Abstract

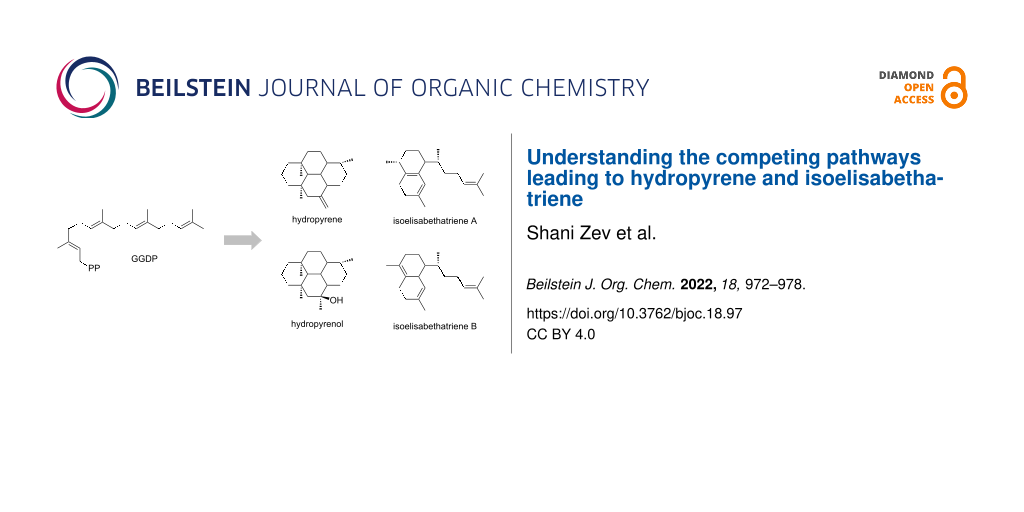

Terpene synthases are responsible for the biosynthesis of terpenes, the largest family of natural products. Hydropyrene synthase generates hydropyrene and hydropyrenol as its main products along with two byproducts, isoelisabethatrienes A and B. Fascinatingly, a single active site mutation (M75L) diverts the product distribution towards isoelisabethatrienes A and B. In the current work, we study the competing pathways leading to these products using quantum chemical calculations in the gas phase. We show that there is a great thermodynamic preference for hydropyrene and hydropyrenol formation, and hence most likely in the synthesis of the isoelisabethatriene products kinetic control is at play.

Graphical Abstract

Introduction

Terpenes constitute a ubiquitous class of natural molecules that are synthesized by terpene synthases (TPS). TPS generate a plethora of terpenes employing rich carbocation chemistry from a very limited number of substrates, known as geranyl pyrophosphate (GPP), farnesyl pyrophosphate (FPP), and geranylgeranyl pyrophosphate (GGPP), to produce mono-, sesqui-, and diterpenes, respectively. The formation of terpenes relies on an assortment of carbocation steps like cyclization, methyl migrations, rearrangements, proton or hydride transfers, hydroxylations, and epoxidations. TPS and downstream functionalizing enzymes, like P450s, together produce more than 80,000 known terpenes and terpenoids [1-3].

Hydropyrene synthase (HpS) from Streptomyces clavuligerus generates a mixture of diterpenes named hydropyrene (HP) (52%) and diterpenoid named hydropyrenol (HPol) (26%) as its main GGPP cyclization products, along with two minor compounds, namely the isoelisabethatrienes (IEs) A (13%) and B (9%), respectively. Interestingly, the elisabethatriene diterpene macrocycle and its isoforms can act as biosynthetic precursors of the bioactive compounds erogorgiaene and pseudopterosin, having antibiotic and anti-inflammatory activities, respectively [4,5]. Unexpectedly, a single active site mutation, M75L, significantly shifts the product distribution and IE A becomes the dominant product (44%) in this enzyme variant [6].

