Abstract

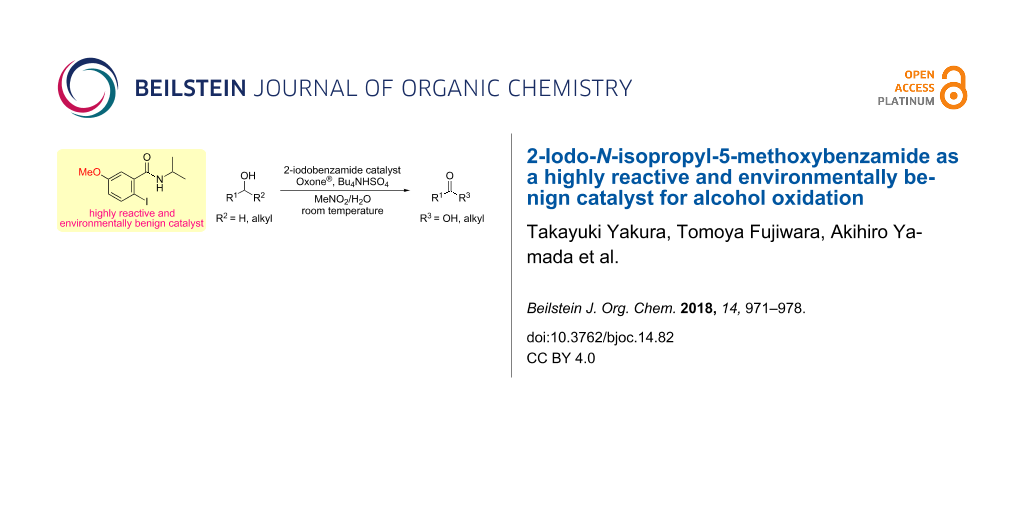

Several N-isopropyliodobenzamides were evaluated as catalysts for the oxidation of benzhydrol to benzophenone in the presence of Oxone® (2KHSO5·KHSO4·K2SO4) as a co-oxidant at room temperature. A study on the substituent effect of the benzene ring of N-isopropyl-2-iodobenzamide on the oxidation revealed that its reactivity increased in the following order of substitution: 5-NO2 < 5-CO2Me, 3-OMe < 5-OAc < 5-Cl < H, 4-OMe < 5-Me < 5-OMe. The oxidation of various benzylic and aliphatic alcohols using a catalytic amount of the most reactive 5-methoxy derivative successfully resulted in moderate to excellent yields of the corresponding carbonyl compounds. The high reactivity of the 5-methoxy derivative at room temperature is a result of the rapid generation of the pentavalent species from the trivalent species during the reaction. 5-Methoxy-2-iodobenzamide would be an efficient and environmentally benign catalyst for the oxidation of alcohols, especially benzylic alcohols.

Graphical Abstract

Introduction

The development of an efficient and environmentally benign organic synthesis is required for minimizing material use, energy consumption, and environmental pollution in the production of both bulk and fine chemicals. Oxidation is a fundamental and frequently used transformation in organic synthesis. Heavy metal-based oxidants such as chromium(VI), lead(IV), and mercury(II) have been extensively used for this purpose for a long time. However, these oxidants are highly toxic and produce hazardous waste. Recently, hypervalent iodine oxidants have been widely employed for oxidation in organic synthesis [1-9] because they are nonmetallic, less toxic, and easy to handle, and they allow mild reaction conditions in most cases. Pentavalent iodine reagents such as Dess–Martin periodinane (DMP, 1) [10] and 2-iodoxybenzoic acid (IBX, 2) [11] are well known as representative environmentally benign oxidants for alcohol oxidation (Figure 1). However, despite the utility and versatility of these oxidants, they still have several drawbacks: both are potentially explosive, DMP is moisture-sensitive, and IBX is insoluble in common organic solvents. To overcome these drawbacks, IBX analogs [12-22] and several iodoxyarene derivatives [23-38] have been developed, and the stabilization of IBX by combining it with benzoic and isophthalic acids (SIBX) [39] has been reported. Nevertheless, from a green chemistry viewpoint, pentavalent iodine oxidants are not ideal because oxidation reactions require a stoichiometric amount of the oxidant that produces an equimolar amount of organoiodine waste. The catalytic use of pentavalent iodine species is an effective method for reducing the use of iodine compounds and the produced waste [40-44]. 2-Iodobenzoic acid (3) [45,46] and its derivatives such as 4–7 [20,47-51] and 2-iodobenzenesulfonic acid (8) and its derivatives 9–11 [52-57] have been developed as catalysts for the oxidation of alcohols in the presence of Oxone® (2KHSO5·KHSO4·K2SO4) as a co-oxidant. In these reported systems, high temperatures (40–70 °C) are often required to generate potentially explosive pentavalent iodine compounds in situ except for the reactions involving multisubstituted benzoic acids and benzenesulfonic acid (4–6 and 10) which can be performed at room temperature [20,48-51,57]. In contrast, the use of a combination of a catalytic amount of RuCl3 and a stoichiometric amount of Oxone® as the co-oxidation system does not require heating despite the use of iodobenzene and 4-iodobenzenesulfonic acid (12) as catalysts [58,59]. As part of our study on the development of multifunctionalized organocatalysts based on hypervalent iodine chemistry [60-66], we found that N-isopropyl-2-iodobenzamide (13), when utilized as a catalyst with Oxone® at room temperature, appears to be a promising catalyst for efficient and environmentally benign alcohol oxidation reactions [67]. Herein, we report our efforts on improving the reactivity of 2-iodobenzamide catalysts.

Figure 1: Structures of pentavalent iodine oxidants 1 and 2, and iodine catalysts 3–13.

Figure 1: Structures of pentavalent iodine oxidants 1 and 2, and iodine catalysts 3–13.

