Abstract

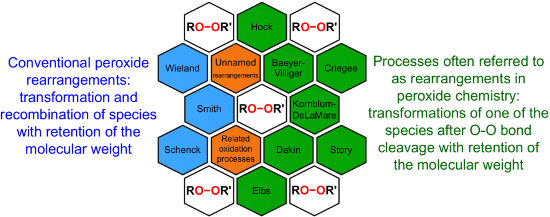

This review is the first to collate and summarize main data on named and unnamed rearrangement reactions of peroxides. It should be noted, that in the chemistry of peroxides two types of processes are considered under the term rearrangements. These are conventional rearrangements occurring with the retention of the molecular weight and transformations of one of the peroxide moieties after O–O-bond cleavage. Detailed information about the Baeyer−Villiger, Criegee, Hock, Kornblum−DeLaMare, Dakin, Elbs, Schenck, Smith, Wieland, and Story reactions is given. Unnamed rearrangements of organic peroxides and related processes are also analyzed. The rearrangements and related processes of important natural and synthetic peroxides are discussed separately.

Graphical Abstract

Introduction

The chemistry of organic peroxides has more than a hundred-year history. Currently, organic peroxides are widely used as oxidizing agents and initiators for free-radical reactions both in industry and in laboratory. These compounds are produced and involved in various natural and biological processes and were explored extensively as antimalarial agents, anthelmintics, and anticancer drugs.

Organic peroxides, such as alkyl hydroperoxides, aryl hydroperoxides, ketone peroxides, dialkyl peroxides, diacyl peroxides, peroxy esters, peroxydicarbonates, peroxyacetals, and inorganic peroxides are the most important radical initiators that are widely used in industrial processes in the manufacture of polymers from unsaturated monomers [1-9].

Nowadays, the progress in the chemistry of organic peroxides is mainly a result of their biological activity and pharmaceutical application. The search of effective antimalarial and antihelminthic drugs is the main challenge of medicinal chemistry of peroxides. According to the World Health Organization (WHO) malaria is a widely distributed illness. About 3.2 billion people remain at risk of malaria and in 2015 214 million cases of malaria and 438 thousands deaths from it have been registered [10]. Compounds with high antimalarial [11-23], antihelminthic [24-28], and antitumor activities [29-34] were found among natural, semisynthetic, and synthetic peroxides. The main biologically active frame of these compounds includes five-membered 1,2-dioxolane [35-37], 1,2,4-trioxolane [38,39], and six-membered 1,2-dioxane [40-42], 1,2-dioxene [43], 1,2,4-trioxane [22,44,45] cycles. The naturally occuring peroxide artemisinin and its semisynthetic derivatives, artemether, arteether, and artesunate, are applied in large scale for malaria treatment [46,47].

Organic peroxides, their rearrangements and related processes play an important role in the chemistry of oxidation processes. Thus, the key reagent in the Sharpless epoxidation of allylic alcohols [48] and in the manufacture of propylene oxide via the Prilezhaev reaction [49-51] is tert-butyl hydroperoxide. In industry, phenol and acetone are mainly produced by the Hock process, which is based on the rearrangement of cumene hydroperoxide. In 2003, phenol was produced to more than 95% by this oxidation process [52-54]. Another important application of organic peroxides is the synthesis of lactones from cyclic ketones via the Baeyer−Villiger oxidation and it is one of the methods for the synthesis of commercially important caprolactone from cyclohexanone with peracetic acid [55,56].

Autoxidation processes with formation of hydroperoxides and their subsequent free-radical transformations with generation of carbon- and oxygen-centered radicals are key reactions in the drying process of oil-based and alkyd paints containing double bonds [57-61].

Organic peroxides and their transformation play an important role not only in industrial but also in biological processes. Thus, the firefly luciferase-catalyzed oxidation of luciferin yields the peroxy compound 1,2-dioxetane. This four-membered peroxide cycle is unstable and spontaneously decays to carbon dioxide and excited ketones, which release excess energy through light emission (bioluminescence) [62-65]. The in vivo oxidation of cholesterol by singlet oxygen produces the hydroperoxide cholesterol-5α-OOH, which undergoes a Hock oxidation to form atheronal A. The latter possesses proatherogenic effects and triggers the development of cardiovascular diseases [66-71].

The development of the chemistry of organic peroxides is closely related to the application and preparation of unsaturated compounds, such as epoxides, aldehydes, ketones, carboxylic acids, and their derivatives [72-113]. Organic peroxides are widely used as oxidants in oxidative coupling processes [114-120].

Industrial-scale production of readily available and efficient initiators of free radical polymerization and effective biologically active compounds promotes the search for new synthetic methods for peroxides starting from carbonyl compounds, hydrogen peroxide, and hydroperoxides [121-182].

In many cases, rearrangements and related reactions of peroxides are key pathways in laboratory, industrial, and biological processes. The rearrangements of organic peroxides are covered in the literature in hundreds of publications and in several specialized and partial reviews [183-188]. The present review is the first to combine the key data on both, name rearrangements and less well-known rearrangements and related oxidative processes, and to summarize systematically related and different features of these reactions, compares their mechanisms, and assesses the prospects of their application.

By definition, a rearrangement is a migration of an atom or a group of atoms from one atom to another within the same molecule [189]. In contrast, a rearrangement of organic peroxides means a change in the structure of the starting molecule to form an isomeric compound without a peroxy group [183]. The terminology of rearrangements of organic peroxides and related processes encountered in the literature shows that this definition is not generally applicable as rearrangements of peroxides can give both isomeric and non-isomeric compounds either containing a peroxy group or without the latter. In most cases, a rearrangement involves the migration or cleavage of the peroxide group in an intermediate molecule, and the stability of the latter is responsible for the further pathway of the process.

The review covers main studies published over the last 15–20 years with a brief excursion to the history of the development of various reactions and transformations. The review consists of three parts: the first part considers named transformations of organic peroxides (Figure 1), the second one deals with unnamed reactions, and the third part covers transformations of some important natural and synthetic peroxides. Since the term “rearrangements”, as applied to transformations of peroxides, is not clearly defined all parts of the review include processes related to rearrangements.

Figure 1: The named transformations considered in this review.

Figure 1: The named transformations considered in this review.

Review

1 Named rearrangements of organic peroxides

Rearrangements of organic peroxides are the key steps in many well-known processes such as the Baeyer–Villiger (BV), the Criegee and Hock reactions, the Kornblum–DeLaMare rearrangement, Dakin, and Elbs oxidation.

The BV oxidation is widely used in organic synthesis for the preparation of esters and lactones and the Criegee reaction is applied to transform tertiary alcohols into ketones and aldehydes. The Hock rearrangement is a key step in the cumene (cumene–phenol) process and the Kornblum–DeLaMare is an important tool in the synthesis of functionalized ketones and alcohols, including γ-hydroxy enones. The Dakin oxidation finds application for the synthesis of phenols from arylaldehydes or aryl ketones and the Elbs persulfate oxidation allows the preparation of hydroxyphenols from phenols. Finally, the Schenck and Smith rearrangements are of interest in allyl hydroperoxide transformations.

1.1 Baeyer–Villiger oxidation

The BV reaction is the oxidation of ketones or aldehydes A under the action of hydrogen peroxide, hydroperoxides, Caro’s acid (H2SO5), or organic peracids to yield esters, lactones, or carboxylic acids B (Scheme 1) [190,191].

Baeyer and Villiger accomplished the oxidation of ketones to esters for the first time in 1899 while they attempted the reaction of Caro’s acid (H2SO5) with menthone, tetrahydrocarvone, and camphor to transform these compounds into the corresponding lactones [192-194].

Since that time, this reaction has shown to be of general applicability and it has gained wide application for the oxidation of carbonyl compounds of different structures. In this reaction, cyclic ketones are transformed into lactones, acyclic ketones, into esters and aldehydes into carboxylic acids. The BV oxidation is one of the most important reactions in organic chemistry because it produces lactones, which are useful synthetic products in polymer, agrochemical, and pharmaceutical industry.

m-Chloroperbenzoic, peracetic, and perfluoroacetic acids, as well as hydrogen peroxide/protic acid, hydrogen peroxide/Lewis acid, and hydrogen peroxide/base systems are widely employed in the Baeyer–Villiger oxidation [185,194,195].

The general mechanism of the peracid-promoted Baeyer–Villiger oxidation involves two main steps. In the first step, the oxygen atom of the peroxide moiety of the peracid 2 binds to the carbonyl group of ketone 1 to form the tetrahedral intermediate 3 which is referred to as the Criegee intermediate. The next step involves the concerted migration of the R2 group to the peroxide oxygen atom, resulting in the formation of ester 4 and carboxylic acid 5 (Scheme 2).

Scheme 2: The general mechanism of the peracid-promoted Baeyer–Villiger oxidation.

Scheme 2: The general mechanism of the peracid-promoted Baeyer–Villiger oxidation.

The ability of peracids to oxidize cyclic and acyclic ketones and aldehydes to the corresponding lactones, esters, and carboxylic acids decreases in the series peroxotrifluoroacetic acid > monopermaleic acid > mono-o-perphthalic acid > 3,5-dinitroperbenzoic acid > p-nitroperbenzoic acid > MCPBA ≈ performic acid > perbenzoic acid > peracetic acid >> H2O2 > t-BuOOH [196].

The migratory ability of substituents in the Criegee intermediate decreases in the following series: tertiary alkyl > cyclohexyl > secondary alkyl > benzyl > phenyl > primary alkyl > cyclopentyl, cyclopropyl > methyl. In some cases, stereoelectronical effects strongly influence the regioselectivity of the reaction, specifically the ability of the migrating C–C to align with the back of the breaking O–O bond, and the presence or absence of strain in cyclic ketone substrates [197,198]. The strongest electron-donating group migrates in unsymmetrical ketones [199].

There are thousands of publications on the Baeyer–Villiger reaction. In the latest reviews published by Krow [195] in 1993 and by Renz and Meunier [185] in 1999, the field of application, the reactivity of substrates, and the reaction kinetics and mechanisms are considered in detail. In the review by Strukul, special emphasis was placed on metal-catalyzed Baeyer–Villiger oxidations [196]. Green approaches in the Baeyer–Villiger reaction were highlighted by another review [200].