As suggested by Rinkel et al., both routes (HP and IE routes) proceed from the same substrate (GGPP) with an initial C1–C10 cyclization. In other TPS enzymes, the initial fold of GGPP in the active site can result in different initial cyclization, for example C1–C6, C1–C7, C1–C10, C1–C11, C1–C14, and C1–C15. The main difference between the two pathways to HP and IE, is that in the HP pathway C1–C10 cyclization occurs immediately, while in the IE pathway a substrate transoid to cisoid conformational change occurs, shifting the covalent attachment point (i.e., C1 to C3) between the substrate hydrocarbon and the pyrophosphate group [7] (Figure 1). Presumably, this isomerization is responsible for a slightly different substrate fold inside the active site, hence shifting the product distribution in favor of the IE products in certain enzyme variants rather than the HP products.

Figure 1: Summary of yields of HP and IE products in hydropyrene synthase.

Figure 1: Summary of yields of HP and IE products in hydropyrene synthase.

Oxidation of IEs A and B by lipases results in the formation of the advanced pseudopterosin (P) precursor erogorgiaene and (1R)-epoxyelisabetha-5,14-diene (EED), respectively [6,7]. Ps, marine amphilectane-type diterpenoids from the gorgonian coral Antillogorgia elisabethae, feature superior anti-inflammatory properties which render them innovative target compounds for drug development [8,9]. Hence, increasing the IE products at the expense of the HP products is an important biotechnology mission for sustainable supply of the latter. In order to modulate the IE and HP enzyme pathways accordingly, it is important to understand the factors determining both synthetic routes.

In the current work, we focus on the mechanistic details of the HP and IE pathways using computational methods in the gas phase. Gas-phase studies have been crucial in understanding terpene chemistry [10-22]. This work sheds light on the thermodynamic and kinetic parameters of the inherent chemistry in these reactions and also points to some understanding of the possible thermodynamic and kinetic control in the enzyme.

Results

Reaction mechanism

To better understand the HP and IE reaction pathways, we performed quantum mechanics (QM) calculations using density functional theory (DFT). We studied the inherent chemistry of the reaction leading to HP and IE using gas-phase calculations. This provided the free energy of distinct carbocation intermediates and transition states along the proposed reaction path leading to products in the gas phase. The gas phase is a natural choice as a reference environment for terpene synthases [10-12,15,16,21-25]. The proposed reaction mechanisms yielding HP and IE and are presented in Scheme 1, while the reaction free energy profile is presented in Figure 2. Here, we modeled the transformations A→I (HP) and A’→E’ (IE). The gas-phase calculations commenced with geranylgeranyl cation (A and A’) in a fully extended form.

Scheme 1: Proposed mechanism for HP and IE routes.

Scheme 1: Proposed mechanism for HP and IE routes.

![[1860-5397-18-97-2]](/bjoc/content/figures/1860-5397-18-97-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: Free energy profile of hydropyrene cation (a), and IE cation (b) formation in the gas phase. The free energy of cation A and A’ is set to zero. Bonds breaking/forming in the transition states are marked by dotted lines. All calculations were performed in the gas phase at the M06-2X/6-31G+(d,p) level of theory.

Figure 2: Free energy profile of hydropyrene cation (a), and IE cation (b) formation in the gas phase. The fr...

HP pathway

The HP gas-phase pathway commences with a C1–C10 cyclization, which yields cation B, which is more stable than A by −11.4 kcal/mol. A subsequent 1,3-hydride transfer results in an allyl cation (C), which is −18.5 kcal/mol more stable than A. The barrier for the 1,3-hydride transfer is 16.2 kcal/mol for B→C. Subsequently, the double bond on C14–C15 reacts with the cationic charge on C1 to form intermediate D, which is slightly less stable than C (−17.3 kcal/mol) In the enzyme environment intermediate D deprotonates to form intermediate E, while intermediate E is re-protonated to form intermediate F, which immediately transforms to intermediate G (i.e., F is not stable). G is significantly more stable than D (by −16.5 kcal/mol). G then transforms to the very stable 4-ring intermediate I without any free energy barrier. The deprotonation and re-protonation steps are not included in our calculations. The overall exergonicity of this process which transforms four π-bonds to σ-bonds, with accompanying gains in intramolecular dispersion interactions, is −62.8 kcal/mol.

