Abstract

The effect of depositing FeO nanoparticles with a diameter of 10 nm onto the surface of MgB2 thin films on the critical current density was studied in comparison with the case of uncoated MgB2 thin films. We calculated the superconducting critical current densities (Jc) from the magnetization hysteresis (M–H) curves for both sets of samples and found that the Jc value of FeO-coated films is higher at all fields and temperatures than the Jc value for uncoated films, and that it decreases to ~105 A/cm2 at B = 1 T and T = 20 K and remains approximately constant at higher fields up to 7 T.

Introduction

After the discovery of superconductivity in MgB2 [1], this material became attractive for researchers all over the world not only because of its special physical properties but also due to its possible technical applications. This material, with a hexagonal crystal structure and a critical temperature of Tc = 39 K, raised a lot of questions about its transport properties. This strong type-II superconductor has a fairly high critical current density in zero magnetic field, i.e., up to Jc ~ 1.6 × 107 A/cm2 at 15 K [2]. This superconducting parameter makes it a very attractive candidate to replace Nb in various superconducting devices, namely for devices operating at temperatures around 20 K, which are attainable in low-cost cryocoolers. However, the dramatic fall of the critical current in an external magnetic field at temperatures around 20 K limits the possible use of magnesium diboride in engineering applications. Therefore, for a wide-scale technical application of MgB2 it is necessary to solve the problem of the enhancement of its critical current in an external magnetic field.

Results and Discussion

There have been many attempts to solve the above-mentioned problem relating to the decay of the critical current in an external magnetic field. Various research teams have tried to increase the critical current density either by doping MgB2 with various substances (carbon [3], aluminium [4], etc.) or by adding nanoparticles of SiC [5], nanodiamonds [6], etc. As we can conclude from these works, the highest value of the critical current in the zero magnetic field is Jc ~ 106 A/cm2 in a temperature range of 5–25 K, and the highest value at a magnetic field of 8 T is Jc ~ 104 A/cm2 at 4.2 K; no significant increase was reported at higher temperatures and higher fields (Jc ~ 102 A/cm2 at 6 T and 20 K).

In our previous study of the resistive transitions of MgB2 films in an external magnetic field [7], we showed that the rapid decrease of the activation energy of the flux flow for MgB2 in the field region B > 1 T represents a dramatic loss of the current-carrying abilities of this superconductor due to the weakening of the flux-line pinning with increasing magnetic field. The problem to be solved is how to increase the pinning force and to overcome the dramatic dropdown of the critical current in a strong external magnetic field for this superconducting material. For this purpose, a novel method of depositing self-assembled nanoparticles with various distance parameters onto the sample surface was used in our experiments. Our suggestion for tackling this problem was the following: The presence of magnetic nanoscale pinning centers should increase the pinning force due to the magnetic interaction between nanoparticles and vortices, which was calculated in [8]. Based on these calculations one can choose the appropriate diameter of nanoparticles to efficiently increase the magnetic pinning force. One more argument is that ferromagnets strongly suppress superconductivity, and even a small ferromagnetic region can be a strong pin, as was confirmed in experiments with NbTi wires containing nanometer-sized arrays of Ni pins [9]. We placed the ferromagnetic nanoparticles on the surface, instead of in the volume of the films, in order to avoid the strong suppression of the critical temperature of the film. The proximity effect of nanoparticles has a very small effect on the superconducting properties of our MgB2 thin films, reducing their critical temperature by about 1 K. Taking into account these ideas, we studied the effect of nanoparticles deposited onto the surface of MgB2 thin films on the transport properties of these films.

In order to carry out the proposed research, MgB2 films with a thickness of about 600 nm were prepared on the MgO (100) substrates by using a “two-step” synthesis technology similar to the method described in detail in [10]. The X-ray diffraction patterns show the high quality of the prepared polycrystalline MgB2 films, with the parameters of the MgB2 unit cell being a = 3.08 Å, c = 3.53 Å, which are close to the values for a and c of bulk MgB2, as was investigated in detail in our previous work [11].