The present review covers a more modern aspect of this reaction, viz., the performance of the process using hydrogen peroxide. Oxidizing systems containing hydrogen peroxide as the oxidizing agent allow the usual and asymmetric oxidation of the substrate to the target product with high conversion and yield. In recent years, the inexpensive, commercially available, and environmentally friendly H2O2 was utilized in the Baeyer–Villiger reaction with increasing frequency. Various catalysts that activate hydrogen peroxide, such as heterogeneous catalysts based on solid acids [201], zeolites [202,203], Se [204], As [205], Co [206], sulfonated organic ion exchange resins [203,207], and homogeneous catalysts based on Pt [208], Zr [209], Re [210,211], Se [212,213], As [205], Mo [214], Co [215], Brønsted [216], and Lewis acids [217] are described in the literature. The general mechanism of a Lewis acid-catalyzed Baeyer–Villiger rearrangement is presented in Scheme 3 [200,218].

Scheme 3: General mechanism of the Lewis acid-catalyzed Baeyer–Villiger rearrangement.

Scheme 3: General mechanism of the Lewis acid-catalyzed Baeyer–Villiger rearrangement.

Scheme 4 shows the theoretically studied mechanism of the oxidation reaction promoted by H2O2 and the Lewis acid BF3 [217,219]. In the first step, the hydrogen peroxide–boron trifluoride complex 8 reacts with ketone 9 to form adduct 10. The latter intermediate rearranges through transition state 11 into the tetrahedral peroxyacetal intermediate 12. Then BF3 migrates to another oxygen atom through transition state 13 to give the second Criegee intermediate 14. The decomposition of intermediate 14 finally produces 15, hydrogen fluoride (16) and ester 17.

Scheme 4: The theoretically studied mechanism of the BV oxidation reaction promoted by H2O2 and the Lewis acid BF3.

Scheme 4: The theoretically studied mechanism of the BV oxidation reaction promoted by H2O2 and the Lewis aci...

Despite the fact that the Baeyer–Villiger reaction is known since 1899, the mechanism of this reaction is still not fully understood. The nature of the acid catalyst [220] and the type of O–O-bond cleavage in the Criegee intermediate [221] were found to play an important role in this reaction. Probably the hydrogen bonds in Baeyer–Villiger reactions play an important role [222]. The tetramolecular transition states TS1 and TS2 are considered to be the two key steps determining the course of the oxidation: the nucleophilic addition of a peroxy acid molecule to ketone (TS1) and the migration of R and cleavage of O–O bond (TS2). Thus, electrophilic substrates favor TS1 and nucleophilic migrating groups prefer TS2 (Scheme 5).

Scheme 5: Proton movements in the transition states of the Baeyer–Villiger oxidation.

Scheme 5: Proton movements in the transition states of the Baeyer–Villiger oxidation.

The dependence of the course of the Baeyer–Villiger oxidation on the type of O−O-bond cleavage in the Criegee intermediate was studied in the oxidation reaction of 1,2-quinone 18 with perbenzoic acid [221]. The reaction gave two oxidation products – anhydride 20 and the seven-membered α-ketolactone 21. The investigation of the reaction mechanism demonstrated that the formation of the seven-membered α-ketolactone 21 proceeds through the heterolytic O–O-bond cleavage in Criegee intermediate 19, whereas the homolytic O–O cleavage affords anhydride 20 (Scheme 6).

Scheme 6: The dependence of the course of the Baeyer–Villiger oxidation on the type of O–O-bond cleavage in the Criegee intermediate.

Scheme 6: The dependence of the course of the Baeyer–Villiger oxidation on the type of O–O-bond cleavage in t...

The acid-catalyzed Baeyer–Villiger oxidation of cyclic epoxy ketones 22 produces lactones of type 23, which convert into carbenium ions 24 in the presence of the acid. Subsequently, these ions can be transformed with participation of H2O2 through three different pathways into dihydroperoxides 25, dicarboxylic acids 28, carboxylic acids 26, and keto carboxylic acids 27 (Scheme 7, Table 1) [223].

Scheme 7: The acid-catalyzed Baeyer–Villiger oxidation of cyclic epoxy ketones 22.

Scheme 7: The acid-catalyzed Baeyer–Villiger oxidation of cyclic epoxy ketones 22.

Table 1: Oxidation of cyclic epoxy ketones 22a–c by H2O2.

| Epoxy ketone | R | 25, % | 26, % | 27, % | 28, % |

|---|---|---|---|---|---|

| 22a | Me | 25a, 12 | 26a, 6 | 27a, 15 | 28a, 53 |

| 22b | Et | 25b, 19 | a | a | a |

| 22c | Ph | 25c, 19 | – | 27c, 35 | 28c, 18 |

aThe aqueous phase consisted of a complex mixture and could not be analyzed.

The oxidation of isophorone oxide (29) is an industrial process for the production of dimethylglutaric acid 30 (Scheme 8) [223].

Scheme 8: Oxidation of isophorone oxide 29.

Scheme 8: Oxidation of isophorone oxide 29.

Acyl phosphate 32 can be synthesized from acyl phosphonate 31 in high yield by oxidation with H2O2 (Scheme 9) [224].

Scheme 9: Synthesis of acyl phosphate 32 from acyl phosphonate 31.

Scheme 9: Synthesis of acyl phosphate 32 from acyl phosphonate 31.

The Baeyer–Villiger oxidation provides a valuable tool for the synthesis of oxygenated natural products [218,225,226] as exemplified by the synthesis of aflatoxin B2 (36, Scheme 10) [227].

Scheme 10: Synthesis of aflatoxin B2 (36).

Scheme 10: Synthesis of aflatoxin B2 (36).

The Baeyer–Villiger reaction is also a key step in the multistep synthesis of cannabinergic lactones from dimethylheptylresorcinol. Two regioisomeric cannabinergic lactones were obtained, one of which possessed pronounced affinity towards the CB1 receptor and lower affinities for mCB2 and hCB2 receptors [228].

Oxidation with H2O2–acid systems: With in situ generated peracids from carbodiimide, hydrogen peroxide, and carboxylic acids as catalysts ketones 37 are rearranged to lactones 38 (Scheme 11) [229].

Scheme 11: The Baeyer–Villiger rearrangement of ketones 37 to lactones 38.

Scheme 11: The Baeyer–Villiger rearrangement of ketones 37 to lactones 38.

3,4-Dimethoxybenzoic acid (40) was prepared with 78% yield by a Baeyer–Villiger reaction of substrate 39 with 30% H2O2, HCOOH and 1,2-dichloroethane at 50 °C for 24 h (Scheme 12) [230].

Scheme 12: Synthesis of 3,4-dimethoxybenzoic acid (40) via Baeyer–Villiger oxidation.

Scheme 12: Synthesis of 3,4-dimethoxybenzoic acid (40) via Baeyer–Villiger oxidation.

Oxone is a convenient reagent for the transformation of α,β-unsaturated ketones 43 of determined stereochemistry into vinyl acetates 44 via the Baeyer–Villiger reaction in dry DMF for 7–39 h (Scheme 13) [231].

Scheme 13: Oxone transforms α,β-unsaturated ketones 43 into vinyl acetates 44.

Scheme 13: Oxone transforms α,β-unsaturated ketones 43 into vinyl acetates 44.

Oxidation with H2O2–heteroorganic catalyst systems: The activity of oxidizing systems such as H2O2/aryl benzyl selenoxide and H2O2/diaryl diselenide is similar to that of m-chloroperbenzoic acid [212,232,233]. The main advantage of these selenium-containing systems is that the catalysts are regenerated and can therefore be used at low loadings [234-236]. Some results of the oxidation of ketones and aldehydes 45a–c to the corresponding esters 46a–c using the H2O2/aryl benzyl selenoxide system are collected in Table 2 [232].

The oxidation results of ketones 47a,b and aldehydes 47c–e to lactones 48a,b and carboxylic acids 49a–c promoted by the H2O2/diaryl diselenide system is presented in Table 3 [212].

Table 3: Baeyer–Villiger oxidation of ketones 47a,b and aldehydes 47c–e promoted by the H2O2/diaryl diselenide system.

|

|

||||

| Ketone | Time, h | Product | Conversion, %a | Selectivity (BV product), %a |

|---|---|---|---|---|

|

47a |

1 |

48a |

99 | 90 |

|

47b |

8 |

48b |

95 | 94 |

|

47cb |

2 |

49a |

98 | 98 |

|

47db |

3 |

49b |

88 | 96 |

|

47eb |

3 |

49c |

>90 | 99 |

aDetermined by GC; b60 °C.

In the first step of the catalytic cycle of the Baeyer–Villiger oxidation using diaryl diselenide 50 and hydrogen peroxide seleninic acid 51 is generated, which is then oxidized to perseleninic acid 52. Oxidation of the ketone 45 by perseleninic acid 52 involves the intermediate peroxide 53 (Scheme 14) [235].

Scheme 14: The Baeyer–Villiger oxidation of ketones 45 using diaryl diselenide and hydrogen peroxide.

Scheme 14: The Baeyer–Villiger oxidation of ketones 45 using diaryl diselenide and hydrogen peroxide.

Similarly, the versatile 4-methylenebutanolides 55 can be prepared from (E)-2-methylenecyclobutanones 54 in the presence of (PhSe)2/H2O2 at room temperature (Scheme 15). Likely the Baeyer–Villiger reaction proceeds through the formation of benzeneseleninoperoxoic anhydride [PhSe(O)O]2O in the first step, which then transforms to the active oxidant benzeneseleninoperoxoic acid PhSe(O)OOH [233].

Scheme 15: Baeyer–Villiger oxidation of (E)-2-methylenecyclobutanones.

Scheme 15: Baeyer–Villiger oxidation of (E)-2-methylenecyclobutanones.

The Baeyer–Villiger oxidation of (E)-α,β-unsaturated ketones to (E)-vinyl esters was performed with hydrogen peroxide and dibenzyl diselenide as pre-catalyst at room temperature [236]. Catalyzed by the dibenzyl diselenide, β-ionone (56) was oxidized by H2O2 with formation of (E)-2-(2,6,6-trimethylcyclohex-1-en-1-yl)vinyl acetate (57) with 91% yield (Scheme 16) [237].

