Abstract

Triptolide is a complex triepoxide diterpene natural product that has attracted considerable interest in the organic chemistry and medicinal chemistry societies due to its intriguing structural features and multiple promising biological activities. In this review, progress in the total syntheses of triptolide are systematically summarized. We hope to gain a better understanding of the field and provide constructive suggestions for future studies of triptolide.

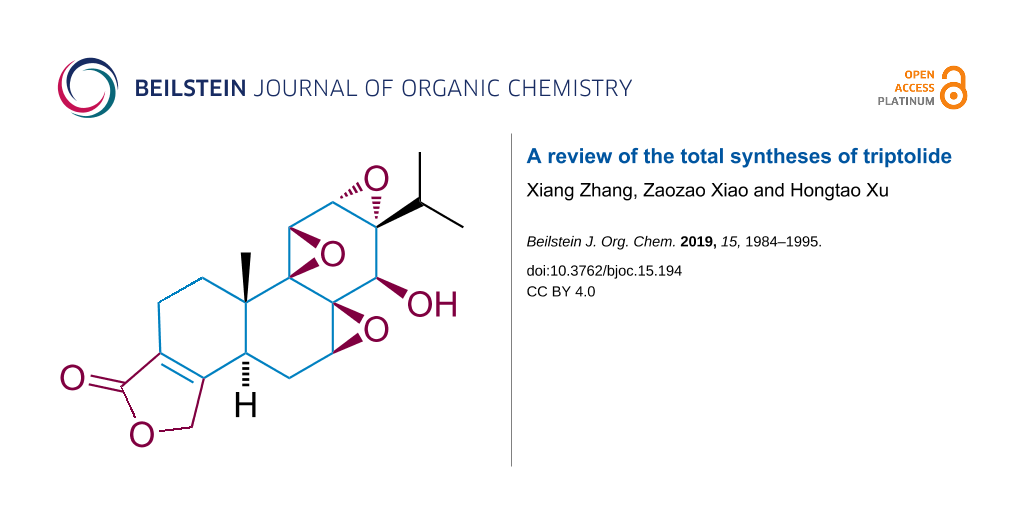

Graphical Abstract

Introduction

Triptolide (1, Figure 1) is the first diterpenoid triepoxide isolated from Tripterygium wilfordii Hook F. (TWHF) in 1972 [1]. It has attracted an ever-increasing attention due to its intriguing structural features and various promising pharmacological activities [2-4], such as antiproliferative, antifertility [5], anti-osteoporosis [6], immunosuppressive and anti-inflammatory activities [7]. Reports have indicated that triptolide induces apoptosis, triggers autophagy [8], and arrests cell cycle progression through modulating the relevant signaling pathways involved in the regulation of reactive oxygen species (ROS) and/or nitric oxide (NO) [9], histone methyltransferase [10], HSP70 [11], Jak2, Bcl-2/Bax [12], caspase 8 [13], NF-κB [14], X-linked inhibitor of apoptosis protein (XIAP) [15], MAPK, PI3K [16], and MPK1, ERK-1/2, and JNK-1/2 [17]. The cross-talk network amongst these targets and signaling pathways are considered to be responsible for the multiple anticancer activities of triptolide [18-24]. Triptolide could also suppress inflammation and stimulate cytoprotection by regulating pro-inflammatory cytokines and chemokines such as IFN-γ [25], RANTES [26], IL-8 [27], COX-2 and NO [28]. These may associate with its effect on inflammatory relating diseases such as Parkinson’s disease [28], and kidney disease [29,30]. Meanwhile, through regulating immune-related cells, triptolide also showed great potential for the treatment of rheumatoid arthritis (RA) [31], systemic lupus erythematosus (SLE) and skin allograft rejection [32].

Figure 1: Structures of triptolide (1), triptonide (2), tripdiolide (3), 16-hydroxytriptolide (4), triptriolide (5), minnelide (6) and LLDT-8 (7).

Figure 1: Structures of triptolide (1), triptonide (2), tripdiolide (3), 16-hydroxytriptolide (4), triptrioli...

Despite the promising biological activities of triptolide, the narrow therapeutic window and multi-organ toxicity hindered greatly its clinical progress. Reports have shown that triptolide could cause reproductive toxicity [33], nephrotoxicity [34], hepatotoxicity [35], myocardial damage [36] and gastrointestinal tract symptoms [37]. In order to overcome the above issues and find derivatives with good drug-like properties, extensive total syntheses and structure modifications have been executed in the past two decades [38-51]. With the increasingly clear structure–activity relationships (SARs) [52-61], some derivatives of triptolide, such as minnelide 6 and (5R)-5-hydroxytriptolide (LLDT-8, 7) have progressed into clinic for the treatment of pancreatic cancer and rheumatoid arthritis (RA) [61,62], respectively.

In order to gain a comprehensive and deep understanding of the area and provide suggestions for triptolide’s future studies, the recent progress of the total syntheses was systematically reviewed in this article. Syntheses were clustered based on: i) syntheses using tetralone (Figure 2, route A nad B), ʟ-abietic acid and/or ʟ-dehydroabietic acid as starting materials (route C, D and E); ii) syntheses using Diels–Alder reactions for the construction the A, B and C-rings (route F and G); iii) syntheses using polyene cyclization to construct the core structure (route H, I, J, K, and L); iv) syntheses highlight the utilization of metal-catalyzed reactions (M and N).

Review

The intriguing structural features of triptolide and its relatives have provided a rich playing field for the design and development of total synthesis strategies. Structurally, it has nine chiral centers, three successive epoxides and a butenolide. Since the pioneering works of Berchtold, Tahara and their co-workers [45,63-65], several racemic and/or asymmetric total syntheses of triptolide and its relatives have been carried out in many research groups.

The first racemic total synthesis of triptolide was reported 1980 by Berchtold and co-workers (Figure 2, route A, and Scheme 1) [66]. The key steps include: i) construction of the A-ring by aldol condensation, ii) construction of the butenolide (D-ring) by acid-catalyzed lactonization, and iii) construction of the epoxides by a newly developed methodology. The synthesis commenced from the alkylation of tetralone 22 with 3-(2-iodoethyl)dihydrofuran-2(3H)-one (23) to give diastereomeric lactones that subsequently reacted with dimethylamine to afford a 1:1 mixture of diastereomeric amides 39. Collins oxidation of 39 gave an aldehyde intermediate, which subsequently subjected to an aldol condensation using a ten-fold weight excess of neutral alumina quantitatively provided 40 and 41 in a small-scale reaction. The yield varied in large-scale reactions mainly due to the difficulty in extraction of 40 and 41 from the large quantity of alumina. Dehydration of the mixture of 40 and 41 in benzene quantitatively afforded a 1:2 mixture of 42 and its C-3 epimer 41. Reduction of the epimers with sodium borohydride and subsequent treatment with hydrochloric acid (2 N) gave single isomer 43. Treatment of 43 with methoxide ions in methanol at room temperature for 15 min gave the desired C-5 trans-butenolide 8 (40%) along with its C-5 cis-epimer 44 (60%), which is the sole product from the base-catalyzed isomerization of 43. Epoxidation of 43 gave a C-4,5-epoxide intermediate, which was isomerized in the presence of base and dehydrated to give diene 45. Reduction of 45 with 10% Pd/C afforded 8 in good yield (60%) after recrystallization. Benzylic oxidation of 8 (CrO3/HOAc, 45%), followed by C-14 ether cleavage (BBr3) and subsequent sodium borohydride reduction afforded 46 with the desired stereochemistry of the C-7 benzylic hydroxy group. Compound 46 was converted to triptonide 2 by Alder periodate reaction (NaIO4, 74%), and a sequencing m-CPBA epoxidation and basic hydrogen peroxide oxidation (H2O2/OH−) procedure (two steps, 28%). Finally, sodium borohydride reduction of 2 afforded triptolide (1, 21%) and 14-epitriptolide (48, 68%). Overall, the first total synthesis of racemic triptolide was finished from tetralone 22 in 16 steps. Although the intractable problems in some transformations, such as the neutral alumina-mediated aldol condensation to produce 40 and 41, the isomerization of olefin 43, the benzylic oxidation of 8, the use of m-CPBA to introduce the C-9,11 epoxide and the non-stereoselective reduction of the C-14 carbonyl group using sodium borohydride, caused an unacceptable overall yield (1.6%). This pioneering work undoubtedly established the basis for the future syntheses of triptolide.