Results and Discussion

We evaluated several 2-iodobenzoic acid derivatives including esters and amides as catalysts for alcohol oxidation in the presence of Oxone®, and we found that the simply modified derivative, N-isopropylamide 13, exhibited excellent catalytic properties at room temperature [67]. Interestingly, the reactivity of 13 was much higher than that of 3 at room temperature but was lower at 70 °C. However, the reactivity of 13 itself was not so high: the oxidation of benzhydrol (14a) with 0.3 equiv of 13, 2.5 equiv of Oxone®, and 1 equiv of Bu4NHSO4 in MeNO2/H2O (8:3) completed in 12 h at room temperature (25 °C) to produce a 98% yield of benzophenone (15a, Table 1, entry 1) [67]. Therefore, enhancement of the reactivity of the catalyst was desired for practical use. To develop a more reactive catalyst, we evaluated several types of N-isopropyliodobenzamides (Table 1). Although most of the previously reported iodoarene catalysts based on pentavalent iodine compounds have a carboxyl or sulfoxyl group at the ortho-position to the iodine atom, Zhdankin and colleagues reported that both 2-iodobenzenesulfonic acid (8) and 4-iodobenzensulfonic acid (12) exhibited high reactivity in their RuCl3–Oxone® co-oxidant system [58,59]. Therefore, we expected that the reactivity of 4-iodobenzamide 16 (Figure 2) would be similar to that of 13. However, the oxidation of 14a with 16 under the above conditions did not complete even after 24 h, and the yield of 15a and of recovered 14a was 30% and 67%, respectively (Table 1, entry 2). These results indicate that the reactivity of the iodobenzamides depends on the ortho-relationship of the iodine atom to the amide group. Therefore, we then investigated N-isopropyl-2-iodobenzamides that have an additional functional group on the benzene ring. Based on the results of our studies on phenol oxidation [60,62] and Ishihara’s [52] and Moorthy’s [20,48] studies on alcohol oxidation, an electron-donating group at the para-position to the iodine should be expected to enhance the reactivity of iodoarene catalysts. The investigation began with the 5-substituted 2-iodobenzamides 17–22 (Figure 2). Oxidation of 14a with 5-methoxy-2-iodobenzamide 17 was much faster than that with 13 and was completed within 6 h to produce 15a in 97% yield (Table 1, entry 3). The 5-methyl derivative 18 exhibited a slightly higher reactivity than 13 (Table 1, entry 4). The introduction of an electron-withdrawing group such as a chloro, acetoxy, methoxycarbonyl, or nitro group at the 5-position led to a decrease in reactivity (Table 1, entries 5–8). These results are in good agreement with the reported studies [20,48,52,60,62]. To confirm the importance of the electron-withdrawing carboxyamide group at the ortho-position, we examined the oxidation of 14a with 4-iodophenoxyacetic acid (23); the results showed excellent reactivity for phenol oxidations [60-64]. When 14a was oxidized with 23, the reaction was very slow and yielded only 23% of 15a and 75% of recovered 14a even after 48 h (Table 1, entry 9) [68]. Since the 5-methoxy derivative 17 was the most reactive, we then investigated the reactivities of 24 and 25, which have methoxy groups at the meta- and ortho-positions to the iodine atom, and found that 4-methoxyamide 24 exhibited the same reactivity as nonsubstituted 13 (Table 1, entry 10). On the other hand, oxidation with 3-methoxyamide 25 was much slower than that with 13 and needed 23 h to complete (Table 1, entry 11). Although the ortho- and the para-methoxy groups should show a similar electronic effect on the iodine atom, the lower reactivity of 25 might be explained by the steric hindrance around the iodine atom of 25. Consequently, the reactivities of the 2-iodobenzamides 17–22, 24, and 25 decreased in the following order of substitution: 5-OMe (17) > 5-Me (18) > H (13), 4-OMe (24) > 5-Cl (19) > 5-OAc (20) > 5-CO2Me (21), 3-OMe (25) > 5-NO2 (22).

Figure 2: Structures of the catalysts 16–25.

Figure 2: Structures of the catalysts 16–25.

Table 1: Oxidation of benzhydrol (14a) to benzophenone (15a) catalyzed by 13 and 16–25.

|

|

||||

| entrya | iodobenzamide | time (h) | yield (%)b | recovery of 14a (%)b |

|---|---|---|---|---|

| 1c | 13 | 12 | 98 | – |

| 2 | 16 | 24 | 30 | 67 |

| 3 | 17 | 6 | 97 | – |

| 4 | 18 | 10 | 98 | – |

| 5 | 19 | 18 | 98 | – |

| 6 | 20 | 19 | 98 | – |

| 7 | 21 | 23 | 96 | – |

| 8 | 22 | 46 | 98 | – |

| 9 | 23 | 48 | 23 | 75 |

| 10 | 24 | 13 | 98 | – |

| 11 | 25 | 23 | 99 | – |

aAll reactions were performed on a 0.5 mmol scale. bIsolated yield. cRef. [67]

With a highly reactive catalyst in hand, we examined the oxidation of various secondary alcohols 14b–f and primary alcohols 14g–k with 0.3 equiv of 17 in the presence of 2.5 equiv of Oxone® and 1 equiv of Bu4NHSO4 in an 8:3 mixture of MeNO2 and water at room temperature. These results as well as those obtained from a similar oxidation using 13 as a catalyst are summarized in Table 2. The secondary benzylic alcohols 14b–e were oxidized with 17 in much shorter reaction times than those oxidized with 13 to give the corresponding ketones 15b–e in good to excellent yields (Table 2, entries 1–4). Oxidation of the aliphatic secondary alcohol 14f with 17 required a slightly longer reaction time than that with 13 (Table 2, entry 5). The primary alcohols 14g–k were converted into the corresponding carboxylic acids 26g–k in moderate to excellent yields (Table 2, entries 6–10). However, the reaction times of the oxidations of 14h, 14i, and 14k with 17 were similar to those involving 13. These results may be due to the slow oxidation of the aldehydes to carboxylic acids [69]. The catalyst 17 was stable under the oxidation conditions and it was recovered in 67–92% after reductive treatment.

Table 2: Oxidation of various alcohols 14b–k with 17.a

|

|

||||

| entry | alcohol | carbonyl compound | time (h)b | yield (%)b,c |

|---|---|---|---|---|

| 1 |

14b |

15b |

9 (15) | 95 (74) |

| 2 |

14c |

15c |

7 (17) | 86 (71) |

| 3 |

14d |

15d |

11 (14) | 62 (70) |

| 4 |

14e |

15e |

10 (20) | 98 (97) |

| 5 |

14f |

15f |

36 (30) | 64 (74) |

| 6 |

14g |

26g |

10 (20) | 89 (82) |

| 7 |

14h |

26h |

24 (24) | 83 (74) |

| 8 |

14i |

26i |

16 (16) | 96 (89) |

| 9 |

14j |

26j |

9 (20) | 85 (90) |

| 10 |

14k |

26k |

36 (36) | 59 (58) |

aAll reactions were performed on a 0.5 mmol scale. bThe results obtained for the oxidation using 13 are shown in parentheses [67]. cIsolated yield.

