Abstract

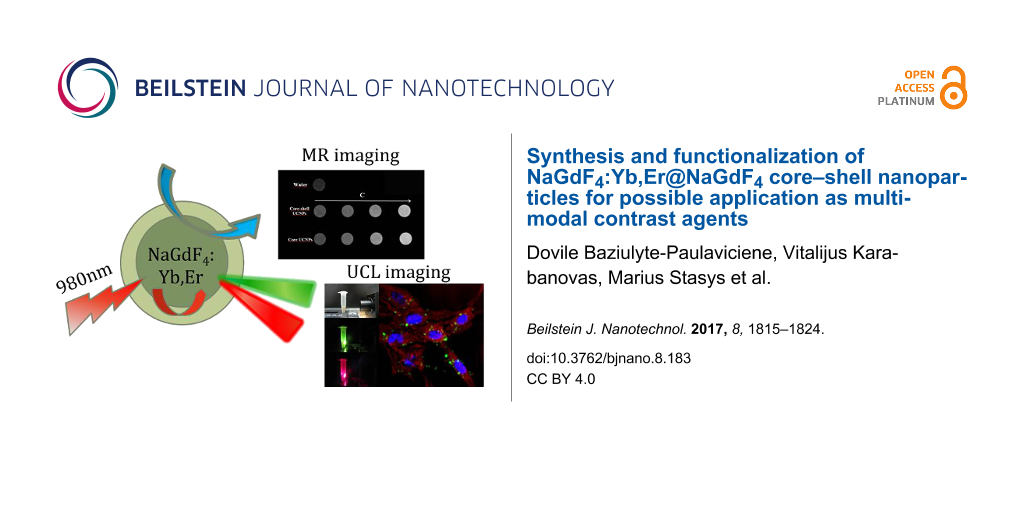

Upconverting nanoparticles (UCNPs) are promising, new imaging probes capable of serving as multimodal contrast agents. In this study, monodisperse and ultrasmall core and core–shell UCNPs were synthesized via a thermal decomposition method. Furthermore, it was shown that the epitaxial growth of a NaGdF4 optical inert layer covering the NaGdF4:Yb,Er core effectively minimizes surface quenching due to the spatial isolation of the core from the surroundings. The mean diameter of the synthesized core and core–shell nanoparticles was ≈8 and ≈16 nm, respectively. Hydrophobic UCNPs were converted into hydrophilic ones using a nonionic surfactant Tween 80. The successful coating of the UCNPs by Tween 80 has been confirmed by Fourier transform infrared (FTIR) spectroscopy. Scanning electron microscopy (SEM), powder X-ray diffraction (XRD), photoluminescence (PL) spectra and magnetic resonance (MR) T1 relaxation measurements were used to characterize the size, crystal structure, optical and magnetic properties of the core and core–shell nanoparticles. Moreover, Tween 80-coated core–shell nanoparticles presented enhanced optical and MR signal intensity, good colloidal stability, low cytotoxicity and nonspecific internalization into two different breast cancer cell lines, which indicates that these nanoparticles could be applied as an efficient, dual-modal contrast probe for in vivo bioimaging.

Introduction

Lanthanide-doped multimodal upconverting nanoparticles (UCNPs), which can convert near-infrared (NIR) radiation into visible light, have been extensively investigated due to the advantages associated with their unique optical properties [1]. Compared with traditional semiconductor quantum dots (QDs) or organic fluorophores, UCNPs show superior features such as sharp emission peaks, low toxicity, high photochemical stability, high resistance to photobleaching, and long emission lifetime [2,3]. As a unique class of luminescent phosphors, UCNPs show great promise in a broad range of applications ranging from bioimaging, biosensors, drug delivery, to photodynamic therapy [4-8]. Through combination with biologically active molecules, UCNPs could be multifunctional in both therapy and diagnostics (theranostics) [9]. However, biomedical applications require ultrasmall multifunctional nanoparticles to be hydrophilic, biocompatible and have intense upconversion emission and efficient paramagnetic properties. Hexagonal phase sodium gadolinium fluoride β-NaGdF4 is an ideal matrix for the creation optical/magnetic dual-modal bioprobes, but upconversion luminescence (UCL) efficiency of this host material is still low and needs to be improved. A major method to enhance the UCL intensity is to use a core–shell structure, where the nonactive shell protects the luminescent rare earth ions in the core from quenching caused by surface defects and organic ligands [10]. A wide variety of studies were performed to synthesize dual functional core–shell UCNPs [11-13]. However, it remains difficult to obtain hexagonal phase NaGdF4 (a host material exhibiting about an order of magnitude higher upconversion luminescence efficiency compared to cubic ones) with great optical and magnetic properties while maintaining a small size (<20 nm).

The next problem is that those nanoparticles are often synthesized in an organic phase and stabilized with hydrophobic ligands, such as oleic acid. Consequently, they can only be dispersed in nonpolar solvents (e.g., toluene, cyclohexane). In the past few years, several methods including surface silanization [14], ligand exchange [15], ligand oxidation [16], ligand removal [17], and amphiphilic polymer coating [18] have been developed in order to transfer nanoparticles with hydrophobic surfaces into aqueous media. Furthermore, the multimodal UCNP surface modification field still lacks reference materials and established protocols for functionalization and targeting. Some studies showed that the nonionic surfactant Tween 80 helps different nanoparticles (gold, silver and iron oxide) to become well-dispersed in aqueous solution even in the presence of biological molecules, such as different serum proteins [19-21]. However, information about Tween 80-coated gadolinium-based UCNPs behavior in biological systems and biocompatibility/nanotoxicity is still limited. The study of Cascales et al. showed that ultrasmall Yb:Er:NaGd(WO4)2 UCNPs could be successfully covered with Tween 80 and are internalized by human mesenchymal stem cells without triggering their metabolic activity, but still no information has been presented about uptake of these nanoparticles into different types of cancer cells [22]. Although different gadolinium chelates are widely used in clinics as contrast agents for magnetic resonance imaging (MRI), the literature for the last two years shows increased awareness of the effects of gadolinium toxicity [23,24]. Moreover, the possible influence of gadolinium-based UCNPs on cells is not yet investigated and understood.

