Abstract

The synthesis of indoles and their derivatives, more specifically bis(indolyl)methanes (BIMs), has been an area of great interest in organic chemistry, since these compounds exhibit a range of interesting biological and pharmacological properties. BIMs are naturally found in cruciferous vegetables and have been shown to be effective antifungal, antibacterial, anti-inflammatory, and even anticancer agents. Traditionally, the synthesis of BIMs has been achieved upon the acidic condensation of an aldehyde with indole, utilizing a variety of protic or Lewis acids. However, due to the increased environmental awareness of our society, the focus has shifted towards the development of greener synthetic technologies, like photocatalysis, organocatalysis, the use of nanocatalysts, microwave irradiation, ball milling, continuous flow, and many more. Thus, in this review, we summarize the medicinal properties of BIMs and the developed BIM synthetic protocols, utilizing the reaction between aldehydes with indoles, while focusing on the more environmentally friendly methods developed over the years.

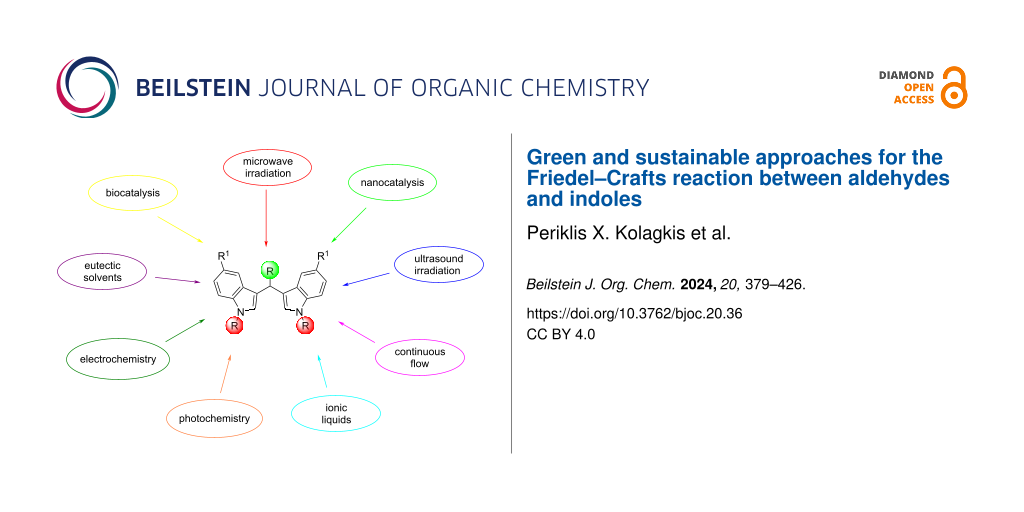

Graphical Abstract

Review

Medicinal properties

In recent years, diindolylmethane (DIM, 1) and its derivatives known as bis(indolyl)methanes (BIMs) have found increased use either as standalone medicine or in combination with other compounds for their bactericidal and fungicidal properties (Scheme 1). BIMs are natural products that are found in certain marine species of sponges and have also been isolated from cruciferous vegetables, as hydrolysis products from the metabolism of glucosinolates [1].

Scheme 1: Examples of BIMs used for their medicinal properties.

Scheme 1: Examples of BIMs used for their medicinal properties.

In 2017, Müller and her research team showcased the ability of BIMs to operate as anti-inflammatory drugs by acting as GPR84 agonists [2]. GPR84 is a protein-coupled receptor found in immune cells, which regulates a number of inflammatory processes, which can lead to inflammatory bowel disease or Alzheimer’s disease. Therefore, GPR84 agonists are used as medicine for the treatment of various inflammatory diseases, but they have been also linked to the reduction of leukemia cells, since the continuous expression of the GPR receptor can aggravate the symptoms of myeloid leukemia. In contrast to most GPR84 agonists which contain long alkyl chains, BIMs are not lipophilic molecules, which allow them to bind to the GPR receptor via an allosteric binding site and modulate GPR84’s rate of expression [2].

One application of BIMs, as referenced above, that is gaining attraction is the treatment of Crohn’s disease, which is an inflammatory bowel disease (IBD). Kang and his research team monitored the production of IL-8 and IL-1β, which are cytokines produced in response to inflammation, and they observed the reduction in the concentration of these cytokines, as well as, increased intestinal permeability and improved expression of tight junction proteins that control the polarity of cells when using DIM in Caco-2 human cells [3].

BIMs have also been linked with the therapy of various cancers with one of their most common applications being the treatment of breast cancer. Studies have shown that breast cancer is tied to the ratio of 16α-hydroxyestrone (16αOHE1) and 2-hydroxyestrone (2OHE1), which are products of the metabolism of the estrogen 17β-estradiol. BIMs can shift the process of estrogen metabolism towards the production of 2OHE1, thus reducing the risk for estrogen-sensitive cancers, especially in combination with tamoxifen, which is an estrogen receptor modulator used in the treatment of breast cancer [4]. BIMs increase the efficacy of the antitumor activity of tamoxifen and reduce the side-effects that it can cause in the more sensitive subgroups of patients. Specifically, when DIM was used in tandem with tamoxifen, the ratio between 2OHE1/16αOHE1 increased up to 229%, as well as the concentration of the sex hormone binding globulin (SHBG) that inhibits the growth of breast cancer cells [4]. DIM has also been found to initiate the expression of tumor suppressing proteins (ATM, p21, p27kip), which control cell growth and protect cells against ionizing radiation, which can cause DNA mutations, decreasing the overall risk of breast cancer [1,5,6].

The cytotoxicity of DIM and BIMs in general extends to other types of cancers as well, such as prostate cancer by being an androgen receptor (AR) agonist in LNCaP prostate cancer cells [6]. DIM controls cell growth rates in AR-negative cells, while also targeting the mitochondria inducing apoptosis, which alleviates some of the symptoms of prostate cancer. The same apoptotic function can be observed in colon and pancreatic cancer, since BIMs (specifically DIM-C-pPhOCH3 (5)) can act as a Nur77 (Nuclear Receptor 4A1) antagonist, which modulates the life cycle of cells [6]. The correlation between lower lung cancer risk and the consumption of cruciferous vegetables has also been showcased, due to the function of BIMs as oxidative stress inhibitors; however, the specific mechanism of action has yet to be determined [1,6].

This capability of BIMs to act as Nur77 antagonists, has resulted in their examination as potential anti-Parkinson’s disease drugs by halting the growth of brain tumor cells and inhibiting the expression of inflammatory genes [7]. Since they can be administered orally, and they display satisfying distribution to the brain and plasma without leading to serious unwanted side effects, they have entered advanced stages of clinical trials as neuroprotective agents, presenting an attractive alternative to traditional anti-inflammatory and anti-Parkinson’s disease drugs [7].

With the increased drug resistance of bacteria to modern medicine, BIMs have emerged as an interesting alternative, due to their antibacterial and antiviral properties. BIMs function as selective antibacterial agents against several virulent Escherichia coli (E. coli) strains, which can cause many gut and urinary tract infections. They act by damaging DNA molecules and inhibiting their replication in bacteria, while also targeting the proteins that are responsible for bacterial cell division, such as FtsZ, which reduces the rate of bacterial growth in a reversible manner. BIMs have also been implemented against methicillin-resistant Staphylococcus aureus (MRSA), which is a drug-resistant bacterium that is usually encountered in health-care related environments [8]. The mechanism of action involves the binding of BIMs to the penicillin-restricting protein PBP2a which inhibits the biosynthesis of the bacterial cell wall, making the treatment feasible without any toxicity to human cells [9,10].

The applications of BIMs have also been extended to agriculture, since there is a need for the development of new greener fungicidal and antiviral agents that can combat the more common plant diseases [11]. One instance of their antiviral property being implemented in drug development involves the treatment of tobacco mosaic virus (TMV), which infects a great number of agricultural plants, causing great harm to production by evolving to resist most of the existing drugs. Thus, BIMs have emerged as a new natural alternative class of antiviral agents, surpassing commonly used drugs such as ribavirin that has been observed to damage the DNA strands of TMV, inhibiting their ability to multiply and cause damage to the plant. At the same time, they also display fungicidal activities against more than fourteen types of common fungi, such as Phytophthora alternaria, based on their DNA damaging properties with the thiourea derivative, showing the highest fungicidal activity [11].

