Abstract

The molybdenum and tungsten complexes M2(OR)6 (Mo2F6, M = Mo, R = C(CF3)2Me; W2F3, M = W, R = OC(CF3)Me2) were synthesized as bimetallic congeners of the highly active alkyne metathesis catalysts [MesC≡M{OC(CF3)nMe3−n}] (MoF6, M = Mo, n = 2; WF3, M = W, n = 1; Mes = 2,4,6-trimethylphenyl). The corresponding benzylidyne complex [PhC≡W{OC(CF3)Me2}] (WPhF3) was prepared by cleaving the W≡W bond in W2F3 with 1-phenyl-1-propyne. The catalytic alkyne metathesis activity of these metal complexes was determined in the self-metathesis, ring-closing alkyne metathesis and cross-metathesis of internal and terminal alkynes, revealing an almost equally high metathesis activity for the bimetallic tungsten complex W2F3 and the alkylidyne complex WPhF3. In contrast, Mo2F6 displayed no significant activity in alkyne metathesis.

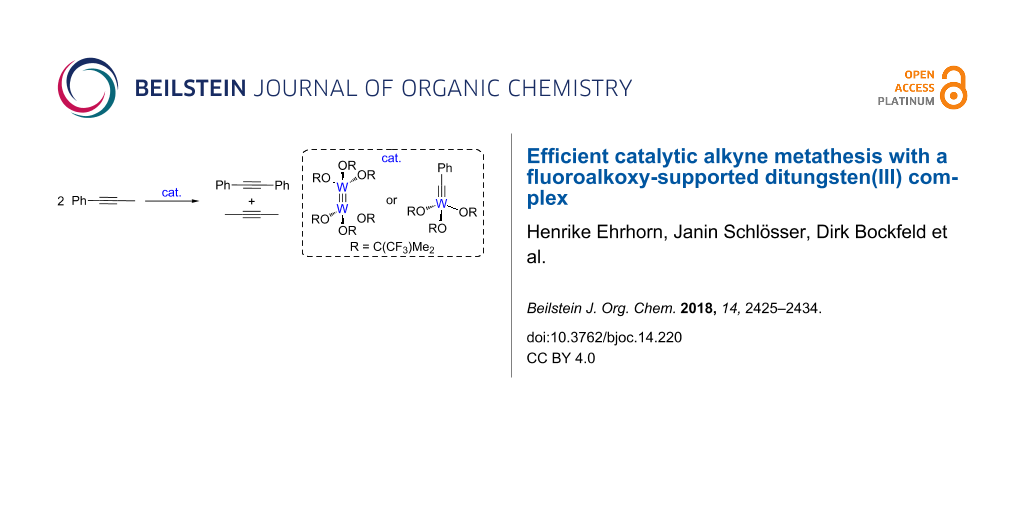

Graphical Abstract

Introduction

While the field of olefin metathesis has seen significant progress in the past decades [1-5], the synthetic potential of alkyne metathesis has been growing only recently [6-11]. Alkyne metathesis represents a transition-metal-catalyzed transformation in which carbon–carbon triple bonds are cleaved and formed under mild conditions via metallacyclobutadiene (MCBD) intermediates [12]. Ongoing progress in the development of highly active homogeneous alkyne metathesis catalysts (Figure 1) has increased the value of this method in natural product and materials chemistry.

Figure 1: Selected homogeneous catalysts for alkyne metathesis.

Figure 1: Selected homogeneous catalysts for alkyne metathesis.

The contributions from our group to the development of alkyne metathesis catalysts were initially based on a design strategy inspired by the structure of highly active olefin metathesis catalysts, the Schrock-type molybdenum and tungsten alkylidene complexes [13-15]. Imidazolin-2-iminato ligands were used to modify Schrock-type alkylidyne complexes, resulting in new active alkyne metathesis catalysts such as I (Figure 1) [16-20]. Initially, the neopentylidyne tungsten complex was synthesized via the conventional “high-oxidation-state route” developed by R. R. Schrock [16,17,21,22]; later, the “low-oxidation-state route”, starting from M(CO)6 (M = Mo, W), was employed, which gave rise to the corresponding molybdenum and tungsten benzylidyne complexes [18-20].

In addition to these, several well-defined alkylidyne complexes have been developed and successfully utilized in alkyne metathesis in the past decade. The molybdenum alkylidyne complex with triphenylsiloxide ligands (type II) introduced by A. Fürstner and co–workers is frequently used in the total synthesis of natural products [23-27]. A unique catalytic reactivity towards conjugated diynes was observed for the tungsten benzylidyne complex with OSi(Ot-Bu)3 ligands (type III) [28-30]. The catalyst III, which is capable of promoting conventional alkyne metathesis [19], also proved to be highly active in the cross metathesis of symmetric 1,3-butadiynes to form unsymmetrically substituted 1,3-butadiynes [30]. W. Zhang and his group introduced several multidentate phenoxide ligands to molybdenum propylidyne precursors to form chelate complexes of type IV [31-34]. These catalysts were especially successful in the construction of supramolecular materials such as ethynylene-linked polymers [11,35], porous networks [36] and molecular cages [37-43]. Furthermore, living ring-opening alkyne metathesis polymerization (ROAMP) has been intensely studied for different molybdenum alkylidyne complexes by the group of F. R. Fischer, who was able to monitor the influence of both the alkylidyne moiety as well as the ancillary ligands [44-48].

More recently, we expanded the “low-oxidation-state route” to the synthesis of 2,4,6-trimethylbenzylidyne complexes of molybdenum and tungsten [18,49,50], which led to an increased steric demand at the metal center. This proved to be advantageous for the catalytic activity, since the removal of coordinating solvents like THF or DME was facilitated [49]. The molybdenum 2,4,6-trimethylbenzylidyne complex [MesC≡Mo{OC(CF3)2Me}3] (Figure 1, MoF6) represents the first alkyne metathesis catalyst capable of effective and highly selective terminal alkyne metathesis [49,51-53]. Later, a study was conducted to determine the optimum degree of fluorination of the alkoxide ligands for tungsten alkylidyne complexes [53,54]. It was found that the tungsten alkylidyne complex [MesC≡W{OC(CF3)Me2}3] (Figure 1, WF3) showed excellent catalytic performance not only in the metathesis of internal but also, for the first time with the metal tungsten, terminal alkynes at room temperature [54]. Our studies clearly display a strong dependency of the catalytic alkyne metathesis activity on the metal-alkoxide combination. The electrophilicity of the metal sites can be controlled by the number of fluorine atoms of the ancillary fluoroalkoxide ligands [55-57]. The difference in the optimum degree of fluorination for molybdenum and tungsten is rationalized by the increased intrinsic electrophilicity of tungsten compared to molybdenum [56].

Based on these insights into the structure–activity relationship of alkyne metathesis catalysts, we wanted to establish an alternative and convenient access to highly active catalysts. Herein, we report the systematic study on the metathesis performance of bimetallic hexaalkoxide complexes M2(OR)6 (M = Mo, R = OC(CF3)2Me, Mo2F6; M = W, R = OC(CF3)Me2, W2F3), which draw upon the most catalytically active alkylidyne complexes MoF6 and WF3. R. R. Schrock synthesized the first alkylidyne complex which was able to undergo alkyne metathesis, [t-BuC≡W(Ot-Bu)3] (V), originally from [NEt4][t-BuC≡WCl4] [22,58-61]. Subsequently, he reported a protocol to synthesize the alkylidyne complex V by a stoichiometric alkyne metathesis reaction of the ditungsten complex [(t-BuO)3W≡W(Ot-Bu)3] with MeC≡Ct-Bu (Scheme 1) [62]. Even though Schrock’s catalyst V was the most established alkyne metathesis catalyst for many years [63,64], it does not promote terminal alkyne metathesis efficiently and leads to polymerization initiated by intermediate deprotiometallacyclobutadiene species [55,60,61,65-67]. Moreover, the bimetallic [(t-BuO)3W≡W(Ot-Bu)3] complex has not been directly employed in catalytic alkyne metathesis.

Scheme 1: Synthesis of alkylidyne complex V from bimetallic [(t-BuO)3W≡W(Ot-Bu)3]; the catalytically active ditungsten complex [W2(MMPO)6] (VI, MMPO = 1-methoxy-2-methylpropan-2-ol) [68].

Scheme 1: Synthesis of alkylidyne complex V from bimetallic [(t-BuO)3W≡W(Ot-Bu)3]; the catalytically active d...

A. Mortreux and his group found that the alkyne metathesis selectivity of Schrock’s original catalyst V can be enhanced by adding an external ligand like quinuclidine to the reaction mixture [61]. Thereby, the self-metathesis yield of 1-heptyne could be increased to 80% at elevated temperatures. Based on this approach, the dinuclear tungsten complex [W2(MMPO)6] (VI, MMPO = 1-methoxy-2-methylpropan-2-ol) was isolated which catalyzed alkyne metathesis of 1-heptyne at elevated temperatures [68] and to date represents the only well-defined ditungsten complex which has been successfully used in alkyne metathesis.

The organometallic chemistry of the M2X6 complexes (X = R (alkyl), NR2, OR) with metal-metal triple bonds (M = Mo, W) has attracted attention for many years (mainly during the 70s, 80s and 90s) [69]. A plethora of dinuclear compounds has been published [70-78], and detailed studies on their reactivity have been conducted [79-85]. Therefore, the reactivity of ditungsten complexes towards alkynes has been known for quite some time. The metal–metal triple bond of many ditungsten complexes can be cleaved by alkynes in a metathesis-like reaction to form the corresponding alkylidyne complexes [62,86]. Dinuclear Mo≡Mo complexes, however, have not yet been cleaved efficiently by alkynes [87].

Results and Discussion

Complex synthesis

The dimeric molybdenum complex [Mo2Cl6(dme)2] (dme = 1,2-dimethoxyethane) serves as an excellent starting material for compounds of the type Mo2X6 (X = alkyl, alkoxide) [73]. The desired hexakis(fluoroalkoxide) dimer [Mo2{OC(CF3)2Me}6] (Mo2F6) was first isolated by D. Rogers and his group by salt metathesis of [Mo2Cl6(dme)2] with 6 equiv of NaOC(CF3)2Me (Scheme 2) [73]. This reaction affords a red, sparingly soluble complex in moderate yield (28%).

Scheme 2: Synthesis of hexakis(fluoroalkoxide) dimers Mo2F6 [73] and W2F3.