Scheme 1: Berchtold’s synthesis of triptolide.

Scheme 1: Berchtold’s synthesis of triptolide.

In 2014, Li and co-workers further reported a formal asymmetric synthesis of triptolide from tetralone 24 (Figure 2, route B and Scheme 2) [50], featuring a Robinson annulation of Nazarov’s reagent 25 with 5-methoxy-2-tetralone 24 in the presence of enantiomerically pure (R)-α-phenylethylamine (49) to generate key tricyclic intermediates 51 and 52, a Pd(II)-catalyzed carbonylation–lactonization reaction of 9 to construct the butenolide (D-ring), and a Friedel–Crafts isopropylation to install the C-13 isopropyl group. Still, the construction of the C-5 trans junction A-/B-ring was problematic, direct reduction of 51 and 52 with either Pd/BaSO4/H2 or Li/NH3/t-BuOH could not give the desired ketoester 54 in satisfactory yield for a target-oriented synthesis. Fortunately, after trying many conditions and procedures, a three-step indirect approach that include silyl ether formation of the mixture of 51 and 52, subsequent Pd/C-catalyzed hydrogenation and tetrabutylammonium fluoride (TBAF)-mediated desilylation yielding the desired tricyclic 54 (83% yield, 98% ee). Overall, the known intermediate 7-oxotriptophenlide 59 was obtained in an efficient, elegant and scalable way in 10 steps with 18.5% overall yield. Importantly, by late-stage installation of the C-13 isopropyl group, this synthesis also provided a useful approach for the synthesis of other structurally relevant derivatives of triptolide such as C-15 and C-16 modified derivatives of triptolide.

Scheme 2: Li’s formal synthesis of triptolide.

Scheme 2: Li’s formal synthesis of triptolide.

In 1980, van Tamelen and co-workers reported an asymmetric synthesis of triptolide using readily available ʟ-dehydroabietic acid (26) as starting material (Figure 2, route C and Scheme 3) [67]. In this synthesis, the key step was the construction of the butenolide (D-ring). ʟ-Dehydroabietic acid was converted to C-14 trifluoroacetate 60 by a known electrophilic substitution procedure that was developed by Tahara and co-workers [64]. Curtius rearrangement of 60 gave an isocyanate intermediate, which was reduced with LiAlH4 followed by reductive amination affording tertiary amine intermediate 61. Oxidation of 61 to its corresponding N-oxide followed by Cope elimination gave olefin 62. Cleavage of olefin 62 with OsO4 and NaIO4 afforded ketone intermediate 10, which was enolized by (iPr)2NLi (LDA) and further reacted with formaldehyde to afford hydroxy ketone 63. Protection of the hydroxy group of 63 as 2-methoxypropyl ether, followed by successive treatment with PhCH2OCH2Li and HCl–THF (pH 1) gave triolmonobenzyl ether 64. Protection of the phenolic hydroxy group to its corresponding monoacetate followed by oxidation of the primary hydroxy group and dehydration yielded α,β-unsaturated aldehyde 65. Oxidation of 65 to the corresponding carboxylic acid followed by hydrogenolysis with H2/Pd-C led in spontaneous lactonization to give the key butenolide 66. Oxidation of 66 with CrO3/AcOH–H2O, followed by saponification and reduction afforded known benzyl alcohol 46 (19% from 66). Then, phenol 46 was converted to the corresponding epoxydienone via the methodology developed by Alder et al., which was treated without purification with basic H2O2 to yield diepoxide 67, along with its 12,13-β-isomer. The mixture was immediately oxidized with 3,5-(NO2)2C6H3CO3H and Na2HPO4 to give triptonide (2, 15% from 67), and reduction of triptonide via the reported procedure finalized the synthesis of triptolide. Overall, the first asymmetric total synthesis of (−)-triptonide (19 steps, 0.06% yield) and formal synthesis of triptolide were realized from ʟ-dehydroabietic acid (26). Although the overall yield of the synthesis is very low, the authors can ensure the optical purity of tripolide by utilizing the natural building block ʟ-dehydroabietic acid, and therefore could give a lot of inspiration for the future syntheses of triptolide and other related natural products from resource-abundant natural scaffolds.

Scheme 3: van Tamelen’s asymmetric synthesis of triptonide and triptolide.

Scheme 3: van Tamelen’s asymmetric synthesis of triptonide and triptolide.

Alternatively, inspired by the use of a natural diterpene scaffold as starting material for the synthesis of triptolide by van Tamelen and Tahara, Alvarez-Manzaneda’s group and Li’s group, respectively, reported formal syntheses of triptolide from ʟ-abietic acid (27, Figure 2, route D and E) [68,69]. In both syntheses, the key steps include the regioselective dihydroxylation and etherification to introduce the C-14 hydroxy group and the construction of the butenolide moiety. Particularly, the characteristics of Li’s route are low cost, high yield (9 steps, 44% yield) and easy handling (all intermediates could be scaled up to 100 grams without losing of yield) for the synthesis of key intermediate 8.

In order to further improve the synthesis of the key intermediate triptophenolide methyl ether (8), van Tamelen and co-workers further developed a synthesis as shown in Scheme 4 (Figure 2, route F) [70]. This synthesis features two new methodologies of butenolide formation. The first butenolide formation started with the reaction of ketone 68 with carbon disulfide (CS2) and iodomethane (MeI) to give the ketene dithioacetal intermediate 69, which was subjected to a Corey–Chaykovsky epoxidation, followed by acid hydrolysis to give butenolide 70. The second one is the reaction of alicyclic alcohol 73 with dimethylformamide dimethylacetal to give an allylic amide by means of a [2,3]-sigmatropic rearrangement of a carbene intermediate. Epoxidation the allylic amide with m-CPBA gave 74, followed by lithium hexamethyldisilazide-induced β-elimination and acid hydrolysis to give the key triptophenolide methyl ether (8) in racemic form (16.5%).

Scheme 4: Van Tamelen’s (method II) formal synthesis of triptolide.

Scheme 4: Van Tamelen’s (method II) formal synthesis of triptolide.

In 2008, Sherburn and co-workers developed an approach to the formal synthesis of triptolide (Figure 2, route G, Scheme 5) [71]. Key features of the synthesis include two intermolecular Diels–Alder reactions and a newly developed deoxygenative aromatization procedure. The first enantioselective Diels–Alder reaction, which is an intermolecular cycloaddition and lactonization between (Z)-3-iodo-4-methylpenta-2,4-dien-1-ol (29) and methyl acrylate (30) in the presence of Mikami’s (binol)TiCl2 catalyst to form the A- and D-ring. The second one involves the reaction of the bicyclic intermediate 13 and 2-isopropyl-1,4-benzoquinone (14) to form the B- and C-ring. Finally, a regio- and stereoselective reduction, methylation and dehydration procedure and a selenylation, oxidation and elimination procedure were employed to successfully achieve Berchtold’s tetracyclic C-5,C-6 olefin intermediate 45 in only 7 steps with 8.1% overall yield in a protecting-group-free synthesis. However, we know the conversion of Berchtold’s C-5,C-6 tetracyclic olefin intermediate 45 to triptophenolide methyl ether (8) is a troublesome work (60% yield) due to the formation of the thermodynamic more stable C-5 cis-epimer 44 [66]. Thus, it may not be possible to obtain the desired triptophenolide methyl ether (8) in a satisfactory yield for a target-oriented synthesis.

Scheme 5: Sherburn’s formal synthesis of triptolide.

Scheme 5: Sherburn’s formal synthesis of triptolide.