In this work, we focus on studies of multimodal core–shell NaGdF4:Yb,Er coated with NaGdF4 (NaGdF4:Yb,Er@NaGdF4) UCNPs synthesis and demonstrate the effective surface modification method that uses a surfactant polysorbate 80 (Tween 80, polyoxyethylene sorbitan laurate). Hexagonal phase β-NaGdF4 was chosen as host lattice for its ability to combine optical and MRI. Tween 80 was used to make the UCNPs colloidally stable and dispersible in water while protecting the surface from nonspecific adsorption of biomolecules. Our results show that Tween 80-coated NaGdF4:Yb,Er@NaGdF4 core–shell nanoparticles exhibit excellent dispersibility in a biological medium and are photostable. We also do not observe any changes in the overall upconversion (UC) emission intensity of Tween 80-coated nanoparticles in comparison with oleic acid coated UCNPs. In addition, the nonspecific uptake and distribution of non-targeted Tween 80-coated UCNPs in human MCF-7 and MDB-MA-231 breast cancer cells was visualized by using confocal fluorescence microscopy. Our results showed that Tween 80-coated UCNPs exhibited low cytotoxicity even at a high-dose concentration.

Results and Discussion

The SEM images of the NaGdF4:Yb,Er core and NaGdF4:Yb,Er@NaGdF4 core–shell nanoparticles are shown in Figure 1. Core nanoparticles are monodisperse, and have a spherical shape with an average diameter of approximately 8 nm with polydispersity index (PDI) of 1.02. The resulting core–shell nanoparticles are polydisperse and have an average diameter of ≈16 nm with PDI of 1.16. This indicates that polydispersity occurred from secondary nucleation during the shell growth process. However, an increase of the size suggests that the NaGdF4 has been successfully epitaxial grown on the NaGdF4:Yb,Er core nanoparticles. The diffraction peaks of the core (Figure 2a) and core–shell (Figure 2b) nanoparticles can be indexed as pure hexagonal β-NaGdF4 phase (JCPDS, Card No. 27-0699), indicating no change in the crystalline phase during the shell growth.

![[2190-4286-8-183-1]](/bjnano/content/figures/2190-4286-8-183-1.png?scale=1.84&max-width=1024&background=FFFFFF)

Figure 1: SEM images of the core NaGdF4:Yb,Er (A) and core@shell NaGdF4:Yb,Er@NaGdF4 (B) nanoparticles. The insets display the UCNP diameter distributions.

Figure 1: SEM images of the core NaGdF4:Yb,Er (A) and core@shell NaGdF4:Yb,Er@NaGdF4 (B) nanoparticles. The i...

![[2190-4286-8-183-2]](/bjnano/content/figures/2190-4286-8-183-2.png?scale=1.68&max-width=1024&background=FFFFFF)

Figure 2: XRD pattern of NaGdF4:Yb,Er core only (a), and NaGdF4:Yb,Er@NaGdF4 core–shell (b) nanoparticles.

Figure 2: XRD pattern of NaGdF4:Yb,Er core only (a), and NaGdF4:Yb,Er@NaGdF4 core–shell (b) nanoparticles.

The as-obtained core and core–shell UCNPs were hydrophobic as they were stabilized by oleic acid molecules. In this work, hydrophobic core and core–shell nanoparticles were converted into hydrophilic ones using a nonionic surfactant Tween 80.

The presence of the Tween 80 coating was verified by comparing its FTIR spectra to that of pure oleic acid, oleate ligands coated particles, pure Tween 80, and the final coated nanoparticles (Figure 3). NaGdF4:Yb,Er UCNPs prepared in the presence of oleic acid shows characteristic absorption peaks of oleate ligands. The absorption peak at 1710 cm−1 (Figure 3f) corresponds to the stretching vibration of C=O in pure oleic acid (Figure 3a) which is replaced by two carboxylate stretching bands (1560 and 1447 cm−1 in Figure 3e), which indicates oleate ligand adsorption on the UCNP surface.

![[2190-4286-8-183-3]](/bjnano/content/figures/2190-4286-8-183-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: The structure of (a) oleic acid (OA) and (b) Tween 80. FTIR spectra of (c) pure Tween 80, (d) NaGdF4:Yb,Er@Tween80, (e) NaGdF4:Yb,Er@OA, and (f) pure OA.

Figure 3: The structure of (a) oleic acid (OA) and (b) Tween 80. FTIR spectra of (c) pure Tween 80, (d) NaGdF4...

Tween 80 is composed of three building blocks: aliphatic ester chains, three-terminal hydroxyl groups and an aliphatic chain (Figure 3b). The aliphatic chain can be adsorbed on the hydrophobic surface by hydrophobic interactions of UCNPs as synthesized in oleic acid [25]. The strong band around 3400 cm−1 can be assigned to the O–H stretching vibrations (Figure 3d) from terminal hydroxyl groups of Tween 80 (Figure 3b) and the remaining moisture in the samples. The bands centred at 2922 and 2855 cm−1 are associated with the asymmetric (νas) and symmetric (νs) stretching vibrations of methylene (–CH2), respectively. The adsorption peaks at 1730 and 1094 cm−1 are attributed to the ester group stretching. The band at 946 cm−1 is present, which corresponds to the ether bond from the aliphatic ester chains (Figure 3c). The FTIR data of UCNPs@Tween80 (Figure 3d) is highly comparable with that of pure Tween 80 (Figure 3c), indicating that the Tween 80 was successfully coated onto the UCNPs. Additionally, dynamic light scattering (DLS) was employed to measure the hydrodynamic diameter of Tween-coated UCNPs in the cell culture medium as well as their surface zeta potential. The measured mean hydrodynamic diameter of the Tween-coated core NaGdF4:Yb,Er UCNPs was 38 nm and the core–shell NaGdF4:Yb,Er@NaGdF4 particles was 48 nm. The zeta potential of Tween 80-coated core nanoparticles was about 26 mV and for core–shell nanoparticles it was slightly higher at about 33 mV. More detailed information about the DLS results is presented in the Supporting Information File 1.

