Abstract

Herein we report the syntheses of two porous hyper-crosslinked polymers (HCPs) via thiol–yne reaction with rigid tetrahedral and pseudo-octahedral core structures. Sorption measurements with nitrogen gas at 77 K revealed BET-surface areas up to 650 m²/g. Those networks also showed a high thermal stability as well as insolubility in common organic solvents.

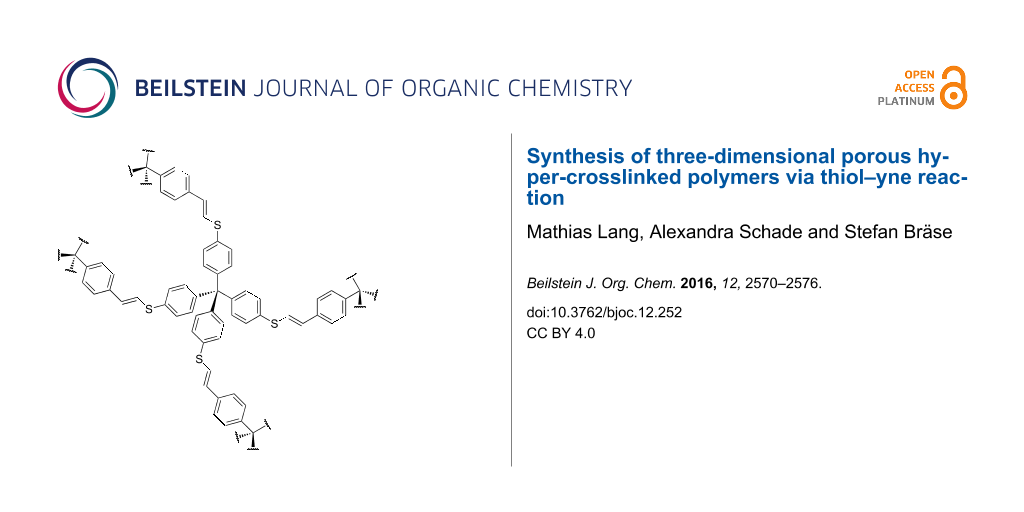

Graphical Abstract

Introduction

The synthesis of different organic networks has been previously reported. Among them, especially tetraphenylmethane cores are widely employed in the synthesis of covalent organic frameworks (COFs) [1,2], porous aromatic frameworks (PAFs) [3], porous polymer networks (PPNs) [4] and hyper-crosslinked polymers (HCPs) [5]. These organic networks are, due to their large surface areas, of interest in gas storage [6], gas separation [7] and catalysis [8-10]. For the synthesis of organic networks, many different reaction types such as condensation reactions [11,12], coupling reactions [3] and click reactions [5,13] have been reported. Herein we present the synthesis of porous, three-dimensional tetraphenylmethane-based networks by another click reaction, the thiol–yne reaction [14-19]. This reaction type has been known for several decades and relived a renaissance in the past decade, especially in material sciences [20-32], due to its mild, and metal-free reaction conditions, high yields and easy purification.

Results and Discussion

The first network shown here was synthesized by crosslinking the two tetrahedral tetraphenylmethane core structures 1 and 2 via the radical-mediated thiol–yne reaction using AIBN as initiator. The second network was synthesized with tetraphenylmethane core 2 and the pseudo-octahedral bistritylbenzene core 4 under the same reaction conditions (Scheme 1). The resulting HCPs 3 and 5 were obtained in 90% and 95% yields, respectively. Both HCPs showed complete insolubility in common organic solvents. The monomers 1 [13], 2 [33] and 4 [34] were synthesized according to literature procedures.

Scheme 1: Syntheses of the HCPs 3 and 5 via thiol–yne reaction.

Scheme 1: Syntheses of the HCPs 3 and 5 via thiol–yne reaction.