Scheme 16: Oxidation of β-ionone (56) by H2O2/(BnSe)2 with formation of (E)-2-(2,6,6-trimethylcyclohex-1-en-1-yl)vinyl acetate (57).

Scheme 16: Oxidation of β-ionone (56) by H2O2/(BnSe)2 with formation of (E)-2-(2,6,6-trimethylcyclohex-1-en-1-...

The Baeyer–Villiger oxidation of ketones 58a–f to form esters 59a–f can be accomplished in good yields in the presence of H2O2 and arsenic-containing ion exchange resins on polystyrene as the catalyst (Table 4) [203,205].

The mechanism of the oxidation of ketones 58a–f by hydrogen peroxide in the presence of arsonated polystyrene 60 as the catalyst is shown in Scheme 17. First, hydrogen peroxide reacts with the arsonic acid 60 to form peroxyarsonic acid 61 or it adds to ketones 58a–f to form vicinal hydroperoxyalkanols 63. In the second step the peroxyarsonic acid 61 adds to ketones 58a–f or the vicinal hydroperoxyalkanols 63 interact with arsonated polystyrene 60 under formation of perester 62. Finally, the decomposition of 62 gives esters 59a–f.

Scheme 17: The mechanism of oxidation of ketones 58a–f by hydrogen peroxide in the presence of arsonated polystyrene 60.

Scheme 17: The mechanism of oxidation of ketones 58a–f by hydrogen peroxide in the presence of arsonated polys...

A number of other modern oxidizing systems are based on transition metal-peroxo complexes. The use of transition metal complexes were also used as catalysts for the Baeyer–Villiger reaction and the first example was documented in 1978 [196,214]. For example, Mo(VI) peroxo complexes 64 and 65 were employed as the catalysts and 90% H2O2 served as the oxidizer (Table 5).

The results obtained from the reactions using molybdenum systems have stimulated the search for new catalysts based on transition metal complexes. The usage of the platimum complex [(dppe)Pt(CF3(CH2Cl2)]BF4 (66·BF4) allowed the oxidation of 2-methylcyclohexanone (58b) in the presence of 32% H2O2 at room temperature to form 6-methylcaprolactone (59b) in 22% yield (Scheme 18) [238].

Scheme 18: Oxidation of ketone (58b) by H2O2 to 6-methylcaprolactone (59b) catalyzed by Pt complex 66·BF4.

Scheme 18: Oxidation of ketone (58b) by H2O2 to 6-methylcaprolactone (59b) catalyzed by Pt complex 66·BF4.

Acyclic ketones 67 could be oxidized to the corresponding esters 68 in the presence of the catalyst [(dppb}Pt(µ-OH)]22+, where dppb is butane-1,4-diylbis(diphenylphosphane) (Scheme 19) [208].

Scheme 19: Oxidation of ketones 67 with H2O2 in the presence of [(dppb}Pt(µ-OH)]22+.

Scheme 19: Oxidation of ketones 67 with H2O2 in the presence of [(dppb}Pt(µ-OH)]22+.

The oxidation mechanism of ketones 67 is displayed in Scheme 20.

Scheme 20: The mechanism of oxidation of ketones 67 in the presence of [(dppb}Pt(µ-OH)]22+ and H2O2.

Scheme 20: The mechanism of oxidation of ketones 67 in the presence of [(dppb}Pt(µ-OH)]22+ and H2O2.

The use of variable-valence metal complexes opened up a new field of application of the Baeyer–Villiger oxidation and there are now dozens of studies on this topic [196,239-246].

Hydroxylated and methoxylated benzaldehydes 69 (Scheme 21) and acetophenones 72 (Scheme 22) can be oxidized to the corresponding phenols 70a–d, and 73 in good yields in the presence of the H2O2/MeReO3 system in ionic liquids [bmim]BF4 or [bmim]PF6 [247]. Benzoic acids 71a–d, 74 and phenyl esters 75a–d were reported as oxidation byproducts.

Scheme 21: Oxidation of benzaldehydes 69 in the presence of the H2O2/MeReO3 system.

Scheme 21: Oxidation of benzaldehydes 69 in the presence of the H2O2/MeReO3 system.

Scheme 22: Oxidation of acetophenones 72 in the presence of the H2O2/MeReO3 system.

Scheme 22: Oxidation of acetophenones 72 in the presence of the H2O2/MeReO3 system.

Sn-containing mesoporous silica nanospheres (Sn-MSNSs) with uniform crater-like mesopores exhibited high activities in the Baeyer–Villiger oxidation of 2-adamantanone (45c) (Scheme 23) [248].

Scheme 23: Baeyer–Villiger oxidation of 2-adamantanone (45c) in the presence of Sn-containing mesoporous silica nanospheres (Sn-MSNSs).

Scheme 23: Baeyer–Villiger oxidation of 2-adamantanone (45c) in the presence of Sn-containing mesoporous silic...

The Baeyer–Villiger rearrangement of 2-adamantanone (45с) was performed using hydrogen peroxide (H2O2) and stannosilicate zeolites with nanosheet morphology and MFI topology (Sn-MFI-ns) as highly efficient catalysts [249]. The Sn-beta zeolites prepared by a steam-assisted conversion method are efficient catalysts for the Baeyer–Villiger reaction of cyclohexanone to ε-caprolactone [250]. A mesoporous Mg–Al-mixed oxide showed good catalytic efficiency in the Baeyer–Villiger oxidation of a series of ketones to the corresponding lactones and esters in the presence of diluted aqueous H2O2 and benzonitrile [251].

The Baeyer–Villiger oxidation of ketones 76 under the action of oxygen to the related esters 77 was performed using metal-free carbon (Ketjen Black) as a solid catalyst and benzaldehyde as the sacrificing agent. This metal-free carbon catalyst showed excellent catalytic activity and can be recycled after the reaction under oxygen atmosphere at 50 °C (Scheme 24) [252].

Scheme 24: Aerobic Baeyer–Villiger oxidation of ketones 76 using metal-free carbon.

Scheme 24: Aerobic Baeyer–Villiger oxidation of ketones 76 using metal-free carbon.

The boron-containing catalysts LiB(C6F5)4 or Ca[B(C6F5)4]2 were developed for the Baeyer–Villiger oxidation of ketones with aqueous H2O2 to give the lactones in high yields [253,254].

A regioselective Baeyer–Villiger oxidation of functionalized cyclohexenones 78 lead to dihydrooxepine structures 79. Here, the combination of SnCl4 and bis(trimethylsilyl)peroxide (BTSP), in the presence of trans-1,2-diaminocyclohexane as the ligand, generated the desired products 79 in high yields (Scheme 25) [255].

Scheme 25: A regioselective Baeyer-Villiger oxidation of functionalized cyclohexenones 78 into a dihydrooxepine structures 79.

Scheme 25: A regioselective Baeyer-Villiger oxidation of functionalized cyclohexenones 78 into a dihydrooxepin...

The Co4HP2Mo15V3O62-catalyzed oxidation of aldehydes and ketones 80 by hydrogen peroxide in ionic liquid [TEBSA][BF4] resulted in carboxylic acids and esters 81 in good to high yields (Scheme 26) [256].

Scheme 26: The oxidation of aldehydes and ketones 80 by H2O2 catalyzed by Co4HP2Mo15V3O62.

Scheme 26: The oxidation of aldehydes and ketones 80 by H2O2 catalyzed by Co4HP2Mo15V3O62.

Oxidation with H2O2–base systems: The oxidative cleavage of ketones 82 with hydrogen peroxide in alkaline solution yielded carboxylic acids 84. The authors suggested that the reaction of a ketone with the hydroperoxide anion resulted in the intermediate esters 83, which hydrolyzed in the basic reaction medium with formation of acids 84 (Scheme 27) [257].

Scheme 27: The cleavage of ketones 82 with hydrogen peroxide in alkaline solution.

Scheme 27: The cleavage of ketones 82 with hydrogen peroxide in alkaline solution.

The use of hydrotalcites in the Baeyer–Villiger oxidation of various ketones resulted in high yields of the corresponding lactones or esters [258-260]. The esters 86 were synthesized by the reaction of ketones 85 with H2O2 and benzonitrile under basic reaction conditions (KHCO3) with the intermediate generation of peroxyimidic acids. This oxidation can be successfully applied to alkyl-containing ketones to give the target products in yields of 30–91% and good regioselectivity 7:1 to 20:1 (Scheme 28) [261].

Scheme 28: Oxidation of ketones 85 to esters 86 with H2O2–urea in the presence of KHCO3.

Scheme 28: Oxidation of ketones 85 to esters 86 with H2O2–urea in the presence of KHCO3.

Asymmetric oxidation: Asymmetric Baeyer–Villiger oxidation reactions can be performed using chiral acetals, organic hydroperoxides, chiral metal complexes and organocatalysts [262,263]. There are also Green chemistry approaches for Baeyer−Villiger oxidations based on enzyme-mediated processes, which are used for the preparation of chiral lactones. This type of biocatalysis is useful in synthetic chemistry and either isolated enzymes or living whole cells are applied for the oxidative production of valuable intermediates [264-269].

The asymmetric oxidation of 3-substituted cyclopentane-1,2-diones 87a–f is an efficient tool in organic synthesis for the preparation of unsymmetrical γ-lactone acids 88a–f with high optical purity and good yields (Table 6). These γ-lactone acids are valuable substrates for the synthesis of compounds with potentially useful pharmacological properties, such as homocitrates, alkyl- and aryl-substituted nucleosides [270-272].

The reaction starts with an asymmetric epoxidation of the substituted cyclopentane-1,2-dione 87a to form epoxide 89a. The second step involves the Baeyer–Villiger oxidation of epoxide 89a to peroxide 90a followed by the rearrangement into intermediate 91a. The latter is hydrolyzed by H2O to form dicarboxylic acid 92a, which is cyclized under the acidic conditions to γ-lactone acid 88a (Scheme 29) [270].

