Abstract

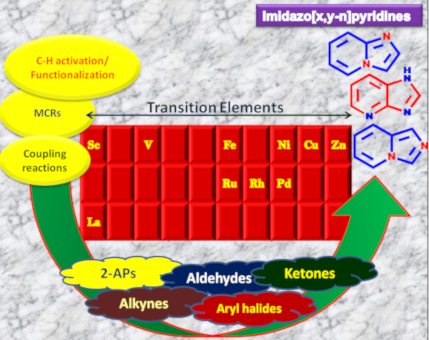

A comprehensive account of recent advances in the synthesis of imidazopyridines, assisted through transition-metal-catalyzed multicomponent reactions, C–H activation/functionalization and coupling reactions are highlighted in this review article. The basic illustration of this review comprises of schemes with concise account of explanatory text. The schemes depict the reaction conditions along with a quick look into the mechanism involved to render a deep understanding of the catalytic role. At some instances optimizations of certain features have been illustrated through tables, i.e., selectivity of catalyst, loading of the catalyst and percentage yield with different substrates. Each of the reported examples has been rigorously analyzed for reacting substrates, reaction conditions and transition metals used as the catalyst. This review will be helpful to the chemists in understanding the challenges associated with the reported methods as well as the future possibilities, both in the choice of substrates and catalysts. This review would be quite appealing to a wider range of organic chemists in academia and industrial R&D sectors working in the field of heterocyclic syntheses. In a nutshell, this review will be a guiding torch to envisage: (i) the role of various transition metals in the domain dedicated towards method development and (ii) for the modifications needed thereof in the R&D sector.

Graphical Abstract

Introduction

The structural diversity and biological importance of nitrogen-containing heterocycles have blossomed in the last many years. These heterocyclic scaffolds occupy a pivotal role in the realm of both natural products and synthetic organic chemistry. Their importance as precursors to many biologically active compounds has created a tremendous amount of focused attention on developing methods to functionalize these systems [1,2]. In one such context, imidazopyridines are one of the fascinating classes of fused N-heterocyclic scaffolds of versatile concern. Their chemistry has drawn substantial attention in last few years owing to their involvement in various medicinal applications viz., anti-inflammatory, anticancer, antibacterial, anxioselective and antiprotozoal [3-5]. Furthermore, a number of drugs embracing the imidazopyridine (IP) skeleton have been commercially marketed with their trade names as minodronic acid (for the treatment of osteoporosis), olprinone (for acute heart failure), zolpidem (for treatment of insomnia), zolimidine (antiulcer drug), alpidem and saripidem (anxiolytic agents) and some are under development, like GSK812397 (for the treatment of HIV), ND-09759 and Q203 (for tuberculosis) (Figure 1) [6-10].

Figure 1: Various drugs having IP nucleus.

Figure 1: Various drugs having IP nucleus.

The synthesis of imidazopyridines (IPs) is widely described in the literature encompassing a number of reactions like oxidative cyclizations [11], oxidative coupling reactions [12], Vilsmeier type cyclizations [13], intramolecular aminooxygenation/C–H amination reactions [14,15], Groebke–Blackburn–Bienayme (GBB) reactions [16-18] and many more. It was observed that most of the methods utilize 2-aminopyridines as one of the starting materials due to its binucleophilic nature; associated with exocyclic amino group and endocyclic pyridinium nitrogen [19]. Recently, A3 coupling of alkynes, aldehydes, and aminopyridines have been developed for efficient syntheses of IPs [20]. In recent years much attention has been paid towards the exploration of transition metals (TMs) as homogeneous as well as heterogeneous catalytic system like Pd(OAc)2 [21], CuI [22], ZnO [23], ZnI2 [24], Cu(OTf)2 [25], Sc(OTf)3 [26], RuCl3 [27], [Cp*RhCl2]2 (Cp*: pentamethylcyclopentadiene) [28], FeCl3 [29], NiFe2O4 [30], CuO [31], mixed-metal oxides [32] etc. Some of the reactions have utilized metal salts like Cu(OAc)2, Ag2CO3, AgOAc, etc. (reference papers of this review) as an oxidant to carry out the synthesis among which preference was given to the use of oxygen and air as greener oxidants [33].

During the writing of this review, we came across some reviews on IPs, however, their coverage is limited to the imidazo[1,2-a]pyridine nucleus deriving from either a particular starting material or to one type of reaction procedure (particularly C–H activation) with literature up to 2015 [34-39]. This review covers a substantial time period of the literature, from the year 2006 to August 2018 (except for the reports mentioned under previously reported reviews), with state-of-the-art methodologies, and reflecting some of the changing approaches and challenges encountered in the field of catalytic synthetic chemistry.

The prime focus of this review is on the TM-catalyzed synthesis of differently fused IPs. In this review, a concise account on imidazopyridine (IP) syntheses has been documented for the benefit of the chemists working in the field. This will assist them in unraveling the possibilities for efficient synthesis of different IP derivatives supported by TMs as the catalysts. It will be of great help for them to consider this as ready reckoner of rich literature for TM-catalyzed IP syntheses and to help the chemists to understand some of the challenges associated with the reported methodologies. Amongst various reported TMs, the participation of copper as the catalyst has been used in the largest number of cases followed by the use of palladium, rhodium, and others. It has been further observed that lanthanum, scandium, and vanadium have been very seldomly used. An overview of the participation of various TMs is depicted in Figure 2.

![[1860-5397-15-165-2]](/bjoc/content/figures/1860-5397-15-165-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: Participation percentage of various TMs for the syntheses of IPs.

Figure 2: Participation percentage of various TMs for the syntheses of IPs.

The role of copper in synthetic chemistry

In comparison with other TMs copper-metal-based catalysts are cheap, nontoxic, abundant and environmentally benign [40]. Chemistry of Cu is extremely rich as it can exist in variable oxidation states (Cu(0), Cu(I), Cu(II), and Cu(III)). Copper has been known for a long time to act as a catalyst for cross-coupling reactions (Ullmann–Goldberg reaction), cyanation of aryl halides (Rosenmund–von Braun reaction), Hurtley reaction and intermolecular oxidative cyclization of haloalkynes [41-44]. Various copper salts have been used as Lewis acid in homogeneous catalysis. CuO nanoparticles (NPs) were used for C–N, C–S, C–O cross-coupling reactions and C-arylation. Recently, exploiting the cross-coupling tendency of CuO NPs, Reddy et al. have reported their use as a heterogeneous, recyclable catalyst in the N-arylation of indoles [45,46]. Copper catalysts have shown exceptional enantioselectivity for reactions such as hydrosilylation, hydroboration, and heterogeneous as well as homogeneous hydrogenation [47-49]. Also, the copper salts found used as oxidants in a number of organic reactions. In the syntheses of IPs, various forms of copper viz., salts, complexes, MOFs, oxides, and nanoparticles (NPs) have been used as the catalytic system in both multicomponent reactions (MCRs) as well as derivatization methodologies.

The role of palladium in synthetic chemistry

Pd-catalyzed cross-coupling reactions have laid down the foundation of new C–C bond formations [50,51]. A number of Pd-catalyzed organic reactions viz., C–N coupling, amination and intramolecular amidation, cyclization, and Suzuki–Miyaura coupling [52-55] have recently been reported in the literature. The Pd-catalyzed Sonogashira reaction has successfully constructed arylated internal alkynes that are important intermediates in organic synthesis, molecular electronics and polymers [56]. C–N bond forming reactions between aryl halides and amines/amides/sulfonamides have been extensively studied in the past few years [57]. Recently, Buchwald and Castillo have reviewed the exceptional utility of Pd-catalyzed C–N cross-coupling reactions for the preparation of anilines and aniline derivatives [58]. In many of the reactions, palladium was used along with a co-catalyst to enhance its catalytic activity. It is revealed from the literature that next to the copper, palladium catalysts in the form of salts (with or without ligands), complexes, NPs, etc. find their usage on mass scale syntheses of IPs.

The role of zinc in synthetic chemistry

Zinc salts being inexpensive, environmentally benign, low in toxicity and fits to the tenets of green chemistry. Zinc in the form of its salts, complexes (chelated by mono/di/tri/tetradentate ligands), oxides and sulfides proved to be a promising and active catalyst for organic chemists in both homogeneous as well as heterogeneous reaction systems [23,59,60]. They have been employed for a number of organic reactions viz., hydrosilylation of aldehydes and ketones, acetylation reactions, redox reactions, oxidative esterification, etc. [61-63]. Thus, in concern with increasing demand for sustainable development, a growing number of catalytic systems based on zinc with excellent activity has been designed and used.

The role of iron in synthetic chemistry

Iron being the most abundant heavy element on earth with low biological toxicity along with cost economy and high reactivity was explored by Kharasch and Fields in the 1940s and Tamura and Kochi in 1970s in the field of catalysis [64,65]. Iron in the form of its salts, oxides, iron–NHC complexes, iron pincer complexes, ferrocenes and half sandwiched iron complexes found to be the center of attraction in the field of catalytic organic synthesis. Variable oxidation states of iron (–2 to +5) allow it to catalyze a number of organic reactions viz., nucleophilic substitutions, addition reactions, hydrogenations/hydrosilylations, cycloisomerizations, electrophilic aromatic substitutions, cross-coupling reactions, oxidative additions and reductive eliminations [66]. Iron–catalyzed C–H functionalization helped in the introduction of various organic groups to numerous substrates [67,68]. Recently attention has been diverted towards the use of magnetic NPs, in this context iron oxide played a pivotal role as a catalyst or as support for some homogeneous or other metal catalysts for the sake of easy recovery and reusability [69].

