Abstract

The most common variant of fullerene core functionalization is the [2 + 1] cycloaddition process. Of these, reactions leading to methanofullerenes are the most promising. They are synthesized in two main reactions: nucleophilic cyclopropanation according to the Bingel method and thermal addition of diazo compounds. This present review summarizes the material on the synthesis of monofunctionalized methanofullerenes – analogues of [60]PCBM – based on various diazo compounds. The main cyclopropanating agents for the synthesis of monosubstituted methanofullerenes, the optimal conditions and the mechanism of the [2 + 1] cycloaddition, as well as the practical application of the target products are analyzed.

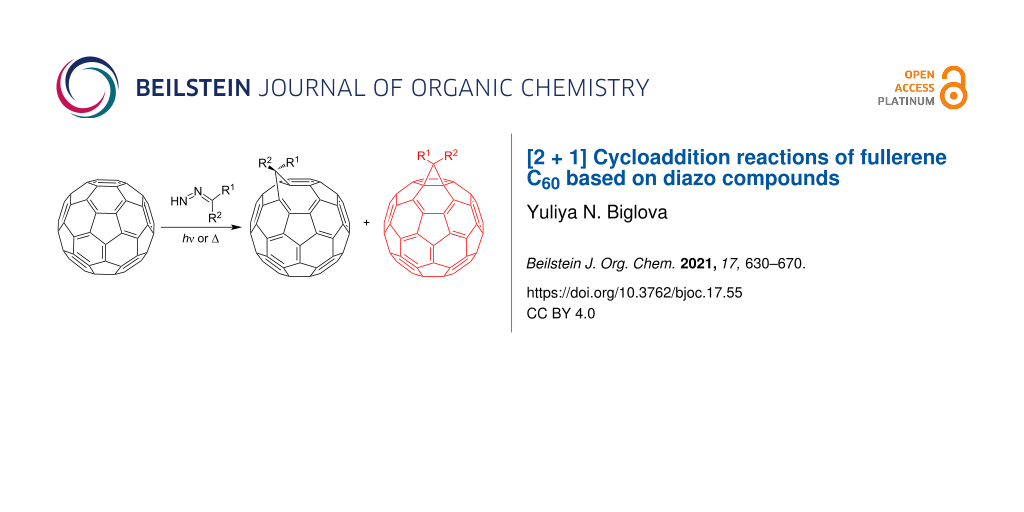

Graphical Abstract

Introduction

Taking into consideration that all life on Earth is of organic origin. with carbon as its basic element (20% by weight of every living organism, and the fourth most abundant element in the universe), the discovery in 1985 of its new allotropic modification, fullerene, has resulted in an avalanche-like expansion of studies in this area [1]. The exceptional physicochemical properties of the fullerene family and, above all, its main representative, C60, predetermine the broad practical interest in the use of these compounds. This is quite understandable: compounds with unique optical [2-4], electrophysical [5-7], mechanical [8-10], tribological [11-13], sorption [14-17], and biological properties [18-20], and even new dyes and catalysts [21-25], have already been discovered among functionalized fullerenes.

Bearing in mind the fact that numerous fullerene derivatives with a wide range of biological activity have been synthesized to date, the idea of using functionalized fullerenes in the field of medical chemistry, especially for the treatment of socially significant diseases, is fruitful.

The design of biologically active compounds based on C60 is determined, on the one hand, by the ability of its shell to serve as a transportation unit for pharmacophore groups, and on the other by the need to identify the capability of the fullerene core itself (depending on the nature of the attached fragment) to exhibit inherent bioactive properties in a living organism. The efforts of chemists in the design and synthesis of organofunctionalized C60 derivatives for medicine are primarily focused on the creation of water-soluble compounds [18,26,27]. Fullerene-containing compounds with antiviral (various forms of influenza, herpes, HIV) [28-30], antibacterial [31-33], and anticancer activity [34,35] have been found among them. An important approach in this area involves the synthesis of complex- and covalent-bound fullerene derivatives with biologically active molecules that already find practical use. It has been found that complexation improves the transportation of a drug and prolongs its effect, and a synergistic effect is observed in some cases [36].

The situation with covalent binding in fullerene–drug conjugates is different. C60 is an ideal partner for drug lipophilization by conjugation [37]. Highly efficient fullerene conjugates with chemotherapeutic agents have been synthesized and patented; moreover, the biological activity profile is often preserved, but in some cases it can also change since a molecular structure with a fundamentally new architecture appears [38].

The neuroprotective activity of fullerene derivatives may not be ignored either. Encouraging results of their use for the treatment of neurodegenerative pathologies (Alzheimer's and Parkinson's diseases and other diseases accompanied by cognitive impairment) leading to dementia have been demonstrated [39,40]. Moreover, it is noted that the almost nonexistent toxicity of the C60 derivatives allows to use them in living systems without negative consequences.

Studies on the use of C60 derivatives in micro- and nanoelectronics are also important and very promising. For example, fullerene-containing materials are used as electron-withdrawing components and buffer layers in the development and design of photoconductors [41,42], supercapacitors [43,44], field effect transistors (FET) [45,46], organic light-emitting diodes (OLEDs) [47,48] and organic or hybrid solar cells [49,50]. In view of the globalization of energy problems, the issues of switching to alternative energy sources are becoming increasingly relevant. Solar energy, like the majority of renewable energy sources, is environmentally friendly and has almost no negative impact on the environment.

Catalysis is the next area that is gaining an ever-increasing practical focus in the studies on the use of C60 and fullerene-containing materials [51]. A comparative analysis of the activity of fullerene-containing compounds and noble metals as dehydrogenation catalysts allows to consider the former as alternatives that favorably differ in cost. However, the efficiency is similar to the functional analogs of catalytic additives based on noble metals [52]. The presence of metal–fullerene chemical bonding results in catalysts that reliably provide high process selectivity due to the simultaneous adsorption of the substrate on two sites, namely a metal and a fullerene [53]. This allows to level out some negative features that are characteristic of heterogeneous catalysts. Thus, in dehydrogenation processes, catalytic amounts of a coordinated fullerene in metal fullerides act as a hydrogen acceptor in reactions with compounds containing activated C–H bonds [54].

An ample body of data on the chemistry of fullerenes has been accumulated to date. It is covered in a number of monographs [55-58] and reviews [59-75]. This review, in which we discuss the primary functionalization of the fullerene core with diazo compounds to synthesize solely monosubstituted carbochain products, covers the main achievements of organic chemistry over the past 20 years in the field of [2 + 1] cycloadditions to fullerene.

Review

[2 + 1] Cycloaddition to C60 to give methanofullerenes

Scientists are currently focusing on methods for the functionalization of the fullerene core that provide a high selectivity and yield. The electron-deficient polyene C60 readily undergoes radical addition, nucleophilic addition, and cycloaddition processes. Therein, the decrease in the strain in the fullerene core should be considered as the driving force of the reactivity. The [2 + n] cycloaddition reactions, where n varies from 1 to 4, are the most promising in the functionalization of the fullerene sphere. The [2 + 1] cycloaddition is the most popular variant among synthetic organic chemists as it allows to obtain methanofullerenes, fullerenoaziridines, or fullerenooxyranes. These reactions can involve, for example, the addition of stabilized carbanions, carbenes, and nitrenes and can involve various reaction mechanisms. While in the early years of intense research on reactions of cycloaddition to C60, the search for diverse addends for various cycloaddition variants as well as the determination of the main regularities of these processes were of primary interest, but the trends of studies recently changed. They are now focused on the targeted synthesis of fullerene derivatives with specific useful properties, creation of fundamentally new reagents for cycloaddition, and detailed studies on the multiaddition processes and the characteristics of polycyclic adducts.

The majority of researchers developing methods for C60 functionalization prefer [2 + 1] cycloaddition processes, among which reactions leading to methanofullerenes are widely used. Two main synthetic methods for the production of methanofullerenes can be distinguished (Scheme 1): nucleophilic cyclopropanation with stabilized carbanions that occurs by the addition–cleavage mechanism – the Bingel reaction (I) and addition of diazo compounds at elevated temperatures with subsequent release of N2 (II). The cyclopropanation of C60 with stabilized α-halocarbanions, i.e., the Bingel reaction, is the most efficient way to synthesize methanofullerenes [76]. It is almost versatile; in the presence of a reactive methylene function in halo-substituted substrates and with facilitation of bases, methanofullerenes with various structures are formed rather smoothly. It is believed that nucleophilic addition of an α-halocarbanion to C60 occurs initially, followed by intramolecular substitution of the halogen atom by an anionic center (which is generated on the fullerene sphere). In the initial variant, cyclopropanation occurs upon treatment of C60 with 2-bromomalonic ester in the presence of a base; the reaction is completed quickly, and the yields are good in most cases. However, this technique involves an additional stage, viz, it becomes necessary to preliminarily halogenate the cyclopropanating agent. As a rule, a hardly separable mixture of mono- and dihalo-containing products is formed.

Scheme 1: Methods for the synthesis of methanofullerenes C60.

Scheme 1: Methods for the synthesis of methanofullerenes C60.

The Hirsch-modified Bingel method makes it possible to isolate methanofullerenes by a one-pot reaction using simultaneously CBr4 or I2, 1,8-diazabicyclo[5.4.0]undec-7-ene (DBU) or NaH as the base, and a malonate-derived substrate. The adduct is synthesized in a slightly higher yield by direct treatment of fullerene with malonates.

As noted above, a decrease in the strain of the fullerene core is the driving force of its reactivity. According to the theory, monosubstituted fullerenes can exist as the four isomers shown in Figure 1: [5,6]-closed, [5,6]-open, [6,6]-closed, and [6,6]-open. Only [5,6]-open and [6,6]-closed have been isolated experimentally. This is explained by the preservation of energy-favorable levels in these isomers [77,78]. It has been shown by calculations that two of the four possible structures mentioned above are thermodynamically stable: [6,6]-isomers of methanofullerenes, which are characterized by a closed transannular bond (π-homoaromatic structure), as well as [5,6]-isomers, which have an open transannular bond (σ-homoaromatic structure) [79]. It was found that, as a rule, the [5,6]-open adducts formed initially can undergo rearrangement into [6,6]-closed isomers that are more thermodynamically stable.

Figure 1: Four theoretically possible isomeric methanofullerenes C60.

Figure 1: Four theoretically possible isomeric methanofullerenes C60.

An alternative variant of [2 + 1] cycloadditions to the fullerene frame involves the thermal addition of diazo compounds (the well-known carbene precursors), followed by N2 elimination. However, it occurs much more difficultly for diazo compounds than with singlet carbenes. This is due to the formation of a mixture of [5,6]-closed and [6,6]-open isomeric cyclic adducts. This phenomenon can be due to a number of reasons. First, two cyclopropanation mechanisms are equally likely in the thermal reaction of diazo compounds with C60 fullerene: a) preliminary carbene formation due to the thermal decomposition of diazo compounds, followed by synchronous addition to the double [6,6]-bond in C60 or b) possible formation of both isomers as a result of 1,3-dipolar cycloaddition of the diazo compound to the fullerene, followed by elimination of molecular nitrogen from the pyrazoline intermediate. Second, the rearrangement of [5,6]-open isomers into thermodynamically more stable [6,6]-closed ones is plausible. In fact, it has been proved convincingly [79] that a series of [5,6]-open fulleroids with stabilizing substituents in the methane bridge are rearranged into [6,6]-closed fullerenes, both by a photochemical process of zero-order kinetics and by a high-energy monomolecular route. The latter involves the closure into a [5,6]-closed fullerene, which is then regrouped into a [6,6]-closed fullerene via a biradical intermediate (Scheme 1). Nevertheless, examples of the synthesis of both individual isomeric cycloadducts and mixtures of isomeric fullerene and fulleroid structures upon addition of diazo compounds to C60 have appeared in recent years. Though the reaction has to be performed with heating, the yield of a functionalized C60 is much higher than in the nucleophilic cyclopropanation with stabilized carbanions. This variant for synthesizing methanofullerenes is also attractive because the variability of the substituents in the cyclopropane moiety is very high.