The upconversion emission spectra of different NaGdF4:Yb,Er@NaGdF4@Tween80 core–shell and NaGdF4:Yb,Er@Tween80 core nanoparticles dispersed in water are shown in Figure 4a. The major emissions located at 381, 408, 521, 540, 654 and 756 nm can be attributed to radiative transitions from 4G11/2 2H9/2, 2H11/2, 4S3/2, 4F9/2 and 4I9/2 levels to the 4I15/2 level of Er3+ (Figure 4b), respectively. The comparison with the core-only nanoparticles showed that coating the NaGdF4:Yb3+,Er3+ core with a shell that has the same crystal lattice structure reduce the effects of luminescence quenching from the addition of ligands and/or surface defects and therefore a significant increase in the UCL can be observed. For the core-only nanoparticles, lanthanide dopants are exposed to surface deactivations owing to the high surface-to-volume ratio at the nanometer dimension, thus yielding UCL at low efficiency. The integrated intensity (521 nm) of the core–shell NaGdF4:Yb,Er@NaGdF4 nanoparticles was estimated to be about two magnitudes higher than the core-only NaGdF4:Yb,Er UCNPs. The results indicate that the core–shell structure can effectively spatially isolate lanthanide dopants from being quenched, and also negate the influence of surface defects. The results correlate well with what is presented in the literature. Yi et al. reported that the UC emissions of hexagonal phase NaYF4:Yb3+,Er3+ were enhanced by as much as seven times by growth of a 2 nm layer of NaYF4 [26]. In a later publication, the same conclusion was independently verified in core–shell UCNPs of NaGdF4:Yb3+,Tm3+@NaGdF4 and KGdF4:Yb3+,Tm3+@KGdF4 when compared to the core under 980 nm excitation [11,12,27].

![[2190-4286-8-183-4]](/bjnano/content/figures/2190-4286-8-183-4.png?scale=1.84&max-width=1024&background=FFFFFF)

Figure 4: (a) Upconversion luminescence spectra of Tween 80-coated UCNPs upon 980 nm excitation [28] and (b) energy level diagram of Yb3+ and Er3+ ions.

Figure 4: (a) Upconversion luminescence spectra of Tween 80-coated UCNPs upon 980 nm excitation [28] and (b) ener...

As shown in Figure 5 (inset), a positive enhancement for the magnetic resonance (MR) signal was observed for all the UCNPs samples when compared to water. Moreover, with the increase of the concentration of UCNPs, the T1-weighted MRI signal intensity (SI) continuously increased, resulting in brighter images for both types of UCNPs. The MR SI values of UCNPs are presented in Figure 5. The maximum MR signal enhancement was of approximately 3.5-fold compared with the reference. There was no significant difference observed in MR signal enhancement between the core and core–shell UCNPs. Therefore, it can be concluded that the UCNP coating does not affect the favorable MRI properties of UCNPs. That signifies that the Gd3+ ions in the shell of the UCNPs are the major contributors toward the relaxation of water protons, and the UCNP core does not show any significant effect towards relaxivity enhancement. However, it has been shown in the literature that reduced water access to the Gd3+ ions may yield reduced values for MR signal enhancement [29,30]. These observations indicate that both core and core–shell UCNPs could be applied as efficient MRI contrast agents as they both present enhanced MR signal intensity.

![[2190-4286-8-183-5]](/bjnano/content/figures/2190-4286-8-183-5.png?scale=1.84&max-width=1024&background=FFFFFF)

Figure 5: Magnetic resonance (MR) signal intensity (SI) plot of core (red dots) and core–shell (black squares) UCNPs of different concentrations of aqueous solutions. Water SI is marked as a dashed line as a reference; Inset: T1-weighted MR in vitro images of core and core–shell UCNPs at different concentrations of aqueous solutions.

Figure 5: Magnetic resonance (MR) signal intensity (SI) plot of core (red dots) and core–shell (black squares...

The as-prepared Tween 80-coated core–shell NaGdF4:Yb,Er@NaGdF4 nanoparticles were studied to evaluate their application to biological imaging using MDA-MB-231 breast cancer cells. The confocal image of MDA-MB-231 breast cancer cells after 24 h incubation with UCNPs is shown in Figure 6A. The scatter of excitation light by intracellular cell structures was marked with red color. This was obtained by excitation at 514 nm and detected at 500–530 nm. Tween 80-coated core–shell UCNPs were marked with green color (excitation was continuous wave at 980 nm and detection at 500–530 nm). The cell nuclei were labeled with DAPI and imaged using an excitation of 405 nm and detected at using a bandpass filter with a center wavelength of 450 nm and bandwidth of 35 nm. As seen from Figure 6A, the luminescence of the UCNPs came from the intracellular region, suggesting that Tween 80-coated nanoparticles were non-specifically internalized into cells and concentrated within the cytoplasm. The similar localization of Tween 80-coated nanoparticles was observed in MCF-7 cells as well. The same results of endocytic NP accumulation in cells was demonstrated in different studies with UCNPs [31], quantum dots [32], magnetic nanomaterials [33] and noble metal nanoparticles [34].

![[2190-4286-8-183-6]](/bjnano/content/figures/2190-4286-8-183-6.png?scale=1.84&max-width=1024&background=FFFFFF)

Figure 6: A) Confocal images of MDA-MB-231 cells after 24 h treatment with Tween 80-coated core–shell UCNPs (10 µg/mL); UCNPs are green, DAPI staining is blue, the red color represents excitation scattering from intracellular structures. Scale bar equals 10 µm. B) Viability of MCF-7 and MDA-MB-213 cells, treated with different concentrations of UCNPs for 24 h. Toxicity of UCNPs was investigated using XTT cell viability assay.