The role of rhodium in synthetic chemistry

Rhodium in the form of Wilkinsons catalyst [RhCl(PPh3)3] played a major role in the field of catalysis [70]. Rhodium is capable of catalyzing a number of organic reactions viz., heterocyclic alkylation and arylation with a high level of functional group compatibility, intramolecular alkylations, inter and intramolecular C–H bond activation and regio/stereoselective homocoupling of alkynes [71-73]. Group of Cho and Chang have unprecedentedly reported a Rh catalytic system for facile addition of heteroarenes to both alkenes and alkynes [74]. Rh(I)/Rh(II)/Rh(III) catalysts have been used in asymmetric syntheses of chiral heterocycles that have been effectively reviewed by Chen and Xu in 2017 [75].

The role of ruthenium in synthetic chemistry

Over the past decade, Ru and its complexes were used as a catalyst in various organic processes and have attracted considerable interest in this regard. Ru has efficiently catalyzed C–H activation reactions for C–C bond formation, aza-Michael reactions and many more MCRs [27,76,77]. During the writing of this review, we came through the fact that ruthenium catalysts were mostly used for functionalization/derivatization reactions compared to MCRs in the syntheses of IPs.

The role of lanthanum/scandium/nickel/vanadium in synthetic chemistry

The application of scandium complexes in organic chemistry has been very scarce due to their low availability and difficulties in separation. This problem was resolved by the introduction of scandium triflate (Sc(OTf)3) as a promising reusable Lewis acid in Diels–Alder reactions by Kobayashi [78]. However, in recent years scandium(III) trifluoromethanesulfonate (Sc(OTf)3) has emerged as an efficient, mild, commercially available, inexpensive, water-tolerant Lewis acid catalyst in the formation of both carbon–carbon and carbon–heteroatom bonds, and thereby the formation of various biologically promising organic compounds [68]. Important advances in scandium-catalyzed chemistry include [4 + 2] and [2 + 2] cycloaddition reactions, Baeyer–Villiger reactions, epoxidations of alkenes, intramolecular ring expansions, hydroaminations, and amination reactions and carbonyl–ene reactions for the formation of C–C bond. Scandium-catalyzed reactions represented remarkable enantioselectivities [79-81]. Recently the group of Rani has developed fly ash-supported Sc(OTf)3 for Friedal–Crafts acylation reaction, also the group of Fukuzawa has exploited Sc(OTf)3 in the synthesis of N-substituted 1,4-DHPs [26,82].

Enhancement in reactivity and selectivity of many reactions, ability to polarize bonds upon coordination and thus altering their electrophilicity made lanthanides a catalyst of choice. Lanthanum complexes are widely used in synthetic chemistry for cycloadditions, reductions, benzimidazole syntheses, Biginelli reactions, hydrophosphinations of unsaturated substrates, double hydrophosphinylations of unactivated nitriles, Grignard additions, C–C bond formations, and ring opening reactions [83-87]. Along with these nickel and vanadium were also well known to catalyze a number of organic reactions. Recent reviews published on the catalytic applications of these metals in various forms have underlined the indispensable contribution in the field of TM catalysis [88]. Vanadium in the form of vanadium oxide and complexes has been reported to participate in numerous organic reactions including aerobic oxidation [89,90]. A report of Carsten Bolm has delineated the use of vanadium complexes in enantioselective oxidation of alcohols and asymmetric sulfide oxidation [91]. Diverse reactivity, cost efficiency and variable oxidation state [Ni(0)–Ni(IV)] associated with nickel led to remarkable developments in the field of catalytic applications [68]. Nickel catalysis involved cycloaddition, cyclization, C–H bond functionalization, and multicomponent coupling reactions [92,93].

Review

Multicomponent reactions for the synthesis of imidazopyridines

One of the major challenges in organic synthesis is the creation of diverse and complex molecules from simple and readily available substrates. MCRs constitute one of the most efficient tools in modern synthetic chemistry, with high atom efficiency, quick and simple implementation, ecofriendliness and a diverse target-oriented synthesis [94]. In addition, both waste production and multistep problems resulting in the expenditure of human labor are significantly reduced. MCRs have been given much attention in various research fields, such as the discovery of lead compounds in medicinal chemistry, or combinatorial chemistry [95,96].

Copper-catalyzed synthetic protocols

Ghosh and Mishra [97] have successfully reported the synthesis of imidazo[1,2-a]pyridines in a three-component domino reaction of aldehydes 1, 2-aminopyridines (2-APs) 3 and terminal alkynes 2, catalyzed by CuI and co-catalyzed by the NaHSO4·SiO2 system (Scheme 1).

Scheme 1: CuI–NaHSO4·SiO2-catalyzed synthesis of imidazo[1,2-a]pyridines.

Scheme 1: CuI–NaHSO4·SiO2-catalyzed synthesis of imidazo[1,2-a]pyridines.

The reaction performed with CuI alone gave a moderate yield of the product (only 45%) whereas NaHSO4·SiO2 alone was unable to complete the reaction. Therefore, the synergistic effect of the CuI–NaHSO4·SiO2 system for successful completion of the reaction was proven under optimized conditions. (Scheme 2, A, B and C). In order to ascertain the mechanistic pathways, the reaction was performed in two different ways; in a first way, 2-APs 3 were allowed to react with aldehydes 1 in the presence of NaHSO4·SiO2 and the product obtained was refluxed with phenylacetylene (as terminal alkyne, 2) in the presence of CuI to obtain the product, however, in the second pathway, 1 and 2 were taken together in the presence of CuI and the product obtained was treated with 3 in the presence of NaHSO4·SiO2 to produce the desired IP. Both the routes resulted in the same final product without any substantial change in the yield. The generality of the reaction was studied with differently substituted 1, 3 and 2 having both electron-withdrawing (EW) and electron-donating groups (EDGs) at different positions on the phenyl ring. However, the use of aliphatic aldehydes such as 3-methylbutanal and cyclohexanecarbaldehyde and aliphatic acetylene viz., hex-1-yne resulted in a comparatively lower yield of 66, 70 and 60%, respectively. Heteroaromatic aldehydes such as thiophene-2-carbaldehyde on the other hand resulted in appreciable yields under similar reaction conditions. The authors have successfully constructed a big library of 28 compounds with varying structure.

Scheme 2: Experimental examination of reaction conditions.

Scheme 2: Experimental examination of reaction conditions.

In 2013, Gao et al. have exploited the TM-catalyzed nucleophilic addition reactions of haloalkynes 5 followed by carbon–nitrogen bond formation, as an efficient methodology for the synthesis of 2-haloimidazopyridines 6 [44] The reaction was catalyzed by copper in an atmosphere of oxygen for approximately 12 h of reaction time. The major challenge before their developed protocol was to retain the reactive halide substituent in the product which was successfully overcome by this protocol along with the synthesis of pyrazines and pyrimidines in high yield (Scheme 3).

Scheme 3: One-pot tandem reaction for the synthesis of 2-haloimidazopyridines.

Scheme 3: One-pot tandem reaction for the synthesis of 2-haloimidazopyridines.

Furthermore, easy functionalization of the products from the viewpoint of reactive halide made them valuable synthons. Molecular oxygen used served the role of oxidant for generating a Cu(III) intermediate during the reaction. The absence of oxygen atmosphere gave the yield in a slightly lesser amount with increased loading of catalyst to almost 1 equivalent. This reaction avoided the use of any additive; moreover, the presence of bases in this methodology resulted in homocoupling of bromoalkynes. Among the examined Cu(I) and Cu(II) salts, Cu(OTf)2 was proven to be the optimal one. Both EW and EDGs were well tolerated except 2-amino-6-methylpyridine which might be sterically hindered due to methyl group at 6-position. The use of aliphatic alkynes gave an optimal yield of the final product in the range of 50–78%. Successful formation of the product on application of 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO: a radical scavenger) has nullified the probability of radical pathway. It was thought to be initiated by the coordination of 2-AP to Cu(OTf)2, forming an intermediate 7, that was followed by migratory insertion by haloalkyne (Scheme 4). The organocopper species 8 thus formed would undergo deprotonation/oxidation and finally reductive elimination to give the cyclized product 6 (Scheme 4). Along with the unprecedented intermolecular oxidative diamination of haloalkynes, mild reaction conditions and efficient conversion of the alkyl-substituted haloalkynes to the halogenated product were great improvements over existing methods. Stimulated by the work of Luz et al. [98] and Phan et al. [99] with Cu(BDC)MOF (BDC: 1,4-benzenedicarboxylate), Puthiaraj and co-workers have unprecedently discovered the catalytic activity of this metal-organic framework (MOF) for the synthesis of imidazo[1,2-a]pyridines [100]. The three-component, one-pot reaction between 1, 3 and nitromethane (10, Scheme 5) involved an intermolecular aza-Michael addition with a subsequent intramolecular cyclization catalyzed by Cu(BDC)MOF. Further, the LC–MS study of the reaction mixture has shown the imine formation to be the major pathway rather than β-nitrostyrene. The reaction involved a two-step reaction mechanism in which aza-Michael adduct 13 was formed in the first step which was converted to the final product via radical cation intermediate 17 in the second step (Scheme 6). This additive-free approach offered an easy separation and reusability of heterogeneous catalyst along with the use of air as environmentally benign oxidant.

Scheme 4: Mechanistic scheme for the synthesis of 2-haloimidazopyridine.

Scheme 4: Mechanistic scheme for the synthesis of 2-haloimidazopyridine.

Scheme 5: Copper-MOF-catalyzed three-component reaction (3-CR) for imidazo[1,2-a]pyridines.

