Abstract

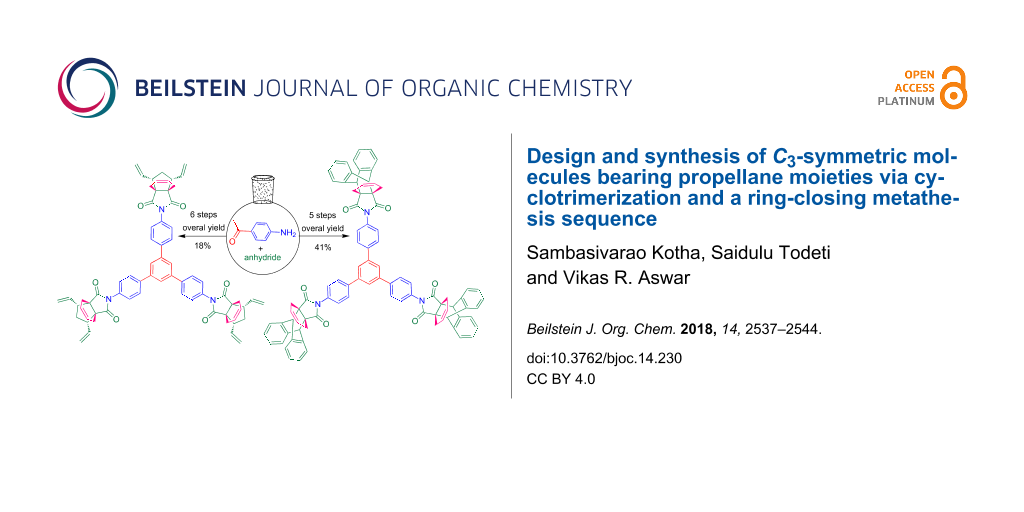

We have developed an efficient synthetic strategy to assemble C3-symmetric molecules containing propellane moieties as end groups and a benzene ring as a central core. The synthesis of these C3-symmetric molecules involves simple starting materials. Our approach to C3-symmetric compounds relies on a Diels–Alder reaction, cyclotrimerization and ring-closing metathesis as key steps.

Graphical Abstract

Introduction

In 1966 Ginsburg coined the word “propellane” [1,2] and Wiberg reviewed various aspects of medium and small ring propellanes [3,4]. Propellanes consist of tricyclic compounds where three rings are conjoined by a common C–C bond [1,5,6]. Heterocyclic systems contain a heteroatom (e.g., oxygen, nitrogen, and sulfur, etc.) along with carbon atoms. The name of a heterocyclic propellane may be organized by prefixing aza, oxa, etc.

Among various propellanes, nitrogen-containing compounds occupy a special place because they are present as core structural units in bioactive natural products and pharmaceuticals. Some of these propellanes exhibit intresting properties like antibiotic, antifungal, anticancer, platelet-activating factor antagonistic and antibacterial activities. The propellane skeleton is present in many alkaloids such as aknadinine (1), aknadilactam (2), and the known morphinane alkaloid sinococuline (3), which was identified as a bioactive component from S. japonica [7]. In 1963 Brown et al. isolated 1-acetyl-aspidoalbidine (4) from Vallesia dichtoma [8] and subsequently, Djerassi proposed its structure [9]. Another alkaloid (−)-aspidophytine (5) differs from 1-acetylaspidoalbidine (4) only in the degree of unsaturation and the substitution pattern on the aromatic ring (Figure 1).

Figure 1: Various alkaloids containing propellane frame work.

Figure 1: Various alkaloids containing propellane frame work.

The design of propellanes demands unique synthetic methods and these include: manganese or palladium-catalyzed transformations [10], the Diels–Alder (DA) reaction [11,12], and rearrangement of spiro-ketones, nucleophilic substitutions of alkenes, and photochemical addition reactions. Multicomponent reactions (MCRs) are also used for the synthesis of hetero-propellanes [13,14]. Recently, heterocyclic propellanes have been reviewed [15,16]. Our group also developed simple synthetic approaches to propellanes via ring-closing metathesis (RCM) as a key step [17,18].

The development of new synthetic strategies to C3-symmetric molecules bearing propellane moieties from commercially available starting materials is worthy of systematic investigation. To this end, our efforts are directed to design star-shaped molecules that involve a wide range of structural variations. To the best of our knowledge there are no synthetic reports available for C3-symmetric molecules bearing propellane moieties. As part of our major program aimed at designing star-shaped C3-symmetric molecules [19-30], here, we conceived new strategies to N-containing star-shaped molecules. Such star-shaped molecules are generally used in organic light-emitting diodes (OLEDs) [31-33], organic photovoltaics (OPVs) [34], organic field-effect transistors (OFETs) [35,36], and other optoelectronic devices. Our approach to C3-symmetric molecules containing propellane moieties involve DA reaction [37], cyclotrimerization [19] and RCM [38-41] as key steps.

Results and Discussion

The synthesis of propellane-bearing C3-symmetric derivatives starts with commercially available dicyclopentadiene and maleic anhydride (7). Here, we used a DA reaction of freshly cracked cyclopentadiene (6) and maleic anhydride (7) to obtain the endo-DA adduct 8 [42] in 98% yield. Next, this cycloadduct 8 was treated with commercially available 4-aminoacetophenone (9) in the presence of triethylamine (Et3N) in toluene at 140 °C to obtain the acetophenone derivative 10 in excellent yield (92%) [43]. Later, the acetophenone derivative 10 was subjected to trimerization reaction under ethanol/silicon tetrachloride (EtOH/SiCl4) conditions to deliver the trimerized product 11 (64%). Having the trimerized product 11, we attempted to open the norbornene system due to the fact that not all norbornene rings open up during RCM to generate propellane derivative. After allylation, RCM is not a clean reaction and it gave a mixture of the C3-symmetrical compounds. Therefore it is desirable to open the norbornene double bond before the trimerization sequence. To this end, the trimerized product 11 was treated with Grubbs first generation (G-I) catalyst in CH2Cl2 under ethylene atmosphere but, we were unable to get the ring-opened product 12 (Scheme 1).

