Abstract

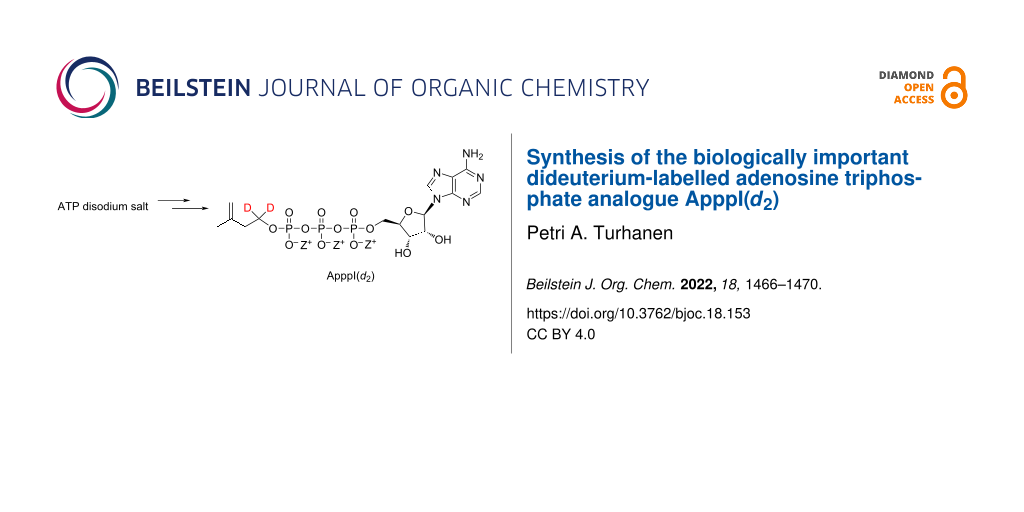

The chemical synthesis of the dideuterium-labelled ATP analogue 1-adenosin-5’-yl-3-(3-methylbut-3-en-1,1-d2-1-ol) triphosphoric acid diester (ApppI(d2)) is described. ApppI has been reported to be an important mevalonate pathway metabolite, induced by nitrogen-containing bisphosphonates used for the treatment of several diseases related to the calcium metabolism, of which osteoporosis is the most well-known. The availability of ApppI(d2) opens possibilities to quantitative measurements of ApppI in biological samples by mass spectrometry. The synthesized target compound ApppI(d2) was purified by high-performance counter current chromatography and characterized by 1H, 13C, and 31P NMR spectroscopy as well as high-resolution mass spectrometry.

Graphical Abstract

Introduction

It has become clear and evident that phosphonate chemistry plays a crucial role in drug research and development [1-4]. There are several phosphonate-containing compounds under research or already in clinical use as antiviral or anticancer drugs [2,5,6]. Bisphosphonates (BPs), the stable analogues of the natural pyrophosphate (Figure 1) found in cells, have been used for decades in the treatment of bone-related diseases, such as osteoporosis [7,8]. BPs can be categorized by the chemical structure into first-generation non-nitrogen-containing BPs (non-NBPs) and into second- and third-generation nitrogen-containing BPs (NBPs). Some examples of NBPs are alendronate, risedronate, and zoledronate (Figure 1) [9]. NBPs and non-NBPs have different mechanisms of action, and NBPs have been shown to prevent protein isoprenylation by inhibiting farnesyl pyrophosphate synthase in the mevalonate pathway. This process leads to the formation of a series of compounds of which the structures have been reported elsewhere [10-13]. In 2006, Mönkkönen et al. have reported that the use of NBPs led to the formation of ApppI, i.e., the isopentenyl ester of ATP (Figure 2), which may also isomerize to ApppD (Figure 2). The authors have also concluded that these compounds can act in two different ways: inhibition of the mevalonate pathway and blockade of mitochondrial ADP/ATP translocase, which is known to be involved in the induction of cell death [14]. The mechanism of action related to the antiresorptive and anticancer effects of NBPs has been proposed to be attributable to the metabolites formed in the mevalonate pathway induced by NBPs [15].