Scheme 29: Mechanism of the asymmetric oxidation of cyclopentane-1,2-dione 87a with the Ti(OiPr)4/(+)DET/t-BuOOH system.

Scheme 29: Mechanism of the asymmetric oxidation of cyclopentane-1,2-dione 87a with the Ti(OiPr)4/(+)DET/t-BuO...

In most cases, the Baeyer–Villiger oxidation is a stereospecific and regioselective process with retention of the configuration. The oxidation of cis-4-tert-butyl-2-fluorocyclohexanone (93) with m-chloroperbenzoic acid in the presence of NaHCO3 affords fluorolactones 94 and 95 in 91% and 9% yields, respectively (Scheme 30) [273].

Scheme 30: The oxidation of cis-4-tert-butyl-2-fluorocyclohexanone (93) with m-chloroperbenzoic acid.

Scheme 30: The oxidation of cis-4-tert-butyl-2-fluorocyclohexanone (93) with m-chloroperbenzoic acid.

However, in order to perform the asymmetric oxidation of 3-substituted cyclobutanones 96a–f to the corresponding lactones 97a–f (Table 7) [274], it is necessary to employ chiral Brønsted acids [274-277], organocatalysts [278,279] or enzymes [280-282] as the catalyst. The obtained asymmetric oxidation products can be used in the multistep synthesis of new biologically active compounds.

Possible mechanisms for the asymmetric oxidation of 3-substituted cyclobutanone 96a with H2O2 catalyzed by chiral phosphoric acid are presented in Scheme 31 [275].

Scheme 31: The mechanism of the asymmetric oxidation of 3-substituted cyclobutanone 96a in the presence of chiral phosphoric acid.

Scheme 31: The mechanism of the asymmetric oxidation of 3-substituted cyclobutanone 96a in the presence of chi...

A number of optically active ε- and γ-lactones 99, 100 was prepared by the enantioselective Baeyer–Villiger oxidation of racemic cyclic ketones 98 in up to 99% yield and 95% ee using the chiral N,N′-dioxide–Sc(III) complex as catalyst (Scheme 32) [283].

Scheme 32: Enantioselective Baeyer–Villiger oxidation of cyclic ketones 98.

Scheme 32: Enantioselective Baeyer–Villiger oxidation of cyclic ketones 98.

In another work, a chiral N,N′-dioxide–Sc(III) complex promoted Baeyer–Villiger oxidation was applied as instrument for a kinetic resolution of racemic 2-substituted cyclopentanones with formation of the 6-substituted δ-lactones in up to 98% ee and >95% regioselectivity [284].

A highly regio- and enantioselective Baeyer–Villiger oxidation of cyclic ketones 101 bearing amido, ureido, or sulfonamido functional groups to lactones 102 and 103 was carried out using the peptide-based catalyst 104. Hydrogen-bonding interactions are responsible for both types of selectivity. Notably, a reversal of the typically seen selectivity was observed with the peptide catalyst (Scheme 33) [285].

Scheme 33: Regio- and enantioselective Baeyer–Villiger oxidation of cyclic ketones 101.

Scheme 33: Regio- and enantioselective Baeyer–Villiger oxidation of cyclic ketones 101.

Versatility of the Baeyer–Villiger reaction with respect to starting reactants: The Baeyer–Villiger reaction cannot only be performed with ketones but also with acetals and aldimines as the starting substrates. The oxidation of cycloalkanone acetals 105a–g with performic acid generated in situ provides a new route to dicarboxylic acids 106a–g and hydroxycarboxylic acids 107a–g (Table 8) [286].

The proposed mechanism of the oxidation of acetal 105f is shown in Scheme 34.

Scheme 34: The proposed mechanism of the Baeyer–Villiger oxidation of acetal 105f.

Scheme 34: The proposed mechanism of the Baeyer–Villiger oxidation of acetal 105f.

In the first step of the reaction, the elimination of methanol from 105f and formation of 108 takes place. Probably perester 109 is formed alongside of 108. After formation of 109, the reaction proceeds by two different routes A and B (second stage). The first route A leads to formation of epoxide 110, whereas the second route (B) proceeds through the Baeyer–Villiger reaction with formation of lactone 111 and subsequent acid hydrolysis to give 107f. At the third stage (route A), ether 112 is formed from 110 and subsequently rearranged by a Baeyer–Villiger reaction into 113, which is oxidized to form 106f.

This method can be applied to the synthesis of dodecanedioic acid, which is used in anticorrosive composites, polyester and polyamide threads, and lubricants, for the synthesis of tridecanedioic acid, and as a component of perfume formulations.

Scheme 35 presents the synthesis of hydroxy-10H-acridin-9-one 117 starting from tetramethoxyanthracene 114 through the formation of peroxide 115, which rearranges through an acid-catalyzed Baeyer–Villiger-type rearrangement into 116. Hydroxy-10H-acridin-9-ones 117 proved to be promising antipsoriatic agents [287].

Scheme 35: Synthesis of hydroxy-10H-acridin-9-one 117 from tetramethoxyanthracene 114.

Scheme 35: Synthesis of hydroxy-10H-acridin-9-one 117 from tetramethoxyanthracene 114.

The oxidation of aldimines 118a–f with m-chloroperbenzoic acid in the presence of boron trifluoride etherate produces amides 119a–f in good yields (Table 9). The products of this transformation are strongly dependent on the electronic properties of the aromatic substituents at the carbon atom of the aldimines [288]. In the case of electron-donating substituents on the aryl fragment (Ar), formamides 119a–c are obtained as the result of imine oxidation and aryl migration. On the other hand, electron-withdrawing substituents on the aryl group (Ar) promote the formation of amides 119d–f as result of hydride migration.

Table 9: Oxidation of aldimines 118a-f to amides by m-CPBA-BF3·Et2O system.

|

|

|||

| Compound | Imine | Product | Yield, % |

|---|---|---|---|

| 118a | C6H5CH=NC6H5 | HCON(C6H5)2 | 82 |

| 118b | p-Me-C6H4CH=NC6H5 | HCONC6H5 p-Me-C6H4 | 90 |

| 118c | p-MeO-C6H4CH=NC6H5 | HCONC6H5 p-MeO-C6H4 | 91 |

| 118d | p-NO2-C6H4CH=NC6H5 | p-NO2-C6H4CONHC6H5 | 71 |

| 118e | p-NC-C6H4CH=NC6H5 | p-NC-C6H4CONHC6H5 | 79 |

| 118f | p-F3C-C6H4CH=NC6H5 | p-F3C-C6H4CONHC6H5 | 75 |

The sterically hindered and fully substituted pyrrole 120 underwent a Baeyer–Villiger reaction to yield a 4,5-dihydro-1H-ketopyrrole 121 (Scheme 36) [289].

Scheme 36: The Baeyer–Villiger oxidation of the fully substituted pyrrole 120.

Scheme 36: The Baeyer–Villiger oxidation of the fully substituted pyrrole 120.

1.2 Criegee rearrangement

The Criegee rearrangement involves the transformation of a peroxide, mainly peroxyesters B, into carbonates, esters, or ketones C and alcohols D through an oxygen insertion or consecutive oxygen insertions. The peroxyester B is initially prepared from a tertiary alcohol A and a peracid. In addition, the peroxy ester can also be prepared via the reaction of a ketone and a peracid (i.e., through a Baeyer–Villiger oxidation); the additional product of peracid to ketone is often referred to as the Criegee intermediate. From this point of view, the Baeyer–Villiger oxidation is a subset of the Criegee rearrangement (Scheme 37) [290].

As mentioned above the Criegee reaction and the Baeyer–Villiger oxidation are related processes and both reactions involve the formation of the Criegee intermediate. The distinguishing feature of the Criegee rearrangement is that the Criegee intermediate rearranges into a carbocation. The mechanism of the Criegee reaction is presented in Scheme 38.

Scheme 38: The mechanism of the Criegee reaction of a peracid with a tertiary alcohol 122.

Scheme 38: The mechanism of the Criegee reaction of a peracid with a tertiary alcohol 122.

Initially the reaction of the peracid with the tertiary alcohol 122 produces perester (Criegee intermediate) 123. One alkyl substituent migrates from the carbon atom to the adjacent oxygen atom and replaces the carboxylic acid moiety to form carbocation 124. Then, the addition of water to carbocation 124 affords ketone 125 and alcohol 126. p-Nitroperbenzoic acid is usually used to oxidize tertiary alcohols because the anion of this acid is a good leaving group.

The Criegee rearrangement was discovered in 1944 in the reaction of decaline ethylperoxoate 127 that rearranged into isomeric ester ketal 128 (Scheme 39) [291].

Scheme 39: Criegee rearrangement of decaline ethylperoxoate 127 into ketal 128.

Scheme 39: Criegee rearrangement of decaline ethylperoxoate 127 into ketal 128.

The mechanism of the Criegee rearrangement was studied using 2-alkoxy-2-propyl per-4-nitrobenzoates [292]. It was shown that the ionic cleavage of 2-methoxy-2-propyl perester 129 to p-nitrobenzoic acid (132), methyl acetate (133) and dimethyl ether (134) occurred through transition state 130 with generation of dimethoxycarbonium ion 131 (Scheme 40).

Scheme 40: The ionic cleavage of 2-methoxy-2-propyl perester 129.

Scheme 40: The ionic cleavage of 2-methoxy-2-propyl perester 129.

Investigations using aromatic peroxy esters 129 demonstrated that the migratory ability of the migrating group R decreases in the series t-Bu > C6H5 > iPr > OEt > OMe > Et > Me [293,294].

The Criegee rearrangement of α-methoxy hydroperoxide 136 obtained from (+)-trans-dihydrocarvone 135 produces trans-5-acetoxy-2-methylcyclohexanone 137 and intermediate peroxyacetate 138 (Scheme 41) [295].

Scheme 41: The Criegee rearrangement of α-methoxy hydroperoxide 136.

Scheme 41: The Criegee rearrangement of α-methoxy hydroperoxide 136.

Later on, the Criegee rearrangement was extended [296] to peroxides 139, 142, and 145 which made it possible to selectively synthesize both cyclic 140, 141, 144 and acyclic enol esters 146 and acetal 143 (Scheme 42).