Figure 6: A) Confocal images of MDA-MB-231 cells after 24 h treatment with Tween 80-coated core–shell UCNPs (...

Cell viability assay XTT was performed to measure the cellular metabolic activity of human breast cancer MCF-7 and MDA-MB-231 cell lines after 24 h treatment with core–shell Tween 80-coated UCNPs (Figure 6B). Untreated cells were used as a control group. After 24 h of incubation in the UCNP concentration range from 5 to 100 μg/mL, the viability of human breast cancer MCF-7 cells remained over 92–100% and the viability of MDA-MB-231 cells remained 85–93%. These results clearly express that core–shell gadolinium-based UCNPs have low cytotoxicity and are in good agreement with previous studies [35,36].

Conclusion

In summary we have successfully synthesized ultrasmall, monodisperse, hexagonal phase core NaGdF4:Yb,Er nanoparticles and polydisperse, core–shell NaGdF4:Yb,Er@NaGdF4 nanoparticles.

Oleate-capped core NaGdF4:Yb,Er nanoparticles and core–shell NaGdF4:Yb,Er@NaGdF4 nanoparticles were successfully transferred to aqueous solutions after surface modification with the surfactant Tween 80. The core–shell UCNPs presented enhanced upconversion intensity and MR signal intensity, which indicates that these nanoparticles could be applied as an efficient dual optical, MRI contrast agent. Moreover, an in vitro uptake and cytotoxicity evaluation study showed that the UCNPs internalized into breast cancer cell lines and possessed low cytotoxicity and good biocompatibility. All these findings indicate that Tween 80-coated NaGdF4:Yb,Er@NaGdF4 UCNPs are a promising nanomaterial platform for imaging and detection in oncology.

Experimental

Materials: All of the chemicals used in our experiments were of analytical grade and used without further purification. Ln oxides (Ln2O3, 99.99%, Ln: Gd, Yb, Er) were obtained from Treibacher Industrie AG (Germany). Oleic acid (OA, 90%) was purchased from Fisher Scientific, 1-octadecene (ODE, 90%) was obtained from Sigma-Aldrich. Tween 80 (polysorbate 80) was purchased from Merck Millipore. Other chemicals including hydrochloric acid, sodium hydroxide, ammonium fluoride, methanol, chloroform, cyclohexane and acetone were obtained from Reachem Slovakia.

Synthesis of core β-NaGdF4:Yb,Er nanoparticles: The synthesis of β-NaGdF4:Yb,Er NPs was developed via a modified procedure from the literature [11]. In a typical experiment, 1.6 mmol Gd2O3, 0.36 mmol Yb2O3 and 0.04 mmol Er2O3 were dissolved in HCl at an elevated temperature (≈80 °C) to prepare the rare earth chloride stock solution. Metal chlorides were mixed with 12 mL oleic acid (OA) and 30 mL 1-octadecene (ODE) in three-neck round-bottom flask and then heated to 150 °C for 40 min. 10 mL of methanol solution containing NaOH (5 mmol) and NH4F (8 mmol) was slowly introduced and the solution was stirred at 50 °C for 30 min. After the methanol was evaporated, the solution was heated to 300 °C for 1 h under argon atmosphere. The resultant nanoparticles were precipitated by hexane/acetone (1:4 v/v), collected by centrifugation, washed with acetone and DI water several times, and finally redispersed in cyclohexane.

Synthesis of core–shell β-NaGdF4:Yb,Er@NaGdF4 nanoparticles: The subsequent deposition of the NaGdF4 shell followed a similar process for the preparation of NaGdF4:Yb,Er core particles. 1 mmol Gd2O3 was dissolved in HCl at an elevated temperature (≈80 °C) to prepare a 2 mmol gadolinium chloride stock solution. 2 mmol gadolinium chloride was added to a three-neck round-bottom flask containing 8 mL OA and 30 mL ODE and then heated to 150 °C for 40 min under argon atmosphere to form a homogeneous solution and then cooled to room temperature. 10 mL of cyclohexane solution of 0.66 mmol NaGdF4:Yb,Er nanoparticles was added dropwise into the solution. The mixture was degassed at 100 °C for 10 min to remove cyclohexane and cooled to room temperature. Then 10 mL methanol solution of NaOH (5 mmol) and NH4F (8 mmol) was added and stirred at 50 °C for 30 min. After the methanol evaporated, the solution was heated to 300 °C for 1 h under argon atmosphere. The resultant core–shell nanoparticles were precipitated by hexane/acetone (1:4 v/v), collected by centrifugation, washed with acetone and DI water several times, and finally redispersed in cyclohexene.

Tween modification of oleate-capped β-NaGdF4:Yb,Er and β-NaGdF4:Yb,Er@NaGdF4 nanoparticles: The surface modification of β-NaGdF4:Yb,Er and β-NaGdF4:Yb,Er@NaGdF4 nanoparticles was carried out following a literature protocol with slight modifications [37]. In a typical experiment, 400 μL of Tween 80 was added into a round-bottom flask containing ≈20 mg of β-NaGdF4:Yb,Er (β-NaGdF4:Yb,Er@NaGdF4) and 8 mL of CHCl3, and the solution was stirred for 1 h at room temperature. 20 mL of deionized water was poured in the flask and the dispersion was kept in a 80 °C water bath for 3 h. During this period, the CHCl3 was evaporated and the hydrophobic UCNPs were gradually converted into hydrophilic ones. A principle mechanism by which the Tween 80 surfactant stabilizes the UCNPs is shown in Figure 7.

![[2190-4286-8-183-7]](/bjnano/content/figures/2190-4286-8-183-7.png?scale=1.84&max-width=1024&background=FFFFFF)

Figure 7: Formation of water-soluble core and core–shell UCNPs by coating with Tween 80.

Figure 7: Formation of water-soluble core and core–shell UCNPs by coating with Tween 80.

Characterization: The polydispersity index of UCNPs was calculated by finding the weight (Dw) and number-average diameter (Dn) ratio using the following equations:

where ni and Di are the number and diameter of the particle, respectively.