Figure 1: Structure of natural pyrophosphate and examples of NBPs (Z = Na or H).

Figure 1: Structure of natural pyrophosphate and examples of NBPs (Z = Na or H).

Figure 2: Structures of ATP analogues ApppI and ApppD (Z = Na or H).

Figure 2: Structures of ATP analogues ApppI and ApppD (Z = Na or H).

In 2020 in Finland, the wholesaling of BPs has been reported to amount to around 3.2 million EUR, and most were NBP sales. As such, it can be imagined that the worldwide sale is significant [16]. In light of the remarkable use of NBPs all over the world, and with the biological effects of ApppI already discovered, it is difficult to conceive how little is still known about this class of compounds: a recent search of the structure of ApppI on SciFinder led to only 18 references. It is not a whole truth, but it can be said that this is a very underexplored area of research. Interestingly, it has been reported that BP-based ATP analogs inhibit cell signaling pathways and that ApppI has a role in pain relief [17,18]. It can be proposed that some NBPs might represent a significant lead for the treatment of problematic chronic pain. Perhaps the main reason for the lack of research results on ApppI and ApppD is that these molecules are not commercially available, and in fact only few papers describe corresponding synthetic methods [19-22]. It is well known that labelled compounds (such as those with 2H and 13C labels) can be used as internal standards for the quantitative measurements of the equal compound without label, e.g., straight from the biological samples by MS [23-25]. This paper describes the synthesis of dideuterium-labelled ApppI(d2) in detail, which hopefully opens up possibilities for the develop of a quantitative MS method for the measurement of ApppI in (biological) samples, providing the research community with information related to biological functions of ApppI.

Results and Discussion

The synthesis of the target compound ApppI(d2) started with commercially available 3-methylbut-3-en-1-ol (1), which was first oxidized to 3-methylbut-3-enoic acid (2) using freshly prepared Jones reagent as oxidizing agent. 3-Methylbut-3-enoic acid (2) was then reduced to 3-methylbut-3-en-1,1-d2-1-ol (3) with lithium aluminium deuteride, followed by tosylation with tosyl chloride. Tosylated 3-methylbut-3-en-1,1-d2-1-ol 4 was then treated with ATP TBA salt in acetonitrile at 45 °C for 55 h to give the target product ApppI(d2) (Scheme 1).

Scheme 1: Synthetic route to target compound ApppI(d2) (Z = TBA).

Scheme 1: Synthetic route to target compound ApppI(d2) (Z = TBA).

The first synthetic step from 1 to 2 was rather straightforward, leading to 50% yield of 3-methylbut-3-enoic acid (2) in about 88% purity, which was reasonable enough to continue with the second step. The synthesis of 3-methylbut-3-en-1,1-d2-1-ol (3) from 2 proceeded smoothly as expected. However, when evaporating the diethyl ether solvent from the final mixture, the concomitant evaporation of the desired product 3 was also noted, leading to only 31% yield. This is to be taken into account carefully when preparing 3-methylbut-3-en-1,1-d2-1-ol (3). In the final step to produce 4 from 3, the main problem was the isolation. It was challenging to determine an appropriate eluent for TLC purification. Ultimately, using ethyl acetate/hexane 5:95 still led to only 24% yield. It can be said that the step from 3-methylbut-3-en-1-ol (1) to tosylated 3-methylbut-3-en-1,1-d2-1-ol 4 was not very efficient. However, according to the literature, this is the first example reported.

The procedure followed for the final synthetic step to ApppI(d2) and the detailed purification method by high-performance counter current chromatography (HPCCC) have previously been described elsewhere [21]. NMR spectroscopic methods were used to confirm the formation of the intermediate products 2–4 and the deuterated target compound ApppI(d2). The formation of 2 could easily be confirmed by the presence of carbonyl signal at 178 ppm in the 13C NMR spectrum. Further, the reduction of 2 by LiAlD4 led to the desired compound 3, which was finally confirmed after the tosylation step and purification of compound 4. The signal at 68 ppm with clear carbon–deuterium coupling (1JCD = 22.9 Hz) in the 13C NMR spectrum was unambiguous proof of the doubly deuterated product 4. ApppI(d2) was isolated using two different amounts of TBA salt. This was due to the solvation effect, which had already been reported earlier for the HPCCC purifications of ApppI [21] and ApppD [22]. A typical HPCCC chromatogram for the purification of ApppI(d2) is available in Supporting Information File 1.