Cyclopropanation of C60 with diazo compounds

At the end of 1991, Suzuki [80] reported the first fullerene-containing derivative obtained by nucleophilic addition of diphenyldiazomethane to C60. The reaction of C60 with more than one equivalent of diphenyldiazomethane in toluene at room temperature for ca. 1 hour gives a monoadduct, i.e., a diphenyl derivative, in a yield of about 40%, with the characterized preferred structure 2 (Scheme 2).

Scheme 2: Synthesis of diphenyl-substituted fulleroids 1 and 2.

Scheme 2: Synthesis of diphenyl-substituted fulleroids 1 and 2.

As a result of diazo addition to the fullerene core, the loss of molecular nitrogen occurs according to Scheme 3:

Scheme 3: The reaction mechanism of a family of fulleroids by cyclopropanation of C60 with diazo compounds.

Scheme 3: The reaction mechanism of a family of fulleroids by cyclopropanation of C60 with diazo compounds.

Subsequently, it was shown in papers on the chemical reactions of C60 that this reaction allows substituents to be present in phenyl rings, which implies a general applicability for the development of functionalized fullerene derivatives.

Treatment of C60 with an ethereal solution of diazomethane in toluene at 0 °C resulted in pyrazoline derivative C [81]. The adduct isolated chromatographically was exposed to ultraviolet (UV) irradiation for 25 min at 25 °C in a quartz tube. The resulting isomers 3 and 4 were separated by reversed-phase high-performance liquid chromatography (HPLC) (methanol/toluene as the eluent) to isolate a reddish-brown powder of methanofullerene 3 in 21% yield (Scheme 4).

Scheme 4: Synthesis of 1,2-methanobuckminsterfullerene 3 and related fulleroid 4.

Scheme 4: Synthesis of 1,2-methanobuckminsterfullerene 3 and related fulleroid 4.

Similar to photolysis, the thermal rearrangement of kinetic products gives [6,6]-closed isomers that are thermodynamically more stable. After some time, the team of scientists mentioned the synthesis of dimethylmethanofullerene 6 from dimethyldiazomethane via the formation of annulene 5 according to Scheme 5 [82]. The reactions of C60 with other diazo derivatives also result in mixtures of various isomers. The ratio between the [5,6]-open fulleroid type and [6,6]-open methanofullerene in the reaction mixture after the loss of H2 depends on the diazo compound used for the cycloaddition. According to 13C NMR data, the [6,5]-bridged compound 5 has an open transannular bond, while the [6,6]-bridged compound 6 has a closed trans-ring bond.

Scheme 5: Synthesis of dimethylmethanofullerene 6 from dimethyldiazomethane via the formation of annulene 5. ODCB = orthodichlorobenzene.

Scheme 5: Synthesis of dimethylmethanofullerene 6 from dimethyldiazomethane via the formation of annulene 5. ...

A synthetically interesting building block, dimethoxymethanofullerene 7, was obtained by Diederich and Isaacs according to Scheme 6 [83]:

Scheme 6: Synthesis of dimethoxymethanofullerene 7.

Scheme 6: Synthesis of dimethoxymethanofullerene 7.

It was demonstrated that electron-withdrawing diazoacetates 8–10 and symmetric diazomalonates 11 and 12 can be involved in the reaction with C60 to give the corresponding methanofullerenes (Scheme 7) [77,83,84]. Later, the C60 adduct 8 and diethyl dicarboxymethanofullerene 11 were synthesized in Rh2(OAc)4-catalyzed reactions. Using Rh2(OAc)4, the selectivity of the process was improved, and the yield of the target products slightly increased to 42 and 32%, respectively [85].

Scheme 7: Synthesis of fullerene monoesters and symmetric diesters 8–10 and 11–12, respectively.

Scheme 7: Synthesis of fullerene monoesters and symmetric diesters 8–10 and 11–12, respectively.

The ability of derivatives to effectively preserve the main characteristics of C60 stimulated a great interest in the application of fullerenes in medical chemistry. Of the fullerene-based biologically significant molecules, amino acid derivatives are of particular interest. In fact, Prato and co-workers synthesized and characterized the first peptide with a covalently attached fullerene molecule [86]. To this end, adduct 13 was obtained from 4-(tert-butoxycarbonyl)phenyldiazomethane and fullerene. Subsequent acid hydrolysis of the protective ester group quantitatively gave a derivative of carboxylic acid 14, a versatile synthon for the synthesis of amphiphilic C60 derivatives. Treatment of 14 with oxalyl chloride gives reactive acid chloride 15. Acylation of the presynthesized (ʟ-Ala-Aib)2-ʟ-Ala-OMe peptide with compound 15 gives the expected fullerene–peptide conjugate 16 (Scheme 8).

Scheme 8: The synthetic route to the first fullerene–peptide conjugate 16.

Scheme 8: The synthetic route to the first fullerene–peptide conjugate 16.

A somewhat modified version for the synthesis of peptidofullerenes is given in Scheme 9 [87]. On this pathway for the synthesis of conjugates 19 and 20, acid 18 is cross-linked with a peptide component using a milder carbodiimide method via the starting methanofullerene 17. Similar to Scheme 8, fullerene adducts 21 and 22 with glycine and phenylalanine, respectively, were synthesized (Scheme 10) [83].

Scheme 9: Synthesis of bioactive fullerene peptides 19 and 20.

Scheme 9: Synthesis of bioactive fullerene peptides 19 and 20.

Scheme 10: Synthesis of amino acid–fullerene derivatives 21 and 22. (BtOH is 1H-benzotriazol-1-ol.)

Scheme 10: Synthesis of amino acid–fullerene derivatives 21 and 22. (BtOH is 1H-benzotriazol-1-ol.)

As an alternative, a more efficient direct route for synthesizing fullerenylpeptides 23 [83] and 24 [88] by prolonged thermolysis of various diazoamides in the presence of C60 was developed (Scheme 11).

Scheme 11: Synthesis of fullerenylpeptides 23 and 24.

Scheme 11: Synthesis of fullerenylpeptides 23 and 24.

For conjugation, some scientists successfully used mono- and diphenyldiazomethanes, available reagents carrying substituents on the phenyl rings. For example, covalent attachment of C60 to peptides is performed through a phenyl spacer, as it was demonstrated in a synthesis of fulleride 27 [89]. The latter compound was designed specifically for suppressing a HIV enzyme. The reaction of 4,4'-bis(N-acetyl-2-aminoethyl)diphenyldiazomethane with C60 in toluene gave adduct 25 that was isolated in 38% yield in the first stage. After that, it was quantitatively converted into primary diamine compound 26 in an acid medium. Upon addition of succinic anhydride in dry pyridine, conversion to water-soluble biologically active fullerene–peptide derivative 27 occurs (Scheme 12).

Scheme 12: The synthetic route to the water-soluble biologically active fullerene–peptide derivative 27.

Scheme 12: The synthetic route to the water-soluble biologically active fullerene–peptide derivative 27.

Reactions of monophenyldiazomethanes with C60 were used in the syntheses of adducts 28, 29 [90], and 30 (Figure 2) [91]. Moreover, diphenyldiazomethanes were used for synthesizing 31 [79], 32, 33 [90], and 34 (Figure 3) [92]. In all instances, a mixture of isomeric adducts is formed in a toluene solution. Heating the mixture at the solvent boiling point results in the single target product.

Figure 2: Structures of monophenyldiazomethanes 28–30.

Figure 2: Structures of monophenyldiazomethanes 28–30.

Figure 3: Structures of diphenyldiazomethanes 31–34.

Figure 3: Structures of diphenyldiazomethanes 31–34.

The reaction of C60 with diazoesters at room temperature gives adducts of benzo-15-crown-5 with phenylmethanofullerenes 35 [92] and 36–38 (Figure 4) [93]. A synthesis based on benzo-18-crown-6 to give 39 showed that attachment of the crown ether to the surfaces of fullerene molecules makes it easier to detect them by mass spectrometry [94]. This method was used to incorporate benzocrown ether residues in order to study the complexing properties of new fullerene derivatives.

Figure 4: Conjugates of benzocrown ethers with phenylmethanofullerenes 35–39.

Figure 4: Conjugates of benzocrown ethers with phenylmethanofullerenes 35–39.

An interesting approach was developed [95] for the synthesis of diphenyl-substituted fulleroids 40 and 41 as a two-section precursor of “pearl necklace” polymers with a C60 core in the main chain (Figure 5). However, the adducts were poorly soluble in the majority of organic solvents and only partially soluble in carbon disulfide, which is expected to ultimately lead to similar insoluble hard-to-recover polymers. It is believed [95] that the best solution to the problem seems to involve the incorporation of solubilizing groups into the structure.

Figure 5: Structures of para-phenylenebis(phenylfulleroid) 40 and meta-phenylenebis(phenylfulleroid) 41.

Figure 5: Structures of para-phenylenebis(phenylfulleroid) 40 and meta-phenylenebis(phenylfulleroid) 41.

Of the series of monophenylmethanofullerenes, the practically important so-called [6,6]-phenyl-C61-butyric acid methyl ester [60]PCBM synthesized by Hummelen, Wudl, and co-workers is most prominent (Scheme 13) [96]. The authors modified [60]PCBM via acid chloride 43 to give derivatives of cholesterol 44 and histamine 45.

Scheme 13: Serial synthesis of monophenylmethanofullerenes.

Scheme 13: Serial synthesis of monophenylmethanofullerenes.

Scientific literature [97] reports a three-step continuous synthesis of [6,6]-tert-butyl phenyl-C61-butyrate 47 based on tert-butyl 4-benzoylbutyrate hydrazone in a microstructured flow reactor that eliminates the need for stage-by-stage isolation of intermediate products and is environmentally friendly (Scheme 14).

Scheme 14: Four-step synthesis of the [6,6]-tert-butyl phenyl-C61-butyrate 47.

Scheme 14: Four-step synthesis of the [6,6]-tert-butyl phenyl-C61-butyrate 47.

Researchers obtained various nitrofullerene derivatives, viz, nitrophenylfullerenes 48 and 50, reduction of which gave the corresponding aminophenylfullerenes 49 and 51 (Scheme 15) [98,99]. C60 adducts were doped with tetrakis(dimethylamino)ethylene (TDAE) and cobaltocene (Cp2Co) in order to create charge-transfer complexes with the purpose of searching for efficient magnetic materials based on fullerenes. It can be seen in Scheme 16 that methanofullerene 52 was obtained from the initial, also para-substituted, ethyl diazo(4-nitrophenyl)acetate in 32% yield [100].

Scheme 15: Synthesis of aminophenylfullerenes 49 and 51 based on nitrophenylfullerenes 48 and 50.

Scheme 15: Synthesis of aminophenylfullerenes 49 and 51 based on nitrophenylfullerenes 48 and 50.

Scheme 16: Synthesis of conjugate 52 of C60 with ethyl diazo(4-nitrophenyl)acetate.

