Abstract

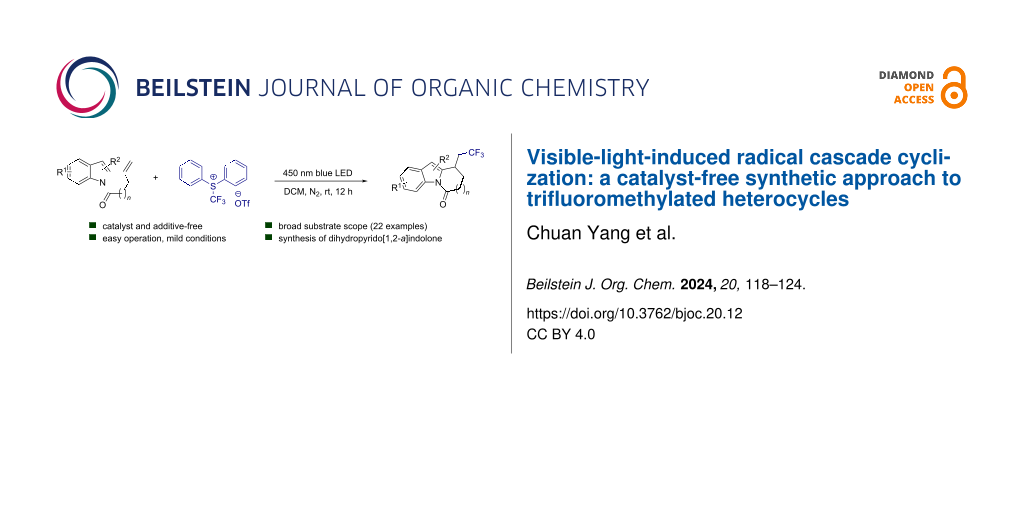

A visible-light-promoted research protocol for constructing dihydropyrido[1,2-a]indolone skeletons is herein described proceeding through a cascade cyclization mediated by trifluoromethyl radicals. This method allows the efficient synthesis of various indole derivatives without the need of photocatalysts or transition-metal catalysts. Mechanism experiments indicate that the process involves a radical chain process initiated by the homolysis of Umemoto's reagent. This straightforward method enables a rapid access to heterocycles containing a trifluoromethyl group.

Graphical Abstract

Introduction

Dihydropyrido[1,2-a]indolone (DHPI) skeletons are commonly found in natural products and pharmaceutical compounds (Figure 1) [1-3], which exhibit a wide range of biological and pharmaceutical activities [4]. For example, mersicarpine has been found to inhibit protein translation and induce apoptosis [5] and vinburnine acts as a vasodilator for the treatment of cerebrovascular insufficiency [6,7].

Figure 1: Representative dihydropyrido[1,2-a]indolone derivatives.

Figure 1: Representative dihydropyrido[1,2-a]indolone derivatives.

Given their biological activity and potential applications, continuous efforts have been dedicated to the synthesis of DHPI derivatives. Various synthetic strategies have been explored (Scheme 1), including transition-metal-catalyzed cross-coupling reactions [8-10], annulation reaction of carbenoids [11], Friedel–Crafts acylation [12], radical cascade reactions [2,13], and photoinduced radical cyclizations [14-17]. However, these methods often suffer from drawbacks such as harsh reaction conditions and the requirement of transition-metal catalysts. Although photocatalyzed cyclization reactions usually occur under mild conditions, they typically require expensive metal-based photocatalysts or structurally complex organic dyes [18]. Therefore, the development of a photoinduced cascade reaction without the need of additional catalysts or additives remains highly desirable [19].

Scheme 1: Selected works for the construction of dihydropyrido[1,2-a]indolones and current methodology.

Scheme 1: Selected works for the construction of dihydropyrido[1,2-a]indolones and current methodology.