Scheme 42: Synthesis of enol esters and acetals via the Criegee rearrangement.

Scheme 42: Synthesis of enol esters and acetals via the Criegee rearrangement.

The Criegee rearrangement of 1-hydroperoxy-2-oxabicycloalkanes 147a–d in formic or acetic acid containing catalytic amounts of sulfuric acid affords ω-alkoxy-(ω-3)-hydroxyalkanoic acid lactones 148a–d and 149a–d (Table 10) [297].

Table 10: Synthesis of ω-alkoxy-(ω-3)-hydroxyalkanoic acid lactones 148a–d and 149a–d from 1-hydroperoxy-2-oxabicycloalkanones 147a–d.

|

|

||||

| Substrate | RCOOH | Time (min) | Lactone | Yield, % |

|---|---|---|---|---|

| 147a | HCOOH | 20 | 148a | 64 |

| 147a | AcOH | 20 | 149a | 65 |

| 147b | HCOOH | 20 | 148b | 68 |

| 147b | AcOH | 20 | 149b | 70 |

| 147c | HCOOH | 30 | 148c | 57 |

| 147c | AcOH | 30 | 149c | 65 |

| 147d | HCOOH | 90 | 148d | 68 |

| 147d | AcOH | 90 | 149d | 53 |

The transformation of 1-hydroperoxy-2-oxabicycloalkanones 147a–d into ω-alkoxy-(ω-3)-hydroxyalkanoic acid lactones 148a–d and 149a–d is proposed to occur through intermediate peroxy ester 150 (Scheme 43).

Scheme 43: Proposed mechanism of the transformation of 1-hydroperoxy-2-oxabicycloalkanones 147a–d.

Scheme 43: Proposed mechanism of the transformation of 1-hydroperoxy-2-oxabicycloalkanones 147a–d.

1,2-Dioxolanes and related cyclic systems have attracted considerable attention from synthetic chemists as they may be used for the preparation of biologically active compounds. Under acidic conditions, 3-hydroxy-1,2-dioxolanes 151 are rearranged similarly to the Criegee mechanism into diketone derivatives 152 (Scheme 44) [298].

Scheme 44: Transformation of 3-hydroxy-1,2-dioxolanes 151 into diketone derivatives 152.

Scheme 44: Transformation of 3-hydroxy-1,2-dioxolanes 151 into diketone derivatives 152.

Unlike the Baeyer–Villiger rearrangement, in which only mono-O-insertion can take place, the Criegee rearrangement of peroxide 153 in an acidic medium and under solvent-free conditions does not have such limitations. Thus, the latter reaction can proceed sequentially through the mono-, di-, and tri-O-insertion steps with formation of ketone 154, ester 155 and carbonate ester 156 (Scheme 45) [299,300].

Scheme 45: Criegee rearrangement of peroxide 153 with the mono-, di-, and tri-O-insertion.

Scheme 45: Criegee rearrangement of peroxide 153 with the mono-, di-, and tri-O-insertion.

The selective double Criegee rearrangement next to a tertiary carbon was shown in the oxidative fragmentation at the bridgehead position of adamantanes 157a,b. The reaction employed the trifluoroperacetic acid (TFPAA)/trifluoroacetic acid (TFAA) system and afforded compounds 158a,b in high yields (Scheme 46) [300].

Scheme 46: The sequential Criegee rearrangements of adamantanes 157a,b.

Scheme 46: The sequential Criegee rearrangements of adamantanes 157a,b.

This method for the insertion of an oxygen atom was applied to the oxidation of triarylmethanols 159a–d [299]. The successive insertion of oxygen atoms gave rise to diaryl carbonates 160a–d in good yields (Scheme 47).

Scheme 47: Synthesis of diaryl carbonates 160a–d from triarylmethanols 159a–d through successive oxygen insertion.

Scheme 47: Synthesis of diaryl carbonates 160a–d from triarylmethanols 159a–d through successive oxygen insert...

In the last years, new enantiospecific approaches for the synthesis of sesquiterpenes 162 from ketone 161 were developed [301-307]. In these methods, the Criegee rearrangement represents one key step and one example is presented in Scheme 48 [303].

Scheme 48: The synthesis of sesquiterpenes 162 from ketone 161 with a Criegee rearrangement as one key step.

Scheme 48: The synthesis of sesquiterpenes 162 from ketone 161 with a Criegee rearrangement as one key step.

A method for the large-scale synthesis of a trans-hydrindan derivatives 164, 165 related to vitamin D, based on the Criegee rearrangement of alkene 163 was realized (Scheme 49) [308].

Scheme 49: Synthesis of trans-hydrindan derivatives 164, 165.

Scheme 49: Synthesis of trans-hydrindan derivatives 164, 165.

Carbonyl oxides (Criegee intermediates) are one of the most important compounds in tropospheric chemistry [309]. Direct investigations of formaldehyde oxide (CH2OO) or acetaldehyde oxide (CH3CHOO) reactions with water vapor, SO2, NO2 were carried out [310-312].

1.3 Hock rearrangement

The Hock rearrangement is a protic or Lewis acid-promoted rearrangement of hydroperoxides A resulting in a C–C bond cleavage to form alcohol B and carbonyl compound C (Scheme 50) [313].

The Hock rearrangement is a key step in the cumene process, which is used for the industrial production of phenol (170) and acetone (171) from benzene (166) and propylene (167) in the presence of air and radical initiators. The cumene process was described by Udris and Sergeev in 1947 [314,315] and independently by Hock in 1944 [316,317]. The general scheme of the cumene process, involving the formation of cumene hydroperoxide is shown in Scheme 51.

Scheme 51: The general scheme of the cumene process.

Scheme 51: The general scheme of the cumene process.

The cumene process involves the acid-catalyzed rearrangement of cumene hydroperoxide (168) as a key step. The reaction starts with the protonation of the terminal oxygen atom of cumene hydroperoxide (168) followed by the migration of the phenyl group from the benzylic carbon atom to the peroxide oxygen atom and the elimination of a water molecule to form carbocation 169. The carbocation 169 is attacked by a water molecule, a proton is transferred to the oxygen atom attached to the phenyl group, and finally the cleavage of the adduct yields phenol (170) and acetone (171).

The Hock rearrangement of aliphatic hydroperoxides proceeds quite readily in concentrated H2SO4 [318] or superacids [319] (Scheme 52). This is associated with higher resistance of these compounds toward acid-catalyzed rearrangements compared with benzylic or allylic hydroperoxides. For example, aliphatic hydroperoxides are not cleaved in 5–50% aqueous H2SO4 but on the contrary, these compounds are produced under these conditions. More efficient catalysts are the compounds Sn(OTf)2 and La(OTf)3 which can be used for the transformation of 2-hydroperoxy-2,4,4-trimethylpentane (172) into neopentyl alcohol (173) and acetone (171). The Sn(OTf)2 and La(OTf)3-catalyzed reaction afforded neopentyl alcohol (173) in 62 and 70% yield, respectively [320].

Scheme 52: The Hock rearrangement of aliphatic hydroperoxides.

Scheme 52: The Hock rearrangement of aliphatic hydroperoxides.

The hydrogen peroxide promoted ring expansion for the synthesis of oxabicycles 176a–c was described for the first time in 1985 [321]. The reaction involved the solvolysis of homoallylic brosylates 174a–c or spiro cyclopropyl carbinols 175a–c in the THF/H2O2 system, resulting in the increase in the ring size by two atoms and the formation of hydroperoxy oxabicyclo derivatives 176a–c (Table 11).

The mechanism of the solvolysis of 174 or 175 in the THF/H2O2 system involves the formation of solvolytically generated cyclobutyl hydroperoxides 177 followed by the rearrangement of the latter into oxa-bridged, hydroperoxyhemiketals 176 (Scheme 53).

Scheme 53: The mechanism of solvolysis of brosylates 174a–c and spiro cyclopropyl carbinols 175a–c in THF/H2O2.

Scheme 53: The mechanism of solvolysis of brosylates 174a–c and spiro cyclopropyl carbinols 175a–c in THF/H2O2....

The fragmentation of hydroperoxy acetals 178a–e in the presence of Ca(OCl)2 or t-BuOCl as the catalysts in CH3CN generating esters 179a–e proceeds through the Hock-like rearrangement mechanism (Table 12) [322].

Table 12: Fragmentation of hydroperoxy acetals 178a–e catalyzed by Ca(OCl)2 or t-BuOCl.

|

|

|||||||

| Substrate | Product | Ca(OCl)2 (equiv) | Time (min) | Yield, % | t-BuOCl (equiv) | Time (min) | Yield, % |

|---|---|---|---|---|---|---|---|

| 178a | 179a | 1.3 | 10 | 75 | 0.25 | 15 | 78 |

| 178b | 179b | 1.3 | 10 | 86 | 1.2 | 10 | 85 |

| 178c | 179c | 1.3 | 10 | 83 | 1.2 | 10 | 84 |

| 178d | 179d | 1.3 | 10 | 85 | 0.25 | 15 | 85 |

| 178e | 179e | 1.3 | 10 | 82 | 1.2 | 10 | 84 |

The fragmentation of hydroperoxy acetals 178 to esters 179 involves the formation and heterolytic fragmentation of intermediate secondary chloroperoxides 180. The possible mechanism of the process is presented in Scheme 54.

Scheme 54: The fragmentation mechanism of hydroperoxy acetals 178 to esters 179.

Scheme 54: The fragmentation mechanism of hydroperoxy acetals 178 to esters 179.

The acid-catalyzed rearrangement of phenylcyclopentyl hydroperoxide 181, involving the Hock reaction, is accompanied by the formation of a series of products: 1-phenylcyclopentene (182), phenol (170), cyclopentanone (183), and 5-acetoxyvalerophenone (184) (Scheme 55) [323].

Scheme 55: The acid-catalyzed rearrangement of phenylcyclopentyl hydroperoxide 181.

Scheme 55: The acid-catalyzed rearrangement of phenylcyclopentyl hydroperoxide 181.