Thin MgB2 film samples with dimensions ~4.5 × 5.0 mm2 were used in our work. These samples were obtained by cutting a MgB2 film into two similar pieces: One 4.38 × 5.18 mm2 piece was covered with FeO nanoparticles, which had a diameter of 10 nm, by spin coating at 4000 rpm centrifuge, and the other 4.28 × 4.84 mm2 piece remained uncoated for comparison measurements. The Ginzburg–Landau coherence length of our films was obtained from the slope of the upper critical magnetic field measurements, Bc2(T), close to the critical temperature, resulting in ξGL(0) = 3.0 nm [12].

We measured the magnetization hysteresis (M–H) curves of the FeO-covered and uncovered MgB2 films at H perpendicular to the sample surface at various temperatures from 4.2 K to 20 K. All the magnetization measurements were performed in a superconducting quantum interference device (SQUID) magnetometer (Quantum Design, Magnetic Property Measurement System, MPMS-XL). The SQUID magnetometer has a sensitivity of l0−8 emu and operates in the temperature range 1.9–400 K, with magnetic fields up to 7 T; it has a high field uniformity of 0.01% over 4 cm. Pd was used as a standard for the SQUID magnetometer.

The magnetic measurements were first done for the substrate by itself and the magnetic moments of the substrate were subtracted (after mass normalization) from the magnetic signal of each of the MgB2 thin-film samples. The measured (M–H) curves are shown in Figure 1 and Figure 2.

![[2190-4286-2-89-1]](/bjnano/content/figures/2190-4286-2-89-1.png?scale=2.4&max-width=1024&background=FFFFFF)

Figure 1: Magnetization hysteresis (M–H) curves for the pure MgB2 sample at various temperatures: 4.2 K, 10 K, 15 K, and 20 K.

Figure 1: Magnetization hysteresis (M–H) curves for the pure MgB2 sample at various temperatures: 4.2 K, 10 K...

![[2190-4286-2-89-2]](/bjnano/content/figures/2190-4286-2-89-2.png?scale=2.4&max-width=1024&background=FFFFFF)

Figure 2: Magnetization hysteresis (M–H) curves for the FeO-covered MgB2 sample at various temperatures: 4.2 K, 10 K, 15 K, and 20 K.

Figure 2: Magnetization hysteresis (M–H) curves for the FeO-covered MgB2 sample at various temperatures: 4.2 ...

At first glance, the values of the magnetic moment of the sample covered with FeO nanoparticles are considerably higher than the respective values of the uncovered sample; as is especially clear to see in the field range 0–4 T at 4.2 K.

The curves in Figure 3 to Figure 6 show the values of the critical current density Jc as a function of the applied magnetic field at various temperatures, which are estimated from the M–H curves by using the Bean’s critical-state model formula: Jc = 30 ΔM/r, where ΔM is the height of the M–H curve. We choose the effective sample size r as the radius of the circle whose total area is the same as the sample size, i.e., by using πr12 = 4.28 × 4.84 mm2 for the pure sample and πr22 = 4.38 × 5.18 mm2 for the FeO-covered sample. Thus, we used the effective sample sizes r1 = 2.57 mm and r2 = 2.69 mm, which are orders of magnitude larger than the grain size.

![[2190-4286-2-89-3]](/bjnano/content/figures/2190-4286-2-89-3.png?scale=2.4&max-width=1024&background=FFFFFF)

Figure 3: Magnetic-field dependence of the critical current density Jc for the pure (red triangles) and for the FeO-covered (blue squares) MgB2 samples at 4.2 K.

Figure 3: Magnetic-field dependence of the critical current density Jc for the pure (red triangles) and for t...

![[2190-4286-2-89-4]](/bjnano/content/figures/2190-4286-2-89-4.png?scale=2.4&max-width=1024&background=FFFFFF)

Figure 4: Magnetic-field dependence of the critical current density Jc for the pure (red triangles) and for the FeO-covered (blue squares) MgB2 samples at 10 K.

Figure 4: Magnetic-field dependence of the critical current density Jc for the pure (red triangles) and for t...

![[2190-4286-2-89-5]](/bjnano/content/figures/2190-4286-2-89-5.png?scale=2.4&max-width=1024&background=FFFFFF)

Figure 5: Magnetic-field dependence of the critical current density Jc for the pure (red triangles) and for the FeO-covered (blue squares) MgB2 samples at 15 K.

