Search results

Search for "roughness" in Full Text gives 472 result(s) in Beilstein Journal of Nanotechnology. Showing first 200.

Ultrathin hydrophobic films based on the metal organic framework UiO-66-COOH(Zr)

Beilstein J. Nanotechnol. 2019, 10, 654–665, doi:10.3762/bjnano.10.65

- position and cover MOF particles. Moreover, the presence of MOF particles significantly enhances the surface roughness and allows ultrathin, hydrophobic coverage to be obtained. Finally, it has been shown that the crystallinity and the porosity of the MOF remains almost unaltered in MOF/ODP films

- structure of the pure ODP films seems to be preserved in mixed MOF/ODP films and, in addition, MOF sMPs can be also observed. The presence of MOF particles significantly increases the roughness of the film (pure ODP LB film RMS values are close to 6 nm, while mixed films present RMS values between 40 and 60

- an almost vertical position, and MOF sMPs, covered by ODP molecules, distributed over the whole surface, providing an elevated roughness to the mixed films that significantly contributes to increase the value of the water contact angle. Moreover, the crystallinity of the MOF particles is preserved in

Topochemical engineering of composite hybrid fibers using layered double hydroxides and abietic acid

Beilstein J. Nanotechnol. 2019, 10, 589–605, doi:10.3762/bjnano.10.60

- increase the surface roughness of the fibers and yield good adhesion properties. Bleached and unbleached fibers, refined and unrefined, were used as starting materials to synthesize direct composites (AA + fiber), hybrid fibers (LDH + fiber) and composite hybrid fibers (AA + LDH + fiber). We expect that

Biomimetic synthesis of Ag-coated glasswing butterfly arrays as ultra-sensitive SERS substrates for efficient trace detection of pesticides

Beilstein J. Nanotechnol. 2019, 10, 578–588, doi:10.3762/bjnano.10.59

- successfully fabricated by magnetron sputtering. The thickness of the Ag nanofilms can be well controlled by adjusting the sputtering time. The Ag-G.b.-20 substrate with large-scale “hot spots” and an increased roughness shows the highest enhancement efficiency for CV molecules. The EF for Ag-G.b.-20 arrays is

Nanocomposite–parylene C thin films with high dielectric constant and low losses for future organic electronic devices

Beilstein J. Nanotechnol. 2019, 10, 428–441, doi:10.3762/bjnano.10.42

- modifies the film density as well as the degree of crystallinity and the size of parylene C crystallites. Moreover, silver is incorporated in the parylene matrix as an oxide phase. The average size of the Ag oxide nanoparticles is lower than 20 nm and influences the roughness of the NCPC films. Samples

- work [64]. The roughness of different NCPC samples was measured by AFM and displayed in Table 2. In the case of pure parylene films (samples K and O), the surface is relatively smooth and the roughness is around 10 nm. It has to be noted that the plasma-induced increase of the deposition rate does not

- change the film roughness. When Ag is incorporated in the parylene matrix, the films become increasingly rough with increasing Ag amount, the roughness increasing from 20–25 nm for samples A, B and D to more than 50 nm for samples C, E and F. Even if it has been previously shown that an increase in

Advanced scanning probe lithography using anatase-to-rutile transition to create localized TiO2 nanorods

Beilstein J. Nanotechnol. 2019, 10, 412–418, doi:10.3762/bjnano.10.40

- contrast, local light scattering, high-resolution surface roughness gradients or microchannels. This set of extensions for rutile TiO2 nanorod applications is a valuable toolkit for lab-on-a-chip devices [33][34][35]. Recently, we investigated the influence of rutile seed layers on the growth and shape of

- surface roughness of the anatase TiO2 film causes a dithering movement of the tip that broadens the line width. This effect disconnects the line width from the shape of the tip partly. The density of nanorods is controlled slightly with the number of repetitions. In Figure 4C, the density was increased

Biocompatible organic–inorganic hybrid materials based on nucleobases and titanium developed by molecular layer deposition