An attempt was made [324] to synthesize hydroperoxides through the peroxidation of tertiary alcohols in the presence of a catalytic amount of acid. The treatment of 185 with H2O2 in the presence of a catalytic amount of H2SO4 for 72 hours did not lead to the formation of products via the Hock rearrangement of hydroperoxides, bicyclic hydroperoxides and о-hydroxyphenyl alkyl ketones. Instead, cyclic 2-methylchroman-2-yl hydroperoxide 188, geminal bishydroperoxides 190, and condensation products of peroxides such as 191 were isolated (Scheme 56).

Scheme 56: The peroxidation of tertiary alcohols in the presence of a catalytic amount of acid.

Scheme 56: The peroxidation of tertiary alcohols in the presence of a catalytic amount of acid.

The reaction mechanism presumably involves the following steps: the replacement of the hydroxy group by hydrogen peroxide to form tertiary hydroperoxides 186, the acid-catalyzed rearrangement of compounds 186 into cyclic phenoxycarbenium ions 187, and the addition of the second hydrogen peroxide molecule to 187 resulting in the formation of cyclic phenoxy hydroperoxide 188. The latter was isolated as the major product in the case of the six-membered ring (n = 1). In the case of the seven-membered ring (n = 2), geminal dihydroperoxide 190 and bridged bis(hydroxy)dialkyl peroxide 191 were obtained instead of 188. In case of the eight-membered ring (n = 3) an exclusive transformation into geminal dihydroperoxide 190 was observed (Table 13).

The formation of geminal dihydroperoxides 195 was also observed in the acid-catalyzed reaction of bicyclic secondary alcohols 192 with hydrogen peroxide. This reaction starts with the formation of bicyclic hydroperoxides 193 followed by the acid-catalyzed rearrangement with intermediate formation of peroxy hemiacetal 194. The latter is finally transformed into primary geminal bishydroperoxides 195 (Scheme 57) [325].

Scheme 57: The acid-catalyzed reaction of bicyclic secondary alcohols 192 with hydrogen peroxide.

Scheme 57: The acid-catalyzed reaction of bicyclic secondary alcohols 192 with hydrogen peroxide.

The photooxidation of 5,6-disubstituted 3,4-dihydro-2H-pyrans 196 generates the stable hydroperoxide 197 as the major product, which rearranges into dioxetane 198 at 28 °C in CCl4 within 13 h. Compounds 198 can be further transformed into keto esters 199 by treatment for 24 h with triphenylphosphine in CCl4 or concentrated HCl in CCl4. When compound 197 is heated at 70 °C its rearrangement into 199 occurs very rapidly and dioxetane 198 was not detected (Scheme 58) [326,327].

Scheme 58: The photooxidation of 5,6-disubstituted 3,4-dihydro-2H-pyrans 196.

Scheme 58: The photooxidation of 5,6-disubstituted 3,4-dihydro-2H-pyrans 196.

The oxidation of tertiary alcohols 200a–g, 203a,b, and 206, involving the rearrangement of hydroperoxides 201a–g, 204a,b, and 207, occurs in good yields in the presence of such systems as NaBO3·4H2O/BF3·Et2O [328], H2O2/BF3·Et2O, and H2O2/p-TsOH [329] (Scheme 59). The Hock rearrangement can be used to prepare alcohols 202a–g, 205, and 208 containing electron-donating substituents.

Scheme 59: The oxidation of tertiary alcohols 200a–g, 203a,b, and 206.

Scheme 59: The oxidation of tertiary alcohols 200a–g, 203a,b, and 206.

The intramolecular capture of the cationic intermediate derived from the Hock rearrangement of peroxyketone 209 provides a direct and efficient one-step synthesis of 2,3-disubstituted furans 210 (Scheme 60) [330].

Scheme 60: Transformation of functional peroxide 209 leading to 2,3-disubstitued furans 210 in one step.

Scheme 60: Transformation of functional peroxide 209 leading to 2,3-disubstitued furans 210 in one step.

The benzannulation of indoles 211 can be performed with γ-carbonyl tert-butyl peroxides 212 catalyzed by trifluoromethanesulfonic acid to give carbazoles 213. The key step of this approach is based on the acid-catalyzed rearrangement of tert-butyl peroxides (Scheme 61) [331].

Scheme 61: The synthesis of carbazoles 213 via peroxide rearrangement.

Scheme 61: The synthesis of carbazoles 213 via peroxide rearrangement.

The direct dehydrogenative construction of C–N bonds between unprotected phenols 215 and a series of 10H-phenoxazines and 10H-phenothiazines 214 with formation of 216 was carried out using a Hock-like activation with O2 followed by amine oxidation (Scheme 62) [332].

Scheme 62: The construction of C–N bonds using the Hock rearrangement.

Scheme 62: The construction of C–N bonds using the Hock rearrangement.

The Hock rearrangement plays an important role not only in fine organic synthesis but also in biological processes. Scheme 63 shows the proposed mechanism for the biosynthetic conversion of 217 to 218, which is an important component of the structural skeleton of the antitumor–antibiotic CC-1065 [333].

Scheme 63: The synthesis of moiety 218 from 217 which is a structural motif in the antitumor–antibiotic of CC-1065.

Scheme 63: The synthesis of moiety 218 from 217 which is a structural motif in the antitumor–antibiotic of CC-...

The synthetic model of the in vivo oxidation of cholesterol (219) by singlet oxygen produces cholesterol-5α-OOH 220, which is subjected to a Hock reaction to form the aldolization product 221 and keto aldehyde (atheronal A, 222) (Scheme 64) [67].

Scheme 64: The in vivo oxidation steps of cholesterol (219) by singlet oxygen.

Scheme 64: The in vivo oxidation steps of cholesterol (219) by singlet oxygen.

Keto aldehyde (atheronal A, 222) exhibits proatherogenic activity and plays a causal role in the development of cardiovascular diseases [66]. The proposed mechanism of the rearrangement of cholesterol-5α-OOH 220 is presented in Scheme 65.

Scheme 65: The proposed mechanism of the rearrangement of cholesterol-5α-OOH 220.

Scheme 65: The proposed mechanism of the rearrangement of cholesterol-5α-OOH 220.

Therefore, the acid-catalyzed Hock rearrangement of hydroperoxide 220 is a key step in the oxidation of cholesterol (219).

In a photochemical route developed for the synthesis of artemisinin the Hock rearrangement of hydroperoxide 223 selectively affords enol 224. This reactive intermediate 224 is then finally oxidized into artemisinin (Scheme 66) [334].

Scheme 66: Photochemical route to artemisinin via Hock rearrangement of 223.

Scheme 66: Photochemical route to artemisinin via Hock rearrangement of 223.

1.4 Kornblum−DeLaMare rearrangement

The Kornblum−DeLaMare rearrangement (KDLM) is a rearrangement of organic peroxides A containing a primary or secondary carbon atom into ketones B and alcohols C mainly under base-catalyzed reaction conditions (Scheme 67) [335].

Scheme 67: The Kornblum–DeLaMare rearrangement.

Scheme 67: The Kornblum–DeLaMare rearrangement.

In 1951, Kornblum and DeLaMare observed that the treatment of 1-phenylethyl tert-butyl peroxide (225) with KOH, NaOEt, or pyridine resulted in the decomposition of 225 to give acetophenone (227) and tert-butanol (228). A three-step mechanism for this reaction was proposed (Scheme 68) [336,337].

Scheme 68: Kornblum–DeLaMare transformation of 1-phenylethyl tert-butyl peroxide (225).

Scheme 68: Kornblum–DeLaMare transformation of 1-phenylethyl tert-butyl peroxide (225).

The reaction commences with a base-mediated α-proton abstraction from 225 to form carbanion 226 and the latter decomposes to yield the tert-butoxide anion and acetophenone (227). These steps occur presumably in a concerted manner. Finally, the protonation of the tert-butoxide anion results in the formation of tert-butanol (228). As alternative bases Et3N [338,339], phosphorus ylides [340] and LiOH [341,342] can be used and the Kornblum–DeLaMare rearrangement proceeds also on SiO2 [343].

The Kornblum–DeLaMare rearrangement is a convenient tool in organic chemistry for the conversion of monocyclic endoperoxides. These compounds are discussed in this review in the order of increasing ring size and the number of the starting substrates.

The treatment of unsubstituted bicyclic endoperoxides 229 by bases affords 4-hydroxyenones 230 [344] which are useful precursors in asymmetric organic syntheses. Alternative synthetic methods towards this class of compounds normally require a metal-catalyzed or biocatalyzed oxidation of diols 231 in an additional reaction step [345] (Scheme 69).

Scheme 69: The synthesis 4-hydroxyenones 230 from peroxide 229.

Scheme 69: The synthesis 4-hydroxyenones 230 from peroxide 229.

The treatment of endoperoxide 232 with triethylamine in ethanol at room temperature results in the O–O-bond cleavage to form 5-hydroxytropolone (233) (Scheme 70) [346].

Scheme 70: The Kornblum–DeLaMare rearrangement of peroxide 232.

Scheme 70: The Kornblum–DeLaMare rearrangement of peroxide 232.

It is interesting to note, that a reduction of the bicyclic endoperoxide 234 with thiourea in methanol at 10 °C produces similar to KDLM product tropolone 235 in 94% yield (Scheme 71) [347].

Scheme 71: The reduction of peroxide 234.

Scheme 71: The reduction of peroxide 234.

The Kornblum–DeLaMare reaction of the endoperoxide 236 with triethylamine in chloroform at −30 °C affords tropolone 237 in 97% yield (Scheme 72) [347].

Scheme 72: The Kornblum–DeLaMare rearrangement of endoperoxide 236.

Scheme 72: The Kornblum–DeLaMare rearrangement of endoperoxide 236.

Tropolones exhibit a broad spectrum of biological activities, including antibacterial, antiviral, antifungal, anti-allergic, anti-oxidant, and anti-inflammatory [348,349].

The treatment of endoperoxide 238 with Et3N gave 1,4-diketone 240 in quantitative yield instead of expected hydroxy ketone 239 (Scheme 73) [350-352].

Scheme 73: The rearrangement of peroxide 238 under Kornblum–DeLaMare conditions.

Scheme 73: The rearrangement of peroxide 238 under Kornblum–DeLaMare conditions.

The endoperoxide 238 is presumably converted into hemiketal 241, which is rearranged in several steps into diketone 240 (Scheme 74) [351].