As the key structure element of various di- and triterpenes, the trans-decalin scaffold is the ideal objective of numerous methodology studies. Inspired by nature’s highly efficient and stereochemically controlled syntheses of terpenes, up to now, various synthetic strategies to trans-decalin have been developed, e.g., Brønsted acid or Lewis acid-mediated cationic polyene cyclization, transition-metal- or photocatalyst-mediated radical polyene cyclization [72]. The key to such transformation is to install a proper initiator within the substrate such as an allylic alcohol, an acetal, an aziridine, an N-acetal, a hydroxylactam, or a 1,3-dicarbonyl moiety.

van Tamelen and co-workers originally reported a nature-inspired acid-induced cationic polyene cyclization to construct the key trans-decalin scaffold (A- and B-ring) of triptolide (Figure 2, Scheme 6 and route H) [73]. In their synthesis, 2-isopropylphenol (31) was used as starting material to construct the key cyclization precursor ketoester 15, which was cyclized in the presence of SnCl4 to give tricyclic intermediate 83, followed by steps of functional group modification to install the butenolide (D-ring), and to finish the racemic synthesis of the key intermediate triptophenolide methyl ether (8) in 12 steps with 15% yield. Interestingly, in this synthesis only four intermediates needed to be purified.

Scheme 6: van Tamelen’s biogenetic type total synthesis of triptolide.

Scheme 6: van Tamelen’s biogenetic type total synthesis of triptolide.

In 1999, Yang and co-workers reported an elegant chiral auxiliary-assisted, lanthanide triflate-catalyzed oxidative radical polycyclization of olefin-cation-based enantioselective synthesis of triptolide (Figure 2, route I and Scheme 7) [74]. In this synthesis, commercially available 2-isopropylphenol (31) was used as starting material, protection of 31 with chloromethyl methyl ether (MOM), followed by ortho lithiation and methylation with iodomethane, provided intermediate 85, which was lithiated and reacted with 3,3-dimethylallyl bromide, followed by changing the protecting group from MOM ether to methyl ether to provide olefin 86. Allylic oxidation of 86 followed by nucleophilic bromination of the resulting allylic alcohol gave bromide 87. Dianion displacement of the bromide of 87 gave ester 88. Ester exchange of 88 with (+)-8-phenylmenthol gave the key cyclization precursor 16. Oxidative radical cyclization of 16 in the presence of Mn(OAc)3 and Yb(OTf)3·H2O afforded the major tricyclic diastereomer 89 (dr = 38:1). Then the construction of the unsaturated lactone was performed by conversion of 89 to vinyl triflate 90, followed by reduction and palladium-catalyzed carbonylation–lactone formation to give key intermediate 8 [75-77]. After that, the three successive epoxides were installed by known procedures with some modification. The highlights were the introduction of the second epoxide as a single diastereomer via in situ-generated methyl(trifluoromethyl)dioxirane and the reduction of the C-14 ketone in the presence of Eu(fod)3 to give triptolide (47%) together with its C-14 α-hydroxy epimer epi-triptolide (47%).

Scheme 7: Yang’s total synthesis of triptolide.

Scheme 7: Yang’s total synthesis of triptolide.

In 2014, Li’s group reported a divergent synthesis for triptolide and its relatives from commercially available acid 32 (Figure 2, route J and Scheme 8) [46]. This synthesis highlights the utilization of an indium(III)-catalyzed cationic polycyclization of 17 and a palladium-catalyzed carbonylation–in situ lactone formation to construct the key intermediate 94, which could readily be converted to triptolide and its relatives such as triptophenolid, tripdiolide, and 16-hydroxytriptolide via palladium-catalyzed cross-coupling or Claisen rearrangement reactions. Importantly, by modification of the C-2,C3 olefin and late-stage installation of the C-13 isopropyl group, the synthesis also provides a new useful approach for the synthesis of other structurally relevant derivatives of triptolide.

Scheme 8: Key intermediates or transformations of routes J–N.

Scheme 8: Key intermediates or transformations of routes J–N.

In 2011, as their ongoing work that devoted to the synthesis of triptolide, Batti and co-workers developed a novel highly diastereoselective methodology that features 6-endo-trig cyclization of 2-alkenyl-1,3-dithiolanes to access trans-decalins (Figure 2, route K) [78]. Density functional theory calculation (DFT) studies indicated that the 2-alkenyl-1,3-dithiolane moiety acts as a latent initiator, which triggers the cationic 6-endo-trig cyclization in the presence of trimethylsilyl trifluoromethanesulfonate (TMSOTf) in a diastereoselective and stepwise manner. This novel methodology provides a shorter access to the intermediate 97, which is a key intermediate for the synthesis of triptolide.

Recently, photoredox catalysis has emerged as a powerful and high-yielding method for the generation of carbon radicals via single-electron transfer (SET). In 2016, Barriault and co-workers reported a methodology that features the utilization of dimeric gold complex [Au2(dppm)2]Cl2 and ultraviolet A (UV, 365 nm) light to direct arylation of bromide-substituted butenolides or cyclic enones [51]. Photoexcitation (UV, 365 nm) of [Au-Au]2+ generated [Au-Au]2+*, which could then effectively reduce the vinyl C–Br bond via a SET to generate the vinyl radical. This radical then cyclizes with an aryl group to generated a tricyclic intermediate bearing a tertiary radical. A simultaneous oxidation of the tertiary radical and reduction of the [Au-Au]3+ ion could give the cyclization product and regenerate the dimeric gold photocatalyst. Later, the utility of this photoredox methodology was demonstrated in a concise formal synthesis of triptolide (1) via the reaction of bromobutenolide 19 under the optimal photoredox conditions to provide tetracyclic intermediate 19i (dr = 1:1, Scheme 8, route L), with a cis A-/B-ring connection rather than the desired trans connection. Treatment of 19i with H2SO4, followed by RuCl2(PPh3)3-catalyzed double bond isomerization gave the known intermediate 45.

Thanks to the great advance of transition metal-mediated or catalyzed reactions that have been widely used for the construction of C–C, C–N, C–O, C–S, and C–X (X = F, Cl, Br or I) bonds in synthetic organic chemistry, and especially the transition metal-catalyzed functionalization of unreactive C–H bonds, either Csp2 or Csp3, a revolution in the synthesis of complex natural products (NPs) has been evolved. It provides a powerful toolbox to access complex natural structures and has the potential to streamline the synthesis. In 2014, Li and co-workers reported a metal-mediated reaction-based formal synthesis of triptolide and triptonide (Figure 2, route M) [48]. This synthesis highlights the use of Noyori’s ruthenium-catalyzed enantioselective transfer hydrogenation to introduce the chiral center; the indium(III)-catalyzed cationic polyene cyclization to construct the tricyclic A-, B- and C-ring system; palladium-catalyzed carbonylation and in situ lactone formation, and rhodium(II)-catalyzed double bond migration to construct the D-ring; and palladium-catalyzed Csp2–H oxygenation to install the C-14 hydroxy group. In 2016, Qin and co-workers developed a catalytic asymmetric route toward the formal synthesis of triptolide (Figure 2, route N) [43]. This synthesis highlighted the palladium-catalyzed asymmetric addition of arylboronic acid 37 to 3-methylcyclohex-2-en-1-one (38) to form the C-10 quaternary chiral center, and a subsequent Claisen rearrangement and an aldol reaction to furnish the trans-decalin A/B ring system.

Conclusion and Future Perspectives

Taken together, the intriguing structural features, the promising multiple biological activities and the lack of natural sources have made triptolide an attractive target for total synthesis. So far, lots of total syntheses and formal syntheses of triptolide and its relatives have been established since the pioneering works of Berchtold and Tahara. Each synthesis has its advantages and disadvantages, the key points in the synthesis of triptolide are: i) the construction of the trans-decalin A-/B-ring system; ii) the construction of the butenolide (D-ring) and iii) the installation of the three successive epoxides (C-ring). In future syntheses the following issues should be considered: i) avoiding the isomerization of the C-5 chiral center; ii) development of a new method for the β-selective reduction of the C-14 carbonyl group of triptonide; iii) development of a new or improved synthesis to further satisfy the increasing demand of triptolide for the synthesis of clinical compounds such as LLDT-8 and minnelide.

References

-

Kupchan, S. M.; Court, W. A.; Dailey, R. G.; Gilmore, C. J.; Bryan, R. F. J. Am. Chem. Soc. 1972, 94, 7194–7195. doi:10.1021/ja00775a078

Return to citation in text: [1] -

Liu, Q. Int. Immunopharmacol. 2011, 11, 377–383. doi:10.1016/j.intimp.2011.01.012

Return to citation in text: [1] -

Ziaei, S.; Halaby, R. A. Avicenna J. Phytomed. 2016, 6, 149–164.