Brønsted or Lewis acid catalysis – conventional synthetic methods

The indole moiety is part of many natural products, agrochemicals, and pharmaceuticals. In medicinal chemistry, indole and its derivatives are considered important compounds, since they exhibit valuable pharmaceutical and biological activities. Among indole derivatives, bis(indolyl)methanes (BIMs) are profoundly interesting, due to their wide range of pharmaceutical properties. The most common approach involves the electrophilic substitution of various aldehydes and ketones by indoles, utilizing either protic or Lewis acids as catalysts. In 2010, Shiri published a review, where the majority of the acidic catalysts that have been employed for the synthesis of these compounds were presented [12]. Since then, various alternative acids have been applied including protic acids, such as silica-bonded S-sulfonic acid [13], polyvinylsulfonic acid (PVSA) [14], kaolin-supported H2SO4 [15], polyvinylpolypyrrolidone-supported triflic acid (PVPP.OTf) [16], ascorbic acid [17], phosphoric acid [18], benzenesulfonic acid [19], chitosan–SO3H (CTSA) [20], phthalimide-N-sulfonic acid (PISA) [21] and SiO2-KHSO4 [22] as well as Lewis acids, such as FeCl3 [23,24], RuCl3·3H2O [25], AgNO3 [26], glycerol and [Fe(III)-(salen)]Cl [27], Fe(DS)3·nH2O [28], Sc(OTf)3 [29], B(C6F5)3 or PhSiCl3 [30] and Cp2TiCl2 [31]. However, most of these reactions face some serious drawbacks, such as the requirement of large quantities of the catalyst due to present moisture or formation of adducts with the substrate, long reaction times, lower yields, and production of large amounts of toxic waste during work-up.

The general mechanisms of protic acid and Lewis acid-catalyzed syntheses of BIMs is shown in Scheme 2. In either case, the first step involves the activation of the carbonyl group by the catalyst. This renders it susceptible to a nucleophilic attack from the indole, leading to the formation of the intermediate product. Subsequently, a second nucleophilic attack occurs by another molecule of indole, yielding the final BIM product. The difference between the two mechanistic pathways is the nature of activation of the carbonyl group. Protic acids induce the protonation of the carbonyl group of the aldehyde or ketone, enhancing its electrophilic character. Whereas, Lewis acid catalysts bind to the heteroatom of the carbonyl group, lowering its LUMO energy, by withdrawing electron-density through a variety of covalent interactions.

Scheme 2: Mechanisms for the synthesis of BIMs using protic or Lewis acids as catalysts.

Scheme 2: Mechanisms for the synthesis of BIMs using protic or Lewis acids as catalysts.

Green and sustainable approaches

Solvent-free processes

Alternative processes, that limit environmental pollution and toxic byproducts, came to the forefront of research for the introduction of novel synthetic pathways in organic chemistry [32-34]. Common organic syntheses require the use of harmful chemicals, such as toxic solvents, hazardous reagents, catalysts and reaction conditions, which contribute to environmental pollution and soil degradation [35,36]. Wanting to enhance the sustainability and viability of these synthetic protocols, organic chemists have been opting towards the use of greener catalysts and solvents in drug development.

Chemists dream to perform reactions under solvent-free conditions, which provide a greener approach towards organic transformations. Nowadays, the use of solvent-free reaction conditions has been introduced as a popular alternative to common organic solvents for many different organic transformations. The lack of an organic solvent can result in improved yields and reaction rates, more facile work-up processes and reduced waste, which are among the goals of green chemistry.

Organocatalysis is the acceleration of chemical reactions with the use of small organic compounds, which do not contain any amounts of enzyme or inorganic elements [37-39]. The benefits of solid acid catalysis render them as an appealing choice, compared to their liquid counterparts, due to their recyclability, ease of handling, and low cost [40]. Carbon-based solid acid catalysts especially are an interesting catalyst class, because they display low corrosiveness, toxicity, and higher catalytic activity, while also being insoluble in most organic solvents. The large amount of strong acidic sites that are on the carbon-based solid acids enhance their catalytic ability, compared to traditional Lewis and protic acids [41-43].

The most common examples in literature for the reaction of the synthesis of BIMs under solvent-free conditions utilize either protic acids, such as camphorsulfonic acid (CSA) [44], diammonium hydrogen phosphate (DAHP) [45], Amberlyst 15 [46], P2O5/MeSO3H [47], p-sulfonic acid calix[4]arene [48], xanthan sulfuric acid (XSA) [49], H5PW10V2O40/pyridino-santa barbara amorphous-15 (SBA-15) [50], TiO2-SO42− [51,52], humic acid [53] or Lewis acids, such as N-bromosuccinimide (NBS) [54], silica chloride [55], Ph3CCl [56], ZnO [57], La(NO3)3·6H2O [58], V(HSO4)3 [59], Cu(ClO4)2·6H2O [60], Fe/Al pillared clay [61], trimethylsilyl chloride (TMSCl) [62], BiCl3-loaded montmorillonite K10 [63-67], ZrO2-MgO [68] or CaO [69]. Silica gel is an intriguing solid support, since it is a low cost, commercially available and non-hazardous support, that can be employed in tandem with various traditional catalysts [70]. Some examples in literature are ZrOCl2·8H2O/SiO2 [71], P2O5/SiO2 [72], LiHSO4/SiO2 [73], (PhCH2PPh3)+Br−/SiO2 [74], H2SO4/SiO2 [75], ZnCl2/SiO2 [76], heteropoly-11-tungsto-1-vanadophosphoric acid, H4[PVV W11O40] (HPV) (20%) supported on natural clay (HPVAC-20) [77], V2O5/SiO2 [78], strongly acidic cation exchange resin (Seralite SRC-120) [79] or HCl/SiO2 [80].

Among all the protocols mentioned above, it is worth mentioning that Hojati et al., in 2013, developed a simple, novel and efficient procedure for the synthesis of BIMs, utilizing 1,3-dibromo-5,5-dimethylhydantoin (DBDMH) as the catalyst (Scheme 3). DBDMH is an N-halo-reagent, which has found widespread applications in industrial processes, due to its economic advantages. DBDMH is a well-known brominating and oxidizing agent that has recently gained special attention as a highly efficient, commercially available and inexpensive homogeneous catalyst [81]. After optimization, it was found that when employing a molar ratio of benzaldehyde, indole and DBDMH of 1:2:0.05, under solvent-free conditions at 50 °C for 50 min, the product was obtained in 90% yield. To emphasize the role of DBDMH, when the reaction was performed without DBDMH, no product was observed. The generality of this protocol was also tested by employing various aromatic aldehydes, which formed the corresponding BIMs in good to excellent yields (70–95%). It is important to mention that electron-withdrawing groups led to enhanced reaction rates and product yields, compared to their electron-donating substituents. However, aliphatic aldehydes and ketones displayed significantly lower reactivities in this methodology, affording low product yields, which limits some applications. The selectivity of this protocol was also investigated (Scheme 4). It was surprisingly observed that aromatic aldehydes produced the corresponding BIM as the major product in the presence of other substrates, rendering this protocol applicable for the chemoselective conversion of aromatic aldehydes to corresponding bis(indolyl)methanes in the presence of aliphatic aldehydes and ketones [81].

Scheme 3: Synthesis of bis(indolyl)methanes using DBDMH.

Scheme 3: Synthesis of bis(indolyl)methanes using DBDMH.

Scheme 4: Competition experiments and synthesis of bis(indolyl)methanes using DBDMH.

Scheme 4: Competition experiments and synthesis of bis(indolyl)methanes using DBDMH.

The proposed reaction mechanism for this protocol is showcased in Scheme 5. At the beginning of the reaction, the bromide ion activates the carbonyl group of the aldehyde, enabling a nucleophilic attack by a molecule of indole, producing the azafulvenium salt IV. The azafulvenium salt is formed, only when utilizing aromatic aldehydes, as opposed to aliphatic aldehydes, which cannot produce a stable conjugated system. Finally, another nucleophilic attack by a second molecule of indole to IV is occurring, forming the desired BIM 12, while simultaneously releasing the catalyst, rendering it available for another catalytic cycle [80].

Scheme 5: Proposed mechanism for formation of BIM of using DBDMH.

Scheme 5: Proposed mechanism for formation of BIM of using DBDMH.

Halogen bonding processes

Recently, halogen bonding (XB) interactions have emerged as an interesting alternative to hydrogen bonding, which constitute an indispensable type of non-covalent interaction utilized in several catalytic approaches [81-88]. In 2008, Bolm introduced the use of perfluoroiodoalkanes as XB catalysts and the field gained widespread attention as an intriguing tool in the catalysis of various organic transformations that were previously considered unfeasible [89].

In 2003, the reaction of indoles with aldehydes and ketones under XB catalysis was reported by Bandgar and his research group utilizing I2 as the catalyst and acetonitrile as the optimum solvent (Scheme 6) [90]. The scope of this methodology was tested with a variety of substituted aliphatic, aromatic or heterocyclic aldehydes and ketones, affording excellent results. Product conversion rates ranged from 81%, for the less reactive ketones, to 100% for activated aromatic aldehydes bearing electron-withdrawing substituents. The reaction mechanism is based on the activation of the carbonyl group by molecular I2, through the formation of a halogen bond, which lowers the LUMO of the carbonyl moiety, increasing its electrophilicity, and thus allowing the addition of the indole group (Scheme 7). The employment of this inexpensive and easily available catalyst under mild reaction conditions, in very short reaction times (<1 min) and with a vast substrate scope, render this protocol practical and economical (Scheme 6) [90].