Scheme 5: Copper-MOF-catalyzed three-component reaction (3-CR) for imidazo[1,2-a]pyridines.

Scheme 6: Mechanism for copper-MOF-driven synthesis.

Scheme 6: Mechanism for copper-MOF-driven synthesis.

The use of zinc and iron MOFs have resulted in lesser yield than Cu-MOF. The reaction has well tolerated different substituent on the reactants except for 4-NO2; 3,4-dichlorobenzaldehyde, 2-aminopyrimidine, and 2,4,6-triamino-1,3,5-triazine which failed to give the desired product. Also, benzaldehydes substituted with EDGs at p- and m-positions gave a higher yield than sterically hindered o-substituents and EWGs. Moreover, the absence of metal leaching as tested by atomic absorption spectroscopy (AAS) demonstrated the heterogeneous nature of the used catalyst. Recently, a robust, ligand and additive-free heterogeneously catalyzed synthesis of imidazo[1,2-a]pyridines from 3 and ketones 20 has been reported (Scheme 7) [101]. Titania-supported CuCl2 (CuCl2/nano TiO2) played the role of catalyst in this transformation under aerobic conditions. Titania support helped in recyclability of the copper salt to four synthetic cycles without loss in activity. In addition to this, TiO2 is more stable, abundant, nontoxic, and economical [102]. Out of different supports examined like Al2O3, ZrO2, CeO2, SiO2, Al-Ti, OMS-2, C, etc., TiO2 was found to be the best for this transformation. Furthermore, a library of compounds was synthesized considering ketones having ED and EWGs, with sensitive –NO2 groups along with heteroaromatic ketones as well as α,β-unsaturated ketones. Differently substituted compound 3 (except –NO2 substitution) gave moderate to good yields (55–84%). Moreover, the protocol has demonstrated the successful synthesis of drug zolimidine on a gram scale. The mandatory role of oxygen or air as an oxidant for this reaction was proved by reaction failure under the nitrogen atmosphere. This synthesis ruled out the possibility of Ortoleva–King reaction under these conditions as the use of a catalytic amount of iodine in the absence of copper did not result in the desired product keeping the reaction conditions intact. However, based on control experiments and the works of Zhang and Ma’s group [103,104], oxidative C–H functionalization was expected to be more likely involved in the cyclization strategy (Scheme 8).

Scheme 7: Heterogeneous synthesis via titania-supported CuCl2.

Scheme 7: Heterogeneous synthesis via titania-supported CuCl2.

Scheme 8: Mechanism involving oxidative C–H functionalization.

Scheme 8: Mechanism involving oxidative C–H functionalization.

Heterogenization of organic catalysts on Fe3O4 NPs has attracted much attention as these catalysts can be recovered by an external magnetic field and reused in subsequent reactions. Some metal complexes of 2,2-biimidazole (H2Biim) found to be effective catalysts in many organic transformations [105,106]. Inspired from the history of IP synthesis Tajbakhsh et al. have utilized the biimidazole Cu(I) complex supported on magnetic Fe3O4 (MNP@BiimCu) as a heterogenous catalyst for the synthesis of imidazo[1,2-a]pyridine in an aqueous medium (Scheme 9) [107]. By their approach, they have avoided the use of toxic reagents and solvents, harsh reaction conditions and long reaction times. The use of a heterogeneous catalyst and water made this method a green and sustainable approach for organic transformations.

Scheme 9: Heterogeneous synthesis of IPs.

Scheme 9: Heterogeneous synthesis of IPs.

This transformation involved the well known three-component reaction of 3 with 1 and 2 in an aqueous medium (Scheme 9). In order to increase the solubility of reactants in aqueous medium cationic surfactant (cetyl trimethylammonium bromide: CTAB) has been used which has also increased the yield of the product. Aliphatic aldehydes resulted in lower yields (65 and 76%) whereas dimethylamino- or nitro-substituted aldehydes did not result in the target compound that might be due to the deactivation caused by coordination of these groups with the catalyst. Metal–carbene complexes attracted the attention of organic chemists and have become an important branch of organometallic chemistry. Recently in 2014, metal–carbene complexes have been used as catalysts for the synthesis of imidazo[1,2-a]pyridines, via Cu(I) and Pd(II)-catalyzed cyclization (Scheme 10) [108]. The remarkable feature of this report was the metal carbene complex-catalyzed, one-pot process for the formation of C=O and C=C bonds to prepare functionalized imidazo[1,2-a]pyridines. Screening of the reaction conditions has proven the CuI–bipyridine (bipy) combination as the best catalyst–ligand symbiosis for this transformation at room temperature. In this synthesis, temperature and atmosphere both played the decisive role in product yield, as the reaction carried out at higher temperatures and under anaerobic atmosphere resulted in a trace amount of product. Differently substituted 2-aminopyridines 3 along with aryl and alkyl as well as terminal propiolaldehydes 25 were well tolerated.

Scheme 10: One-pot regiospecific synthesis of imidazo[1,2-a]pyridines.

Scheme 10: One-pot regiospecific synthesis of imidazo[1,2-a]pyridines.

The yield was >70% except for the products of 3-methyl- and 5-methyl-2-AP with propiolaldehyde. The protocol has also demonstrated a novel Pd(OAc)-catalyzed synthesis of 3-vinylimidazo[1,2-a]pyridines via 1,2-H shift of Pd–carbene complexes. This methodology has been considered as an efficient, one-pot regiospecific synthesis for a number of biologically active imidazo[1,2-a] pyridine derivatives [108]. Encouraged by the direct synthetic strategies for imidazo[1,2-a]pyridines (IPs), Donthiri et al. have reported an efficient Cu-catalyzed C–H functionalization of pyridines with vinyl azide derivatives [109]. Their use of vinyl azide derivatives 29 for the synthesis of IPs was unprecedented. In this strategy, vinyl azide acts as a source of nitrogen with the liberation of N2 as a benign byproduct under aerobic and mild reaction conditions (Scheme 11). The protocol has surpassed the use of 2-AP as one of the mostly used reactants and replaced it with pyridine 28.

Scheme 11: Vinyl azide as an unprecedented substrate for imidazo[1,2-a]pyridines.

Scheme 11: Vinyl azide as an unprecedented substrate for imidazo[1,2-a]pyridines.

The reaction proceeded through both radical and ionic pathways, yielding the products in moderate to good yields. The ionic pathway was similar to that reported by Yu et al. [110] on the other hand the radical pathway was supposed to occur as shown in Scheme 12. This involved generation of iminyl radical intermediate 31 by homolytic cleavage of the C–N bond which was followed by reductive elimination and oxidation to yield final compound 21. Inspired by the work of Wang et al. [15] who have exploited a Cu(II)-catalyst for the construction of pyrido[1,2-a]benzimidazoles Li and Xie have described a Cu(I)-catalyzed direct transannulation of N-heteroaryl aldehydes/ketones 36a,b with aryl/alkylamines 35 to form imidazo[1,5-a]pyridines 37 [11]. They have utilized aerial oxygen as a greener oxidant for oxidation during the reaction (Scheme 13). Mechanistically, the reaction involved the formation of radical intermediates, as use of TEMPO inhibited intramolecular C(sp3)–H amination of imine species. Aerial oxidation of the Cu(I) species bonded to the N-atom of pyridine and imine 39 resulted in Cu(II) superoxo radical intermediate 40. This was followed by intramolecular hydrogen abstraction from the sp3 carbon atom leading to the formation of six-membered Cu(III) species 42. Furthermore, consecutive isomerization/oxidation/reductive elimination leads to the generation of final compound 37 with regeneration of the Cu(I) catalyst (Scheme 14).

Scheme 13: Cu(I)-catalyzed transannulation approach for imidazo[1,5-a]pyridines.

Scheme 13: Cu(I)-catalyzed transannulation approach for imidazo[1,5-a]pyridines.

Scheme 14: Plausible radical pathway for the synthesis of imidazo[1,5-a]pyridines.

Scheme 14: Plausible radical pathway for the synthesis of imidazo[1,5-a]pyridines.

The presence of EDGs as compared to EWGs on N-heteroaryls gave a good yield. On the other hand, benzylamine has well tolerated both the EW and EDGs to give the products in appreciable yields. Moreover, various aliphatic amines irrespective of their steric hinderance resulted in appreciable yields of the product. Inspired from the excellent catalytic activity exhibited by Cu(0) NPs Chenglong et al. have reported an efficient, three-component one-pot reaction for the synthesis of imidazo[1,2-a]pyridines [111]. The protocol enjoyed a solvent-free domino reaction between compounds 3, 1 and 2 under nitrogen atmosphere at 120 °C (Scheme 15). However, the reaction was unsuccessful with aliphatic and low-boiling aldehydes (as the reaction was taking place at high temperature). The reaction mechanism involved a Cu-NPs-mediated C–H bond activation of the alkyne which further reacted with the iminium ion to form propargylamine 45 and Cu NPs were again released into the system. The propargylamine formed went through 5-exo-dig cyclization to form IPs (Scheme 16). An unprecedented CuI-catalyzed two-component synthesis of isoxazolylimidazo[1,2-a]pyridines 49 was reported by the group of Rajanarendar under aerial conditions. Differently substituted 2-AP 3 and substituted nitrostyrylisoxazole 48 were used as reaction substrates at 80 °C (Scheme 17) [112]. The method has tolerated a variety of functional groups with good yield. Moreover, highly functionalized imidazo[1,2-a]pyridines have been synthesized by applying a Sonogashira coupling reaction to the product of 4-bromo-substituted nitrostyrylisoxazole 48a (Scheme 18). The attractive feature was successful substitution of the bromo atom with terminal alkynes. Different alkynes applied gave a good yield of up to 81%. This reaction provided a direct and efficient method to produce highly functionalized imidazo[1,2-a]pyridines.