Scheme 2: Synthesis of hexakis(fluoroalkoxide) dimers Mo2F6 [73] and W2F3.

The bimetallic tungsten analogue to WF3, [W2{OC(CF3)Me2}6] (W2F3), can be prepared by the reaction of [NaW2Cl7(THF)5] with 6 equiv of NaOC(CF3)Me2 [86], but this procedure requires one equivalent of toxic sodium amalgam. Therefore, we decided to attempt the protonolysis of hexakis(dimethylamido)ditungsten [W2(NMe2)6] with the alcohol HOC(CF3)Me2 [71,88], which has been described very briefly in the literature [89]. [W2(NMe2)6] is easily accessible from WCl4 and LiNMe2 and has emerged as an important starting material for various dinuclear tungsten compounds [90]. M. H. Chisholm and co-workers used 6 equiv of the free alcohol to exchange the amide ligands and isolated the bis(dimethylamino) adduct of the ditungsten complex [89]. The amine ligands were liberated under reduced pressure and at elevated temperature. However, in our hands, an excess of HOC(CF3)Me2 was required to drive the reaction to completion and led to the formation of the complex [W2{OC(CF3)Me2}6(NHMe2)] (W2F3·NHMe2) (Scheme 2). The additional amine ligand stems from the protonolysis reaction of the amide with the fluorinated alcohol. Brown crystals suitable for X-ray diffraction analysis were isolated from a saturated pentane solution at −40 °C. The molecular structure of this complex was established by X-ray diffraction analysis. The ORTEP diagram is shown in Figure 2, and selected bond lengths and angles are displayed in Table 1.

![[1860-5397-14-220-2]](/bjoc/content/figures/1860-5397-14-220-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: Molecular structure of W2F3·NHMe2 with thermal displacement parameters drawn at 50% probability. Hydrogen atoms are omitted for clarity.

Figure 2: Molecular structure of W2F3·NHMe2 with thermal displacement parameters drawn at 50% probability. Hy...

Table 1: Selected bond lengths [Å] and angles [°]:

| Bond | Bond length [Å] | Bond angle | Angle [°] | Bond angle | Angle [°] |

|---|---|---|---|---|---|

| W1–W2 | 2.3452(2) | O1–W1–O2 | 93.75(11) | O5-W2-O4 | 122.91(11) |

| W1–O1 | 1.905(2) | O1–W1–O3 | 145.01(10) | O1–W1–W2 | 104.75(8) |

| W1–O2 | 1.911(3) | O2–W1–O3 | 91.61(11) | O2–W1–W2 | 108.97(8) |

| W1–O3 | 1.970(2) | O1–W1–N | 82.15(11) | O3–W1–W2 | 106.06(7) |

| W1–N | 2.270(3) | O2–W1–N | 159.81(11) | N–W1–W2 | 91.17(8) |

| W2–O4 | 1.930(2) | O3–W1–N | 81.06(11) | O4–W2–W1 | 98.33(7 |

| W2–O5 | 1.818(2) | O6–W2–O5 | 110.53(11) | O5–W2–W1 | 99.29(7) |

| W2–O6 | 1.872(2) | O6–W2–O4 | 112.06(11) | O6–W2–W1 | 111.85(8) |

The tungsten–tungsten triple bond of 2.3452(2) Å falls in the range of previously reported bond lengths of this type [69]. For example, the W≡W distance in [W2{OC(CF3)2Me}]6 is 2.309(3) Å [78], 2.430(8) Å in [W2(MMPO)6] [68], and 2.332(1) Å in [W2(OCHMe2)6(py)2] (py = pyridine) [90]. The W1–N bond length of 2.270(3) Å is longer compared to the W–N distances in [W2(NMe2)6] (1.95(2)–1.99(2) Å) [71] and [W2Cl2(NMe2)4] (1.935(8)–1.937(9) Å) [91]. This is attributed to the neutral nature of the NHMe2 ligand compared to the negative NMe2 ligand and indicates a weak bond between the tungsten and the nitrogen atom. Coordination of the NHMe2 ligand to W1 affords markedly longer W1–O bonds (1.905(2)–1.970(2) Å) than the W2–O bonds (1.818(2)–1.930(2) Å). The W1 atom is coordinated in an almost square-pyramidal fashion (τ5 = 0.25) [92] while the W2 atom adopts a nearly tetrahedral geometry (τ4 = 0.89) [93], which is usually observed in X3W≡WX3 complexes [72,83,94]. The coordination of one amine ligand after the protonolysis of the amide ligands in [W2(NMe2)6] has been observed before, e.g., in [W2(OAr)6(HNMe2)] (Ar = 3,5-dimethylphenoxide) [95].

Complex W2F3·NHMe2 appeared to be rather unstable especially in hexane and pentane solutions. Over a period of 24 h, a color change from brown to bright red occurred in solution. This observation indicates the loss of the additional amine ligand, and after recrystallization from pentane at −25 °C, the red complex W2F3 was isolated. The 1H NMR spectrum reveals the only expected signal at 1.51 ppm, which is in line with the previously reported values, where W2F3 had been prepared from [NaW2Cl7(THF)5] [86]. The 13C and 19F NMR spectra are also consistent with literature values. Crystals of W2F3 suitable for X-ray diffraction analysis were obtained upon cooling a saturated pentane solution to −40 °C. Unfortunately, the crystal structure suffers from severe disorder. Each tungsten atom is disordered over four positions, and additionally, the alkoxide ligands are also disordered (for more details, see Supporting Information File 1). Therefore, the crystal structure only confirms the connectivity and does not allow the discussion of bond lengths and angles. This disorder pattern has been reported repeatedly for molybdenum and tungsten hexaalkoxides and silanolates [73,78,83,96-98]. An ORTEP diagram of W2F3 is displayed in Supporting Information File 1 (Scheme S13).

As stated above, R. R. Schrock could generate alkyne metathesis catalysts of type V (Scheme 1) from the corresponding bimetallic complex [62,99]. Thus, we attempted the cleavage of the M≡M bond of Mo2F6 and W2F3 by an alkyne to generate the corresponding benzylidyne complexes. Unfortunately, as reported in the past by Schrock [62,87], we could not achieve the selective cleavage of the triple bond in Mo2F6 by internal or terminal alkynes to isolate the corresponding alkylidyne complex. In an NMR study on the cleavage of the Mo≡Mo triple bond, in which Mo2F6 was treated with two equivalents of 1-phenyl-1-propyne, no signals corresponding to a possible molybdenum alkylidyne complex were detected in the 1H and 19F NMR spectra over a period of three days.

In contrast, the reaction of the bimetallic tungsten complex W2F3 with two equivalents of 1-phenyl-1-propyne in toluene afforded the light yellow benzylidyne complex WPhF3 (Scheme 3) in satisfactory yield after recrystallization from n-pentane. In a metathesis-like reaction, the W≡W bond is cleaved, with 2-butyne forming as a side product. Following this reaction by 1H and 19F NMR spectroscopy revealed fast and selective formation of WPhF3, and after 14 minutes, most of the starting material W2F3 was already consumed, with full conversion observed after 28 minutes. Selected 19F NMR spectra can be found in Figure S7 of Supporting Information File 1.

Scheme 3: Preparation of the alkylidyne complex WPhF3.

Scheme 3: Preparation of the alkylidyne complex WPhF3.

The 1H NMR spectrum of WPhF3 displays two multiplets in the aromatic region for the benzylidyne hydrogen atoms and one singlet for the methyl groups of the trifluoro-tert-butoxy ligand at 1.65 ppm. In the 13C NMR spectrum, the signal of the carbyne carbon atom can be found at 266.9 ppm, which is in the range typically observed for RC≡W moieties [16-18,49,50,54]. The 19F NMR spectrum only exhibits one singlet for the complex with a chemical shift of −82.4 ppm. Crystals suitable for X-ray diffraction analysis were isolated from a saturated pentane solution at −40 °C; again, the crystal structure suffers from crystallographic problems: one alkoxide ligand is refined on two positions, while another one is refined on three positions. The crystal structure, which is displayed in Figure 3, only confirms the connectivity of this molecule, and discussion of any bond length is not meaningful (for more details, see Supporting Information File 1). A similar crystal structure with the 2,4,6-trimethylbenzylidyne moiety at the tungsten atom, which does not exhibit disorder, has been reported previously [54].

![[1860-5397-14-220-3]](/bjoc/content/figures/1860-5397-14-220-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: Molecular structure of WPhF3 with thermal displacement parameters drawn at 50% probability. Hydrogen atoms and minor components of the disordered OC(CF3)Me2 groups are omitted for clarity.

Figure 3: Molecular structure of WPhF3 with thermal displacement parameters drawn at 50% probability. Hydroge...

Catalytic studies

With the bimetallic complexes Mo2F6 and W2F3 and the new alkylidyne complex WPhF3 at hand, we aimed at systematically investigating the catalytic activity of those complexes. Even though we failed in selectively cleaving the Mo≡Mo triple bond, we attempted catalytic alkyne metathesis with Mo2F6. Interestingly, a marginal catalytic activity could be detected for complex Mo2F6: over the course of four days, the dimolybdenum complex achieved a conversion of 70% in the self-metathesis of the standard substrate 3-pentynyl benzyl ether in toluene in the presence of molecular sieves (MS 5 Å) as 2-butyne scavenger. The conversion versus time diagram (Supporting Information File 1, Figure S8) exhibits a sigmoidal curve progression, which indicates the slow formation of a catalytically active species, presumably an alkylidyne complex, despite our inability to monitor the formation of such a species by NMR spectroscopy. We attribute the poor catalytic performance of Mo2F6 to the low solubility in all common solvents [73], since most of the compound still remained undissolved in the reaction mixture after four days. However, all efforts to optimize the metathesis conditions and to achieve higher conversions failed. Attempts to increase the solubility of Mo2F6 in toluene by performing the metathesis reaction at 60 °C led to no detectable conversion of the starting material. Furthermore, catalysis in CH2Cl2 afforded even lower conversions compared to toluene, while the metathesis failed completely in diethyl ether.

For the potential tungsten catalysts, toluene solutions of 1-phenyl-1-propyne were treated with W2F3 (0.5 mol %) and WPhF3 (1 mol %) and stirred in the presence of molecular sieves (MS 5 Å) as 2-butyne scavenger and n-decane as internal standard at room temperature (Scheme 4). The catalysis was initially monitored over time through gas chromatography, affording the conversion versus time diagram depicted in Figure 4.