IE pathway

As described above both pathways commence with a C1–C10 cyclization. However, in the IE pathway a preliminary isomerization step occurs via rotation around the C2–C3 bond, transforming from the trans to the cis form. In the enzyme this process occurs with the help of a pyrophosphate group. The C1–C10 cyclization yields cation B’, which is more stable than A’ by −15.7 kcal/mol. A subsequent 1,3-hydride transfer results in an allyl cation (C’, −32.1 kcal/mol relative to A’), with a barrier of 5.4 kcal/mol. Cation C’ collapses into D’ via a barrierless 1,6-ring closure (ΔGr of −35.9 kcal/mol relative to A’). D’ can be deprotonated to yield IE B or conversely may undergo a 1,2-hydride transfer, forming carbocation E’ (ΔGr of −34.4 kcal/mol relative to A’). This transformation has a ΔG‡ of 6.6 kcal/mol. Cation E’ may then be deprotonated to form IE A. Overall, the exergonicity for the formation of IEs A/B from carbocation A’ is significant, due to the exchange of two π-bonds for σ-bonds, as well as gain in dispersion interactions on folding of the extended geranylgeranyl cation.

Discussion

Although the current calculations were performed in the gas phase without inclusion of the enzyme environment, we may still generate some hypotheses regarding the enzymatic process. First, considering the similar free energy of IEs A and B and the small kinetic barrier separating them, these isomers may exist in equilibrium in the enzyme active site. The relative amount of IEs A and B may then be determined by their proximity to an active site base, as has been observed in other cases, like taxadiene synthase [26]. Second, the chemical changes occurring up to intermediates C and C’ in both routes are similar and diverge in the transformation of C→D and C’→D’. Here, we suggest that the ring closure in the IE pathway (C’→D’) occurs immediately due to the cis conformation and the short distance between the cation and the double bond (≈2 Å), which could be due to the active site substrate fold. In intermediate C, the trans conformation and possibly slightly different substrate fold, results in an alternative reaction route being followed (Figure 3). Lastly, considering the huge thermodynamic preference for the HP pathway, it is unlikely that a thermodynamic equilibrium exists between this pathway and the IE pathway. Rather, an equilibrium may exist between GGDP and LGDP, but once cyclization commences, the reactions will proceed until completion along their respective pathways. Hence, the difference in the product profile in WT and enzyme variants may be largely due to different folding of the initial substrate. Future in-enzyme studies can shed light on the preferred folding of GGDP inside the WT and variant enzymes and potentially the roles specific active site residues play during catalysis [23,24,27].

![[1860-5397-18-97-3]](/bjoc/content/figures/1860-5397-18-97-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: Structures of intermediates C‘ and C. The distance between the double bond and the cation in intermediate C‘ is 2.0 Å while in C the distance is 3.5 Å.

Figure 3: Structures of intermediates C‘ and C. The distance between the double bond and the cation in interm...

Conclusion

In the current work we performed gas-phase quantum chemistry calculations for the competing reaction pathways leading to IEs A and B as well as hydropyrene and hydropyrenol. In the former two reactions there is an exchange of two π-bonds for σ-bonds, resulting in a total exergonicity of −34.4 and −35.9 kcal/mol, respectively. In the latter two reactions which replace four π-bonds for σ-bonds and share a common final carbocation, the exergonicity is −62.8 kcal/mol. These values reflect the energetics of exchanging π-bonds for σ-bonds. In spite of the current calculations being performed in the gas phase, we may still generate some propositions regarding the enzymatic process. First, considering the similar free energy of IEs A and B and the low barrier between them, IEs A and B may exist in equilibrium in the enzyme active site. The proximity to an active site base may then determine the relative amount of IEs A and B. Second, it is unlikely that a thermodynamic equilibrium exists between the HP and IE pathways, due to the significant free energy barriers required for reverse barriers in the enzyme. Rather, an equilibrium may exist between GGDP and LGDP.