Scheme 74: The proposed mechanism of rearrangement of peroxide 238.

Scheme 74: The proposed mechanism of rearrangement of peroxide 238.

The reaction of endoperoxide 242a containing an electron-donating substituent at the double bond with bases results in the rearrangement product diketone 243. Under the same conditions, the base-catalyzed rearrangement of endoperoxide 242b containing an electron-withdrawing substituent leads to a product mixture of hydroxy ketone 244, and diketones 245 and 246 (Scheme 75) [353].

Scheme 75: The Kornblum–DeLaMare rearrangement of peroxides 242a,b.

Scheme 75: The Kornblum–DeLaMare rearrangement of peroxides 242a,b.

A further study [352] on the base-catalyzed rearrangements of substituted bicyclic endoperoxides showed that the pathway of the rearrangement is largely determined by the position of the substituent. The rearrangement of endoperoxides 247a,b containing an electron-withdrawing substituent in the seven-membered ring occurs mainly via a retro-aldol cleavage giving rise to formyl benzoates 248a,b (Scheme 76).

Scheme 76: The base-catalyzed rearrangements of bicyclic endoperoxides having electron-withdrawing substituents.

Scheme 76: The base-catalyzed rearrangements of bicyclic endoperoxides having electron-withdrawing substituent...

On the other hand, endoperoxides 249a,b bearing electron-withdrawing groups (ester, acetyl) attached to the seven-membered ring are isomerized to diketones 250a,b (Scheme 77) [345].

Scheme 77: The base-catalyzed rearrangements of bicyclic endoperoxides 249a,b having electron-donating substituents.

Scheme 77: The base-catalyzed rearrangements of bicyclic endoperoxides 249a,b having electron-donating substit...

The Kornblum–DeLaMare reaction of endoperoxide 251a containing an electron-withdrawing substituent at the bridge head atom lead to the 1,2-dicarbonyl compound 252a whereas the ester 251b polymerized upon treatment with triethylamine (Scheme 78).

Scheme 78: The base-catalyzed rearrangements of bridge-head substituted bicyclic endoperoxides 251a,b.

Scheme 78: The base-catalyzed rearrangements of bridge-head substituted bicyclic endoperoxides 251a,b.

The disproportionation of endoperoxide 253 promoted by triethylamine affords β- and γ-hydroxy hydroperoxides 254 and 256. Under these conditions, the reaction afforded oxodiol 255 and diketone 257, which cyclized to hemiketal 258 as the products (Scheme 79) [354].

Scheme 79: The Kornblum–DeLaMare rearrangement of hydroperoxide 253.

Scheme 79: The Kornblum–DeLaMare rearrangement of hydroperoxide 253.

As the above reaction did not allow the isolation of hydroperoxide 254, an alternative strategy towards this compound was developed. The introduction of a protecting group into endoperoxide 253 using 2-methoxypropene gave protected peroxide 259. The subsequent triethylamine-catalyzed rearrangement of 259 leads to protected intermediate 260 the treatment of which under acidic conditions afforded hydroperoxide 254 in 70% yield (Scheme 80).

Scheme 80: Synthesis of β-hydroxy hydroperoxide 254 from endoperoxide 253.

Scheme 80: Synthesis of β-hydroxy hydroperoxide 254 from endoperoxide 253.

One approach to the enantioselective synthesis of 4-hydroxyenones 262 is based on the Kornblum–DeLaMare rearrangement of meso-endoperoxides 261 catalyzed by a chiral base [345] (Table 14).

Table 14: Enantioselective rearrangement of meso-endoperoxides 261a–f into 4-hydroxy enones 262a–f.

| No | Endoperoxide | Reaction conditionsa | No | Product | Yield,% | eе, % | |

|---|---|---|---|---|---|---|---|

| 261a |

|

R = H | 5 mol % cat., rt, 6 h | 262a |

|

97 | 99 |

| 261b | R,R = OC(Me)2O | 5 mol % cat., rt, 10 h | 262b | 99 | 99 | ||

| 261c |

|

R = H |

5 mol % cat.,

0 °C, 24 h |

262c |

|

99 | 87 |

| 261d | R = TBS | 5 mol % cat., rt, 12 h | 262d | 83 | 99 | ||

| 261e |

|

R = Bn | 10 mol % cat., rt, 24 h | 262e |

|

90 | 96 |

| 261f | R = -C(Me)2- | 10 mol % cat., rt, 36 h | 262f | 76 | 89 | ||

acat. =

The amine-catalyzed rearrangement of bicyclic endoperoxide 263 produced (S)-(+)-4-hydroxycyclohept-2-en-1-one (264), which was oxidized to bicyclic ketone 265. The synthetic value of chiral bicyclic ketone 265 was demonstrated by the transformation of this compound into (+)-sundiversifolide (266) (Scheme 81) [355].

Scheme 81: The amine-catalyzed rearrangement of bicyclic endoperoxide 263.

Scheme 81: The amine-catalyzed rearrangement of bicyclic endoperoxide 263.

The photooxidation of diene 267 followed by the base-catalyzed rearrangement of meso-endoperoxide 268 lead to (±)-trans,cis-4-hydroxy-5,6-di-O-isopropylidenecyclohex-2-en-1-one (269). The protection of the hydroxy group in compound 269 provides an efficient route to functionalized 4-hydroxy-2-cyclohexene-1-ones 270 (Scheme 82) [356].

Scheme 82: The base-catalyzed rearrangement of meso-endoperoxide 268 into 269.

Scheme 82: The base-catalyzed rearrangement of meso-endoperoxide 268 into 269.

The photooxidation of 271 in the presence of tetraphenylporphyrin produces endoperoxide 272, which undergoes a Kornblum–DeLaMare transformation when treated with triethylamine. The obtained product 4-hydroxycyclohexen-2-one 273 releases benzoic acid through β-elimination under the basic conditions to give cyclohexadienone 274 (Scheme 83) [357].

Scheme 83: The photooxidation of 271 and subsequent Kornblum–DeLaMare reaction.

Scheme 83: The photooxidation of 271 and subsequent Kornblum–DeLaMare reaction.

The base-catalyzed isomerization of bicyclic saturated fulvene endoperoxides 275 is employed as one approach to the preparation of 2-alkenylcyclopentanones 276 and cyclopentenones 277 [358]. Thus, the treatment of a solution of endoperoxides 275 in CH2Cl2 with triethylamine while increasing the temperature from 0 °C to room temperature affords hydroxyketone 276. The use of the stronger base DBU results in the formation of 2-vinyl-2-cyclopentenones 277 in high yield (Table 15).

In the case of acyclic enamine 278, the initial dioxetane product from the photochemical oxidation of 279 rearranged to amide 280. The reactions using cyclic enamines 281 involve the Kornblum–DeLaMare rearrangement of dioxetanes 282 into 1,2-diketones 283 (Scheme 84) [359,360].

Scheme 84: The Kornblum–DeLaMare rearrangement as one step in the oxidation reaction of enamines.

Scheme 84: The Kornblum–DeLaMare rearrangement as one step in the oxidation reaction of enamines.

The Kornblum–DeLaMare rearrangement of 1,2-dioxenes 284 [361], 1,2-dioxanes 286 [362], and tert-butyl peroxides 288 [330,363] produces 1,4-dicarbonyl compounds 285, 287, and 289, respectively (Scheme 85). These compounds are versatile starting substrates for the synthesis of various heterocyclic systems, such as furan, thiophene, and pyrrole derivatives.

Scheme 85: The Kornblum–DeLaMare rearrangement of 3,5-dihydro-1,2-dioxenes 284, 1,2-dioxanes 286, and tert-butyl peroxides 288.

Scheme 85: The Kornblum–DeLaMare rearrangement of 3,5-dihydro-1,2-dioxenes 284, 1,2-dioxanes 286, and tert-but...

The reaction of unsymmetrical epoxy dioxanes 290a–d with triethylamine is accompanied by the 1,2-dioxane-ring opening to form 4-hydroxy-2,3-epoxy ketones 291a–d in high yields. The base catalysis involves the abstraction of the most acidic α-proton in the vicinity of the O–O bond followed by the rearrangement accompanied by the O–O-bond cleavage to form 4-hydroxy-2,3-epoxy ketones (Scheme 86) [364].

Scheme 86: The Kornblum–DeLaMare rearrangement of epoxy dioxanes 290a–d.

Scheme 86: The Kornblum–DeLaMare rearrangement of epoxy dioxanes 290a–d.

The Kornblum–DeLaMare rearrangement is of special synthetic value in view of the synthesis of biologically active compounds. For instance, prostaglandin H2 (292) containing the bicyclic [2.2.1]endoperoxide moiety is rearranged in situ into prostaglandin Е2 (293) (Scheme 87) [365,366].

Scheme 87: Rearrangement of prostaglandin H2 292.

Scheme 87: Rearrangement of prostaglandin H2 292.

Nicolaou et al. [367] described the synthesis of epicoccin G (297) and related diketopiperazines 296 through the photooxidation of 294 and the Kornblum–DeLaMare rearrangement of peroxide 295 (Scheme 88).

Scheme 88: The synthesis of epicoccin G (297).

Scheme 88: The synthesis of epicoccin G (297).

The base-catalyzed transformation of organic peroxide 298 was used to synthesize compound 299, a precursor for the synthesis of the natural compound phomactin A (300). Phomactin A is a representative of a new class of platelet-activating factor (PAF) antagonists (Scheme 89) [368].

Scheme 89: The Kornblum–DeLaMare rearrangement used in the synthesis of phomactin A.

Scheme 89: The Kornblum–DeLaMare rearrangement used in the synthesis of phomactin A.

In another study [369], the transformation of peroxide 302, produced from 301, was applied to prepare compounds such as 3H-quinazolin-4-one 303, which is a core subunit of some important quinazolinone-based drugs (Scheme 90).

Scheme 90: The Kornblum–DeLaMare rearrangement in the synthesis of 3H-quinazolin-4-one 303.

Scheme 90: The Kornblum–DeLaMare rearrangement in the synthesis of 3H-quinazolin-4-one 303.