The structures of HCPs 3 and 5 were analysed by elemental analysis and IR spectroscopy. The IR spectra of the monomers show the characteristic vibration bands of alkynes at 3300 cm−1 and the vibration band at 2550 cm−1 of thiols, respectively. However, these characteristic bands are nearly extinguished in the IR spectra of the HCPs showing a high ratio of crosslinking for these reactions. In addition, the vibration bands of the HCPs at 3000 cm−1 correspond to the presence of olefinic bonds, which is in accordance to a monoaddition of a thiol to an alkyne. The absence of a vibration band at 2900 cm−1 reveals that there are no saturated fragments in the HCPs, again showing that only a monoaddition and no further addition to the corresponding thioacetal or 1,2-disulfide took place (Figure 1 and Figure 2).

![[1860-5397-12-252-1]](/bjoc/content/figures/1860-5397-12-252-1.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 1: IR-spectra of tetrathiol 2 (blue), tetraalkyne 1 (red) and HCP 3 (black).

Figure 1: IR-spectra of tetrathiol 2 (blue), tetraalkyne 1 (red) and HCP 3 (black).

![[1860-5397-12-252-2]](/bjoc/content/figures/1860-5397-12-252-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: IR-spectra of tetrathiol 2 (blue), hexaalkyne 4 (red) and HCP 3 (black).

Figure 2: IR-spectra of tetrathiol 2 (blue), hexaalkyne 4 (red) and HCP 3 (black).

The elemental analyses (Table 1) of networks 3 and 5 showed equimolar turnover regarding the number of functional groups of the monomers. Further, TGA measurements showed a high thermal stability of the HCPs. The TGA curves of HCP 3 and 5 are shown in Supporting Information File 1, Figures S5 and S6.

The SEM pictures (Figure 3) show the amorphous character of the HCPs, which is consistent with the PXRD measurements (see Supporting Information File 1, Figures S3 and S4). The SEM pictures also reveal that HCP 3 consists of particles in the micrometer range while the particle size of HCP 5 is in the sub-micrometre area.

![[1860-5397-12-252-3]](/bjoc/content/figures/1860-5397-12-252-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: SEM images of HCP 3 (left) and HCP 5 (right).

Figure 3: SEM images of HCP 3 (left) and HCP 5 (right).

Furthermore, adsorption measurements of HCPs 3 and 5 were carried out with nitrogen gas at 77 K after pre-drying for 16 h at 80 °C in vacuum. Both HCPs showed BET-surface areas >400 m2/g and the values of the specific surface area and cumulative volumes of the HCPs are collected in Table 2. The corresponding adsorption isotherms are depicted in Figure 4. The strong slope of the isotherms at low relative pressures indicates a permanent porous character of the materials. Also the step around p/p0 = 0.5 at desorption isotherms (Supporting Information File 1, Figures S1 and S2) indicates the mesoporous character of HCPs 3 and 5. The low-pressure hysteresis is most probable due to swelling effects or ill-connected pores. The pore-size distributions of HCPs 3 and 5 both show a broad distribution in the microporous scale as well as in the mesoporous scale. These findings also point out that both HCPs have amorphous character as the networks are built up by an irreversible reaction leading to kinetically controlled networks with different sizes of the pores, which is in accordance with the PXRD and SEM measurements stated above. The pore-size distributions of HCPs 3 and 5 are illustrated in Supporting Information File 1 (Figure S8 and S9, respectively).

Table 2: Data of adsorption measurements of HCPs 3 and 5.

| HCP |

Specific surface areaa (BET)

[m²/g] |

Specific surface areaa (Langmuir)

[m²/g] |

Cumulative volumeb

[cm³/g] |

|---|---|---|---|

| 3 | 470 | 696 | 0.314 |

| 5 | 650 | 989 | 0.510 |

aSurface areas were calculated at a relative pressure range of p/p0 = 0.05–0.3. bCumulative volumes were calculated at a relative pressure of p/p0 = 0.35–0.95 using the Horvat & Kavazoe method.