Scheme 6: Synthesis of bis(indolyl)methanes using I2.

Scheme 6: Synthesis of bis(indolyl)methanes using I2.

Scheme 7: General reaction mechanism upon halogen bonding.

Scheme 7: General reaction mechanism upon halogen bonding.

In 2004, the Ji group developed a simple and convenient protocol for the synthesis of BIMs, using a catalytic amount of I2 under solvent-free conditions at room temperature (Scheme 8) [91]. The differentiating factor of this technique is the employment of solid grind, which avoids the need for a reaction medium, while also utilizing the same amount of I2 (20 mol %) compared to Bandgar’s approach, while achieving product yields of 72–90%. Nonetheless, the slower reaction rates (7–10 min) and the limitation of using only aromatic aldehydes, limited the substrate scope and held back more widespread applications of this methodology [91].

Scheme 8: Synthesis of bis(indolyl)methanes using I2, introduced by Ji.

Scheme 8: Synthesis of bis(indolyl)methanes using I2, introduced by Ji.

In 2014, Liang et al. demonstrated an unexpected Br2-catalyzed synthesis of BIMs from indole and carbonyl compounds in water (Scheme 9) [92]. First, the reaction took place in acetonitrile with a low catalyst loading (2 mol %), proving sufficient to achieve optimal product yields of up to 98% after just 1 minute, when the reaction mixture was heated at 50 °C. The generality of this approach was also excellent with substituted ketones, aldehydes and indoles, all forming the respective BIMs in yields ranging from 65–98% with ketones displaying the lowest reactivity, requiring up to 12 h for reaction completion. Thus, this protocol is associated with low catalyst loading, extremely high efficiency and broad substrate scope and the possibility of use of both organic solvents or water, with the drawback however, of the employment of conventional heating [92].

Scheme 9: Synthesis of bis(indolyl)methanes using Br2 in CH3CN.

Scheme 9: Synthesis of bis(indolyl)methanes using Br2 in CH3CN.

In 2019, Toy et al. proposed an alternative approach for the Friedel–Crafts reaction of aldehydes and ketones with indole [93,94]. Bidentate halogen-bond donors are efficient catalysts, since they can form two halogen bonds with each substrate, instead of just one. Thus, compounds 24, 25 and 26 were screened for their catalytic activity with 26 emerging as the optimum choice (Scheme 10).

Scheme 10: Βidentate halogen-bond donors.

Scheme 10: Βidentate halogen-bond donors.

With catalyst 26 prepared, its use was then studied as a halogen-bond donor in the catalytic synthesis of 28 (Scheme 11) [93,94]. Having identified the optimum reaction conditions, the general applicability was studied by reacting various indoles with a range of aldehydes and ketones to produce a wide range of bis(indolyl)methanes 28 in good to excellent yields (62–93%) [93,94]. Regarding the mechanism of action of this methodology, two halogen bonds are formed between the bidentate halogen-bond donor 26 and the oxygen of the carbonyl group (Scheme 12). This increases the electrophilicity of the carbonyl compound, even more efficiently than the aforementioned catalysts, allowing for the nucleophilic attack of indole as seen in Scheme 12. The following steps are identical to the proposed general catalytic pathway for Lewis acids (Scheme 2). However, this approach did not address the need for conventional heating (70 °C), while also requiring longer reaction times of up to 72 h for sterically hindered substrates [93,94].

Scheme 11: Synthesis of bis(indolyl)methanes using bidentate halogen-bond donor 26.

Scheme 11: Synthesis of bis(indolyl)methanes using bidentate halogen-bond donor 26.

A novel approach for the formation of BIMs was described, in 2020, by Herrera and co-workers, who utilized iodoalkynes as a simple halogen bond-based organocatalyst (Scheme 13) [95]. Haloalkynes have the ability to form strong, directional and selective halogen bonds, which makes them a good choice for the synthesis of BIMs [95]. Several substituted carbonyl compounds, as well as indoles, were screened in the optimum reaction conditions as seen in Scheme 13 to prove the generality of this protocol. Non-activated aldehydes (not bearing an electron-withdrawing group) and heteroaromatic aldehydes showed a lower reactivity and 30 mol % of catalyst 29 was required to achieve high yields (81–95%). In contrast, activated or aliphatic aldehydes afforded excellent yields (85–98%) in a more facile manner. The reaction mechanism is similar to other halogen-bond donor catalysts (Scheme 14). While the broad substrate scope is a crucial benefit of this approach, the use of a toxic solvent and the slow reaction rates were some of the drawbacks that would need to be addressed.

Scheme 13: Synthesis of bis(indolyl)methanes using iodoalkyne as catalyst.

Scheme 13: Synthesis of bis(indolyl)methanes using iodoalkyne as catalyst.

The most recent application of halogen bonding in the synthesis of BIMs was introduced in 2023 by Galathri et al., who employed an N-heterocyclic iod(az)olium salt as the monodentate catalyst [96]. This approach utilized water as the reaction solvent and employed a low catalyst loading of just 0.5 mol %, while providing satisfying yields (60–96%) in just 1 hour. The employment of a green aqueous medium, the mild reaction conditions and the relatively broad substrate scope are some of the benefits that render this protocol more efficient than previous halogen-bonding methodologies [96].

Nanocatalysis

Nanocatalysis has emerged over the last decades as a sustainable and green field of organic catalysis that offers unparalleled opportunities for chemical transformations that were previously deemed unfeasible. The use of nanoparticles, compounds with a cross section of less than 100 nm, exhibit various benefits, such as tailoring the scaffold of the catalyst, the recyclability of the nanocompounds, as well as the elevated catalytic activity offered. These benefits stem from their high surface area, that provides more active sites for the reactants to absorb into and collide with one another. With the new avenues offered by the advent of nanocatalysis, it did not take long for its application in the Friedel–Crafts arylation of indoles with aldehydes, since the development of more resource-efficient catalytic pathways for the synthesis of BIMs had received great interest from the scientific world [97,98].

In 2008, the first application of nanocatalysis for the synthesis of BIMs was introduced by Shailaja and her research group, utilizing a ceria/vinylpyridine nanocomposite as the catalyst [99]. After repeated studies and experiments on the reaction between indole (11) and benzaldehyde (31), methanol emerged as the optimum solvent with the isolated product yield approaching 98%, after 1 hour, when 69 mg of the nanocomposite were added to the reaction mixture [99]. The recovery of the nanocatalyst was feasible by simple filtration and it was found that its catalytic efficiency would not diminish even after 3 cycles [99]. Several substituted indoles, aldehydes and ketones reacted in good yields (74–98%), with ketones requiring longer reaction rates of 3 hours, due to their lower reactivity. The electron-donating or withdrawing effects of the substituents of the benzene ring of the carbonyl groups did not affect this protocol, rendering its generality superior to many traditional approaches. However, the high catalyst loading raised some concerns over the environmental impact of this methodology and left room for improvements for newer approaches [99].

In 2009, Rahimizadeh et al. proposed the use of the nanometal oxide TiO2, which was already reported as an effective nanocatalyst for the promotion of various organic transformations [100]. TiO2 nanoparticles are non-toxic, inexpensive and reusable compounds that are synthesized through a sol–gel method. This method involves gradually adding titanium tetra-n-butoxide to a solution of deionized water in ethanol and calcinating it to form the desired nanocompounds. 10 mol % of the nano-TiO2 heated at 80 °C, provided an optimum yield of 95% for the reaction of indole with benzaldehyde, under solvent-free conditions after just 3 minutes [100]. With the optimum reaction conditions in hand, both aromatic and aliphatic aldehydes reached promising conversion rates of formed BIMs of 77–95%. Sterically hindered substituted aldehydes exhibited longer reaction times, while substituted indoles also showed no issue, reaching yields of 85% after 20 minutes of stirring. The nano-TiO2 catalyst was easily recovered by centrifugation, where it could be reused up to four times, without any reductions in product conversion. What holds back the efficiency of this nanocatalytic protocol is the application of conventional heating, as well as the use of a metal oxide at a significant quantity, which can be a water and soil pollutant [100].

In 2013, Ramshini and his research group employed H5PW10V2O40/pyridino-Fe3O4 (HPA/TPI-Fe3O4) as a magnetic nanocatalyst, based on the extensive reported literature about the catalytic properties of Fe3O4 nanoparticles (Scheme 15) [101,102]. This organic–inorganic hybrid material was synthesized by the immobilization of the dodecatungstovanadophosphoric acid (HPA) on TPI-Fe3O4 with N-[3-(triethoxysilyl)propyl]isonicotinamide (TPI), acting as the linker for the heterogeneous catalyst, while preventing leeching, since the HPA is anchored on the inert and porous Fe3O4. After obtaining the magnetic nanocompound, different reaction conditions were tested, where it was surprisingly discovered that in the absence of any solvent, higher product yields (96%) were attained with a catalyst loading of just 0.06 mol % in just 25 minutes [101,102]. Furthermore, the nanocatalyst could be easily retrieved by applying a magnetic field on the reaction mixture, where it could be reused for at least 8 cycles, before there was a noticeable drop in effectiveness. This boosted the sustainability of this protocol significantly, with the drawback of needing conventional heating at 100 °C for the composite material to activate the reacting carbonyl group by lowering its LUMO orbital, rendering it a more potent electrophile so that the nucleophilic indole can attack it (Scheme 16) [101,102].