Experimental

Dynamics and Monte Carlo simulations

We generated conformers using simulated annealing (SA) molecular dynamics followed by SA Monte Carlo simulation using CHARMM [28]. Force field parameters were generated using CGenFF [29] and an in-house code which modifies parameters for cations from existing parameters for neutral molecules. For each intermediate in the reaction mechanism (path HP and IE) we created 100 conformers which were subsequently clustered (a cluster width of 1.0 Å was used). For each unique conformer we performed QM calculations and then chose the lowest energy conformer as representative of each carbocation intermediate in the mechanism. Hence, each intermediate state is represented by a single conformer, which is the lowest energy conformer found.

Quantum chemistry calculations

Optimizations and subsequent frequency calculations were performed using the Gaussian 16 program [30] at the M06-2X/6-31G+(d,p) level of theory [31,32]. This combination has been employed previously to TPS reactions [17,18,20,24,25,33-36]. The Gibbs free energies were calculated within the standard harmonic approximation and at a pressure of 1 bar and temperature of 298 K. We note that for some reaction steps, a transition state could not be located.

Supporting Information

| Supporting Information File 1: All coordinate files for intermediates and TS structures. | ||

| Format: RAR | Size: 14.3 KB | Download |

Funding

MR and TB gratefully acknowledge funding by the Werner Siemens foundation for establishing the field of Synthetic Biotechnology at TUM. This work was supported by a grant from the Israel Science Foundation (Grant 1683/18) (DTM) and by a grant from the German-Israeli Foundation for Scientific Research and Development (Grant I-85-302.14-2018) (DTM, TB, BL).

References

-

Croteau, R. Chem. Rev. 1987, 87, 929–954. doi:10.1021/cr00081a004

Return to citation in text: [1] -

Christianson, D. W. Chem. Rev. 2017, 117, 11570–11648. doi:10.1021/acs.chemrev.7b00287

Return to citation in text: [1] -

Cane, D. E. Chem. Rev. 1990, 90, 1089–1103. doi:10.1021/cr00105a002

Return to citation in text: [1] -

Movahhed, S.; Westphal, J.; Kempa, A.; Schumacher, C. E.; Sperlich, J.; Neudörfl, J.-M.; Teusch, N.; Hochgürtel, M.; Schmalz, H.-G. Chem. – Eur. J. 2021, 27, 11574–11579. doi:10.1002/chem.202101863

Return to citation in text: [1] -

Kohl, A. C.; Kerr, R. G. Mar. Drugs 2003, 1, 54–65. doi:10.3390/md101054

Return to citation in text: [1] -

Ringel, M.; Reinbold, M.; Hirte, M.; Haack, M.; Huber, C.; Eisenreich, W.; Masri, M. A.; Schenk, G.; Guddat, L. W.; Loll, B.; Kerr, R.; Garbe, D.; Brück, T. Green Chem. 2020, 22, 6033–6046. doi:10.1039/d0gc01697g

Return to citation in text: [1] [2] -

Rinkel, J.; Rabe, P.; Chen, X.; Köllner, T. G.; Chen, F.; Dickschat, J. S. Chem. – Eur. J. 2017, 23, 10501–10505. doi:10.1002/chem.201702704

Return to citation in text: [1] [2] -

Berrué, F.; McCulloch, M. W. B.; Kerr, R. G. Bioorg. Med. Chem. 2011, 19, 6702–6719. doi:10.1016/j.bmc.2011.06.083

Return to citation in text: [1] -

Mayer, A. M. S.; Jacobson, P. B.; Fenical, W.; Jacobs, R. S.; Glaser, K. B. Life Sci. 1998, 62, PL401–PL407. doi:10.1016/s0024-3205(98)00229-x

Return to citation in text: [1] -

Hong, Y. J.; Tantillo, D. J. Nat. Chem. 2009, 1, 384–389. doi:10.1038/nchem.287

Return to citation in text: [1] [2] -

Tantillo, D. J. Wiley Interdiscip. Rev.: Comput. Mol. Sci. 2020, 10, e1453. doi:10.1002/wcms.1453