Beilstein J. Nanotechnol. 2019, 10, 399–411, doi:10.3762/bjnano.10.39

- for 15 minutes was measured by atomic force microscopy (AFM) (Figure 8). All as-deposited films exhibit high surface roughness; however, the roughness of the Ti-adenine film is caused by small islands appearing on an otherwise almost flat surface. After water treatment, the surface roughness decreases

- drastically for all three systems and leaves an almost flat surface, except for the Ti-uracil system, where holes with a distinct pattern were observed. This system was also studied more closely with SEM after water treatment (Figure 9a). This SEM image also shows a low surface roughness; however, there is no

Removal of toxic heavy metals from river water samples using a porous silica surface modified with a new β-ketoenolic host

Beilstein J. Nanotechnol. 2019, 10, 262–273, doi:10.3762/bjnano.10.25

- volume to 0.62 ± 0.01 cm3·g−1 for SiNL. The increase of SBET to 339.84 ± 2.01 m2·g−1 for SiNL is presumably due to the increasing surface roughness, as noticed by SEM imaging (Figure 2), or due to the pore plugging of the support by the ligand. Solid–liquid adsorption of metal ions by SiNL Effect of pH

Interaction of Te and Se interlayers with Ag or Au nanofilms in sandwich structures

Beilstein J. Nanotechnol. 2019, 10, 238–246, doi:10.3762/bjnano.10.22

- deposited with a Ge interlayer – they cannot be observed at angles greater than 2° for silver films and 4° for gold films. This indicates a much higher surface roughness than for the Ge-wetted films. Metal layers deposited on Se exhibit an even worse adhesion – there is almost no change in the grain size

- have segregated to the surface. The poor wetting (or even dewetting) of silver by Se and Te has one more attribute. The intensity of the modified Lorentz band [37] centered at 275–300 nm decreased while the intensity of the bands from 325 to 400 nm increased. The latter are connected to the roughness

- of the layer (so the intensity would naturally increase with increased roughness) [26], but also to the interband transitions at the L-point in the Brillouin zone, while the former is connected to the interband transitions at the X-point in the Brillouin zone [38][39]. As the carriers at the X-point

Sputtering of silicon nanopowders by an argon cluster ion beam

Beilstein J. Nanotechnol. 2019, 10, 135–143, doi:10.3762/bjnano.10.13

- target density. The energy dependence demonstrated an unusual non-monotonic behavior. At 17.3 keV a maximum of the sputtering yield was observed, which was more than forty times higher than that of the bulk Si. The surface roughness at low energy demonstrates a similar energy dependence with a maximum

- surface, with energy in the range of 10.4–69 keV and dose of 7.2 × 1014–2.3 × 1016 cluster/cm2 at room temperature. The sputtering depth and surface roughness RRMS (root mean squared roughness) were monitored by AFM with a Shimadzu SPM-9500 J3 device, operated in tapping mode with a measuring area of 7

- huge increase of the surface roughness after the bombardment, from an initial roughness RRMS = 6.7 nm up to a few hundreds of nanometers, which complicates the depth measurement by AFM. We explain the increase of the sputtering yield of the nanopowder sample, in comparison with the bulk Si, by the

Scanning probe microscopy for energy-related materials

Beilstein J. Nanotechnol. 2019, 10, 132–134, doi:10.3762/bjnano.10.12

- interfaces is therefore essential. Furthermore, these interface phenomena are strongly linked to material properties such as grain size, roughness, mechanical properties and work function. In an attempt to address the diversity of phenomena on the nanoscale, scanning probe microscopy (SPM) methods play an

Pull-off and friction forces of micropatterned elastomers on soft substrates: the effects of pattern length scale and stiffness