Conclusion

In conclusion, the synthesis of doubly deuterium-labelled highly important ATP analogue ApppI(d2) has been described in detail. This leaves the possibility to develop a quantitative MS method for the determination of ApppI in biological samples by using ApppI(d2) as internal standard. Samples of ApppI(d2) are available from the author upon request.

Experimental

1H, 31P, and 13C NMR spectra were recorded on a 600 MHz spectrometer operating at 600.2, 243.0, and 150.9 MHz, respectively. The residual solvent signals (D2O, δ 4.79 ppm and CDCl3, δ 7.26 ppm) were used as references for 1H NMR measurements [26]. For ApppI(d2), the calibration peak used in the 13C NMR spectrum for characterization is mentioned in the data reported for ApppI(d2) below. The nJCP couplings were calculated from the carbon spectra, with the coupling constant given in parentheses in Hz. The HPCCC purification method has previously been reported elsewhere and was used for the purification of ApppI(d2) [21]. HRMS spectra were recorded on a qTOF mass spectrometer using electrospray ionization (ESI) in negative mode. The purity of the products was determined from the 1H and 31P NMR spectra to be ≥95%, unless stated otherwise.

ApppI(d2)⋅3.25 and ⋅5.25 TBA salts: ATP disodium salt (269 mg, 0.49 mmol) was converted to the corresponding TBA salt by rapid treatment (5 min of stirring) with Dowex H+ cation exchange resin and the addition of 4 equiv of 40% TBAOH in H2O (1260 µL). The mixture was evaporated to dryness in vacuum and kept several days in vacuum to obtain a dry product. This ATP TBA salt was dissolved in dry CH3CN (3 mL), and 3-methylbut-3-en-1-yl-1,1-d2 4-methylbenzenesulfonate (4, 130 mg, 0.54 mmol) was added. The reaction mixture stirred at 45 °C for 55 h before being evaporated to dryness in vacuum. The residue was stirred in diethyl ether (5 mL) for 10 min, and diethyl ether was removed. This was repeated twice. The residue was then dried in vacuum and purified by HPCCC following the method described in Reference [21]. When the appropriate fractions from the HPCCC purification were evaporated, the pure product was obtained in two different portions (70 mg as the ⋅5.25 TBA salt and 24 mg as the ⋅3.25 TBA salt, calculated total yield 11.4%, which was comparable to earlier results [20], see also HPCCC chromatogram in Supporting Information File 1). The product was obtained as very hygroscopic colorless foamy solid. NMR data for ApppI(d2)⋅3.25 TBA salt: 1H NMR (D2O) δ 8.52 (s, 1H), 8.21 (s, 1H), 6.08 (d, J = 6.1, 1H), 4.76–4.73 (m, 1H), 4.69–4.67 (m, 1H), 4.67–4.65 (m, 1H), 4.54–4.52 (m, 1H), 4.36–4.33 (m, 1H), 4.26–4.21 (m, 1H), 4.20–4.15 (m, 1H), 3.17–3.09 (m, 26H, from TBA salt), 2.25–2.18 (m, 2H), 1.61 (s, 3H), 1.63–1.54 (m, 26H, from TBA salt), 1.35–1.25 (m, 26H, from TBA salt), 0.90 (t, J = 7.3, 39H, from TBA salt); 13C NMR (D2O) δ 156.5, 153.7, 150.1, 144.3, 140.9, 119.5, 112.3, 87.6, 85.1 (d, 2JCP = 9.3), 75.4, 71.5, 66.2 (d, 3JCP = 5.4), 65.1 (m, 2H-C-2H, hardly visible), 59.0 (virtual t, from TBA salt), 38.5 (d, 3JCP = 7.5), 24.1 (from TBA salt), 22.6, 20.1 (from TBA salt), 13.8 (from TBA salt, used as calibration peak: value marked same as in the earlier characterization of ApppI [20]); 31P NMR (D2O): δ −11.2 d (2JPP = 19.4), −11.7 d (2JPP = 19.4), −23.4 t (2JPP = 19.4); HRMS–ESI (qTOF, m/z): [M − H]− calcd for C15H212H2N5O13P3, 576.0631; found, 576.0630. All NMR data were comparable to those reported elsewhere for conventional ApppI [19,21].