Figure 4: Adsorption isotherms of HCP 3 (green) and HCP 5 (blue) with nitrogen at 77 K. Desorption isotherms are not shown for the sake of improved clarity; they can be viewed in Supporting Information File 1, Figures S1 and S2.

Figure 4: Adsorption isotherms of HCP 3 (green) and HCP 5 (blue) with nitrogen at 77 K. Desorption isotherms ...

Conclusion

Herein we synthesised amorphous porous tetraphenylmethane-based organic hyper-crosslinked polymers (HCPs) through the thiol–yne reaction. The use of this versatile method reveals advantages such as high yields, cost effectiveness and metal-free crosslinking reaction conditions. The obtained HCPs showed BET surface areas up to 650 m²/g and are insoluble in common organic solvents. The characterisation of the networks was performed using IR spectroscopy, elemental analysis, thermogravimetric analysis (TGA), scanning electron microscopy (SEM), powder X-ray diffraction (PXRD) and adsorption measurements using nitrogen at 77 K.

Supporting Information

| Supporting Information File 1: Experimental procedures and additional measurements. | ||

| Format: PDF | Size: 600.4 KB | Download |

References

-

El-Kaderi, H. M.; Hunt, J. R.; Mendoza-Cortés, J. L.; Côté, A. P.; Taylor, R. E.; O’Keeffe, M.; Yaghi, O. M. Science 2007, 316, 268–272. doi:10.1126/science.1139915

Return to citation in text: [1] -

Uribe-Romo, F. J.; Hunt, J. R.; Furukawa, H.; Klöck, C.; O’Keeffe, M.; Yaghi, O. M. J. Am. Chem. Soc. 2009, 131, 4570–4571. doi:10.1021/ja8096256

Return to citation in text: [1] -

Ben, T.; Ren, H.; Ma, S.; Cao, D.; Lan, J.; Jing, X.; Wang, W.; Xu, J.; Deng, F.; Simmons, J. M.; Qiu, S.; Zhu, G. Angew. Chem., Int. Ed. 2009, 48, 9457–9460. doi:10.1002/anie.200904637

Return to citation in text: [1] [2] -

Lu, W.; Yuan, D.; Zhao, D.; Schilling, C. I.; Plietzsch, O.; Muller, T.; Bräse, S.; Guenther, J.; Blümel, J.; Krishna, R.; Li, Z.; Zhou, H.-C. Chem. Mater. 2010, 22, 5964–5972. doi:10.1021/cm1021068

Return to citation in text: [1] -

Plietzsch, O.; Schilling, C. I.; Grab, T.; Grage, S. L.; Ulrich, A. S.; Comotti, A.; Sozzani, P.; Muller, T.; Bräse, S. New J. Chem. 2011, 35, 1577–1581. doi:10.1039/c1nj20370c

Return to citation in text: [1] [2] -

Ben, T.; Pei, C.; Zhang, D.; Xu, J.; Deng, F.; Jing, X.; Qiu, S. Energy Environ. Sci. 2011, 4, 3991–3999. doi:10.1039/c1ee01222c

Return to citation in text: [1] -

Lindemann, P.; Tsotsalas, M.; Shishatskiy, S.; Abetz, V.; Krolla-Sidenstein, P.; Azucena, C.; Monnereau, L.; Beyer, A.; Gölzhäuser, A.; Mugnaini, V.; Gliemann, H.; Bräse, S.; Wöll, C. Chem. Mater. 2014, 26, 7189–7193. doi:10.1021/cm503924h

Return to citation in text: [1] -

Ma, P.; Lv, L.; Zhang, M.; Yuan, Q.; Cao, J.; Zhu, C. J. Porous Mater. 2015, 22, 1567–1571. doi:10.1007/s10934-015-0039-1

Return to citation in text: [1] -

Kaur, P.; Hupp, J. T.; Nguyen, S. T. ACS Catal. 2011, 1, 819–835. doi:10.1021/cs200131g