Return to citation in text: [1] [2] -

Tantillo, D. J. Angew. Chem., Int. Ed. 2017, 56, 10040–10045. doi:10.1002/anie.201702363

Return to citation in text: [1] [2] -

Smentek, L.; Hess, B. A., Jr. J. Am. Chem. Soc. 2010, 132, 17111–17117. doi:10.1021/ja1039133

Return to citation in text: [1] -

Hess, B. A., Jr.; Smentek, L. Angew. Chem., Int. Ed. 2013, 52, 11029–11033. doi:10.1002/anie.201302886

Return to citation in text: [1] -

Tantillo, D. J. Chem. Soc. Rev. 2018, 47, 7845–7850. doi:10.1039/c8cs00298c

Return to citation in text: [1] [2] -

Tantillo, D. J. Nat. Prod. Rep. 2011, 28, 1035–1053. doi:10.1039/c1np00006c

Return to citation in text: [1] [2] -

Dixit, M.; Weitman, M.; Gao, J.; Major, D. T. ACS Catal. 2017, 7, 812–818. doi:10.1021/acscatal.6b02584

Return to citation in text: [1] [2] -

Major, D. T. ACS Catal. 2017, 7, 5461–5465. doi:10.1021/acscatal.7b01328

Return to citation in text: [1] [2] -

Weitman, M.; Major, D. T. J. Am. Chem. Soc. 2010, 132, 6349–6360. doi:10.1021/ja910134x

Return to citation in text: [1] -

Ansbacher, T.; Freud, Y.; Major, D. T. Biochemistry 2018, 57, 3773–3779. doi:10.1021/acs.biochem.8b00452

Return to citation in text: [1] [2] -

Hong, Y. J.; Tantillo, D. J. J. Am. Chem. Soc. 2009, 131, 7999–8015. doi:10.1021/ja9005332

Return to citation in text: [1] [2] -

Hong, Y. J.; Tantillo, D. J. J. Am. Chem. Soc. 2014, 136, 2450–2463. doi:10.1021/ja4106489

Return to citation in text: [1] [2] -

Raz, K.; Levi, S.; Gupta, P. K.; Major, D. T. Curr. Opin. Biotechnol. 2020, 65, 248–258. doi:10.1016/j.copbio.2020.06.002

Return to citation in text: [1] [2] -

Major, D. T.; Freud, Y.; Weitman, M. Curr. Opin. Chem. Biol. 2014, 21, 25–33. doi:10.1016/j.cbpa.2014.03.010

Return to citation in text: [1] [2] [3] -

Raz, K.; Driller, R.; Dimos, N.; Ringel, M.; Brück, T.; Loll, B.; Major, D. T. J. Am. Chem. Soc. 2020, 142, 21562–21574. doi:10.1021/jacs.0c11348

Return to citation in text: [1] [2] -

Schrepfer, P.; Buettner, A.; Goerner, C.; Hertel, M.; van Rijn, J.; Wallrapp, F.; Eisenreich, W.; Sieber, V.; Kourist, R.; Brück, T. Proc. Natl. Acad. Sci. U. S. A. 2016, 113, E958–E967. doi:10.1073/pnas.1519680113

Return to citation in text: [1] -

Das, S.; Shimshi, M.; Raz, K.; Nitoker Eliaz, N.; Mhashal, A. R.; Ansbacher, T.; Major, D. T. J. Chem. Theory Comput. 2019, 15, 5116–5134. doi:10.1021/acs.jctc.9b00366

Return to citation in text: [1] -

Brooks, B. R.; Bruccoleri, R. E.; Olafson, B. D.; States, D. J.; Swaminathan, S.; Karplus, M. J. Comput. Chem. 1983, 4, 187–217. doi:10.1002/jcc.540040211

Return to citation in text: [1] -

Vanommeslaeghe, K.; Hatcher, E.; Acharya, C.; Kundu, S.; Zhong, S.; Shim, J.; Darian, E.; Guvench, O.; Lopes, P.; Vorobyov, I.; Mackerell, A. D., Jr. J. Comput. Chem. 2010, 31, 671–690. doi:10.1002/jcc.21367

Return to citation in text: [1] -

Gaussian 16, Rev. A.03; Gaussian, Inc.: Wallingford, CT, 2016.