Scheme 15: A solvent-free domino reaction for imidazo[1,2-a]pyridines.

Scheme 15: A solvent-free domino reaction for imidazo[1,2-a]pyridines.

Scheme 16: Cu-NPs-mediated synthesis of imidazo[1,2-a]pyridines.

Scheme 16: Cu-NPs-mediated synthesis of imidazo[1,2-a]pyridines.

Scheme 17: CuI-catalyzed synthesis of isoxazolylimidazo[1,2-a]pyridines.

Scheme 17: CuI-catalyzed synthesis of isoxazolylimidazo[1,2-a]pyridines.

Scheme 18: Functionalization of 4-bromo derivative via Sonogashira coupling reaction.

Scheme 18: Functionalization of 4-bromo derivative via Sonogashira coupling reaction.

Mechanistically, the reaction proceeded by Michael type addition of 2-AP and nitrostyryl isoxazole. Further, a CuI-promoted one-electron oxidation followed by loss of a hydrogen radical and a proton, led to the formation of enamine 55. The so formed enamine underwent single-electron transfer (SET) with CuI followed by hydride abstraction/intramolecular nucleophilic addition and loss of a proton forming the desired compound 49 (Scheme 19).

Cu(I)-catalyzed intramolecular oxidative C–H amidation of N-pyridylenaminones 61 for the synthesis of imidazo[1,2-a]pyridine derivatives have been reported by the group of R. K. Reddy [113]. The protocol offered an open air, ligand- and base-free methodology with an extension towards the synthesis of imidazo[1,2-a]pyrazines/pyrimidines and benzo[d]imidazo[2,1-b]thiazoles. For this reaction, they have synthesized the respective enaminones 61 by conjugative addition of heteroarylamines 3 with α,β-ynones 60 (Scheme 20). Optimization of the reaction inferred that CuI with dimethylformamide (DMF) at 100 °C under air would be the best conditions for a maximum yield. The reaction viability was also tested without the isolation of product 61 in a one-pot fashion, by reacting 2-AP 3 and 1,3-diphenylprop-2-yn-1-one 60 under the given conditions. This one-pot methodology provided the final product with a yield of 50% (Scheme 21). For pyridine synthesis, both N-pyridyl as well as enone fragment have well tolerated a large number of functional groups. Also, the effect of steric congestion has been nullified as the product yield was up to 95%. Mechanistically, an intermediate complex was formed by coordination of the pyridine ring with Cu compound 63. The intermediate thus obtained was further oxidized by oxygen (air) to the Cu(III) complex 64, which on reductive elimination gave the final product 62 (Scheme 22). Also, Irina V. Rassokhina and others have employed Cu(OAc)2 for the synthesis of imidazo[1,2-a]pyridines under aerobic conditions (Scheme 23) [114]. They have performed aminomethylation and cycloisomerization of propiolates 66 with imines 65 for the first time, using aerobic conditions with a Cu(II) catalyst. EWGs on aldehydes gave a high yield of the product whereas the yield was decreased with EDGs (2,4-OMe, 4-Me, 5-Br, 5-Me and 4-Et ≤37%). Also, the reaction of unsubstituted benzaldehyde with substituted 2-AP gave poor yields (5-Cl, 5-Me; 14 and 23%, respectively) whereas no target compound was synthesized with unsubstituted 2-AP 3.

Scheme 20: Cu(I)-catalyzed intramolecular oxidative C–H amidation reaction.

Scheme 20: Cu(I)-catalyzed intramolecular oxidative C–H amidation reaction.

Scheme 21: One-pot synthetic reaction for imidazo[1,2-a]pyridine.

Scheme 21: One-pot synthetic reaction for imidazo[1,2-a]pyridine.

Scheme 23: Cu(OAc)2-promoted synthesis of imidazo[1,2-a]pyridines.

Scheme 23: Cu(OAc)2-promoted synthesis of imidazo[1,2-a]pyridines.

This methodology also provides a simple and concise route for the synthesis of the anxiolytic drug alpidem. The use of a Cu(I) catalyst was not fruitful for this synthesis. This might be due to the formation of Cu(II)-mediated propargylamine 68 from the alkyne and Schiff base-copper complex that was cyclized and aromatized to form the target compound 67 (Scheme 24).

Scheme 24: Mechanism for aminomethylation/cycloisomerization of propiolates with imines.

Scheme 24: Mechanism for aminomethylation/cycloisomerization of propiolates with imines.

Kumar et al. have described a Cu(OTf)2-catalyzed three-component reaction for the synthesis of imidazo[1,2-a]pyridines under microwave irradiation [115]. 1-Butyl-3-methylimidazolium tetrafluoroborate ([bmim]BF4) was used as ionic liquid for this three-component reaction of pyridine-2(1H)-one 70, acetophenone 71 and o-tosylhydroxylamine (72, Scheme 25). The reason behind the use of an ionic liquid as reaction medium was its environmentally benign nature, air stability and significantly its compatibility with various organic compounds.

Scheme 25: Three-component synthesis of imidazo[1,2-a]pyridines.

Scheme 25: Three-component synthesis of imidazo[1,2-a]pyridines.

This reaction was first of its kind in using pyridine-2(1H)-ones (precursor of 2-AP) directly for the synthesis of IPs. The generality of the present protocol lied in tolerance towards differently substituted reacting compounds. Acetophenones bearing EWGs reacted faster than those with EDGs as these groups might be unfavorable for the nucleophilic addition step during the reaction (Figure 3). The advantageous point of the protocol involves the recovery and reusability of the copper catalyst dissolved in ionic liquid to four synthetic cycles.

Figure 3: Scope of pyridin-2(1H)-ones and acetophenones.

Figure 3: Scope of pyridin-2(1H)-ones and acetophenones.

Nanotechnology coupled with heterogeneous catalysis has emerged as an efficient field of catalysis for various organic transformations. Inspired from this Bagdi et al. have reported a nano-copper oxide-mediated three-component A3 coupling reaction for the synthesis of 2-triazolylimidazo[1,2-a]pyridine 74 (Scheme 26) [31].

Scheme 26: CuO NPS-promoted A3 coupling reaction.

Scheme 26: CuO NPS-promoted A3 coupling reaction.

The reaction involved the use of copper oxide as a catalyst and sodium ascorbate as a reducing agent using triazolyl aldehyde 73, amidine 3 and terminal alkynes 2 as reaction substrates at 70 °C (Scheme 26). Here sodium ascorbate (NaOAs) helped in the reduction of Cu(II) to Cu(I) which then reacted with the alkyne moiety. The species thus formed participated in the reaction by reacting with imine of aldehyde and amidine. The intermediate thus formed undergo 5-exo-dig cyclization and 1,3-H shift to form the final product. This was an unprecedented report for the synthesis of a library of targeted moieties using a nano-click catalyst. The triazole precursor was also synthesized by the group using nano-copper oxide in an aqueous medium. The reaction has well tolerated variedly substituted starting materials whether aromatic or aliphatic, only in case of triazoles substituted with an acetate group the final product was obtained in 66% yield. An open-flask, one-pot, Cu(II)-catalyzed ligand-free approach towards C–N bond formation was reported by Rasheed et al. [116]. The reaction was catalyzed by Cu(OAc)2 with cesium carbonate as a base under aerobic conditions. Along with the synthesis of pyrido[1,2-a]benzimidazoles 78, they have reported the synthesis of benzimidazo[1,2-a]quinoline 79 and benzimidazo[1,2-a]isoquinoline 80 in good to excellent yields. They have used differently substituted arylboronic acids 77 as one of the common reactants with 2-aminopyridines/2-aminoquinolines/1-aminoisoquinolines 3, 75, 76 to give the desired products, respectively (Scheme 27).

Scheme 27: Cu(II)-catalyzed C–N bond formation reaction.

Scheme 27: Cu(II)-catalyzed C–N bond formation reaction.

Both EWGs and EDGs on the reactants resulted in good to excellent yields of the product. This process followed two types of coupling reaction mechanisms, i.e., a Chan–Lam coupling and an Ullmann coupling. The Chan–Lam coupling involved a C–N bond formation (intermediate I, 84) which then entered into the Ullmann coupling to undergo intramolecular cyclization to form final product 78 and release Cu(III) to Cu(I) by reductive elimination. In this process oxygen (air) acts as oxidant which resulted in the oxidation of Cu(II) to Cu(III) and Cu(I) back to Cu(II) (Scheme 28).

Scheme 28: Mechanism involving Chan–Lam/Ullmann coupling.

Scheme 28: Mechanism involving Chan–Lam/Ullmann coupling.

A copper-catalyzed oxidative cyclization approach has been used for the synthesis of formyl-substituted imidazo[1,2-a]pyridines 89. The remarkable feature of this method was the preservance of the sensitive aldehyde group in the product structure, which can act as a precursor for the synthesis of some new motifs (Scheme 29) [117]. The reaction was carried out between 2-APs 3 and cinnamaldehyde derivatives 88 under aerobic conditions. ZnCl2 and pyridine act as additives, where ZnCl2 was supposed to promote the reaction rate by coordinating with the oxygen of the aldehyde. 2-APs with EWGs gave a higher yield of products than those substituted with EDGs while this thing got reversed with cinnamaldehyde (Table 1). 2-Methylbenzaldehyde and 5-chloro-2-aminopyridine resulted in the trace of final product, whereas the reaction was not completed with (E)-but-2-enal (entry 17 and 18, Table 1). Wang et al. have developed a Cu(II)-catalyzed tandem reaction between ketonic pyridine 90 and benzylamine 91 using DMF as a solvent at 110 °C, in the presence of oxygen as a clean oxidant (Scheme 30) [118]. Reaction optimization has shown Cu(OAc)2 to be suitable for this transformation whereas other Lewis acids like CuI, Cu(OTf)2 and FeCl3 gave lower yields, whereas Zn(OAc)2 did not result in any product. The strategy has well tolerated different substituents on pyridine and benzylamine as well, giving the corresponding products in excellent yields. This protocol served as a novel route for the synthesis of imidazo[1,5-a]pyridines 37 via oxidative amination of sp3 C–H bonds in the aerial atmosphere.