Return to citation in text: [1] -

Zhang, K.; Farha, O. K.; Hupp, J. T.; Nguyen, S. T. ACS Catal. 2015, 5, 4859–4866. doi:10.1021/acscatal.5b01388

Return to citation in text: [1] -

Rabbani, M. G.; Sekizkardes, A. K.; Kahveci, Z.; Reich, T. E.; Ding, R.; El-Kaderi, H. M. Chem. – Eur. J. 2013, 19, 3324–3328. doi:10.1002/chem.201203753

Return to citation in text: [1] -

Côté, A. P.; Benin, A. I.; Ockwig, N. W.; O’Keeffe, M.; Matzger, A. J.; Yaghi, O. M. Science 2005, 310, 1166–1170. doi:10.1126/science.1120411

Return to citation in text: [1] -

Pandey, P.; Farha, O. K.; Spokoyny, A. M.; Mirkin, C. A.; Kanatzidis, M. G.; Hupp, J. T.; Nguyen, S. T. J. Mater. Chem. 2011, 21, 1700–1703. doi:10.1039/c0jm03483e

Return to citation in text: [1] [2] -

Lowe, A. B. Polymer 2014, 55, 5517–5549. doi:10.1016/j.polymer.2014.08.015

Return to citation in text: [1] -

Massi, A.; Nanni, D. Org. Biomol. Chem. 2012, 10, 3791–3807. doi:10.1039/c2ob25217a

Return to citation in text: [1] -

Griebenow, N.; Bräse, S.; Dilmac, A. M. RSC Adv. 2015, 5, 54301–54303. doi:10.1039/C5RA08787B

Return to citation in text: [1] -

Hoogenboom, R. Angew. Chem., Int. Ed. 2010, 49, 3415–3417. doi:10.1002/anie.201000401

Return to citation in text: [1] -

Feng, W.; Li, L.; Ueda, E.; Li, J.; Heißler, S.; Welle, A.; Trapp, O.; Levkin, P. A. Adv. Mater. Interfaces 2014, 1, 1400269. doi:10.1002/admi.201400269

Return to citation in text: [1] -

Quick, A. S.; de los Santos Pereira, A.; Bruns, M.; Bückmann, T.; Rodriguez-Emmenegger, C.; Wegener, M.; Barner-Kowollik, C. Adv. Funct. Mater. 2015, 25, 3735–3744. doi:10.1002/adfm.201500683

Return to citation in text: [1] -

Al Samad, A.; Bakkour, Y.; Fanny, C.; El Omar, F.; Coudane, J.; Nottelet, B. Polym. Chem. 2015, 6, 5093–5102. doi:10.1039/C5PY00391A

Return to citation in text: [1] -

Chen, C.; Xu, H.; Qian, Y.-C.; Huang, X.-J. RSC Adv. 2015, 5, 15909–15915. doi:10.1039/C4RA14012E

Return to citation in text: [1] -

Durham, O. Z.; Norton, H. R.; Shipp, D. A. RSC Adv. 2015, 5, 66757–66766. doi:10.1039/C5RA12553G

Return to citation in text: [1] -

Lee, H.; Kim, H.; Choi, T. J.; Park, H. W.; Chang, J. Y. Chem. Commun. 2015, 51, 9805–9808. doi:10.1039/C5CC02269J

Return to citation in text: [1] -

Martella, D.; Parmeggiani, C.; Wiersma, D. S.; Piñol, M.; Oriol, L. J. Mater. Chem. C 2015, 3, 9003–9010. doi:10.1039/C5TC01290B

Return to citation in text: [1] -

Pötzsch, R.; Stahl, B. C.; Komber, H.; Hawker, C. J.; Voit, B. I. Polym. Chem. 2014, 5, 2911–2921. doi:10.1039/c3py01740k