Scheme 4: Self-metathesis of 1-phenyl-1-propyne derivatives by tungsten complexes W2F3 and WPhF3.

Scheme 4: Self-metathesis of 1-phenyl-1-propyne derivatives by tungsten complexes W2F3 and WPhF3.

![[1860-5397-14-220-4]](/bjoc/content/figures/1860-5397-14-220-4.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 4: Conversion versus time diagram for the self-metathesis of 1-phenyl-1-propyne catalyzed by 0.5 mol % W2F3 (grey) and 1 mol % WPhF3 (black).

Figure 4: Conversion versus time diagram for the self-metathesis of 1-phenyl-1-propyne catalyzed by 0.5 mol % ...

Figure 4 clearly shows that both tungsten complexes are active in the metathesis of 1-phenyl-1-propyne, with the bimetallic compound W2F3 (grey) showing a slower initiation rate compared to the alkylidyne complex WPhF3. For the bimetallic complex W2F3, an additional initiation step is required, in which the W≡W triple bond is cleaved and catalytically active alkylidyne species are formed. Therefore, the conversion of the substrate with catalyst W2F3 is significantly slower at the beginning of the reaction. The initial catalyst turnover frequencies were calculated from the conversion of 1-phenyl-1-propyne after one minute (TOF1min). The TOF of the alkylidyne complex WPhF3 reaches 78 min−1 (1.30 s−1), while W2F3 has a significantly lower TOF of 13 min−1 (0.21 s−1) after one minute; this value is based on the formation of two catalytically active alkylidyne species upon treatment with the alkyne substrate. After 10 minutes, the alkylidyne complex WPhF3 has accomplished nearly full conversion and after 20 minutes, catalyst W2F3 achieves the same conversion of the starting material. The maximum conversion of around 97% is reached for both catalysts within 60 minutes. Accordingly, we aimed at further monitoring the substrate scope of the complexes including the metathesis of terminal alkynes as well as ring-closing alkyne metathesis (RCAM).

Table 2 summarizes the isolated yields for various self-metathesis and RCAM reactions. These findings are in line with our initial results regarding the conversion of 1-phenyl-1-propyne (Table 2, entry 1). Both tungsten complexes afforded excellent yields in the metathesis of different para-substituted phenylpropynes (Table 2, entries 2–4). For both catalysts, the yields are identical within the error of the experiment. Furthermore, the well-established substrates 3-pentynyl (R = Me) and 3-butynyl (R = H) benzyl ether (Table 2, entry 5) and 3-pentynyl (R = Me) and 3-butynyl (R = H) benzyl ester (Table 2, entry 6) afforded good isolated yields. The bimetallic complex W2F3 is even capable of metathesizing terminal alkynes at room temperature and performs in the same manner as the alkylidyne complex WPhF3. Additional conversion versus time diagrams are displayed in Figures S9 and S10 in Supporting Information File 1. Finally, the ditungsten catalyst W2F3 was also employed in alkyne cross-metathesis (ACM), a reaction which is of large interest for the application of alkyne metathesis, but often leads to product mixtures. Therefore, (trimethylsilyl)propyne and (trimethylsilyl)acetylene were chosen as reaction partners in ACM, since this reaction proved to be quite efficient in the past [25,54,100]. A toluene solution of both substrates (1:2 ratio, TMS–alkyne in excess) was charged with the catalyst W2F3 (0.5–1 mol %) in the presence of molecular sieves 5 Å and stirred for two hours at room temperature. The isolated yields of the ACM are summarized in Table 3. The depicted reactions selectively afforded the unsymmetrical alkynes, corroborating that the bimetallic tungsten complex W2F3 is able to introduce a trimethylsilyl protecting group to alkynes.

Table 2: Alkyne metathesis of different substrates.a

| Entry | Substrate | Product | Cat. | R | Yield [%] |

|---|---|---|---|---|---|

| 1 |

|

|

W2F3

WPhF3 |

96

95 |

|

| 2 |

|

|

W2F3

WPhF3 |

95

96 |

|

| 3 |

|

|

W2F3

WPhF3 |

94

97 |

|

| 4 |

|

|

W2F3

WPhF3 |

98

97 |

|

| 5 |

|

|

W2F3 |

R = Me

R = H |

96

88 |

| WPhF3 |

R = Me

R = H |

94

88 |

|||

| 6 |

|

|

W2F3 |

R = Me

R = H |

93

79 |

| WPhF3 |

R = Me

R = H |

94

72 |

|||

| 7 |

|

|

W2F3

WPhF3 |

86

84 |

|

| 8 |

|

|

W2F3

WPhF3 |

93

96 |

|

aSelf-metathesis: substrate (0.5 mmol), catalyst (0.5 mol % W2F3; 1 mol % WPhF3), toluene (internal alkynes: 2.5 mL, 200 mM; terminal alkynes: 24 mL, 21 mM), MS 5 Å (500 mg), 25 °C, 2 h. RCAM: substrate (0.5 mmol), catalyst (1 mol % W2F3; 2 mol % WPhF3), toluene (24 mL, 21 mM), MS 5 Å (1.0 g), 25 °C, 2 h.

Table 3: Alkyne cross metathesis (ACM) with catalyst W2F3.a

| Entry | Substrates | Product | Cat. | Yield [%] | |

|---|---|---|---|---|---|

| 1 |

|

|

|

0.5 mol % | 87 |

| 2 |

|

|

|

1 mol % | 82 |

| 3 |

|

|

|

0.5 mol % | 93 |

| 4 |

|

0.5 mol % | 92 | ||

aSubstrate (0.5 mmol), TMS-propyne or TMS-acetylene (1 mmol), toluene (internal alkynes: 2.5 mL, terminal alkynes: 24 mL), MS 5 Å (500 mg), 25 °C, 2 h.

Conclusion

Previously, we have reported the optimum level of fluorination in MoF6 and WF3 as the most catalytically active alkylidyne complexes [54]. Thus, we intended to study the catalytic activity of the well-known bimetallic molybdenum and tungsten complexes bearing the same fluoroalkoxide ligands. Indeed, W2F3 as the bimetallic analogue to mononuclear WF3 is highly active in the metathesis of internal and even terminal alkynes and also promotes alkyne cross-metathesis efficiently. The Mo2F6 complex, however, does not exhibit satisfactory alkyne metathesis activity, which we attribute to its low solubility. Furthermore, the corresponding mononuclear benzylidyne complex WPhF3 is easily accessible from the dinuclear W2F3 complex and performs equally well compared to the latter.

The finding that W2F3 is a highly active alkyne metathesis pre-catalyst and does not have to be converted into an alkylidyne species prior to catalysis could be beneficial for future applications of alkyne metathesis since this protocol represents a convenient approach to alkyne metathesis catalysts in two steps starting from WCl4.

Supporting Information

CCDC 1850924−1850926 contain the supplementary crystallographic data for this paper. These data can be obtained free of charge via http://www.ccdc.cam.ac.uk/data_request/cif.

| Supporting Information File 1: Experimental section, NMR spectra, catalysis procedure and product characterization, crystallographic details for W2F3·(NHMe2), W2F3 and WPhF3. | ||

| Format: PDF | Size: 1.3 MB | Download |

Acknowledgements

H.E. wishes to thank the Fonds der Chemischen Industrie (FCI) for a Chemiefonds Fellowship. This work was funded by the Deutsche Forschungsgemeinschaft (DFG) through project TA 189/12−1 (“Mechanistic studies on the catalytic metathesis of internal and terminal alkynes and diynes”). The authors wish to thank Dr. M. Freytag for the crystal structure determination of W2F3·(NHMe2).

References

-

Fürstner, A. Angew. Chem., Int. Ed. 2000, 39, 3012–3043. doi:10.1002/1521-3773(20000901)39:17<3012::aid-anie3012>3.3.co;2-7

Return to citation in text: [1] -

Connon, S. J.; Blechert, S. Angew. Chem., Int. Ed. 2003, 42, 1900–1923. doi:10.1002/anie.200200556

Return to citation in text: [1] -

Grela, K. Olefin Metathesis; John Wiley & Sons: Hoboken, NJ, U.S.A., 2014. doi:10.1002/9781118711613

Return to citation in text: [1] -

Hoveyda, A. H.; Zhugralin, A. R. Nature 2007, 450, 243–251. doi:10.1038/nature06351

Return to citation in text: [1] -

Grubbs, R. H.; Wenzel, A. G.; O'Leary, D. J.; Khosravi, E., Eds. Handbook of Metathesis; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2015. doi:10.1002/9783527674107

Return to citation in text: [1] -

Fürstner, A.; Davies, P. W. Chem. Commun. 2005, 2307–2320. doi:10.1039/b419143a

Return to citation in text: [1] -

Mortreux, A.; Coutelier, O. J. Mol. Catal. A: Chem. 2006, 254, 96–104. doi:10.1016/j.molcata.2006.03.054

Return to citation in text: [1] -

Zhang, W.; Moore, J. S. Adv. Synth. Catal. 2007, 349, 93–120. doi:10.1002/adsc.200600476

Return to citation in text: [1] -

Wu, X.; Tamm, M. Beilstein J. Org. Chem. 2011, 7, 82–93. doi:10.3762/bjoc.7.12

Return to citation in text: [1] -

Fürstner, A. Angew. Chem., Int. Ed. 2013, 52, 2794–2819. doi:10.1002/anie.201204513

Return to citation in text: [1] -

Yang, H.; Jin, Y.; Du, Y.; Zhang, W. J. Mater. Chem. A 2014, 2, 5986–5993. doi:10.1039/c3ta14227b

Return to citation in text: [1] [2] -

Katz, T. J.; McGinnis, J. J. Am. Chem. Soc. 1975, 97, 1592–1594. doi:10.1021/ja00839a063

Return to citation in text: [1] -

Schrock, R. R.; Hoveyda, A. H. Angew. Chem., Int. Ed. 2003, 42, 4592–4633. doi:10.1002/anie.200300576

Return to citation in text: [1] -

Schrock, R. R.; Czekelius, C. Adv. Synth. Catal. 2007, 349, 55–77. doi:10.1002/adsc.200600459

Return to citation in text: [1] -

Cortez, G. A.; Schrock, R. R.; Hoveyda, A. H. Angew. Chem., Int. Ed. 2007, 46, 4534–4538. doi:10.1002/anie.200605130

