductive C–H arylation scope with polysulfide conPET (top) and selected examples from the subst...

A large variety of electron-poor aryl bromides bearing different functional groups readily underwent SET reductions to give biaryl cross-coupled products 4 in poor to excellent yields (20–93%) (Figure 15A). The protocol was also applicable to both electron-rich and electron-poor heteroaryl halides. Due to the inherently higher C(sp2)–Cl bond dissociation energies of reductively more inert aryl bromides or aryl chlorides [76], the bottom-up generation of polysulfides from Li2S or iPr3SiSH was found to provide better results than the use of K2Sx. Unactivated aryl bromides such as 4-bromobiphenyl, 2-bromonaphthalene and 4-bromoanisole could also be reduced, but the sluggish reaction of 4-bromoanisole to 4e (20% yield) indicates the limit of the reductive power of the polysulfide catalyst system. Notably, several polyhalogenated aromatics could be chemoselectively engaged at one C–X bond, even for 1-bromo-4-iodobenzene (1f). Apart from N-methylpyrrole, other substituted pyrroles, thiazine (4o), pyrazine (4p) and electron-rich benzenes (4q) were found to be suitable trapping reagents with varying efficiency. The polysulfide catalyst system was also efficiently applied for a dehaloborylation with B2pin2 (Figure 15B) and a net-reductive hydrodehalogenation (Figure 15C).

Both the C–H arylation (Figure 16A) and the dehaloborylation (Figure 16B) of aryl chlorides were smoothly transferred to continuous-flow providing products 4a and 17k in very good yields and gram-scale per hour productivities demonstrating the ease of scaling up conPET reactions in continuous flow. In general, standardized flow photoreactors which are already widely available enable immediate integration of conPET reactions. On the other hand, PEC reactions require tailor-made reactors that present technical challenges, although in principle these challenges are surmountable by adapting engineering from the already well-established fields of PEC water splitting/fuel cells/photovoltaic fields. So far, the examples of large-scale processes with PEC are limited to the use of recirculated flow or batch (vide infra).

Figure 16: Scale-up of A) C–H arylation and B) dehaloborylation with polysulfide photocatalysis in continuous-flow.

Figure 16: Scale-up of A) C–H arylation and B) dehaloborylation with polysulfide photocatalysis in continuous-...

As another alternative to organic photocatalysts, the Polyzos group presented a tandem photocatalytic sequence applying [IrIII(ppy)2(dtbbpy)]PF6 ([Ir1]+) in combination with Et3N to accumulate the energy of two visible-light photons [77]. In their previous work, the Polyzos group discovered the capability of [Ir1]+ to reduce diarylimines via SET in presence of Et3N albeit the large difference in the oxidation potential of [Ir1]0 (E1/2 = −1.47 V vs SCE) and the reduction potentials of imines (e.g., Epred = −2.18 V vs SCE for N-(diphenylmethylene)-1-phenylmethanamine) [78]. Spectroscopic investigations later revealed that the change in absorption and luminescence of deaerated solutions of [Ir1]+ and Et3N were neither related to i) the formation of [Ir1]0 via a single-excitation reductive quenching photocatalytic cycle nor ii) *[Ir1]0 via a conPET mechanism. Rather, changes related to a chemical transformation of the dtbbpy ligand of the catalyst under the reaction conditions. Charge neutrality and diamagnetism of the new catalyst species, as well as loss of the C2v symmetry of [Ir1]+, indicated the nonsymmetric transformation of the dtbbpy ligand to a monoanionic ligand. Extensive NMR analysis confirmed that upon the formation of [Ir1]0 via SET from Et3N to *[Ir1]+, partial saturation of the dtbbpy ligand generates [Ir2]0 and initiates the second catalytic cycle (Figure 17A). Upon excitation with blue light, *[Ir2]0 reduces aryl halides via SET and is simultaneously oxidized to the IrIV species [Ir2]+ (Figure 17B). [Ir2]+ then undergoes SET with [Ir1]0 to regenerate both [Ir2]0 and [Ir1]+, thereby closing both catalytic cycles.

Figure 17: A) Formation of [Ir1]0 and [Ir2]0 upon PET between [Ir1]+ and Et3N. B) Mechanism of multi-photon tandem photocatalysis for the hydrodehalogenation and the carbonylative amidation of aryl halides.

Figure 17: A) Formation of [Ir1]0 and [Ir2]0 upon PET between [Ir1]+ and Et3N. B) Mechanism of multi-photon ta...