Dynamic light scattering (DLS) was used to determine the hydrodynamic particle diameter and zeta potential. These experiments were performed with Brookhaven ZetaPALS zeta potential analyzer (Brookhaven Instruments, USA). Powder X-ray diffraction (XRD) analysis has been carried out by employing a Rigaku MiniFlex II diffractometer working in the Bragg–Brentano (θ/2θ) geometry. The data were collected within a 2θ angle from 10° to 65° at a step of 0.01° and scanning speed of 10 °/min using the Ni-filtered Cu Kα line. The particle morphology was characterized using a field emission scanning electron microscope (SU-70 Hitachi, FE-SEM) at an acceleration voltage of 10 kV. The UC luminescence spectra were recorded using an Edinburgh Instruments FLS980 spectrometer equipped with a double emission monochromator, a cooled (−20 °C) single-photon counting photomultiplier (Hamamatsu R928), and a 1 W continuous wavelength 980 nm laser diode. The emission slit was set to 1 nm, the step size was 1 nm, and the integration time was 0.1 s with 5 scans to gain more intensity. The emission spectra were corrected by a correction file obtained from a tungsten incandescent lamp certified by National Physics Laboratory, UK. The measurements were performed in standard 1 cm quartz cuvettes at room temperature. Fourier transform infrared (FTIR) spectra were recorded on an infrared spectrometer (Perkin Elmer Spectrum).

Cell culturing and imaging: Human breast cancer cell lines MDA-MB-231 and MCF-7 were obtained from the American Type Culture Collection (ATCC HTB-26™; ATCC HTB-22™). MDA-MB-231 and MCF-7 cells were cultured in cell growth medium (DMEM, Gibco, US), supplemented with 10% (v/v) fetal bovine serum (FBS) (Gibco, US), 100 U/mL penicillin and 100 mg/mL streptomycin. The cells were maintained at 37 °C in a humidified atmosphere containing 5% of CO2. The cells were routinely subcultured 2–3 times a week in 25 cm2 culture dishes. Prior to the UCNP experimentation, the uptake cells were seeded and allowed to grow for 24 h and then treated with 10 µg/mL of Tween 80-coated core–shell UCNPs for 24 h. Then the cells were fixed with 4% paraformaldehyde and stained with DAPI. The high-resolution imaging system for UCNP imaging was based on a confocal microscopy system Nikon C1si (Japan). A 980 nm continuous wave laser with an intensity control module was introduced into the confocal microscopy system for excitation of samples in the NIR spectral region. 450/35 nm, 515/30 nm and 605/75 nm band pass filters (where the first value is the center/peak wavelength and the second refers to the bandwidth of the filter) were used to block detectors from reflected and scattered NIR light.

Cell viability assay: MCF-7 and MDA-MB-231 human breast cancer cells were seeded on a 96-well plate at a density of 20,000 cells/well. After 24 h, the old medium was replaced with a fresh medium containing 5, 10, 20, 50 and 100 µg/mL core–shell UCNPs. 12 wells were left without upconverting particles to serve as the control group. After 24 h of treatment, the cell growth medium with nanoparticles was aspirated and cells were washed with DPBS (pH 7.0) three times. To prepare an XTT solution, 0.1 mL activation solution (N-methyl dibenzopyrazine methyl sulfate) was mixed with 5 mL XTT reagent (tetrazolium derivative). 100 µL of a fresh medium and 50 μL of the reaction solution were added to each well and the plate was incubated for 5 h in an incubator at 37 °C. After incubation, optical density values at 490 nm were measured using the Biotek (USA) microplate reader. Values obtained from measuring optical density were recalculated as percentage values of viability. The absorbance value of the control group was set to 100% and the rest of the values were recalculated accordingly.

in vitro MR imaging: The MR signal enhancement measurements were carried out on a 1.5 T clinical MRI scanner (Achieva, Philips Medical Systems, Best, The Netherlands) in conjunction with a Sense Flex-M coil (Philips Medical Systems, Best, The Netherlands). Dilutions of core and core–shell UCNPs (0.125, 0.25, 0.5, 1.0 mg/mL) in deionized water were prepared for T1-weighted MR imaging and T1-weighted contrast enhancement. A series of aqueous solutions of UCNPs were placed in an array of 2.0 mL Eppendorf tubes with the order of UCNP concentrations and deionized water (0 mg/mL) was used as the reference. The parameters for T1-weighted MR imaging sequence was set as follows: echo time (TE) = 15.0 ms, repetition time (TR) = 500 ms, number of averages (NSA) = 8, matrix = 1024 × 1024, FOV = 200 × 200 mm, and slice thickness = 1.5 mm. The MR signal intensity (SI) in the tubes was determined by the average intensity in the defined regions of interests (ROIs). The resulting SI values in ROIs were plotted as a ratio of UCNP:water against the concentration of UCNPs.

Statistical analysis: Data are shown as the representative result or as mean of at least three independent experiments ±SD. Statistical analyses were performed using the two-tailed Student’s t-test; differences were considered significant at p < 0.05.

Supporting Information

| Supporting Information File 1:

The hydrodynamic particle size and zeta potential.

The results representing hydrodynamic size distribution of UCNPs and their zeta potential that were measured using dynamic light scattering method (DLS). |

||

| Format: PDF | Size: 136.1 KB | Download |

Acknowledgements

This work was supported by the grant “Study of optical properties and biocompatibility of Na(Gd/Y)F4 nanoparticles” (No.MIP-030/2014) from the Research Council of Lithuania. A part of this work has been presented at the International Conference of Lithuanian Society of Chemistry on April 28–29, 2016.