The next objective was to investigate the oxidation mechanism of 2-iodobenzamide catalysts. Zhdankin and colleagues reported the oxidation of alcohols to their corresponding carbonyl compounds using several 2-iodoxybenzamides [23]. Therefore, we tried to confirm the formation of 2-iodoxybenzamide 29 from 2-iodobenzamide 17 in an oxidation reaction (Scheme 1). Iodoarene 17 was treated with 2.5 equiv of Oxone® and 1 equiv of Bu4NHSO4 in a 4:1 mixture of acetonitrile-d3 and D2O at a low concentration (0.01 M) at room temperature, and the reaction was monitored by 1H NMR spectroscopy. The reaction profiles for 17 as well as for 2-iodobenzoic acid (3) are summarized in Figure 3. In the reaction involving 17, the amount of pentavalent iodine derivative 29 gradually increased with a decrease in the amount of 17 and only a small amount of trivalent iodine derivative 27 was observed during the reaction. The ratio of 17 to trivalent 27 and pentavalent 29 was determined to be 38:9:53 after 36 h. In the oxidation of 3, monovalent 3 was consumed at almost the same rate as the oxidation of 17. However, the formation of pentavalent 2 was much slower than that of 29, and a considerable amount of trivalent 28 remained during the reaction. After 36 h, the oxidation of 3 generated 27% of 2 with 35% unreacted 3 and 38% trivalent 28. Thus, it is clear that the pentavalent iodine species 2 and 29 were generated during the oxidation reactions of monovalent 3 and 17 and that the oxidation of trivalent 27 to pentavalent 29 is much faster than that of 28 to 2 at room temperature. These results also suggest that the formation of the pentavalent iodine species from the corresponding trivalent iodine species might be the rate-determining step in the catalytic hypervalent iodine oxidation of 17 [70].

Scheme 1: Oxidation of the monovalent iodine derivatives 17 and 3 to the pentavalent iodine derivatives 29 and 2 using Oxone®.

Scheme 1: Oxidation of the monovalent iodine derivatives 17 and 3 to the pentavalent iodine derivatives 29 an...

![[1860-5397-14-82-3]](/bjoc/content/figures/1860-5397-14-82-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: Reaction profile of the oxidation of (a) iodobenzamide 17 and (b) 2-iodobenzoic acid (3) with Oxone® in the presence of Bu4NHSO4 in a 4:1 mixture of CD3CN and D2O: monovalent iodine derivatives 17 and 3 (blue), trivalent iodine derivatives 27 and 28 (green), and pentavalent iodine derivatives 29 and 2 (red).

Figure 3: Reaction profile of the oxidation of (a) iodobenzamide 17 and (b) 2-iodobenzoic acid (3) with Oxone®...

On the basis of the above results, a plausible mechanism for the oxidation catalyzed by the 2-iodobenzamides is shown in Scheme 2. Iodobenzamide A is readily oxidized by tetra-n-butylammonium peroxymonosulfate (Bu4NHSO5, 30), which is derived from Bu4NHSO4 and Oxone®, to pentavalent iodine species C at room temperature. The resultant C oxidizes alcohol 14 to ketone 15 or aldehyde 31 during its reduction to trivalent iodine B. Aldehyde 31 is further oxidized with 30 with the assistance of A or C [67] to give carboxylic acid 26. Iodine B is re-oxidized with 30 to regenerate C. The oxidation proceeds at room temperature because of the fast oxidation of trivalent B to pentavalent C.

Scheme 2: Plausible reaction mechanism for the oxidation of alcohols catalyzed by the 2-iodobenzamides.

Scheme 2: Plausible reaction mechanism for the oxidation of alcohols catalyzed by the 2-iodobenzamides.

Conclusion

In summary, we have developed 2-iodo-N-isopropyl-5-methoxybenzamide (17) as an efficient catalyst for the oxidation of primary and secondary alcohols. The reaction of benzylic and aliphatic alcohols 14 with a catalytic amount of 17 in the presence of Oxone® and Bu4NHSO4 at room temperature proceeded smoothly to provide good to excellent yields of the corresponding carbonyl compounds 15 and 26. The higher reactivity of 17 at room temperature results from the rapid oxidation of trivalent iodine compound 27 to the pentavalent compound 29. 5-Methoxy-2-iodobenzamide 17 promises to be an efficient and environmentally benign catalyst for oxidation of alcohol, especially benzylic alcohols.

Experimental

Typical experimental procedure for the oxidation of secondary alcohols 14a–f: Secondary alcohol 14 (0.50 mmol) was added to a solution of the catalyst (0.15 mmol) and Bu4NHSO4 (170 mg, 0.50 mmol) in a mixture of MeNO2 (1.6 mL) and water (0.6 mL), followed by Oxone® (768 mg, 1.25 mmol) at room temperature (25 °C). After 14 was completely consumed, as indicated by TLC, the resulting mixture was diluted using EtOAc and was washed with water. The organic layer was then washed with saturated aqueous Na2S2O3 and saturated aqueous NaHCO3, dried over MgSO4, filtered, and concentrated under reduced pressure. The residue was purified by silica gel column chromatography to give pure ketone 15 and the catalyst.

Typical experimental procedure for the oxidation of primary alcohols 14g–k: Primary alcohol 14 (0.50 mmol) was added to a solution of the catalyst (0.15 mmol) and Bu4NHSO4 (170 mg, 0.50 mmol) in a mixture of MeNO2 (1.6 mL) and water (0.6 mL), followed by Oxone® (768 mg, 1.25 mmol) at room temperature (25 °C). After 14 was completely consumed, as indicated by TLC, the resulting mixture was diluted with EtOAc, water, and saturated aqueous Na2S2O3. The organic layer was then washed with saturated aqueous Na2S2O3, saturated aqueous NaHCO3, and brine, dried over MgSO4, filtered, and concentrated under reduced pressure. The residue was purified by silica gel column chromatography to give the catalyst. The combined aqueous layers were acidified with 10% HCl and extracted with EtOAc. The organic layer was washed with brine, dried over MgSO4, filtered, and concentrated under reduced pressure. The residue was purified by silica gel column chromatography to give pure carboxylic acid 26.

Supporting Information

| Supporting Information File 1: Experimental details and the 1H and 13C NMR spectra of the catalysts, the substrates, and the products. | ||

| Format: PDF | Size: 4.5 MB | Download |

Acknowledgments

This research was partially supported by a Grant-in-Aid for Scientific Research on Innovative Areas “Advanced Molecular Transformations by Organocatalysts” from the Ministry of Education, Culture, Sports, Science and Technology, Japan; JSPS Core-to-Core Program, B. Asia-Africa Science Platforms; and Toyama Prefecture Citizens' Personal Development Foundation (TPCPDF).