An alternative pathway for the regeneration of [Ir1]+ via proton-coupled electron transfer (PCET) from [Ir2]+ could not be ruled out. With no trapping reagents or further reactants present, the aryl radicals generated by C(sp2)–X bond cleavage yield hydrodehalogenated products 2 via HAT. Under irradiation with blue light, [Ir2]0 was found to reduce a variety of aryl halides to their hydrodehalogenated products 2 in excellent yields (93–99%) including the electron-rich 4-iodoanisole and 4-bromoanisole that were quantitatively reduced to anisole (2e) (Figure 18). Notably, the C(sp2)–I bond of 1-bromo-4-iodobenzene was chemoselectively defunctionalized to 2l in 93% yield under the reaction conditions.

Figure 18: A) Reductive hydrodehalogenation of aryl halides via multi-photon tandem photocatalysis. B) Selected examples from the substrate scope.

Figure 18: A) Reductive hydrodehalogenation of aryl halides via multi-photon tandem photocatalysis. B) Selecte...

In 2020, the Polyzos group also demonstrated the carbonylative amidation of aryl halides in continuous flow with the in situ-generated [Ir2]0 (Figure 19A) [79]. This multi-photon tandem photocatalysis protocol provides an elegant alternative to established classical procedures for condensing carboxylic acids with amines that typically generate stochiometric amounts of harmful byproducts released [80,81], while simultaneously operating under milder reaction conditions than those applied in transition metal-catalyzed carbonylative amidation protocols [82,83]. Following the same distinct, yet interconnected photocatalytic cycles as the hydrodehalogenation, an aryl radical 2• is formed via successive PET and C(sp2)–X bond cleavage (Figure 17B). Carbon monoxide, introduced to the reaction mixture by a tube-in-tube reactor, traps the aryl radical to generate the acyl radical 23 (Figure 17B). Nucleophilic addition of the amine to the acyl radical and amine-assisted intermolecular proton transfer [84] generates the α-hydroxy radical 24 from which formation of the amide 25 proceeds either via i) oxidation by [Ir2]+ and deprotonation or ii) radical chain propagation [85]. Electron-deficient, electron-neutral, and electron-rich aryl halides bearing different functional groups were all well-tolerated and their products obtained in poor to excellent yields (27–88%). 1-Bromo-4-chlorobenzene and 1-chloro-4-iodobenzene were chemoselectively transformed to 26b without activation of the C(sp2)–Cl bond.

Figure 19: A) Carbonylative amidation of aryl halides in continuous flow. B) Selected examples from the substrate scope.

Figure 19: A) Carbonylative amidation of aryl halides in continuous flow. B) Selected examples from the substr...

Notably, carbonylative amidation of a borylated aryl bromide to 26d proceeded well, where a Pd-catalyzed carbonylative amidation reaction would be plagued by undesired Suzuki coupling. Several secondary cyclic and acyclic amines, as well as primary amines were successfully employed as amine coupling partners. The scope of the protocol was further expanded to a radical cyclization/aminocarbonylation cascade reaction yielding the bis-carbonylated α-keto amide 26h in 31% yield.

2.1.2 C(sp3)–X activation: The generation of alkyl radicals using alkyl halides as precursors proves very challenging due their deep reduction potentials and bond dissociation energies comparable to aryl halides [86,87]. Classical activation modes for the homolytic C(sp3)–X bond cleavage consist of thermolytic or photolytic methods using high temperatures (>220 °C) or irradiation with UV light (λ < 300 nm). These harsh conditions were later replaced by the use of unstable or toxic radical initiators/chain carriers such as peroxides, azo-nitriles, or very prominently Bu3SnH [88,89]. Only recently have PRC methods emerged, that mostly relied on the use of metal-based photocatalysts and high energy UV/near-UV light [90,91].

In 2019, the Prato group demonstrated how the PDI catalyst first disclosed by the König group (vide supra) could be leveraged for conPET reductions of perfluoroalkyl iodides, providing a photocatalytic alternative for the generation of perfluoroalkyl radicals used in atom transfer radical addition (ATRA) reactions with alkenes [92]. Since the ATRA mechanism involves radical chain propagation, minimal loadings of the PDI (0.05 mol %) could be employed as an initiator together with a sub-stoichiometric amount of sodium ascorbate for reductive quenching of PDI to generate PDI•−. While terminal olefin partners were generally well-tolerated, the protocol was limited to perfluoroalkyl iodides. The reductive power of *PDI•− (*E1/2 = −1.87 V vs SCE) was well-matched to the redox potentials of perfluoroalkyl iodides, but was insufficient for perfluorobromides (e.g., Epred = −1.52 V vs SCE for CF3I and Epred = −2.10 V vs SCE for CF3Br) [93].