The introduction of an electron-withdrawing functional moiety into drug molecules would increase their metabolic stability [20], by avoiding, e.g., fast oxidation by cytochrome P450 oxidases [21]. In particular, the introduction of a trifluoromethyl group (–CF3) was shown to increase the metabolic stability of molecules and at the same time improved cell membrane permeability. Therefore, it became a commonly used strategy to modify medicine candidates [22-24]. Based on these advantages, we envisioned a one-step synthesis of dihydropyrido[1,2-a]indolone skeletons utilizing an indole substrate and a trifluoromethyl radical source under light irradiation. Umemoto’s reagent, which is capable of releasing a trifluoromethyl radical via a photoinduced single-electron-transfer (SET) process, is usually employed to enable the trifluoromethylation of unsaturated substrates [25-27]. Herein, we report a protocol to furnish trifluoromethylated dihyropyrido[1,2-a]indolones under mild conditions, without the need of photocatalysts or transition metals [28].

Results and Discussion

We initialized our study by employing Ru(bpy)3Cl2·6H2O and Umemoto’s reagent to generate trifluoromethyl radicals via a photo-reductive quench process (Table 1). The indole substrate 1a was chosen as a model substrate, and the reaction mixture was irradiated under 450 nm visible light for 12 h, resulting in the formation of the desired product 3a, albeit in a relatively low yield (Table 1, entry 1). Control experiments revealed that omitting the photocatalyst led to an even higher yield (Table 1, entry 2), but light irradiation was essential to the reaction (Table 1, entries 3 and 4). Initially, some bases were added into the reaction system considering a deprotonation process, but subsequent investigations indicated that bases were not required. Among the solvents examined, DCM was found to be the most effective (Table 1, entries 5–8). However, due to the low boiling point of DCM, more solvent was added to avoid complete volatilization (Table 1, entry 8). The screening of different irradiation wavelengths revealed that 450 nm visible light irradiation is optimal (Table 1, entries 9–12). Furthermore, various types of Umemoto’s reagent were also screened (Table 1, entries 13–15). As Umemoto’s reagent 2b was easier to prepare [29] and the use of 2b did not significantly affect the reaction yield, it was chosen as the most suitable CF3 radical source. Further optimization involved screening the substrates’ ratios, which revealed that an excess of substrate 1a resulted in improved yields. Finally, experimenting with anhydrous DCM as the solvent showed that anhydrous conditions were not necessary for the reaction (Table 1, entry 16).

Table 1: Optimization of reaction conditions.a

|

|

||||||

| Entry |

CF3· source

(equiv) |

Photocatalyst | Solvent |

λ Irradiation

(nm) |

Time | Yield 3a |

| 1 | 2a (2) | Ru(bpy)3Cl2 | MeCN | 450 | 12 h | 21% |

| 2 | 2a (2) | – | MeCN | 450 | 12 h | 43% |

| 3b | 2a (2) | – | MeCN | 450 | 12 h | 52% |

| 4b | 2a (2) | – | MeCN | dark | 12 h | trace |

| 5b | 2a (2) | – | 1,4-dioxane | 450 | 12 h | trace |

| 6b | 2a (2) | – | toluene | 450 | 12 h | trace |

| 7b | 2a (2) | – | DCM (1 mL) | 450 | 12 h | 45% |

| 8b | 2a (2) | – | DCM (2 mL) | 450 | 12 h | 55% |

| 9b | 2a (2) | – | DCM (2 mL) | 365 | 12 h | 33% |

| 10b | 2a (2) | – | DCM (2 mL) | 390 | 12 h | 40% |

| 11b | 2a (2) | – | DCM (2 mL) | 420 | 12 h | 51% |

| 12c | 2a (1) | – | DCM (2 mL) | 450 | 22 h | 68% |

| 13b,c | 2a (1) | – | DCM (2 mL) | 450 | 22 h | 68% |

| 14c | 2b (1) | – | DCM (2 mL) | 450 | 18 h | 67% |

| 15c | 2c (1) | – | DCM (2 mL) | 450 | 18 h | 58% |

| 16c | 2b (1) | – | dry DCM | 450 | 12 h | 72% |

aStandard reaction conditions: 1a (0.1 mmol, 1.0 equiv), 2a (0.2 mmol, 2.0 equiv), solvent (1 mL). b2.0 equiv of KH2PO4 were added. c3.0 equiv of substrate 1a were utilized in the reaction.