Scheme 1: Synthesis of the star-shaped norbornene derivative 11 via trimerization.

Scheme 1: Synthesis of the star-shaped norbornene derivative 11 via trimerization.

Later, we considered an alternate route to synthesize compound 12. In this regard, we employed different ruthenium-based catalysts (Figure 2) and reaction conditions to obtain the ring-opening metathesis (ROM) product 13 from norbornene derivate 10. Under these conditions the starting material was not consumed completely. After some experimentation, we found that G-I catalyst (5 mol %) in CH2Cl2 is suitable to generate the ROM product 13 in 56% yield (Table 1).

Figure 2: Selected list of ruthenium-based catalysts used for ROM.

Figure 2: Selected list of ruthenium-based catalysts used for ROM.

Table 1: Different conditions attempted to obtain the ROM product 13.

|

|

||||||

| entry | catalyst | mol % | solvent | temp | time (h) | yield (%) |

|---|---|---|---|---|---|---|

| 1 | G-I | 5 or 10 | CH2Cl2 | rt | 48 | 56 |

| 2 | G-I | 5 or 10 | CH2Cl2 | reflux | 32 | 48 |

| 4 | G-II | 5 or 10 | toluene | rt | 46 | 24 |

| 5 | G-II | 5 | toluene | reflux | 43 | 20 |

| 6 | Ru-II | 5 or 10 | CH2Cl2 | rt | 48 | 52 |

| 7 | GH-I | 5 or 10 | CH2Cl2 | rt | 40 | 53 |

| 8 | GH-I | 5 or 10 | CH2Cl2 | reflux | 40 | 50 |

Having the ROM product 13 in hand, it was subjected to trimerization in the presence of EtOH/SiCl4 at 0 °C to room temperature to afford the trimerized product 12 in 54% yield. Next, the C3-symmetric product 12 was reacted with allyl bromide in the presence of sodium bis(trimethylsilyl)amide (NaHMDS, 1 M solution in THF) at −75 °C to deliver the RCM precursor 14 in good yield (78%). The hexaallyl derivative 14 was subjected to RCM in the presence of Grubbs second generation (G-II) catalyst in CH2Cl2 under nitrogen to give the propellane moiety bearing C3-symmetric product 15 in good yield (87%). Its structure was established on the basis of NMR spectral data, and its molecular formula was confirmed by HRMS data (Scheme 2).

Scheme 2: Synthesis of the C3-symmetric molecule 15 bearing propellane moieties via trimerization and RCM.

Scheme 2: Synthesis of the C3-symmetric molecule 15 bearing propellane moieties via trimerization and RCM.

Along similar lines, we expanded the scope of this strategy. To this end, commercially available anthracene (16) was reacted with maleic anhydride (7) in a screw-capped tube at 150 °C in o-xylene to obtain the DA adduct 17 in 94% yield [44,45]. Later, the DA adduct 17 was treated with 4-aminoacetophenone (9) in the presence of Et3N in toluene at 140 ºC to deliver the acetophenone derivative 18 (91% yield) and it was subjected to trimerization in the presence of EtOH/SiCl4 at 0 °C to rt to obtain the trimerized product 19 in 64% yield. Afterwards, the trimerized product 19 was treated with allyl bromide to accomplish C-allylation in the presence of NaHMDS (1 M solution in THF) at −75 °C to deliver the hexaallyl derivative 20 in 84% yield. Then, RCM in the presence of G-II catalyst in CH2Cl2 under nitrogen atmosphere gave the propellane moieties bearing C3-symmetric product 21 in good yield (91%). Its structure was established with the help of 1H NMR, 13C NMR spectral data and was further supported by HRMS details (Scheme 3).

Scheme 3: Synthesis of C3-symmetric molecule 21 bearing propellane moieties via trimerization and RCM.

Scheme 3: Synthesis of C3-symmetric molecule 21 bearing propellane moieties via trimerization and RCM.

Conclusion

We have demonstrated a simple synthetic methodology to C3-symmetric star-shaped molecules containing propellane moieties at the periphery which may be useful for material science applications. Here, we have prepared DA adducts 8 and 17 from commercially available maleic anhydride (7), which was further utilized for trimerization and RCM sequence. We have successfully synthesized C3-symmetric molecules 15 and 21 bearing propellane moieties by employing RCM in the presence of 2nd generation (G-II) catalyst.

Experimental

General information

Some of these reactions were carried out in screw-capped tubes and other reactions under nitrogen or argon and ethylene atmosphere in oven-dried glassware. Air- and moisture-sensitive reactions were performed in degassed solvents. Transfer of moisture-sensitive materials were carried out using standard syringe−septum techniques. All the commercial grade reagents were used without any purification until otherwise specified. Melting points were recorded on a Veego or Büchi melting point apparatus and are uncorrected. NMR Spectra were generally recorded on Bruker (Avance 400 or Avance III 500) spectrometers operated at 400 or 500 MHz for 1H and 100 or 125.7 MHz for 13C nuclei. NMR Samples were generally made in chloroform-d solvent, and chemical shifts (δ values) are reported in parts per million (ppm). Coupling constants (J values) were reported in hertz (Hz). HRMS measurements were carried out using a Bruker (Maxis Impact) spectrometer. IR spectra were recorded on a Nicolet Impact-400 or Cary 630 FTIR spectrometer.