Return to citation in text: [1] -

Beer, S.; Hrib, C. G.; Jones, P. G.; Brandhorst, K.; Grunenberg, J.; Tamm, M. Angew. Chem., Int. Ed. 2007, 46, 8890–8894. doi:10.1002/anie.200703184

Return to citation in text: [1] [2] [3] -

Beer, S.; Brandhorst, K.; Hrib, C. G.; Wu, X.; Haberlag, B.; Grunenberg, J.; Jones, P. G.; Tamm, M. Organometallics 2009, 28, 1534–1545. doi:10.1021/om801119t

Return to citation in text: [1] [2] [3] -

Haberlag, B.; Wu, X.; Brandhorst, K.; Grunenberg, J.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Chem. – Eur. J. 2010, 16, 8868–8877. doi:10.1002/chem.201000597

Return to citation in text: [1] [2] [3] [4] -

Lysenko, S.; Haberlag, B.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. ChemCatChem 2011, 3, 115–118. doi:10.1002/cctc.201000355

Return to citation in text: [1] [2] [3] -

Lysenko, S.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. J. Organomet. Chem. 2013, 744, 7–14. doi:10.1016/j.jorganchem.2013.03.035

Return to citation in text: [1] [2] -

Clark, D. N.; Schrock, R. R. J. Am. Chem. Soc. 1978, 100, 6774–6776. doi:10.1021/ja00489a049

Return to citation in text: [1] -

Schrock, R. R.; Clark, D. N.; Sancho, J.; Wengrovius, J. H.; Rocklage, S. M.; Pedersen, S. F. Organometallics 1982, 1, 1645–1651. doi:10.1021/om00072a018

Return to citation in text: [1] [2] -

Heppekausen, J.; Stade, R.; Goddard, R.; Fürstner, A. J. Am. Chem. Soc. 2010, 132, 11045–11057. doi:10.1021/ja104800w

Return to citation in text: [1] -

Heppekausen, J.; Stade, R.; Kondoh, A.; Seidel, G.; Goddard, R.; Fürstner, A. Chem. – Eur. J. 2012, 18, 10281–10299. doi:10.1002/chem.201200621

Return to citation in text: [1] -

Persich, P.; Llaveria, J.; Lhermet, R.; de Haro, T.; Stade, R.; Kondoh, A.; Fürstner, A. Chem. – Eur. J. 2013, 19, 13047–13058. doi:10.1002/chem.201302320

Return to citation in text: [1] [2] -

Willwacher, J.; Heggen, B.; Wirtz, C.; Thiel, W.; Fürstner, A. Chem. – Eur. J. 2015, 21, 10416–10430. doi:10.1002/chem.201501491

Return to citation in text: [1] -

Schaubach, S.; Gebauer, K.; Ungeheuer, F.; Hoffmeister, L.; Ilg, M. K.; Wirtz, C.; Fürstner, A. Chem. – Eur. J. 2016, 22, 8494–8507. doi:10.1002/chem.201601163

Return to citation in text: [1] -

Lysenko, S.; Volbeda, J.; Jones, P. G.; Tamm, M. Angew. Chem., Int. Ed. 2012, 51, 6757–6761. doi:10.1002/anie.201202101

Return to citation in text: [1] -

Li, S. T.; Schnabel, T.; Lysenko, S.; Brandhorst, K.; Tamm, M. Chem. Commun. 2013, 49, 7189–7191. doi:10.1039/c3cc43108h

Return to citation in text: [1] -

Tamm, M.; Schnabel, T.; Melcher, D.; Brandhorst, K.; Bockfeld, D. Chem. – Eur. J. 2018, 24, 9022–9032. doi:10.1002/chem.201801651

Return to citation in text: [1] [2] -

Jyothish, K.; Zhang, W. Angew. Chem., Int. Ed. 2011, 50, 3435–3438. doi:10.1002/anie.201007559

Return to citation in text: [1] -

Jyothish, K.; Wang, Q.; Zhang, W. Adv. Synth. Catal. 2012, 354, 2073–2078. doi:10.1002/adsc.201200243

Return to citation in text: [1] -

Yang, H.; Liu, Z.; Zhang, W. Adv. Synth. Catal. 2013, 355, 885–890. doi:10.1002/adsc.201201105

Return to citation in text: [1] -

Du, Y.; Yang, H.; Zhu, C.; Ortiz, M.; Okochi, K. D.; Shoemaker, R.; Jin, Y.; Zhang, W. Chem. – Eur. J. 2016, 22, 7959–7963. doi:10.1002/chem.201505174

Return to citation in text: [1] -

Hu, K.; Yang, H.; Zhang, W.; Qin, Y. Chem. Sci. 2013, 4, 3649–3653. doi:10.1039/c3sc51264a

Return to citation in text: [1] -

Yang, H.; Zhu, Y.; Du, Y.; Tan, D.; Jin, Y.; Zhang, W. Mater. Chem. Front. 2017, 1, 1369–1372. doi:10.1039/c6qm00359a

Return to citation in text: [1] -

Zhang, C.; Wang, Q.; Long, H.; Zhang, W. J. Am. Chem. Soc. 2011, 133, 20995–21001. doi:10.1021/ja210418t

Return to citation in text: [1] -

Wang, Q.; Zhang, C.; Noll, B. C.; Long, H.; Jin, Y.; Zhang, W. Angew. Chem., Int. Ed. 2014, 53, 10663–10667. doi:10.1002/anie.201404880

Return to citation in text: [1] -

Wang, Q.; Yu, C.; Long, H.; Du, Y.; Jin, Y.; Zhang, W. Angew. Chem., Int. Ed. 2015, 54, 7550–7554. doi:10.1002/anie.201501679

Return to citation in text: [1] -

Yu, C.; Long, H.; Jin, Y.; Zhang, W. Org. Lett. 2016, 18, 2946–2949. doi:10.1021/acs.orglett.6b01293

Return to citation in text: [1] -

Wang, Q.; Yu, C.; Zhang, C.; Long, H.; Azarnoush, S.; Jin, Y.; Zhang, W. Chem. Sci. 2016, 7, 3370–3376. doi:10.1039/c5sc04977f

Return to citation in text: [1] -

Ortiz, M.; Cho, S.; Niklas, J.; Kim, S.; Poluektov, O. G.; Zhang, W.; Rumbles, G.; Park, J. J. Am. Chem. Soc. 2017, 139, 4286–4289. doi:10.1021/jacs.7b00220

Return to citation in text: [1] -

Ortiz, M.; Yu, C.; Jin, Y.; Zhang, W. Top. Curr. Chem. 2017, 375, 69. doi:10.1007/s41061-017-0156-1

Return to citation in text: [1] -

Paley, D. W.; Sedbrook, D. F.; Decatur, J.; Fischer, F. R.; Steigerwald, M. L.; Nuckolls, C. Angew. Chem., Int. Ed. 2013, 52, 4591–4594. doi:10.1002/anie.201300758

Return to citation in text: [1] -

Bellone, D. E.; Bours, J.; Menke, E. H.; Fischer, F. R. J. Am. Chem. Soc. 2015, 137, 850–856. doi:10.1021/ja510919v

Return to citation in text: [1] -

von Kugelgen, S.; Bellone, D. E.; Cloke, R. R.; Perkins, W. S.; Fischer, F. R. J. Am. Chem. Soc. 2016, 138, 6234–6239. doi:10.1021/jacs.6b02422

Return to citation in text: [1] -

von Kugelgen, S.; Sifri, R.; Bellone, D.; Fischer, F. R. J. Am. Chem. Soc. 2017, 139, 7577–7585. doi:10.1021/jacs.7b02225

Return to citation in text: [1] -

Jeong, H.; von Kugelgen, S.; Bellone, D.; Fischer, F. R. J. Am. Chem. Soc. 2017, 139, 15509–15514. doi:10.1021/jacs.7b09390

Return to citation in text: [1] -

Haberlag, B.; Freytag, M.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Angew. Chem., Int. Ed. 2012, 51, 13019–13022. doi:10.1002/anie.201207772

Return to citation in text: [1] [2] [3] [4] -

Haberlag, B.; Freytag, M.; Jones, P. G.; Tamm, M. Adv. Synth. Catal. 2014, 356, 1255–1265. doi:10.1002/adsc.201400051

Return to citation in text: [1] [2] -

Hötling, S.; Bittner, C.; Tamm, M.; Dähn, S.; Collatz, J.; Steidle, J. L. M.; Schulz, S. Org. Lett. 2015, 17, 5004–5007. doi:10.1021/acs.orglett.5b02461

Return to citation in text: [1] -

Estes, D. P.; Bittner, C.; Àrias, Ò.; Casey, M.; Fedorov, A.; Tamm, M.; Copéret, C. Angew. Chem., Int. Ed. 2016, 55, 13960–13964. doi:10.1002/anie.201605129

Return to citation in text: [1] -

Estes, D. P.; Gordon, C. P.; Fedorov, A.; Liao, W.-C.; Ehrhorn, H.; Bittner, C.; Zier, M. L.; Bockfeld, D.; Chan, K. W.; Eisenstein, O.; Raynaud, C.; Tamm, M.; Copéret, C. J. Am. Chem. Soc. 2017, 139, 17597–17607. doi:10.1021/jacs.7b09934

Return to citation in text: [1] [2] -

Bittner, C.; Ehrhorn, H.; Bockfeld, D.; Brandhorst, K.; Tamm, M. Organometallics 2017, 36, 3398–3406. doi:10.1021/acs.organomet.7b00519

Return to citation in text: [1] [2] [3] [4] [5] [6] -

Freudenberger, J. H.; Schrock, R. R.; Churchill, M. R.; Rheingold, A. L.; Ziller, J. W. Organometallics 1984, 3, 1563–1573. doi:10.1021/om00088a019

Return to citation in text: [1] [2] -

Buhro, W. E.; Chisholm, M. H. Adv. Organomet. Chem. 1987, 27, 311–369. doi:10.1016/s0065-3055(08)60030-1

Return to citation in text: [1] [2] -

Schrock, R. R. Chem. Rev. 2002, 102, 145–180. doi:10.1021/cr0103726

Return to citation in text: [1] -

Wengrovius, J. H.; Sancho, J.; Schrock, R. R. J. Am. Chem. Soc. 1981, 103, 3932–3934. doi:10.1021/ja00403a058