References

-

Stang, P. J.; Zhdankin, V. V. Chem. Rev. 1996, 96, 1123–1178. doi:10.1021/cr940424+

Return to citation in text: [1] -

Zhdankin, V. V.; Stang, P. J. Chem. Rev. 2002, 102, 2523–2584. doi:10.1021/cr010003+

Return to citation in text: [1] -

Tohma, H.; Kita, Y. Adv. Synth. Catal. 2004, 346, 111–124. doi:10.1002/adsc.200303203

Return to citation in text: [1] -

Ladziata, U.; Zhdankin, V. V. ARKIVOC 2006, No. ix, 26–58. doi:10.3998/ark.5550190.0007.903

Return to citation in text: [1] -

Zhdankin, V. V.; Stang, P. J. Chem. Rev. 2008, 108, 5299–5358. doi:10.1021/cr800332c

Return to citation in text: [1] -

Zhdankin, V. V. J. Org. Chem. 2011, 76, 1185–1197. doi:10.1021/jo1024738

Return to citation in text: [1] -

Zhdankin, V. V. Hypervalent Iodine Chemistry: Preparation, Structure, and Synthetic Applications of Polyvalent Iodine Compounds; John Wiley & Sons, Ltd, 2013. doi:10.1002/9781118341155

Return to citation in text: [1] -

Kaiho, T., Ed. Iodine Chemistry and Applications; John Wiley & Sons, Ltd, 2014. doi:10.1002/9781118909911

Return to citation in text: [1] -

Yoshimura, A.; Zhdankin, V. V. Chem. Rev. 2016, 116, 3328–3435. doi:10.1021/acs.chemrev.5b00547

Return to citation in text: [1] -

Dess, D. B.; Martin, J. C. J. Org. Chem. 1983, 48, 4155–4156. doi:10.1021/jo00170a070

Return to citation in text: [1] -

Hartmann, C.; Mayer, V. Chem. Ber. 1893, 26, 1727–1732. doi:10.1002/cber.189302602109

Return to citation in text: [1] -

Dess, D. B.; Martin, J. C. J. Am. Chem. Soc. 1991, 113, 7277–7287. doi:10.1021/ja00019a027

Return to citation in text: [1] -

Stickley, S. H.; Martin, J. C. Tetrahedron Lett. 1995, 36, 9117–9120. doi:10.1016/0040-4039(95)01978-Q

Return to citation in text: [1] -

Thottumkara, A. P.; Vinod, T. K. Tetrahedron Lett. 2002, 43, 569–572. doi:10.1016/S0040-4039(01)02217-1

Return to citation in text: [1] -

Richardson, R. D.; Zayed, J. M.; Altermann, S.; Smith, D.; Wirth, T. Angew. Chem., Int. Ed. 2007, 46, 6529–6532. doi:10.1002/anie.200702313

Return to citation in text: [1] -

Moorthy, J. N.; Singhal, N.; Senapati, K. Tetrahedron Lett. 2008, 49, 80–84. doi:10.1016/j.tetlet.2007.11.013

Return to citation in text: [1] -

Kommreddy, A.; Bowsher, M. S.; Gunna, M. R.; Botha, K.; Vinod, T. K. Tetrahedron Lett. 2008, 49, 4378–4382. doi:10.1016/j.tetlet.2008.05.017

Return to citation in text: [1] -

Moorthy, J. N.; Senapati, K.; Parida, K. N. J. Org. Chem. 2010, 75, 8416–8421. doi:10.1021/jo101639j

Return to citation in text: [1] -

Cui, L.-Q.; Dong, Z.-L.; Liu, K.; Zhang, C. Org. Lett. 2011, 13, 6488–6491. doi:10.1021/ol202777h

Return to citation in text: [1] -

Moorthy, J. N.; Senapati, K.; Parida, K. N.; Jhulki, S.; Sooraj, K.; Nair, N. N. J. Org. Chem. 2011, 76, 9593–9601. doi:10.1021/jo201491q

Return to citation in text: [1] [2] [3] [4] [5] -

Harschneck, T.; Hummel, S.; Kirsch, S. F.; Klahn, P. Chem. – Eur. J. 2012, 18, 1187–1193. doi:10.1002/chem.201102680

Return to citation in text: [1] -

Yusubov, M. S.; Postnikov, P. S.; Yusubova, R. Y.; Yoshimura, A.; Jürjens, G.; Kirschning, A.; Zhdankin, V. V. Adv. Synth. Catal. 2017, 359, 3207–3216. doi:10.1002/adsc.201700776

Return to citation in text: [1] -

Zhdankin, V. V.; Koposov, A. Y.; Netzel, B. C.; Yashin, N. V.; Rempel, B. P.; Ferguson, M. J.; Tykwinski, R. R. Angew. Chem., Int. Ed. 2003, 42, 2194–2196. doi:10.1002/anie.200351018

Return to citation in text: [1] [2] -

Zhdankin, V. V.; Litvinov, D. N.; Koposov, A. Y.; Luu, T.; Ferguson, M. J.; McDonald, R.; Tykwinski, R. R. Chem. Commun. 2004, 106–107. doi:10.1039/b312961f

Return to citation in text: [1] -

Koposov, A. Y.; Litvinov, D. N.; Zhdankin, V. V. Tetrahedron Lett. 2004, 45, 2719–2721. doi:10.1016/j.tetlet.2004.02.053

Return to citation in text: [1] -

Zhdankin, V. V.; Goncharenko, R. N.; Litvinov, D. N.; Koposov, A. Y. ARKIVOC 2005, No. iv, 8–18. doi:10.3998/ark.5550190.0006.402

Return to citation in text: [1] -

Koposov, A. Y.; Nemykin, V. N.; Zhdankin, V. V. New J. Chem. 2005, 29, 998–1000. doi:10.1039/b506573a

Return to citation in text: [1] -

Kuhakarn, C.; Kittigowittana, K.; Pohmakotr, M.; Reutrakul, V. ARKIVOC 2005, No. i, 143–153. doi:10.3998/ark.5550190.0006.115

Return to citation in text: [1] -

Zhdankin, V. V.; Koposov, A. Y.; Litvinov, D. N.; Ferguson, M. J.; McDonald, R.; Luu, T.; Tykwinski, R. R. J. Org. Chem. 2005, 70, 6484–6491. doi:10.1021/jo051010r

Return to citation in text: [1] -

Ladziata, U.; Koposov, A. Y.; Lo, K. Y.; Willging, J.; Nemykin, V. N.; Zhdankin, V. V. Angew. Chem., Int. Ed. 2005, 44, 7127–7131. doi:10.1002/anie.200502707

Return to citation in text: [1] -

Ladziata, U.; Carlson, J.; Zhdankin, V. V. Tetrahedron Lett. 2006, 47, 6301–6304. doi:10.1016/j.tetlet.2006.06.103

Return to citation in text: [1] -

Koposov, A. Y.; Karimov, R. R.; Geraskin, I. M.; Nemykin, V. N.; Zhdankin, V. V. J. Org. Chem. 2006, 71, 8452–8458. doi:10.1021/jo0614947

Return to citation in text: [1] -

Boppisetti, J. K.; Birman, V. B. Org. Lett. 2009, 11, 1221–1223. doi:10.1021/ol8029092