Scheme 15: Optimized reaction conditions used by Ramshini.

Scheme 15: Optimized reaction conditions used by Ramshini.

Scheme 16: Activation of the carbonyl group by HPA/TPI-Fe3O4.

Scheme 16: Activation of the carbonyl group by HPA/TPI-Fe3O4.

Both aliphatic and aromatic aldehydes faced no problems, reaching yields ranging from 65–98% of formed products with substituted indoles also showing exceptional reactivity, albeit no ketones were reported forming the respective BIMs, limiting the substrate scope. Therefore, the solvent-free conditions of the reaction, the low catalyst loading and the ability of its retrieval rendered this methodology a green alternative to traditional protocols, however, the costly requirement of conventional heating hinders industrial applications.

At the same time that Ramshini published her approach, Jahanshahi also introduced nano n-propylsulfonated γ-Fe2O3 (NPS-γ-Fe2O3), which constitutes a magnetically recyclable heterogeneous catalyst that works in the exact same manner as HPA/TPI-Fe3O4 [103]. Some small differences between the two methods were the ability of ketones to form the respective BIMs, when NPS-γ-Fe2O3 was employed in contrast to HPA/TPI-Fe3O4, while also using a milder heating at 80 °C. However, Ramshini’s protocol had shorter reaction times of 25 minutes instead of 1 to 5 hours and also the catalyst loading was significantly decreased at 0.06 mol %, instead of the 0.5 mol % needed for NPS-γ-Fe2O3. Other than these differences the mechanism of action, the received yields, the absence of solvent and the recoverability of the nanocompound were identical between these two studies [103].

In the same year, another solvent-free approach was introduced by Chen et al. that utilized sulfated zirconia nanoparticles to conduct the Friedel–Crafts reaction between indoles and aldehydes [104]. In an effort to synthesize the sulfated zirconia nanocompounds, a new two-step precipitation method was developed. The first step involved the employment of zirconium oxychloride and its precipitation with ammonium hydroxide. In the second step, the formed zirconium hydroxide undergoes a sulfate impregnation, utilizing sulfuric acid in the presence of polyvinylpyrrolidone (PVP) as the surfactant, to prevent particle agglomeration, leading to the formation of the desired sulfated zirconia nanoparticles after a last calcination step. After obtaining the nanocompound, its catalytic activity was evaluated for several organic transformations, including the synthesis of BIMs. Diindolylphenylmethane (DIM) was obtained in a yield of 97%, when 30 mol % of the nanocatalyst was added after 24 hours of reaction time in solvent-free and room temperature conditions. In these optimized conditions, several aromatic aldehydes and indoles formed the respective BIMs in excellent yields (84–95%), without any noteworthy differences between the various carbonyl substrates. Indoles, substituted at the 2’ position, were much more reactive, leading to isolated product yields of around 95% just after 6 h. This protocol addressed the issue of conventional heating that the previous methodologies employed, while also maintaining the solvent-free character of the reaction, with the disadvantage of longer reaction times, a high amount of nanocatalyst utilized and a more restricted substrate scope [104].

Karthikeyan and his research team synthesized Ag-Pt nanoparticles suspended in silicate, with the sol–gel method analyzed before, to test their effectiveness in the synthesis of BIMs, since they had already been applied as nanocatalysts in various oxidation and hydrogenation reactions [105]. NanoAg-Pt doped silicate constitutes an efficient and recyclable catalyst that can be reused without a notable loss in catalytic activity (Scheme 17). Wanting to avoid the use of conventional heating, Karthikeyan and his co-workers turned to microwave irradiation (320 W), which resulted in rapid reaction rates with isolated product yield reaching 92% in just 1 minute, while also maintaining solvent-free conditions. Different amounts of silicate were also examined with 50 mg of the nanocompound, providing the most satisfying results, while in the absence of the nanocatalyst, no product was formed, highlighting its importance in this protocol. A wide range of aromatic aldehydes were employed without encountering any difficulties in reactivity and obtaining conversion rates ranging from 78–95% in a maximum of two minutes for substrates containing more than two electron-donating substituents on the benzene ring. However, no ketones or aliphatic substrates managed to exhibit sufficient reactivity. The nanoAg-Pt silicate could be easily recovered by a simple filtration with methanol, allowing it to be reused for several catalytic cycles, before it was rendered inactive. Thus, Karthikeyan’s approach implemented faster reaction rates, while avoiding conventional heating with the application of microwave-assisted irradiation in solvent-free conditions with the drawback of limiting the generality of his methodology [105].

Scheme 17: Synthesis of BIMs in the presence of nanoAg-Pt/SiO2-doped silicate.

Scheme 17: Synthesis of BIMs in the presence of nanoAg-Pt/SiO2-doped silicate.

In 2014, Chabukswar and his research group explored the activity of cadmium sulfide (CdS) nanotubes as heterogeneous nanocatalysts for the electrophilic condensation between aldehydes and indoles [106]. The nanorods were obtained with a solvothermal technique, where thiourea and cadmium nitrate were mixed in ethylenediamine for 10 minutes and subsequently heated at 200 °C for 12 hours. After being centrifuged, washed with water and grinded in a mortar, they were ready to be tested in the model reaction of benzaldehyde with indole. The optimum product yield was reached with a catalyst amount of 5 mol %, as a further increase did not show any further enhancement, in reflux temperature (65 °C) conditions, with methanol emerging as the superior medium over other polar solvents. A wide range of aromatic aldehydes containing both electron-withdrawing and electron-donating substituents were employed with the former, improving the conversion rate of the formed BIM product to 90–95%, compared to the 85–87% of the latter after 15 minutes of reflux. The nanotube catalyst was retrieved with a simple filtration, utilizing ethyl acetate and was reused for four synthetic cycles, before there was a decrease in catalytic activity, which was attributed to deactivation of active sites of the nanorod. Once again, this method provided short reaction times with an efficiently recovered catalyst with the handicap of the necessity of conventional heating and an unfavorable solvent [106].

At the same time, Khalafi-Nezhad et al. developed unique ʟ-proline-modified magnetic nanoparticles (LPMNPs) that combine organocatalytic protocols with nanocatalysis, which enhances the surface-to-volume ratio of the catalyst opening up new possibilities [107]. The ʟ-proline molecules were anchored on a Fe3O4@SiO2 nanoparticle, which was already known for its facile recyclability, with the silica layer preventing the Fe3O4 from aggregation. The LPMNPs managed to provide impressive yields, while employing an amount of 2.5 mol % in water, with the help of conventional heating at 50 °C, which facilitated the organocatalytic process that required 1 to 1.5 hours to reach completion. Various aromatic aldehydes reached conversion rates of 80–94% with electron-donating substituents, enhancing the reactivity of the reagents, compared to their electron-withdrawing counterparts that afforded lower isolated product yields. Subsequently, the catalyst reusability was also evaluated, where it was observed that even after 8 cycles without any treatment the morphology of the nanotubes remained the same, without leaching of considerable amounts of ʟ-proline into the reaction mixture. The mechanism of action involves the activation of the aldehyde by the grafted ʟ-proline on the surface of the magnetic nanoparticle via iminium formation as seen in Scheme 18, allowing the indole to attack the formed double bond and initiate the Michael-type mechanism [107].

Scheme 18: Mechanism of action proposed by Khalafi-Nezhad et al.

Scheme 18: Mechanism of action proposed by Khalafi-Nezhad et al.

In an effort to replace the widespread use of nano-iron oxides, which present issues, such as aggregation, and requires large amounts of capping agents to combat, Pratihar and his research group offered the alternative of iron oxalates for the nanocatalysis of BIMs, which, after thermal decomposition form Fe(ox)-Fe3O4 oxides [108]. Metal oxalates in general are more stable nanoparticles than their oxide counterparts, while retaining their magnetic and catalytic properties preventing the aforementioned drawbacks. Compared to Ramshini’s protocol for the synthesis of BIMs however, a higher catalytic loading was required (5 mol %) and water was added as the solvent, with both approaches also requiring conventional heating of the resulting mixture at 100 °C. Reaction rates were also slightly lower, requiring 1 hour for aromatic aldehydes containing electron-withdrawing groups and upwards of 4 hours for electron-donating substituents compared to the 25 minute Ramshini’s protocol with the additional holdback of the lack of reactivity of aliphatic aldehydes and substituted indoles. The recyclability of the nanocompound was satisfactory, since it could be reused for at least 5 times, before a slight drop in conversion rates was observed. However, due to the choice of water as the solvent, insoluble product clamps were formed, which led to a more complex recovery of the catalyst as firstly the water needed to be removed by decantation and next acetone was added so that the BIMs were dissolved and the nanoparticles could be retrieved with the use of a tiny magnet. All in all, while the iron oxalates combatted some disadvantages of the use of iron oxides, the catalytic approach presented had handicaps that held back its broader applications [108].