Return to citation in text: [1] -

Schrock, R. R. J. Organomet. Chem. 1986, 300, 249–262. doi:10.1016/0022-328x(86)84064-5

Return to citation in text: [1] -

Bray, A.; Mortreux, A.; Petit, F.; Petit, M.; Szymanska-Buzar, T. J. Chem. Soc., Chem. Commun. 1993, 197–199. doi:10.1039/c39930000197

Return to citation in text: [1] [2] -

Coutelier, O.; Mortreux, A. Adv. Synth. Catal. 2006, 348, 2038–2042. doi:10.1002/adsc.200606116

Return to citation in text: [1] [2] [3] -

Listemann, M. L.; Schrock, R. R. Organometallics 1985, 4, 74–83. doi:10.1021/om00120a014

Return to citation in text: [1] [2] [3] [4] -

Fürstner, A.; Seidel, G. Angew. Chem., Int. Ed. 1998, 37, 1734–1736. doi:10.1002/(sici)1521-3773(19980703)37:12<1734::aid-anie1734>3.0.co;2-6

Return to citation in text: [1] -

Nicolaou, K. C.; Bulger, P. G.; Sarlah, D. Angew. Chem., Int. Ed. 2005, 44, 4490–4527. doi:10.1002/anie.200500369

Return to citation in text: [1] -

McCullough, L. G.; Listemann, M. L.; Schrock, R. R.; Churchill, M. R.; Ziller, J. W. J. Am. Chem. Soc. 1983, 105, 6729–6730. doi:10.1021/ja00360a040

Return to citation in text: [1] -

Freudenberger, J. H.; Schrock, R. R. Organometallics 1986, 5, 1411–1417. doi:10.1021/om00138a019

Return to citation in text: [1] -

Mortreux, A.; Petit, F.; Petit, M.; Szymanska-Buzar, T. J. Mol. Catal. A: Chem. 1995, 96, 95–105. doi:10.1016/1381-1169(94)00004-2

Return to citation in text: [1] -

Coutelier, O.; Nowogrocki, G.; Paul, J.-F.; Mortreux, A. Adv. Synth. Catal. 2007, 349, 2259–2263. doi:10.1002/adsc.200700104

Return to citation in text: [1] [2] [3] -

Chisholm, M. H.; Cotton, F. A. Acc. Chem. Res. 1978, 11, 356–362. doi:10.1021/ar50129a006

Return to citation in text: [1] [2] -

Chisholm, M. H.; Cotton, F. A.; Frenz, B. A.; Reichert, W. W.; Shive, L. W.; Stults, B. R. J. Am. Chem. Soc. 1976, 98, 4469–4476. doi:10.1021/ja00431a024

Return to citation in text: [1] -

Chisholm, M. H.; Cotton, F. A.; Extine, M.; Stults, B. R. J. Am. Chem. Soc. 1976, 98, 4477–4485. doi:10.1021/ja00431a025

Return to citation in text: [1] [2] [3] -

Coffindaffer, T. W.; Rothwell, I. P.; Huffmann, J. C. Inorg. Chem. 1985, 24, 1643–1646. doi:10.1021/ic00205a010

Return to citation in text: [1] [2] -

Gilbert, T. M.; Landes, A. M.; Rogers, R. D. Inorg. Chem. 1992, 31, 3438–3444. doi:10.1021/ic00042a020

Return to citation in text: [1] [2] [3] [4] [5] [6] -

Su, K.; Tilley, T. D. Chem. Mater. 1997, 9, 588–595. doi:10.1021/cm960413s

Return to citation in text: [1] -

Chisholm, M. H.; Folting, K.; Wu, D.-D. Chem. Commun. 1998, 379–380. doi:10.1039/a708268a

Return to citation in text: [1] -

Radius, U.; Attner, J. Eur. J. Inorg. Chem. 1998, 299–303. doi:10.1002/(sici)1099-0682(199803)1998:3<299::aid-ejic299>3.0.co;2-q

Return to citation in text: [1] -

Budzichowski, T. A.; Chisholm, M. H.; Tiedtke, D. B.; Gruhn, N. E.; Lichtenberger, D. L. Polyhedron 1998, 17, 705–711. doi:10.1016/s0277-5387(97)00360-4

Return to citation in text: [1] -

Gilbert, T. M.; Bauer, C. B.; Bond, A. H.; Rogers, R. D. Polyhedron 1999, 18, 1293–1301. doi:10.1016/s0277-5387(98)00433-1

Return to citation in text: [1] [2] [3] -

Chetcuti, M. J.; Chisholm, M. H.; Huffman, J. C.; Leonelli, J. J. Am. Chem. Soc. 1983, 105, 292–293. doi:10.1021/ja00340a025

Return to citation in text: [1] -

Chisholm, M. H.; Huffman, J. C.; Ratermann, A. L. Inorg. Chem. 1983, 22, 4100–4105. doi:10.1021/ic00168a055

Return to citation in text: [1] -

Chisholm, M. H.; Conroy, B. K.; Eichhorn, B. W.; Folting, K.; Hoffman, D. M.; Huffman, J. C.; Marchant, N. S. Polyhedron 1987, 6, 783–792. doi:10.1016/s0277-5387(00)86884-9

Return to citation in text: [1] -

Chisholm, M. H.; Eichhorn, B. W.; Folting, K.; Huffman, J. C.; Ontiveros, C. D.; Streib, W. E.; van der Sluys, W. G. Inorg. Chem. 1987, 26, 3182–3186. doi:10.1021/ic00266a024

Return to citation in text: [1] -

Chisholm, M. H.; Cook, C. M.; Huffman, J. C.; Streib, W. E. J. Chem. Soc., Dalton Trans. 1991, 929–937. doi:10.1039/dt9910000929

Return to citation in text: [1] [2] [3] -

Chisholm, M. H.; Huang, J.-H.; Huffman, J. C.; Parkin, I. P. Inorg. Chem. 1997, 36, 1642–1651. doi:10.1021/ic961429n

Return to citation in text: [1] -

Budzichowski, T. A.; Chisholm, M. H.; Folting, K.; Huffman, J. C.; Streib, W. E.; Tiedtke, D. B. Polyhedron 1998, 17, 857–867. doi:10.1016/s0277-5387(97)00290-8

Return to citation in text: [1] -

Girolami, G. S.; Sattelberger, A. P., Eds. Inorganic Syntheses: Volume 36; Inorganic Syntheses; John Wiley & Sons, Inc.: Hoboken, NJ, U.S.A., 2014. doi:10.1002/9781118744994

Return to citation in text: [1] [2] [3] -

Strutz, H.; Schrock, R. R. Organometallics 1984, 3, 1600–1601. doi:10.1021/om00088a030

Return to citation in text: [1] [2] -

Fackler, J. P., Ed. Inorganic syntheses; Wiley: New York, NY, U.S.A., 1982; Vol. 21. doi:10.1002/9780470132524

Return to citation in text: [1] -

Budzichowski, T. A.; Chisholm, M. H.; Tiedtke, D. B.; Huffman, J. C.; Streib, W. E. Organometallics 1995, 14, 2318–2324. doi:10.1021/om00005a033

Return to citation in text: [1] [2] -

Akiyama, M.; Chisholm, M. H.; Cotton, F. A.; Extine, M. W.; Haitko, D. A.; Little, D.; Fanwick, P. E. Inorg. Chem. 1979, 18, 2266–2270. doi:10.1021/ic50198a043

Return to citation in text: [1] [2] -

Chisholm, M. H.; Cotton, F. A.; Extine, M.; Millar, M.; Stults, B. R. J. Am. Chem. Soc. 1976, 98, 4486–4491. doi:10.1021/ja00431a026

Return to citation in text: [1] -

Addison, A. W.; Rao, T. N.; Reedijk, J.; van Rijn, J.; Verschoor, G. C. J. Chem. Soc., Dalton Trans. 1984, 1349–1356. doi:10.1039/dt9840001349

Return to citation in text: [1] -

Yang, L.; Powell, D. R.; Houser, R. P. Dalton Trans. 2007, 955–964. doi:10.1039/b617136b

Return to citation in text: [1] -

Chisholm, M. H.; Parkin, I. P.; Huffman, J. C.; Lobkovsky, E. M.; Folting, K. Polyhedron 1991, 10, 2839–2846. doi:10.1016/s0277-5387(00)86188-4

Return to citation in text: [1] -

Coffindaffer, T. W.; Niccolai, G. P.; Powell, D.; Rothwell, I. P. J. Am. Chem. Soc. 1985, 107, 3572–3583. doi:10.1021/ja00298a029

Return to citation in text: [1] -

Chisholm, M. H.; Folting, K.; Hampden-Smith, M.; Smith, C. A. Polyhedron 1987, 6, 1747–1755. doi:10.1016/s0277-5387(00)86546-8

Return to citation in text: [1] -

Cayton, R. H.; Chisholm, M. H. Inorg. Chem. 1991, 30, 1422–1425. doi:10.1021/ic00006a051

Return to citation in text: [1] -

Chisholm, M. H.; Gallucci, J. C.; Hollandsworth, C. B. Polyhedron 2006, 25, 827–833. doi:10.1016/j.poly.2005.07.010

Return to citation in text: [1] -

Schrock, R. R.; Listemann, M. L.; Sturgeoff, L. G. J. Am. Chem. Soc. 1982, 104, 4291–4293. doi:10.1021/ja00379a061

Return to citation in text: [1] -

Lhermet, R.; Fürstner, A. Chem. – Eur. J. 2014, 20, 13188–13193. doi:10.1002/chem.201404166