Return to citation in text: [1] -

Park, B. Biochimie 2014, 105, 129–136. doi:10.1016/j.biochi.2014.07.003

Return to citation in text: [1] -

Yue, Y.; Hikim, A. P. S.; Wang, C.; Leung, A.; Baravarian, S.; Reutrakul, V.; Sangsawan, R.; Chaichana, S.; Swerdloff, R. S. J. Androl. 1998, 19, 479–486.

Return to citation in text: [1] -

Huang, J.; Zhou, L.; Wu, H.; Pavlos, N.; Chim, S. M.; Liu, Q.; Zhao, J.; Xue, W.; Tan, R. X.; Ye, J.; Xu, J.; Ang, E. S.; Feng, H.; Tickner, J.; Xu, J.; Ding, Y. Mol. Cell. Endocrinol. 2015, 399, 346–353. doi:10.1016/j.mce.2014.10.016

Return to citation in text: [1] -

Qiu, D.; Kao, P. N. Drugs R&D 2003, 4, 1–18. doi:10.2165/00126839-200304010-00001

Return to citation in text: [1] -

Wei, Y.-m.; Wang, Y.-h.; Xue, H.-q.; Luan, Z.-h.; Liu, B.-w.; Ren, J.-h. Chin. J. Integr. Med. 2019, 25, 233–240. doi:10.1007/s11655-018-2847-z

Return to citation in text: [1] -

Bao, X.; Cui, J.; Wu, Y.; Han, X.; Gao, C.; Hua, Z.; Shen, P. J. Mol. Med. (Heidelberg, Ger.) 2007, 85, No. 85. doi:10.1007/s00109-006-0113-x

Return to citation in text: [1] -

Zhao, F.; Chen, Y.; Li, R.; Liu, Y.; Wen, L.; Zhang, C. Toxicology 2010, 267, 70–79. doi:10.1016/j.tox.2009.10.023

Return to citation in text: [1] -

Phillips, P. A.; Dudeja, V.; McCarroll, J. A.; Borja-Cacho, D.; Dawra, R. K.; Grizzle, W. E.; Vickers, S. M.; Saluja, A. K. Cancer Res. 2007, 67, 9407–9416. doi:10.1158/0008-5472.can-07-1077

Return to citation in text: [1] -

Lin, J.; Chen, L.-Y.; Lin, Z.-X.; Zhao, M.-L. J. Int. Med. Res. 2007, 35, 637–643. doi:10.1177/147323000703500508

Return to citation in text: [1] -

YinJun, L.; Jie, J.; YunGui, W. Leuk. Res. 2005, 29, 99–105. doi:10.1016/j.leukres.2004.05.014

Return to citation in text: [1] -

Zhu, W.; Hu, H.; Qiu, P.; Yan, G. Oncol. Rep. 2009, 22, 1397–1401. doi:10.3892/or_00000580

Return to citation in text: [1] -

Carter, B. Z.; Mak, D. H.; Schober, W. D.; McQueen, T.; Harris, D.; Estrov, Z.; Evans, R. L.; Andreeff, M. Blood 2006, 108, 630–637. doi:10.1182/blood-2005-09-3898

Return to citation in text: [1] -

Miyata, Y.; Sato, T.; Ito, A. Biochem. Biophys. Res. Commun. 2005, 336, 1081–1086. doi:10.1016/j.bbrc.2005.08.247

Return to citation in text: [1] -

Tai, C.-J.; Wu, A. T. H.; Chiou, J.-F.; Jan, H.-J.; Wei, H.-J.; Hsu, C.-H.; Lin, C.-T.; Chiu, W.-T.; Wu, C.-W.; Lee, H.-M.; Deng, W.-P. BMC Cancer 2010, 10, 95. doi:10.1186/1471-2407-10-95

Return to citation in text: [1] -

Hou, Z.-y.; Tong, X.-p.; Peng, Y.-b.; Zhang, B.-k.; Yan, M. Biomed. Pharmacother. 2018, 104, 771–780. doi:10.1016/j.biopha.2018.05.088

Return to citation in text: [1] -

Liu, L.; Salnikov, A. V.; Bauer, N.; Aleksandrowicz, E.; Labsch, S.; Nwaeburu, C.; Mattern, J.; Gladkich, J.; Schemmer, P.; Werner, J.; Herr, I. Int. J. Cancer 2014, 134, 2489–2503. doi:10.1002/ijc.28583

Return to citation in text: [1] -

Chen, Z.; Sangwan, V.; Banerjee, S.; Chugh, R.; Dudeja, V.; Vickers, S. M.; Saluja, A. K. Cancer Lett. 2014, 348, 156–166. doi:10.1016/j.canlet.2014.03.016

Return to citation in text: [1] -

Zhou, G.-S.; Hu, Z.; Fang, H.-T.; Zhang, F.-X.; Pan, X.-F.; Chen, X.-Q.; Hu, A.-M.; Xu, L.; Zhou, G.-B. Leuk. Res. 2011, 35, 214–218. doi:10.1016/j.leukres.2010.07.013

Return to citation in text: [1] -

Clawson, K. A.; Borja-Cacho, D.; Antonoff, M. B.; Saluja, A. K.; Vickers, S. M. J. Surg. Res. 2010, 163, 244–249. doi:10.1016/j.jss.2010.03.067

Return to citation in text: [1] -

Carter, B. Z.; Mak, D. H.; Schober, W. D.; Dietrich, M. F.; Pinilla, C.; Vassilev, L. T.; Reed, J. C.; Andreeff, M. Blood 2008, 111, 3742–3750. doi:10.1182/blood-2007-05-091504

Return to citation in text: [1] -

Raghavendra, N. M.; Pingili, D.; Kadasi, S.; Mettu, A.; Prasad, S. V. U. M. Eur. J. Med. Chem. 2018, 143, 1277–1300. doi:10.1016/j.ejmech.2017.10.021

Return to citation in text: [1] -

Krakauer, T.; Chen, X.; Howard, O. M. Z.; Young, H. A. Immunopharmacol. Immunotoxicol. 2005, 27, 53–66. doi:10.1081/iph-51294

Return to citation in text: [1] -

Liu, Q.; Chen, T.; Chen, G.; Li, N.; Wang, J.; Ma, P.; Cao, X. Biochem. Biophys. Res. Commun. 2006, 345, 1122–1130. doi:10.1016/j.bbrc.2006.05.024

Return to citation in text: [1] -

Zhao, G.; Vaszar, L. T.; Qiu, D.; Shi, L.; Kao, P. N. Am. J. Physiol.: Lung Cell. Mol. Physiol. 2000, 279, L958–L966. doi:10.1152/ajplung.2000.279.5.l958

Return to citation in text: [1] -

Zhou, H.-F.; Niu, D.-B.; Xue, B.; Li, F.-Q.; Liu, X.-Y.; He, Q.-H.; Wang, X.-H.; Wang, X.-M. NeuroReport 2003, 14, 1091–1095. doi:10.1097/01.wnr.0000073682.00308.47

Return to citation in text: [1] [2] -

Sun, M.; Song, H.; Ye, Y.; Yang, Q.; Xu, X.; Zhu, X.; Zhang, J.; Shi, S.; Wang, J.; Liu, Z. Biomed. Pharmacother. 2019, 109, 2375–2386. doi:10.1016/j.biopha.2018.11.081

Return to citation in text: [1] -

Chen, D.; Ma, Y.; Wang, X.; Yu, S.; Li, L.; Dai, B.; Mao, Z.; Liu, H.; Liu, S.; Mei, C. A. J. Kidney Dis. 2014, 63, 1070–1072. doi:10.1053/j.ajkd.2014.01.418

Return to citation in text: [1] -

Fan, D.; Guo, Q.; Shen, J.; Zheng, K.; Lu, C.; Zhang, G.; Lu, A.; He, X. Int. J. Mol. Sci. 2018, 19, 376. doi:10.3390/ijms19020376

Return to citation in text: [1] -

Yang, S.-X.; Gao, H.-L.; Xie, S.-S.; Zhang, W. R.; Long, Z.-Z. Int. J. Immunopharmacol. 1992, 14, 963–969. doi:10.1016/0192-0561(92)90139-c