Scheme 29: Synthesis of formyl-substituted imidazo[1,2-a]pyridines.

Scheme 29: Synthesis of formyl-substituted imidazo[1,2-a]pyridines.

Table 1: Effect of substituents on product yield.

| Entry | R1 | R2 | Yield (%) | Entry | R1 | R2 | Yield (%) |

| 1 | H | H | 80 | 10 | H | 4-COOEt | 78 |

| 2 | H | 3-Me | 32 | 11 | H | 5-Br, 6-Me | 52 |

| 3 | H | 5-Me | 42 | 12 | 2-Me | H | 66 |

| 4 | H | 6-Me | trace | 13 | 3-Me | H | 44 |

| 5 | H | 3-OCH2Ph | 38 | 14 | 4-Cl | H | 36 |

| 6 | H | 4-Cl | 52 | 15 | 4-Br | H | 32 |

| 7 | H | 5-Cl | 88 | 16 | 2-NO2 | H | 38 |

| 8 | H | 5-Br | 79 | 17 | 2-Me | 5-Cl | trace |

| 9 | H | 5-F | 95 | 18 |

|

H | – |

Scheme 30: A tandem sp3 C–H amination reaction.

Scheme 30: A tandem sp3 C–H amination reaction.

The reaction involved oxidative dehydrogenation of benzylamine intermediate 92 to form 93 which underwent resonance to give 94. This was followed by intramolecular amination, oxidative dehydrogenation, and rearrangement to yield the final product 37 (Scheme 31). A one-pot, tandem reaction promoted by a I2/CuO system to synthesize imidazo[1,2-a]pyridines was reported by Cai et al. (Scheme 32) [119]. In this reaction, iodine promoted the formation of iodo-intermediate 98 with a carbonyl compound that underwent nucleophilic substitution with 2-AP 3. CuO played multiple roles in this reaction. Firstly it acts as an oxidizing agent to convert molecular iodine to the reactive iodonium ion (I+) species, secondly as a weak base to neutralize HI and next to reoxidize the iodide ion (I−) to molecular iodine (I2, Scheme 33). The reaction has enjoyed a broad substrate scope including arylmethyl, heteroaryl, α,β-unsaturated methyl ketones, β-ketone esters and 2-APs-substituted with EW and EDGs. The protocol also provided a concise route for the synthesis of the antiulcer drug zolimidine in 95% yield. A three-component coupling reaction (3-CCR) for the synthesis of N-fused pyridines was reported by Balijapalli and Iyer [40]. The reaction was catalyzed by CuO/CuAl2O4 and ᴅ-glucose. The reaction had been tried with various Cu(I)- and Cu(II)-based catalysts but the use of a mixed nano-CuO/CuAl2O4 and ᴅ-glucose system has resulted in appreciable yields. This three-component one-pot reaction involved 2-AP, phenylacetylene and substituted benzaldehydes as the starting substrates (Scheme 34).

Scheme 31: Probable mechanistic approach.

Scheme 31: Probable mechanistic approach.

Scheme 32: Dual catalytic system for imidazo[1,2-a]pyridines.

Scheme 32: Dual catalytic system for imidazo[1,2-a]pyridines.

Scheme 34: CuO/CuAl2O4/ᴅ-glucose-promoted 3-CCR.

Scheme 34: CuO/CuAl2O4/ᴅ-glucose-promoted 3-CCR.

The reaction mechanism comprises of an in situ generation of the imine from the aldehyde and 2-AP. Further, the addition of alkyne and activation by CuO(II)/Cu2O(I) yielded the A3-coupled propargyl amine [40]. Tautomerization/5-exo-dig cyclization led to the formation of the final product. The reaction enjoyed a rich library of compounds with good yields except 5-bromo, 4-methyl and 3-methyl substitution on 2-AP with 41, 45 and 49% yield, respectively. Meng et al. have used copper supported on manganese oxide-based octahedral molecular sieves OMS-2 (CuOx/OMS-2) as a heterogeneous catalytic system for a tandem synthesis of 3-iodoimidazo[1,2-a]pyridines (Scheme 35) [120]. The synthesis was similar to that reported by Kumar and co-workers with the difference of a heterogeneous catalytic system and iodination of the product [121]. Molecular iodine was used as an iodinating agent in the reaction.

Scheme 35: A tandem CuOx/OMS-2-based synthetic strategy.

Scheme 35: A tandem CuOx/OMS-2-based synthetic strategy.

In this reaction, OMS-2 acted as support and an electron transfer mediator for copper in order to generate a low energy pathway for rapid electron transfer thereby minimizing the catalyst loading (Figure 4). The reaction was supposed to proceed through iodine-catalyzed Ortoleva–King reaction with the assistance of Cu followed by CuOx/OMS-2-catalyzed electrophilic oxidative iodination.

Figure 4: Biomimetic catalytic oxidation in the presence of electron-transfer mediators (ETMs).

Figure 4: Biomimetic catalytic oxidation in the presence of electron-transfer mediators (ETMs).

The importance of catalyst for iodination was ascertained by the reaction in Scheme 36, which depicted that absence of CuOx/OMS-2 leads to imidazo[1,2-a]pyridine 21 as the major product rather than 3-iodo derivative 101. The reaction has well tolerated differently substituted ketones, with lack of product in case of ortho-substitution due to steric hinderance. Similarly, substituted 2-APs provided a library of compounds with god yield, however, α,β-unsaturated ketones, such as benzalacetone, did not afford any desired product, perhaps because the α,β-unsaturated double bond affected the iodination.

Mohan et al. successfully developed an efficient copper-catalyzed aerobic oxidative amination of C(sp3)–H bonds to synthesize imidazo[1,5-a]pyridine derivatives [122]. The reaction was also applicable to amino acid derivatives, as ethyl glycinate resulted in a 53% yield of the corresponding IP. The method was more atom economic and sustainable than others as it utilized air as a sole oxidant and generated water as the only byproduct. The reaction was carried out between pyridyl esters 102 and benzylamine (35) at 65 °C using pivalic acid as an additive in DMSO under open air (Scheme 37). Although the product yield was decreased when the reaction was performed in oxygen (balloon) atmosphere, might be due to the conversion of benzylamine to imine.

Scheme 37: Copper-catalyzed C(sp3)–H aminatin reaction.

Scheme 37: Copper-catalyzed C(sp3)–H aminatin reaction.

The reaction has beautifully tolerated a huge number of substrates with differently substituted pyridyl esters along with aromatic/heteroaromatic/aliphatic amines to give a good yield of products. However, steric hinderance was observed with 2-OMe-substituted benzylamine giving a trace amount of product. Moreover, 2-(pyridine-2-yl)acetonitrile and 2-picolylamine did not produce the desired product. The reaction with secondary amines 35a also resulted in a trace of the final product (Scheme 38).

The use of TEMPO (a radical scavenger) has shown that the reaction might proceed through a radical pathway as depicted in Scheme 39. In the presence of TEMPO the desired product was not formed. Atmospheric oxygen has oxidized Cu(I) to Cu(II). This Cu(II) acts as an initiator for a single electron transfer (SET) process, to proceed the reaction with benzylamine. A regioselective synthesis of imidazo[1,2-a]pyridines was reported by the group of Kamal and Reddy [123]. They have performed a Cu(OAc)2-Et3N-mediated coupling reaction of α-azido ketones 115 with pyridinium ylides 114 using oxygen as a green oxidant (Scheme 40). The oxo-functionality present in α-azido ketones increased its acidity thus making it a good organic synthon. Optimization of the reaction conditions revealed that the presence of copper salt is mandatory for the formation of the fused heterocycle as its absence resulted in the formation of the enaminone only. The imines 118, generated in situ via the loss of nitrogen from azide derivatives, were found to be reactive towards 1,3-dipoles 117 to form diverse heterocycles. Pyridinium ylides used as 1,3-dipoles in this protocol were synthesized by the reaction of pyridines with α-bromo ketones (Scheme 41). The protocol was applicable to a series of EW and EDGs on phenacyl azides. However, the reaction was not successful with ethyl azidoacetate. On the other hand, EW and EDGs were also well tolerated by pyridinium ylides.

Scheme 40: Coupling reaction of α-azidoketones.

Scheme 40: Coupling reaction of α-azidoketones.

The group of Bharate and Abbat have successfully reported a simple, efficient and excellent C–N bond formation catalyzed by CuBr [124]. The protocol involved the aerobic oxidative coupling of 2-APs with cinnamaldehyde to form 3-formyl-2-phenylimidazo[1,2-a]pyridines (Table 2). Before their work, only three reports of such a formylation have been reported in the literature which suffered from certain drawbacks like difficult to prepare starting materials, multistep reaction, high temperature and the use of expensive catalyst [125-127]. The reaction was initially tried with different catalysts like triflic acid, I2, salts of Pd, Fe, Co and Cu which did not lead to the formation of the final product except CuSO4 and CuCl2 which gave a moderate yield of the products. Further studies revealed CuBr to be the most effective with a maximum yield of 90% in ethanol at 60 °C with optimization reaction between 2-AP and cinnamaldehyde (Table 2, entry 1).