The Kornblum–DeLaMare rearrangement is one of the steps in the synthesis of the natural compound angelone from Nauclea, a plant species widely acclaimed for its anti-inflammatory and antibacterial utilities in traditional Chinese herbal medical formulations [370]. A Kornblum–DeLaMare enantiomeric resolution was also used to obtain both fragments of the polypropionate metabolite dolabriferol from a common precursor. The endoperoxide 304 was converted into ketone 305 with the help of the pseudo-enantiomeric quinine-derived catalyst (deMeQ-Ac) in toluene with moderate 47% yield. The peroxide 306 was transformed into ketone 307 with good 92% yield by using Et3N (Scheme 91) [371].

Scheme 91: The Kornblum–DeLaMare rearrangement in the synthesis of dolabriferol (308).

Scheme 91: The Kornblum–DeLaMare rearrangement in the synthesis of dolabriferol (308).

A sequence consisting of a template-mediated photooxygenation and an acid-catalyzed Kornblum−DeLaMare rearrangement of the intermediate endo-peroxides 310 was used in a one-pot transformation of 3-substituted 2-pyridones 309 into the respective 3-hydroxypyridine-2,6-diones 311 with good enantioselectivity (69–86% ee) (Scheme 92) [372].

Scheme 92: Sequential transformation of 3-substituted 2-pyridones 309 into 3-hydroxypyridine-2,6-diones 311 in one pot.

Scheme 92: Sequential transformation of 3-substituted 2-pyridones 309 into 3-hydroxypyridine-2,6-diones 311 in...

The Kornblum–DeLaMare rearrangement of peroxide 312 into hydroxy enone 313 with high yields and regioselectivity has been reported in the total synthesis of (+)-zeylenol and its congeners (Scheme 93) [373].

Scheme 93: The Kornblum–DeLaMare rearrangement of peroxide 312 into hydroxy enone 313.

Scheme 93: The Kornblum–DeLaMare rearrangement of peroxide 312 into hydroxy enone 313.

The polyfunctionalized carbonyl compounds 317 were prepared via crossover oxidative coupling of ethers 316 with electron-deficient alkenes 315 and vinylarenes 314 in the presence of Co(salen) and TBHP under mild conditions. The transformation involved the combination of a tandem radical reaction and a Kornblum−DeLaMare rearrangement in a one-pot process (Scheme 94) [374].

Scheme 94: The Kornblum–DeLaMare rearrangement in the synthesis of polyfunctionalized carbonyl compounds 317.

Scheme 94: The Kornblum–DeLaMare rearrangement in the synthesis of polyfunctionalized carbonyl compounds 317.

The readily available compounds styrenes 314, amines 318 and perfluoroalkyl iodides 319 were transformed into (Z)-β-perfluoroalkylenaminones 320 via a Co(acac)2/TBHP-promoted multicomponent radical reaction involving sequential fluoroalkylation and Kornblum-DeLaMare rearrangement (Scheme 95) [375].

Scheme 95: The Kornblum–DeLaMare rearrangement in the synthesis of (Z)-β-perfluoroalkylenaminones 320.

Scheme 95: The Kornblum–DeLaMare rearrangement in the synthesis of (Z)-β-perfluoroalkylenaminones 320.

Peroxy products resulted from the reaction of styrenes 314, ethyl diazoacetate (321), and TBHP underwent a Kornblum–DeLaMare rearrangement with formation of γ-ketoester 322 (Scheme 96) [376].

Scheme 96: The Kornblum–DeLaMare rearrangement in the synthesis of γ-ketoester 322.

Scheme 96: The Kornblum–DeLaMare rearrangement in the synthesis of γ-ketoester 322.

The Kornblum–DeLaMare rearrangement is a final step in the total synthesis of the diterpenoids amphilectolide (326) and sandresolide B (328) from a common furan building block 324, which was synthesized from 323. Amphilectolide was obtained through a photooxygenation of 325 in the presence of diisopropylethylamine (DIEA), followed by a one-pot reduction of the intermediate peroxide with sodium borohydride. Sandresolide B was prepared from 327 using tetraphenylporphyrin as a photosensitizer and DBU as a base in 51% yield over two steps (Scheme 97) [377].

Scheme 97: The Kornblum–DeLaMare rearrangement in the synthesis of diterpenoids 326 and 328.

Scheme 97: The Kornblum–DeLaMare rearrangement in the synthesis of diterpenoids 326 and 328.

The total synthesis of the natural products hainanolidol (331) and harringtonolide (332) includes a DBU-promoted Kornblum–DeLaMare rearrangement of endoperoxide 329 to ketone 330 (Scheme 98) [378].

Scheme 98: The synthesis of natural products hainanolidol (331) and harringtonolide (332) from peroxide 329.

Scheme 98: The synthesis of natural products hainanolidol (331) and harringtonolide (332) from peroxide 329.

The reaction of the sodium salts of 1,3-dicarbonyl compounds 333, 334 with endoperoxides 263 and 261a in the presence of an organocatalyst affords the trans-fused butyrolactones 339 and 340 in high yield. The reaction proceeds via the formation of bicycles 335, 336 in the case of method A and 337, 338 in the case of method B (Scheme 99) [379].

Scheme 99: The synthesis of trans-fused butyrolactones 339 and 340.

Scheme 99: The synthesis of trans-fused butyrolactones 339 and 340.

The leucosceptroid A (341) produced leucosceptroid C (343) and its diastereomer in 78% yield (1:1 dr) under the base-induced reduction of the initial endoperoxide intermediate. Irradiation of a solution of leucosceptroid A (341) in an oxygen-saturated dichloromethane solution containing a catalytic amount of tetraphenylporphyrin (TPP) and N,N-diisopropylethylamine cleanly produced 344 (85% yield). The latter compound represents the base-promoted Kornblum–DeLaMare rearrangement product of endoperoxide 342 (Scheme 100) [380].

Scheme 100: The synthesis of leucosceptroid C (343) and leucosceptroid P (344) via the Kornblum–DeLaMare rearrangement.

Scheme 100: The synthesis of leucosceptroid C (343) and leucosceptroid P (344) via the Kornblum–DeLaMare rearra...

It is worth mentioning that the synthesis of 4-hydroxycyclopentenone 343 and litsaverticillols was achieved in a similar way in other works [381-384].

1.5 Dakin oxidation of arylaldehydes or acetophenones

Generally, the Dakin oxidation is a reaction, in which o- or p-hydroxylated benzaldehydes or acetophenones 345 react with hydrogen peroxide in the presence of a base to form o- or p-dihydroxybenzene 346 and carboxylate 347 (Scheme 101) [385,386].

Scheme 101: The Dakin oxidation of arylaldehydes or acetophenones.

Scheme 101: The Dakin oxidation of arylaldehydes or acetophenones.

Actually, the Dakin oxidation is a special case of the Baeyer–Villiger oxidation. Mechanistically, the Dakin oxidation starts with the nucleophilic addition of a hydroperoxide anion to the carbonyl carbon atom of benzaldehyde (348) to form intermediate 349 followed by its rearrangement to phenyl ester 350. The subsequent nucleophilic addition of a hydroxide anion to the carbonyl group of phenyl ester 350 yields intermediate 351, which undergoes a rearrangement accompanied by the elimination of phenoxide anion 352 and carboxylic acid 353. Then, the phenoxide anion 352 deprotonates the carboxylic acid 353 to produce p-dihydroxybenzene (354) and the corresponding carboxylate anion 355 (Scheme 102) [385,387].

Scheme 102: The mechanism of the Dakin oxidation.

Scheme 102: The mechanism of the Dakin oxidation.

The nucleophilic addition of the hydroperoxide to the carbon atom of a carbonyl group and the [1,2]-aryl migration are the two rate-determining reaction steps in the Dakin oxidation process [387]. The total rate of the Dakin oxidation depends on the nucleophilicity of the hydroperoxide, the electrophilicity of the carbonyl carbon atom, the nature of alkyl substituents in the proximity of the carbonyl group, the existence of other functional groups in the aromatic ring, and the alkalinity of the reaction mixture. Generally, hydroxybenzaldehydes are more reactive in the Dakin oxidation than hydroxyacetophenones. This is due to the fact, that the carbonyl carbon atom of ketones is less electrophilic than the carbonyl carbon atom of an aldehyde. Under weakly basic conditions, о-hydroxybenzaldehydes and о-hydroxyacetophenones are oxidized more rapidly than p-hydroxybenzaldehydes and p-hydroxyacetophenones, whereas m-hydroxybenzaldehydes and m-hydroxyacetophenones are unreactive [387]. Electron-donating substituents in the ortho and para positions of the aromatic ring enhance the electron density on the migrating carbon atom thus promoting the [1,2]-aryl migration and accelerating the oxidation. Electron-donating substituents in the meta position have little effect on the electron density on the migrating carbon atom. Electron-withdrawing substituents in the ortho and para positions of the aromatic ring reduce the electron density on the migrating carbon atom, interfering with the [1,2]-aryl migration. The hydroperoxide anion is a more reactive nucleophile than neutral hydrogen peroxide. The reaction rate of the oxidation of hydroxyphenylaldehydes or ketones increases with increasing pH value, however, at pH higher than 13.5 the oxidation does not take place [387].

The efficient oxidation of hydroxylated aldehydes and ketones to hydroquinones and catechols was performed using a complex of urea with hydrogen peroxide as an oxidant [388]. The main advantage of this method is, that the reaction is performed under solvent-free conditions and provides the products in high yields.

A solvent-free Dakin reaction of aromatic aldehydes 356 with m-CPBA resulted in corresponding phenols 357 with high yields within a few minutes (Scheme 103) [389].

Scheme 103: A solvent-free Dakin reaction of aromatic aldehydes 356.

Scheme 103: A solvent-free Dakin reaction of aromatic aldehydes 356.

The phenols 359 were prepared from electron-rich arylaldehydes 358 by a flavin-catalyzed Dakin oxidation under the action of H2O2 and sodium bicarbonate with high yields (Scheme 104) [390].

Scheme 104: The organocatalytic Dakin oxidation of electron-rich arylaldehydes 358.

Scheme 104: The organocatalytic Dakin oxidation of electron-rich arylaldehydes 358.