With the optimized conditions in hand, we started to explore the scope of this photoinduced transformation. Various alkene-tethered indole derivatives were subjected to the reaction. Remarkably, a range of dihydropyrido[1,2-a]indolones bearing a trifluoromethyl group were obtained in moderate to good yields (Scheme 2). In general, substrates with electron-withdrawing groups delivered the products in lower yields, such as -CN (3d, 42%) and -CHO (3j, 28%), while the substrates with electron-donating groups gave higher yields, such as -Me (3b, 70%; 3e, 79%), -OMe (3f, 59%; 3k, 55%). Most of the substrates bearing substituents at the C5 position on the indole skeleton reacted well, furnishing the products in moderate to good yields from 53–79% (3e–i) except the 5-CHO-substituted substrate which afforded product 3j in 28% yield. Indoles with substituents at the C7 position of the indole ring (3m and 3n) furnished the products in moderate yields. The structure of compound 3m (4-Br) was confirmed by X-ray single crystal diffraction (CCDC: 2304916). Reactions of substrates with a longer carbon chain and a branched chain also proceeded well and afforded the products in 43% (3o) and 52% (3p) yields, respectively. If the chains did not involve a carbonyl group, the yields were much lower (3q, 25%; 3s, 29%, and 3t, 29%). When a pyrrole ring was used instead of indole, the reaction proceeded but gave the product in low yield (3r).

Scheme 2: Substrate scope of the cascade reaction.

Scheme 2: Substrate scope of the cascade reaction.

We did not explore the reaction with a primary amine functionalized substrate, because of competition of the reaction site during the synthesis of substrates. However, an amide-substituted indole furnished a clean product without competition; for example, product 3u was derived from melatonin with an amide functional group, whose reaction to the desired product was clean without competitive byproducts. Finally, 3-indoleacetonitrile, a plant growth hormone, furnished the desired product in good yield (3v, 68%). Combined with melatonin, these examples demonstrate the suitability of our approach to be used in drug modification and development. In short, this reaction tolerates different substituents on the indole ring, including electron-donating and electron-withdrawing groups, providing access to a diverse array of dihydropyrido[1,2-a]indolone derivatives.

To gain insight into the reaction process, we performed a series of control experiments. The addition of a typical radical scavenger – TEMPO (2,2,6,6-tetramethylpiperidin-1-yloxyl) significantly inhibited the reaction (as shown in Scheme 3), suggesting the involvement of radical species during the reaction process. Moreover, the radical trapping product was detected and confirmed via 19F NMR (Figure S3 in Supporting Information File 1) [30] and high-resolution mass spectrometry.

You and co-workers proposed a reaction pathway involving the combination of the indole substrate and Umemoto’s reagent to form an electron donor–acceptor (EDA) complex [31]. We excluded the possibility of an EDA charge transfer complex because there was no obvious EDA charge transfer band in the UV–vis spectra (Figure 2). Their indole substrate was more electron-rich in structure. The quantum yield was measured to investigate whether there was a radical chain process or not. The procedure was following a precedent work [32] (see Supporting Information File 1), and the calculated quantum yield was 2.2, which revealed that one photon generates more than one product molecule.

![[1860-5397-20-12-2]](/bjoc/content/figures/1860-5397-20-12-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: UV–vis spectra of substrates; [1a] 0.33 M, [2a] 0.11 M.

Figure 2: UV–vis spectra of substrates; [1a] 0.33 M, [2a] 0.11 M.

Based on preliminary experiments and previous reports [33,34], we propose a plausible mechanism (Scheme 4). Upon light irradiation, Umemoto’s reagent undergoes a homolysis process to generate the trifluoromethyl radical species. The trifluoromethyl radical is trapped by the terminal alkene and forms a relayed radical intermediate 6, which is intercepted by the indole ring realizing an intramolecular cyclization (6-exo-trig). The newly formed radical 7 can be oxidized by 2a or 4 giving a cation 8, which undergoes a deprotonation process and formation of the desired product.

Conclusion

In conclusion, we have developed a visible-light-promoted protocol for the synthesis of dihydropyrido[1,2-a]indolones bearing a trifluoromethyl group at room temperature without additives. Mechanistic investigations support a photochemical process initiated by the homolysis of Umemoto's reagent under visible light irradiation. This method provides rapid access to a diverse range of trifluoromethylated dihydropyrido[1,2-a]indolone derivatives in moderate to good yields.