Table 2: Substrate scope for the synthesis of 3-formyl-2-phenylimidazo[1,2-a]pyridines.

|

|

|||||||

| Entry | R1 | R2 | Yield (%) | Entry | R1 | R2 | Yield (%) |

| 1 | H | H | 90 | 8 | 5-Cl | H | 80 |

| 2 | 3-Me | H | 85 | 9 | 5-Me | 4-OMe | 78 |

| 3 | H | 4-Br | 82 | 10 | H | 2-NO2 | 70 |

| 4 | 5-Me | 4-Br | 78 | 11 | 3-Me | 2-NO2 | 72 |

| 5 | 5-Me | 4-Cl | 80 | 12 | 5-Me | 2-NO2 | 75 |

| 6 | H | 4-OMe | 82 | 13 | 5-Me | H | 85 |

| 7 | 3-Me | 4-OMe | 75 | ||||

The reaction was carried out successfully under an air atmosphere rather than an inert atmosphere of nitrogen. This might be due to the oxidative nature of oxygen present in the air which was thought to be involved in hydrogen abstraction and oxidation of CuBr to Cu2O.

The presence of EW and EDGs on both 2-APs and cinnamaldehyde supported the forward reaction whereas the reaction got failed with aliphatic aldehydes. The reaction mechanism involved the formation of radical intermediates and Cu2O as a byproduct which was marked by the change of color from initial green to red. The theoretical study was carried out to check the feasibility of the reaction by calculating Gibbs free energy difference for each step (Scheme 42). The capability of copper to catalyze the cyanation reaction was well exploited by Wen and Lu for a one-pot MCR for the synthesis of cyanoimidazo[1,2-a]pyridines 129 [128]. A variety of copper salts including CuI, CuBr, CuCl, Cu(OAc)2 and Cu2O were tried but only CuI gave some appreciable results. The product yield was improved by using N-methyl-2-pyrrolidone (NMP) as a solvent without any additive (Scheme 43). A good yield of the product was obtained by using benzyl cyanide substituted with EDG (4-OMe) rather than with an EWG due to the favourable oxidative release of cyanide anions from benzyl cyanide that favored the substitution of the iodide ion. Substituted aryl ketones, heteroaryl methyl ketones, and α,β-unsaturated methyl ketones were also well tolerated by the reaction (Scheme 44). The reaction was also successful in a two-step procedure in which the product of 2-AP and ketone can also be subjected to cyanation with benzyl cyanide thereby proving the viability of the reaction. In this reaction, benzyl cyanide was used as the source of cyanide ions.

Scheme 42: Probable mechanism with free energy calculations.

Scheme 42: Probable mechanism with free energy calculations.

Scheme 43: MCR for cyanated IP synthesis.

Scheme 43: MCR for cyanated IP synthesis.

Scheme 44: Substrate scope for the reaction.

Scheme 44: Substrate scope for the reaction.

Mechanistically the reaction involved the simultaneous release of cyanide ions and the α-iodination of acetophenone catalyzed by CuI. Further, the Ortoleva–King reaction of the iodinated ketone 130 intermediate took place with 2-AP to afford imidazo[1,2-a]pyridine followed by iodination and cyanation to yield the final product 129 (Scheme 45). This method was superior in terms of high conversion yields, the formation of C–N bonds and C–CN bond in a concerted manner. Moreover, this approach was found to have commercial value since it is a good synthetic procedure for the synthesis of the drugs saripidem and necopidem in 62% and 59% yields, respectively. Cu supported on Zinc aluminate (ZnAl2O4) was unprecedentedly used for the three-component coupling reaction of aromatic aldehydes, 2-AP and phenylacetylene under nitrogen atmosphere (Table 3) [20]. In this protocol Cu was the active synthetic site and ZnAl2O4 acted as a support to provide a larger surface area and reduced the aggregation of Cu NPs. This protocol was better than reported by Chenglong et al. [111] in terms of low reaction temperature and lesser reaction time.

Leaching of the metal ion was absent as tested by AAS, which ensured the recyclability of the catalyst to 5 synthetic cycles. Mechanistically the reaction proceeded by a nucleophilic attack of the alkyne on imine 133, resulting in the formation of propargylamine 134. The activation of the C–H bond in the alkyne by copper on ZnAl2O4 initiated an intramolecular nucleophilic attack of pyridine nitrogen to the triple bond (135). This was followed by aromatic isomerization to form imidazo[1,2-a]pyridines (Scheme 46). The importance of Cu for this reaction is mentioned in Table 4, where the absence of copper did not lead to the product formation (Table 4, entry 1).

Scheme 46: Probable mechanistic pathway for Cu/ZnAl2O4-catalyzed reaction.

Scheme 46: Probable mechanistic pathway for Cu/ZnAl2O4-catalyzed reaction.

A double oxidative C–H amination reaction for the synthesis of 2-iodoimidazo[1,2-a]pyridines 137 was reported by Dheer et al. using a copper catalyst (Scheme 47) [129]. The synthesis of this moiety was also reported by the group of Gao in 2013, but it has the disadvantage of using special halogenating reagents for the synthesis of haloalkynes and also the tedious work-up procedure associated with it [44]. Application of another iodinating reagent like NIS proved to be futile under the reported conditions and also the absence of either CuI or I2 from the reaction did not result in the product formation.

Scheme 47: Copper-catalyzed double oxidative C–H amination reaction.

Scheme 47: Copper-catalyzed double oxidative C–H amination reaction.

All the reactions were performed under an oxygen atmosphere. Differently substituted 2-APs and terminal alkynes resulted in an appreciable yield of the product except 6-methyl-substituted 2-AP which did not form any product possibly due to steric hinderance. The advantageous part of this protocol was the synthesis of active pharmaceutical ingredients (API) that could be converted to commercial drugs sarpidem and nicopidem. Also, the compounds synthesized by this methodology could be successfully subjected to Suzuki, Sonogashira and Heck coupling reactions (Scheme 48).

Scheme 48: Application towards different coupling reactions.

Scheme 48: Application towards different coupling reactions.

The reaction proceeded by the formation of 1-iodoalkyne 142 which was characterized by mass and 1H NMR spetra. This iodoalkyne then formed a complex of Cu(I) with 2-AP. This was followed by migratory insertion of haloalkyne to form reactive Cu(III) intermediate 144 which underwent reductive elimination to give the desired product 137 and Cu(I) species (Scheme 49). The mechanism has shown that molecular iodine (I2) used in the reaction was the source of iodine in the final product rather than CuI. A condensation–cyclization reaction between 2-benzoylpyridine (145) and different benzylamines was carried out to synthesize 1,3-diarylated imidazo[1,5-a]pyridines (Scheme 50). The reaction took place under aerobic conditions utilizing Cu-MOF-74 as a catalyst [130]. The reaction was unprecedented in terms of oxidative amination of C(sp3)–H bond catalyzed by Cu-MOF-74. The group of Nguyen have deeply investigated the reaction and found 10 mol % loading of the catalyst with 3 equiv of benzylamine and 0.2 M 2-benzoylpyridine to be optimal for appreciable yield (Scheme 51). The reaction was optimized with different salts and Cu(OAc)2 was found to be effective for this transformation with a 78% yield, but it lacked reusability. They have experimentally demonstrated the importance of solid Cu-MOF for the reaction as there was not any contribution of leached active copper species to the formation of the desired compounds. Encouraged by their previous work Meng et al. have reported the aerobic synthesis of 3-aroylimidazo[1,2-a]pyridines 147 catalyzed by copper on H+-modified OMS-2 as a heterogeneous biomimetic catalyst [120,131]. They have successfully synthesized the desired compound by two systems viz., one-pot two-component reaction (2-CR) by using 2-AP and chalcone 146 (Scheme 52) and another by using a one-pot three-component reaction (3-CR) of 2-AP, aldehydes, and ketones (without the isolation of chalcone) (Scheme 53). The method has utilized a mixed solvent system comprising of Cl2CHCHCl2 (1,1,2,2-tetrachloroethane) and HOAc (acetic acid). Where HOAc was suitable for the formation of the Michael adduct and enhanced the electrophilicity of copper while Cl2CHCHCl2 helped in oxidative cyclization. However, the use of HOAc was not good for –COOMe and –CN substituted 2-AP as it led to their decomposition. A big library of compounds was constructed in which ortho-substituents gave lesser yields, possibly due to steric hinderance (Scheme 52). The advantageous feature of the process lied in the absence of base and ligand which makes it cost-efficient.

Scheme 50: Condensation–cyclization approach for the synthesis of 1,3-diarylated imidazo[1,5-a]pyridines.

Scheme 50: Condensation–cyclization approach for the synthesis of 1,3-diarylated imidazo[1,5-a]pyridines.

Scheme 51: Optimized reaction conditions.

Scheme 51: Optimized reaction conditions.

Scheme 53: One-pot 3-CR without the isolation of chalcone.

Scheme 53: One-pot 3-CR without the isolation of chalcone.