Return to citation in text: [1]

| 68. | Coutelier, O.; Nowogrocki, G.; Paul, J.-F.; Mortreux, A. Adv. Synth. Catal. 2007, 349, 2259–2263. doi:10.1002/adsc.200700104 |

| 61. | Coutelier, O.; Mortreux, A. Adv. Synth. Catal. 2006, 348, 2038–2042. doi:10.1002/adsc.200606116 |

| 68. | Coutelier, O.; Nowogrocki, G.; Paul, J.-F.; Mortreux, A. Adv. Synth. Catal. 2007, 349, 2259–2263. doi:10.1002/adsc.200700104 |

| 73. | Gilbert, T. M.; Landes, A. M.; Rogers, R. D. Inorg. Chem. 1992, 31, 3438–3444. doi:10.1021/ic00042a020 |

| 73. | Gilbert, T. M.; Landes, A. M.; Rogers, R. D. Inorg. Chem. 1992, 31, 3438–3444. doi:10.1021/ic00042a020 |

| 87. | Strutz, H.; Schrock, R. R. Organometallics 1984, 3, 1600–1601. doi:10.1021/om00088a030 |

| 73. | Gilbert, T. M.; Landes, A. M.; Rogers, R. D. Inorg. Chem. 1992, 31, 3438–3444. doi:10.1021/ic00042a020 |

| 79. | Chetcuti, M. J.; Chisholm, M. H.; Huffman, J. C.; Leonelli, J. J. Am. Chem. Soc. 1983, 105, 292–293. doi:10.1021/ja00340a025 |

| 80. | Chisholm, M. H.; Huffman, J. C.; Ratermann, A. L. Inorg. Chem. 1983, 22, 4100–4105. doi:10.1021/ic00168a055 |

| 81. | Chisholm, M. H.; Conroy, B. K.; Eichhorn, B. W.; Folting, K.; Hoffman, D. M.; Huffman, J. C.; Marchant, N. S. Polyhedron 1987, 6, 783–792. doi:10.1016/s0277-5387(00)86884-9 |

| 82. | Chisholm, M. H.; Eichhorn, B. W.; Folting, K.; Huffman, J. C.; Ontiveros, C. D.; Streib, W. E.; van der Sluys, W. G. Inorg. Chem. 1987, 26, 3182–3186. doi:10.1021/ic00266a024 |

| 83. | Chisholm, M. H.; Cook, C. M.; Huffman, J. C.; Streib, W. E. J. Chem. Soc., Dalton Trans. 1991, 929–937. doi:10.1039/dt9910000929 |

| 84. | Chisholm, M. H.; Huang, J.-H.; Huffman, J. C.; Parkin, I. P. Inorg. Chem. 1997, 36, 1642–1651. doi:10.1021/ic961429n |

| 85. | Budzichowski, T. A.; Chisholm, M. H.; Folting, K.; Huffman, J. C.; Streib, W. E.; Tiedtke, D. B. Polyhedron 1998, 17, 857–867. doi:10.1016/s0277-5387(97)00290-8 |

| 62. | Listemann, M. L.; Schrock, R. R. Organometallics 1985, 4, 74–83. doi:10.1021/om00120a014 |

| 86. | Girolami, G. S.; Sattelberger, A. P., Eds. Inorganic Syntheses: Volume 36; Inorganic Syntheses; John Wiley & Sons, Inc.: Hoboken, NJ, U.S.A., 2014. doi:10.1002/9781118744994 |

| 69. | Chisholm, M. H.; Cotton, F. A. Acc. Chem. Res. 1978, 11, 356–362. doi:10.1021/ar50129a006 |

| 70. | Chisholm, M. H.; Cotton, F. A.; Frenz, B. A.; Reichert, W. W.; Shive, L. W.; Stults, B. R. J. Am. Chem. Soc. 1976, 98, 4469–4476. doi:10.1021/ja00431a024 |

| 71. | Chisholm, M. H.; Cotton, F. A.; Extine, M.; Stults, B. R. J. Am. Chem. Soc. 1976, 98, 4477–4485. doi:10.1021/ja00431a025 |

| 72. | Coffindaffer, T. W.; Rothwell, I. P.; Huffmann, J. C. Inorg. Chem. 1985, 24, 1643–1646. doi:10.1021/ic00205a010 |

| 73. | Gilbert, T. M.; Landes, A. M.; Rogers, R. D. Inorg. Chem. 1992, 31, 3438–3444. doi:10.1021/ic00042a020 |

| 74. | Su, K.; Tilley, T. D. Chem. Mater. 1997, 9, 588–595. doi:10.1021/cm960413s |

| 75. | Chisholm, M. H.; Folting, K.; Wu, D.-D. Chem. Commun. 1998, 379–380. doi:10.1039/a708268a |

| 76. | Radius, U.; Attner, J. Eur. J. Inorg. Chem. 1998, 299–303. doi:10.1002/(sici)1099-0682(199803)1998:3<299::aid-ejic299>3.0.co;2-q |

| 77. | Budzichowski, T. A.; Chisholm, M. H.; Tiedtke, D. B.; Gruhn, N. E.; Lichtenberger, D. L. Polyhedron 1998, 17, 705–711. doi:10.1016/s0277-5387(97)00360-4 |

| 78. | Gilbert, T. M.; Bauer, C. B.; Bond, A. H.; Rogers, R. D. Polyhedron 1999, 18, 1293–1301. doi:10.1016/s0277-5387(98)00433-1 |

| 86. | Girolami, G. S.; Sattelberger, A. P., Eds. Inorganic Syntheses: Volume 36; Inorganic Syntheses; John Wiley & Sons, Inc.: Hoboken, NJ, U.S.A., 2014. doi:10.1002/9781118744994 |

| 71. | Chisholm, M. H.; Cotton, F. A.; Extine, M.; Stults, B. R. J. Am. Chem. Soc. 1976, 98, 4477–4485. doi:10.1021/ja00431a025 |

| 88. | Fackler, J. P., Ed. Inorganic syntheses; Wiley: New York, NY, U.S.A., 1982; Vol. 21. doi:10.1002/9780470132524 |

| 89. | Budzichowski, T. A.; Chisholm, M. H.; Tiedtke, D. B.; Huffman, J. C.; Streib, W. E. Organometallics 1995, 14, 2318–2324. doi:10.1021/om00005a033 |

| 71. | Chisholm, M. H.; Cotton, F. A.; Extine, M.; Stults, B. R. J. Am. Chem. Soc. 1976, 98, 4477–4485. doi:10.1021/ja00431a025 |

| 91. | Chisholm, M. H.; Cotton, F. A.; Extine, M.; Millar, M.; Stults, B. R. J. Am. Chem. Soc. 1976, 98, 4486–4491. doi:10.1021/ja00431a026 |

| 68. | Coutelier, O.; Nowogrocki, G.; Paul, J.-F.; Mortreux, A. Adv. Synth. Catal. 2007, 349, 2259–2263. doi:10.1002/adsc.200700104 |

| 90. | Akiyama, M.; Chisholm, M. H.; Cotton, F. A.; Extine, M. W.; Haitko, D. A.; Little, D.; Fanwick, P. E. Inorg. Chem. 1979, 18, 2266–2270. doi:10.1021/ic50198a043 |

| 69. | Chisholm, M. H.; Cotton, F. A. Acc. Chem. Res. 1978, 11, 356–362. doi:10.1021/ar50129a006 |

| 78. | Gilbert, T. M.; Bauer, C. B.; Bond, A. H.; Rogers, R. D. Polyhedron 1999, 18, 1293–1301. doi:10.1016/s0277-5387(98)00433-1 |

| 90. | Akiyama, M.; Chisholm, M. H.; Cotton, F. A.; Extine, M. W.; Haitko, D. A.; Little, D.; Fanwick, P. E. Inorg. Chem. 1979, 18, 2266–2270. doi:10.1021/ic50198a043 |

| 89. | Budzichowski, T. A.; Chisholm, M. H.; Tiedtke, D. B.; Huffman, J. C.; Streib, W. E. Organometallics 1995, 14, 2318–2324. doi:10.1021/om00005a033 |

| 93. | Yang, L.; Powell, D. R.; Houser, R. P. Dalton Trans. 2007, 955–964. doi:10.1039/b617136b |

| 72. | Coffindaffer, T. W.; Rothwell, I. P.; Huffmann, J. C. Inorg. Chem. 1985, 24, 1643–1646. doi:10.1021/ic00205a010 |

| 83. | Chisholm, M. H.; Cook, C. M.; Huffman, J. C.; Streib, W. E. J. Chem. Soc., Dalton Trans. 1991, 929–937. doi:10.1039/dt9910000929 |

| 94. | Chisholm, M. H.; Parkin, I. P.; Huffman, J. C.; Lobkovsky, E. M.; Folting, K. Polyhedron 1991, 10, 2839–2846. doi:10.1016/s0277-5387(00)86188-4 |

| 92. | Addison, A. W.; Rao, T. N.; Reedijk, J.; van Rijn, J.; Verschoor, G. C. J. Chem. Soc., Dalton Trans. 1984, 1349–1356. doi:10.1039/dt9840001349 |

| 1. | Fürstner, A. Angew. Chem., Int. Ed. 2000, 39, 3012–3043. doi:10.1002/1521-3773(20000901)39:17<3012::aid-anie3012>3.3.co;2-7 |

| 2. | Connon, S. J.; Blechert, S. Angew. Chem., Int. Ed. 2003, 42, 1900–1923. doi:10.1002/anie.200200556 |

| 3. | Grela, K. Olefin Metathesis; John Wiley & Sons: Hoboken, NJ, U.S.A., 2014. doi:10.1002/9781118711613 |

| 4. | Hoveyda, A. H.; Zhugralin, A. R. Nature 2007, 450, 243–251. doi:10.1038/nature06351 |

| 5. | Grubbs, R. H.; Wenzel, A. G.; O'Leary, D. J.; Khosravi, E., Eds. Handbook of Metathesis; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2015. doi:10.1002/9783527674107 |

| 16. | Beer, S.; Hrib, C. G.; Jones, P. G.; Brandhorst, K.; Grunenberg, J.; Tamm, M. Angew. Chem., Int. Ed. 2007, 46, 8890–8894. doi:10.1002/anie.200703184 |

| 17. | Beer, S.; Brandhorst, K.; Hrib, C. G.; Wu, X.; Haberlag, B.; Grunenberg, J.; Jones, P. G.; Tamm, M. Organometallics 2009, 28, 1534–1545. doi:10.1021/om801119t |

| 18. | Haberlag, B.; Wu, X.; Brandhorst, K.; Grunenberg, J.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Chem. – Eur. J. 2010, 16, 8868–8877. doi:10.1002/chem.201000597 |

| 19. | Lysenko, S.; Haberlag, B.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. ChemCatChem 2011, 3, 115–118. doi:10.1002/cctc.201000355 |

| 20. | Lysenko, S.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. J. Organomet. Chem. 2013, 744, 7–14. doi:10.1016/j.jorganchem.2013.03.035 |