Return to citation in text: [1] -

Mailyan, A. K.; Geraskin, I. M.; Nemykin, V. N.; Zhdankin, V. V. J. Org. Chem. 2009, 74, 8444–8447. doi:10.1021/jo901638f

Return to citation in text: [1] -

Altermann, S. M.; Schäfer, S.; Wirth, T. Tetrahedron 2010, 66, 5902–5907. doi:10.1016/j.tet.2010.05.079

Return to citation in text: [1] -

Yoshimura, A.; Banek, C. T.; Yusubov, M. S.; Nemykin, V. N.; Zhdankin, V. V. J. Org. Chem. 2011, 76, 3812–3819. doi:10.1021/jo200163m

Return to citation in text: [1] -

Yoshida, Y.; Magara, A.; Mino, T.; Sakamoto, M. Tetrahedron Lett. 2016, 57, 5103–5107. doi:10.1016/j.tetlet.2016.10.016

Return to citation in text: [1] -

Yoshimura, A.; Yusubov, M. S.; Zhdankin, V. V. Org. Biomol. Chem. 2016, 14, 4771–4781. doi:10.1039/C6OB00773B

Return to citation in text: [1] -

Ozanne, A.; Pouységu, L.; Depernet, D.; François, B.; Quideau, S. Org. Lett. 2003, 5, 2903–2906. doi:10.1021/ol0349965

Return to citation in text: [1] -

Richardson, R. D.; Wirth, T. Angew. Chem., Int. Ed. 2006, 45, 4402–4404. doi:10.1002/anie.200601817

Return to citation in text: [1] -

Ochiai, M.; Miyamoto, K. Eur. J. Org. Chem. 2008, 4229–4239. doi:10.1002/ejoc.200800416

Return to citation in text: [1] -

Dohi, T.; Kita, Y. Chem. Commun. 2009, 2073–2085. doi:10.1039/b821747e

Return to citation in text: [1] -

Uyanik, M.; Ishihara, K. Chem. Commun. 2009, 2086–2099. doi:10.1039/b823399c

Return to citation in text: [1] -

Singh, F. V.; Wirth, T. Chem. – Asian J. 2014, 9, 950–971. doi:10.1002/asia.201301582

Return to citation in text: [1] -

Thottumkara, A. P.; Bowsher, M. S.; Vinod, T. K. Org. Lett. 2005, 7, 2933–2936. doi:10.1021/ol050875o

Return to citation in text: [1] -

Schulze, A.; Giannis, A. Synthesis 2006, 257–260. doi:10.1055/s-2005-924764

Return to citation in text: [1] -

Miura, T.; Nakashima, K.; Tada, N.; Itoh, A. Chem. Commun. 2011, 47, 1875–1877. doi:10.1039/C0CC03149F

Return to citation in text: [1] -

Seth, S.; Jhulki, S.; Moorthy, J. N. Eur. J. Org. Chem. 2013, 2445–2452. doi:10.1002/ejoc.201201699

Return to citation in text: [1] [2] [3] [4] -

Jhulki, S.; Seth, S.; Mondal, M.; Moorthy, J. N. Tetrahedron 2014, 70, 2286–2293. doi:10.1016/j.tet.2014.01.034

Return to citation in text: [1] [2] -

Moorthy, J. N.; Parida, K. N. J. Org. Chem. 2014, 79, 11431–11439. doi:10.1021/jo502002w

Return to citation in text: [1] [2] -

Mishra, A. K.; Moorthy, J. N. Org. Chem. Front. 2017, 4, 343–349. doi:10.1039/C6QO00588H

Return to citation in text: [1] [2] -

Uyanik, M.; Akakura, M.; Ishihara, K. J. Am. Chem. Soc. 2009, 131, 251–262. doi:10.1021/ja807110n

Return to citation in text: [1] [2] [3] -

Uyanik, M.; Fukatsu, R.; Ishihara, K. Org. Lett. 2009, 11, 3470–3473. doi:10.1021/ol9013188

Return to citation in text: [1] -

Uyanik, M.; Ishihara, K. Aldrichimica Acta 2010, 43, 83–91.

Return to citation in text: [1] -

Uyanik, M.; Mutsuga, T.; Ishihara, K. Molecules 2012, 17, 8604–8616. doi:10.3390/molecules17078604

Return to citation in text: [1] -

Uyanik, M.; Ishihara, K. Org. Synth. 2012, 89, 105–114. doi:10.15227/orgsyn.089.0105

Return to citation in text: [1] -

Uyanik, M.; Mutsuga, T.; Ishihara, K. Angew. Chem., Int. Ed. 2017, 56, 3956–3960. doi:10.1002/anie.201612463

Return to citation in text: [1] [2] -

Yusubov, M. S.; Zagulyaeva, A. A.; Zhdankin, V. V. Chem. – Eur. J. 2009, 15, 11091–11094. doi:10.1002/chem.200901953

Return to citation in text: [1] [2] -

Yusubov, M. S.; Nemykin, V. N.; Zhdankin, V. V. Tetrahedron 2010, 66, 5745–5752. doi:10.1016/j.tet.2010.04.046

Return to citation in text: [1] [2] -

Yakura, T.; Konishi, T. Synlett 2007, 765–768. doi:10.1055/s-2007-970758

Return to citation in text: [1] [2] [3] [4] -

Yakura, T.; Yamauchi, Y.; Tian, Y.; Omoto, M. Chem. Pharm. Bull. 2008, 56, 1632–1634. doi:10.1248/cpb.56.1632

Return to citation in text: [1] [2] -

Yakura, T.; Tian, Y.; Yamauchi, Y.; Omoto, M.; Konishi, T. Chem. Pharm. Bull. 2009, 57, 252–256. doi:10.1248/cpb.57.252

Return to citation in text: [1] [2] [3] [4] -

Yakura, T.; Omoto, M. Chem. Pharm. Bull. 2009, 57, 643–645. doi:10.1248/cpb.57.643

Return to citation in text: [1] [2] -

Yakura, T.; Omoto, M.; Yamauchi, Y.; Tian, Y.; Ozono, A. Tetrahedron 2010, 66, 5833–5840. doi:10.1016/j.tet.2010.04.124

Return to citation in text: [1] [2] -

Yakura, T.; Ozono, A. Adv. Synth. Catal. 2011, 353, 855–859. doi:10.1002/adsc.201100024

Return to citation in text: [1] -

Nambu, H.; Shimokawa, I.; Fujiwara, T.; Yakura, T. Asian J. Org. Chem. 2016, 5, 486–489. doi:10.1002/ajoc.201600036

Return to citation in text: [1] -

Yakura, T.; Yamada, A.; Noda, N.; Fujiwara, T.; Nambu, H. Asian J. Org. Chem. 2014, 3, 421–424. doi:10.1002/ajoc.201300279

Return to citation in text: [1] [2] [3] [4] [5] [6] -

The oxidation of 14a with 23 at 70 °C was also reported to be very slow [67].