Synthesis of norbornene-based trimerized product 11

To a solution of norbornene derivative 10 (500 mg, 1.77 mmol) in EtOH (8 mL), silicon tetrachloride (SiCl4, 0.61 mL, 5.36 mmol) was added dropwise at 0 °C and the reaction mixture was stirred for 10–15 min at the same temperature. Later, the reaction mixture was stirred at room temperature for 20 h. After completion of the reaction (TLC monitoring), the reaction mixture was quenched with sat. aq NH4Cl. Thereafter, the reaction mixture was diluted with EtOAc (10 mL) washed with water and brine (2 × 10 mL). Then, the aqueous layer was extracted with EtOAc (3 × 10 mL) and the combined organic layers were dried over Na2SO4. The solvent was removed under reduced pressure and the crude product was purified by silica gel column chromatography (65% EtOAc/petroleum ether) to afford the trimerized product 11 (321 mg, 64%) as a colourless solid. Rf = 0.54 (6:4 EtOAc/petroleum ether); mp 203–206 °C; 1H NMR (400 MHz, CDCl3) δ 7.68 (d, J = 5.2 Hz, 6H), 7.66 (s, 3H), 7.24 (d, J = 2.4 Hz, 6H), 6.28 (s, 6H), 3.51–3.44 (m, 12H), 1.79 (d, J = 8.8 Hz, 3H), 1.61 (d, J = 8.8 Hz, 3H) ppm; 13C NMR (125 MHz, CDCl3) δ 177.0, 141.8, 141.3, 134.8, 131.4, 128.2, 127.2, 125.7, 52.4, 46.0, 45.7 ppm; HRMS (ESI, Q-ToF) m/z: [M + H]+ calcd for C51H40N3O6, 790.2912; found, 790.2918; IR (neat) max: 2918, 1706, 1512, 1371, 1173, 754 cm−1.

Synthesis of ring open metathesis (ROM) product 13

The solution of compound 10 (500 mg, 1.76 mmol) in dry CH2Cl2 (25 mL) was degasified by ethylene and G-I (5 mol %) was added to the reaction mixture at rt. Further, the reaction mixture was stirred for 48 h under ethylene atmosphere at rt. After completion of the reaction (TLC monitoring), the solvent was removed under reduced pressure. Later, the crude product was purified by silica gel column chromatography (30% EtOAc/petroleum ether) to obtain the ROM product 13 as a colourless solid (310 mg, 56%); Rf = 0.68 (4:6 EtOAc/petroleum ether); mp 143–145 °C; 1H NMR (400 MHz, CDCl3) δ 8.03 (d, J = 8.4 Hz, 2H), 7.40 (d, J = 8.4 Hz, 2H), 6.12–6.03 (m, 2H), 5.20–5.15 (m, 4H), 3.43 (q, J = 2.0 Hz, 2H), 3.08–3.00 (m, 2H), 2.60 (s, 3H), 2.08–2.02 (m, 1H), 1.57 (t, J = 6.4 Hz, 1H) ppm; 13C NMR (100 MHz, CDCl3) δ 197.2, 175.4, 136.7, 136.2, 136.1, 129.2, 126.5, 116.3, 49.1, 46.4, 35.4, 26.8 ppm; HRMS (ESI, Q-ToF) m/z: [M + Na]+ calcd for C19H19NO3·Na, 332.1257; found, 332.1254; IR (neat) max: 2325, 1671, 1263, 746 cm−1.

Synthesis of trimerized compound 12

Based on the earlier procedure of trimerization, compound 13 (500 mg, 1.61 mmol) was treated with SiCl4 (0.55 mL, 4.84 mmol) in the presence of EtOH (8 mL) for 16 h to afford trimerized product 12 after silica gel column chromatography (60% EtOAc/petroleum ether) as a colourless solid (254 mg, 54%); mp 152–154 °C; Rf = 0.55 (5:5 EtOAc/petroleum ether); 1H NMR (400 MHz, CDCl3) δ 7.72 (d, J = 8.0 Hz, 6H), 7.70 (s, 3H), 7.37 (d, J = 8.4 Hz, 6H), 6.15–6.07 (m, 6H), 5.19 (q, J = 8.4 Hz, 12H), 3.43 (dd, J1 = 2.0 Hz, J2 = 2.0 Hz, 6H), 3.07–2.99 (m, 6H), 2.04 (q, J = 6.8 Hz, 3H), 1.58 (q, J = 13.2 Hz, 3H) ppm; 13C NMR (100 MHz, CDCl3) δ 175.7, 141.7, 141.1, 136.4, 131.4, 128.1, 126.9, 125.6, 116.1, 49.1, 46.3, 35.5 ppm; HRMS (ESI, Q-ToF) m/z: [M + Na]+ calcd for C57H51N3O6·Na, 896.3670; found; 896.3678; IR (neat) max: 2342, 1709, 1512, 1183, 919, 736 cm−1.