In 2016, Sobhani et al. expanded on the use of iron oxide as an effective magnetic nanoparticle by creating a Cu–isatin Schiff base complex supported on nano-iron oxide compounds for the synthesis of BIMs [109,110]. These compounds were synthesized through the reaction between the amino-functionalized modified magnetic nanoparticles (MNPs), which were obtained by a sol–gel methodology, and isatin, producing isatin Schiff base-γ-Fe2O3, which was subsequently dissolved in methanol with CuCl2, yielding the desired Cu–isatin Schiff base complex. The optimum reaction conditions between benzaldehyde and indole were obtained at a nanocatalyst loading of only 0.25 mol % after 2 hours of heating at 80 °C with water as the medium. In the absence of the Cu–isatin Schiff base complex, only trace amounts of product were observed, which further underlined the importance of its presence in the reaction mixture. The biggest benefit, however, of this approach is its generality, since all types of substituted carbonyl compounds and indoles, provided conversion rates ranging from 80–98%, with aromatic aldehydes bearing electron-donating substituents requiring the longest reaction times that approached 5 hours. The recoverability and reusability of the nanocomplex were similar to that of other nano-iron oxide compounds, since it could be reapplied in the reaction mixture for up to 8 cycles before signs of deactivation were observed. The mechanism of action was also identical with the Cu–isatin Schiff base complex activation of the carbonyl group, facilitating the electrophilic addition of indole (Scheme 19). The main drawback of the method, however, is the necessity of conventional heating and solvent compared to other methodologies [109,110].

Scheme 19: Activation of the carbonyl group by the Cu–isatin Schiff base complex.

Scheme 19: Activation of the carbonyl group by the Cu–isatin Schiff base complex.

At the same time, Yavari and his research group also studied the use of hexamine, in place of NPS-γ-Fe2O3, immobilized on Fe3O4 and coated with SiO2 [111]. This protocol, while employing the identical optimum reaction conditions with Ramshini’s method, managed to reduce the reaction times to 10 minutes with 10 mg of the catalyst and could also facilitate the reaction of ketones. This improved upon the previously known nano-iron oxide methodologies without sacrificing their already satisfying product yields, the recyclability of the nanocatalyst or their environmentally benign aspects, such as the solvent-free conditions without, however, addressing the need for conventional heating that still presented an issue [111].

The same year, Jain and her research team opted out of the use of silica as the support for their nanocompounds, instead picking graphene oxide (GO), due to its unique morphology and high chemical stability (Scheme 20) [112]. The graphene oxide was decorated with CuBr nanoparticles, which had already shown great catalytic potential, forming the GO–CuBr complex that was utilized for the synthesis of BIMs. The researchers were delighted to discover that 0.05 mol % of the nanocompound were sufficient to promote the reaction between benzaldehyde and indole at 50 °C affording the product in 92% yield after 1 hour. In the absence of the catalyst, a trace amount of product was formed, while reducing the amount further resulted in a lower conversion. Next, the generality of the method was explored by employing several aliphatic and aromatic aldehydes, as well as substituted indoles, in various positions of the benzene ring. N-Substituted indoles displayed the lowest reactivity, providing yields around 75%, while aldehydes had no difficulties reaching conversion rates of 87–92%. However, no ketones were reported in the substrate scope. The nanocomplex was retrieved following reaction completion by centrifugation and could be reapplied for up to 6 cycles, before a noticeable drop in catalytic activity occurred. Thus, a solvent-free approach was reported with the lowest amount of nanocatalyst applied, compared to previous methodologies. However, conventional heating was still needed and not all carbonyl compounds managed to form the respective BIMs in the present conditions [112].

Scheme 20: Optimum reaction conditions published by Jain.

Scheme 20: Optimum reaction conditions published by Jain.

The introduction of graphene oxide would be expanded upon and enhanced by Masram and his research group a year later [113], who implemented La2O3 nanoparticles in place of the CuBr MNPs that Jain used, in solvent-free conditions. The La2O3/GO complex provided much faster reaction rates (25–60 min) and improved product conversion rates (88–97%) without the necessity for heating that held back the GO–CuBr complex. These benefits came, however, at the cost of a higher catalyst loading of 5 mol % and worse reusability, since after just 2 reaction cycles the product yields dropped by 10%, providing an interesting alternative to the employment of GO–CuBr without overshadowing its applications [113].

Shirini et al. utilized the polymer poly(4-vinylpyridine) (P4VPy) for the immobilization of nanoparticles in lieu of silica, due to the strong affinity of the pyridyl group towards metals and its ability to undergo hydrogen bonding with polar species [114]. The nanoparticle of choice was CuO, which had already displayed several varied catalytic applications, so the P4VPy–CuO nanoparticles were synthesized through an ultrasound irradiation protocol and tested in the reaction between p-chlorobenzaldehyde and indole. An amount of 20 mg of the P4VPy–CuO nanocompound at 80 °C proved sufficient, under solvent-free conditions, at providing an optimum isolated product yield of 92% after 5 minutes. Various indole derivatives and carbonyl compounds were explored, where it was found that ketones were less reactive, due to their lower electrophilicity and required upwards of 2 hours to reach completion, while aldehydes containing electron-withdrawing substituents required just 4 minutes. The nanopolymer was promptly filtered and reused for up to 3 cycles with satisfying activity. BiVO4 nanoparticles were introduced by Lati and his research group for the synthesis of BIMs applying the same catalyst-free conditions as P4VPy–CuO, while employing 30 mg of the nano-BiVO4 compound with the added benefit of slightly improved product yields, ranging from 70 to 98% after 10–80 minutes [115,116]. The need for conventional heating, the reaction rates, the mechanism of action and the recyclability of the nanocatalyst used were comparable in both approaches with the only differences being the choice and amount of the nanocomplex added and certain product conversion rates. Inspired by this technique, in 2019 Boroujeni et al. immobilized carbon nanotubes on sulfonated polyacrylamide creating polymer/carbon nanotube composites, which could also be employed in the synthesis of BIMs [115,116]. This methodology used a catalyst loading of 5 mol % under reflux conditions (85 °C) in acetonitrile for 30–40 minutes with product yields ranging from 90 to 97%. Despite the drawback of the use of a solvent this protocol succeeds in incorporating aliphatic carbonyl compounds in the substrate scope and an effective nanocatalyst that can be retrieved and reused for 8 cycles without a drop in catalytic activity [114-116].

In 2018, Bankar inspired by the use of ʟ-proline-modified magnetic nanoparticles reported by Khalafi-Nezhad et al., synthesized nano-Fe3O4@ʟ-cysteine for the green synthesis of BIMs, employing microwave irradiation to avoid long reaction times [117]. A mixture of the reagents and 100 mg of nano-Fe3O4@ʟ-cysteine per 1 equiv of the carbonyl compound, was exposed to 350 W of microwave irradiation, at an internal temperature of 80 °C, at solvent-free conditions, for 3 to 7 minutes, providing optimum yields for aromatic aldehydes and ketones. Isolated product yields approached 83–93%, even after 10 reaction cycles with the nano-Fe3O4@ʟ-cysteine particles being magnetically recoverable in a facile manner. The reaction could also be realized with conventional heating at 80 °C, however, the reaction rates were more than 20 times lower, and ketones displayed unappealing conversion rates. The mechanism of action follows the one suggested by Khalafi-Nezhad et al. for LPMNPs, where activation of the carbonyl compound by the nanocatalyst initiates the indole attack (Scheme 21) [117].

Scheme 21: Organocatalytic protocol utilizing nanoparticles introduced by Bankar.

Scheme 21: Organocatalytic protocol utilizing nanoparticles introduced by Bankar.

A year later, Chen and his research team created Lewis acid-surfactant-SiO2-combined (LASSC) nanocatalysts by combining Lewis acid surfactants with SiO2, thus, eliminating the drawback of poor recyclability exhibited by the surfactants [118]. Various different Lewis acid surfactants were screened for their catalytic activity in the synthesis of BIMs with the combination of AlCl3∙6H2O as the Lewis acid, sodium dodecyl sulfate (SDS) as the surfactant and silica as the carrier providing the most promising results. Solid grinding was also employed, removing the need for a solvent and accelerating the reaction rate to 20 minutes and product yields to 99% without the need for conventional heating. Replacement of the Lewis acid or the silica greatly diminished the conversion rates of BIMs, while replacing SDS with different surfactants had no effect on the reaction profile. Even though a large amount of 0.5 g of the LASSC nanocatalyst was employed, it displayed impressive stability, since it could be retrieved and reused upwards of 11 times without any structural changes, making up for the high catalyst loading. This protocol was applied to reactions of various aromatic aldehydes and indoles with excellent yields, where it was observed, as in most other cases, that substrates with electron-withdrawing groups achieved better yields in shorter times, compared to their electron-donating counterparts. The mechanism of action involves the Al atom, which is located at the center of the regular octahedron (Scheme 22), forming hydrogen bonds with the carbonyl group, facilitating the electrophilic reaction with indole by lowering the LUMO orbital of the C=O bond. Thus, an innovative approach on nanocatalysis was introduced, incorporating solid grinding in catalyst-free conditions with the challenge of a high catalyst loading and lack of aliphatic aldehydes or ketones being utilized as substrates for the formation of their respective BIMs [118].