Experimental

To a vial equipped with a stirring bar, alkene-tethered indole substrate 1a (0.3 mmol), Umemoto's reagent (2b, 0.1 mmol), and DCM (2 mL) were added. Then, the vial was degassed and backfilled with N2 three times to remove oxygen. The reaction mixture was stirred at room temperature for 12 hours under visible light irradiation (450 nm). After completion, the reaction mixture was concentrated, and the crude product was purified by column chromatography to afford the desired dihydropyrido[1,2-a]indolone product.

Funding

We are grateful for the financial support from the Science and Technology Plan of Shenzhen (No. JCYJ20210324133001004 and GXWD20220817131550002), the Natural Science Foundation of Guangdong (No. 2020A1515010564), and Guangdong Basic and Applied Basic Research Foundation (No. 2021A1515220069). W.X. is grateful for the Talent Recruitment Project of Guangdong (No. 2019QN01L753). The project was also supported by State Key Laboratory of Urban Water Resource and Environment (Harbin Institute of Technology) (No.2022TS23), and the Open Research Fund of the School of Chemistry and Chemical Engineering, Henan Normal University.

Data Availability Statement

The data that supports the findings of this study is available from the corresponding author upon reasonable request.

References

-

Xu, Z.; Wang, Q.; Zhu, J. J. Am. Chem. Soc. 2015, 137, 6712–6724. doi:10.1021/jacs.5b03619

Return to citation in text: [1] -

Kim, R.; Ferreira, A. J.; Beaudry, C. M. Angew. Chem., Int. Ed. 2019, 58, 12595–12598. doi:10.1002/anie.201907455

Return to citation in text: [1] [2] -

Pritchett, B. P.; Kikuchi, J.; Numajiri, Y.; Stoltz, B. M. Angew. Chem., Int. Ed. 2016, 55, 13529–13532. doi:10.1002/anie.201608138

Return to citation in text: [1] -

Park, S.-a.; Park, J.-U.; Kim, Y. L.; Kim, J. H. J. Org. Chem. 2021, 86, 17050–17062. doi:10.1021/acs.joc.1c02176

Return to citation in text: [1] -

Shiobara, T.; Nagumo, Y.; Nakajima, R.; Fukuyama, T.; Yokoshima, S.; Usui, T. Biosci., Biotechnol., Biochem. 2021, 85, 92–96. doi:10.1093/bbb/zbaa070

Return to citation in text: [1] -

Benzi, G.; Arrigoni, E.; Dagani, F.; Marzatico, F.; Curti, D.; Manzini, A.; Villa, R. F. Biochem. Pharmacol. 1979, 28, 2703–2708. doi:10.1016/0006-2952(79)90550-1

Return to citation in text: [1] -

Villa, R. F.; Strada, P.; Marzatico, F.; Dagani, F. Eur. Neurol. 1978, 17 (Suppl. 1), 97–112. doi:10.1159/000115013

Return to citation in text: [1] -

Dong, Z.; Zhang, X.-W.; Li, W.; Li, Z.-M.; Wang, W.-Y.; Zhang, Y.; Liu, W.; Liu, W.-B. Org. Lett. 2019, 21, 1082–1086. doi:10.1021/acs.orglett.8b04128

Return to citation in text: [1] -

Pritchett, B. P.; Kikuchi, J.; Numajiri, Y.; Stoltz, B. M. Heterocycles 2017, 95, 1245–1253. doi:10.3987/com-16-s(s)80

Return to citation in text: [1] -

Zhou, B.; Du, J.; Yang, Y.; Li, Y. Chem. – Eur. J. 2014, 20, 12768–12772. doi:10.1002/chem.201403973

Return to citation in text: [1] -

Li, H.; Cheng, P.; Jiang, L.; Yang, J.-L.; Zu, L. Angew. Chem., Int. Ed. 2017, 56, 2754–2757. doi:10.1002/anie.201611830

Return to citation in text: [1] -

Zhong, X.; Qi, S.; Li, Y.; Zhang, J.; Han, F.-S. Tetrahedron 2015, 71, 3734–3740. doi:10.1016/j.tet.2014.07.095

Return to citation in text: [1] -

Biechy, A.; Zard, S. Z. Org. Lett. 2009, 11, 2800–2803. doi:10.1021/ol900996k

Return to citation in text: [1] -

Tucker, J. W.; Narayanam, J. M. R.; Krabbe, S. W.; Stephenson, C. R. J. Org. Lett. 2010, 12, 368–371. doi:10.1021/ol902703k