Preparation of Jones reagent: CrO3 (25 g) was slowly and carefully added to conc H2SO4 (25 mL) with stirring. After complete addition, the formed mixture was further added in very small portions to ice-cold water (75 mL) with vigorous stirring to form the final Jones reagent.

Synthesis of 3-methylbut-3-enoic acid (2) [27]: 3-Methylbut-3-en-1-ol (1, 3.0 mL, 2.56 g, 0.030 mol) was dissolved in acetone (150 mL), and the reaction mixture was cooled to 0–3 °C. Then, Jones reagent (15.6 mL) was added, and the reaction mixture was stirred at 0–3 °C for 1 h. The reaction mixture was made basic by adding an appropriate volume of 4 M NaOH with stirring (pH value measured by pH paper), and acetone was removed by evaporation in vacuum. The remaining mixture was acidified by addition of 6 M HCl and extracted with diethyl ether (3 × 15 mL). The combined diethyl ether fractions were dried over MgSO4 and filtered. After evaporation of the solvent, the final product was distilled in vacuum. The product was obtained as colorless liquid (1.5 g, 50%), bp 50–53 °C/2.0 mbar. According to the 1H NMR spectrum, the product purity was about 88%, which was considered to be pure enough to be used in the next step. 1H NMR (CDCl3) δ 4.95 (br, 1H), 4.89 (br, 1H), 3.08 (s, 2H), 1.84 (s, 3H); 13C NMR (CDCl3) δ 177.7, 138.1, 115.5, 43.2, 22.5.

Synthesis of 3-methylbut-3-en-1,1-d2-1-ol (3) [28]: LiAlD4 (320 mg, 7.6 mmol, 0.5 equiv) was added to dry and cold (0–3 °C) diethyl ether (15 mL) in an ice–water bath, and 3-methylbut-3-enoic acid (2, 1.5 g, 15 mmol), dissolved in dry diethyl ether (5 mL), was added in small portions with vigorous stirring. After completed addition, the ice–water bath was removed, and the reaction mixture was stirred for 3 h at room temperature before it was cooled again to 0–3 °C. Then, solid Na2SO4·10 H2O (1.0 g) was added, and the reaction mixture was stirred for 0.5 h at 0–3 °C. All solids were filtered off, and diethyl ether was removed slowly using a rotary evaporator in vacuum. The crude product was obtained as colorless liquid (415 mg, 31%). Most of the product had apparently been concomitantly evaporated with diethyl ether, and the remaining crude product still contained diethyl ether and side products. However, most of the obtained material was the desired product 3-methylbut-3-en-1,1-d2-1-ol (3), which was used directly in the next step. 1H NMR (CDCl3) δ 4.87 (br, 1H), 4.78 (br, 1H), 2.28 (s, 2H), 1.76 (s, 3H).