Scheme 22: Activation of the carbonyl group by the AlCl3·6H2O-SDS-SiO2 complex.

Scheme 22: Activation of the carbonyl group by the AlCl3·6H2O-SDS-SiO2 complex.

In 2021, this methodology was reiterated by Wu et al., who conducted the reaction in the exact same conditions, utilizing the ball milling technique, instead of solid grinding, which slightly reduced reaction times and the catalyst loading necessary from 500 mg to 300 mg [119]. The substrate scope was also expanded upon, including aliphatic substrates and enhancing the possible LASSC nanocatalyst applications further [120,121].

In the following years between 2020 and 2022, focus was still on the development of nanocatalysts based on iron oxides applied for the synthesis of BIMs, since they were easy to make, cheap and easily recoverable, while also displaying high catalytic activities. Specifically, three protocols utilizing Fe3O4 nanoparticles were introduced in this time frame, with the first being published in 2020 by Shafiei and her research group [120,121]. They synthesized 3-amino-5-mercapto-1,2,4-triazole (AMTA)-functionalized Fe3O4 nanoparticles coated on silica, based on Khalafi-Nezhad’s approach. Optimum catalytic activity was attained when adding 10 mg of the nanocomplex to the reaction mixture, in solvent-free conditions at 80 °C and after a time period of 1.5–8 hours, depending on the substrate used, with both aromatic and aliphatic aldehydes reaching conversion rates of 98% (Scheme 23). In 2021, a methodology making use of poly(ethylene glycol)-supported Fe3O4 nanoparticles was reported by Mardani et al., who managed to remove the need for conventional heating. 10 mg of Fe3O4@PEG-SO3H complex were added in ethanol for a time period of 5 to 10 minutes, yielding 88–98% of isolated product with only aromatic aldehydes showing a meaningful reactivity (Scheme 23) [122]. In 2022, Boroujeni et al. employed a Cu(II) complex coated in Fe3O4@SiO2 nanoparticles which worked as an efficient nanocatalyst for the synthesis of BIMs in a catalytic amount of 30 mg at 80 °C [123,124]. A mixture of water and ethanol (1:1) was discovered to be the optimum solvent with reaction times starting from 11 to 30 minutes, while approaching yields ranging from 92% for aliphatic aldehydes to 97% for aromatic aldehydes (Scheme 23). All applications shared the same mechanism of action based on the activation of the carbonyl bond as shown in Scheme 22 with each method presenting new environmental benefits compared to the traditional acid-catalyzed approaches [120-124].

Scheme 23: Optimal reaction conditions for the aforementioned nano-Fe3O4 based catalysts.

Scheme 23: Optimal reaction conditions for the aforementioned nano-Fe3O4 based catalysts.

In 2020, Ozturk and his research group developed a novel sulfonic graphitic carbon nitride (g-C3N4-SO3H) as a nanosheet ionic liquid for the one-pot synthesis of BIMs [125]. Graphitic carbon nitride is a non-metal and non-toxic chemically stable nanostructure, which is obtained through a facile pyrolysis process that has not seen wide applications in nanocatalysis despite its numerous benefits. Therefore, Ozturk made it usable by coupling it with an ionic liquid, creating g-C3N4-SO3H nanoparticles, which displayed high catalytic activity for the Friedel–Crafts arylation of indoles with aldehydes. The optimum product yields were achieved with 15 mg of g-C3N4-SO3H (IL) added in a mixture of ethanol and water (3:1) at 70 °C after a period of 1 hour. Several aliphatic and aromatic aldehydes completed the reaction successfully with conversion rates of 82–98%, with the electronic effect of the substituents having no effect on reaction times or yields. The nanostructure could be recovered by simple filtration, where it could be reemployed upwards of 5 times before a drop in catalytic activity was noticed. The low reactivity exhibited by ketones, the use of ethanol as a solvent and the need for conventional heating were some issues that held back the universality of this protocol [125].

More recently, in 2022, Kaur et al. utilized CdS nanostructures which possess good Lewis acidity for the heterogeneous catalysis of various organic transformations including the synthesis of BIMs as shown by Chabukswar and his research group [126]. Kaur et al. synthesized various CdS nanostructures with differences in their morphology and screened them for their catalytic potential, while avoiding the use of surfactants, which were too difficult to remove from the reaction mixture (Scheme 24). CdS_3a which was a porous and hollow open interconnected network of CdS nanoparticles emerged as the optimal catalyst structure. This structure was found to promote the reaction between indole and p-chlorobenzaldehyde in solvent-free conditions after 5 hours at a catalyst loading of 3 mol %. Several aromatic aldehydes were also tested in these conditions with substrates bearing electron-withdrawing groups, displaying much higher conversion rates of 60–99% than electron-donating groups, whose reactivity was low, with conversion rates ranging from 30 to 45%. The CdS_3a nanoparticles were easily retrievable through the application of centrifugation and could be reused three times, before an observable change in their catalytic activity occurred. While the mild reaction conditions and the lack of solvent or conventional heating aided the environmental impact of this approach, the limited substrate scope of just aromatic aldehydes bearing electron-withdrawing groups hindered its application and generality considerably leaving room for further improvements for the employment of CdS nanoparticles. However, the employment of CdS nanoparticles is not considered sustainable, despite their recyclability, due to their toxicity and carcinogenic properties (Scheme 24) [126].

Scheme 24: Nanocatalytic protocol proposed by Kaur et al.

Scheme 24: Nanocatalytic protocol proposed by Kaur et al.

Microwaves

With the increased interest in the development of greener catalytic protocols targeting the decrease in chemical waste, microwave irradiation (MW) has emerged as a popular heating technique for the synthesis of BIMs and many other organic compounds, presenting appealing pharmacological properties. Under microwave irradiation, chemical reactions are accelerated by the absorption of microwaves by polar organic molecules, which renders reactions that are not catalyzed with conventional heating possible. This was made apparent in Karthikeyan’s and Bankar’s nanocatalysis protocols for the synthesis of BIMs, who incorporated MW, which led to an impressive surge in reaction rates [105-117]. The prominent benefits of the microwave approach over traditional protocols, are low energy consumption, accelerated reaction rates, avoiding the use of toxic organic solvents and ease of regulation of the reaction parameters [127,128].

The first solvent-free methodology based on the microwave approach for the Friedel–Crafts reaction of aldehydes with indoles was presented by Yuan and his research team in 2004 [129]. They tested a range of Lewis acids for their catalytic activity in the electrophilic substitution with indole. It was found that FeCl3 at 20 mol % catalyst loading provided the best yield (93%) for the reaction of p-chlorobenzaldehyde with indole, while also having a reaction time of just 2 minutes (Scheme 25). The best option for the irradiation power was found to be 235 W, since when it was weaker, the yield of the product was lower than 93% and when it exceeded 235 W, the acid was deactivated, and no product was formed. After the reaction conditions were optimized, many substituted aldehydes were tested, and it was discovered that aromatic substrates gave the products in satisfying yields (72–93%). However, aliphatic carbonyl compounds were not able to form the corresponding BIMs with the use of this protocol [129]. In the next years, there were more microwave approaches published with the following one emerging in 2008 by Zahran et al., who used glacial acetic acid (1 mL), instead of FeCl3, and an irradiation power of 750 W (Scheme 26) [128]. The reaction mixture was subjected to successive 30 second irradiation periods to prevent deactivation of the catalyst. The reaction reached completion in 1 to 60 minutes depending on the substrate, with aliphatic aldehydes once again displaying low yields and reaction rates. The reactions were also carried out in acetic acid with conventional heating, where it was observed that compared to the microwave approach, the isolated product yields were lower and the reaction rates more than 10 times slower. Another benefit of this methodology is the facile work-up of the formed products for their isolation, however, the high catalyst loading of the glacial acetic acid and low tolerance for aliphatic substrates limited some of its applications [128].

Scheme 25: Microwave approach introduced by Yuan.

Scheme 25: Microwave approach introduced by Yuan.

Scheme 26: Microwave approach introduced by Zahran et al.

Scheme 26: Microwave approach introduced by Zahran et al.