Return to citation in text: [1] -

Zhao, Y.; Truhlar, D. G. Theor. Chem. Acc. 2008, 120, 215–241. doi:10.1007/s00214-007-0310-x

Return to citation in text: [1] -

Nagy, B.; Jensen, F. Rev. Comput. Chem. 2017, 30, 93–149. doi:10.1002/9781119356059.ch3

Return to citation in text: [1] -

Das, S.; Dixit, M.; Major, D. T. Bioorg. Med. Chem. 2016, 24, 4867–4870. doi:10.1016/j.bmc.2016.07.002

Return to citation in text: [1] -

Pahima, E.; Zhang, Q.; Tiefenbacher, K.; Major, D. T. J. Am. Chem. Soc. 2019, 141, 6234–6246. doi:10.1021/jacs.8b13411

Return to citation in text: [1] -

Levi, S.; Zhang, Q.; Major, D. T. ACS Catal. 2020, 10, 6843–6853. doi:10.1021/acscatal.0c00278

Return to citation in text: [1] -

Zev, S.; Gupta, P. K.; Pahima, E.; Major, D. T. J. Chem. Theory Comput. 2022, 18, 167–178. doi:10.1021/acs.jctc.1c00746

Return to citation in text: [1]

| 1. | Croteau, R. Chem. Rev. 1987, 87, 929–954. doi:10.1021/cr00081a004 |

| 2. | Christianson, D. W. Chem. Rev. 2017, 117, 11570–11648. doi:10.1021/acs.chemrev.7b00287 |

| 3. | Cane, D. E. Chem. Rev. 1990, 90, 1089–1103. doi:10.1021/cr00105a002 |

| 6. | Ringel, M.; Reinbold, M.; Hirte, M.; Haack, M.; Huber, C.; Eisenreich, W.; Masri, M. A.; Schenk, G.; Guddat, L. W.; Loll, B.; Kerr, R.; Garbe, D.; Brück, T. Green Chem. 2020, 22, 6033–6046. doi:10.1039/d0gc01697g |

| 7. | Rinkel, J.; Rabe, P.; Chen, X.; Köllner, T. G.; Chen, F.; Dickschat, J. S. Chem. – Eur. J. 2017, 23, 10501–10505. doi:10.1002/chem.201702704 |

| 17. | Dixit, M.; Weitman, M.; Gao, J.; Major, D. T. ACS Catal. 2017, 7, 812–818. doi:10.1021/acscatal.6b02584 |

| 18. | Major, D. T. ACS Catal. 2017, 7, 5461–5465. doi:10.1021/acscatal.7b01328 |

| 20. | Ansbacher, T.; Freud, Y.; Major, D. T. Biochemistry 2018, 57, 3773–3779. doi:10.1021/acs.biochem.8b00452 |

| 24. | Major, D. T.; Freud, Y.; Weitman, M. Curr. Opin. Chem. Biol. 2014, 21, 25–33. doi:10.1016/j.cbpa.2014.03.010 |

| 25. | Raz, K.; Driller, R.; Dimos, N.; Ringel, M.; Brück, T.; Loll, B.; Major, D. T. J. Am. Chem. Soc. 2020, 142, 21562–21574. doi:10.1021/jacs.0c11348 |

| 33. | Das, S.; Dixit, M.; Major, D. T. Bioorg. Med. Chem. 2016, 24, 4867–4870. doi:10.1016/j.bmc.2016.07.002 |

| 34. | Pahima, E.; Zhang, Q.; Tiefenbacher, K.; Major, D. T. J. Am. Chem. Soc. 2019, 141, 6234–6246. doi:10.1021/jacs.8b13411 |

| 35. | Levi, S.; Zhang, Q.; Major, D. T. ACS Catal. 2020, 10, 6843–6853. doi:10.1021/acscatal.0c00278 |