As a further application of conPET to atom transfer processes, the Wärnmark group recently disclosed an alternative protocol for the ATRA reaction of perfluoroalkyl iodides using the iron-based NHC complex [FeIII(btz)3](PF6)3 (btz = (3,3’-dimethyl-1,1’-bis(p-tolyl)-4,4’-bis(1,2,3-triazol-5-ylidene))) as the first example of an earth-abundant transition metal complex capable of accumulating two photon energies via consecutive 2LMCT and 3MLCT excitations in an overall conPET mechanism [94]. Since iron-based photocatalysts generally suffer notoriously short excited state lifetimes [95,96], most reactions employing such photocatalysts require special reaction design (e.g., coordination of substrates as ligands to enable intramolecular metal to ligand charge transfer (MLCT)). Only recently have a few examples been reported that observed bimolecular quenching of iron CT states (in the nanosecond domain) enabled by the relatively longer lifetimes of e.g. Fe–NHC complexes [97-100]. In particular, the Wärnmark group reported two sets of conditions with and without Et3N as a sacrificial electron donor, to achieve reductive and oxidative quenching pathways, respectively (Figure 20A). Both protocols were able to successfully engage perfluoroalkyl iodides and bromotrichloromethane in combination with a diverse scope of alkenes and alkynes (Figure 20B). Products of terminal alkenes and alkynes were generally obtained in good to excellent yields while also tolerating several functional groups. Substrates bearing internal double bonds were engaged with varying efficiencies (30c), but the reaction showed a clear preference for terminal alkenes (30d). The reaction of perfluorohexyl iodide with 3-(allyloxy)-1-propyne gave 30e and 30f as the only products, demonstrating a clear preference for addition to alkenes even in the presence of alkyne functionalities.

Figure 20: A) General scheme for reductive (RQ) and oxidative quenching (OQ) protocols using [FeIII(btz)3](PF6)3 for the ATRA reaction of alkyl halides with alkenes and alkynes. B) Selected examples from the substrate scope. C) conPET mechanism of the RQ pathway.

Figure 20: A) General scheme for reductive (RQ) and oxidative quenching (OQ) protocols using [FeIII(btz)3](PF6)...

Due to basic conditions of the reductive quenching (RQ) route, the formation of lactone side product 30h could be observed with a carboxylic acid functionality. In the absence of Et3N, the mechanism follows a ‘monophotonic’ oxidative quenching (OQ) route in which [FeIII(btz)3]3+ is oxidatively quenched to [FeIV(btz)3]4+ by the alkyl halide substrate after excitation with green light. After addition of the alkyl radical to the alkene or alkyne substrate, the catalyst is regenerated by oxidizing this radical to the corresponding cation. In the presence of Et3N, [FeIII(btz)3]3+ is reductively quenched after excitation to its 2LMCT excited state to generate [FeII(btz)3]2+ (equivalent to PC•− in the classical conPET mechanism) (Figure 20C). [FeII(btz)3]2+ is excited again to the more strongly reducing 3MLCT excited state (*E1/2 = −1.6 V to −1.8 V vs Fc), which then induces SET to the alkyl halide generating an alkyl radical via cleavage of the C(sp3)–X bond. The authors propose that this radical then engages in a radical chain propagation pathway leading to product 30 and a new alkyl radical. This is strongly supported by a single turnover experiment, where exclusive excitation of [FeII(btz)3]2+ with 700 nm LEDs after in situ generation and substrate addition in the dark generated 5% of product even with only 0.5 mol % of catalyst present. In its ground state, [FeII(btz)3]2+ is not reducing enough to engage the model substrate perfluorooctyl iodide and instead *[FeII(btz)3]2+ was verified as the key catalytic species by transient absorption spectroscopy; even though the strongly reducing α-amino alkyl radical intermediate might also engage in the reduction of alkyl halides or act as a halogen atom transfer (XAT) agent [101].