Return to citation in text: [1] -

Yang, F.; Ren, L.; Zhuo, L.; Ananda, S.; Liu, L. Exp. Toxicol. Pathol. 2012, 64, 905–911. doi:10.1016/j.etp.2011.03.013

Return to citation in text: [1] -

Li, J.; Shen, F.; Guan, C.; Wang, W.; Sun, X.; Fu, X.; Huang, M.; Jin, J.; Huang, Z. PLoS One 2014, 9, e100685. doi:10.1371/journal.pone.0100685

Return to citation in text: [1] -

Yang, F.; Wu, L.; Li, Y.; Wang, D. Drug Des., Dev. Ther. 2015, 9, 6095–6107. doi:10.2147/dddt.s92022

Return to citation in text: [1] -

Liu, J.; Jiang, Z.; Liu, L.; Zhang, Y.; Zhang, S.; Xiao, J.; Ma, M.; Zhang, L. Drug Chem. Toxicol. 2011, 34, 1–7. doi:10.3109/01480541003774358

Return to citation in text: [1] -

Xu, L.; Qiu, Y.; Xu, H.; Ao, W.; Lam, W.; Yang, X. Food Chem. Toxicol. 2013, 57, 371–379. doi:10.1016/j.fct.2013.03.044

Return to citation in text: [1] -

Chen, S.-W.; Zhou, N.-N.; Li, C. Mini-Rev. Org. Chem. 2012, 9, 151–162. doi:10.2174/157019312800604661

Return to citation in text: [1] -

Xu, H.; Liu, B. Eur. J. Med. Chem. 2019, 164, 342–351. doi:10.1016/j.ejmech.2018.12.058

Return to citation in text: [1] -

Hou, W.; Liu, B.; Xu, H. Eur. J. Med. Chem. 2019, 176, 378–392. doi:10.1016/j.ejmech.2019.05.032

Return to citation in text: [1] -

Yang, Y.-q.; Liang, J.; Han, X.-d.; Tian, R.-m.; Liu, X.-s.; Mao, W.; Xu, H.-t.; Liu, B.; Xu, P. Biomed. Pharmacother. 2019, 109, 1932–1939. doi:10.1016/j.biopha.2018.11.031

Return to citation in text: [1] -

Yang, Y.-Q.; Yan, X.-T.; Wang, K.; Tian, R.-M.; Lu, Z.-Y.; Wu, L.-L.; Xu, H.-T.; Wu, Y.-S.; Liu, X.-S.; Mao, W.; Xu, P.; Liu, B. Front. Pharmacol. 2018, 9, No. 999. doi:10.3389/fphar.2018.00999

Return to citation in text: [1] -

Xu, W.-D.; Li, L.-Q.; Li, M.-M.; Geng, H.-C.; Qin, H.-B. Nat. Prod. Bioprospect. 2016, 6, 183–186. doi:10.1007/s13659-016-0100-z

Return to citation in text: [1] [2] -

Lai, C. K.; Buckanin, R. S.; Chen, S. J.; Zimmerman, D. F.; Sher, F. T.; Berchtold, G. A. J. Org. Chem. 1982, 47, 2364–2369. doi:10.1021/jo00133a026

Return to citation in text: [1] -

Sher, F. T.; Berchtold, G. A. J. Org. Chem. 1977, 42, 2569–2574. doi:10.1021/jo00435a008

Return to citation in text: [1] [2] -

Xu, H.; Tang, H.; Feng, H.; Li, Y. J. Org. Chem. 2014, 79, 10110–10122. doi:10.1021/jo501744j

Return to citation in text: [1] [2] -

Xu, H.; Tang, H.; Yang, Z.; Feng, H.; Li, Y. Tetrahedron 2014, 70, 3107–3115. doi:10.1016/j.tet.2014.03.070

Return to citation in text: [1] -

Xu, H.; Tang, H.; Feng, H.; Li, Y. Tetrahedron Lett. 2014, 55, 7118–7120. doi:10.1016/j.tetlet.2014.11.010

Return to citation in text: [1] [2] -

Yang, D.; Wong, M.-K.; Cheung, K.-K.; Chan, E. W. C.; Xie, Y. Tetrahedron Lett. 1997, 38, 6865–6868. doi:10.1016/s0040-4039(97)01581-5

Return to citation in text: [1] -

Zhang, H.; Li, H.; Xue, J.; Chen, R.; Li, Y.; Tang, Y.; Li, C. Org. Biomol. Chem. 2014, 12, 732–736. doi:10.1039/c3ob42183j

Return to citation in text: [1] [2] -

Cannillo, A.; Schwantje, T. R.; Bégin, M.; Barabé, F.; Barriault, L. Org. Lett. 2016, 18, 2592–2595. doi:10.1021/acs.orglett.6b00968

Return to citation in text: [1] [2] -

Zhou, Z.-L.; Yang, Y.-X.; Ding, J.; Li, Y.-C.; Miao, Z.-H. Nat. Prod. Rep. 2012, 29, 457. doi:10.1039/c2np00088a

Return to citation in text: [1] -

Kaloun, E. B.; Long, C.; Molinier, N.; Brel, V.; Cantagrel, F.; Massiot, G. Tetrahedron Lett. 2016, 57, 1895–1898. doi:10.1016/j.tetlet.2016.03.060

Return to citation in text: [1] -

Xu, H.; Tang, H.; Feng, H.; Li, Y. ChemMedChem 2014, 9, 290–295. doi:10.1002/cmdc.201300409

Return to citation in text: [1] -

Xu, H.; Chen, Y.; Tang, H.; Feng, H.; Li, Y. Bioorg. Med. Chem. Lett. 2014, 24, 5671–5674. doi:10.1016/j.bmcl.2014.10.069

Return to citation in text: [1] -

Xu, H.; Tang, H.; Feng, H.; Li, Y. Eur. J. Med. Chem. 2014, 73, 46–55. doi:10.1016/j.ejmech.2013.11.044

Return to citation in text: [1] -

Xu, H.; Fan, X.; Zhang, G.; Liu, X.; Li, Z.; Li, Y.; Jiang, B. Biomed. Pharmacother. 2017, 93, 1004–1009. doi:10.1016/j.biopha.2017.06.041

Return to citation in text: [1] -

Xu, H.; Liu, L.; Fan, X.; Zhang, G.; Li, Y.; Jiang, B. Bioorg. Med. Chem. Lett. 2017, 27, 505–510. doi:10.1016/j.bmcl.2016.12.032

Return to citation in text: [1] -

Aoyagi, Y.; Hitotsuyanagi, Y.; Hasuda, T.; Matsuyama, S.; Fukaya, H.; Takeya, K.; Aiyama, R.; Matsuzaki, T.; Hashimoto, S. Bioorg. Med. Chem. Lett. 2008, 18, 2459–2463. doi:10.1016/j.bmcl.2008.02.039

Return to citation in text: [1] -

Aoyagi, Y.; Hitotsuyanagi, Y.; Hasuda, T.; Fukaya, H.; Takeya, K.; Aiyama, R.; Matsuzaki, T.; Hashimoto, S. Bioorg. Med. Chem. 2006, 16, 1947–1949. doi:10.1016/j.bmcl.2005.12.098

Return to citation in text: [1] -

Patil, S.; Lis, L. G.; Schumacher, R. J.; Norris, B. J.; Morgan, M. L.; Cuellar, R. A. D.; Blazar, B. R.; Suryanarayanan, R.; Gurvich, V. J.; Georg, G. I. J. Med. Chem. 2015, 58, 9334–9344. doi:10.1021/acs.jmedchem.5b01329

Return to citation in text: [1] [2] -

Zhou, R.; Zhang, F.; He, P.-L.; Zhou, W.-L.; Wu, Q.-L.; Xu, J.-Y.; Zhou, Y.; Tang, W.; Li, X.-Y.; Yang, Y.-F.; Li, Y.-C.; Zuo, J.-P. Int. Immunopharmacol. 2005, 5, 1895–1903. doi:10.1016/j.intimp.2005.06.009

Return to citation in text: [1] -

Frieze, D. M.; Berchtold, G. A.; Blount, J. F. Tetrahedron Lett. 1978, 19, 4607–4610. doi:10.1016/s0040-4039(01)85683-5