Cheng et al. have reported a Cu(II)–Pybox-catalyzed reaction between 2-aminopyridines (2-APs) and propargyl alcohol derivatives bearing terminal alkyne substrates 148 to synthesize imidazo[1,2-a]pyridines (Scheme 54) [132]. The Pybox ligand was introduced by Nishiyama in the year 1989 [133]. The ligand consists of a pyridine ring surrounded by two oxazoline groups. Pybox ligands have the merit of the big binding site which could complex even with lanthanide cations and the increased rigidity associated with the tridentate Pybox scaffold [134]. 2-APs with EDGs like methyl and methoxy substitution at either meta or para-position gave good yield in relatively shorter reaction time (6 h) than those with EWGs like Cl/Br or CF3 (18 h). Moreover, the presence of EW/EDGs at 6-position of 2-AP did not afford the desired product due to the steric effect. In the case of propargyl alcohol derivatives, those with aliphatic substituent did not lead to the desired product. This reaction strategy has worked well up to gram scale level.

Scheme 54: Copper–Pybox-catalyzed cyclization reaction.

Scheme 54: Copper–Pybox-catalyzed cyclization reaction.

This reaction protocol has avoided the harsh reaction conditions like the use of high temperature and polar-aprotic solvents of a high boiling point such as DMF and DMSO. The added advantage of the method was regioselective propargylation at pyridine nitrogen 151, followed by an intramolecular cyclization catalyzed by Cu–Pybox complex 152 (Scheme 55). Furthermore, the reaction was also utilized for gram scale synthesis of 2-methyl-3-phenyl-2,3-dihydroimidazo[1,2-a]pyridine, followed by its bromination and nucleophillic coupling for further derivatization. Xie et al. have reported a novel methodology via amination of the C(sp3)–H bond with TMSN3, catalyzed by Cu(II) salt to form imidazo[1,5-a]pyridines [135]. This three-component reaction involved benzyl-substituted N-heterocycles 154, aldehydes 1 and TMSN3 155 (Scheme 56), where heterocyclic nitrogen acted as both a directing group and an intramolecular nucleophile. The reaction was carried out under an inert atmosphere of argon with a total of 4 equiv of TMSN3 (3 + 1) to obtain the maximum yield of the desired product. Differently substituted benzaldehydes have been examined which showed good tolerance to EW as well as EDGs present at different positions. However, aliphatic aldehydes were failed to produce the desired product. Also, 2-benzylpyridines with EDGs afforded the product in higher yield than those substituted with EWGs. Other than pyridines this methodology gave good results with 2-benzylthiazole, 2-benzylbenzoxazole, and isoquinolines (Scheme 57).

Scheme 55: Mechanistic pathway catalyzed by Cu–Pybox complex.

Scheme 55: Mechanistic pathway catalyzed by Cu–Pybox complex.

Scheme 56: Cu(II)-promoted C(sp3)-H amination reaction.

Scheme 56: Cu(II)-promoted C(sp3)-H amination reaction.

Scheme 57: Wider substrate applicability for the reaction.

Scheme 57: Wider substrate applicability for the reaction.

The authors were not sure about the exact mechanism thus based on previous reports it was believed to be propagated by the coordination of Cu(II) with the pyridinyl nitrogen 158 that facilitated deprotonation by the pivaloate anion to give an intermediate 159 [136,137]. This intermediate then involved the replacement of TFA by the azido group. The reaction was then expected to follow C–N bond formation, condensation with aldehydes, cycloaddition and finally, oxidative aromatization by Cu(II) to produce the desired product (Scheme 58). The C–N cross-coupling activity of copper was utilized by the group of Wan and Hu who have described a novel route for the synthesis of 2-unsubstituted imidazo[1,2-a]pyridines via intramolecular C–N bond forming cross-coupling reaction [138]. The reaction involved a copper-catalyzed C(sp2)–H amination. The reaction was carried out with N-pyridinyl secondary enaminones (61) [139] in the presence of CuI (20 mol %) in DMSO at 100 °C under open atmosphere (Scheme 59). The literature revealed that β-enaminones containing a free NH group and an additional β-substituent have been employed for the synthesis of 2,3-disubstituted imidazo[1,2-a]pyridines [140]. These enaminone-based protocols were not viable for the synthesis of imidazo[1,2-a]pyridine without 2-substitution. However, the protocol designed by Wan and Wen has successfully reported the synthesis of IPs without any substitution at the 2-position. The aryl ring associated with enaminones here has shown good functional group tolerance with moderate to excellent yields.

Scheme 59: CuI assisted C–N cross-coupling reaction.

Scheme 59: CuI assisted C–N cross-coupling reaction.

On the other hand, the product yield was reduced with EWGs on the pyridine ring. Mechanistically, the pyridine nitrogen from enaminone acted as a chelating site to form a cuprous intermediate 168. Oxidative addition of an iodide ion (I−) to this cuprous intermediate resulted in the Cu(III) intermediate 169 in the presence of air (O2). Reductive elimination of this intermediate resulted in the target compound with the release of Cu(I) which further participated in the catalytic process (Scheme 60). Inspired from these findings Zhang et al. have described the synthesis of imidazo[1,2-a]pyridines as a one-pot-3-CR [141]. A similar kind of reaction was also reported by Puthiaraj and co-workers, with Cu(BDC) as a heterogeneous catalyst and DMF as solvent [100]. The reaction reported by Zhang et al. between 3, 1 and 10 was catalyzed by magnetic carbon nanotube supported Cu NPs (CoFe2O4/CNT-Cu) as an efficient magnetic heterogeneous catalyst (Scheme 61). Previously, the group has reported CuFeO2-catalyzed syntheses of imidazo[1,2-a]pyridines [142]. The reaction system has well tolerated EW and EDGs giving a good product yield of 80–96%. The Cu was inferred to play a major role in catalyzing the reaction as was explained by the mechanistic approach of the reaction. The reaction involved a Michael addition of nitromethane to imine intermediate 170, which underwent loss of an electron and hydride ion twice, to form a cationic intermediate 178. This cation then suffered nucleophilic addition and proton elimination to produce the final compound (Scheme 62).

Scheme 60: Probable reaction mechanism involving sp3 C–H amination.

Scheme 60: Probable reaction mechanism involving sp3 C–H amination.

Scheme 61: One-pot MCR-catalyzed by CoFe2O4/CNT-Cu.

Scheme 61: One-pot MCR-catalyzed by CoFe2O4/CNT-Cu.

The beauty of the process lies in the reusability of the catalyst up to eight synthetic cycles along with the reusability of the PEG-400 which was found to be an optimal solvent for the reaction. A similar reaction was reported initially by the group of Yan and Yan who have utilized CuBr as a catalyst at 80 °C under aerobic conditions (Scheme 63) [143]. This reaction has tolerated a limited number of substituents where aldehydes with EDGs gave good yields as compared to EWGs, moreover, groups such as o-NO2, p-NO2, and CN resulted in a complex mixture and not the desired compounds. 2-APs also gave a similar outcome with a low yield of about 58% with the presence of an ortho substituent on it. However different 2-aminoheterocycles (2-aminopyrimidine/2-aminobenzimidazole) and aliphatic aldehydes viz., n-butyraldehyde and isobutyraldehyde were not found to be suitable substrates for this reaction. The reaction was thought to proceed via subsequent radical-cation intermediates, hydride abstraction and finally nucleophilic addition to give the desired product (Scheme 64). In the reported mechanism, the Cu catalyst was supposed to help in the formation of radical cation by taking up an electron in each of the two intermediate stages.

Scheme 63: Synthetic scheme for 3-nitroimidazo[1,2-a]pyridines.

Scheme 63: Synthetic scheme for 3-nitroimidazo[1,2-a]pyridines.

Scheme 64: Plausible mechanism for CuBr-catalyzed reaction.

Scheme 64: Plausible mechanism for CuBr-catalyzed reaction.

In order to develop an easy and economic method for regio-divergent synthesis of halosubstituted imidazo[1,2-a]pyridines, Samanta et al. have reported a copper-catalyzed regioselective synthesis of 2- and 3-iodoimidazo[1,2-a]pyridines 137 and 101 [144]. Binucleophilic 2-AP and alkenes 189/alkynes 2 in the presence of iodine and air were utilized as starting substrates (Scheme 65).

Scheme 65: Regioselective synthesis of halo-substituted imidazo[1,2-a]pyridines.

Scheme 65: Regioselective synthesis of halo-substituted imidazo[1,2-a]pyridines.

Coupling of 2-APs with terminal alkynes resulted in 2-iodoimidazo[1,2-a]pyridines as the only products, the yield was quite appreciable with aromatic/aliphatic as well as heteroaromatic alkynes. However, coupling with alkene (styrene) resulted in 3-iodoimidazo[1,2-a]pyridines (150 mol % I2) and by varying the amount of iodine to 50 mol % 2-phenylimidazo[1,2-a]pyridines were obtained as the final product without iodine substitution (Scheme 66). The beauty of the process lied in the syntheses of different products just by varying the amount of iodine. Interestingly the use of symmetrical internal alkynes 190 resulted in the formation of 2,3-diarylimidazo[1,2-a]pyridines in good yield 191 (Scheme 67). Whereas, the inseparable regioisomeric mixture was obtained with unsymmetrical internal alkynes and no product was obtained with 4-octyne and 1-phenyl-1-propyne.

Scheme 66: Synthesis of 2-phenylimidazo[1,2-a]pyridines.

Scheme 66: Synthesis of 2-phenylimidazo[1,2-a]pyridines.

Scheme 67: Synthesis of diarylated compounds.

Scheme 67: Synthesis of diarylated compounds.

A copper-mediated aerobic oxidative coupling of pyridines 28 and enamides 192 was carried out in a one-pot fashion for the synthesis of 3-bromo-imidazo[1,2-a]pyridines 193 [145]. These 3-bromo substrates can be used as versatile synthetic blocks for further transformations. In this protocol CuBr2 act as a catalyst as well as a brominating agent. The reaction was carried out at 70 °C using dichloroethane (DCE) as a solvent under the atmosphere of oxygen which acted as an oxidant (Scheme 68).