Scheme 16: Synthesis of conjugate 52 of C60 with ethyl diazo(4-nitrophenyl)acetate.

Photolysis of derivatives of para-substituted 3-fluoromethyl-3-phenyldiazirones in the presence of C60 gave phenylmethanofullerenes 53–56 in acceptable yields (Scheme 17) [101]. The electrochemical properties of the products were characterized by cyclic voltammetry and differential pulse voltammetry.

Scheme 17: Synthesis of fluoride-containing phenylmethanofullerenes 53–56.

Scheme 17: Synthesis of fluoride-containing phenylmethanofullerenes 53–56.

One of the approaches for in situ generation of unstable diazo compounds involves the use of stable hydrazones, followed by their oxidation with MnO2. For example, the scientists led by van Koten and co-workers synthesized a group of methanofullerenes with monoanionic terdentate diaminoaryl pincer ligands 57, 58 [102], 59 [103], and 60 [104], or the so-called “bucky ligands” (Scheme 18).

Scheme 18: Synthesis of “bucky ligands” 57–60.

Scheme 18: Synthesis of “bucky ligands” 57–60.

In the development of new organometallic C60 compounds that can be used as homogeneous catalysts, new blocks 61 and 62, cross-conjugated through cyclopropane, were synthesized (Scheme 19) [104]. Attaching such an electron-enriched metal-containing system to C60 can result in push–pull blocks with new electronic and photochemical properties, as demonstrated by complexes 63, 64 [103], and 65 [104] in Figure 6. The syntheses of new types of N-containing fullerene ligands for metal complexes 66–68 are illustrated in Scheme 20 [105].

Scheme 19: The synthetic route to methanofullerene-based palladium–bisaminoaryl complex 62.

Scheme 19: The synthetic route to methanofullerene-based palladium–bisaminoaryl complex 62.

Scheme 20: Synthesis of N-containing fullerene ligands 66–68.

Scheme 20: Synthesis of N-containing fullerene ligands 66–68.

A methanofullerene variety 69 with a pincer ligand containing a disulfidoaryl moiety was synthesized from 3,5-bis(phenylsulfidomethyl)benzaldehyde hydrazone. In the presence of [Pd(CH3CN)4](BF4)2, the latter gives the corresponding palladium complex 70 (Scheme 21) [106].

Scheme 21: Synthesis of C60-attached SCS pincer–palladium(II) complex 70.

Scheme 21: Synthesis of C60-attached SCS pincer–palladium(II) complex 70.

A series of spiromethanofullerenes was synthesized using various diazo derivatives. For example, compounds spiro-bound with glycosides are the first chiral and enantiomerically pure derivatives of fullerenes 71 and 72 (Scheme 22) [107]. It should be noted that though a considerable amount of information on the synthesis of fulleropyrazolines is available, their decomposition has been studied insufficiently. The factors determining the relative stability of monoadducts obtained in reactions of C60 with diazo compounds also remain an open issue.

Scheme 22: Synthesis of spiro-linked C-glycosides of fullerenes 71 and 72.

Scheme 22: Synthesis of spiro-linked C-glycosides of fullerenes 71 and 72.

Some of the studies by Wudl and co-workers [108] deal with the synthesis of various spiromethanofullerenes. For example, spiro derivatives 73–75 were obtained in one of the first works on this subject (Figure 7). The authors obtained quinone-derived [6,6]-closed spiromethanofullerenes 76–78 by reactions of C60 with the corresponding diazo compounds upon heating, or photochemically in a nitrogen atmosphere (Scheme 23) [109]. The reaction of spiro[10-anthron-9,61'-methanofullerene] (79) [110] with bis(trimethylsilyl)carbodiimide and malononitrile in pyridine in the presence of TiCl4 resulted in spirocyclic blocks 80 and 81, respectively (Scheme 24) [111].

Figure 7: Structures of spiromethanofullerenes 73–75.

Figure 7: Structures of spiromethanofullerenes 73–75.

Scheme 23: Synthesis of quinone-substituted methanofullerene derivatives 76–78.

Scheme 23: Synthesis of quinone-substituted methanofullerene derivatives 76–78.

Scheme 24: Synthesis of spiroannelated methanofullerenes 79–81.

Scheme 24: Synthesis of spiroannelated methanofullerenes 79–81.

Subsequently, the scope of quinone-substituted methanofullerenes was expanded by derivatives 82 and 83, and the scope of indanedione-substituted derivatives by compound 84. All of them were synthesized under conditions similar to those indicated in Scheme 24 (Figure 8) [112].

Figure 8: Quinone-substituted spiromethanofullerenes 82–84.

Figure 8: Quinone-substituted spiromethanofullerenes 82–84.

Synthesis of methanofullerenes with tosylhydrazone

The first publication on the synthesis of methanofullerenes via tosyl derivatives appeared in 1993 [83]. According to the original source, C60 cyclopropanation is assumed to involve a diazo compound preliminarily synthesized from an aldehyde- or ketone-based tosylhydrazone. The authors aimed at finding a versatile approach for synthesizing methanofullerenes that would allow incorporating any functional group into the fullerene core: hydrophilic groups for biological tests and hydrophobic ones for photovoltaic studies. According to Reference [83], the intermediate methanofullerene-appended dicarboxylic acid 85 synthesized from 10 is a versatile synthon for conversion into numerous derivatives (Scheme 25). The reactivity of compound 85 was studied under DCC-promoted esterification conditions (see adducts 8 and 86) and amidation conditions (see adducts 21 and 22).

Scheme 25: The synthetic route for methanofullerenes via tosyl derivatives. (BtOH is 1H-benzotriazol-1-ol.)

Scheme 25: The synthetic route for methanofullerenes via tosyl derivatives. (BtOH is 1H-benzotriazol-1-ol.)

Hummelen, Wudl, et al. [96] performed an optimized methanofullerene synthesis by carrying out the cyclopropanation in the one-pot version presented in reference [83]. Therein, fullerene was added directly to the solution of tosylhydrazone in the presence of a base. This procedure makes it possible to generate diazo compounds in situ, without the need for purification prior to the addition of C60. The process is successful even in the presence of unstable diazo compounds, and the yield of the target product increases significantly. The technique was tested in a synthesis of an acceptor component of organic solar cells, [60]PCBM, as an example (Scheme 26).

Scheme 26: The synthetic route to [60]PCBM via tosylhydrazine.

Scheme 26: The synthetic route to [60]PCBM via tosylhydrazine.

The mechanism of fullerene cyclopropanation is presented in Scheme 27.

Scheme 27: The reaction mechanism of fullerene cyclopropanation via tosylhydrazine derivatives.

Scheme 27: The reaction mechanism of fullerene cyclopropanation via tosylhydrazine derivatives.

Using a similar procedure, the reaction of C60 and alkyl-4-benzoyl butyrate p-tosylhydrazone in the presence of sodium methoxide and pyridine, the following [6,6]-phenyl-C61-butyric acid esters 87–97 with various alkyl-chain lengths were synthesized (Scheme 28). According to reference [113], the solubility of C60 derivatives in organic solvents increases with an increase in the length of alkyl substituents. The photovoltaic devices designed using poly(3-hexylthiophene)/methanofullerenes as the acceptor component, and compared to [60]PCBM, demonstrated that the derivative based on butyl ester 90 exhibited the best characteristics [113], but the best result in the study was obtained with the compound based on [60]PCBM methyl ester [63].

Scheme 28: Serial synthesis of [6,6]-phenyl-C61-butyric acid esters 87–91 [114], 92–96 [113,115], and 97 [116].

Scheme 28: Serial synthesis of [6,6]-phenyl-C61-butyric acid esters 87–91 [114], 92–96 [113,115], and 97 [116].

The next group of [60]PCBM derivatives synthesized by a similar technique and containing aromatic groups Ar on the one hand and alkyl groups Alk on the other, bound to the C60 core through a cyclopropane ring, most of which were tested in organic solar elements, is presented in Scheme 29, and the substituents are listed in Table 1 [117-140].

Scheme 29: Typical procedure for a synthesis of [60]PCBM derivatives.

Scheme 29: Typical procedure for a synthesis of [60]PCBM derivatives.

Table 1: [60]PCBM derivatives containing various aromatic and alkyl groups bound to the C60 core.

| compound | Ar | Alk | yield (%) | Reference |

| 98 |

|

|

38 | [117] |

| 99 |

|

|

35 | [117] |

| 100 |

|

|

25 | [118] |

| 101 |

|

|

36, 53 | [118,119] |

| 102 |

|

|

40 | [120] |

| 103 |

|

|

46 | [120] |

| 104 |

|

|

50 | [120] |

| 105 |

|

|

43 | [120] |

| 106 |

|

|

42 | [120] |

| 107 |

|

|

72 | [119] |

| 108 |

|

|

20 | [118] |

| 109 |

|

|

20 | [121] |

| 110 |

|

|

50 | [79] |

| 111 |

|

|

nra | [122] |

| 112 |

|

|

nr | [122] |

| 113 |

|

|

nr | [123,124] |

| 114 |

|

|

nr | [123] |

| 115 |

|

|

nr | [123] |

| 116 |

|

|

40 | [125] |

| 117 |

|

|

nr | [123] |

| 118 |

|

|

nr | [124] |

| 119 |

|

|

nr | [124] |

| 120 |

|

|

nr | [124] |

| 121 |

|

|

nr | [123] |

| 122 |

|

|

nr | [126] |

| 123 |

|

|

nr | [126] |

| 124 |

|

|

30 | [127] |

| 125 |

|

|

nr | [128] |

| 126 |

|

|

nr | [128] |

| 127 |

|

|

nr | [128] |

| 128 |

|

|

nr | [122] |

| 28 |

|

|

42 | [79] |

| 129 |

|

|

nr | [126] |

| 130 |

|

|

17 | [129] |

| 131 |

|

|

34 | [130] |

| 132 |

|

|

96 | [131] |

| 133 |

|

|

nr | [132] |

| 134 |

|

|

7.5 | [133] |

| 135 |

|

|

40 | [79] |

| 136 |

|

|

50 | [132] |

| 137 |

|

|

51 | [132] |

| 138 |

|

|

43 | [132] |

| 139 |

|

|

44 | [132] |

| 140 |

|

|

35 | [132] |

| 141 |

|

|

28 | [132] |

| 142 |

|

|

49 | [133] |

| 143 |

|

|

37 | [79] |

| 144 |

|

|

39 | [134] |

| 145 |

|

|

47 | [134] |

| 146 |

|

|

46 | [135] |

| 147 |

|

|

50 | [135] |

| 148 |

|

|

44 | [135] |

| 149 |

|

|

27 | [136] |

| 150 |

|

|

11 | [136] |

| 151 |

|

|

22 | [136] |

| 152 |

|

|

41 | [136] |

| 153 |

|

|

33 | [137] |

| 154 |

|

|

42 | [138] |

| 155 |

|

|

35 | [137] |

| 156 |

|

|

18 | [139] |

| 157 |

|

|

52 | [140] |

| 158 |

|

|

49 | [140] |

aThe yield has not been reported.

The tosylhydrazone method discussed above was used to obtain monoaryl derivatives, such as the aforementioned 29 [79], 30 (in 55% yield) [141] as well as 159 [142] and 160 (Figure 9) [143]. Representatives containing polycyclic aromatic systems based on phenothiazine 161 [144], carbazole 162 [145], and tetrathiofulvalenes 163 and 164 [146] and 1,1-binaphthalenes 165 and 166 [147] are known. They are shown in Figure 10.