Synthesis of trimerized product 19

Based on the earlier procedure of trimerization, compound 18 (500 mg, 1.27 mmol) was treated with SiCl4 (0.43 mL, 3.83 mmol) in the presence of EtOH (8 mL) for 20 h to give the trimerized product 19 after silica gel (100–200 mesh) column chromatography (50% EtOAc/petroleum ether) as a colourless solid (324 mg, 64%); Rf = 0.61 (4:6 EtOAc/petroleum ether); mp 224–226 °C; 1H NMR (500 MHz, CDCl3) δ 7.56 (s, 3H), 7.51 (d, J = 8.0 Hz, 6H), 7.43 (d, J = 3.0 Hz, 6H), 7.37 (d, J = 3.0 Hz, 6H), 7.24–7.22 (m, 12H), 6.62 (d, J = 8.5 Hz, 6H), 4.92 (s, 6H), 3.41 (s, 6H) ppm; 13C NMR (125 MHz, CDCl3) δ 176.3, 141.5, 141.4, 138.9, 128.2, 127.4, 127.1, 127.0, 125.3, 124.5, 47.2, 46.1 ppm; HRMS (ESI, Q-ToF) m/z: [M + Na]+ calcd for C78H51N3O6·Na, 1148.3670; found, 1148.3672; IR (neat) max: 2318, 1266, 745, 707 cm−1.

Synthesis of hexaallyl derivative 14

To the solution of compound 12 (200 mg, 0.22 mmol) in anhydrous THF (15 mL) was added NaHMDS (2 mL of 1 M solution in THF, 1.93 mmol) at −75 °C and the reaction mixture was stirred for 30 min under nitrogen atmosphere. Then allyl bromide (0.11 mL, 1.60 mmol) was added to the reaction mixture and stirred for 2 h at −75 °C. Later, the reaction mixture was stirred to room temperature for 10 h. After completion of the reaction (TLC monitoring), the reaction mixture was quenched with 1 M aq HCl solution, and the aqueous layer was extracted by EtOAc (3 × 10 mL). Then the organic fraction was washed with brine solution, dried over Na2SO4 and concentrated. The crude residue was purified by silica gel column chromatography (10% EtOAc/petroleum ether) to afford hexa-allyl derivative 14 as a colourless solid (199 mg, 78%). Rf = 0.60 (3:7 EtOAc/petroleum ether); mp 204–206 °C; 1H NMR (500 MHz, CDCl3) δ 7.71 (d, J = 5.5 Hz, 6H), 7.69 (s, 3H), 7.33 (d, J = 8.5 Hz, 6H), 6.08–5.96 (m, 12H), 5.28–5.13 (m, 24H), 2.77–2.66 (m, 18H), 2.04–2.00 (m, 3H), 1.65 (q, J = 12.5 Hz, 3H) ppm; 13C NMR (125 MHz, CDCl3) δ 178.2, 141.9, 141.3, 136.5, 132.8, 131.5, 128.1, 127.1, 125.7, 120.3, 117.1, 59.9, 51.2, 36.6, 35.1 ppm; HRMS (ESI, Q-ToF) m/z: [M + Na]+ calcd for C75H75N3O6·Na, 1136.5548; found, 1136.5544; IR (neat) max: 2345, 1671, 1263, 746 cm−1.

Synthesis of hexaallyl product 20

Based on the earlier procedure of allylation, compound 19 (336 mg, 0.29 mmol) was treated with NaHMDS (2.3 mL of 1 M solution in THF, 2.39 mmol) and allyl bromide (0.14 mL, 1.93 mmol) for 17 h to deliver hexaallyl product 20 after silica gel column chromatography (20% EtOAc/petroleum ether) as a colourless solid (345 mg, 84%); Rf = 0.83 (2:8 EtOAc/petroleum ether); mp 195–197 °C; 1H NMR (400 MHz, CDCl3) δ 7.57 (s, 3H), 7.51 (d, J = 8.8 Hz, 6H), 7.40 (q, J = 3.2 Hz, 6H), 7.32 (q, J = 3.2 Hz, 6H), 7.24–7.20 (m, 12H), 6.58 (d, J = 8.0 Hz, 6H), 6.33–6.23 (m, 6H), 5.20 (dd, J1 = 11.6 Hz, J2 = 17.2 Hz, 12H), 4.68 (s, 6H), 2.45 (dd, J1 = 5.6 Hz, J2 = 5.6 Hz, 6H), 2.16 (q, J = 8.8 Hz, 6H) ppm; 13C NMR (100 MHz, CDCl3) δ 178.5, 141.7, 141.4, 139.9, 139.4, 133.6, 131.0, 128.1, 127.2, 127.1, 126.7, 126.5, 125.6, 125.3, 119.4, 55.7, 51.6, 37.3 ppm; HRMS (ESI, Q-ToF) m/z: [M + Na]+ calcd for C96H75N3O6·Na, 1388.5548; found, 1389.5585; IR (neat) max: 2925, 2335, 1706, 1461, 1376, 1273, 741 cm–1.

General procedure for ring-closing metathesis (RCM)

The solution of hexaallyl derivatives 14 or 20 in dry CH2Cl2 (20 mL) was degassed by nitrogen and G-II (10 mol %) was added to the reaction mixture. Further, the reaction mixture was stirred for 6 h under nitrogen atmosphere at room temperature. After completion of the reaction (TLC monitoring), the solvent was removed under reduced pressure. The crude product was purified by silica gel column chromatography (EtOAc/petroleum ether) to afford the propellane bearing C3-symmetric products 15 or 21.