| 37. | Zhang, C.; Wang, Q.; Long, H.; Zhang, W. J. Am. Chem. Soc. 2011, 133, 20995–21001. doi:10.1021/ja210418t |

| 38. | Wang, Q.; Zhang, C.; Noll, B. C.; Long, H.; Jin, Y.; Zhang, W. Angew. Chem., Int. Ed. 2014, 53, 10663–10667. doi:10.1002/anie.201404880 |

| 39. | Wang, Q.; Yu, C.; Long, H.; Du, Y.; Jin, Y.; Zhang, W. Angew. Chem., Int. Ed. 2015, 54, 7550–7554. doi:10.1002/anie.201501679 |

| 40. | Yu, C.; Long, H.; Jin, Y.; Zhang, W. Org. Lett. 2016, 18, 2946–2949. doi:10.1021/acs.orglett.6b01293 |

| 41. | Wang, Q.; Yu, C.; Zhang, C.; Long, H.; Azarnoush, S.; Jin, Y.; Zhang, W. Chem. Sci. 2016, 7, 3370–3376. doi:10.1039/c5sc04977f |

| 42. | Ortiz, M.; Cho, S.; Niklas, J.; Kim, S.; Poluektov, O. G.; Zhang, W.; Rumbles, G.; Park, J. J. Am. Chem. Soc. 2017, 139, 4286–4289. doi:10.1021/jacs.7b00220 |

| 43. | Ortiz, M.; Yu, C.; Jin, Y.; Zhang, W. Top. Curr. Chem. 2017, 375, 69. doi:10.1007/s41061-017-0156-1 |

| 54. | Bittner, C.; Ehrhorn, H.; Bockfeld, D.; Brandhorst, K.; Tamm, M. Organometallics 2017, 36, 3398–3406. doi:10.1021/acs.organomet.7b00519 |

| 13. | Schrock, R. R.; Hoveyda, A. H. Angew. Chem., Int. Ed. 2003, 42, 4592–4633. doi:10.1002/anie.200300576 |

| 14. | Schrock, R. R.; Czekelius, C. Adv. Synth. Catal. 2007, 349, 55–77. doi:10.1002/adsc.200600459 |

| 15. | Cortez, G. A.; Schrock, R. R.; Hoveyda, A. H. Angew. Chem., Int. Ed. 2007, 46, 4534–4538. doi:10.1002/anie.200605130 |

| 44. | Paley, D. W.; Sedbrook, D. F.; Decatur, J.; Fischer, F. R.; Steigerwald, M. L.; Nuckolls, C. Angew. Chem., Int. Ed. 2013, 52, 4591–4594. doi:10.1002/anie.201300758 |

| 45. | Bellone, D. E.; Bours, J.; Menke, E. H.; Fischer, F. R. J. Am. Chem. Soc. 2015, 137, 850–856. doi:10.1021/ja510919v |

| 46. | von Kugelgen, S.; Bellone, D. E.; Cloke, R. R.; Perkins, W. S.; Fischer, F. R. J. Am. Chem. Soc. 2016, 138, 6234–6239. doi:10.1021/jacs.6b02422 |

| 47. | von Kugelgen, S.; Sifri, R.; Bellone, D.; Fischer, F. R. J. Am. Chem. Soc. 2017, 139, 7577–7585. doi:10.1021/jacs.7b02225 |

| 48. | Jeong, H.; von Kugelgen, S.; Bellone, D.; Fischer, F. R. J. Am. Chem. Soc. 2017, 139, 15509–15514. doi:10.1021/jacs.7b09390 |

| 12. | Katz, T. J.; McGinnis, J. J. Am. Chem. Soc. 1975, 97, 1592–1594. doi:10.1021/ja00839a063 |

| 11. | Yang, H.; Jin, Y.; Du, Y.; Zhang, W. J. Mater. Chem. A 2014, 2, 5986–5993. doi:10.1039/c3ta14227b |

| 35. | Hu, K.; Yang, H.; Zhang, W.; Qin, Y. Chem. Sci. 2013, 4, 3649–3653. doi:10.1039/c3sc51264a |

| 62. | Listemann, M. L.; Schrock, R. R. Organometallics 1985, 4, 74–83. doi:10.1021/om00120a014 |

| 87. | Strutz, H.; Schrock, R. R. Organometallics 1984, 3, 1600–1601. doi:10.1021/om00088a030 |

| 6. | Fürstner, A.; Davies, P. W. Chem. Commun. 2005, 2307–2320. doi:10.1039/b419143a |

| 7. | Mortreux, A.; Coutelier, O. J. Mol. Catal. A: Chem. 2006, 254, 96–104. doi:10.1016/j.molcata.2006.03.054 |

| 8. | Zhang, W.; Moore, J. S. Adv. Synth. Catal. 2007, 349, 93–120. doi:10.1002/adsc.200600476 |

| 9. | Wu, X.; Tamm, M. Beilstein J. Org. Chem. 2011, 7, 82–93. doi:10.3762/bjoc.7.12 |

| 10. | Fürstner, A. Angew. Chem., Int. Ed. 2013, 52, 2794–2819. doi:10.1002/anie.201204513 |

| 11. | Yang, H.; Jin, Y.; Du, Y.; Zhang, W. J. Mater. Chem. A 2014, 2, 5986–5993. doi:10.1039/c3ta14227b |

| 36. | Yang, H.; Zhu, Y.; Du, Y.; Tan, D.; Jin, Y.; Zhang, W. Mater. Chem. Front. 2017, 1, 1369–1372. doi:10.1039/c6qm00359a |

| 16. | Beer, S.; Hrib, C. G.; Jones, P. G.; Brandhorst, K.; Grunenberg, J.; Tamm, M. Angew. Chem., Int. Ed. 2007, 46, 8890–8894. doi:10.1002/anie.200703184 |

| 17. | Beer, S.; Brandhorst, K.; Hrib, C. G.; Wu, X.; Haberlag, B.; Grunenberg, J.; Jones, P. G.; Tamm, M. Organometallics 2009, 28, 1534–1545. doi:10.1021/om801119t |

| 18. | Haberlag, B.; Wu, X.; Brandhorst, K.; Grunenberg, J.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Chem. – Eur. J. 2010, 16, 8868–8877. doi:10.1002/chem.201000597 |

| 49. | Haberlag, B.; Freytag, M.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Angew. Chem., Int. Ed. 2012, 51, 13019–13022. doi:10.1002/anie.201207772 |

| 50. | Haberlag, B.; Freytag, M.; Jones, P. G.; Tamm, M. Adv. Synth. Catal. 2014, 356, 1255–1265. doi:10.1002/adsc.201400051 |

| 54. | Bittner, C.; Ehrhorn, H.; Bockfeld, D.; Brandhorst, K.; Tamm, M. Organometallics 2017, 36, 3398–3406. doi:10.1021/acs.organomet.7b00519 |

| 28. | Lysenko, S.; Volbeda, J.; Jones, P. G.; Tamm, M. Angew. Chem., Int. Ed. 2012, 51, 6757–6761. doi:10.1002/anie.201202101 |

| 29. | Li, S. T.; Schnabel, T.; Lysenko, S.; Brandhorst, K.; Tamm, M. Chem. Commun. 2013, 49, 7189–7191. doi:10.1039/c3cc43108h |

| 30. | Tamm, M.; Schnabel, T.; Melcher, D.; Brandhorst, K.; Bockfeld, D. Chem. – Eur. J. 2018, 24, 9022–9032. doi:10.1002/chem.201801651 |

| 30. | Tamm, M.; Schnabel, T.; Melcher, D.; Brandhorst, K.; Bockfeld, D. Chem. – Eur. J. 2018, 24, 9022–9032. doi:10.1002/chem.201801651 |

| 73. | Gilbert, T. M.; Landes, A. M.; Rogers, R. D. Inorg. Chem. 1992, 31, 3438–3444. doi:10.1021/ic00042a020 |

| 78. | Gilbert, T. M.; Bauer, C. B.; Bond, A. H.; Rogers, R. D. Polyhedron 1999, 18, 1293–1301. doi:10.1016/s0277-5387(98)00433-1 |

| 83. | Chisholm, M. H.; Cook, C. M.; Huffman, J. C.; Streib, W. E. J. Chem. Soc., Dalton Trans. 1991, 929–937. doi:10.1039/dt9910000929 |

| 96. | Chisholm, M. H.; Folting, K.; Hampden-Smith, M.; Smith, C. A. Polyhedron 1987, 6, 1747–1755. doi:10.1016/s0277-5387(00)86546-8 |

| 97. | Cayton, R. H.; Chisholm, M. H. Inorg. Chem. 1991, 30, 1422–1425. doi:10.1021/ic00006a051 |

| 98. | Chisholm, M. H.; Gallucci, J. C.; Hollandsworth, C. B. Polyhedron 2006, 25, 827–833. doi:10.1016/j.poly.2005.07.010 |

| 23. | Heppekausen, J.; Stade, R.; Goddard, R.; Fürstner, A. J. Am. Chem. Soc. 2010, 132, 11045–11057. doi:10.1021/ja104800w |

| 24. | Heppekausen, J.; Stade, R.; Kondoh, A.; Seidel, G.; Goddard, R.; Fürstner, A. Chem. – Eur. J. 2012, 18, 10281–10299. doi:10.1002/chem.201200621 |

| 25. | Persich, P.; Llaveria, J.; Lhermet, R.; de Haro, T.; Stade, R.; Kondoh, A.; Fürstner, A. Chem. – Eur. J. 2013, 19, 13047–13058. doi:10.1002/chem.201302320 |

| 26. | Willwacher, J.; Heggen, B.; Wirtz, C.; Thiel, W.; Fürstner, A. Chem. – Eur. J. 2015, 21, 10416–10430. doi:10.1002/chem.201501491 |

| 27. | Schaubach, S.; Gebauer, K.; Ungeheuer, F.; Hoffmeister, L.; Ilg, M. K.; Wirtz, C.; Fürstner, A. Chem. – Eur. J. 2016, 22, 8494–8507. doi:10.1002/chem.201601163 |

| 31. | Jyothish, K.; Zhang, W. Angew. Chem., Int. Ed. 2011, 50, 3435–3438. doi:10.1002/anie.201007559 |

| 32. | Jyothish, K.; Wang, Q.; Zhang, W. Adv. Synth. Catal. 2012, 354, 2073–2078. doi:10.1002/adsc.201200243 |