Return to citation in text: [1] -

Tahara, A.; Akita, H. Chem. Pharm. Bull. 1975, 23, 1976–1983. doi:10.1248/cpb.23.1976

Return to citation in text: [1] [2] -

Koike, H.; Tokoroyama, T. Tetrahedron Lett. 1978, 19, 4531–4534. doi:10.1016/s0040-4039(01)95270-0

Return to citation in text: [1] -

Buckanin, R. S.; Chen, S. J.; Frieze, D. M.; Sher, F. T.; Berchtold, G. A. J. Am. Chem. Soc. 1980, 102, 1200–1201. doi:10.1021/ja00523a065

Return to citation in text: [1] [2] -

Van Tamelen, E. E.; Demers, J. P.; Taylor, E. G.; Koller, K. J. Am. Chem. Soc. 1980, 102, 5424–5425. doi:10.1021/ja00536a065

Return to citation in text: [1] -

Alvarez-Manzaneda, E.; Chahboun, R.; Bentaleb, F.; Alvarez, E.; Escobar, M. A.; Sad-Diki, S.; Cano, M. J.; Messouri, I. Tetrahedron 2007, 63, 11204–11212. doi:10.1016/j.tet.2007.07.088

Return to citation in text: [1] -

Zhou, B.; Li, X.; Feng, H.; Li, Y. Tetrahedron 2010, 66, 5396–5401. doi:10.1016/j.tet.2010.05.035

Return to citation in text: [1] -

Garver, L. C.; Van Tamelen, E. E. J. Am. Chem. Soc. 1982, 104, 867–869. doi:10.1021/ja00367a046

Return to citation in text: [1] -

Miller, N. A.; Willis, A. C.; Sherburn, M. S. Chem. Commun. 2008, 1226. doi:10.1039/b718754h

Return to citation in text: [1] -

Barrett, A.; Ma, T.-K.; Mies, T. Synthesis 2019, 51, 67–82. doi:10.1055/s-0037-1610382

Return to citation in text: [1] -

Van Tamelen, E. E.; Leiden, T. M. J. Am. Chem. Soc. 1982, 104, 1785–1786. doi:10.1021/ja00370a077

Return to citation in text: [1] -

Yang, D.; Ye, X.-Y.; Gu, S.; Xu, M. J. Am. Chem. Soc. 1999, 121, 5579–5580. doi:10.1021/ja9901664

Return to citation in text: [1] -

Yang, D.; Ye, X.-Y.; Xu, M. J. Org. Chem. 2000, 65, 2208–2217. doi:10.1021/jo9919613

Return to citation in text: [1] -

Yang, D.; Ye, X.-Y.; Xu, M.; Pang, K.-W.; Zou, N.; Letcher, R. M. J. Org. Chem. 1998, 63, 6446–6447. doi:10.1021/jo981362g

Return to citation in text: [1] -

Yang, D.; Xu, M.; Bian, M.-Y. Org. Lett. 2001, 3, 111–114. doi:10.1021/ol0068243

Return to citation in text: [1] -

Goncalves, S.; Santoro, S.; Nicolas, M.; Wagner, A.; Maillos, P.; Himo, F.; Baati, R. J. Org. Chem. 2011, 76, 3274–3285. doi:10.1021/jo2001116

Return to citation in text: [1]

| 36. | Liu, J.; Jiang, Z.; Liu, L.; Zhang, Y.; Zhang, S.; Xiao, J.; Ma, M.; Zhang, L. Drug Chem. Toxicol. 2011, 34, 1–7. doi:10.3109/01480541003774358 |

| 37. | Xu, L.; Qiu, Y.; Xu, H.; Ao, W.; Lam, W.; Yang, X. Food Chem. Toxicol. 2013, 57, 371–379. doi:10.1016/j.fct.2013.03.044 |

| 38. | Chen, S.-W.; Zhou, N.-N.; Li, C. Mini-Rev. Org. Chem. 2012, 9, 151–162. doi:10.2174/157019312800604661 |

| 39. | Xu, H.; Liu, B. Eur. J. Med. Chem. 2019, 164, 342–351. doi:10.1016/j.ejmech.2018.12.058 |

| 40. | Hou, W.; Liu, B.; Xu, H. Eur. J. Med. Chem. 2019, 176, 378–392. doi:10.1016/j.ejmech.2019.05.032 |

| 41. | Yang, Y.-q.; Liang, J.; Han, X.-d.; Tian, R.-m.; Liu, X.-s.; Mao, W.; Xu, H.-t.; Liu, B.; Xu, P. Biomed. Pharmacother. 2019, 109, 1932–1939. doi:10.1016/j.biopha.2018.11.031 |

| 42. | Yang, Y.-Q.; Yan, X.-T.; Wang, K.; Tian, R.-M.; Lu, Z.-Y.; Wu, L.-L.; Xu, H.-T.; Wu, Y.-S.; Liu, X.-S.; Mao, W.; Xu, P.; Liu, B. Front. Pharmacol. 2018, 9, No. 999. doi:10.3389/fphar.2018.00999 |

| 43. | Xu, W.-D.; Li, L.-Q.; Li, M.-M.; Geng, H.-C.; Qin, H.-B. Nat. Prod. Bioprospect. 2016, 6, 183–186. doi:10.1007/s13659-016-0100-z |

| 44. | Lai, C. K.; Buckanin, R. S.; Chen, S. J.; Zimmerman, D. F.; Sher, F. T.; Berchtold, G. A. J. Org. Chem. 1982, 47, 2364–2369. doi:10.1021/jo00133a026 |

| 45. | Sher, F. T.; Berchtold, G. A. J. Org. Chem. 1977, 42, 2569–2574. doi:10.1021/jo00435a008 |

| 46. | Xu, H.; Tang, H.; Feng, H.; Li, Y. J. Org. Chem. 2014, 79, 10110–10122. doi:10.1021/jo501744j |

| 47. | Xu, H.; Tang, H.; Yang, Z.; Feng, H.; Li, Y. Tetrahedron 2014, 70, 3107–3115. doi:10.1016/j.tet.2014.03.070 |

| 48. | Xu, H.; Tang, H.; Feng, H.; Li, Y. Tetrahedron Lett. 2014, 55, 7118–7120. doi:10.1016/j.tetlet.2014.11.010 |

| 49. | Yang, D.; Wong, M.-K.; Cheung, K.-K.; Chan, E. W. C.; Xie, Y. Tetrahedron Lett. 1997, 38, 6865–6868. doi:10.1016/s0040-4039(97)01581-5 |

| 50. | Zhang, H.; Li, H.; Xue, J.; Chen, R.; Li, Y.; Tang, Y.; Li, C. Org. Biomol. Chem. 2014, 12, 732–736. doi:10.1039/c3ob42183j |

| 51. | Cannillo, A.; Schwantje, T. R.; Bégin, M.; Barabé, F.; Barriault, L. Org. Lett. 2016, 18, 2592–2595. doi:10.1021/acs.orglett.6b00968 |

| 64. | Tahara, A.; Akita, H. Chem. Pharm. Bull. 1975, 23, 1976–1983. doi:10.1248/cpb.23.1976 |

| 68. | Alvarez-Manzaneda, E.; Chahboun, R.; Bentaleb, F.; Alvarez, E.; Escobar, M. A.; Sad-Diki, S.; Cano, M. J.; Messouri, I. Tetrahedron 2007, 63, 11204–11212. doi:10.1016/j.tet.2007.07.088 |

| 69. | Zhou, B.; Li, X.; Feng, H.; Li, Y. Tetrahedron 2010, 66, 5396–5401. doi:10.1016/j.tet.2010.05.035 |

| 50. | Zhang, H.; Li, H.; Xue, J.; Chen, R.; Li, Y.; Tang, Y.; Li, C. Org. Biomol. Chem. 2014, 12, 732–736. doi:10.1039/c3ob42183j |

| 67. | Van Tamelen, E. E.; Demers, J. P.; Taylor, E. G.; Koller, K. J. Am. Chem. Soc. 1980, 102, 5424–5425. doi:10.1021/ja00536a065 |

| 45. | Sher, F. T.; Berchtold, G. A. J. Org. Chem. 1977, 42, 2569–2574. doi:10.1021/jo00435a008 |