Beilstein J. Nanotechnol. 2019, 10, 79–94, doi:10.3762/bjnano.10.8

- . The decreased Eeff of a fibrillar geometry also leads to decreased contact stiffness [11] and higher conformability to substrate roughness [12]. The abovementioned effects of fibrillary geometries can be further enhanced with altering the pillar geometry. For example, Gorb et al. fabricated

- micropillars of 100 μm height and a stem diameter of 60 μm, terminated with a thin (2 μm) disc of 40 μm in diameter [11]. These so-called mushroom-shaped micropillars generated higher pull-off forces than flat-punch micropillars, a phenomenon attributed to a higher adaptability to substrate roughness due to

- microstructure is not considerably lower than that of coarser microstructure [14]. Greiner et al. found that with increasing aspect ratio of micropattern features, their compliance increases, resulting in a better conformability to substrate roughness [20]. Hierarchical geometries, that is, architectures with

A comparison of tarsal morphology and traction force in the two burying beetles Nicrophorus nepalensis and Nicrophorus vespilloides (Coleoptera, Silphidae)

Beilstein J. Nanotechnol. 2019, 10, 47–61, doi:10.3762/bjnano.10.5

- attachment with respect to various surface properties was investigated by using a 2 × 3 experimental design. Traction force was measured for two different surface energies (hydrophilic vs hydrophobic) varying in roughness from smooth to micro-rough to rough. Nanotribometric tests on single legs were also

- smooth and rough surfaces with clipped claws. Both species demonstrated poor traction forces on micro-rough surfaces. Results concerning the impact of surface polarity were inconclusive, whereas roughness more strongly affected the attachment performance in both species. Nanotribometric analyses of the

- . nepalensis, have recently been proposed as a potential reason for these observed differences, especially on smooth surfaces [3]. Surface roughness is known to affect attachment performance in insects, spiders and geckos [9][10][11][12][13][14], whereby often so-called critical roughness values have been

Zn/F-doped tin oxide nanoparticles synthesized by laser pyrolysis: structural and optical properties

Beilstein J. Nanotechnol. 2019, 10, 9–21, doi:10.3762/bjnano.10.2

- bandgap, grain size, oxygen deficiency, surface roughness, and impurity centers [21]. The direct bandgaps of the nanoparticles were determined from the Tauc relation [50][51][52] given by: where α is the absorption coefficient, A is a constant, hν is the photon energy, n is an index that can take

Contact splitting in dry adhesion and friction: reducing the influence of roughness

Beilstein J. Nanotechnol. 2019, 10, 1–8, doi:10.3762/bjnano.10.1

- , stronger adhesion, and a more uniform stress distribution with higher tolerance to defects. However, while it is widely believed that contact splitting helps to mitigate the negative effects of roughness on adhesion- and friction-based attachment, no decisive experimental validation of this hypothesis has

- been performed so far for thin-film-based adhesives. To this end, we report on the behavior of original and split, wall-shaped adhesive microstructures on different surfaces ranging across four orders of magnitude in roughness. Our results clearly demonstrate that the adhesion- and friction-driven

- attachment of the wall-shaped microstructure degrades, regardless of the surface waviness, when the surface roughness increases. Second, splitting the wall-shaped microstructure indeed helps to mitigate the negative effect of the increasing surface unevenness by allowing the split microstructure to adapt

Electrolyte tuning in dye-sensitized solar cells with N-heterocyclic carbene (NHC) iron(II) sensitizers

Beilstein J. Nanotechnol. 2018, 9, 3069–3078, doi:10.3762/bjnano.9.285

- electrolyte. The constant phase element was employed in this study because of the surface roughness [51][52]. We chose to focus on understanding the observations involving the MBI additive, and EIS studies were conducted for electrolytes E2b, E2c and E2e. Measurements and curve fitting were made for duplicate