Return to citation in text: [1] -

Saget, T.; König, B. Chem. – Eur. J. 2020, 26, 7004–7007. doi:10.1002/chem.202001324

Return to citation in text: [1] -

Wei, Y.-L.; Chen, J.-Q.; Sun, B.; Xu, P.-F. Chem. Commun. 2019, 55, 5922–5925. doi:10.1039/c9cc02388g

Return to citation in text: [1] -

Chen, J.-Q.; Tu, X.; Qin, B.; Huang, S.; Zhang, J.; Wu, J. Org. Lett. 2022, 24, 642–647. doi:10.1021/acs.orglett.1c04082

Return to citation in text: [1] -

Yang, R.; Yi, D.; Shen, K.; Fu, Q.; Wei, J.; Lu, J.; Yang, L.; Wang, L.; Wei, S.; Zhang, Z. Org. Lett. 2022, 24, 2014–2019. doi:10.1021/acs.orglett.2c00472

Return to citation in text: [1] -

Liao, J.; Yang, X.; Ouyang, L.; Lai, Y.; Huang, J.; Luo, R. Org. Chem. Front. 2021, 8, 1345–1363. doi:10.1039/d0qo01453b

Return to citation in text: [1] -

Xiao, H.; Zhang, Z.; Fang, Y.; Zhu, L.; Li, C. Chem. Soc. Rev. 2021, 50, 6308–6319. doi:10.1039/d1cs00200g

Return to citation in text: [1] -

Nagib, D. A.; MacMillan, D. W. C. Nature 2011, 480, 224–228. doi:10.1038/nature10647

Return to citation in text: [1] -

Kornfilt, D. J. P.; MacMillan, D. W. C. J. Am. Chem. Soc. 2019, 141, 6853–6858. doi:10.1021/jacs.9b03024

Return to citation in text: [1] -

Yin, D.; Su, D.; Jin, J. Cell Rep. Phys. Sci. 2020, 1, 100141. doi:10.1016/j.xcrp.2020.100141

Return to citation in text: [1] -

Qi, X.-K.; Zhang, H.; Pan, Z.-T.; Liang, R.-B.; Zhu, C.-M.; Li, J.-H.; Tong, Q.-X.; Gao, X.-W.; Wu, L.-Z.; Zhong, J.-J. Chem. Commun. 2019, 55, 10848–10851. doi:10.1039/c9cc04977k

Return to citation in text: [1] -

Xu, J.; Fu, Y.; Luo, D.-F.; Jiang, Y.-Y.; Xiao, B.; Liu, Z.-J.; Gong, T.-J.; Liu, L. J. Am. Chem. Soc. 2011, 133, 15300–15303. doi:10.1021/ja206330m

Return to citation in text: [1] -

Pan, X.; Xia, H.; Wu, J. Org. Chem. Front. 2016, 3, 1163–1185. doi:10.1039/c6qo00153j

Return to citation in text: [1] -

Merino, E.; Nevado, C. Chem. Soc. Rev. 2014, 43, 6598–6608. doi:10.1039/c4cs00025k

Return to citation in text: [1] -

Xia, W. Green Preparation of Pyrido[1,2-a]Indole Compounds. Chin. Patent CN115947726A, April 11, 2023.

Return to citation in text: [1] -

Wang, S.-M.; Wang, X.-Y.; Qin, H.-L.; Zhang, C.-P. Chem. – Eur. J. 2016, 22, 6542–6546. doi:10.1002/chem.201600991

Return to citation in text: [1] -

Wang, X.; Ye, Y.; Zhang, S.; Feng, J.; Xu, Y.; Zhang, Y.; Wang, J. J. Am. Chem. Soc. 2011, 133, 16410–16413. doi:10.1021/ja207775a

Return to citation in text: [1] -

Zhu, M.; Zhou, K.; Zhang, X.; You, S.-L. Org. Lett. 2018, 20, 4379–4383. doi:10.1021/acs.orglett.8b01899

Return to citation in text: [1] -

Cismesia, M. A.; Yoon, T. P. Chem. Sci. 2015, 6, 5426–5434. doi:10.1039/c5sc02185e