References

-

Wang, M.; Abbineni, G.; Clevenger, A.; Mao, C.; Xu, S. Nanomedicine: NBM 2011, 7, 710–729. doi:10.1016/j.nano.2011.02.013

Return to citation in text: [1] -

Mader, H. S.; Kele, P.; Saleh, S. M.; Wolfbeis, O. S. Curr. Opin. Chem. Biol. 2010, 14, 582–596. doi:10.1016/j.cbpa.2010.08.014

Return to citation in text: [1] -

Liu, C.; Gao, Z.; Zeng, J.; Hou, Y.; Fang, F.; Li, Y.; Qiao, R.; Shen, L.; Lei, H.; Yang, W.; Gao, M. ACS Nano 2013, 7, 7227–7240. doi:10.1021/nn4030898

Return to citation in text: [1] -

Deng, R.; Qin, F.; Chen, R.; Huang, W.; Hong, M.; Liu, X. Nat. Nanotechnol. 2015, 10, 237–242. doi:10.1038/nnano.2014.317

Return to citation in text: [1] -

Sun, Y.; Feng, W.; Yang, P.; Huang, C.; Li, F. Chem. Soc. Rev. 2015, 44, 1509–1525. doi:10.1039/C4CS00175C

Return to citation in text: [1] -

Zhou, J.; Liu, Z.; Li, F. Chem. Soc. Rev. 2012, 41, 1323–1349. doi:10.1039/C1CS15187H

Return to citation in text: [1] -

Wang, F.; Banerjee, D.; Liu, Y.; Chen, X.; Liu, X. Analyst 2010, 135, 1839–1854. doi:10.1039/c0an00144a

Return to citation in text: [1] -

Wang, F.; Liu, X. Chem. Soc. Rev. 2009, 38, 976–989. doi:10.1039/b809132n

Return to citation in text: [1] -

Guanying, C.; Gang, H. Theranostics 2013, 3, 289–291. doi:10.7150/thno.6382

Return to citation in text: [1] -

Qiu, H.; Yang, C.; Shao, W.; Damasco, J.; Wang, X.; Ågren, H.; Prasad, P. N.; Chen, G. Nanomaterials 2014, 4, 55. doi:10.3390/nano4010055

Return to citation in text: [1] -

Liu, Y.; Tu, D.; Zhu, H.; Li, R.; Luo, W.; Chen, X. Adv. Mater. 2010, 22, 3266. doi:10.1002/adma.201000128

Return to citation in text: [1] [2] [3] -

Wang, F.; Wang, J.; Liu, X. Angew. Chem. 2010, 49, 7456. doi:10.1002/anie.201003959

Return to citation in text: [1] [2] -

Chen, D.; Lei, L.; Yang, A.; Wang, Z.; Wang, Y. Chem. Commun. 2012, 48, 5898–5900. doi:10.1039/c2cc32102e

Return to citation in text: [1] -

Liu, F.; He, X.; Liu, L.; You, H.; Zhang, H.; Wang, Z. Biomaterials 2013, 34, 5218–5225. doi:10.1016/j.biomaterials.2013.03.058

Return to citation in text: [1] -

Cao, T.; Yang, T.; Gao, Y.; Yang, Y.; Hu, H.; Li, F. Inorg. Chem. Commun. 2010, 13, 392–394. doi:10.1016/j.inoche.2009.12.031

Return to citation in text: [1] -

Chen, Z.; Chen, H.; Hu, H.; Yu, M.; Li, F.; Zhang, Q.; Zhou, Z.; Yi, T.; Huang, C. J. Am. Chem. Soc. 2008, 130, 3023–3029. doi:10.1021/ja076151k

Return to citation in text: [1] -

Bogdan, N.; Vetrone, F.; Ozin, G. A.; Capobianco, J. A. Nano Lett. 2011, 11, 835–840. doi:10.1021/nl1041929

Return to citation in text: [1] -

Cheng, L.; Yang, K.; Zhang, S.; Shao, M.; Lee, S.; Liu, Z. Nano Res. 2010, 3, 722–732. doi:10.1007/s12274-010-0036-2

Return to citation in text: [1] -

Zhao, Y.; Wang, Z.; Zhang, W.; Jiang, X. Nanoscale 2010, 2, 2114–2119. doi:10.1039/c0nr00309c

Return to citation in text: [1] -

Huang, Y.; Zhang, B.; Xi, S.; Yang, B.; Xu, Q.; Tan, J. ACS Appl. Mater. Interfaces 2016, 8, 11336–11341. doi:10.1021/acsami.6b02838

Return to citation in text: [1] -

Baalousha, M.; Arkill, K. P.; Romer, I.; Palmer, R. E.; Lead, J. R. Sci. Total Environ. 2015, 502, 344–353. doi:10.1016/j.scitotenv.2014.09.035

Return to citation in text: [1] -

Cascales, C.; Paíno, C. L.; Bazán, E.; Zaldo, C. Nanotechnology 2017, 28, 185101. doi:10.1088/1361-6528/aa6834

Return to citation in text: [1] -

Rogosnitzky, M.; Branch, S. BioMetals 2016, 29, 365–376. doi:10.1007/s10534-016-9931-7

Return to citation in text: [1] -

Swaminathan, S. Magn. Reson. Imaging 2016, 34, 1373–1376. doi:10.1016/j.mri.2016.08.016

Return to citation in text: [1] -

Park, S.; Mohanty, N.; Suk, J. W.; Nagaraja, A.; An, J.; Piner, R. D.; Cai, W.; Dreyer, D. R.; Berry, V.; Ruoff, R. S. Adv. Mater. 2010, 22, 1736–1740. doi:10.1002/adma.200903611

Return to citation in text: [1] -

Yi, G.-S.; Chow, G.-M. Chem. Mater. 2007, 19, 341. doi:10.1021/cm062447y

Return to citation in text: [1] -

Wong, H.-T.; Vetrone, F.; Naccache, R.; Chan, H. L. W.; Hao, J.; Capobianco, J. A. J. Mater. Chem. 2011, 21, 16589. doi:10.1039/c1jm12796a

Return to citation in text: [1] -

Baziulyte, D.; Karabanovas, V.; Stalnionis, M.; Jurciukonis, I.; Sakirzanovas, S. In Book of abstracts of the “Chemistry and Chemical Technology, International Conference of Lithuanian Society of Chemistry; 2016; p 150.