Figure 9: Structures of 4-C61-phenylorganofullerenes 159 and 160.

Figure 9: Structures of 4-C61-phenylorganofullerenes 159 and 160.

Figure 10: Structures of methanofullerenes containing aromatic polycyclic systems.

Figure 10: Structures of methanofullerenes containing aromatic polycyclic systems.

Various diaryl derivatives of C60 can also be obtained by this approach. Thus, the structures of 4,4'-diphenylfullerene derivatives synthesized are shown in Figure 11, and a number of diphenylmethanofullerenes 169–177 with electron-withdrawing groups are reported in reference [148] (Figure 12).

Figure 11: 4,4-Diphenylfullerene derivatives 31, 32, 167, and 168.

Figure 11: 4,4-Diphenylfullerene derivatives 31, 32, 167, and 168.

Figure 12: Polysubstituted diphenylmethanofullerenes 169–177.

Figure 12: Polysubstituted diphenylmethanofullerenes 169–177.

Publication [149] describes compound 178 containing triphenylamine donor groups (Scheme 30). An interesting approach was used in reference [150], and the syntheses of phenylacetylene dendrimers of the 1st (see 179) and 2nd generation (see 180) are reported (Figure 13).

Scheme 30: The synthetic route to triphenylamine-substituted methanofullerene 178.

Scheme 30: The synthetic route to triphenylamine-substituted methanofullerene 178.

Figure 13: Fullerene-containing phenylacetylene dendrimers of the 1st and 2nd generation.

Figure 13: Fullerene-containing phenylacetylene dendrimers of the 1st and 2nd generation.

In reference [151], the reaction of fullerene with 3.3',4.4'-tetrakis(methoxycarbonyl)benzophenone tosylhydrazone first gave ester 181 and then acid 182 (Scheme 31), the sodium and potassium salts of which are well soluble in water. The compound has antiviral and anticancer activity as well as pronounced antioxidant properties combined with low toxicity.

Scheme 31: The synthetic route to water-soluble methano[60]fullerene-appended tetracarboxylic acid derivatives.

Scheme 31: The synthetic route to water-soluble methano[60]fullerene-appended tetracarboxylic acid derivatives....

Diarylmethanofullerene 183 was synthesized according to Scheme 32 from 9,9-didecyl-9H-fluorene and monomethyl terephthalate chloride [152].

Scheme 32: The synthetic route to diarylmethanofullerene 183.

Scheme 32: The synthetic route to diarylmethanofullerene 183.

The authors of reference [153] presented a series of 2,2';6',2"-terpyridine (tpy)-substituted methanofullerenes and pyrrolidinofullerene dyads 184–186 linked through para-phenylene or para-phenyleneethynylphenylene units (Scheme 33). Сoordination of these compounds with ruthenium(II) leads to a donor–bridge–acceptor assembly of complexes with various lengths, 187–189. It is believed [153] that the photophysical and electrochemical properties of the complexes presented are promising for the formation of charge-separated photoinduced states for artificial photosynthetic devices, in particular where assemblies are expanded from dyads to triads by including a lateral organic or organometallic donor.

Scheme 33: The synthetic route to tpy-containing methanofullerene dyads 184–186, coordination of which with ruthenium(II) gives donor–bridge–acceptor assemblies 187–189.

Scheme 33: The synthetic route to tpy-containing methanofullerene dyads 184–186, coordination of which with ru...

The synthesis of a whole series of spiromethanofullerenes was carried out through the stage where tosylhydrazone derivatives were formed. In fact, a series of spirocyclopentalydenemethanofullerenes 190–193 were obtained by the reaction of C60 with lithium salts of tosylhydrazone (Scheme 34) [154].

Scheme 34: Synthesis of a series of spirocyclopentalydenemethanofullerenes 190–193.

Scheme 34: Synthesis of a series of spirocyclopentalydenemethanofullerenes 190–193.

Spiromethanofullerene 194 was prepared on the basis of monoethylene glycol tosylhydrazone. Hydrolysis of the former resulted in 6,6-spiro[cyclohexanone-4,61'-methanofullerene] (195) (Scheme 35) [111]. Fullerene-containing adducts such as benzocyclopentanefullerene 196, acenaphthenefullerene 197 [155], and dibenzosuberanefullerene 73 [156] are also known (Figure 14).

Scheme 35: Synthesis of spiromethanofullerenes 194 and 195.

Scheme 35: Synthesis of spiromethanofullerenes 194 and 195.

Figure 14: Dibenzosuberane-substituted fullerene derivatives 196 and 197.

Figure 14: Dibenzosuberane-substituted fullerene derivatives 196 and 197.

Unusual spiromethanofullerenes were presented in reference [157], where the synthesis of N,N-(tetrachlorophthaloyl)dehydroabietylamine derivatives 198–201 from dehydroabietylamine substituted by fullerene in ring B was reported (Scheme 36). These compounds were obtained in a search for new derivatives of rosin amines with potential biological activity.

Scheme 36: The synthetic route to ring-B-C60-attached derivatives of N,N-(tetrachlorophthaloyl)dehydroabietylamine, 198–201.

Scheme 36: The synthetic route to ring-B-C60-attached derivatives of N,N-(tetrachlorophthaloyl)dehydroabietyla...

Further, an unusual ferrocene-containing block 202 was synthesized (Scheme 37) [158].

Scheme 37: The synthetic route to methano-bridged diferrocenylfullerene 202.

Scheme 37: The synthetic route to methano-bridged diferrocenylfullerene 202.

1-(3-(Benzoyl)propyl)-1-phenyl[6,6]methanofullerene (203) was obtained by 1,3-dipolar cycloaddition of a tosylhydrazone derivative (obtained from 1,3-dibenzoylpropane) to C60 (Scheme 38) [159]. 2-Benzoylpropionic acid was used as the starting material for synthesizing adduct 204 (Scheme 39) [123]. A synthesis and a self-assembly of flavin-functionalized fullerene derivative 205 consisting of [60]PCBM and isoalloxazine moieties attached at both ends of a linear 12-carbon aliphatic spacer, based on the same acid (Scheme 40), was reported [160].

Scheme 38: The synthetic route to 1-(3-(benzoyl)propyl)-1-phenyl[6,6]-C60 203.

Scheme 38: The synthetic route to 1-(3-(benzoyl)propyl)-1-phenyl[6,6]-C60 203.

Scheme 39: The synthetic route to methanofullerene 204.

Scheme 39: The synthetic route to methanofullerene 204.

Scheme 40: The synthetic route to C60-functionalized flavin 205.

Scheme 40: The synthetic route to C60-functionalized flavin 205.

In a study by Kumar and co-workers [161], the synthesis of methanofullerenes 206 and 207 was based on 3-methoxy-4-hydroxycinnamic aldehyde and a chalcon obtained by Claison condensation of acetophenone with 2-hydroxy-5-nitrobenzaldehyde (Scheme 41). Further, the same team obtained methanofullerene adduct 208 based on 2-nitrocinnamic aldehyde (Scheme 42) [116].

Scheme 41: The synthetic route to conjugates of C60 with cinnamaldehyde 206 and with chalcone 207.

Scheme 41: The synthetic route to conjugates of C60 with cinnamaldehyde 206 and with chalcone 207.

Scheme 42: The synthetic route to conjugate C60 with a 2-nitrocinnamyl group.

Scheme 42: The synthetic route to conjugate C60 with a 2-nitrocinnamyl group.

Hummelen and co-workers [131] worked on creating derivatives of H-bound fullerene associates. For instance, methyl 5-oxo-5-(3,4-bishexyloxy)phenylpentanoate was converted via a tosyl derivative to a methanofullerene derivative of butyric acid 209. Based on this, fullerene dimer 210 with four hydrogen bonds having a very high dimerization constant was obtained (Scheme 43).

Scheme 43: The synthetic route to a C60 dimer connected through a highly directional fourfold hydrogen bonding motif.

Scheme 43: The synthetic route to a C60 dimer connected through a highly directional fourfold hydrogen bonding...

Diethyl 4-oxopimelate was used as the precursor of polymer 213. The former was converted via diacid 211 to the target methanofullerene 212, the solution of which in chloroform shows typical resonance signals of six hydrogen-bonded protons (Scheme 44) [162].

Scheme 44: The synthetic route to quadruple hydrogen‐bonded fullerene array 213.

Scheme 44: The synthetic route to quadruple hydrogen‐bonded fullerene array 213.

In order to improve the optical absorption of fullerene acceptors for utilization in solar cells with a bulk heterojunction, a series of dye–fullerene dyads with strong absorption in the visible region was synthesized [163]. A synthesis of C60 fullerene conjugate 214 with a benzothiadiazole moiety is shown in Scheme 45, while Scheme 46 presents a synthetic pathway to diketopyrrolopyrrole-modified conjugate 215.

Scheme 45: The synthetic route to conjugates 214 of fullerene with benzothiadiazole.

Scheme 45: The synthetic route to conjugates 214 of fullerene with benzothiadiazole.

Scheme 46: The synthetic route to conjugates 215 of fullerene with diketopyrrolopyrrole.

Scheme 46: The synthetic route to conjugates 215 of fullerene with diketopyrrolopyrrole.

Other methanofullerenes without aromatic groups obtained by this method are presented below. Fullerene–acetylene derivatives 218 and 219 obtained by the tosylhydrazone method (Scheme 47) are also reported in the literature [164,165]. First, orthogonally protected diethinylmethanofullerene 216 was obtained and then converted to 217 by protodesilylation. Finally, blocks 218 and 219 were obtained by oxidative hetero- and homocoupling of 217, respectively. It is also noted that dumbbell-like fullerene-containing compound 219 is the first example of a dimeric fullerene that was fully characterized.

Scheme 47: The synthetic route to fullerene–acetylene hybrids.

Scheme 47: The synthetic route to fullerene–acetylene hybrids.

Conclusion

Summarizing our analysis of scientific literature on [2 + 1] cycloaddition reactions to C60 fullerene based on diazo compounds allows us to state the following: An alternative to the synthesis of methanofullerenes by the Bingel methodology is provided by the thermal [2 + 1] cycloaddition of diazo compounds to the fullerene. Then follows the photolysis or thermolysis of pyrazoline intermediates by N2 extrusion. Therein, the formed [5,6]-opened adducts are transformed into [6,6]-closed isomers, which are more thermodynamically stable. While the range of reagents used in nucleophilic cyclopropanation with stabilized carbanions is mainly limited to malonates, the range of cyclopropanating agents involved in C60 reactions with diazo compounds is much wider. In addition, the high yield of the target products and the nearly unlimited variability of substituents in the cyclopropane moiety should be noted as advantages of the latter method. Nevertheless, a drawback that all the [2 + 1] cycloaddition reactions to fullerene have in common is that, due to functionalization of the C60 core, formation of a mixture of hardly separable polyaddition products is observed, rather than selective formation of a certain compound. It is the reason why the search for methods for controlling the C60 cyclopropanation process is so relevant.

The scope of the fields of use of fullerenes discussed in the scientific literature is almost unlimited, while the synthesis of derivatives based thereon and the subsequent studies expand the borders of the application areas. Taking all of the above into consideration, it can be assumed that the fruitful development of the chemistry of fullerene derivatives will continue for many years to come. We believe that information presented herein will be useful to synthetic chemists for analyzing their achievements and for choosing their own areas of research in this area.