Return to citation in text: [1] -

The corresponding aldehyde remained even after the starting alcohols were completely oxidized (checked by TLC).

Return to citation in text: [1] -

Ishihara and colleagues also suggested that the rate-determining step of their oxidations might be the regeneration of I(V) species [52].

Return to citation in text: [1]

| 70. | Ishihara and colleagues also suggested that the rate-determining step of their oxidations might be the regeneration of I(V) species [52]. |

| 67. | Yakura, T.; Yamada, A.; Noda, N.; Fujiwara, T.; Nambu, H. Asian J. Org. Chem. 2014, 3, 421–424. doi:10.1002/ajoc.201300279 |

| 67. | Yakura, T.; Yamada, A.; Noda, N.; Fujiwara, T.; Nambu, H. Asian J. Org. Chem. 2014, 3, 421–424. doi:10.1002/ajoc.201300279 |

| 1. | Stang, P. J.; Zhdankin, V. V. Chem. Rev. 1996, 96, 1123–1178. doi:10.1021/cr940424+ |

| 2. | Zhdankin, V. V.; Stang, P. J. Chem. Rev. 2002, 102, 2523–2584. doi:10.1021/cr010003+ |

| 3. | Tohma, H.; Kita, Y. Adv. Synth. Catal. 2004, 346, 111–124. doi:10.1002/adsc.200303203 |

| 4. | Ladziata, U.; Zhdankin, V. V. ARKIVOC 2006, No. ix, 26–58. doi:10.3998/ark.5550190.0007.903 |

| 5. | Zhdankin, V. V.; Stang, P. J. Chem. Rev. 2008, 108, 5299–5358. doi:10.1021/cr800332c |

| 6. | Zhdankin, V. V. J. Org. Chem. 2011, 76, 1185–1197. doi:10.1021/jo1024738 |

| 7. | Zhdankin, V. V. Hypervalent Iodine Chemistry: Preparation, Structure, and Synthetic Applications of Polyvalent Iodine Compounds; John Wiley & Sons, Ltd, 2013. doi:10.1002/9781118341155 |

| 8. | Kaiho, T., Ed. Iodine Chemistry and Applications; John Wiley & Sons, Ltd, 2014. doi:10.1002/9781118909911 |

| 9. | Yoshimura, A.; Zhdankin, V. V. Chem. Rev. 2016, 116, 3328–3435. doi:10.1021/acs.chemrev.5b00547 |

| 23. | Zhdankin, V. V.; Koposov, A. Y.; Netzel, B. C.; Yashin, N. V.; Rempel, B. P.; Ferguson, M. J.; Tykwinski, R. R. Angew. Chem., Int. Ed. 2003, 42, 2194–2196. doi:10.1002/anie.200351018 |

| 24. | Zhdankin, V. V.; Litvinov, D. N.; Koposov, A. Y.; Luu, T.; Ferguson, M. J.; McDonald, R.; Tykwinski, R. R. Chem. Commun. 2004, 106–107. doi:10.1039/b312961f |

| 25. | Koposov, A. Y.; Litvinov, D. N.; Zhdankin, V. V. Tetrahedron Lett. 2004, 45, 2719–2721. doi:10.1016/j.tetlet.2004.02.053 |

| 26. | Zhdankin, V. V.; Goncharenko, R. N.; Litvinov, D. N.; Koposov, A. Y. ARKIVOC 2005, No. iv, 8–18. doi:10.3998/ark.5550190.0006.402 |

| 27. | Koposov, A. Y.; Nemykin, V. N.; Zhdankin, V. V. New J. Chem. 2005, 29, 998–1000. doi:10.1039/b506573a |

| 28. | Kuhakarn, C.; Kittigowittana, K.; Pohmakotr, M.; Reutrakul, V. ARKIVOC 2005, No. i, 143–153. doi:10.3998/ark.5550190.0006.115 |

| 29. | Zhdankin, V. V.; Koposov, A. Y.; Litvinov, D. N.; Ferguson, M. J.; McDonald, R.; Luu, T.; Tykwinski, R. R. J. Org. Chem. 2005, 70, 6484–6491. doi:10.1021/jo051010r |

| 30. | Ladziata, U.; Koposov, A. Y.; Lo, K. Y.; Willging, J.; Nemykin, V. N.; Zhdankin, V. V. Angew. Chem., Int. Ed. 2005, 44, 7127–7131. doi:10.1002/anie.200502707 |

| 31. | Ladziata, U.; Carlson, J.; Zhdankin, V. V. Tetrahedron Lett. 2006, 47, 6301–6304. doi:10.1016/j.tetlet.2006.06.103 |

| 32. | Koposov, A. Y.; Karimov, R. R.; Geraskin, I. M.; Nemykin, V. N.; Zhdankin, V. V. J. Org. Chem. 2006, 71, 8452–8458. doi:10.1021/jo0614947 |

| 33. | Boppisetti, J. K.; Birman, V. B. Org. Lett. 2009, 11, 1221–1223. doi:10.1021/ol8029092 |

| 34. | Mailyan, A. K.; Geraskin, I. M.; Nemykin, V. N.; Zhdankin, V. V. J. Org. Chem. 2009, 74, 8444–8447. doi:10.1021/jo901638f |

| 35. | Altermann, S. M.; Schäfer, S.; Wirth, T. Tetrahedron 2010, 66, 5902–5907. doi:10.1016/j.tet.2010.05.079 |

| 36. | Yoshimura, A.; Banek, C. T.; Yusubov, M. S.; Nemykin, V. N.; Zhdankin, V. V. J. Org. Chem. 2011, 76, 3812–3819. doi:10.1021/jo200163m |

| 37. | Yoshida, Y.; Magara, A.; Mino, T.; Sakamoto, M. Tetrahedron Lett. 2016, 57, 5103–5107. doi:10.1016/j.tetlet.2016.10.016 |

| 38. | Yoshimura, A.; Yusubov, M. S.; Zhdankin, V. V. Org. Biomol. Chem. 2016, 14, 4771–4781. doi:10.1039/C6OB00773B |

| 67. | Yakura, T.; Yamada, A.; Noda, N.; Fujiwara, T.; Nambu, H. Asian J. Org. Chem. 2014, 3, 421–424. doi:10.1002/ajoc.201300279 |

| 12. | Dess, D. B.; Martin, J. C. J. Am. Chem. Soc. 1991, 113, 7277–7287. doi:10.1021/ja00019a027 |

| 13. | Stickley, S. H.; Martin, J. C. Tetrahedron Lett. 1995, 36, 9117–9120. doi:10.1016/0040-4039(95)01978-Q |