| 63. | Frieze, D. M.; Berchtold, G. A.; Blount, J. F. Tetrahedron Lett. 1978, 19, 4607–4610. doi:10.1016/s0040-4039(01)85683-5 |

| 64. | Tahara, A.; Akita, H. Chem. Pharm. Bull. 1975, 23, 1976–1983. doi:10.1248/cpb.23.1976 |

| 65. | Koike, H.; Tokoroyama, T. Tetrahedron Lett. 1978, 19, 4531–4534. doi:10.1016/s0040-4039(01)95270-0 |

| 66. | Buckanin, R. S.; Chen, S. J.; Frieze, D. M.; Sher, F. T.; Berchtold, G. A. J. Am. Chem. Soc. 1980, 102, 1200–1201. doi:10.1021/ja00523a065 |

| 52. | Zhou, Z.-L.; Yang, Y.-X.; Ding, J.; Li, Y.-C.; Miao, Z.-H. Nat. Prod. Rep. 2012, 29, 457. doi:10.1039/c2np00088a |

| 53. | Kaloun, E. B.; Long, C.; Molinier, N.; Brel, V.; Cantagrel, F.; Massiot, G. Tetrahedron Lett. 2016, 57, 1895–1898. doi:10.1016/j.tetlet.2016.03.060 |

| 54. | Xu, H.; Tang, H.; Feng, H.; Li, Y. ChemMedChem 2014, 9, 290–295. doi:10.1002/cmdc.201300409 |

| 55. | Xu, H.; Chen, Y.; Tang, H.; Feng, H.; Li, Y. Bioorg. Med. Chem. Lett. 2014, 24, 5671–5674. doi:10.1016/j.bmcl.2014.10.069 |

| 56. | Xu, H.; Tang, H.; Feng, H.; Li, Y. Eur. J. Med. Chem. 2014, 73, 46–55. doi:10.1016/j.ejmech.2013.11.044 |

| 57. | Xu, H.; Fan, X.; Zhang, G.; Liu, X.; Li, Z.; Li, Y.; Jiang, B. Biomed. Pharmacother. 2017, 93, 1004–1009. doi:10.1016/j.biopha.2017.06.041 |

| 58. | Xu, H.; Liu, L.; Fan, X.; Zhang, G.; Li, Y.; Jiang, B. Bioorg. Med. Chem. Lett. 2017, 27, 505–510. doi:10.1016/j.bmcl.2016.12.032 |

| 59. | Aoyagi, Y.; Hitotsuyanagi, Y.; Hasuda, T.; Matsuyama, S.; Fukaya, H.; Takeya, K.; Aiyama, R.; Matsuzaki, T.; Hashimoto, S. Bioorg. Med. Chem. Lett. 2008, 18, 2459–2463. doi:10.1016/j.bmcl.2008.02.039 |

| 60. | Aoyagi, Y.; Hitotsuyanagi, Y.; Hasuda, T.; Fukaya, H.; Takeya, K.; Aiyama, R.; Matsuzaki, T.; Hashimoto, S. Bioorg. Med. Chem. 2006, 16, 1947–1949. doi:10.1016/j.bmcl.2005.12.098 |

| 61. | Patil, S.; Lis, L. G.; Schumacher, R. J.; Norris, B. J.; Morgan, M. L.; Cuellar, R. A. D.; Blazar, B. R.; Suryanarayanan, R.; Gurvich, V. J.; Georg, G. I. J. Med. Chem. 2015, 58, 9334–9344. doi:10.1021/acs.jmedchem.5b01329 |

| 61. | Patil, S.; Lis, L. G.; Schumacher, R. J.; Norris, B. J.; Morgan, M. L.; Cuellar, R. A. D.; Blazar, B. R.; Suryanarayanan, R.; Gurvich, V. J.; Georg, G. I. J. Med. Chem. 2015, 58, 9334–9344. doi:10.1021/acs.jmedchem.5b01329 |

| 62. | Zhou, R.; Zhang, F.; He, P.-L.; Zhou, W.-L.; Wu, Q.-L.; Xu, J.-Y.; Zhou, Y.; Tang, W.; Li, X.-Y.; Yang, Y.-F.; Li, Y.-C.; Zuo, J.-P. Int. Immunopharmacol. 2005, 5, 1895–1903. doi:10.1016/j.intimp.2005.06.009 |

| 70. | Garver, L. C.; Van Tamelen, E. E. J. Am. Chem. Soc. 1982, 104, 867–869. doi:10.1021/ja00367a046 |

| 71. | Miller, N. A.; Willis, A. C.; Sherburn, M. S. Chem. Commun. 2008, 1226. doi:10.1039/b718754h |

| 66. | Buckanin, R. S.; Chen, S. J.; Frieze, D. M.; Sher, F. T.; Berchtold, G. A. J. Am. Chem. Soc. 1980, 102, 1200–1201. doi:10.1021/ja00523a065 |

| 51. | Cannillo, A.; Schwantje, T. R.; Bégin, M.; Barabé, F.; Barriault, L. Org. Lett. 2016, 18, 2592–2595. doi:10.1021/acs.orglett.6b00968 |

| 48. | Xu, H.; Tang, H.; Feng, H.; Li, Y. Tetrahedron Lett. 2014, 55, 7118–7120. doi:10.1016/j.tetlet.2014.11.010 |

| 46. | Xu, H.; Tang, H.; Feng, H.; Li, Y. J. Org. Chem. 2014, 79, 10110–10122. doi:10.1021/jo501744j |

| 78. | Goncalves, S.; Santoro, S.; Nicolas, M.; Wagner, A.; Maillos, P.; Himo, F.; Baati, R. J. Org. Chem. 2011, 76, 3274–3285. doi:10.1021/jo2001116 |

| 74. | Yang, D.; Ye, X.-Y.; Gu, S.; Xu, M. J. Am. Chem. Soc. 1999, 121, 5579–5580. doi:10.1021/ja9901664 |

| 75. | Yang, D.; Ye, X.-Y.; Xu, M. J. Org. Chem. 2000, 65, 2208–2217. doi:10.1021/jo9919613 |

| 76. | Yang, D.; Ye, X.-Y.; Xu, M.; Pang, K.-W.; Zou, N.; Letcher, R. M. J. Org. Chem. 1998, 63, 6446–6447. doi:10.1021/jo981362g |

| 77. | Yang, D.; Xu, M.; Bian, M.-Y. Org. Lett. 2001, 3, 111–114. doi:10.1021/ol0068243 |

| 72. | Barrett, A.; Ma, T.-K.; Mies, T. Synthesis 2019, 51, 67–82. doi:10.1055/s-0037-1610382 |

| 73. | Van Tamelen, E. E.; Leiden, T. M. J. Am. Chem. Soc. 1982, 104, 1785–1786. doi:10.1021/ja00370a077 |

| 43. | Xu, W.-D.; Li, L.-Q.; Li, M.-M.; Geng, H.-C.; Qin, H.-B. Nat. Prod. Bioprospect. 2016, 6, 183–186. doi:10.1007/s13659-016-0100-z |

| 1. | Kupchan, S. M.; Court, W. A.; Dailey, R. G.; Gilmore, C. J.; Bryan, R. F. J. Am. Chem. Soc. 1972, 94, 7194–7195. doi:10.1021/ja00775a078 |

| 7. | Qiu, D.; Kao, P. N. Drugs R&D 2003, 4, 1–18. doi:10.2165/00126839-200304010-00001 |

| 17. | Tai, C.-J.; Wu, A. T. H.; Chiou, J.-F.; Jan, H.-J.; Wei, H.-J.; Hsu, C.-H.; Lin, C.-T.; Chiu, W.-T.; Wu, C.-W.; Lee, H.-M.; Deng, W.-P. BMC Cancer 2010, 10, 95. doi:10.1186/1471-2407-10-95 |

| 6. | Huang, J.; Zhou, L.; Wu, H.; Pavlos, N.; Chim, S. M.; Liu, Q.; Zhao, J.; Xue, W.; Tan, R. X.; Ye, J.; Xu, J.; Ang, E. S.; Feng, H.; Tickner, J.; Xu, J.; Ding, Y. Mol. Cell. Endocrinol. 2015, 399, 346–353. doi:10.1016/j.mce.2014.10.016 |