References

-

Kroto, H. W.; Heath, J. R.; O’Brien, S. C.; Curl, R. F.; Smalley, R. E. Nature 1985, 318, 162–163. doi:10.1038/318162a0

Return to citation in text: [1] -

Lu, X.; Feng, L.; Akasaka, T.; Nagase, S. Chem. Soc. Rev. 2012, 41, 7723–7760. doi:10.1039/c2cs35214a

Return to citation in text: [1] -

Das, S.; Presselt, M. J. Mater. Chem. C 2019, 7, 6194–6216. doi:10.1039/c9tc00889f

Return to citation in text: [1] -

Kang, S.; Zhang, J.; Sang, L.; Shrestha, L. K.; Zhang, Z.; Lu, P.; Li, F.; Li, M.; Ariga, K. ACS Appl. Mater. Interfaces 2016, 8, 24295–24299. doi:10.1021/acsami.6b06221

Return to citation in text: [1] -

Badamshina, E.; Estrin, Y.; Gafurova, M. J. Mater. Chem. A 2013, 1, 6509–6529. doi:10.1039/c3ta10204a

Return to citation in text: [1] -

Stroyuk, O.; Raevskaya, A.; Gaponik, N. Chem. Soc. Rev. 2018, 47, 5354–5422. doi:10.1039/c8cs00029h

Return to citation in text: [1] -

Martynov, I. V.; Akkuratov, A. V.; Luchkin, S. Y.; Tsarev, S. A.; Babenko, S. D.; Petrov, V. G.; Stevenson, K. J.; Troshin, P. A. ACS Appl. Mater. Interfaces 2019, 11, 21741–21748. doi:10.1021/acsami.9b01729

Return to citation in text: [1] -

Zhu, S.-E.; Li, F.; Wang, G.-W. Chem. Soc. Rev. 2013, 42, 7535–7570. doi:10.1039/c3cs35494f

Return to citation in text: [1] -

Badamshina, E.; Gafurova, M. J. Mater. Chem. 2012, 22, 9427–9438. doi:10.1039/c2jm15472b

Return to citation in text: [1] -

Cao, Z.; Zhao, W.; Liu, Q.; Liang, A.; Zhang, J. Adv. Mater. Interfaces 2018, 5, 1701303. doi:10.1002/admi.201701303

Return to citation in text: [1] -

Sun, J.; Du, S. RSC Adv. 2019, 9, 40642–40661. doi:10.1039/c9ra05679c

Return to citation in text: [1] -

Zhang, R.; Xiong, L.; Pu, J.; Lu, Z.; Zhang, G.; He, Z. Adv. Mater. Interfaces 2019, 6, 1901386. doi:10.1002/admi.201901386

Return to citation in text: [1] -

Wu, K.; Qiang, L.; Gong, Z.; Zhao, G.; Gao, K.; Zhang, B.; Zhang, J. Surf. Interface Anal. 2015, 47, 903–910. doi:10.1002/sia.5793

Return to citation in text: [1] -

Uchikawa, S.; Kawasaki, A.; Hoshino, N.; Takeda, T.; Noro, S.-i.; Takahashi, K.; Nakamura, T.; Sato, N.; Kokubo, K.; Sakurai, H.; Akutagawa, T. J. Phys. Chem. C 2019, 123, 23545–23553. doi:10.1021/acs.jpcc.9b06951

Return to citation in text: [1] -

Velzeboer, I.; Kwadijk, C. J. A. F.; Koelmans, A. A. Environ. Sci. Technol. 2014, 48, 4869–4876. doi:10.1021/es405721v

Return to citation in text: [1] -

Avanasi, R.; Jackson, W. A.; Sherwin, B.; Mudge, J. F.; Anderson, T. A. Environ. Sci. Technol. 2014, 48, 2792–2797. doi:10.1021/es405306w

Return to citation in text: [1] -

Zhang, M.; Tao, S.; Wang, X. Environ. Sci.: Nano 2020, 7, 2486–2508. doi:10.1039/d0en00515k

Return to citation in text: [1] -

Nierengarten, I.; Nierengarten, J.-F. Chem. – Asian J. 2014, 9, 1436–1444. doi:10.1002/asia.201400133

Return to citation in text: [1] [2] -

Hashimoto, A.; Takamura‐Enya, T.; Oda, Y. Photochem. Photobiol. 2019, 95, 1403–1411. doi:10.1111/php.13138

Return to citation in text: [1] -

Bianco, A.; Da Ros, T. Biological Applications of Fullerenes. Fullerenes: Principles and Applications; The Royal Society of Chemistry: London, UK, 2011; Vol. 2, pp 507–545. doi:10.1039/9781849732956-00507

Return to citation in text: [1] -

Plehn, T.; Megow, J.; May, V. Phys. Chem. Chem. Phys. 2014, 16, 12949–12958. doi:10.1039/c4cp01081g

Return to citation in text: [1] -

Chen, T.; Zou, H.; Wu, X.; Chen, Y.; Situ, B.; Zheng, L.; Yang, G. ACS Biomater. Sci. Eng. 2019, 5, 3079–3088. doi:10.1021/acsbiomaterials.9b00372

Return to citation in text: [1] -

Zhai, Y.; Zhu, Z.; Dong, S. ChemCatChem 2015, 7, 2806–2815. doi:10.1002/cctc.201500323

Return to citation in text: [1] -

Shah, S.; Tiwari, N.; Kumar, Y.; Jha, S. N.; Auroux, A.; Pandey, J. K.; Chowdhury, B. ChemistrySelect 2017, 2, 5640–5645. doi:10.1002/slct.201700203

Return to citation in text: [1] -

Gopiraman, M.; Saravanamoorthy, S.; Ullah, S.; Ilangovan, A.; Kim, I. S.; Chung, I. M. RSC Adv. 2020, 10, 2545–2559. doi:10.1039/c9ra09244g

Return to citation in text: [1] -

Nakamura, E.; Isobe, H. Acc. Chem. Res. 2003, 36, 807–815. doi:10.1021/ar030027y

Return to citation in text: [1] -

Wang, J.; Zhang, Z.; Wu, W.; Jiang, X. Chin. J. Chem. 2014, 32, 78–84. doi:10.1002/cjoc.201300737

Return to citation in text: [1] -

Friedman, S. H.; DeCamp, D. L.; Sijbesma, R. P.; Srdanov, G.; Wudl, F.; Kenyon, G. L. J. Am. Chem. Soc. 1993, 115, 6506–6509. doi:10.1021/ja00068a005

Return to citation in text: [1] -

Schuster, D. I.; Wilson, S. R.; Schinazi, R. F. Bioorg. Med. Chem. Lett. 1996, 6, 1253–1256. doi:10.1016/0960-894x(96)00210-7

Return to citation in text: [1] -

Marcorin, G. L.; Da Ros, T.; Castellano, S.; Stefancich, G.; Bonin, I.; Miertus, S.; Prato, M. Org. Lett. 2000, 2, 3955–3958. doi:10.1021/ol000217y

Return to citation in text: [1] -

Durka, M.; Buffet, K.; Iehl, J.; Holler, M.; Nierengarten, J.-F.; Taganna, J.; Bouckaert, J.; Vincent, S. P. Chem. Commun. 2011, 47, 1321–1323. doi:10.1039/c0cc04468g

Return to citation in text: [1] -

Pantarotto, D.; Bianco, A.; Pellarini, F.; Tossi, A.; Giangaspero, A.; Zelezetsky, I.; Briand, J.-P.; Prato, M. J. Am. Chem. Soc. 2002, 124, 12543–12549. doi:10.1021/ja027603q

Return to citation in text: [1] -

Ballatore, M. B.; Spesia, M. B.; Milanesio, M. E.; Durantini, E. N. Eur. J. Med. Chem. 2014, 83, 685–694. doi:10.1016/j.ejmech.2014.06.077

Return to citation in text: [1] -

Mashino, T.; Nishikawa, D.; Takahashi, K.; Usui, N.; Yamori, T.; Seki, M.; Endo, T.; Mochizuki, M. Bioorg. Med. Chem. Lett. 2003, 13, 4395–4397. doi:10.1016/j.bmcl.2003.09.040

Return to citation in text: [1] -

Ikeda, A.; Hatano, T.; Kawaguchi, M.; Shinkai, S.; Suenaga, H. Chem. Commun. 1999, 1403–1404. doi:10.1039/a903872h

Return to citation in text: [1] -

Panchuk, R. R.; Prylutska, S. V.; Chumak, V. V.; Skorokhyd, N. R.; Lehka, L. V.; Evstigneev, M. P.; Prylutskyy, Y. I.; Berger, W.; Heffeter, P.; Scharff, P.; Ritter, U.; Stoika, R. S. J. Biomed. Nanotechnol. 2015, 11, 1139–1152. doi:10.1166/jbn.2015.2058

Return to citation in text: [1] -

Zakharian, T. Y.; Seryshev, A.; Sitharaman, B.; Gilbert, B. E.; Knight, V.; Wilson, L. J. J. Am. Chem. Soc. 2005, 127, 12508–12509. doi:10.1021/ja0546525

Return to citation in text: [1] -

Kumar, A.; Patel, G.; Menon, S. K. Chem. Biol. Drug Des. 2009, 73, 553–557. doi:10.1111/j.1747-0285.2009.00804.x

Return to citation in text: [1] -

Kotelnikova, R. A.; Smolina, A. V.; Grigoryev, V. V.; Faingold, I. I.; Mischenko, D. V.; Rybkin, A. Y.; Poletayeva, D. A.; Vankin, G. I.; Zamoyskiy, V. L.; Voronov, I. I.; Troshin, P. A.; Kotelnikov, A. I.; Bachurin, S. O. MedChemComm 2014, 5, 1664–1668. doi:10.1039/c4md00194j

Return to citation in text: [1] -

Dugan, L. L.; Tian, L.; Quick, K. L.; Hardt, J. I.; Karimi, M.; Brown, C.; Loftin, S.; Flores, H.; Moerlein, S. M.; Polich, J.; Tabbal, S. D.; Mink, J. W.; Perlmutter, J. S. Ann. Neurol. 2014, 76, 393–402. doi:10.1002/ana.24220

Return to citation in text: [1] -

Wang, Y.; West, R.; Yuan, C. H. J. Am. Chem. Soc. 1993, 115, 3844–3845. doi:10.1021/ja00062a088

Return to citation in text: [1] -

Giacalone, F.; Martín, N. Adv. Mater. (Weinheim, Ger.) 2010, 22, 4220–4248. doi:10.1002/adma.201000083

Return to citation in text: [1] -

Gao, Z.; Chen, C.; Chang, J.; Chen, L.; Wu, D.; Xu, F.; Jiang, K. Electrochim. Acta 2018, 260, 932–943. doi:10.1016/j.electacta.2017.12.070

Return to citation in text: [1] -

Bairi, P.; Maji, S.; Hill, J. P.; Kim, J. H.; Ariga, K.; Shrestha, L. K. J. Mater. Chem. A 2019, 7, 12654–12660. doi:10.1039/c9ta00520j

Return to citation in text: [1] -

Xu, H.; Xiao, T.; Li, J.; Mai, J.; Lu, X.; Zhao, N. J. Phys. Chem. C 2015, 119, 25598–25605. doi:10.1021/acs.jpcc.5b07810

Return to citation in text: [1] -

Li, C.-Z.; Chueh, C.-C.; Yip, H.-L.; Zou, J.; Chen, W.-C.; Jen, A. K.-Y. J. Mater. Chem. 2012, 22, 14976–14981. doi:10.1039/c2jm32693k