Return to citation in text: [1] -

Johnson, N. J. J.; Oakden, W.; Stanisz, G. J.; Scott Prosser, R.; van Veggel, F. C. J. M. Chem. Mater. 2011, 23, 3714–3722. doi:10.1021/cm201297x

Return to citation in text: [1] -

Hou, Y.; Qiao, R.; Fang, F.; Wang, X.; Dong, C.; Liu, K.; Liu, C.; Liu, Z.; Lei, H.; Wang, F.; Gao, M. ACS Nano 2013, 7, 330–338. doi:10.1021/nn304837c

Return to citation in text: [1] -

Vetrone, F.; Naccache, R.; de la Fuente, A. J.; Sanz-Rodriguez, F.; Blazquez-Castro, A.; Rodriguez, E. M.; Jaque, D.; Solé, J. G.; Capobianco, J. A. Nanoscale 2010, 2, 495–498. doi:10.1039/B9NR00236G

Return to citation in text: [1] -

Karabanovas, V.; Zitkus, Z.; Kuciauskas, D.; Rotomskis, R.; Valius, M. J. Biomed. Nanotechnol. 2014, 10, 775–786. doi:10.1166/jbn.2014.1770

Return to citation in text: [1] -

Osman, O.; Zanini, L. F.; Frénéa-Robin, M.; Dumas-Bouchiat, F.; Dempsey, N. M.; Reyne, G.; Buret, F.; Haddour, N. Biomed. Microdevices 2012, 14, 947–954. doi:10.1007/s10544-012-9673-4

Return to citation in text: [1] -

Wang, S.-H.; Lee, C.-W.; Chiou, A.; Wei, P.-K. J. Nanobiotechnol. 2010, 8, 33. doi:10.1186/1477-3155-8-33

Return to citation in text: [1] -

Woźniak, A.; Noculak, A.; Gapiński, J.; Kociolek, D.; Boś-Liedke, A.; Zalewski, T.; Grześkowiak, B. F.; Kołodziejczak, A.; Jurga, S.; Banski, M.; Misiewicz, J.; Podhorodecki, A. RSC Adv. 2016, 6, 95633–95643. doi:10.1039/C6RA20415E

Return to citation in text: [1] -

Guller, A. E.; Generalova, A. N.; Petersen, E. V.; Nechaev, A. V.; Trusova, I. A.; Landyshev, N. N.; Nadort, A.; Grebenik, E. A.; Deyev, S. M.; Shekhter, A. B.; Zvyagin, A. V. Nano Res. 2015, 8, 1546–1562. doi:10.1007/s12274-014-0641-6

Return to citation in text: [1] -

Ren, W.; Tian, G.; Jian, S.; Gu, Z.; Zhou, L.; Yan, L.; Jin, S.; Yin, W.; Zhao, Y. RSC Adv. 2012, 2, 7037–7041. doi:10.1039/c2ra20855e

Return to citation in text: [1]

| 1. | Wang, M.; Abbineni, G.; Clevenger, A.; Mao, C.; Xu, S. Nanomedicine: NBM 2011, 7, 710–729. doi:10.1016/j.nano.2011.02.013 |

| 10. | Qiu, H.; Yang, C.; Shao, W.; Damasco, J.; Wang, X.; Ågren, H.; Prasad, P. N.; Chen, G. Nanomaterials 2014, 4, 55. doi:10.3390/nano4010055 |

| 25. | Park, S.; Mohanty, N.; Suk, J. W.; Nagaraja, A.; An, J.; Piner, R. D.; Cai, W.; Dreyer, D. R.; Berry, V.; Ruoff, R. S. Adv. Mater. 2010, 22, 1736–1740. doi:10.1002/adma.200903611 |

| 4. | Deng, R.; Qin, F.; Chen, R.; Huang, W.; Hong, M.; Liu, X. Nat. Nanotechnol. 2015, 10, 237–242. doi:10.1038/nnano.2014.317 |

| 5. | Sun, Y.; Feng, W.; Yang, P.; Huang, C.; Li, F. Chem. Soc. Rev. 2015, 44, 1509–1525. doi:10.1039/C4CS00175C |

| 6. | Zhou, J.; Liu, Z.; Li, F. Chem. Soc. Rev. 2012, 41, 1323–1349. doi:10.1039/C1CS15187H |

| 7. | Wang, F.; Banerjee, D.; Liu, Y.; Chen, X.; Liu, X. Analyst 2010, 135, 1839–1854. doi:10.1039/c0an00144a |

| 8. | Wang, F.; Liu, X. Chem. Soc. Rev. 2009, 38, 976–989. doi:10.1039/b809132n |

| 22. | Cascales, C.; Paíno, C. L.; Bazán, E.; Zaldo, C. Nanotechnology 2017, 28, 185101. doi:10.1088/1361-6528/aa6834 |

| 2. | Mader, H. S.; Kele, P.; Saleh, S. M.; Wolfbeis, O. S. Curr. Opin. Chem. Biol. 2010, 14, 582–596. doi:10.1016/j.cbpa.2010.08.014 |

| 3. | Liu, C.; Gao, Z.; Zeng, J.; Hou, Y.; Fang, F.; Li, Y.; Qiao, R.; Shen, L.; Lei, H.; Yang, W.; Gao, M. ACS Nano 2013, 7, 7227–7240. doi:10.1021/nn4030898 |

| 23. | Rogosnitzky, M.; Branch, S. BioMetals 2016, 29, 365–376. doi:10.1007/s10534-016-9931-7 |

| 24. | Swaminathan, S. Magn. Reson. Imaging 2016, 34, 1373–1376. doi:10.1016/j.mri.2016.08.016 |

| 16. | Chen, Z.; Chen, H.; Hu, H.; Yu, M.; Li, F.; Zhang, Q.; Zhou, Z.; Yi, T.; Huang, C. J. Am. Chem. Soc. 2008, 130, 3023–3029. doi:10.1021/ja076151k |