Synthesis of 3-methylbut-3-en-1-yl-1,1-d2 4-methylbenzenesulfonate (4) [28]: 3-Methylbut-3-en-1,1-d2-1-ol (3, 415 mg, 4.7 mmol) was dissolved in dry acetonitrile (5 mL), and distilled pyridine (375 µL, 368 mg, 4.7 mmol) and tosyl chloride (900 mg, 4.7 mmol) were added. Then, the reaction mixture was stirred for 4 h at room temperature before being evaporated to dryness in vacuum. The residue was dissolved in diethyl ether, filtered, and evaporated to dryness in vacuum. The crude product (635 mg) was purified by preparative TLC using EtOAc/hexane 5:95 as eluent. The pure product was obtained at Rf = 0.11 (139 mg). However, also the fraction at Rf = 0.21 (181 mg) was observed to contain the desired product with some impurities, according to the 1H NMR spectrum. The fraction at Rf = 0.21 was further purified twice by analytical TLC, and the desired product was obtained purely with Rf = 0.27 (140 mg). The total amount of purified 3-methylbut-3-en-1-yl-1,1-d2 4-methylbenzenesulfonate (4) was 279 mg (24%). 1H NMR (CDCl3) 7.79 (d, J = 8.0, 2H), 7.34 (d, J = 8.0, 2H), 4.79 (br, 1H), 4.67 (br, 1H), 2.45 (s, 3H), 2.34 (s, 2H), 1.66 (s, 3H);13C NMR (CDCl3) δ 144.9, 140.2, 133.3, 130.0 (2C), 128.0 (2C), 113.2, 68.0 (m, 2H-C-2H, 1JCD = 22.9, hardly visible), 36.7, 22.5, 21.8.

Supporting Information

| Supporting Information File 1: 1H, 13C, and 31P NMR spectra as well as HPCCC chromatogram of ApppI(d2) purification. | ||

| Format: PDF | Size: 512.1 KB | Download |

Acknowledgements

I would like to thank Mrs. Maritta Salminkoski for her expert technical assistance and Dr. Marko Lehtonen for MS measurement. I also express my deepest gratitude to Erasmus student Mena Bantran (University of Bradford) for her help to find procedures for the preparation of compounds 3 and 4.

References

-

Rodriguez, J. B.; Gallo-Rodriguez, C. ChemMedChem 2019, 14, 190–216. doi:10.1002/cmdc.201800693

Return to citation in text: [1] -

Turhanen, P. A:. J. Biomed. Res. Environ. Sci. 2022, 3, 195–197. doi:10.37871/jbres1421

Return to citation in text: [1] [2] -

Turhanen, P. A.; Demadis, K. D.; Kafarski, P. Front. Chem. (Lausanne, Switz.) 2021, 9, 10.3389/fchem.2021.695128. doi:10.3389/fchem.2021.695128

Return to citation in text: [1] -

Krečmerová, M.; Majer, P.; Rais, R.; Slusher, B. S. Front. Chem. (Lausanne, Switz.) 2022, 10, 10.3389/fchem.2022.889737. doi:10.3389/fchem.2022.889737

Return to citation in text: [1] -

Kraszewski, A.; Sobkowski, M.; Stawinski, J. Front. Chem. (Lausanne, Switz.) 2020, 8, 10.3389/fchem.2020.595738. doi:10.3389/fchem.2020.595738

Return to citation in text: [1] -

Kusy, D.; Marchwicka, A.; Małolepsza, J.; Justyna, K.; Gendaszewska-Darmach, E.; Błażewska, K. M. Front. Chem. (Lausanne, Switz.) 2021, 8, 10.3389/fchem.2020.596162. doi:10.3389/fchem.2020.596162

Return to citation in text: [1] -

Russell, R. G. G. Bone 2011, 49, 2–19. doi:10.1016/j.bone.2011.04.022

Return to citation in text: [1] -

Ebetino, F. H.; Hogan, A.-M. L.; Sun, S.; Tsoumpra, M. K.; Duan, X.; Triffitt, J. T.; Kwaasi, A. A.; Dunford, J. E.; Barnett, B. L.; Oppermann, U.; Lundy, M. W.; Boyde, A.; Kashemirov, B. A.; McKenna, C. E.; Russell, R. G. G. Bone 2011, 49, 20–33. doi:10.1016/j.bone.2011.03.774

Return to citation in text: [1] -

Popov, K.; Oshchepkov, M.; Tkachenko, S.; Sergienko, V.; Oshchepkov, A. J. Mol. Liq. 2022, 351, 118619. doi:10.1016/j.molliq.2022.118619

Return to citation in text: [1] -

Martin, M. B.; Arnold, W.; Heath, H. T., III; Urbina, J. A.; Oldfield, E. Biochem. Biophys. Res. Commun. 1999, 263, 754–758. doi:10.1006/bbrc.1999.1404