| 18. | Hou, Z.-y.; Tong, X.-p.; Peng, Y.-b.; Zhang, B.-k.; Yan, M. Biomed. Pharmacother. 2018, 104, 771–780. doi:10.1016/j.biopha.2018.05.088 |

| 19. | Liu, L.; Salnikov, A. V.; Bauer, N.; Aleksandrowicz, E.; Labsch, S.; Nwaeburu, C.; Mattern, J.; Gladkich, J.; Schemmer, P.; Werner, J.; Herr, I. Int. J. Cancer 2014, 134, 2489–2503. doi:10.1002/ijc.28583 |

| 20. | Chen, Z.; Sangwan, V.; Banerjee, S.; Chugh, R.; Dudeja, V.; Vickers, S. M.; Saluja, A. K. Cancer Lett. 2014, 348, 156–166. doi:10.1016/j.canlet.2014.03.016 |

| 21. | Zhou, G.-S.; Hu, Z.; Fang, H.-T.; Zhang, F.-X.; Pan, X.-F.; Chen, X.-Q.; Hu, A.-M.; Xu, L.; Zhou, G.-B. Leuk. Res. 2011, 35, 214–218. doi:10.1016/j.leukres.2010.07.013 |

| 22. | Clawson, K. A.; Borja-Cacho, D.; Antonoff, M. B.; Saluja, A. K.; Vickers, S. M. J. Surg. Res. 2010, 163, 244–249. doi:10.1016/j.jss.2010.03.067 |

| 23. | Carter, B. Z.; Mak, D. H.; Schober, W. D.; Dietrich, M. F.; Pinilla, C.; Vassilev, L. T.; Reed, J. C.; Andreeff, M. Blood 2008, 111, 3742–3750. doi:10.1182/blood-2007-05-091504 |

| 24. | Raghavendra, N. M.; Pingili, D.; Kadasi, S.; Mettu, A.; Prasad, S. V. U. M. Eur. J. Med. Chem. 2018, 143, 1277–1300. doi:10.1016/j.ejmech.2017.10.021 |

| 5. | Yue, Y.; Hikim, A. P. S.; Wang, C.; Leung, A.; Baravarian, S.; Reutrakul, V.; Sangsawan, R.; Chaichana, S.; Swerdloff, R. S. J. Androl. 1998, 19, 479–486. |

| 15. | Carter, B. Z.; Mak, D. H.; Schober, W. D.; McQueen, T.; Harris, D.; Estrov, Z.; Evans, R. L.; Andreeff, M. Blood 2006, 108, 630–637. doi:10.1182/blood-2005-09-3898 |

| 2. | Liu, Q. Int. Immunopharmacol. 2011, 11, 377–383. doi:10.1016/j.intimp.2011.01.012 |

| 3. | Ziaei, S.; Halaby, R. A. Avicenna J. Phytomed. 2016, 6, 149–164. |

| 4. | Park, B. Biochimie 2014, 105, 129–136. doi:10.1016/j.biochi.2014.07.003 |

| 16. | Miyata, Y.; Sato, T.; Ito, A. Biochem. Biophys. Res. Commun. 2005, 336, 1081–1086. doi:10.1016/j.bbrc.2005.08.247 |

| 11. | Phillips, P. A.; Dudeja, V.; McCarroll, J. A.; Borja-Cacho, D.; Dawra, R. K.; Grizzle, W. E.; Vickers, S. M.; Saluja, A. K. Cancer Res. 2007, 67, 9407–9416. doi:10.1158/0008-5472.can-07-1077 |

| 13. | YinJun, L.; Jie, J.; YunGui, W. Leuk. Res. 2005, 29, 99–105. doi:10.1016/j.leukres.2004.05.014 |

| 10. | Zhao, F.; Chen, Y.; Li, R.; Liu, Y.; Wen, L.; Zhang, C. Toxicology 2010, 267, 70–79. doi:10.1016/j.tox.2009.10.023 |

| 14. | Zhu, W.; Hu, H.; Qiu, P.; Yan, G. Oncol. Rep. 2009, 22, 1397–1401. doi:10.3892/or_00000580 |

| 9. | Bao, X.; Cui, J.; Wu, Y.; Han, X.; Gao, C.; Hua, Z.; Shen, P. J. Mol. Med. (Heidelberg, Ger.) 2007, 85, No. 85. doi:10.1007/s00109-006-0113-x |

| 8. | Wei, Y.-m.; Wang, Y.-h.; Xue, H.-q.; Luan, Z.-h.; Liu, B.-w.; Ren, J.-h. Chin. J. Integr. Med. 2019, 25, 233–240. doi:10.1007/s11655-018-2847-z |

| 12. | Lin, J.; Chen, L.-Y.; Lin, Z.-X.; Zhao, M.-L. J. Int. Med. Res. 2007, 35, 637–643. doi:10.1177/147323000703500508 |

| 27. | Zhao, G.; Vaszar, L. T.; Qiu, D.; Shi, L.; Kao, P. N. Am. J. Physiol.: Lung Cell. Mol. Physiol. 2000, 279, L958–L966. doi:10.1152/ajplung.2000.279.5.l958 |

| 25. | Krakauer, T.; Chen, X.; Howard, O. M. Z.; Young, H. A. Immunopharmacol. Immunotoxicol. 2005, 27, 53–66. doi:10.1081/iph-51294 |

| 26. | Liu, Q.; Chen, T.; Chen, G.; Li, N.; Wang, J.; Ma, P.; Cao, X. Biochem. Biophys. Res. Commun. 2006, 345, 1122–1130. doi:10.1016/j.bbrc.2006.05.024 |

| 34. | Li, J.; Shen, F.; Guan, C.; Wang, W.; Sun, X.; Fu, X.; Huang, M.; Jin, J.; Huang, Z. PLoS One 2014, 9, e100685. doi:10.1371/journal.pone.0100685 |

| 35. | Yang, F.; Wu, L.; Li, Y.; Wang, D. Drug Des., Dev. Ther. 2015, 9, 6095–6107. doi:10.2147/dddt.s92022 |

| 32. | Yang, S.-X.; Gao, H.-L.; Xie, S.-S.; Zhang, W. R.; Long, Z.-Z. Int. J. Immunopharmacol. 1992, 14, 963–969. doi:10.1016/0192-0561(92)90139-c |

| 33. | Yang, F.; Ren, L.; Zhuo, L.; Ananda, S.; Liu, L. Exp. Toxicol. Pathol. 2012, 64, 905–911. doi:10.1016/j.etp.2011.03.013 |

| 29. | Sun, M.; Song, H.; Ye, Y.; Yang, Q.; Xu, X.; Zhu, X.; Zhang, J.; Shi, S.; Wang, J.; Liu, Z. Biomed. Pharmacother. 2019, 109, 2375–2386. doi:10.1016/j.biopha.2018.11.081 |

| 30. | Chen, D.; Ma, Y.; Wang, X.; Yu, S.; Li, L.; Dai, B.; Mao, Z.; Liu, H.; Liu, S.; Mei, C. A. J. Kidney Dis. 2014, 63, 1070–1072. doi:10.1053/j.ajkd.2014.01.418 |

| 31. | Fan, D.; Guo, Q.; Shen, J.; Zheng, K.; Lu, C.; Zhang, G.; Lu, A.; He, X. Int. J. Mol. Sci. 2018, 19, 376. doi:10.3390/ijms19020376 |

| 28. | Zhou, H.-F.; Niu, D.-B.; Xue, B.; Li, F.-Q.; Liu, X.-Y.; He, Q.-H.; Wang, X.-H.; Wang, X.-M. NeuroReport 2003, 14, 1091–1095. doi:10.1097/01.wnr.0000073682.00308.47 |

| 28. | Zhou, H.-F.; Niu, D.-B.; Xue, B.; Li, F.-Q.; Liu, X.-Y.; He, Q.-H.; Wang, X.-H.; Wang, X.-M. NeuroReport 2003, 14, 1091–1095. doi:10.1097/01.wnr.0000073682.00308.47 |

© 2019 Zhang et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0). Please note that the reuse, redistribution and reproduction in particular requires that the authors and source are credited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (https://www.beilstein-journals.org/bjoc)