Return to citation in text: [1] -

Sprafke, J. K.; Spruell, J. M.; Mattson, K. M.; Montarnal, D.; McGrath, A. J.; Pötzsch, R.; Miyajima, D.; Hu, J.; Latimer, A. A.; Voit, B. I.; Aida, T.; Hawker, C. J. J. Polym. Sci., Part A: Polym. Chem. 2015, 53, 319–326. doi:10.1002/pola.27345

Return to citation in text: [1] -

Sardo, C.; Nottelet, B.; Triolo, D.; Giammona, G.; Garric, X.; Lavigne, J.-P.; Cavallaro, G.; Coudane, J. Biomacromolecules 2014, 15, 4351–4362. doi:10.1021/bm5013772

Return to citation in text: [1] -

van Hensbergen, J. A.; Burford, R. P.; Lowe, A. B. Polym. Chem. 2014, 5, 5339–5349. doi:10.1039/C4PY00604F

Return to citation in text: [1] -

Wei, Q.; Pötzsch, R.; Komber, H.; Pospiech, D.; Voit, B. Polymer 2014, 55, 5600–5607. doi:10.1016/j.polymer.2014.07.030

Return to citation in text: [1] -

Yao, B.; Mei, J.; Li, J.; Wang, J.; Wu, H.; Sun, J. Z.; Qin, A.; Tang, B. Z. Macromolecules 2014, 47, 1325–1333. doi:10.1021/ma402559a

Return to citation in text: [1] -

Zhao, B.; Zheng, Y.; Weng, Z.; Cai, S.; Gao, C. Polym. Chem. 2015, 6, 3747–3753. doi:10.1039/C5PY00307E

Return to citation in text: [1] -

Zuo, Y.; Wang, D.; Zhang, J.; Feng, S. RSC Adv. 2014, 4, 62827–62834. doi:10.1039/C4RA13620A

Return to citation in text: [1] -

Plietzsch, O.; Schade, A.; Hafner, A.; Huuskonen, J.; Rissanen, K.; Nieger, M.; Muller, T.; Bräse, S. Eur. J. Org. Chem. 2013, 283–299. doi:10.1002/ejoc.201201162

Return to citation in text: [1] -

Monnereau, L.; Nieger, M.; Muller, T.; Bräse, S. Adv. Funct. Mater. 2014, 24, 1054–1058. doi:10.1002/adfm.201302483

Return to citation in text: [1]

| 1. | El-Kaderi, H. M.; Hunt, J. R.; Mendoza-Cortés, J. L.; Côté, A. P.; Taylor, R. E.; O’Keeffe, M.; Yaghi, O. M. Science 2007, 316, 268–272. doi:10.1126/science.1139915 |

| 2. | Uribe-Romo, F. J.; Hunt, J. R.; Furukawa, H.; Klöck, C.; O’Keeffe, M.; Yaghi, O. M. J. Am. Chem. Soc. 2009, 131, 4570–4571. doi:10.1021/ja8096256 |

| 6. | Ben, T.; Pei, C.; Zhang, D.; Xu, J.; Deng, F.; Jing, X.; Qiu, S. Energy Environ. Sci. 2011, 4, 3991–3999. doi:10.1039/c1ee01222c |

| 34. | Monnereau, L.; Nieger, M.; Muller, T.; Bräse, S. Adv. Funct. Mater. 2014, 24, 1054–1058. doi:10.1002/adfm.201302483 |

| 5. | Plietzsch, O.; Schilling, C. I.; Grab, T.; Grage, S. L.; Ulrich, A. S.; Comotti, A.; Sozzani, P.; Muller, T.; Bräse, S. New J. Chem. 2011, 35, 1577–1581. doi:10.1039/c1nj20370c |

| 4. | Lu, W.; Yuan, D.; Zhao, D.; Schilling, C. I.; Plietzsch, O.; Muller, T.; Bräse, S.; Guenther, J.; Blümel, J.; Krishna, R.; Li, Z.; Zhou, H.-C. Chem. Mater. 2010, 22, 5964–5972. doi:10.1021/cm1021068 |