Synthesis of RCM derivative 15

Colourless solid, 87% (121 mg, starting with 150 mg of hexaallyl compound 14); Rf = 0.60 (3:7 EtOAc/petroleum ether); mp 272–275 °C; 1H NMR (400 MHz, CDCl3) δ 7.71 (d, J = 2.0 Hz, 6H), 7.69 (s, 3H), 7.35 (d, J = 8.4 Hz, 6H), 6.08–5.99 (m, 12H), 5.18–5.14 (m, 12H), 2.76 (dd, J1 = 4.0 Hz, J2 = 3.2 Hz, 6H), 2.67–2.61 (m, 6H), 2.23 (dd, J1 = 2.0 Hz, J2 = 2.0 Hz, 6H), 2.04–1.98 (m, 3H), 1.58 (q, J = 12.8, 3H) ppm; 13C NMR (100 MHz, CDCl3) δ 178.2, 141.8, 141.2, 136.2, 131.6, 128.5, 128.1, 126.9, 125.7, 116.4, 58.7, 53.3, 35.7, 30.9 ppm; HRMS (ESI, Q-ToF) m/z: [M + Na]+ calcd for C69H63N3O6·Na, 1052.4609; found, 1052.4617; IR (neat) max: 2305, 1651, 1363, 844 cm−1.

Synthesis of RCM derivative 21

Colourless solid, 91% (258 mg, starting with 300 mg of hexaallyl product 20); Rf = 0.75 (3:7 EtOAc/petroleum ether); mp 264–267 °C; 1H NMR (400 MHz, CDCl3) δ 7.56 (s, 3H), 7.49 (d, J = 6.8 Hz, 6H), 7.43 (d, J = 2.4 Hz, 6H), 7.34 (d, J = 2.4 Hz, 6H), 7.25–7.23 (m, 12H), 6.57 (d, J = 7.6 Hz, 6H), 5.83 (s, 6H), 4.47 (s, 6H), 2.90 (d, J = 14.4 Hz, 6H), 1.80 (d, J = 14.8 Hz, 6H) ppm; 13C NMR (100 MHz, CDCl3) δ 180.0, 141.6, 141.4, 140.4, 140.2, 131.2, 128.0, 127.9, 127.2, 127.1, 127.0, 126.5, 125.6, 125.2, 57.4, 51.5, 30.2 ppm; HRMS (ESI, Q-ToF) m/z: [M + K]+ calcd for C90H63N3O6·K, 1320.4348; found, 1320.4344; IR (neat) max: 2328, 1708, 1383, 837, 690 cm−1.

Supporting Information

| Supporting Information File 1: Copies of 1H, 13C NMR and HRMS spectra of new compounds. | ||

| Format: PDF | Size: 2.0 MB | Download |

Acknowledgements

We thank the Department of Science and Technology (DST), New Delhi, India, for financial support and IIT Bombay, for recording spectral data. S.K. thanks the Department of Science and Technology for the award of a J. C. Bose fellowship (SR/S2/JCB-33/2010), Praj industries, Pune for Pramod Chaudhari Chair Professorship (Green Chemistry) and CSIR (02(0272)/16/EMR-II). S.T. thanks the IIT Bombay for the award of a research fellowship. V.R.A. thanks the CSIR-New Delhi and IIT Bombay for the award of a research fellowship.

References

-

Altman, J.; Babad, E.; Itzchaki, J.; Ginsburg, D. Tetrahedron 1966, 22, 279–304. doi:10.1016/S0040-4020(01)82189-X

Return to citation in text: [1] [2] -

Ginsburg, D. Acc. Chem. Res. 1969, 2, 121–128. doi:10.1021/ar50016a005

Return to citation in text: [1] -

Wiberg, K. B. Acc. Chem. Res. 1984, 17, 379–386. doi:10.1021/ar00107a001

Return to citation in text: [1] -

Wiberg, K. B. Acc. Chem. Res. 1996, 29, 229–234. doi:10.1021/ar950207a

Return to citation in text: [1] -

Weber, R. W.; Cook, J. M. Can. J. Chem. 1978, 56, 189–192. doi:10.1139/v78-030

Return to citation in text: [1] -

Schneider, L. M.; Schmiedel, V. M.; Pecchioli, T.; Lentz, D.; Merten, C.; Christmann, M. Org. Lett. 2017, 19, 2310–2313. doi:10.1021/acs.orglett.7b00836

Return to citation in text: [1] -

Carroll, A. R.; Arumugan, T.; Redburn, J.; Ngo, A.; Guymer, G. P.; Forster, P. I.; Quinn, R. J. J. Nat. Prod. 2010, 73, 988–991. doi:10.1021/np100009j

Return to citation in text: [1] -

Brown, K., Jr.; Budzikiewicz, H.; Djerassi, C. Tetrahedron Lett. 1963, 4, 1731–1736. doi:10.1016/S0040-4039(01)90904-9

Return to citation in text: [1] -

Walser, A.; Djerassi, C. Helv. Chim. Acta 1965, 48, 391–404. doi:10.1002/hlca.19650480220

Return to citation in text: [1] -

Asahi, K.; Nishino, H. Tetrahedron 2008, 64, 1620–1634. doi:10.1016/j.tet.2007.12.017

Return to citation in text: [1] -

Diels, O.; Alder, K. Chem. Ber. 1929, 62, 2081–2087. doi:10.1002/cber.19290620829

Return to citation in text: [1] -

Diels, O.; Alder, K. Justus Liebigs Ann. Chem. 1931, 486, 191–202. doi:10.1002/jlac.19314860110

Return to citation in text: [1] -

Yamamoto, N.; Fujii, H.; Nemoto, T.; Nakajima, R.; Momen, S.; Izumimoto, N.; Hasebe, K.; Mochizuki, H.; Nagase, H. Bioorg. Med. Chem. Lett. 2011, 21, 4104–4107. doi:10.1016/j.bmcl.2011.04.147

Return to citation in text: [1] -

Alizadeh, A.; Bayat, F.; Sadeghi, V. Lett. Org. Chem. 2015, 12, 153–158. doi:10.2174/1570178612666150108003359