While yields of the monophotonic oxidative quenching route and the (biphotonic) conPET reductive quenching route were generally well comparable, the RQ route clearly benefits from a longer lifetime of the key catalytic species, shorter reaction times and lower catalyst loading. The requirement for sub-stoichiometric amounts of the sacrificial electron donor can be justified. While the work of Wärnmark is remarkable on a conceptual level, the protocol is still limited by the reductive power of the excited state and thus restricted to rather activated alkyl halides like perfluoroalkyl iodides.

Following their work on carbonylative amidation with [IrIII(ppy)2(dtbbpy)]PF6 (vide supra), the Polyzos group also disclosed a slightly modified procedure for the carbonylative amidation of alkyl iodides in continuous flow with an impressive substrate scope engaging substrates with notably deep reduction potentials (e.g., Epred = −2.33 V vs SCE for n-butyl iodide) (Figure 21A) [79]. The reaction follows the same tandem photocatalysis mechanism as the carbonylative amidation of aryl halides (Figure 17B).

Figure 21: A) Carbonylative amidation of alkyl iodides with [IrIII(ppy)2(dtbbpy)]PF6. B) Selected examples from the substrate scope. C) Flow scale up of the 31e‘s synthesis.

Figure 21: A) Carbonylative amidation of alkyl iodides with [IrIII(ppy)2(dtbbpy)]PF6. B) Selected examples fro...

Tertiary, secondary, and primary alkyl iodides all readily underwent carbonylative amination with morpholine derivatives to afford morpholinoamides in acceptable to excellent yields (46–99%) (Figure 21B). The high yields obtained with primary alkyl iodides are particularly noteworthy due to the competing SN2 reaction with amines. Several cholesterol amides were efficiently prepared using this protocol in 1:1 dr (31d).

Several primary and secondary amines were successfully employed as coupling partners whereas diisopropylamine led to diminished yield (31f), likely due to steric hindrance in reacting with the carbonylated intermediate. Besides, primary anilines bearing a large variety of functional groups proved suitable coupling partners with no obvious influence of the aromatic ring’s electron density on the efficiency (32a–c). The amenability of p-haloanilines 32c demonstrates orthogonality of this photocatalytic manifold to Pd-catalyzed carbonylative amidation protocols, while competing hydrodehalogenation was not observed as a notable advantage of the former. Scale-up of the reaction employing cyclohexyl iodide (27a) and 1-Boc-piperazine (24a) gave 5.17 g of 31e after a collection time of ≈13 h (Figure 21C).

Apart from C(sp3)–halogen bond activations and cleavages, conPET also enables other C(sp3)–X bond cleavages. Ye, Yu and co-workers very recently disclosed a protocol for the reductive C–N bond cleavage and carboxylation of cyclic amines 33 for the generation of β-, γ-, δ- and ε-amino acids (generally referred to as 34) using the isophthalonitrile-derived catalysts 4DPAIPN and 3DPAFIPN (Figure 22A) [102]. The authors demonstrated the applicability of the synthetic protocol with a broad substrate scope consisting of 2-arylazetidines and 2-carbonylazetidines for formation of γ-amino acids (42–95%), 2-arylaziridines for formation of β-amino acids (53–94%), pyrrolidines for formation of δ-amino acids (38–66%) and piperidines for formation of ε-amino acids (42–54%) (Figure 22B).

Figure 22: A) Carboxylative C–N bond cleavage in cyclic amines. B) Selected examples from the substrate scope. C) Proposed mechanism.

Figure 22: A) Carboxylative C–N bond cleavage in cyclic amines. B) Selected examples from the substrate scope....

Notably, the reaction of model substrate N-Boc-2-phenylazetidine to 34a could be performed efficiently on a gram scale in 71% yield. Considering that cyclic amines have highly negative reduction potentials (e.g., Epred = −3.0 V vs SCE for N-Boc-2-phenylazetidine), the authors propose that 4-DPAIPN and 3-DPAFIPN undergo a conPET cycle for generation of their excited radical anions as the active catalyst (Figure 22C). These highly reducing compounds then engage the amine substrate 33 in a SET reduction. Upon generation of the amine radical anion 33•−, the C–N bond is then cleaved which leads to ring-opening and formation of the benzylic radical 34•−. This was observed in HRMS via TEMPO radical trapping experiments by the authors. The authors propose that protonation (X = H) or carboxylation (X = CO2) of this amide anion and a second SET happen either consecutively or in a concerted fashion, leading to formation of a benzylic anion (34−) which then undergoes carboxylation and protonation to generate the N-protected amino acid 34. An alternative pathway via protonation of 34− and subsequent photocatalytic carboxylation of the benzylic C–H bond with CO2 was ruled out.