Return to citation in text: [1] -

Sun, Q.; Li, D.; Dong, G.; Jin, X.; Duan, L.; Wang, L.; Qiu, Y. Sens. Actuators, B 2013, 188, 879–885. doi:10.1016/j.snb.2013.07.087

Return to citation in text: [1] -

Rance, W. L.; Ferguson, A. J.; McCarthy-Ward, T.; Heeney, M.; Ginley, D. S.; Olson, D. C.; Rumbles, G.; Kopidakis, N. ACS Nano 2011, 5, 5635–5646. doi:10.1021/nn201251v

Return to citation in text: [1] -

Ali, A. M.; Said, D. A.; Khayyat, M.; Boustimi, M.; Seoudi, R. Results Phys. 2020, 16, 102819. doi:10.1016/j.rinp.2019.102819

Return to citation in text: [1] -

Wang, W.; Sun, R.; Guo, J.; Guo, J.; Min, J. Angew. Chem., Int. Ed. 2019, 58, 14556–14561. doi:10.1002/anie.201908232

Return to citation in text: [1] -

Goldshleger, N. F. Fullerene Sci. Technol. 2001, 9, 255–280. doi:10.1081/fst-100104493

Return to citation in text: [1] -

Kushch, S. D.; Kuyunko, N. S. Russ. J. Gen. Chem. 2011, 81, 345–353. doi:10.1134/s1070363211020113

Return to citation in text: [1] -

Coq, B.; Brotons, V.; Planeix, J. M.; de Ménorval, L. C.; Dutartre, R. J. Catal. 1998, 176, 358–364. doi:10.1006/jcat.1998.2040

Return to citation in text: [1] -

Shestakov, A. F.; Goldshleger, N. F. J. Organomet. Chem. 2015, 793, 17–33. doi:10.1016/j.jorganchem.2015.04.040

Return to citation in text: [1] -

Brabec, C.; Scherf, U.; Dyakonov, V., Eds. Organic Photovoltaics: materials, device physics, and manufacturing technologies, 2nd ed.; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2014. doi:10.1002/9783527656912

Return to citation in text: [1] -

Hirsch, A.; Brettreich, M. Fullerenes. Chemistry and reactions; Wiley-VCH: Weinheim, Germany, 2005.

Return to citation in text: [1] -

Martín, N.; Giacalone, F., Eds. Fullerene polymers: synthesis, properties and applications; John Wiley & Sons: Hoboken, NJ, USA, 2009. doi:10.1002/9783527628742

Return to citation in text: [1] -

Verner, R. F.; Benvegnu, C. Handbook on fullerene: synthesis, properties, and applications; Nova Science Publishers: Hauppauge, NY, USA, 2012.

Return to citation in text: [1] -

Diederich, F.; Thilgen, C. Science 1996, 271, 317–324. doi:10.1126/science.271.5247.317

Return to citation in text: [1] -

Biglova, Y. N.; Mustafin, A. G. RSC Adv. 2019, 9, 22428–22498. doi:10.1039/c9ra04036f

Return to citation in text: [1] -

Jennepalli, S.; Pyne, S. G.; Keller, P. A. RSC Adv. 2014, 4, 46383–46398. doi:10.1039/c4ra07310j

Return to citation in text: [1] -

Ganesamoorthy, R.; Sathiyan, G.; Sakthivel, P. Sol. Energy Mater. Sol. Cells 2017, 161, 102–148. doi:10.1016/j.solmat.2016.11.024

Return to citation in text: [1] -

Zhu, S.-E.; Li, F.; Wang, G.-W. Chem. Soc. Rev. 2013, 42, 7535–7570. doi:10.1039/c3cs35494f

Return to citation in text: [1] [2] -

Winkler, K.; Balch, A. L.; Kutner, W. J. Solid State Electrochem. 2006, 10, 761–784. doi:10.1007/s10008-006-0171-6

Return to citation in text: [1] -

Dennler, G.; Scharber, M. C.; Brabec, C. J. Adv. Mater. (Weinheim, Ger.) 2009, 21, 1323–1338. doi:10.1002/adma.200801283

Return to citation in text: [1] -

Yurovskaya, M. A.; Trushkov, I. V. Russ. Chem. Bull. 2002, 51, 367–443. doi:10.1023/a:1015565600068

Return to citation in text: [1] -

Martín, N.; Sánchez, L.; Illescas, B.; Pérez, I. Chem. Rev. 1998, 98, 2527–2548. doi:10.1021/cr9701039

Return to citation in text: [1] -

Tzirakis, M. D.; Orfanopoulos, M. Chem. Rev. 2013, 113, 5262–5321. doi:10.1021/cr300475r

Return to citation in text: [1] -

Li, C.-Z.; Yip, H.-L.; Jen, A. K.-Y. J. Mater. Chem. 2012, 22, 4161–4177. doi:10.1039/c2jm15126j

Return to citation in text: [1] -

Kästner, C.; Ulbricht, C.; Egbe, D. A. M.; Hoppe, H. J. Polym. Sci., Part B: Polym. Phys. 2012, 50, 1562–1566. doi:10.1002/polb.23141

Return to citation in text: [1] -

He, Y.; Li, Y. Phys. Chem. Chem. Phys. 2011, 13, 1970–1983. doi:10.1039/c0cp01178a

Return to citation in text: [1] -

Thompson, B. C.; Fréchet, J. M. J. Angew. Chem., Int. Ed. 2008, 47, 58–77. doi:10.1002/anie.200702506

Return to citation in text: [1] -

Diederich, F.; Isaacs, L.; Philp, D. Chem. Soc. Rev. 1994, 23, 243–255. doi:10.1039/cs9942300243

Return to citation in text: [1] -

Tuktarov, A. R.; Dzhemilev, U. M. Russ. Chem. Rev. 2010, 79, 585–610. doi:10.1070/rc2010v079n07abeh004111

Return to citation in text: [1] -

Yamada, M.; Akasaka, T.; Nagase, S. Chem. Rev. 2013, 113, 7209–7264. doi:10.1021/cr3004955

Return to citation in text: [1] -

Bingel, C. Chem. Ber. 1993, 126, 1957–1959. doi:10.1002/cber.19931260829

Return to citation in text: [1] -

Diederich, F.; Isaacs, L.; Philp, D. J. Chem. Soc., Perkin Trans. 2 1994, 391–394. doi:10.1039/p29940000391

Return to citation in text: [1] [2] -

Raghavachari, K.; Sosa, C. Chem. Phys. Lett. 1993, 209, 223–228. doi:10.1016/0009-2614(93)80097-9

Return to citation in text: [1] -

Hall, M. H.; Lu, H.; Shevlin, P. B. J. Am. Chem. Soc. 2001, 123, 1349–1354. doi:10.1021/ja003042w

Return to citation in text: [1] [2] [3] [4] [5] [6] [7] [8] -

Suzuki, T.; Li, Q.; Khemani, K. C.; Wudl, F.; Almarsson, O. Science 1991, 254, 1186–1188. doi:10.1126/science.254.5035.1186

Return to citation in text: [1] -

Smith, A. B.; Strongin, R. M.; Brard, L.; Furst, G. T.; Romanow, W. J.; Owens, K. G.; King, R. C. J. Am. Chem. Soc. 1993, 115, 5829–5830. doi:10.1021/ja00066a063

Return to citation in text: [1] -

Smith, A. B.; Strongin, R. M.; Brard, L.; Furst, G. T.; Romanow, W. J.; Owens, K. G.; Goldschmidt, R. J.; King, R. C. J. Am. Chem. Soc. 1995, 117, 5492–5502. doi:10.1021/ja00125a009

Return to citation in text: [1] -

Isaacs, L.; Diederich, F. Helv. Chim. Acta 1993, 76, 2454–2464. doi:10.1002/hlca.19930760705

Return to citation in text: [1] [2] [3] [4] [5] [6] [7] -

Isaacs, L.; Wehrsig, A.; Diederich, F. Helv. Chim. Acta 1993, 76, 1231–1250. doi:10.1002/hlca.19930760310

Return to citation in text: [1] -

Pellicciari, R.; Annibali, D.; Costantino, G.; Marinozzi, M.; Natalini, B. Synlett 1997, 1196–1198. doi:10.1055/s-1997-980

Return to citation in text: [1] -

Prato, M.; Bianco, A.; Maggini, M.; Scorrano, G.; Toniolo, C.; Wudl, F. J. Org. Chem. 1993, 58, 5578–5580. doi:10.1021/jo00073a004

Return to citation in text: [1] -

Toniolo, C.; Bianco, A.; Maggini, M.; Scorrano, G.; Prato, M.; Marastoni, M.; Tomatis, R.; Spisani, S.; Palu, G.; Blair, E. D. J. Med. Chem. 1994, 37, 4558–4562. doi:10.1021/jm00052a015

Return to citation in text: [1] -

Skiebe, A.; Hirsch, A. J. Chem. Soc., Chem. Commun. 1994, 335–336. doi:10.1039/c39940000335

Return to citation in text: [1] -

Sijbesma, R.; Srdanov, G.; Wudl, F.; Castoro, J. A.; Wilkins, C.; Friedman, S. H.; DeCamp, D. L.; Kenyon, G. L. J. Am. Chem. Soc. 1993, 115, 6510–6512. doi:10.1021/ja00068a006

Return to citation in text: [1] -

Prato, M.; Lucchini, V.; Maggini, M.; Stimpfl, E.; Scorrano, G.; Eiermann, M.; Suzuki, T.; Wudl, F. J. Am. Chem. Soc. 1993, 115, 8479–8480. doi:10.1021/ja00071a080

Return to citation in text: [1] [2] -

Eiermann, M.; Wudl, F.; Prato, M.; Maggini, M. J. Am. Chem. Soc. 1994, 116, 8364–8365. doi:10.1021/ja00097a053

Return to citation in text: [1] -

Osterodt, J.; Windscheif, P.-M.; Vögtle, F.; Nieger, M. Chem. Ber. 1993, 126, 2331–2336. doi:10.1002/cber.19931261023

Return to citation in text: [1] [2] -

Osterodt, J.; Zett, A.; Vögtle, F. Tetrahedron 1996, 52, 4949–4962. doi:10.1016/0040-4020(96)00103-2

Return to citation in text: [1] -

Wilson, S. R.; Wu, Y. J. Chem. Soc., Chem. Commun. 1993, 784–786. doi:10.1039/c39930000784

Return to citation in text: [1] -

Suzuki, T.; Li, Q.; Khemani, K. C.; Wudl, F.; Almarsson, O. J. Am. Chem. Soc. 1992, 114, 7300–7301. doi:10.1021/ja00044a054

Return to citation in text: [1] [2] -

Hummelen, J. C.; Knight, B. W.; LePeq, F.; Wudl, F.; Yao, J.; Wilkins, C. L. J. Org. Chem. 1995, 60, 532–538. doi:10.1021/jo00108a012

Return to citation in text: [1] [2] -

Rossi, E.; Carofiglio, T.; Venturi, A.; Ndobe, A.; Muccini, M.; Maggini, M. Energy Environ. Sci. 2011, 4, 725–727. doi:10.1039/c0ee00314j

Return to citation in text: [1] -

Umek, P.; Omerzu, A.; Mihailović, D.; Tokumoto, M. Chem. Phys. 2000, 253, 361–366. doi:10.1016/s0301-0104(99)00404-8

Return to citation in text: [1] -

Mrzel, A.; Umek, P.; Cevc, P.; Omerzu, A.; Mihailovic, D. Carbon 1998, 36, 603–606. doi:10.1016/s0008-6223(98)00012-8