Figure 5: Magnetic-field dependence of the critical current density Jc for the pure (red triangles) and for t...

![[2190-4286-2-89-6]](/bjnano/content/figures/2190-4286-2-89-6.png?scale=2.4&max-width=1024&background=FFFFFF)

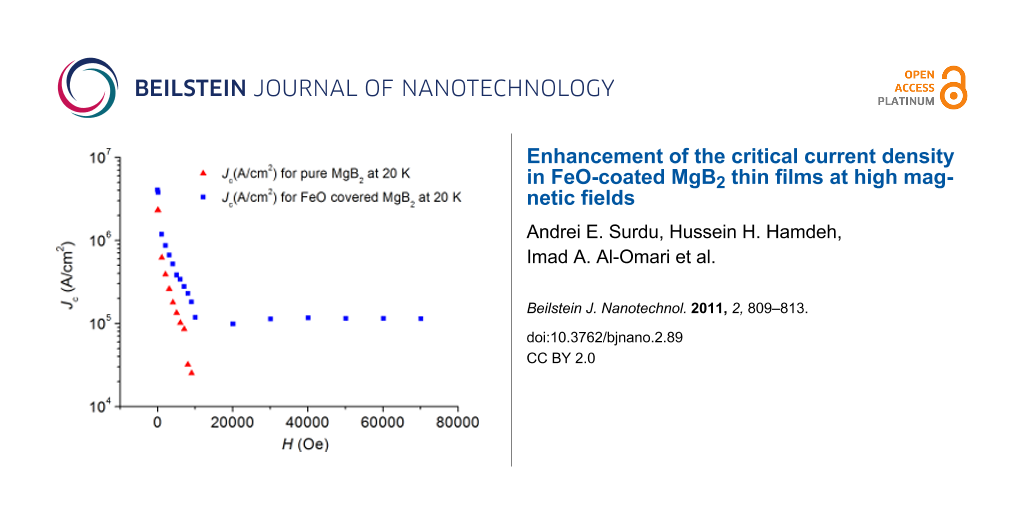

Figure 6: Magnetic-field dependence of the critical current density Jc for the pure (red triangles) and for the FeO-covered (blue squares) MgB2 samples at 20 K.

Figure 6: Magnetic-field dependence of the critical current density Jc for the pure (red triangles) and for t...

Figure 3 shows that after FeO coating of the sample the values of Jc at T = 4.2 K increased by one order of magnitude in the field range of 1–4 T; the critical current density for the coated sample decreased gradually with an increase of the applied magnetic field and was equal to 105 A/cm2 at B = 7 T, whereas for the uncoated sample Jc dropped down abruptly and became negligibly small at fields B > 3 T.

In the temperature range 10–20 K (Figure 4, Figure 5 and Figure 6) we observe the same behavior of Jc for both samples: Jc was approximately equal to 105 A/cm2 for the coated sample in the field range of 3–7 T, whereas the Jc value of the pure sample dropped down and was negligibly small at fields B > 1 T.

We believe that the observed effect of an increase of Jc after the coating of the sample with FeO nanoparticles is related to an increase of the pinning force due to the magnetic interaction between nanoparticles and vortices. The obtained value of Jc ~ 105 A/cm2 at T = 20 K and B = 7 T (see Figure 6) is higher than the Jc value of 104 A/cm2 at T = 5 K and B = 7 T, and the Jc value of 102 A/cm2 at T = 10 K and B = 7 T reported recently in [13], which was obtained by doping of MgB2 with C60.

Conclusion

In summary, we obtained the Jc dependence on the applied magnetic field from the M–H curves for pure MgB2 thin films and from films covered with FeO (10 nm nanoparticles). We report a significant increase of the critical current density for the FeO-coated MgB2 thin films obtained by the two-step method. After deposition of the nanoparticles the critical temperature of the films decreased by 0.7 K, whereas the Jc value rose to ~105 A/cm2 at T = 20 K and B = 7 T. This value of the critical current density is higher than any previously published in the literature, to our knowledge. As the main result of the present work, we have elaborated a simple method for the enhancement of the flux pinning and the supercurrent-carrying ability of magnesium diboride thin films.