Interestingly, while conPET technology forges ahead in reductive processes for ring opening and functionalization of cyclic amines that has just been summarized, PEC has recently found applications in oxidative ring-opening/functionalization of cyclic alcohols, again demonstrating a complementarity between the two methods (vide infra, Figure 64 and Figure 65).

2.1.3 C(sp2)–C(sp2) Bond activation: Alkene activation: Since olefins present a fundamental and ubiquitous group of commodity chemicals directly accessible from readily available petroleum feedstocks, their activation via hydrofunctionalization for the construction of saturated hydrocarbon scaffolds is an extensively studied chemical transformation. Classical approaches employ Brønsted acids or transition metal catalysts for electrophilic activation of the target π bond to a cationic or bridged intermediate for subsequent reaction with a nucleophile that generally results in formation of Markovnikov products [103]. Modern orthogonal approaches for the generation of nucleophilic radical anion intermediates relying on PRC, however, are strongly limited in their scope by the highly negative reduction potentials of unactivated olefins (Epred < −2 V vs SCE) [104,105].

The Polyzos group was able to overcome this limitation by employing their tandem iridium photocatalytic system (vide supra, Figure 17A) for generation of a super-reductants that readily engaged in the reduction of various styrene derivatives via transfer hydrogenation (Figure 23A/B) or by nucleophilic addition to unactivated ketones (Figure 23C) [106]. After its generation via excitation and reductive quenching of [Ir1]+ with DIPEA, [Ir2]0 can be further excited effecting SET reduction of styrenes to their radical anions 28•− (Figure 23D). In the case of transfer hydrogenation, 28•− is then protonated to afford benzylic radical 35•. The alkane product 35 is obtained in the major pathway via a second SET reduction and subsequent protonation, while a major contribution by a concerted HAT from DIPEA•+ could be ruled out. Addition of formic acid was required to transform DIPEA to its formate salt and thus suppress unproductive reaction of 28•− and DIPEA•+ to form the α-amino adduct. The hydrofunctionalization of ketones to tertiary alcohols 37 likely also involves 28•− as a key intermediate, but the mechanism has yet to be elucidated.

Figure 23: A) Formal reduction of alkenes to alkanes via transfer hydrogenation. B) Selected examples from the substrate scope. C) Hydrofunctionalization of alkenes with ketones and selected examples. D) Proposed mechanism for the reduction of alkenes via tandem Ir photocatalysis with [IrIII(ppy)2(dtbbpy)]PF6.

Figure 23: A) Formal reduction of alkenes to alkanes via transfer hydrogenation. B) Selected examples from the...

The transfer hydrogenation protocol tolerated both electron-poor and electron-rich 1,1-diarylethylenes. Competing reduction of aryl halide functionalities (35c) was not observed. Cyclic and acyclic α-alkyl styrenes, α,β-unsubstituted styrenes and β-substituted styrenes were all suitable substrates. For the hydrofunctionalization of olefins with ketones, the reduction was performed with tetramethylpiperidine derivative 36 as reductive quencher using the ketone coupling partner as solvent.

The reaction proceeded slowly with limited conversion even after 60 h, but the tertiary alcohol products could be obtained in 40–55% yield in a controlled anti-Markovnikov manner with both acetone (37a–c) and cyclobutanone (37d).