| 18. | Cheng, L.; Yang, K.; Zhang, S.; Shao, M.; Lee, S.; Liu, Z. Nano Res. 2010, 3, 722–732. doi:10.1007/s12274-010-0036-2 |

| 15. | Cao, T.; Yang, T.; Gao, Y.; Yang, Y.; Hu, H.; Li, F. Inorg. Chem. Commun. 2010, 13, 392–394. doi:10.1016/j.inoche.2009.12.031 |

| 19. | Zhao, Y.; Wang, Z.; Zhang, W.; Jiang, X. Nanoscale 2010, 2, 2114–2119. doi:10.1039/c0nr00309c |

| 20. | Huang, Y.; Zhang, B.; Xi, S.; Yang, B.; Xu, Q.; Tan, J. ACS Appl. Mater. Interfaces 2016, 8, 11336–11341. doi:10.1021/acsami.6b02838 |

| 21. | Baalousha, M.; Arkill, K. P.; Romer, I.; Palmer, R. E.; Lead, J. R. Sci. Total Environ. 2015, 502, 344–353. doi:10.1016/j.scitotenv.2014.09.035 |

| 14. | Liu, F.; He, X.; Liu, L.; You, H.; Zhang, H.; Wang, Z. Biomaterials 2013, 34, 5218–5225. doi:10.1016/j.biomaterials.2013.03.058 |

| 11. | Liu, Y.; Tu, D.; Zhu, H.; Li, R.; Luo, W.; Chen, X. Adv. Mater. 2010, 22, 3266. doi:10.1002/adma.201000128 |

| 12. | Wang, F.; Wang, J.; Liu, X. Angew. Chem. 2010, 49, 7456. doi:10.1002/anie.201003959 |

| 13. | Chen, D.; Lei, L.; Yang, A.; Wang, Z.; Wang, Y. Chem. Commun. 2012, 48, 5898–5900. doi:10.1039/c2cc32102e |

| 17. | Bogdan, N.; Vetrone, F.; Ozin, G. A.; Capobianco, J. A. Nano Lett. 2011, 11, 835–840. doi:10.1021/nl1041929 |

| 29. | Johnson, N. J. J.; Oakden, W.; Stanisz, G. J.; Scott Prosser, R.; van Veggel, F. C. J. M. Chem. Mater. 2011, 23, 3714–3722. doi:10.1021/cm201297x |

| 30. | Hou, Y.; Qiao, R.; Fang, F.; Wang, X.; Dong, C.; Liu, K.; Liu, C.; Liu, Z.; Lei, H.; Wang, F.; Gao, M. ACS Nano 2013, 7, 330–338. doi:10.1021/nn304837c |

| 11. | Liu, Y.; Tu, D.; Zhu, H.; Li, R.; Luo, W.; Chen, X. Adv. Mater. 2010, 22, 3266. doi:10.1002/adma.201000128 |

| 12. | Wang, F.; Wang, J.; Liu, X. Angew. Chem. 2010, 49, 7456. doi:10.1002/anie.201003959 |

| 27. | Wong, H.-T.; Vetrone, F.; Naccache, R.; Chan, H. L. W.; Hao, J.; Capobianco, J. A. J. Mater. Chem. 2011, 21, 16589. doi:10.1039/c1jm12796a |

| 28. | Baziulyte, D.; Karabanovas, V.; Stalnionis, M.; Jurciukonis, I.; Sakirzanovas, S. In Book of abstracts of the “Chemistry and Chemical Technology, International Conference of Lithuanian Society of Chemistry; 2016; p 150. |

| 37. | Ren, W.; Tian, G.; Jian, S.; Gu, Z.; Zhou, L.; Yan, L.; Jin, S.; Yin, W.; Zhao, Y. RSC Adv. 2012, 2, 7037–7041. doi:10.1039/c2ra20855e |

| 35. | Woźniak, A.; Noculak, A.; Gapiński, J.; Kociolek, D.; Boś-Liedke, A.; Zalewski, T.; Grześkowiak, B. F.; Kołodziejczak, A.; Jurga, S.; Banski, M.; Misiewicz, J.; Podhorodecki, A. RSC Adv. 2016, 6, 95633–95643. doi:10.1039/C6RA20415E |

| 36. | Guller, A. E.; Generalova, A. N.; Petersen, E. V.; Nechaev, A. V.; Trusova, I. A.; Landyshev, N. N.; Nadort, A.; Grebenik, E. A.; Deyev, S. M.; Shekhter, A. B.; Zvyagin, A. V. Nano Res. 2015, 8, 1546–1562. doi:10.1007/s12274-014-0641-6 |

| 11. | Liu, Y.; Tu, D.; Zhu, H.; Li, R.; Luo, W.; Chen, X. Adv. Mater. 2010, 22, 3266. doi:10.1002/adma.201000128 |

| 33. | Osman, O.; Zanini, L. F.; Frénéa-Robin, M.; Dumas-Bouchiat, F.; Dempsey, N. M.; Reyne, G.; Buret, F.; Haddour, N. Biomed. Microdevices 2012, 14, 947–954. doi:10.1007/s10544-012-9673-4 |

| 34. | Wang, S.-H.; Lee, C.-W.; Chiou, A.; Wei, P.-K. J. Nanobiotechnol. 2010, 8, 33. doi:10.1186/1477-3155-8-33 |

| 31. | Vetrone, F.; Naccache, R.; de la Fuente, A. J.; Sanz-Rodriguez, F.; Blazquez-Castro, A.; Rodriguez, E. M.; Jaque, D.; Solé, J. G.; Capobianco, J. A. Nanoscale 2010, 2, 495–498. doi:10.1039/B9NR00236G |

| 32. | Karabanovas, V.; Zitkus, Z.; Kuciauskas, D.; Rotomskis, R.; Valius, M. J. Biomed. Nanotechnol. 2014, 10, 775–786. doi:10.1166/jbn.2014.1770 |

© 2017 Baziulyte-Paulaviciene et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Nanotechnology terms and conditions: (http://www.beilstein-journals.org/bjnano)