Acknowledgements

The authors would like to thank E. Scutelnic, L. Roller and I. Belotserkovski for technical assistance and Dr. Thomas Koch for providing us with FeO nanoparticles, which were used in this work. The work was supported by the following grants: Alexander-von-Humboldt Stiftung Institutspartnerschaft Nr. Fokoop-DEU/1009845, and the project 11.836.05.01A of the RM State Program on Nanotechnologies.

References

-

Nagamatsu, J.; Nakagawa, N.; Muranaka, T.; Zenitani, Y.; Akimitsu, J. Nature 2001, 410, 63. doi:10.1038/35065039

Return to citation in text: [1] -

Kim, H.-J.; Kang, W. N.; Choi, E.-M.; Kim, M.-S.; Kim, K. H. P.; Lee, S.-I. Phys. Rev. Lett. 2001, 87, 087002. doi:10.1103/PhysRevLett.87.087002

Return to citation in text: [1] -

Chen, J.; Ferrando, V.; Orgiani, P.; Pogrebnyakov, A. V.; Wilke, R. H. T.; Betts, J. B.; Mielke, C. H.; Redwing, J. M.; Xi, X. X.; Li, Q. Phys. Rev. B 2006, 74, 174511. doi:10.1103/PhysRevB.74.174511

Return to citation in text: [1] -

Zheng, D. N.; Xiang, J. Y.; Lang, P. L.; Li, J. Q.; Che, G. C.; Zhao, Z. W.; Wen, H. H.; Tian, H. Y.; Ni, Y. M.; Zhao, Z. X. Physica C 2004, 408–410, 136. doi:10.1016/j.physc.2004.02.072

Return to citation in text: [1] -

Dou, S. X.; Shcherbakova, O.; Yeoh, W. K.; Kim, J. H.; Soltanian, S.; Wang, X. L.; Senatore, C.; Flukiger, R.; Dhalle, M.; Husnjak, O.; Babic, E. Phys. Rev. Lett. 2007, 98, 097002. doi:10.1103/PhysRevLett.98.097002

Return to citation in text: [1] -

Gupta, A.; Narlikar, A. V. Supercond. Sci. Technol. 2009, 22, 125029. doi:10.1088/0953-2048/22/12/125029

Return to citation in text: [1] -

Sidorenko, A.; Zdravkov, V.; Ryazanov, V.; Horn, S.; Klimm, S.; Tidecks, R.; Wixforth, A.; Koch, T.; Schimmel, T. Philos. Mag. 2005, 85, 1783. doi:10.1080/14786430500036678

Return to citation in text: [1] -

Snezhko, A.; Prozorov, T.; Prozorov, R. Phys. Rev. B 2005, 71, 024527. doi:10.1103/PhysRevB.71.024527

Return to citation in text: [1] -

Rizzo, N. D.; Wang, J. Q.; Prober, D. E.; Motowidlo, L. R.; Zeitlin, B. A. Appl. Phys. Lett. 1996, 69, 2286. doi:10.1063/1.117535

Return to citation in text: [1] -

Bu, S. D.; Kim, D. M.; Choi, J. H.; Giencke, J.; Hellstrom, E. E.; Larbalestier, D. C.; Patnaik, S.; Cooley, L.; Eom, C. B.; Lettieri, J.; Schlom, D. G.; Tian, W.; Pan, X. Q. Appl. Phys. Lett. 2002, 81, 1851. doi:10.1063/1.1504490

Return to citation in text: [1] -

Zdravkov, V.; Sidorenko, A.; Rossolenko, A.; Ryazanov, V.; Bdikin, I.; Krömer, O.; Nold, E.; Koch, T.; Schimmel, T. J. Phys.: Conf. Ser. 2007, 61, 606. doi:10.1088/1742-6596/61/1/122

Return to citation in text: [1] -

Sidorenko, A. S.; Tagirov, L. R.; Rossolenko, A. N.; Sidorov, N. S.; Zdravkov, V. I.; Ryazanov, V. V.; Klemm, M.; Horn, S.; Tidecks, R. JETP Lett. 2002, 76, 17. doi:10.1134/1.1507218