A year later, in 2009, Bindu and her research group introduced Selectfluor (37), which is an electrophilic fluorinating agent that can act as a Lewis acid for the synthesis of BIMs with the use of microwave irradiation (600 W) (Scheme 27) [130]. This protocol utilized 5 mol % of catalyst loading, which is an advantage over previous methodologies and reaction times of 5 to 10 minutes to reach optimal yields of isolated products (85–96%). However, just like previously the drawback presented is the low reactivity of aliphatic products, which present a challenge for microwave-based catalysis [130].

Scheme 27: Microwave irradiation protocol introduced by Bindu.

Scheme 27: Microwave irradiation protocol introduced by Bindu.

In 2014 Gu, and his research group reported an interesting application of SiO2, which acts as a solid support under microwave irradiation and is slightly acidic (pH 6–7), rendering the use of another Lewis acid or solvent redundant (Scheme 28) [131]. SiO2 was discovered to be the best solid support over other similar compounds like Al2O3, possibly due to its larger surface area and low gravity, while also being relatively inexpensive and commercially available only facilitated its choice as the optimum choice. The reaction mixture containing SiO2 (1.0 g) was irradiated for 10 minutes under 250 W to achieve the best possible yield, since any time exceeding that of 10 minutes lowered the product formation, possibly due to its carbonization. All products from aromatic aldehydes were isolated in satisfying yields ranging from 85–98% with the existence of electron-withdrawing substituents on the benzene ring of the aldehyde leading to higher yields, in contrast to electron-donating substituents. Aliphatic aldehydes once again did not lead to the formation of the desired BIM, however, many BIMs containing isoxazole groups were synthesized with this method which have displayed many interesting medicinal applications [131].

Scheme 28: Silica-supported microwave irradiation protocol.

Scheme 28: Silica-supported microwave irradiation protocol.

A year later, in 2015, Nongkhlaw and his research lab incorporated phase-transfer catalysts into their microwave irradiation protocol to utilize water as the reaction solvent, in order to avoid the possibility of combustion or charring of the reaction mixture [132]. Several different phase-transfer catalysts were tested for their efficacy with benzyltriethylammonium chloride (TEBA, 38), emerging as the optimum choice, while only needing a catalyst loading of 0.25 mol % to achieve product yields of around 95% at a low irradiation power of 120 W. Reaction times varied depending on the substrates used from 2 to 4 minutes and in contrast to previous protocols, aliphatic aldehydes can also react giving high product yields of 85–98%. Another benefit of the TEBA/water catalytic system is its reusability, since it can be reused for three catalytic cycles before there is a significant decrease in the yield of the product observed. The proposed mechanism of action of TEBA (as seen in Scheme 29) involves its chloride anions, transferring the reactants towards the aqueous phase so they can react leading to the formation of the corresponding BIM using a simple Michael-type mechanism. This protocol can also be used for the synthesis of tetraindolylmethanes, justifying the drawback of the use of a solvent compared to the rest of the microwave-assisted methodologies [132].

Scheme 29: Proposed mechanism for formation of BIM by Nongkhlaw.

Scheme 29: Proposed mechanism for formation of BIM by Nongkhlaw.

Following Nongkhlaw’s study, in 2017, Rao and his research group introduced a new microwave-assisted catalytic protocol, utilizing water once again as the solvent and succinic acid as the catalyst in place of TEBA (Scheme 30) [133]. Succinic acid provided the most promising results, compared to other naturally derived organic acids, and the fact that it is a safe, commercially available, non-toxic and biodegradable compound made it an appealing choice. The reaction conditions were optimized for the reaction between indole and benzaldehyde, where it was found that the corresponding BIM was formed with a yield of 96%. This result was obtained when the reaction mixture was irradiated under 300 W for 20 minutes with 10 mol % of succinic acid. After optimizing the reaction conditions, the focus shifted towards the substrate efficiency of the succinic acid protocol. Both aliphatic and aromatic aldehydes afforded the respective products in excellent yields (78–96%) although, ketones displayed low reactivity and did not provide any product. Control experiments were also conducted, and it was observed that no product was formed in the absence of succinic acid. At the same time, the product yield only reached 50% after 24 hours without microwave irradiation, highlighting the necessity of both for the synthesis of BIMs. The reaction mechanism is a simple acid-catalyzed Friedel–Crafts bisarylation. The aldehyde is activated by the succinic acid and subsequently undergoes an electrophilic substitution at C-3 and after the loss of water and the addition of the second molecule of indole the corresponding BIM is formed [133].

Scheme 30: Microwave-assisted synthesis of BIMs catalyzed by succinic acid.

Scheme 30: Microwave-assisted synthesis of BIMs catalyzed by succinic acid.

The most recent study for the arylation of aldehydes with indoles under microwave irradiation was published in 2018 by Nguyen et al., who made use of porous metal oxides derived from Cu-Al layered double hydroxide as heterogeneous catalysts [134]. Four different mixed metal oxides (MMOs) and layered double hydroxides (LDHs) were tested with different analogies of Cu-Mg-Al to find the one that displayed the highest catalytic activity with MMO-4 (0:3:1) prevailing over the rest. MMO-4 is the result of the calcination of LDH-4, which leads to the increase of its surface area and explains the difference in catalytic activity despite having the same analogies of Cu-Mg-Al. After finding the most suitable catalyst, the reaction conditions were optimized. It was found that the highest product yields were achieved, when 10 mg of catalyst was used for 10–20 minutes of microwave irradiation at 160 °C and in solvent-free conditions. Both substituted aromatic aldehydes and indoles provided the expected product in the range of 71–98% yield with benzaldehydes substituted at the para-position with a halogen, displaying the lowest yields, while indoles and benzaldehydes substituted with strong electron-withdrawing substituents had the highest reactivity. MMO-4 also has the benefit of reusability, since it can be easily retrieved from the reaction mixture and it only starts to lose catalytic activity after the fifth cycle, which makes it a promising choice for the application on industrial processes. The proposed mechanism of action as shown in Scheme 31 begins with MMO-4, increasing the electrophilicity of the carbonyl group by lowering its LUMO orbital and next the reaction follows the steps of a simple Michael addition, like TEBA. The drawback of this method is the use of a metal catalyst, however, the low catalyst loading, the recyclability of the catalyst and the absence of solvent renders this protocol more environmentally benign than other traditional alternatives that utilize metal catalysts [134].

Scheme 31: Proposed mechanism of action of MMO-4.

Scheme 31: Proposed mechanism of action of MMO-4.

Ultrasound

Ultrasound irradiation is an unconventional energy source, compared to conventional heating, that is receiving increased interest for its applications in organic catalysis as a more sustainable and byproduct-free alternative synthetic protocol. Sonochemistry is based on the local depression of liquids, which causes a drop in their vapor pressure, leading to the generation of cavitation bubbles. These cavitation bubbles absorb the energy provided by the generated sound wave, causing them to grow in size until they collapse, resulting in the generation of shock waves or radicals that can initiate various chemical processes. Ultrasound irradiation enhances product selectivity, while having a low energy consumption overall and it activates new mechanical pathways for known reactions [135].

The first practical synthesis of BIMs under ultrasound irradiation was introduced by Li and his research group in 2005, who utilized aminosulfonic acid under 250 W to carry out the arylation of aldehydes with indoles [136]. Aminosulfonic acid proved to be the best choice for higher product conversion rates between a group of other Lewis and Brønsted acids, so the optimum reaction conditions were studied next. It was discovered that targeted BIMs were synthesized more efficiently, when a mixture of ethanol and water (3:2) was used as the solvent, with the amount of catalyst needed being 150 mol %. Reactions reached completion after 15–360 minutes, depending on the reagents. A wide selection of aromatic and aliphatic aldehydes, substituted indoles and ketones provided encouraging yields of isolated products, ranging from 45% to 95%. Αromatic aldehydes bearing electron-donating substituents underwent the reaction at a much faster rate than other substrates with the exception of nitrobenzaldehydes, which displayed poor solubility thus, emphasizing the generality of this protocol. The drawbacks of a high, non-recyclable catalyst loading and the lack of reactivity of aliphatic ketones under these reaction conditions were issues that could be addressed by other methodologies in the future [136].

In 2006, Muhammadpoor-Baltork et al., wanting to eliminate some of the issues of the previous approach, made use of Bi(OTf)3 as a relatively less toxic and environmentally friendly catalyst, under ultrasound irradiation (400 W) (Scheme 32) [137]. The amount of catalyst required to reach optimum product yields was significantly lower (5 mol %) with acetonitrile emerging as the most effective reaction medium with ultrasound irradiation having much faster reaction rates, compared to conventional heating techniques, and a wider substrate scope. All aromatic, aliphatic or heterocyclic aldehydes afforded excellent yields of 80–99% in just 5–10 minutes of reaction. Ketones also afforded the corresponding BIMs in good yields, although they required longer reaction times (60–75 min), managing to provide a solution to the drawbacks presented earlier. Nevertheless, the amount and choice of the solvent used (10 mL) and the acidic catalyst had more room for improvement, regarding their environmental impact [137].

Scheme 32: Catalytic approach introduced by Muhammadpoor-Baltork et al.