2.1.4 Arene activation: Similar to olefins, arenes and heteroarenes are important, readily available and versatile commodity chemicals produced in large quantities from petroleum feedstocks. While functionalization of arenes (e.g., by substitution reactions) is generally well-investigated, procedures for the dearomatization via reduction to semi-saturated cyclic products remain scarce. The most established and still widely used method for such transformations is the classical Birch reduction, that employs solvated electrons generated by dissolving alkali metals such as lithium and sodium in cryogenic liquid ammonia [107,108]. For the sake of safety and practicability, variations of the Birch reduction under ammonia-free [109-111], transition metal-catalyzed [112], electrochemical [113], or photochemical conditions [114-117] were developed, however, each of these methods require harsh conditions themselves or suffer other strict limitations. Reported photochemical approaches rely on UV irradiation and large stoichiometric loadings of strong reducing agents to overcome the deeply negative reduction potentials of arenes (e.g., Epred = −3.42 V vs SCE for benzene) [118], rendering such methods unfavorable. While efforts to accumulate visible light photons via conPET provided super-reducing catalysts that should be capable of reducing arenes on thermodynamic grounds, no dearomatized products were observed in the studies on hydrodehalogenation of aryl halides. In 2019, the König group for the first time disclosed a protocol for a Birch-type reduction by visible light iridium photocatalysis employing [Ir{dF(CF3)ppy}2(dtbbpy)]PF6 ([IrIII]) in a combined energy-transfer (EnT) and SET process (not shown) [119]. Key to success was leveraging a triplet-triplet EnT from the excited photocatalyst *[IrIII] (ET = 61.8 kcal mol−1) to the substrate, successfully lowering its reduction potential (e.g., E1/2 = −1.98 V vs SCE vs *E1/2 = −0.13 V vs SCE for anthracene). Due to requirement of this EnT step, only substrates with sufficiently low triplet energies accessible to *[IrIII] (naphthalenes, etc) could successfully be reduced by this protocol, which excludes arenes with small conjugated system such as benzene (ET = 84.4 kcal mol−1).

Miyake and co-workers overcame this issue by a modified conPET mechanism [120]. They demonstrated how benzo[ghi]perylene monoimides (BPIs) could be successfully reduced to their radical anions via an addition of OH− to the imide, followed by homolysis, whereas commonly applied trialkylamines failed to achieve this. Optimal results were obtained with Me4NOH as the electron source for reductive quenching in a solvent mixture of MeOH and t-amyl alcohol (t-AmOH) under irradiation with blue LEDs (λ = 405 nm). Of the investigated photocatalysts, p-OMePh-substituted BPI (PMP-BPI, see Figure 25 for structure) performed best, even in very low catalyst loadings, but due to presumed catalyst degradation the catalyst had to be added sequentially in three portions (0.25 mol % each) over the long course of the reaction (96 h for most substrates) to achieve sufficient conversion. With optimized conditions, the authors were able to reduce various benzene derivatives (38) to the corresponding 1,4-dihydrobenzenes (39) in poor to high (24–91%) yields (Figure 24B).

Figure 24: A) Birch-type reduction of benzenes with PMP-BPI. B) Selected examples from the substrate scope (scale up reactions under slightly modified conditions). C) Selective reduction by modulation of reaction conditions (reactions conducted under slightly modulated reaction conditions, see original publication for details).

Figure 24: A) Birch-type reduction of benzenes with PMP-BPI. B) Selected examples from the substrate scope (sc...

Apart from the model substrate 2-phenylethanol (39a) and structurally related compounds, benzene (39e) and toluene (not shown) were also readily reduced under the reaction conditions. Several functionalities were well-tolerated, including carbamates, amides and acids, albeit with diminished product yields (e.g., 39f, 39g and 39h). Scale-up to a 10 mmol scale was performed successfully for products 39a and 39i (albeit requiring even longer reaction times and 4 × LEDs). The reaction protocol was not applicable to electron-rich arenes, substrates bearing alkene, alkyne, alkyl halide or unprotected amine functionalities and N-containing heterocycles.

The successful reduction of benzene and toluene via this protocol is the first and so far only example of a visible-light photocatalytic Birch-type reduction that could engage these simple aromatic feedstock compounds. Modification of the reaction conditions, in particular amounts of catalyst and NMe4OH and reaction time allowed for selective reductions (Figure 24C). Benzophenone underwent tandem reductive deoxygenation and Birch-type reduction to 39k. Cinnamyl alcohol could either be reduced on the alkene functionality to 39l or further reduced to 39m while reductive ring-opening of trans-2-phenylcyclopropane-1-carboxylic acid could be modified to yield either 39n or the Birch-type reduction product 39o.