| 36. | Zev, S.; Gupta, P. K.; Pahima, E.; Major, D. T. J. Chem. Theory Comput. 2022, 18, 167–178. doi:10.1021/acs.jctc.1c00746 |

| 7. | Rinkel, J.; Rabe, P.; Chen, X.; Köllner, T. G.; Chen, F.; Dickschat, J. S. Chem. – Eur. J. 2017, 23, 10501–10505. doi:10.1002/chem.201702704 |

| 6. | Ringel, M.; Reinbold, M.; Hirte, M.; Haack, M.; Huber, C.; Eisenreich, W.; Masri, M. A.; Schenk, G.; Guddat, L. W.; Loll, B.; Kerr, R.; Garbe, D.; Brück, T. Green Chem. 2020, 22, 6033–6046. doi:10.1039/d0gc01697g |

| 4. | Movahhed, S.; Westphal, J.; Kempa, A.; Schumacher, C. E.; Sperlich, J.; Neudörfl, J.-M.; Teusch, N.; Hochgürtel, M.; Schmalz, H.-G. Chem. – Eur. J. 2021, 27, 11574–11579. doi:10.1002/chem.202101863 |

| 5. | Kohl, A. C.; Kerr, R. G. Mar. Drugs 2003, 1, 54–65. doi:10.3390/md101054 |

| 31. | Zhao, Y.; Truhlar, D. G. Theor. Chem. Acc. 2008, 120, 215–241. doi:10.1007/s00214-007-0310-x |

| 32. | Nagy, B.; Jensen, F. Rev. Comput. Chem. 2017, 30, 93–149. doi:10.1002/9781119356059.ch3 |

| 26. | Schrepfer, P.; Buettner, A.; Goerner, C.; Hertel, M.; van Rijn, J.; Wallrapp, F.; Eisenreich, W.; Sieber, V.; Kourist, R.; Brück, T. Proc. Natl. Acad. Sci. U. S. A. 2016, 113, E958–E967. doi:10.1073/pnas.1519680113 |

| 28. | Brooks, B. R.; Bruccoleri, R. E.; Olafson, B. D.; States, D. J.; Swaminathan, S.; Karplus, M. J. Comput. Chem. 1983, 4, 187–217. doi:10.1002/jcc.540040211 |

| 10. | Hong, Y. J.; Tantillo, D. J. Nat. Chem. 2009, 1, 384–389. doi:10.1038/nchem.287 |

| 11. | Tantillo, D. J. Wiley Interdiscip. Rev.: Comput. Mol. Sci. 2020, 10, e1453. doi:10.1002/wcms.1453 |

| 12. | Tantillo, D. J. Angew. Chem., Int. Ed. 2017, 56, 10040–10045. doi:10.1002/anie.201702363 |

| 15. | Tantillo, D. J. Chem. Soc. Rev. 2018, 47, 7845–7850. doi:10.1039/c8cs00298c |

| 16. | Tantillo, D. J. Nat. Prod. Rep. 2011, 28, 1035–1053. doi:10.1039/c1np00006c |

| 21. | Hong, Y. J.; Tantillo, D. J. J. Am. Chem. Soc. 2009, 131, 7999–8015. doi:10.1021/ja9005332 |

| 22. | Hong, Y. J.; Tantillo, D. J. J. Am. Chem. Soc. 2014, 136, 2450–2463. doi:10.1021/ja4106489 |

| 23. | Raz, K.; Levi, S.; Gupta, P. K.; Major, D. T. Curr. Opin. Biotechnol. 2020, 65, 248–258. doi:10.1016/j.copbio.2020.06.002 |

| 24. | Major, D. T.; Freud, Y.; Weitman, M. Curr. Opin. Chem. Biol. 2014, 21, 25–33. doi:10.1016/j.cbpa.2014.03.010 |

| 25. | Raz, K.; Driller, R.; Dimos, N.; Ringel, M.; Brück, T.; Loll, B.; Major, D. T. J. Am. Chem. Soc. 2020, 142, 21562–21574. doi:10.1021/jacs.0c11348 |