Return to citation in text: [1] -

Herranz, M. Á.; Beulen, M. W. J.; Rivera, J. A.; Echegoyen, L.; Díaz, M. C.; Illescas, B. M.; Martín, N. J. Mater. Chem. 2002, 12, 2048–2053. doi:10.1039/b202040h

Return to citation in text: [1] -

Yamada, M.; Harada, K.; Maeda, Y.; Hasegawa, T. New J. Chem. 2013, 37, 3762–3769. doi:10.1039/c3nj00796k

Return to citation in text: [1] -

Meijer, M. D.; Rump, M.; Gossage, R. A.; Jastrzebski, J. H. T. B.; van Koten, G. Tetrahedron Lett. 1998, 39, 6773–6776. doi:10.1016/s0040-4039(98)01423-3

Return to citation in text: [1] -

Meijer, M. D.; van Klink, G. P. M.; de Bruin, B.; van Koten, G. Inorg. Chim. Acta 2002, 327, 31–40. doi:10.1016/s0020-1693(01)00685-5

Return to citation in text: [1] [2] -

Meijer, M. D.; Ronde, N.; Vogt, D.; van Klink, G. P. M.; van Koten, G. Organometallics 2001, 20, 3993–4000. doi:10.1021/om010292s

Return to citation in text: [1] [2] [3] -

Meijer, M. D.; de Wolf, E.; Lutz, M.; Spek, A. L.; van Klink, G. P. M.; van Koten, G. Organometallics 2001, 20, 4198–4206. doi:10.1021/om010328g

Return to citation in text: [1] -

Meijer, M. D.; Mulder, B.; van Klink, G. P. M.; van Koten, G. Inorg. Chim. Acta 2003, 352, 247–252. doi:10.1016/s0020-1693(03)00138-5

Return to citation in text: [1] -

Vasella, A.; Uhlmann, P.; Waldraff, C. A. A.; Diederich, F.; Thilgen, C. Angew. Chem., Int. Ed. Engl. 1992, 31, 1388–1390. doi:10.1002/anie.199213881

Return to citation in text: [1] -

Prato, M.; Suzuki, T.; Wudl, F.; Lucchini, V.; Maggini, M. J. Am. Chem. Soc. 1993, 115, 7876–7877. doi:10.1021/ja00070a043

Return to citation in text: [1] -

Ohno, T.; Martín, N.; Knight, B.; Wudl, F.; Suzuki, T.; Yu, H. J. Org. Chem. 1996, 61, 1306–1309. doi:10.1021/jo951738f

Return to citation in text: [1] -

Almy, J.; Herrera, A.; Martín, N.; Seoane, C.; Suzuki, T.; Wudl, F. J. Chem. Educ. 1996, 73, A105. doi:10.1021/ed073pa105

Return to citation in text: [1] -

Knight, B.; Martín, N.; Ohno, T.; Ortí, E.; Rovira, C.; Veciana, J.; Vidal-Gancedo, J.; Viruela, P.; Viruela, R.; Wudl, F. J. Am. Chem. Soc. 1997, 119, 9871–9882. doi:10.1021/ja962299k

Return to citation in text: [1] [2] -

Beulen, M. W. J.; Rivera, J. A.; Herranz, M. Á.; Illescas, B.; Martín, N.; Echegoyen, L. J. Org. Chem. 2001, 66, 4393–4398. doi:10.1021/jo010297z

Return to citation in text: [1] -

Zheng, L.; Zhou, Q.; Deng, X.; Sun, D.; Yuan, M.; Yu, G.; Cao, Y. Synth. Met. 2003, 135–136, 827–828. doi:10.1016/s0379-6779(02)00916-5

Return to citation in text: [1] [2] [3] -

Yang, C.-H.; Chang, J.-Y.; Yeh, P.-H.; Guo, T.-F. Carbon 2007, 45, 2951–2956. doi:10.1016/j.carbon.2007.09.050

Return to citation in text: [1] -

Zheng, L.; Zhou, Q.; Deng, X.; Yuan, M.; Yu, G.; Cao, Y. J. Phys. Chem. B 2004, 108, 11921–11926. doi:10.1021/jp048890i

Return to citation in text: [1] -

Naqvi, S.; Gupta, N.; Kumari, N.; Garg, J.; Kumar, R. New J. Chem. 2017, 41, 1933–1939. doi:10.1039/c6nj03445d

Return to citation in text: [1] [2] -

Moriwaki, K.; Matsumoto, F.; Takao, Y.; Shimizu, D.; Ohno, T. Tetrahedron 2010, 66, 7316–7321. doi:10.1016/j.tet.2010.06.089

Return to citation in text: [1] [2] [3] -

Troshin, P. A.; Khakina, E. A.; Egginger, M.; Goryachev, A. E.; Troyanov, S. I.; Fuchsbauer, A.; Peregudov, A. S.; Lyubovskaya, R. N.; Razumov, V. F.; Sariciftci, N. S. ChemSusChem 2010, 3, 356–366. doi:10.1002/cssc.200900196

Return to citation in text: [1] [2] [3] [4] -

Choi, J. H.; Son, K.-I.; Kim, T.; Kim, K.; Ohkubo, K.; Fukuzumi, S. J. Mater. Chem. 2010, 20, 475–482. doi:10.1039/b916597e

Return to citation in text: [1] [2] [3] -

Takagi, A.; Mizutani, T.; Moriwaki, K.; Takao, Y.; Matsumoto, F.; Hida, K.; Iwai, T.; Ito, T.; Mizuno, T.; Ohno, T. Synth. Met. 2016, 215, 223–228. doi:10.1016/j.synthmet.2016.03.005

Return to citation in text: [1] [2] [3] [4] [5] [6] -

Chuang, S.-C.; Chiu, C.-W.; Chien, S.-C.; Chu, C.-W.; Chen, F.-C. Synth. Met. 2011, 161, 1264–1269. doi:10.1016/j.synthmet.2011.04.021

Return to citation in text: [1] [2] -

Troshin, P. A.; Hoppe, H.; Renz, J.; Egginger, M.; Mayorova, J. Y.; Goryachev, A. E.; Peregudov, A. S.; Lyubovskaya, R. N.; Gobsch, G.; Sariciftci, N. S.; Razumov, V. F. Adv. Funct. Mater. 2009, 19, 779–788. doi:10.1002/adfm.200801189

Return to citation in text: [1] [2] [3] [4] -

Mayorova, J. Y.; Nikitenko, S. L.; Troshin, P. A.; Peregudova, S. M.; Peregudov, A. S.; Kaplunov, M. G.; Lyubovskaya, R. N. Mendeleev Commun. 2007, 17, 175–177. doi:10.1016/j.mencom.2007.05.015

Return to citation in text: [1] [2] [3] [4] [5] [6] [7] -

Zhao, G.; He, Y.; Xu, Z.; Hou, J.; Zhang, M.; Min, J.; Chen, H.-Y.; Ye, M.; Hong, Z.; Yang, Y.; Li, Y. Adv. Funct. Mater. 2010, 20, 1480–1487. doi:10.1002/adfm.200902447

Return to citation in text: [1] [2] [3] [4] [5] -

Kostyanovsky, V. A.; Susarova, D. K.; Peregudov, A. S.; Troshin, P. A. Thin Solid Films 2011, 519, 4119–4122. doi:10.1016/j.tsf.2010.11.059

Return to citation in text: [1] [2] -

Liu, C.; Li, Y.; Li, C.; Li, W.; Zhou, C.; Liu, H.; Bo, Z.; Li, Y. J. Phys. Chem. C 2009, 113, 21970–21975. doi:10.1021/jp907240n

Return to citation in text: [1] [2] [3] [4] -

Liu, C.; Xiao, S.; Shu, X.; Li, Y.; Xu, L.; Liu, T.; Yu, Y.; Zhang, L.; Liu, H.; Li, Y. ACS Appl. Mater. Interfaces 2012, 4, 1065–1071. doi:10.1021/am2016975

Return to citation in text: [1] [2] -

Yamada, I.; Pandey, M.; Hayashi, Y.; Shibata, N.; Soga, T.; Toru, T. Phys. Procedia 2011, 14, 192–197. doi:10.1016/j.phpro.2011.05.039

Return to citation in text: [1] [2] [3] [4] -

Wang, Y.-W.; Zhang, W.; Ai, X.-C.; Zhang, J.-P.; Wang, X.-F.; Kido, J. J. Phys. Chem. C 2013, 117, 25898–25907. doi:10.1021/jp407990d

Return to citation in text: [1] [2] -

Yang, C.; Kim, J. Y.; Cho, S.; Lee, J. K.; Heeger, A. J.; Wudl, F. J. Am. Chem. Soc. 2008, 130, 6444–6450. doi:10.1021/ja710621j

Return to citation in text: [1] [2] -

Rispens, M. T.; Sánchez, L.; Knol, J.; Hummelen, J. C. Chem. Commun. 2001, 161–162. doi:10.1039/b008006n

Return to citation in text: [1] [2] [3] -

Matsumoto, F.; Iwai, T.; Moriwaki, K.; Takao, Y.; Ito, T.; Mizuno, T.; Ohno, T. ACS Appl. Mater. Interfaces 2016, 8, 4803–4810. doi:10.1021/acsami.5b11180

Return to citation in text: [1] [2] [3] [4] [5] [6] [7] [8] -

Cheon, K.-S.; Waller, D. Fullerene derivatives. W.O. Patent WO2011160021A2, Dec 22, 2011.

Return to citation in text: [1] [2] [3] -

Tsumoto, H.; Takahashi, K.; Suzuki, T.; Nakagawa, H.; Kohda, K.; Miyata, N. Bioorg. Med. Chem. Lett. 2008, 18, 657–660. doi:10.1016/j.bmcl.2007.11.065

Return to citation in text: [1] [2] [3] -

Iwai, T.; Matsumoto, F.; Hida, K.; Moriwaki, K.; Takao, Y.; Ito, T.; Mizuno, T.; Ohno, T. Synlett 2015, 26, 960–964. doi:10.1055/s-0034-1380127

Return to citation in text: [1] [2] [3] [4] -

Kim, H. U.; Kim, J.-H.; Kang, H.; Grimsdale, A. C.; Kim, B. J.; Yoon, S. C.; Hwang, D.-H. ACS Appl. Mater. Interfaces 2014, 6, 20776–20785. doi:10.1021/am504939c

Return to citation in text: [1] [2] [3] [4] [5] -

Zhang, Y.; Yip, H.-L.; Acton, O.; Hau, S. K.; Huang, F.; Jen, A. K.-Y. Chem. Mater. 2009, 21, 2598–2600. doi:10.1021/cm9009282

Return to citation in text: [1] [2] [3] -

Kim, S.-O.; Chung, D. S.; Cha, H.; Jang, J. W.; Kim, Y.-H.; Kang, J.-W.; Jeong, Y.-S.; Park, C. E.; Kwon, S.-K. Sol. Energy Mater. Sol. Cells 2011, 95, 432–439. doi:10.1016/j.solmat.2010.08.009

Return to citation in text: [1] [2] -

Kim, H. U.; Mi, D.; Kim, J.-H.; Park, J. B.; Yoon, S. C.; Yoon, U. C.; Hwang, D.-H. Sol. Energy Mater. Sol. Cells 2012, 105, 6–14. doi:10.1016/j.solmat.2012.05.017