Return to citation in text: [1] -

Pihko, A. J.; Koskinen, A. M. Tetrahedron 2005, 61, 8769–8807. doi:10.1016/j.tet.2005.06.013

Return to citation in text: [1] -

Yavari, I.; Khajeh-Khezri, A. Mol. Diversity 2017, 21, 849–854. doi:10.1007/s11030-017-9761-8

Return to citation in text: [1] -

Kotha, S.; Chinnam, A. K.; Tiwari, A. Beilstein J. Org. Chem. 2013, 9, 2709–2714. doi:10.3762/bjoc.9.307

Return to citation in text: [1] -

Kotha, S.; Manivannan, E.; Ganesh, T.; Sreenivasachary, N.; Deb, A. Synlett 1999, 1618–1620. doi:10.1055/s-1999-2896

Return to citation in text: [1] -

Kotha, S.; Chakraborty, K.; Brahmachary, E. Synlett 1999, 1621–1623. doi:10.1055/s-1999-2895

Return to citation in text: [1] [2] -

Dash, B. P.; Satapathy, R.; Maguire, J. A.; Hosmane, N. S. Org. Lett. 2008, 10, 2247–2250. doi:10.1021/ol8005248

Return to citation in text: [1] -

Dash, B. P.; Satapathy, R.; Gaillard, E. R.; Maguire, J. A.; Hosmane, N. S. J. Am. Chem. Soc. 2010, 132, 6578–6587. doi:10.1021/ja101845m

Return to citation in text: [1] -

Kashiki, T.; Kohara, M.; Osaka, I.; Miyazaki, E.; Takimiya, K. J. Org. Chem. 2011, 76, 4061–4070. doi:10.1021/jo2005044

Return to citation in text: [1] -

Mbyas Saroukou, M. S.; Skalski, T.; Skene, W. G.; Lubell, W. D. Tetrahedron 2014, 70, 450–458. doi:10.1016/j.tet.2013.11.043

Return to citation in text: [1] -

Dash, J.; Trawny, D.; Rabe, J. P.; Reissig, H.-U. Synlett 2015, 26, 1486–1489. doi:10.1055/s-0034-1380716

Return to citation in text: [1] -

Preis, E.; Dong, W.; Brunklaus, G.; Scherf, U. J. Mater. Chem. 2015, 3, 1582–1587. doi:10.1039/C4TC02664K

Return to citation in text: [1] -

Shah, S. R.; Thakore, R. R.; Vyas, T. A.; Sridhar, B. Synlett 2016, 27, 294–300. doi:10.1055/s-0035-1560576

Return to citation in text: [1] -

Kotha, S.; Todeti, S.; Gopal, M. B.; Datta, A. ACS Omega 2017, 2, 6291–6297. doi:10.1021/acsomega.7b00941

Return to citation in text: [1] -

Kotha, S.; Todeti, S.; Das, T.; Datta, A. ChemistrySelect 2018, 3, 136–141. doi:10.1002/slct.201702675

Return to citation in text: [1] -

Kotha, S.; Todeti, S.; Das, T.; Datta, A. Tetrahedron Lett. 2018, 59, 1023–1027. doi:10.1016/j.tetlet.2018.01.084

Return to citation in text: [1] -

Thallapally, P. K.; Chakraborty, K.; Carrell, H. L.; Kotha, S.; Desiraju, G. R. Tetrahedron 2000, 56, 6721–6728. doi:10.1016/S0040-4020(00)00493-2

Return to citation in text: [1] -

Justin Thomas, K. R.; Lin, J. T.; Tao, Y.-T.; Ko, C.-W. Chem. Mater. 2002, 14, 1354–1361. doi:10.1021/cm010976q

Return to citation in text: [1] -

Shirota, Y. J. Mater. Chem. 2000, 10, 1–25. doi:10.1039/A908130E

Return to citation in text: [1] -

Kimura, M.; Kuwano, S.; Sawaki, Y.; Fujikawa, H.; Noda, K.; Taga, Y.; Takagi, K. J. Mater. Chem. 2005, 15, 2393–2398. doi:10.1039/b502268a

Return to citation in text: [1] -

Yu, G.; Gao, J.; Hummelen, J. C.; Wudl, F.; Heeger, A. J. Science 1995, 270, 1789–1791. doi:10.1126/science.270.5243.1789

Return to citation in text: [1] -

Hoang, M. H.; Cho, M. J.; Kim, D. C.; Kim, K. H.; Shin, J. W.; Cho, M. Y.; Joo, J.-s.; Choi, D. H. Org. Electron. 2009, 10, 607–617. doi:10.1016/j.orgel.2009.02.021

Return to citation in text: [1] -

Ponomarenko, S. A.; Kirchmeyer, S.; Elschner, A.; Huisman, B.-H.; Karbach, A.; Drechsler, D. Adv. Funct. Mater. 2003, 13, 591–596. doi:10.1002/adfm.200304363

Return to citation in text: [1] -

Fringuelli, F.; Taticchi, A. Dienes in the Diels–Alder Reaction; Wiley: New York, 1990.

Return to citation in text: [1] -

Shafi, S.; Kędziorek, M.; Grela, K. Synlett 2011, 124–128. doi:10.1055/s-0030-1259083

Return to citation in text: [1] -

Grubbs, R. H.; O’Leary, D. J. Handbook of Metathesis, Application in Organic Synthesis, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2015.