| 13. | Pandey, P.; Farha, O. K.; Spokoyny, A. M.; Mirkin, C. A.; Kanatzidis, M. G.; Hupp, J. T.; Nguyen, S. T. J. Mater. Chem. 2011, 21, 1700–1703. doi:10.1039/c0jm03483e |

| 3. | Ben, T.; Ren, H.; Ma, S.; Cao, D.; Lan, J.; Jing, X.; Wang, W.; Xu, J.; Deng, F.; Simmons, J. M.; Qiu, S.; Zhu, G. Angew. Chem., Int. Ed. 2009, 48, 9457–9460. doi:10.1002/anie.200904637 |

| 33. | Plietzsch, O.; Schade, A.; Hafner, A.; Huuskonen, J.; Rissanen, K.; Nieger, M.; Muller, T.; Bräse, S. Eur. J. Org. Chem. 2013, 283–299. doi:10.1002/ejoc.201201162 |

| 3. | Ben, T.; Ren, H.; Ma, S.; Cao, D.; Lan, J.; Jing, X.; Wang, W.; Xu, J.; Deng, F.; Simmons, J. M.; Qiu, S.; Zhu, G. Angew. Chem., Int. Ed. 2009, 48, 9457–9460. doi:10.1002/anie.200904637 |

| 14. | Lowe, A. B. Polymer 2014, 55, 5517–5549. doi:10.1016/j.polymer.2014.08.015 |

| 15. | Massi, A.; Nanni, D. Org. Biomol. Chem. 2012, 10, 3791–3807. doi:10.1039/c2ob25217a |

| 16. | Griebenow, N.; Bräse, S.; Dilmac, A. M. RSC Adv. 2015, 5, 54301–54303. doi:10.1039/C5RA08787B |

| 17. | Hoogenboom, R. Angew. Chem., Int. Ed. 2010, 49, 3415–3417. doi:10.1002/anie.201000401 |

| 18. | Feng, W.; Li, L.; Ueda, E.; Li, J.; Heißler, S.; Welle, A.; Trapp, O.; Levkin, P. A. Adv. Mater. Interfaces 2014, 1, 1400269. doi:10.1002/admi.201400269 |

| 19. | Quick, A. S.; de los Santos Pereira, A.; Bruns, M.; Bückmann, T.; Rodriguez-Emmenegger, C.; Wegener, M.; Barner-Kowollik, C. Adv. Funct. Mater. 2015, 25, 3735–3744. doi:10.1002/adfm.201500683 |

| 11. | Rabbani, M. G.; Sekizkardes, A. K.; Kahveci, Z.; Reich, T. E.; Ding, R.; El-Kaderi, H. M. Chem. – Eur. J. 2013, 19, 3324–3328. doi:10.1002/chem.201203753 |

| 12. | Côté, A. P.; Benin, A. I.; Ockwig, N. W.; O’Keeffe, M.; Matzger, A. J.; Yaghi, O. M. Science 2005, 310, 1166–1170. doi:10.1126/science.1120411 |

| 20. | Al Samad, A.; Bakkour, Y.; Fanny, C.; El Omar, F.; Coudane, J.; Nottelet, B. Polym. Chem. 2015, 6, 5093–5102. doi:10.1039/C5PY00391A |

| 21. | Chen, C.; Xu, H.; Qian, Y.-C.; Huang, X.-J. RSC Adv. 2015, 5, 15909–15915. doi:10.1039/C4RA14012E |

| 22. | Durham, O. Z.; Norton, H. R.; Shipp, D. A. RSC Adv. 2015, 5, 66757–66766. doi:10.1039/C5RA12553G |

| 23. | Lee, H.; Kim, H.; Choi, T. J.; Park, H. W.; Chang, J. Y. Chem. Commun. 2015, 51, 9805–9808. doi:10.1039/C5CC02269J |