Return to citation in text: [1] -

Wang, H.; Xu, Q.; Yu, S. Org. Chem. Front. 2018, 5, 2224–2228. doi:10.1039/c8qo00430g

Return to citation in text: [1] -

Chen, L.; Ma, P.; Yang, B.; Zhao, X.; Huang, X.; Zhang, J. Chem. Commun. 2021, 57, 1030–1033. doi:10.1039/d0cc07502g

Return to citation in text: [1]

| 31. | Zhu, M.; Zhou, K.; Zhang, X.; You, S.-L. Org. Lett. 2018, 20, 4379–4383. doi:10.1021/acs.orglett.8b01899 |

| 29. | Wang, S.-M.; Wang, X.-Y.; Qin, H.-L.; Zhang, C.-P. Chem. – Eur. J. 2016, 22, 6542–6546. doi:10.1002/chem.201600991 |

| 30. | Wang, X.; Ye, Y.; Zhang, S.; Feng, J.; Xu, Y.; Zhang, Y.; Wang, J. J. Am. Chem. Soc. 2011, 133, 16410–16413. doi:10.1021/ja207775a |

| 1. | Xu, Z.; Wang, Q.; Zhu, J. J. Am. Chem. Soc. 2015, 137, 6712–6724. doi:10.1021/jacs.5b03619 |

| 2. | Kim, R.; Ferreira, A. J.; Beaudry, C. M. Angew. Chem., Int. Ed. 2019, 58, 12595–12598. doi:10.1002/anie.201907455 |

| 3. | Pritchett, B. P.; Kikuchi, J.; Numajiri, Y.; Stoltz, B. M. Angew. Chem., Int. Ed. 2016, 55, 13529–13532. doi:10.1002/anie.201608138 |

| 8. | Dong, Z.; Zhang, X.-W.; Li, W.; Li, Z.-M.; Wang, W.-Y.; Zhang, Y.; Liu, W.; Liu, W.-B. Org. Lett. 2019, 21, 1082–1086. doi:10.1021/acs.orglett.8b04128 |

| 9. | Pritchett, B. P.; Kikuchi, J.; Numajiri, Y.; Stoltz, B. M. Heterocycles 2017, 95, 1245–1253. doi:10.3987/com-16-s(s)80 |

| 10. | Zhou, B.; Du, J.; Yang, Y.; Li, Y. Chem. – Eur. J. 2014, 20, 12768–12772. doi:10.1002/chem.201403973 |

| 25. | Xu, J.; Fu, Y.; Luo, D.-F.; Jiang, Y.-Y.; Xiao, B.; Liu, Z.-J.; Gong, T.-J.; Liu, L. J. Am. Chem. Soc. 2011, 133, 15300–15303. doi:10.1021/ja206330m |

| 26. | Pan, X.; Xia, H.; Wu, J. Org. Chem. Front. 2016, 3, 1163–1185. doi:10.1039/c6qo00153j |

| 27. | Merino, E.; Nevado, C. Chem. Soc. Rev. 2014, 43, 6598–6608. doi:10.1039/c4cs00025k |

| 6. | Benzi, G.; Arrigoni, E.; Dagani, F.; Marzatico, F.; Curti, D.; Manzini, A.; Villa, R. F. Biochem. Pharmacol. 1979, 28, 2703–2708. doi:10.1016/0006-2952(79)90550-1 |

| 7. | Villa, R. F.; Strada, P.; Marzatico, F.; Dagani, F. Eur. Neurol. 1978, 17 (Suppl. 1), 97–112. doi:10.1159/000115013 |

| 28. | Xia, W. Green Preparation of Pyrido[1,2-a]Indole Compounds. Chin. Patent CN115947726A, April 11, 2023. |

| 5. | Shiobara, T.; Nagumo, Y.; Nakajima, R.; Fukuyama, T.; Yokoshima, S.; Usui, T. Biosci., Biotechnol., Biochem. 2021, 85, 92–96. doi:10.1093/bbb/zbaa070 |

| 21. | Nagib, D. A.; MacMillan, D. W. C. Nature 2011, 480, 224–228. doi:10.1038/nature10647 |