Return to citation in text: [1] -

Kotha, S.; Aswar, V. R. Org. Lett. 2016, 18, 1808–1811. doi:10.1021/acs.orglett.6b00537

Return to citation in text: [1] -

Kotha, S.; Shah, V. R.; Mandal, K. Adv. Synth. Catal. 2007, 349, 1159–1172. doi:10.1002/adsc.200600469

Return to citation in text: [1] -

Kiriazis, A.; af Gennäs, G. B.; Talman, V.; Ekokoski, E.; Ruotsalainen, T.; Kylänlahti, I.; Rüffer, T.; Wissel, G.; Xhaard, H.; Lang, H.; Tuominen, R. K.; Yli-Kauhaluoma, J. Tetrahedron 2011, 67, 8665–8670. doi:10.1016/j.tet.2011.09.044

Return to citation in text: [1] -

Kocyigit, U. M.; Budak, Y.; Gürdere, M. B.; Tekin, Ş.; Köprülü, T. K.; Ertürk, F.; Özcan, K.; Gülçin, İ.; Ceylan, M. Bioorg. Chem. 2017, 70, 118–125. doi:10.1016/j.bioorg.2016.12.001

Return to citation in text: [1] -

Marsh, B. J.; Adams, H.; Barker, M. D.; Kutama, I. U.; Jones, S. Org. Lett. 2014, 16, 3780–3783. doi:10.1021/ol5016702

Return to citation in text: [1] -

Obermayer, D.; Znidar, D.; Glotz, G.; Stadler, A.; Dallinger, D.; Kappe, C. O. J. Org. Chem. 2016, 81, 11788–11801. doi:10.1021/acs.joc.6b02242

Return to citation in text: [1]

| 42. | Kiriazis, A.; af Gennäs, G. B.; Talman, V.; Ekokoski, E.; Ruotsalainen, T.; Kylänlahti, I.; Rüffer, T.; Wissel, G.; Xhaard, H.; Lang, H.; Tuominen, R. K.; Yli-Kauhaluoma, J. Tetrahedron 2011, 67, 8665–8670. doi:10.1016/j.tet.2011.09.044 |

| 19. | Kotha, S.; Chakraborty, K.; Brahmachary, E. Synlett 1999, 1621–1623. doi:10.1055/s-1999-2895 |

| 38. | Shafi, S.; Kędziorek, M.; Grela, K. Synlett 2011, 124–128. doi:10.1055/s-0030-1259083 |

| 39. | Grubbs, R. H.; O’Leary, D. J. Handbook of Metathesis, Application in Organic Synthesis, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2015. |

| 40. | Kotha, S.; Aswar, V. R. Org. Lett. 2016, 18, 1808–1811. doi:10.1021/acs.orglett.6b00537 |

| 41. | Kotha, S.; Shah, V. R.; Mandal, K. Adv. Synth. Catal. 2007, 349, 1159–1172. doi:10.1002/adsc.200600469 |

| 1. | Altman, J.; Babad, E.; Itzchaki, J.; Ginsburg, D. Tetrahedron 1966, 22, 279–304. doi:10.1016/S0040-4020(01)82189-X |

| 2. | Ginsburg, D. Acc. Chem. Res. 1969, 2, 121–128. doi:10.1021/ar50016a005 |

| 8. | Brown, K., Jr.; Budzikiewicz, H.; Djerassi, C. Tetrahedron Lett. 1963, 4, 1731–1736. doi:10.1016/S0040-4039(01)90904-9 |

| 35. | Hoang, M. H.; Cho, M. J.; Kim, D. C.; Kim, K. H.; Shin, J. W.; Cho, M. Y.; Joo, J.-s.; Choi, D. H. Org. Electron. 2009, 10, 607–617. doi:10.1016/j.orgel.2009.02.021 |

| 36. | Ponomarenko, S. A.; Kirchmeyer, S.; Elschner, A.; Huisman, B.-H.; Karbach, A.; Drechsler, D. Adv. Funct. Mater. 2003, 13, 591–596. doi:10.1002/adfm.200304363 |

| 7. | Carroll, A. R.; Arumugan, T.; Redburn, J.; Ngo, A.; Guymer, G. P.; Forster, P. I.; Quinn, R. J. J. Nat. Prod. 2010, 73, 988–991. doi:10.1021/np100009j |

| 37. | Fringuelli, F.; Taticchi, A. Dienes in the Diels–Alder Reaction; Wiley: New York, 1990. |

| 1. | Altman, J.; Babad, E.; Itzchaki, J.; Ginsburg, D. Tetrahedron 1966, 22, 279–304. doi:10.1016/S0040-4020(01)82189-X |

| 5. | Weber, R. W.; Cook, J. M. Can. J. Chem. 1978, 56, 189–192. doi:10.1139/v78-030 |

| 6. | Schneider, L. M.; Schmiedel, V. M.; Pecchioli, T.; Lentz, D.; Merten, C.; Christmann, M. Org. Lett. 2017, 19, 2310–2313. doi:10.1021/acs.orglett.7b00836 |

| 31. | Justin Thomas, K. R.; Lin, J. T.; Tao, Y.-T.; Ko, C.-W. Chem. Mater. 2002, 14, 1354–1361. doi:10.1021/cm010976q |

| 32. | Shirota, Y. J. Mater. Chem. 2000, 10, 1–25. doi:10.1039/A908130E |

| 33. | Kimura, M.; Kuwano, S.; Sawaki, Y.; Fujikawa, H.; Noda, K.; Taga, Y.; Takagi, K. J. Mater. Chem. 2005, 15, 2393–2398. doi:10.1039/b502268a |

| 3. | Wiberg, K. B. Acc. Chem. Res. 1984, 17, 379–386. doi:10.1021/ar00107a001 |