| 14. | Thottumkara, A. P.; Vinod, T. K. Tetrahedron Lett. 2002, 43, 569–572. doi:10.1016/S0040-4039(01)02217-1 |

| 15. | Richardson, R. D.; Zayed, J. M.; Altermann, S.; Smith, D.; Wirth, T. Angew. Chem., Int. Ed. 2007, 46, 6529–6532. doi:10.1002/anie.200702313 |

| 16. | Moorthy, J. N.; Singhal, N.; Senapati, K. Tetrahedron Lett. 2008, 49, 80–84. doi:10.1016/j.tetlet.2007.11.013 |

| 17. | Kommreddy, A.; Bowsher, M. S.; Gunna, M. R.; Botha, K.; Vinod, T. K. Tetrahedron Lett. 2008, 49, 4378–4382. doi:10.1016/j.tetlet.2008.05.017 |

| 18. | Moorthy, J. N.; Senapati, K.; Parida, K. N. J. Org. Chem. 2010, 75, 8416–8421. doi:10.1021/jo101639j |

| 19. | Cui, L.-Q.; Dong, Z.-L.; Liu, K.; Zhang, C. Org. Lett. 2011, 13, 6488–6491. doi:10.1021/ol202777h |

| 20. | Moorthy, J. N.; Senapati, K.; Parida, K. N.; Jhulki, S.; Sooraj, K.; Nair, N. N. J. Org. Chem. 2011, 76, 9593–9601. doi:10.1021/jo201491q |

| 21. | Harschneck, T.; Hummel, S.; Kirsch, S. F.; Klahn, P. Chem. – Eur. J. 2012, 18, 1187–1193. doi:10.1002/chem.201102680 |

| 22. | Yusubov, M. S.; Postnikov, P. S.; Yusubova, R. Y.; Yoshimura, A.; Jürjens, G.; Kirschning, A.; Zhdankin, V. V. Adv. Synth. Catal. 2017, 359, 3207–3216. doi:10.1002/adsc.201700776 |

| 67. | Yakura, T.; Yamada, A.; Noda, N.; Fujiwara, T.; Nambu, H. Asian J. Org. Chem. 2014, 3, 421–424. doi:10.1002/ajoc.201300279 |

| 11. | Hartmann, C.; Mayer, V. Chem. Ber. 1893, 26, 1727–1732. doi:10.1002/cber.189302602109 |

| 60. | Yakura, T.; Konishi, T. Synlett 2007, 765–768. doi:10.1055/s-2007-970758 |

| 61. | Yakura, T.; Yamauchi, Y.; Tian, Y.; Omoto, M. Chem. Pharm. Bull. 2008, 56, 1632–1634. doi:10.1248/cpb.56.1632 |

| 62. | Yakura, T.; Tian, Y.; Yamauchi, Y.; Omoto, M.; Konishi, T. Chem. Pharm. Bull. 2009, 57, 252–256. doi:10.1248/cpb.57.252 |

| 63. | Yakura, T.; Omoto, M. Chem. Pharm. Bull. 2009, 57, 643–645. doi:10.1248/cpb.57.643 |

| 64. | Yakura, T.; Omoto, M.; Yamauchi, Y.; Tian, Y.; Ozono, A. Tetrahedron 2010, 66, 5833–5840. doi:10.1016/j.tet.2010.04.124 |

| 65. | Yakura, T.; Ozono, A. Adv. Synth. Catal. 2011, 353, 855–859. doi:10.1002/adsc.201100024 |

| 66. | Nambu, H.; Shimokawa, I.; Fujiwara, T.; Yakura, T. Asian J. Org. Chem. 2016, 5, 486–489. doi:10.1002/ajoc.201600036 |

| 10. | Dess, D. B.; Martin, J. C. J. Org. Chem. 1983, 48, 4155–4156. doi:10.1021/jo00170a070 |

| 67. | Yakura, T.; Yamada, A.; Noda, N.; Fujiwara, T.; Nambu, H. Asian J. Org. Chem. 2014, 3, 421–424. doi:10.1002/ajoc.201300279 |

| 20. | Moorthy, J. N.; Senapati, K.; Parida, K. N.; Jhulki, S.; Sooraj, K.; Nair, N. N. J. Org. Chem. 2011, 76, 9593–9601. doi:10.1021/jo201491q |

| 47. | Miura, T.; Nakashima, K.; Tada, N.; Itoh, A. Chem. Commun. 2011, 47, 1875–1877. doi:10.1039/C0CC03149F |

| 48. | Seth, S.; Jhulki, S.; Moorthy, J. N. Eur. J. Org. Chem. 2013, 2445–2452. doi:10.1002/ejoc.201201699 |

| 49. | Jhulki, S.; Seth, S.; Mondal, M.; Moorthy, J. N. Tetrahedron 2014, 70, 2286–2293. doi:10.1016/j.tet.2014.01.034 |

| 50. | Moorthy, J. N.; Parida, K. N. J. Org. Chem. 2014, 79, 11431–11439. doi:10.1021/jo502002w |

| 51. | Mishra, A. K.; Moorthy, J. N. Org. Chem. Front. 2017, 4, 343–349. doi:10.1039/C6QO00588H |

| 20. | Moorthy, J. N.; Senapati, K.; Parida, K. N.; Jhulki, S.; Sooraj, K.; Nair, N. N. J. Org. Chem. 2011, 76, 9593–9601. doi:10.1021/jo201491q |

| 48. | Seth, S.; Jhulki, S.; Moorthy, J. N. Eur. J. Org. Chem. 2013, 2445–2452. doi:10.1002/ejoc.201201699 |

| 49. | Jhulki, S.; Seth, S.; Mondal, M.; Moorthy, J. N. Tetrahedron 2014, 70, 2286–2293. doi:10.1016/j.tet.2014.01.034 |

| 50. | Moorthy, J. N.; Parida, K. N. J. Org. Chem. 2014, 79, 11431–11439. doi:10.1021/jo502002w |

| 51. | Mishra, A. K.; Moorthy, J. N. Org. Chem. Front. 2017, 4, 343–349. doi:10.1039/C6QO00588H |

| 57. | Uyanik, M.; Mutsuga, T.; Ishihara, K. Angew. Chem., Int. Ed. 2017, 56, 3956–3960. doi:10.1002/anie.201612463 |

| 45. | Thottumkara, A. P.; Bowsher, M. S.; Vinod, T. K. Org. Lett. 2005, 7, 2933–2936. doi:10.1021/ol050875o |

| 46. | Schulze, A.; Giannis, A. Synthesis 2006, 257–260. doi:10.1055/s-2005-924764 |