| 24. | Martella, D.; Parmeggiani, C.; Wiersma, D. S.; Piñol, M.; Oriol, L. J. Mater. Chem. C 2015, 3, 9003–9010. doi:10.1039/C5TC01290B |

| 25. | Pötzsch, R.; Stahl, B. C.; Komber, H.; Hawker, C. J.; Voit, B. I. Polym. Chem. 2014, 5, 2911–2921. doi:10.1039/c3py01740k |

| 26. | Sprafke, J. K.; Spruell, J. M.; Mattson, K. M.; Montarnal, D.; McGrath, A. J.; Pötzsch, R.; Miyajima, D.; Hu, J.; Latimer, A. A.; Voit, B. I.; Aida, T.; Hawker, C. J. J. Polym. Sci., Part A: Polym. Chem. 2015, 53, 319–326. doi:10.1002/pola.27345 |

| 27. | Sardo, C.; Nottelet, B.; Triolo, D.; Giammona, G.; Garric, X.; Lavigne, J.-P.; Cavallaro, G.; Coudane, J. Biomacromolecules 2014, 15, 4351–4362. doi:10.1021/bm5013772 |

| 28. | van Hensbergen, J. A.; Burford, R. P.; Lowe, A. B. Polym. Chem. 2014, 5, 5339–5349. doi:10.1039/C4PY00604F |

| 29. | Wei, Q.; Pötzsch, R.; Komber, H.; Pospiech, D.; Voit, B. Polymer 2014, 55, 5600–5607. doi:10.1016/j.polymer.2014.07.030 |

| 30. | Yao, B.; Mei, J.; Li, J.; Wang, J.; Wu, H.; Sun, J. Z.; Qin, A.; Tang, B. Z. Macromolecules 2014, 47, 1325–1333. doi:10.1021/ma402559a |

| 31. | Zhao, B.; Zheng, Y.; Weng, Z.; Cai, S.; Gao, C. Polym. Chem. 2015, 6, 3747–3753. doi:10.1039/C5PY00307E |

| 32. | Zuo, Y.; Wang, D.; Zhang, J.; Feng, S. RSC Adv. 2014, 4, 62827–62834. doi:10.1039/C4RA13620A |

| 8. | Ma, P.; Lv, L.; Zhang, M.; Yuan, Q.; Cao, J.; Zhu, C. J. Porous Mater. 2015, 22, 1567–1571. doi:10.1007/s10934-015-0039-1 |

| 9. | Kaur, P.; Hupp, J. T.; Nguyen, S. T. ACS Catal. 2011, 1, 819–835. doi:10.1021/cs200131g |

| 10. | Zhang, K.; Farha, O. K.; Hupp, J. T.; Nguyen, S. T. ACS Catal. 2015, 5, 4859–4866. doi:10.1021/acscatal.5b01388 |

| 7. | Lindemann, P.; Tsotsalas, M.; Shishatskiy, S.; Abetz, V.; Krolla-Sidenstein, P.; Azucena, C.; Monnereau, L.; Beyer, A.; Gölzhäuser, A.; Mugnaini, V.; Gliemann, H.; Bräse, S.; Wöll, C. Chem. Mater. 2014, 26, 7189–7193. doi:10.1021/cm503924h |

| 5. | Plietzsch, O.; Schilling, C. I.; Grab, T.; Grage, S. L.; Ulrich, A. S.; Comotti, A.; Sozzani, P.; Muller, T.; Bräse, S. New J. Chem. 2011, 35, 1577–1581. doi:10.1039/c1nj20370c |

| 13. | Pandey, P.; Farha, O. K.; Spokoyny, A. M.; Mirkin, C. A.; Kanatzidis, M. G.; Hupp, J. T.; Nguyen, S. T. J. Mater. Chem. 2011, 21, 1700–1703. doi:10.1039/c0jm03483e |

© 2016 Lang et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)