| 4. | Wiberg, K. B. Acc. Chem. Res. 1996, 29, 229–234. doi:10.1021/ar950207a |

| 34. | Yu, G.; Gao, J.; Hummelen, J. C.; Wudl, F.; Heeger, A. J. Science 1995, 270, 1789–1791. doi:10.1126/science.270.5243.1789 |

| 13. | Yamamoto, N.; Fujii, H.; Nemoto, T.; Nakajima, R.; Momen, S.; Izumimoto, N.; Hasebe, K.; Mochizuki, H.; Nagase, H. Bioorg. Med. Chem. Lett. 2011, 21, 4104–4107. doi:10.1016/j.bmcl.2011.04.147 |

| 14. | Alizadeh, A.; Bayat, F.; Sadeghi, V. Lett. Org. Chem. 2015, 12, 153–158. doi:10.2174/1570178612666150108003359 |

| 17. | Kotha, S.; Chinnam, A. K.; Tiwari, A. Beilstein J. Org. Chem. 2013, 9, 2709–2714. doi:10.3762/bjoc.9.307 |

| 18. | Kotha, S.; Manivannan, E.; Ganesh, T.; Sreenivasachary, N.; Deb, A. Synlett 1999, 1618–1620. doi:10.1055/s-1999-2896 |

| 11. | Diels, O.; Alder, K. Chem. Ber. 1929, 62, 2081–2087. doi:10.1002/cber.19290620829 |

| 12. | Diels, O.; Alder, K. Justus Liebigs Ann. Chem. 1931, 486, 191–202. doi:10.1002/jlac.19314860110 |

| 19. | Kotha, S.; Chakraborty, K.; Brahmachary, E. Synlett 1999, 1621–1623. doi:10.1055/s-1999-2895 |

| 20. | Dash, B. P.; Satapathy, R.; Maguire, J. A.; Hosmane, N. S. Org. Lett. 2008, 10, 2247–2250. doi:10.1021/ol8005248 |

| 21. | Dash, B. P.; Satapathy, R.; Gaillard, E. R.; Maguire, J. A.; Hosmane, N. S. J. Am. Chem. Soc. 2010, 132, 6578–6587. doi:10.1021/ja101845m |

| 22. | Kashiki, T.; Kohara, M.; Osaka, I.; Miyazaki, E.; Takimiya, K. J. Org. Chem. 2011, 76, 4061–4070. doi:10.1021/jo2005044 |

| 23. | Mbyas Saroukou, M. S.; Skalski, T.; Skene, W. G.; Lubell, W. D. Tetrahedron 2014, 70, 450–458. doi:10.1016/j.tet.2013.11.043 |

| 24. | Dash, J.; Trawny, D.; Rabe, J. P.; Reissig, H.-U. Synlett 2015, 26, 1486–1489. doi:10.1055/s-0034-1380716 |

| 25. | Preis, E.; Dong, W.; Brunklaus, G.; Scherf, U. J. Mater. Chem. 2015, 3, 1582–1587. doi:10.1039/C4TC02664K |

| 26. | Shah, S. R.; Thakore, R. R.; Vyas, T. A.; Sridhar, B. Synlett 2016, 27, 294–300. doi:10.1055/s-0035-1560576 |

| 27. | Kotha, S.; Todeti, S.; Gopal, M. B.; Datta, A. ACS Omega 2017, 2, 6291–6297. doi:10.1021/acsomega.7b00941 |

| 28. | Kotha, S.; Todeti, S.; Das, T.; Datta, A. ChemistrySelect 2018, 3, 136–141. doi:10.1002/slct.201702675 |

| 29. | Kotha, S.; Todeti, S.; Das, T.; Datta, A. Tetrahedron Lett. 2018, 59, 1023–1027. doi:10.1016/j.tetlet.2018.01.084 |

| 30. | Thallapally, P. K.; Chakraborty, K.; Carrell, H. L.; Kotha, S.; Desiraju, G. R. Tetrahedron 2000, 56, 6721–6728. doi:10.1016/S0040-4020(00)00493-2 |

| 10. | Asahi, K.; Nishino, H. Tetrahedron 2008, 64, 1620–1634. doi:10.1016/j.tet.2007.12.017 |

| 43. | Kocyigit, U. M.; Budak, Y.; Gürdere, M. B.; Tekin, Ş.; Köprülü, T. K.; Ertürk, F.; Özcan, K.; Gülçin, İ.; Ceylan, M. Bioorg. Chem. 2017, 70, 118–125. doi:10.1016/j.bioorg.2016.12.001 |

| 9. | Walser, A.; Djerassi, C. Helv. Chim. Acta 1965, 48, 391–404. doi:10.1002/hlca.19650480220 |

| 15. | Pihko, A. J.; Koskinen, A. M. Tetrahedron 2005, 61, 8769–8807. doi:10.1016/j.tet.2005.06.013 |

| 16. | Yavari, I.; Khajeh-Khezri, A. Mol. Diversity 2017, 21, 849–854. doi:10.1007/s11030-017-9761-8 |

| 44. | Marsh, B. J.; Adams, H.; Barker, M. D.; Kutama, I. U.; Jones, S. Org. Lett. 2014, 16, 3780–3783. doi:10.1021/ol5016702 |

| 45. | Obermayer, D.; Znidar, D.; Glotz, G.; Stadler, A.; Dallinger, D.; Kappe, C. O. J. Org. Chem. 2016, 81, 11788–11801. doi:10.1021/acs.joc.6b02242 |

© 2018 Kotha et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0). Please note that the reuse, redistribution and reproduction in particular requires that the authors and source are credited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (https://www.beilstein-journals.org/bjoc)