Return to citation in text: [1] -

Miu, L.; Aldica, G.; Badica, P.; Ivan, I.; Miu, D.; Jakob, G. Supercond. Sci. Technol. 2010, 23, 095002. doi:10.1088/0953-2048/23/9/095002

Return to citation in text: [1]

| 1. | Nagamatsu, J.; Nakagawa, N.; Muranaka, T.; Zenitani, Y.; Akimitsu, J. Nature 2001, 410, 63. doi:10.1038/35065039 |

| 5. | Dou, S. X.; Shcherbakova, O.; Yeoh, W. K.; Kim, J. H.; Soltanian, S.; Wang, X. L.; Senatore, C.; Flukiger, R.; Dhalle, M.; Husnjak, O.; Babic, E. Phys. Rev. Lett. 2007, 98, 097002. doi:10.1103/PhysRevLett.98.097002 |

| 4. | Zheng, D. N.; Xiang, J. Y.; Lang, P. L.; Li, J. Q.; Che, G. C.; Zhao, Z. W.; Wen, H. H.; Tian, H. Y.; Ni, Y. M.; Zhao, Z. X. Physica C 2004, 408–410, 136. doi:10.1016/j.physc.2004.02.072 |

| 3. | Chen, J.; Ferrando, V.; Orgiani, P.; Pogrebnyakov, A. V.; Wilke, R. H. T.; Betts, J. B.; Mielke, C. H.; Redwing, J. M.; Xi, X. X.; Li, Q. Phys. Rev. B 2006, 74, 174511. doi:10.1103/PhysRevB.74.174511 |

| 13. | Miu, L.; Aldica, G.; Badica, P.; Ivan, I.; Miu, D.; Jakob, G. Supercond. Sci. Technol. 2010, 23, 095002. doi:10.1088/0953-2048/23/9/095002 |

| 2. | Kim, H.-J.; Kang, W. N.; Choi, E.-M.; Kim, M.-S.; Kim, K. H. P.; Lee, S.-I. Phys. Rev. Lett. 2001, 87, 087002. doi:10.1103/PhysRevLett.87.087002 |

| 9. | Rizzo, N. D.; Wang, J. Q.; Prober, D. E.; Motowidlo, L. R.; Zeitlin, B. A. Appl. Phys. Lett. 1996, 69, 2286. doi:10.1063/1.117535 |

| 11. | Zdravkov, V.; Sidorenko, A.; Rossolenko, A.; Ryazanov, V.; Bdikin, I.; Krömer, O.; Nold, E.; Koch, T.; Schimmel, T. J. Phys.: Conf. Ser. 2007, 61, 606. doi:10.1088/1742-6596/61/1/122 |

| 8. | Snezhko, A.; Prozorov, T.; Prozorov, R. Phys. Rev. B 2005, 71, 024527. doi:10.1103/PhysRevB.71.024527 |

| 12. | Sidorenko, A. S.; Tagirov, L. R.; Rossolenko, A. N.; Sidorov, N. S.; Zdravkov, V. I.; Ryazanov, V. V.; Klemm, M.; Horn, S.; Tidecks, R. JETP Lett. 2002, 76, 17. doi:10.1134/1.1507218 |

| 7. | Sidorenko, A.; Zdravkov, V.; Ryazanov, V.; Horn, S.; Klimm, S.; Tidecks, R.; Wixforth, A.; Koch, T.; Schimmel, T. Philos. Mag. 2005, 85, 1783. doi:10.1080/14786430500036678 |

| 6. | Gupta, A.; Narlikar, A. V. Supercond. Sci. Technol. 2009, 22, 125029. doi:10.1088/0953-2048/22/12/125029 |

| 10. | Bu, S. D.; Kim, D. M.; Choi, J. H.; Giencke, J.; Hellstrom, E. E.; Larbalestier, D. C.; Patnaik, S.; Cooley, L.; Eom, C. B.; Lettieri, J.; Schlom, D. G.; Tian, W.; Pan, X. Q. Appl. Phys. Lett. 2002, 81, 1851. doi:10.1063/1.1504490 |

© 2011 Surdu et al; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Nanotechnology terms and conditions: (http://www.beilstein-journals.org/bjnano)