| 33. | Yang, H.; Liu, Z.; Zhang, W. Adv. Synth. Catal. 2013, 355, 885–890. doi:10.1002/adsc.201201105 |

| 34. | Du, Y.; Yang, H.; Zhu, C.; Ortiz, M.; Okochi, K. D.; Shoemaker, R.; Jin, Y.; Zhang, W. Chem. – Eur. J. 2016, 22, 7959–7963. doi:10.1002/chem.201505174 |

| 62. | Listemann, M. L.; Schrock, R. R. Organometallics 1985, 4, 74–83. doi:10.1021/om00120a014 |

| 99. | Schrock, R. R.; Listemann, M. L.; Sturgeoff, L. G. J. Am. Chem. Soc. 1982, 104, 4291–4293. doi:10.1021/ja00379a061 |

| 18. | Haberlag, B.; Wu, X.; Brandhorst, K.; Grunenberg, J.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Chem. – Eur. J. 2010, 16, 8868–8877. doi:10.1002/chem.201000597 |

| 19. | Lysenko, S.; Haberlag, B.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. ChemCatChem 2011, 3, 115–118. doi:10.1002/cctc.201000355 |

| 20. | Lysenko, S.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. J. Organomet. Chem. 2013, 744, 7–14. doi:10.1016/j.jorganchem.2013.03.035 |

| 95. | Coffindaffer, T. W.; Niccolai, G. P.; Powell, D.; Rothwell, I. P. J. Am. Chem. Soc. 1985, 107, 3572–3583. doi:10.1021/ja00298a029 |

| 16. | Beer, S.; Hrib, C. G.; Jones, P. G.; Brandhorst, K.; Grunenberg, J.; Tamm, M. Angew. Chem., Int. Ed. 2007, 46, 8890–8894. doi:10.1002/anie.200703184 |

| 17. | Beer, S.; Brandhorst, K.; Hrib, C. G.; Wu, X.; Haberlag, B.; Grunenberg, J.; Jones, P. G.; Tamm, M. Organometallics 2009, 28, 1534–1545. doi:10.1021/om801119t |

| 21. | Clark, D. N.; Schrock, R. R. J. Am. Chem. Soc. 1978, 100, 6774–6776. doi:10.1021/ja00489a049 |

| 22. | Schrock, R. R.; Clark, D. N.; Sancho, J.; Wengrovius, J. H.; Rocklage, S. M.; Pedersen, S. F. Organometallics 1982, 1, 1645–1651. doi:10.1021/om00072a018 |

| 19. | Lysenko, S.; Haberlag, B.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. ChemCatChem 2011, 3, 115–118. doi:10.1002/cctc.201000355 |

| 86. | Girolami, G. S.; Sattelberger, A. P., Eds. Inorganic Syntheses: Volume 36; Inorganic Syntheses; John Wiley & Sons, Inc.: Hoboken, NJ, U.S.A., 2014. doi:10.1002/9781118744994 |

| 49. | Haberlag, B.; Freytag, M.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Angew. Chem., Int. Ed. 2012, 51, 13019–13022. doi:10.1002/anie.201207772 |

| 51. | Hötling, S.; Bittner, C.; Tamm, M.; Dähn, S.; Collatz, J.; Steidle, J. L. M.; Schulz, S. Org. Lett. 2015, 17, 5004–5007. doi:10.1021/acs.orglett.5b02461 |

| 52. | Estes, D. P.; Bittner, C.; Àrias, Ò.; Casey, M.; Fedorov, A.; Tamm, M.; Copéret, C. Angew. Chem., Int. Ed. 2016, 55, 13960–13964. doi:10.1002/anie.201605129 |

| 53. | Estes, D. P.; Gordon, C. P.; Fedorov, A.; Liao, W.-C.; Ehrhorn, H.; Bittner, C.; Zier, M. L.; Bockfeld, D.; Chan, K. W.; Eisenstein, O.; Raynaud, C.; Tamm, M.; Copéret, C. J. Am. Chem. Soc. 2017, 139, 17597–17607. doi:10.1021/jacs.7b09934 |

| 18. | Haberlag, B.; Wu, X.; Brandhorst, K.; Grunenberg, J.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Chem. – Eur. J. 2010, 16, 8868–8877. doi:10.1002/chem.201000597 |

| 49. | Haberlag, B.; Freytag, M.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Angew. Chem., Int. Ed. 2012, 51, 13019–13022. doi:10.1002/anie.201207772 |

| 50. | Haberlag, B.; Freytag, M.; Jones, P. G.; Tamm, M. Adv. Synth. Catal. 2014, 356, 1255–1265. doi:10.1002/adsc.201400051 |

| 49. | Haberlag, B.; Freytag, M.; Daniliuc, C. G.; Jones, P. G.; Tamm, M. Angew. Chem., Int. Ed. 2012, 51, 13019–13022. doi:10.1002/anie.201207772 |

| 54. | Bittner, C.; Ehrhorn, H.; Bockfeld, D.; Brandhorst, K.; Tamm, M. Organometallics 2017, 36, 3398–3406. doi:10.1021/acs.organomet.7b00519 |

| 73. | Gilbert, T. M.; Landes, A. M.; Rogers, R. D. Inorg. Chem. 1992, 31, 3438–3444. doi:10.1021/ic00042a020 |

| 25. | Persich, P.; Llaveria, J.; Lhermet, R.; de Haro, T.; Stade, R.; Kondoh, A.; Fürstner, A. Chem. – Eur. J. 2013, 19, 13047–13058. doi:10.1002/chem.201302320 |

| 54. | Bittner, C.; Ehrhorn, H.; Bockfeld, D.; Brandhorst, K.; Tamm, M. Organometallics 2017, 36, 3398–3406. doi:10.1021/acs.organomet.7b00519 |

| 100. | Lhermet, R.; Fürstner, A. Chem. – Eur. J. 2014, 20, 13188–13193. doi:10.1002/chem.201404166 |

| 63. | Fürstner, A.; Seidel, G. Angew. Chem., Int. Ed. 1998, 37, 1734–1736. doi:10.1002/(sici)1521-3773(19980703)37:12<1734::aid-anie1734>3.0.co;2-6 |

| 64. | Nicolaou, K. C.; Bulger, P. G.; Sarlah, D. Angew. Chem., Int. Ed. 2005, 44, 4490–4527. doi:10.1002/anie.200500369 |

| 55. | Freudenberger, J. H.; Schrock, R. R.; Churchill, M. R.; Rheingold, A. L.; Ziller, J. W. Organometallics 1984, 3, 1563–1573. doi:10.1021/om00088a019 |

| 60. | Bray, A.; Mortreux, A.; Petit, F.; Petit, M.; Szymanska-Buzar, T. J. Chem. Soc., Chem. Commun. 1993, 197–199. doi:10.1039/c39930000197 |

| 61. | Coutelier, O.; Mortreux, A. Adv. Synth. Catal. 2006, 348, 2038–2042. doi:10.1002/adsc.200606116 |

| 65. | McCullough, L. G.; Listemann, M. L.; Schrock, R. R.; Churchill, M. R.; Ziller, J. W. J. Am. Chem. Soc. 1983, 105, 6729–6730. doi:10.1021/ja00360a040 |

| 66. | Freudenberger, J. H.; Schrock, R. R. Organometallics 1986, 5, 1411–1417. doi:10.1021/om00138a019 |

| 67. | Mortreux, A.; Petit, F.; Petit, M.; Szymanska-Buzar, T. J. Mol. Catal. A: Chem. 1995, 96, 95–105. doi:10.1016/1381-1169(94)00004-2 |

| 22. | Schrock, R. R.; Clark, D. N.; Sancho, J.; Wengrovius, J. H.; Rocklage, S. M.; Pedersen, S. F. Organometallics 1982, 1, 1645–1651. doi:10.1021/om00072a018 |

| 58. | Wengrovius, J. H.; Sancho, J.; Schrock, R. R. J. Am. Chem. Soc. 1981, 103, 3932–3934. doi:10.1021/ja00403a058 |

| 59. | Schrock, R. R. J. Organomet. Chem. 1986, 300, 249–262. doi:10.1016/0022-328x(86)84064-5 |

| 60. | Bray, A.; Mortreux, A.; Petit, F.; Petit, M.; Szymanska-Buzar, T. J. Chem. Soc., Chem. Commun. 1993, 197–199. doi:10.1039/c39930000197 |

| 61. | Coutelier, O.; Mortreux, A. Adv. Synth. Catal. 2006, 348, 2038–2042. doi:10.1002/adsc.200606116 |

| 62. | Listemann, M. L.; Schrock, R. R. Organometallics 1985, 4, 74–83. doi:10.1021/om00120a014 |

| 55. | Freudenberger, J. H.; Schrock, R. R.; Churchill, M. R.; Rheingold, A. L.; Ziller, J. W. Organometallics 1984, 3, 1563–1573. doi:10.1021/om00088a019 |

| 56. | Buhro, W. E.; Chisholm, M. H. Adv. Organomet. Chem. 1987, 27, 311–369. doi:10.1016/s0065-3055(08)60030-1 |

| 57. | Schrock, R. R. Chem. Rev. 2002, 102, 145–180. doi:10.1021/cr0103726 |

| 56. | Buhro, W. E.; Chisholm, M. H. Adv. Organomet. Chem. 1987, 27, 311–369. doi:10.1016/s0065-3055(08)60030-1 |

| 53. | Estes, D. P.; Gordon, C. P.; Fedorov, A.; Liao, W.-C.; Ehrhorn, H.; Bittner, C.; Zier, M. L.; Bockfeld, D.; Chan, K. W.; Eisenstein, O.; Raynaud, C.; Tamm, M.; Copéret, C. J. Am. Chem. Soc. 2017, 139, 17597–17607. doi:10.1021/jacs.7b09934 |

| 54. | Bittner, C.; Ehrhorn, H.; Bockfeld, D.; Brandhorst, K.; Tamm, M. Organometallics 2017, 36, 3398–3406. doi:10.1021/acs.organomet.7b00519 |

| 54. | Bittner, C.; Ehrhorn, H.; Bockfeld, D.; Brandhorst, K.; Tamm, M. Organometallics 2017, 36, 3398–3406. doi:10.1021/acs.organomet.7b00519 |

© 2018 Ehrhorn et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0). Please note that the reuse, redistribution and reproduction in particular requires that the authors and source are credited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (https://www.beilstein-journals.org/bjoc)