Mechanistic investigations revealed that generation of the key catalytic species proceeds via addition of OH− to PMP-BPI, generating PMP-BPI-OH− (Figure 25). After irradiation, a hydroxyl radical is eliminated and PMP-BPI•− can be excited again to *[PMP-BPI•−]. While the fate of the hydroxyl radical is unknown, DFT calculations found this PET occurring from the lowest singlet excited state of PMP-BPI-OH− to be exergonic by 11.5 kcal mol−1 (under irradiation with 405 nm LEDs). PMP-BPI•− that was generated via mediation with hydroxide or fluoride or even by bulk electrolysis (Ecell = −2.26 V vs SCE) all showed the same absorption. A second photoexcitation is required due to the insufficient reducing power of ground state PMP-BPI•− (E1/2 = −1.24 V vs SCE). Based on DFT calculations and nanosecond transient absorption spectroscopy, the authors favored a plausible mechanism via the generation of a solvated electron, rather than direct SET from the photocatalyst. The prolonged lifetime of *PMP-BPI•− observed in nanosecond transient absorption spectroscopy with excitation at 532 nm is assumed to stem from an unreactive quartet excited state *4PMP-BPI•−, arising from ISC from the doublet state *2PMP-BPI•−. Owing to the absence of significant quenching of this long-lived quarted state by arene substrates, the authors proposed instead that photoexcitation to the first doublet state (or higher order doublet states) *2PMP-BPI•− liberates a solvated electron. The solvated electron reduces the arene substrate to its radical anion 38•− and the 1,4-dihydrobenzene product 39 is obtained by sequential protonation, reduction by another solvated electron and a second protonation.

Figure 25: Proposed mechanism of the OH− mediated conPET Birch-type reduction of benzene via generation of solvated electrons.

Figure 25: Proposed mechanism of the OH− mediated conPET Birch-type reduction of benzene via generation of sol...

Alternatively, the authors could not rule out reduction of arene substrates occurring via direct SET from a higher excited state of *PMP-BPI•− (Dn) in an anti-Kasha fashion, which would require a catalyst-substrate preassembly. Given the selectivity observed for arene over amide/carbamate reductions and the extended π-system of PMP-BPI•−, a π–π stacking interaction assembly seems plausible. However, unlike the conPET study of Lee, Chou, You and co-workers [72] and like the e-PRC study of Barham, König and co-workers (vide infra, Figure 72), the authors did not find any evidence for such an assembly of PC•− by UV–vis spectroscopy. Barham, and co-workers as well as Hauer and co-workers (vide infra, Figure 37 and following discussion) showed in their studies of organic radical cations that a lack of change in steady-state UV–vis spectroscopy cannot speak against a preassembly – especially with non-polarized/electronically symmetrical substrates – and only transient absorption spectroscopy kinetics is qualified to reveal the necessary operation of a preassembly for radical ion photocatalysis.

2.1.5 Het–Het bond activation: N–S and O–S bond activation: In their work on reductive hydrodehalogenation of aryl halides, the Nicewicz group also disclosed a protocol for reductive detosylation of N-tosyl amides with Mes-Acr-BF4 via a conPET mechanism [54]. Single-electron reduction of a tosylated amine 40 by the twisted intramolecular charge transfer (TICT) state of the Mes-Acr• radical (Figure 10C) yielded its radical anion, which supposably eliminated a tosylate anion to generate a primary or secondary aromatic or aliphatic amines 41 (Figure 26A). Primary and secondary tosylated anilines were efficiently transformed to the corresponding anilines in moderate to excellent yields (42–99%). Detosylation occurred selectively in presence of a mesylated amine functionality (41c). Alkylamines were readily generated from their tosylated counterparts (Figure 26B). Pyrrolidine was obtained in 61% yield (41h) whereas the introduction of an adjacent carbonyl group increased the yield to 99% (41i). Several heterocyclic amines including pyrrole (41e) and 1H-indazole (41f) as well as natural products like melatonin (41j) or the AMT analogue 41k were also successfully engaged in reductive detosylation.

Figure 26: Reductive detosylation of N-tosylated amides with Mes-Acr-BF4. B) Selected examples from the substrate scope.

Figure 26: Reductive detosylation of N-tosylated amides with Mes-Acr-BF4. B) Selected examples from the substr...

The Wenger group recently disclosed a dual photoredox catalytic approach for the reductive detosylation of N-tosyl amides 40 to secondary amines 41 [121]. Herein, photoexcited [Cu(dap)2]Cl assists in the generation of DCA•− (from DCA) which can be photoexcited to act as a super-reductant. The generation of DCA•− by the Cu catalytic cycle without direct excitation of DCA allows for irradiation with red light whereas the classical conPET mechanism (vide supra, Figure 9) requires near-UV/blue light irradiation to excite DCA [52]. Red photons (for λ = 620 nm, E = 2.0 eV) intrinsically possess substantially lower energy than blue (for λ = 410 nm, E = 3.0 eV) or green photons, which gives the impression they may be unfavorable for photocatalytic reactions. To the contrary, however, the use of red light provides other advantages including less photodamage and greater penetration depth into colored reaction solutions [122]. Furthermore, a dual catalytic system with two fully independent photocatalysts provides increased possibilities for method optimization and development but at the same time requires more careful reaction design. The authors initially developed their dual PRC protocol for the benchmark hydrodehalogenation of various aryl halides and efficiently transformed several moderately difficult-to-reduce substrates to their dehalogenated products.