| 58. | Yusubov, M. S.; Zagulyaeva, A. A.; Zhdankin, V. V. Chem. – Eur. J. 2009, 15, 11091–11094. doi:10.1002/chem.200901953 |

| 59. | Yusubov, M. S.; Nemykin, V. N.; Zhdankin, V. V. Tetrahedron 2010, 66, 5745–5752. doi:10.1016/j.tet.2010.04.046 |

| 40. | Richardson, R. D.; Wirth, T. Angew. Chem., Int. Ed. 2006, 45, 4402–4404. doi:10.1002/anie.200601817 |

| 41. | Ochiai, M.; Miyamoto, K. Eur. J. Org. Chem. 2008, 4229–4239. doi:10.1002/ejoc.200800416 |

| 42. | Dohi, T.; Kita, Y. Chem. Commun. 2009, 2073–2085. doi:10.1039/b821747e |

| 43. | Uyanik, M.; Ishihara, K. Chem. Commun. 2009, 2086–2099. doi:10.1039/b823399c |

| 44. | Singh, F. V.; Wirth, T. Chem. – Asian J. 2014, 9, 950–971. doi:10.1002/asia.201301582 |

| 52. | Uyanik, M.; Akakura, M.; Ishihara, K. J. Am. Chem. Soc. 2009, 131, 251–262. doi:10.1021/ja807110n |

| 39. | Ozanne, A.; Pouységu, L.; Depernet, D.; François, B.; Quideau, S. Org. Lett. 2003, 5, 2903–2906. doi:10.1021/ol0349965 |

| 52. | Uyanik, M.; Akakura, M.; Ishihara, K. J. Am. Chem. Soc. 2009, 131, 251–262. doi:10.1021/ja807110n |

| 53. | Uyanik, M.; Fukatsu, R.; Ishihara, K. Org. Lett. 2009, 11, 3470–3473. doi:10.1021/ol9013188 |

| 54. | Uyanik, M.; Ishihara, K. Aldrichimica Acta 2010, 43, 83–91. |

| 55. | Uyanik, M.; Mutsuga, T.; Ishihara, K. Molecules 2012, 17, 8604–8616. doi:10.3390/molecules17078604 |

| 56. | Uyanik, M.; Ishihara, K. Org. Synth. 2012, 89, 105–114. doi:10.15227/orgsyn.089.0105 |

| 57. | Uyanik, M.; Mutsuga, T.; Ishihara, K. Angew. Chem., Int. Ed. 2017, 56, 3956–3960. doi:10.1002/anie.201612463 |

| 52. | Uyanik, M.; Akakura, M.; Ishihara, K. J. Am. Chem. Soc. 2009, 131, 251–262. doi:10.1021/ja807110n |

| 58. | Yusubov, M. S.; Zagulyaeva, A. A.; Zhdankin, V. V. Chem. – Eur. J. 2009, 15, 11091–11094. doi:10.1002/chem.200901953 |

| 59. | Yusubov, M. S.; Nemykin, V. N.; Zhdankin, V. V. Tetrahedron 2010, 66, 5745–5752. doi:10.1016/j.tet.2010.04.046 |

| 60. | Yakura, T.; Konishi, T. Synlett 2007, 765–768. doi:10.1055/s-2007-970758 |

| 62. | Yakura, T.; Tian, Y.; Yamauchi, Y.; Omoto, M.; Konishi, T. Chem. Pharm. Bull. 2009, 57, 252–256. doi:10.1248/cpb.57.252 |

| 67. | Yakura, T.; Yamada, A.; Noda, N.; Fujiwara, T.; Nambu, H. Asian J. Org. Chem. 2014, 3, 421–424. doi:10.1002/ajoc.201300279 |

| 23. | Zhdankin, V. V.; Koposov, A. Y.; Netzel, B. C.; Yashin, N. V.; Rempel, B. P.; Ferguson, M. J.; Tykwinski, R. R. Angew. Chem., Int. Ed. 2003, 42, 2194–2196. doi:10.1002/anie.200351018 |

| 67. | Yakura, T.; Yamada, A.; Noda, N.; Fujiwara, T.; Nambu, H. Asian J. Org. Chem. 2014, 3, 421–424. doi:10.1002/ajoc.201300279 |

| 69. | The corresponding aldehyde remained even after the starting alcohols were completely oxidized (checked by TLC). |

| 60. | Yakura, T.; Konishi, T. Synlett 2007, 765–768. doi:10.1055/s-2007-970758 |

| 61. | Yakura, T.; Yamauchi, Y.; Tian, Y.; Omoto, M. Chem. Pharm. Bull. 2008, 56, 1632–1634. doi:10.1248/cpb.56.1632 |

| 62. | Yakura, T.; Tian, Y.; Yamauchi, Y.; Omoto, M.; Konishi, T. Chem. Pharm. Bull. 2009, 57, 252–256. doi:10.1248/cpb.57.252 |

| 63. | Yakura, T.; Omoto, M. Chem. Pharm. Bull. 2009, 57, 643–645. doi:10.1248/cpb.57.643 |

| 64. | Yakura, T.; Omoto, M.; Yamauchi, Y.; Tian, Y.; Ozono, A. Tetrahedron 2010, 66, 5833–5840. doi:10.1016/j.tet.2010.04.124 |

| 68. | The oxidation of 14a with 23 at 70 °C was also reported to be very slow [67]. |

| 20. | Moorthy, J. N.; Senapati, K.; Parida, K. N.; Jhulki, S.; Sooraj, K.; Nair, N. N. J. Org. Chem. 2011, 76, 9593–9601. doi:10.1021/jo201491q |

| 48. | Seth, S.; Jhulki, S.; Moorthy, J. N. Eur. J. Org. Chem. 2013, 2445–2452. doi:10.1002/ejoc.201201699 |

| 20. | Moorthy, J. N.; Senapati, K.; Parida, K. N.; Jhulki, S.; Sooraj, K.; Nair, N. N. J. Org. Chem. 2011, 76, 9593–9601. doi:10.1021/jo201491q |

| 48. | Seth, S.; Jhulki, S.; Moorthy, J. N. Eur. J. Org. Chem. 2013, 2445–2452. doi:10.1002/ejoc.201201699 |

| 52. | Uyanik, M.; Akakura, M.; Ishihara, K. J. Am. Chem. Soc. 2009, 131, 251–262. doi:10.1021/ja807110n |

| 60. | Yakura, T.; Konishi, T. Synlett 2007, 765–768. doi:10.1055/s-2007-970758 |

| 62. | Yakura, T.; Tian, Y.; Yamauchi, Y.; Omoto, M.; Konishi, T. Chem. Pharm. Bull. 2009, 57, 252–256. doi:10.1248/cpb.57.252 |

© 2018 Yakura et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (https://www.beilstein-journals.org/bjoc)