Scheme 32: Catalytic approach introduced by Muhammadpoor-Baltork et al.

The next one to incorporate sonochemistry in the Friedel–Crafts bisarylation of aldehydes with indoles in 2008 was Su and his research group, who utilized an ultrasonic bath at a frequency of 40 kHz (250 W) (Scheme 33) [138]. Meldrum’s acid derivative 39 was used as the catalyst (2 mol %) to facilitate the arylation, while water proved to be the best solvent, leading the reaction to competition in 4 to 8 hours, depending on the reagents used. Excellent yields of 63–95% were achieved for both aromatic and aliphatic aldehydes, however, ketones did not show the same reactivity, as even after longer exposure periods under ultrasonic irradiation, only traces of the desired products were detected. Lastly, control experiments revealed that in the absence of either the catalyst or the irradiation the product yields were significantly lower, indicating that they both play a critical role in the catalysis of the reactions. This protocol offered a green solvent (water) for the reaction, while only needing a relatively low amount of catalyst, however, the low reactivity of ketone substrates and the use of an acid for the catalysis of the reaction even at lower yields presented a challenge to be overcome [138].

Scheme 33: Reaction conditions used by Xiao-Ming.

Scheme 33: Reaction conditions used by Xiao-Ming.

Li et al. attempted to build upon the employment of aqueous media, leading them to present the use of dodecylbenzenesulfonic acid (ABS) as a proton acid catalyst in water for the formation of BIMs [139]. An amount of 0.5 mol % of ABS was enough to achieve a yield of 97% of p-Cl-BIM within 10 minutes, improving both the reaction rates and product yields compared to the reported reaction catalyzed by Meldrum’s acid. Absence of ultrasound irradiation resulted in a significant increase in the reaction times and a slight drop in product yield. This indicated the importance of sonochemistry for the acceleration of the reaction rates, while changes in the irradiation frequency had no observable effect on the reaction. Several aromatic aldehydes were subsequently tested both with and without ultrasound, where the divide in reaction rates was made even more evident for substrates containing electron-donating substituents that required more than 3 hours to form the corresponding BIM. The drawback of the ABS approach is the quite limited substrate scope, since the formation of aliphatic BIMs or the use of ketones as substrates was not achieved, hindering many potential applications in medicinal chemistry [139].

In 2013, Nikpassand et al. replaced the use of an acid with a Schiff base complex, which is a green catalyst capable of promoting the synthesis of BIMs from aldehydes and indoles [140]. 50 mg of the complex were sufficient for the reaction to reach completion after just 5 minutes with ethanol proving to be the optimum solvent. The reaction mixture was irradiated in a water bath at 60 °C by ultrasound (45 kHz or 280 W) with isolated product yields ranging around 85–95%. Except from the shorter reaction times, this method also offered better sustainability, since the Schiff’s base could be recovered from the reaction mixture in a facile way through a simple filtration with ethanol and without losing any catalytic activity in the first five cycles. Notwithstanding the benefits over the previous protocol, the use of ethanol instead of water, the need for heating and the limited substrate scope of just aromatic aldehydes, held back the environmental impact of this proposal [140].

Two years later, Saeednia and her research team replaced both the catalyst and the solvent of the reaction with a eutectic solvent comprised of ZnCl2 and urea in an analogy of 1:3.5, which worked more efficiently than several traditional acids for the synthesis of BIMs (Scheme 34) [141]. The optimum reaction parameters involved the use of 1 equivalent of the eutectic solvent at 60 °C, for a period of 10 minutes with yields of isolated BIMs reaching 92% and being much greater than the respective thermal protocol, where the maximum yield approached 65%. A wide selection of aromatic aldehydes was tested, and it was observed that electron-withdrawing substituents accelerated the reaction rates compared to electron-donating substituents. Ketones and substituted indoles also reacted without a significant change in yield, however, no aliphatic aldehyde substrates managed to form the respective BIMs. Some other benefits that the incorporation of the eutectic solvent provides is the ability of catalyst recycling for up to three cycles, before a noticeable drop in yield is noticed and the ease in product isolation, since a simple filtration with water and a recrystallization from ethanol separates the product from the solvent [141].

Scheme 34: Ultrasonic irradiation-based protocol published by Saeednia.

Scheme 34: Ultrasonic irradiation-based protocol published by Saeednia.

More recently, in 2022, Thopate and his research group employed pyruvic acid (41) as a metal-free biodegradable catalyst, which under ultrasound irradiation in water can prove to be a superior alternative method for the synthesis of BIMs (Scheme 35) [142]. This constituted the first report of the catalytic potential of pyruvic acid, so extensive research to discover the optimum reaction conditions was conducted. 10 mol % of pyruvic acid proved sufficient at 50 °C, while higher catalyst loadings and temperatures did not affect the conversion of the product formed. In the absence of irradiation and at room temperature, reaction rates were significantly lowered, while lack of pyruvic acid completely halted the synthesis of BIMs. With the optimized conditions in hand, various aromatic aldehydes were tested for their reactivity with little to no variation in product yields (85–95%) and reaction times (15–20 min) being observed, depending on the substituents on the benzene ring. Substituted indoles also displayed similar results, while ketones failed to provide substantial product conversions. Thus, an approach utilizing both an environmentally benign catalyst and solvent was developed with the holdback of the need for heating at 50 °C and the inability to synthesize any aliphatic BIMs [142].

Scheme 35: Pyruvic acid-mediated synthesis of BIMs proposed by Thopate.

Scheme 35: Pyruvic acid-mediated synthesis of BIMs proposed by Thopate.

Ionic liquids

The development of greener, more economical and environmentally benign processes is one of the main challenges of modern chemistry. An environmentally safe alternative that has gained traction in recent years, in lieu of toxic organic solvents, are ionic liquids [143,144]. Ionic liquids enhance reaction rates and product yields, while also being easily recovered and optimized by exchanging the properties of the anions and cations. The properties mentioned render ionic liquids as excellent catalyst choice for greener catalytic processes in organic synthesis [145,146].

In 2003, Yadav and his research group described a facile and efficient procedure for the preparation of BIMs in 1-butyl-3-methylimidazolium tetrafluoroborate ([bmim]BF4) or 1-butyl-3-methylimidazolium hexafluorophosphate ([bmim]PF6) ionic liquid (Scheme 36) [147]. The mild reaction conditions of this methodology enabled a variety of substituted aromatic aldehydes to afford their corresponding products in excellent yields. In general, the substituent present on the benzene ring of the aldehyde affects the reaction profile, with electron-withdrawing groups affording superior yields (85–94%) after just 10 minutes. The only exception was the nitro group, which required prolonged reaction times to achieve similar results. Furthermore, the reaction of indole with ketones was also achieved with satisfying yields [147]. The catalytic role of the ionic liquid was made evident, when conducting the reaction in its absence, where no product formation was observed. The benefits offered by the [bmim]BF4 and [bmim]PF6 ionic liquids are their high recyclability and facile product extraction, which limits the waste produced by this approach [147].

Scheme 36: Synthesis of BIMs using [bmim]BF4 or [bmim]PF6 ionic liquids.

Scheme 36: Synthesis of BIMs using [bmim]BF4 or [bmim]PF6 ionic liquids.

The same year, Lohs’ group developed an efficient protocol for the electrophilic substitution reaction of indoles with various aldehydes catalyzed by Lewis acids in octylmethylimidazolium hexafluorophosphate ([omim][PF6–]) ionic liquid (Scheme 37) [148]. With the optimum reaction conditions in hand, various aldehydes were tested, with both aliphatic and aromatic aldehydes giving the products 28 in high yields (73–96%) [148].

Scheme 37: Synthesis of BIMs utilizing In(OTf)3 in octylmethylimidazolium hexafluorophosphate as ionic liquid.

Scheme 37: Synthesis of BIMs utilizing In(OTf)3 in octylmethylimidazolium hexafluorophosphate as ionic liquid.

It is well known that FeIII salts catalyze many organic transformations, including oxidation of sulfides, Michael reactions, thia-Fries rearrangements and synthesis of diphenylmethane and 1,6-anhydroglucopyranoses. In 2004, the same group introduced an alternative protocol for the synthesis of BIMs, utilizing FeIII in an ionic liquid as the catalyst (Scheme 38) [149]. It is worth noting that the FeCl3·6H2O/[omim]PF6 catalytic system can be recovered and reused with a simple extraction, at least four times without significant loss in activity. Subsequently, various aldehydes were studied under optimized conditions. In all cases, both aromatic and aliphatic aldehydes reacted smoothly with indoles in high yields (78–98%). Moreover, this method is highly chemoselective, as ketones do not participate in the reaction, which proved to be useful in the separation of aldehydes from ketones through the synthesis of bis(indolyl)methanes [149].

Scheme 38: FeCl3·6H2O-catalyzed synthesis of BIMs with use of ionic liquid.

Scheme 38: FeCl3·6H2O-catalyzed synthesis of BIMs with use of ionic liquid.