Scheme 68: CuBr2-mediated one-pot two-component oxidative coupling reaction.

Scheme 68: CuBr2-mediated one-pot two-component oxidative coupling reaction.

This strategy displayed high functional group tolerance at the aromatic ring of the enamides, however, aliphatic enamides were not found to be suitable. The presence of a furan and thiophene ring in place of the benzene ring gave a product yield of only 27 and 44%, respectively. EW as well as EDGs present at meta-position of pyridine, gave good results as compared to the methyl group present at o- and p-positions which did not result in product formation. The overall yield of the products in this reaction was not much appreciable, also the product of meta-methyl- and meta-fluoro-substituted pyridines were obtained in an 1:1 isomeric mixture. Application of TEMPO (a radical scavenger) did not yield the desired product indicating the existence of a radical intermediate in the mechanism. This radical intermediate resulted in the formation of a carbocation which undergoes a nucleophilic attack by pyridine followed by isomerization of the so formed intermediate. The reaction then proceeded through a number of subsequent steps viz., intramolecular cycloaddition, hydrolysis, oxidative aromatization, and bromination thus yielding the final product. A copper/iodine co-catalytic system has been found to synthesize 1,3-diarylimidazo[1,5-a]pyridines 37 by decarboxylative cyclization of α-amino acids 194 with 2-benzoylpyridines 145 (Scheme 69) [146]. The reaction was supposed to obey an ionic pathway rather than a radical pathway. Mechanistically, decarboxylation step 196 was followed by oxidative iodination which was followed by elimination of iodine, intramolecular amination, dehydrogenation and rearrangement to yield the final product 37 (Scheme 70).

Scheme 69: Decarboxylative cyclization route to synthesize 1,3-diarylimidazo[1,5-a]pyridines.

Scheme 69: Decarboxylative cyclization route to synthesize 1,3-diarylimidazo[1,5-a]pyridines.

The reaction remained unaffected by the nature of substrates on the phenyl ring of 2-benzoylpyridines. Both EW and EDGs demonstrated excellent efficiency, only the o-substitution led to a decrease in the yield. However, with 1-(pyridin-2-yl)ethanone as the substrate, no corresponding product was detected. Assessment of the amino acids has shown that linear, branched and α-aryl-substituted amino acids were excellent reaction substrates. This method provided an effective alternative for the synthesis of 1,3-diaryl and 3-alkyl-1-arylimidazo[1,5-a]pyridines which were difficult to synthesize by the existing methods.

An efficient CuI/I2-mediated direct C–H functionalization reaction, compatible with both N-heteroaryl and N-aryl-substituted enamines 203 and 204 has been established to produce imidazo[1,2-a]pyridine 147 and indole derivatives 205 (Scheme 71) [147]. The reaction was feasible with both EDGs and EWGs present on the pyridine ring. The strategy was applicable in the synthesis of 2-methyl-3-acetyl derivatives of IP from 5-methylpyridin-2-amine and acetylacetone with no isolation of unstable condensation intermediate. Gratifyingly, the reaction worked well without the purification of crude enamines, produced by the reaction of arylamines and ketones. Moreover, no requirement of preliminary activation of the reaction centers, initiation of substrates, and reduced waste product generation are among some of the associated benefits of this strategy. In this reaction, I2 resulted in the formation of β-iodoenamide 206, that underwent oxidative addition with Cu(I) followed by cyclization to form a metal complex 208 followed by reductive elimination to yield the final product (Scheme 72). A synthetic methodology for imidazo[1,2-a]pyridines by aerobic oxidative cyclization of ketoxime acetates 209 with pyridines or fused pyridines have been developed by the group of Ren and Zhao [148]. The reaction was catalyzed by CuI under mild conditions (Scheme 73). Ketoximes are valuable chemicals that are readily accessible through condensation of ketones with hydroxylammonium salts under mild conditions. Different copper salts have been tested for this reaction and Cu(II) salts were found to be inactive. With this methodology, they have successfully constructed a large library of compounds having both electron rich as well as deficient ketoxime acetates bearing methyl/methoxy/halogen substituents along with substituted pyridines. However, with 3-methyl and 3-halo-substituted pyridines two regioisomers were obtained in each case where 8-substituted imidazopyridines were the major isomer.

Scheme 71: C–H functionalization reaction of enamines to produce diversified heterocycles.

Scheme 71: C–H functionalization reaction of enamines to produce diversified heterocycles.

Scheme 73: CuI-promoted aerobic oxidative cyclization reaction of ketoxime acetates and pyridines.

Scheme 73: CuI-promoted aerobic oxidative cyclization reaction of ketoxime acetates and pyridines.

This protocol was also successful in synthesizing the antiulcer drug zolimidine in 81% yield on 10 mmol scale. The group has proposed a tentative mechanism, where CuI was involved in the reduction of ketoxime ester to the iminium radical 210, which rapidly isomerized to the α-carbon radical. Subsequently, the radical formed get coupled with pyridine followed by intramolecular cyclization and oxidation in the presence of Cu/O2 to generate the final product (Scheme 74).

Scheme 74: CuI-catalyzed pathway for the formation of imidazo[1,2-a]pyridine.

Scheme 74: CuI-catalyzed pathway for the formation of imidazo[1,2-a]pyridine.

An efficient copper-catalyzed four-component reaction was reported by Allahabadi et al. for the synthesis of imidazo[1,2-a]pyridines [149]. The novelty of the methodology lied in their use of 2-bromopyridine as one of the starting reactants rather than 2-AP (Table 5). Optimization of the reaction conditions has shown ʟ-proline to be the best out of different ligands used viz. 1,10-phenanthroline, pipecolic acid and ʟ-proline. To develop the best catalytic reaction conditions different copper salts were screened and CuI was found to be most effective using DMSO as solvent at 110 °C. The reaction mechanism involved Cu-catalyzed reductive amination of 2-bromopyridine with sodium azide to gave 2-AP. This 2-AP underwent imine formation with aldehyde which was followed by nucleophilic addition of the isocyanide. This step was followed by intramolecular cyclization 220 and tautomerization to produce the targeted molecule (Scheme 75). An unprecedented work for the synthesis of 2-haloimidazo[1,2-a]pyridines in terms of alkynoic acid as one of the reaction substrate was reported in the year 2017 by the group of Liu and Wang [150]. They have successfully reported the two-component, Cu(II)-promoted one-pot reaction of 2-AP and alkynoic acid 221 for the synthesis of IPs (Table 6). Before this report, three synthetic routes have been reported which suffered from certain bottlenecks like the use of prefunctionalized haloalkynes, limited substituent type at the C-3 position and limited halogenated starting material [44,129,144,151]. The two-component reaction did not require the presence of any base, as initial use of basic reagents like pyridine, Et3N, K2CO3 or Cs2CO3 resulted in a trace amount of final compounds. Moreover, the reaction did not proceed in the absence of CuBr2 and also the use of NaBr as brominating agent (to reduce catalyst loading) did not give satisfactory results. Air or oxygen atmosphere was required for successful completion of the reaction whereas use of oxidants such as TBHP/DTBP resulted in a decrease in the product yield. Alkynoic acids were easier to handle than the corresponding terminal alkynes and haloalkynes, the reason is their high boiling point. The reaction was not affected by steric and electronic factors as a wide variety of substituents along with aliphatic acids resulted in moderate to good yields of the products. Apart from copper bromide, its chloride salt also acted as good halogenating agent for synthesizing 2-chlorinated compounds (Table 7).

Control experiments performed for the reaction displayed that alkynoic acid formed a Cu(II) intermediate 224 with CuBr2 followed by reductive elimination to generate an in situ bromoalkyne 226. Diamination of this bromoalkyne with 2-AP in the presence of CuBr2 resulted in the final product (Scheme 76). These reaction conditions were also feasible for gram-scale synthesis.

Scheme 76: Mechanistic rationale for the synthesis of products.

Scheme 76: Mechanistic rationale for the synthesis of products.

A novel regio- and stereoselective approach for the synthesis of vinyloxy-IP 228 catalyzed by CuI has been reported. The reaction has utilized 2-APs, 2-oxoaldehydes 227 and alkynes as reactive substrate (Scheme 77). This methodology was successful only in the presence of Cu(I) salt and no reaction occurred in the presence of Cu(II) salts [152]. The library of compounds designed by this methodology was quite interesting as aliphatic/aromatic/heteroaromatic alkynes substituted with both EW and EDGs were well tolerated under the optimized conditions. 2-AP moiety with EDGs (3-CH3/4-CH3) gave excellent yields whereas EWGs (5-Cl, 5-Br) resulted in 2-aroyl-IPs 229 than expected vinyloxy-IPs (Scheme 77). The reaction with propiolate 66 resulted in regioselective products due to the formation of a new C–O bond at the C-3 position of 1-alkyne (Scheme 78). Moreover, the use of internal alkynes like methyl 3-phenylpropiolate and dimethyl/diethyl acetylenedicarboxylate resulted in products with Z-selectivity. Use of radical scavenger BHT did not affect the product yield thereby showing no involvement of radical intermediate in the mechanism as depicted in Scheme 79.

Scheme 77: Copper-catalyzed synthesis of vinyloxy-IP.

Scheme 77: Copper-catalyzed synthesis of vinyloxy-IP.

Scheme 78: Regioselective product formation with propiolates.

Scheme 78: Regioselective product formation with propiolates.

Scheme 79: Proposed mechanism for vinyloxy-IP formation.

Scheme 79: Proposed mechanism for vinyloxy-IP formation.