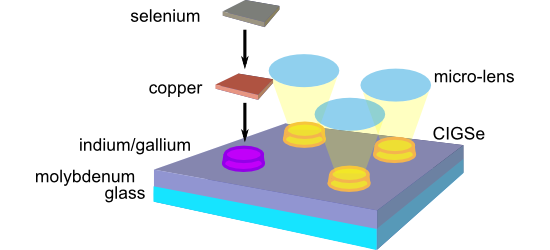

Femtosecond laser-assisted fabrication of chalcopyrite micro-concentrator photovoltaics

Beilstein J. Nanotechnol. 2018, 9, 3025–3038, doi:10.3762/bjnano.9.281

- indium accumulation occurs at the spot centers, which exhibit the highest roughness, indicates that the island growth is driven by the condensation of indium in the capillary-like structures. For the desired growth of flat and homogeneous indium islands, the data shows that a moderate roughening of the

- , left column, top) with a depth of about 300 nm in the center and a roughness Ra of about 25 nm averaged over the whole area (Figure 6, left column, bottom). In general, the diameter of indium islands, the geometrical aspect ratio and the nucleation density of indium islands all depend on the deposition

Ternary nanocomposites of reduced graphene oxide, polyaniline and hexaniobate: hierarchical architecture and high polaron formation

Beilstein J. Nanotechnol. 2018, 9, 2936–2946, doi:10.3762/bjnano.9.272

- shown in Figure 2. AFM images of the rGO-25 sample show particles of well-defined edges and size ranging from 5 to 25 μm. The height profile (Figure 2, right column) shows thickness of ca. 1.0 nm and a surface roughness (RMS) of 0.24 nm for the rGO flake. These results clearly indicate the presence of

- hand, this nanocomposite presents several creases and folds and, more interestingly, shows higher flake thickness and higher surface roughness (ca. 10 and ca. 4.0 nm, respectively). These results clearly indicate that the deposition of PANI on rGO flakes induces an increase of the surface heterogeneity

- . Analogously, the AFM images of rGO/PANI/hexNb also indicate the presence of large flakes in the nanocomposite and, as shown by the 5 μm scan-size image (and corresponding height profile), the flake thickness and surface roughness are ca. 19 and ca. 7.2 nm, respectively. These results clearly indicate that the

In situ characterization of nanoscale contaminations adsorbed in air using atomic force microscopy

Beilstein J. Nanotechnol. 2018, 9, 2925–2935, doi:10.3762/bjnano.9.271

- , about 1 nm mean roughness, see for example [47]). A few higher structures (3–4 nm height) can be recognized in the topographic images. Interestingly only one of these higher structures gives a contrast in the contact-potential image (Figure 2Ce, −90 mV as compared to +70 mV for the substrate), otherwise

Site-controlled formation of single Si nanocrystals in a buried SiO2 matrix using ion beam mixing

Beilstein J. Nanotechnol. 2018, 9, 2883–2892, doi:10.3762/bjnano.9.267

- fluence is too small (see Figure 3a), insufficient mixing occurs and consequently only poorly defined NCs are formed. A too high fluence, on the other hand, will result in Si NC formation, but the interface roughness increases (see Figure 3b). The phase separation process during post-irradiation thermal

- beam mixing conditions (170 Si+ nm−2 at 60 keV) a too small TB (1323 K, 30 s) results in incomplete (see Figure 3c) or no NC formation while a too high TB (1323 K, 240 s) will result in the decomposition of the earlier formed NCs and an increased interface roughness (see Figure 3d). Complete

Charged particle single nanometre manufacturing

Beilstein J. Nanotechnol. 2018, 9, 2855–2882, doi:10.3762/bjnano.9.266

- the precursor. At such high resolution, the line edge roughness (LER) is an important parameter. While it is reported as being considerably smaller than the line width, it would be of interest to study it further to determine the origin of LER and its dependence on experimental parameters and

Controlling surface morphology and sensitivity of granular and porous silver films for surface-enhanced Raman scattering, SERS

Beilstein J. Nanotechnol. 2018, 9, 2813–2831, doi:10.3762/bjnano.9.263

- plasmas on the surface morphology of thin silver films. It was found that different surface structures and different degrees of surface roughness could be obtained by a systematic variation of the plasma type and condition as well as plasma power and treatment time. The differently roughened silver