| 4. | Park, S.-a.; Park, J.-U.; Kim, Y. L.; Kim, J. H. J. Org. Chem. 2021, 86, 17050–17062. doi:10.1021/acs.joc.1c02176 |

| 22. | Kornfilt, D. J. P.; MacMillan, D. W. C. J. Am. Chem. Soc. 2019, 141, 6853–6858. doi:10.1021/jacs.9b03024 |

| 23. | Yin, D.; Su, D.; Jin, J. Cell Rep. Phys. Sci. 2020, 1, 100141. doi:10.1016/j.xcrp.2020.100141 |

| 24. | Qi, X.-K.; Zhang, H.; Pan, Z.-T.; Liang, R.-B.; Zhu, C.-M.; Li, J.-H.; Tong, Q.-X.; Gao, X.-W.; Wu, L.-Z.; Zhong, J.-J. Chem. Commun. 2019, 55, 10848–10851. doi:10.1039/c9cc04977k |

| 14. | Tucker, J. W.; Narayanam, J. M. R.; Krabbe, S. W.; Stephenson, C. R. J. Org. Lett. 2010, 12, 368–371. doi:10.1021/ol902703k |

| 15. | Saget, T.; König, B. Chem. – Eur. J. 2020, 26, 7004–7007. doi:10.1002/chem.202001324 |

| 16. | Wei, Y.-L.; Chen, J.-Q.; Sun, B.; Xu, P.-F. Chem. Commun. 2019, 55, 5922–5925. doi:10.1039/c9cc02388g |

| 17. | Chen, J.-Q.; Tu, X.; Qin, B.; Huang, S.; Zhang, J.; Wu, J. Org. Lett. 2022, 24, 642–647. doi:10.1021/acs.orglett.1c04082 |

| 19. | Liao, J.; Yang, X.; Ouyang, L.; Lai, Y.; Huang, J.; Luo, R. Org. Chem. Front. 2021, 8, 1345–1363. doi:10.1039/d0qo01453b |

| 2. | Kim, R.; Ferreira, A. J.; Beaudry, C. M. Angew. Chem., Int. Ed. 2019, 58, 12595–12598. doi:10.1002/anie.201907455 |

| 13. | Biechy, A.; Zard, S. Z. Org. Lett. 2009, 11, 2800–2803. doi:10.1021/ol900996k |

| 20. | Xiao, H.; Zhang, Z.; Fang, Y.; Zhu, L.; Li, C. Chem. Soc. Rev. 2021, 50, 6308–6319. doi:10.1039/d1cs00200g |

| 12. | Zhong, X.; Qi, S.; Li, Y.; Zhang, J.; Han, F.-S. Tetrahedron 2015, 71, 3734–3740. doi:10.1016/j.tet.2014.07.095 |

| 32. | Cismesia, M. A.; Yoon, T. P. Chem. Sci. 2015, 6, 5426–5434. doi:10.1039/c5sc02185e |

| 11. | Li, H.; Cheng, P.; Jiang, L.; Yang, J.-L.; Zu, L. Angew. Chem., Int. Ed. 2017, 56, 2754–2757. doi:10.1002/anie.201611830 |

| 18. | Yang, R.; Yi, D.; Shen, K.; Fu, Q.; Wei, J.; Lu, J.; Yang, L.; Wang, L.; Wei, S.; Zhang, Z. Org. Lett. 2022, 24, 2014–2019. doi:10.1021/acs.orglett.2c00472 |

| 33. | Wang, H.; Xu, Q.; Yu, S. Org. Chem. Front. 2018, 5, 2224–2228. doi:10.1039/c8qo00430g |

| 34. | Chen, L.; Ma, P.; Yang, B.; Zhao, X.; Huang, X.; Zhang, J. Chem. Commun. 2021, 57, 1030–1033. doi:10.1039/d0cc07502g |

© 2024 Yang et al.; licensee Beilstein-Institut.

This is an open access article licensed under the terms of the Beilstein-Institut Open Access License Agreement (https://www.beilstein-journals.org/bjoc/terms), which is identical to the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0). The reuse of material under this license requires that the author(s), source and license are credited. Third-party material in this article could be subject to other licenses (typically indicated in the credit line), and in this case, users are required to obtain permission from the license holder to reuse the material.