Return to citation in text: [1] [2] -

Sakthivel, P.; Kranthiraja, K.; Saravanan, C.; Gunasekar, K.; Kim, H. I.; Shin, W. S.; Jeong, J.-E.; Woo, H. Y.; Jin, S.-H. J. Mater. Chem. A 2014, 2, 6916–6921. doi:10.1039/c4ta00013g

Return to citation in text: [1] [2] [3] -

Liu, C.; Li, Y.; Chi, D.; Chen, S.; Liu, T.; Wang, J.; Liu, H.; Li, Y. Fullerenes, Nanotubes, Carbon Nanostruct. 2014, 22, 289–298. doi:10.1080/1536383x.2013.801837

Return to citation in text: [1] -

Liu, C.; Xu, L.; Chi, D.; Li, Y.; Liu, H.; Wang, J. ACS Appl. Mater. Interfaces 2013, 5, 1061–1069. doi:10.1021/am3028475

Return to citation in text: [1] -

Ohno, T.; Moriwaki, K.; Miyata, T. J. Org. Chem. 2001, 66, 3397–3401. doi:10.1021/jo001100q

Return to citation in text: [1] -

Mi, D.; Kim, J.-H.; Xu, F.; Lee, S.-H.; Yoon, S. C.; Shin, W. S.; Moon, S.-J.; Lee, C.; Hwang, D.-H. Sol. Energy Mater. Sol. Cells 2011, 95, 1182–1187. doi:10.1016/j.solmat.2010.12.052

Return to citation in text: [1] -

Mi, D.; Kim, J.-H.; Yoon, S. C.; Lee, C.; Lee, J.-K.; Hwang, D.-H. Synth. Met. 2011, 161, 1330–1335. doi:10.1016/j.synthmet.2011.04.031

Return to citation in text: [1] -

Martín, N.; Sánchez, L.; Guldi, D. M. Chem. Commun. 2000, 113–114. doi:10.1039/a908770b

Return to citation in text: [1] -

Giacalone, F.; Segura, J. L.; Martín, N. J. Org. Chem. 2002, 67, 3529–3532. doi:10.1021/jo020088u

Return to citation in text: [1] -

Sukeguchi, D.; Singh, S. P.; Reddy, M. R.; Yoshiyama, H.; Afre, R. A.; Hayashi, Y.; Inukai, H.; Soga, T.; Nakamura, S.; Shibata, N.; Toru, T. Beilstein J. Org. Chem. 2009, 5, No. 7. doi:10.3762/bjoc.5.7

Return to citation in text: [1] -

Chang, C.-L.; Liang, C.-W.; Syu, J.-J.; Wang, L.; Leung, M.-k. Sol. Energy Mater. Sol. Cells 2011, 95, 2371–2379. doi:10.1016/j.solmat.2011.04.008

Return to citation in text: [1] -

Avent, A. G.; Birkett, P. R.; Paolucci, F.; Roffia, S.; Taylor, R.; Wachter, N. K. J. Chem. Soc., Perkin Trans. 2 2000, 1409–1414. doi:10.1039/b002178o

Return to citation in text: [1] -

Kornev, A. B.; Peregudov, A. S.; Martynenko, V. M.; Guseva, G. V.; Sashenkova, T. E.; Rybkin, A. Y.; Faingold, I. I.; Mishchenko, D. V.; Kotelnikova, R. A.; Konovalova, N. P.; Balzarini, J.; Troshin, P. A. Mendeleev Commun. 2013, 23, 323–325. doi:10.1016/j.mencom.2013.11.006

Return to citation in text: [1] -

Nagarjuna, P.; Bagui, A.; Hou, J.; Singh, S. P. J. Phys. Chem. C 2016, 120, 13390–13397. doi:10.1021/acs.jpcc.6b03768

Return to citation in text: [1] -

Barthelmes, K.; Kübel, J.; Winter, A.; Wächtler, M.; Friebe, C.; Dietzek, B.; Schubert, U. S. Inorg. Chem. 2015, 54, 3159–3171. doi:10.1021/ic502431x

Return to citation in text: [1] [2] -

Li, Z.; Bouhadir, K. H.; Shevlin, P. B. Tetrahedron Lett. 1996, 37, 4651–4654. doi:10.1016/0040-4039(96)00917-3

Return to citation in text: [1] -

Tian, C.-B.; Deng, L.-L.; Zhang, Z.-Q.; Dai, S.-M.; Gao, C.-L.; Xie, S.-Y.; Huang, R.-B.; Zheng, L.-S. Sol. Energy Mater. Sol. Cells 2014, 125, 198–205. doi:10.1016/j.solmat.2014.03.015

Return to citation in text: [1] -

Yang, T.; Jiang, Z.; Huang, X.; Wei, H.; Yuan, J.; Yue, W.; Li, Y.; Ma, W. Org. Electron. 2013, 14, 2184–2191. doi:10.1016/j.orgel.2013.05.017

Return to citation in text: [1] -

Zhou, Z.; Lin, Z.-X.; Liang, D.; Hu, J.-Q. Tetrahedron 2013, 69, 43–49. doi:10.1016/j.tet.2012.10.071

Return to citation in text: [1] -

Kay, K.-Y.; Kim, L. H.; Oh, I. C. Tetrahedron Lett. 2000, 41, 1397–1400. doi:10.1016/s0040-4039(99)02301-1

Return to citation in text: [1] -

Lin, G.; Cui, R.; Huang, H.; Guo, X.; Yang, S.; Li, C.; Dong, J.; Sun, B. Tetrahedron 2015, 71, 7998–8002. doi:10.1016/j.tet.2015.08.064

Return to citation in text: [1] -

Mollahosseini, M.; Karunaratne, E.; Gibson, G. N.; Gascón, J. A.; Papadimitrakopoulos, F. J. Am. Chem. Soc. 2016, 138, 5904–5915. doi:10.1021/jacs.5b13496

Return to citation in text: [1] -

Naqvi, S.; Gupta, N.; Kumari, N.; Jewariya, M.; Kumar, P.; Kumar, R.; Chand, S. RSC Adv. 2016, 6, 24889–24897. doi:10.1039/c6ra01189f

Return to citation in text: [1] -

Sanchez, L.; Rispens, M. T.; Hummelen, J. C. Angew. Chem., Int. Ed. 2002, 41, 838–840. doi:10.1002/1521-3773(20020301)41:5<838::aid-anie838>3.0.co;2-f

Return to citation in text: [1] -

Cowart, J. S., Jr.; Liman, C.; Garnica, A.; Page, Z. A.; Lim, E.; Zope, R. R.; Baruah, T.; Hawker, C. J.; Chabinyc, M. L. Inorg. Chim. Acta 2017, 468, 192–202. doi:10.1016/j.ica.2017.07.008

Return to citation in text: [1] -

Anderson, H. L.; Faust, R.; Rubin, Y.; Diederich, F. Angew. Chem. 1994, 106, 1427–1429. doi:10.1002/ange.19941061314

Return to citation in text: [1] -

Timmerman, P.; Anderson, H. L.; Faust, R.; Nierengarten, J.-F.; Habicher, T.; Seiler, P.; Diederich, F. Tetrahedron 1996, 52, 4925–4947. doi:10.1016/0040-4020(96)00102-0

Return to citation in text: [1]

| 83. | Isaacs, L.; Diederich, F. Helv. Chim. Acta 1993, 76, 2454–2464. doi:10.1002/hlca.19930760705 |

| 83. | Isaacs, L.; Diederich, F. Helv. Chim. Acta 1993, 76, 2454–2464. doi:10.1002/hlca.19930760705 |

| 111. | Knight, B.; Martín, N.; Ohno, T.; Ortí, E.; Rovira, C.; Veciana, J.; Vidal-Gancedo, J.; Viruela, P.; Viruela, R.; Wudl, F. J. Am. Chem. Soc. 1997, 119, 9871–9882. doi:10.1021/ja962299k |

| 112. | Beulen, M. W. J.; Rivera, J. A.; Herranz, M. Á.; Illescas, B.; Martín, N.; Echegoyen, L. J. Org. Chem. 2001, 66, 4393–4398. doi:10.1021/jo010297z |

| 110. | Almy, J.; Herrera, A.; Martín, N.; Seoane, C.; Suzuki, T.; Wudl, F. J. Chem. Educ. 1996, 73, A105. doi:10.1021/ed073pa105 |

| 164. | Anderson, H. L.; Faust, R.; Rubin, Y.; Diederich, F. Angew. Chem. 1994, 106, 1427–1429. doi:10.1002/ange.19941061314 |

| 165. | Timmerman, P.; Anderson, H. L.; Faust, R.; Nierengarten, J.-F.; Habicher, T.; Seiler, P.; Diederich, F. Tetrahedron 1996, 52, 4925–4947. doi:10.1016/0040-4020(96)00102-0 |

| 163. | Cowart, J. S., Jr.; Liman, C.; Garnica, A.; Page, Z. A.; Lim, E.; Zope, R. R.; Baruah, T.; Hawker, C. J.; Chabinyc, M. L. Inorg. Chim. Acta 2017, 468, 192–202. doi:10.1016/j.ica.2017.07.008 |

| 63. | Zhu, S.-E.; Li, F.; Wang, G.-W. Chem. Soc. Rev. 2013, 42, 7535–7570. doi:10.1039/c3cs35494f |

| 113. | Zheng, L.; Zhou, Q.; Deng, X.; Sun, D.; Yuan, M.; Yu, G.; Cao, Y. Synth. Met. 2003, 135–136, 827–828. doi:10.1016/s0379-6779(02)00916-5 |

| 116. | Naqvi, S.; Gupta, N.; Kumari, N.; Garg, J.; Kumar, R. New J. Chem. 2017, 41, 1933–1939. doi:10.1039/c6nj03445d |

| 113. | Zheng, L.; Zhou, Q.; Deng, X.; Sun, D.; Yuan, M.; Yu, G.; Cao, Y. Synth. Met. 2003, 135–136, 827–828. doi:10.1016/s0379-6779(02)00916-5 |

| 161. | Naqvi, S.; Gupta, N.; Kumari, N.; Jewariya, M.; Kumar, P.; Kumar, R.; Chand, S. RSC Adv. 2016, 6, 24889–24897. doi:10.1039/c6ra01189f |

| 96. | Hummelen, J. C.; Knight, B. W.; LePeq, F.; Wudl, F.; Yao, J.; Wilkins, C. L. J. Org. Chem. 1995, 60, 532–538. doi:10.1021/jo00108a012 |

| 162. | Sanchez, L.; Rispens, M. T.; Hummelen, J. C. Angew. Chem., Int. Ed. 2002, 41, 838–840. doi:10.1002/1521-3773(20020301)41:5<838::aid-anie838>3.0.co;2-f |

| 83. | Isaacs, L.; Diederich, F. Helv. Chim. Acta 1993, 76, 2454–2464. doi:10.1002/hlca.19930760705 |

| 131. | Rispens, M. T.; Sánchez, L.; Knol, J.; Hummelen, J. C. Chem. Commun. 2001, 161–162. doi:10.1039/b008006n |

| 117. | Moriwaki, K.; Matsumoto, F.; Takao, Y.; Shimizu, D.; Ohno, T. Tetrahedron 2010, 66, 7316–7321. doi:10.1016/j.tet.2010.06.089 |

| 124. | Zhao, G.; He, Y.; Xu, Z.; Hou, J.; Zhang, M.; Min, J.; Chen, H.-Y.; Ye, M.; Hong, Z.; Yang, Y.; Li, Y. Adv. Funct. Mater. 2010, 20, 1480–1487. doi:10.1002/adfm.200902447 |