- investigation of the effect of different rf plasmas on sputtered silver surfaces to determine the potential of plasma treatment in a controlled increase of the surface roughness of silver as well as the formation of hot spots on the silver surface for the use in SERS. To the best of our knowledge this is the

- silver films were characterized using atomic force microscopy (AFM) in contact mode on a CP-II AFM (Bruker-Veeco) with SiC cantilevers to determine the topography and surface roughness (root mean square roughness, Rq). Scanning electron microscopy (SEM) of the silver films was performed on a Philips XL

Biomimetic surface structures in steel fabricated with femtosecond laser pulses: influence of laser rescanning on morphology and wettability

Beilstein J. Nanotechnol. 2018, 9, 2802–2812, doi:10.3762/bjnano.9.262

- the laser beam many times over the same sample area, i.e., laser rescanning. From a physical point of view, one fundamental difference between a single scan and multiple rescans is that the incident laser pulse during the second and subsequent scans “sees” not only a higher surface roughness, but in

- . Interestingly, the morphology of these very deep fields is rather smooth, which holds promise for low roughness material processing applications. Moreover, we have analyzed the SEM images shown in Figure 2 in terms of number density of structure units using the outlining of a structural unit given in the same

- rough surfaces, an important question is whether the liquid on top completely fills up the roughness grooves (homogeneous wetting regime) or leaves air inclusions entrapped inside the grooves (homogeneous wetting regime), which strongly affects the apparent contact angle [44][45]. For these two regimes

Low cost tips for tip-enhanced Raman spectroscopy fabricated by two-step electrochemical etching of 125 µm diameter gold wires

Beilstein J. Nanotechnol. 2018, 9, 2718–2729, doi:10.3762/bjnano.9.254

- addition, all the above-cited methods require very expensive lab equipment and skilled operators. Electrochemical etching, although suffering from surface roughness issues (mainly for silver), reproducibility issues and lack of tip dimension control, is a technique that is easy to implement, accessible to

- diameter of 125 µm (blue line, upper taper) and of 77 µm (orange line, lower taper). (a) SEM image of an etched tip (t1 = 20 s, V1 = 5 VDC, t2 = 75 s, V2 = 2.1 VDC) and details on its apex (b), showing the roughness of the gold surface. Sharp protrusions (r ≈ 15 nm) can occur at the apex of such blunt tips

Disorder in H+-irradiated HOPG: effect of impinging energy and dose on Raman D-band splitting and surface topography

Beilstein J. Nanotechnol. 2018, 9, 2708–2717, doi:10.3762/bjnano.9.253

- techniques is advantageous in order to gain a better insight into the origin of defects. Atomic force microscopy (AFM) can help to reveal an increase in the graphene/graphite surface roughness, which has been correlated with the disorder generated by increasing hydrogen irradiation doses [21][22][23

Optimization of Mo/Cr bilayer back contacts for thin-film solar cells

Beilstein J. Nanotechnol. 2018, 9, 2700–2707, doi:10.3762/bjnano.9.252

- different deposition powers and working pressures. Good adhesion to the SLG substrate has been achieved by means of an ultra-thin Cr layer under the Mo layer. By optimizing the deposition conditions we achieved low surface roughness, high optical reflectance and low sheet resistivity while we could decrease

- conditions and was set to obtain Mo layers with 600 nm thickness. Film characterization The film thickness measurements were conducted using a Bruker Dektak stylus profiler. Morphology studies and surface roughness measurements were carried out using a JEOL 7001F scanning electron microscope (SEM) and a

- morphology are also confirmed by AFM images (see Supporting Information File 1). AFM roughness analysis (Figure 4) reveals an increase of the surface roughness with the sputtering power. Surface roughness is also directly proportional to the working pressure. The average roughness increases from 1.61 to 3.06