| 29. | Vanommeslaeghe, K.; Hatcher, E.; Acharya, C.; Kundu, S.; Zhong, S.; Shim, J.; Darian, E.; Guvench, O.; Lopes, P.; Vorobyov, I.; Mackerell, A. D., Jr. J. Comput. Chem. 2010, 31, 671–690. doi:10.1002/jcc.21367 |

| 10. | Hong, Y. J.; Tantillo, D. J. Nat. Chem. 2009, 1, 384–389. doi:10.1038/nchem.287 |

| 11. | Tantillo, D. J. Wiley Interdiscip. Rev.: Comput. Mol. Sci. 2020, 10, e1453. doi:10.1002/wcms.1453 |

| 12. | Tantillo, D. J. Angew. Chem., Int. Ed. 2017, 56, 10040–10045. doi:10.1002/anie.201702363 |

| 13. | Smentek, L.; Hess, B. A., Jr. J. Am. Chem. Soc. 2010, 132, 17111–17117. doi:10.1021/ja1039133 |

| 14. | Hess, B. A., Jr.; Smentek, L. Angew. Chem., Int. Ed. 2013, 52, 11029–11033. doi:10.1002/anie.201302886 |

| 15. | Tantillo, D. J. Chem. Soc. Rev. 2018, 47, 7845–7850. doi:10.1039/c8cs00298c |

| 16. | Tantillo, D. J. Nat. Prod. Rep. 2011, 28, 1035–1053. doi:10.1039/c1np00006c |

| 17. | Dixit, M.; Weitman, M.; Gao, J.; Major, D. T. ACS Catal. 2017, 7, 812–818. doi:10.1021/acscatal.6b02584 |

| 18. | Major, D. T. ACS Catal. 2017, 7, 5461–5465. doi:10.1021/acscatal.7b01328 |

| 19. | Weitman, M.; Major, D. T. J. Am. Chem. Soc. 2010, 132, 6349–6360. doi:10.1021/ja910134x |

| 20. | Ansbacher, T.; Freud, Y.; Major, D. T. Biochemistry 2018, 57, 3773–3779. doi:10.1021/acs.biochem.8b00452 |

| 21. | Hong, Y. J.; Tantillo, D. J. J. Am. Chem. Soc. 2009, 131, 7999–8015. doi:10.1021/ja9005332 |

| 22. | Hong, Y. J.; Tantillo, D. J. J. Am. Chem. Soc. 2014, 136, 2450–2463. doi:10.1021/ja4106489 |

| 8. | Berrué, F.; McCulloch, M. W. B.; Kerr, R. G. Bioorg. Med. Chem. 2011, 19, 6702–6719. doi:10.1016/j.bmc.2011.06.083 |

| 9. | Mayer, A. M. S.; Jacobson, P. B.; Fenical, W.; Jacobs, R. S.; Glaser, K. B. Life Sci. 1998, 62, PL401–PL407. doi:10.1016/s0024-3205(98)00229-x |

| 23. | Raz, K.; Levi, S.; Gupta, P. K.; Major, D. T. Curr. Opin. Biotechnol. 2020, 65, 248–258. doi:10.1016/j.copbio.2020.06.002 |

| 24. | Major, D. T.; Freud, Y.; Weitman, M. Curr. Opin. Chem. Biol. 2014, 21, 25–33. doi:10.1016/j.cbpa.2014.03.010 |

| 27. | Das, S.; Shimshi, M.; Raz, K.; Nitoker Eliaz, N.; Mhashal, A. R.; Ansbacher, T.; Major, D. T. J. Chem. Theory Comput. 2019, 15, 5116–5134. doi:10.1021/acs.jctc.9b00366 |

© 2022 Zev et al.; licensee Beilstein-Institut.

This is an open access article licensed under the terms of the Beilstein-Institut Open Access License Agreement (https://www.beilstein-journals.org/bjoc/terms), which is identical to the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0). The reuse of material under this license requires that the author(s), source and license are credited. Third-party material in this article could be subject to other licenses (typically indicated in the credit line), and in this case, users are required to obtain permission from the license holder to reuse the material.