N-Tosyl amides were also suitable substrates, affording detosylated products in mostly good to even quantitative yields with a few exceptions (Figure 27A, B). Several carbazoles (41l) and diarylamines (41m) were readily generated, however, aryl ethers such as di(p-anisyl)amine (41n) and phenoxazine (41o) were only obtained in modest yields (35–45%). The efficiency seems to be influenced by electronic effects; an electron-poor benzylic (trifluoromethyl)aniline (41p) resulted in >95% yield whereas a more electron-rich benzylic toluidine (41q) gave <10% yield. A ditosylated aniline was selectively detosylated once to afford 41r in >95% yield which is in good accordance with the low conversion observed for the detosylation of 41r to 41s. Several heteroaromatic amines including pyrrole (41e) were also generated in good to excellent yields (67–98%). Electron-withdrawing carbonyl functionalities enabled the efficient detosylation of cyclic aliphatic amines (e.g., 41t) whereas detosylation of unsubstituted pyrrolidine gave no product. Several tosylated phenols including a doubly tosylated substrate were efficiently detosylated under the reaction conditions (Figure 27C). Additionally, selected examples demonstrate the large scope of the dual catalytic system including reductive C(sp2)–S desulfonylations (44), eliminations of tosylates (45a) and acetates (45b) and reductive anhydride cleavages (46) (Figure 27D). Reduction of a mesylated carbazole was not viable and resulted in minimal formation of product 41l.

Figure 27: A) Reductive detosylation of N-tosyl amides by dual PRC. B) Selected examples from the substrate scope for the detosylation of N-tosyl amides. C) Reductive detosylation of tosylates. D) Scope expansion to other reductive transformations achieved by dual PRC.

Figure 27: A) Reductive detosylation of N-tosyl amides by dual PRC. B) Selected examples from the substrate sc...

The authors proposed two possible mechanisms for the dual PRC with [Cu(dap)2]Cl and DCA; one relying on PET (Figure 28A) and another relying on triple-triplet energy transfer (TTEnT) (Figure 28B) as the interconnection between both catalytic cycles. For the PET mechanism (Figure 28A), [CuI(dap)2]+ ([CuI]+) is initially photoexcited to 3*[CuI]+ which then undergoes SET to DCA to directly access DCA•−. [CuI]+ is subsequently regenerated via reductive quenching of [CuII]2+ by DIPEA to close the Cu catalytic cycle whereas DCA•− is excited to 2*DCA•− by the absorption of a red photon. A second SET between 2*DCA•− and the substrate regenerates DCA and generates the substrate radical anion. In the TTEnT mechanism (Figure 28B), DCA•− is formed in a SenI-ET via the generation of 3*DCA through energy transfer of 3*[CuI]+ to DCA and subsequent reductive quenching by DIPEA. As before, DCA•− is then excited to 2*DCA•− to enable substrate reduction via SET.

Figure 28: A) Mechanism of the dual PRC based on PET between [Cu(dap)2]+ and DCA. B) Mechanism of the dual PRC based on TTEnT between [Cu(dap)2]+ and DCA.

Figure 28: A) Mechanism of the dual PRC based on PET between [Cu(dap)2]+ and DCA. B) Mechanism of the dual PRC...

Based on cyclic voltammetry, spectroscopic and spectroelectrochemical data, it was concluded that both pathways are thermodynamically feasible and could simultaneously operate in MeCN as the reaction solvent due to spectroscopic evidence for [CuII]2+ and 3*DCA. Based on relative intensity and molar extinction coefficients of the absorption by DCA•− and 3*DCA upon excitation of [CuI]+, the authors provided estimations for the concentrations of both species and thus, estimated the relative prevalences of the PET and TTEnT mechanism in MeCN and acetone. Lower concentrations of 3*DCA than of DCA•− in MeCN suggest that the PET mechanism herein accounts for roughly 70% of product formation while higher relative concentrations of 3*DCA in acetone indicate that TTEnT dominates here. Although this proposal has to be judged with caution due to severe simplifications, the study nonetheless emphasizes the critical influence of solvation on photocatalytic mechanisms and their elucidation.