Return to citation in text: [1] -

van Beek, E.; Pieterman, E.; Cohen, L.; Löwik, C.; Papapoulos, S. Biochem. Biophys. Res. Commun. 1999, 264, 108–111. doi:10.1006/bbrc.1999.1499

Return to citation in text: [1] -

Lehenkari, P. P.; Kellinsalmi, M.; Näpänkangas, J. P.; Ylitalo, K. V.; Mönkkönen, J.; Rogers, M. J.; Azhayev, A.; Väänänen, H. K.; Hassinen, I. E. Mol. Pharmacol. 2002, 61, 1255–1262. doi:10.1124/mol.61.5.1255

Return to citation in text: [1] -

Rogers, M. J.; Mönkkönen, J.; Munoz, M. A. Bone 2020, 139, 115493. doi:10.1016/j.bone.2020.115493

Return to citation in text: [1] -

Mönkkönen, H.; Auriola, S.; Lehenkari, P.; Kellinsalmi, M.; Hassinen, I. E.; Vepsäläinen, J.; Mönkkönen, J. Br. J. Pharmacol. 2006, 147, 437–445. doi:10.1038/sj.bjp.0706628

Return to citation in text: [1] -

Santini, D.; Stumbo, L.; Spoto, C.; D’Onofrio, L.; Pantano, F.; Iuliani, M.; fioramonti, M.; Zoccoli, A.; Ribelli, G.; Virzì, V.; Vincenzi, B.; Tonini, G. Breast Cancer Res. 2015, 17, 121. doi:10.1186/s13058-015-0634-8

Return to citation in text: [1] -

Suomen lääketilasto 2020 (in finnish), page 187, Julkari shared open repository for the publications of the Ministry of Social Affairs and Health’s administrative branch organizations;. https://www.julkari.fi/handle/10024/143550

Return to citation in text: [1] -

Malwal, S. R.; O’Dowd, B.; Feng, X.; Turhanen, P.; Shin, C.; Yao, J.; Kim, B. K.; Baig, N.; Zhou, T.; Bansal, S.; Khade, R. L.; Zhang, Y.; Oldfield, E. J. Am. Chem. Soc. 2018, 140, 7568–7578. doi:10.1021/jacs.8b02363

Return to citation in text: [1] -

Ishchenko, Y.; Shakirzyanova, A.; Giniatullina, R.; Skorinkin, A.; Bart, G.; Turhanen, P.; Määttä, J. A.; Mönkkönen, J.; Giniatullin, R. J. Pharmacol. Exp. Ther. 2017, 361, 472–481. doi:10.1124/jpet.116.238840

Return to citation in text: [1] -

Weisell, J.; Vepsäläinen, J.; Turhanen, P. A. Beilstein J. Org. Chem. 2015, 11, 2189–2193. doi:10.3762/bjoc.11.237

Return to citation in text: [1] [2] -

Sandholm, J.; Lehtimäki, J.; Ishizu, T.; Velu, S. E.; Clark, J.; Härkönen, P.; Jukkola-Vuorinen, A.; Schrey, A.; Harris, K. W.; Tuomela, J. M.; Selander, K. S. Oncotarget 2016, 7, 87373–87389. doi:10.18632/oncotarget.13570

Return to citation in text: [1] [2] [3] -

Puljula, E.; Turhanen, P. A. J. Chromatogr., B 2017, 1063, 180–182. doi:10.1016/j.jchromb.2017.08.038

Return to citation in text: [1] [2] [3] [4] [5] [6] -

Turhanen, P. A. ACS Omega 2017, 2, 2835–2838. doi:10.1021/acsomega.7b00531

Return to citation in text: [1] [2] -

Häkkinen, M. R.; Keinänen, T. A.; Khomutov, A. R.; Auriola, S.; Weisell, J.; Alhonen, L.; Jänne, J.; Vepsäläinen, J. Tetrahedron 2009, 65, 547–562. doi:10.1016/j.tet.2008.10.071

Return to citation in text: [1] -

Khamis, M. M.; Adamko, D. J.; El‐Aneed, A. Mass Spectrom. Rev. 2021, 40, 31–52. doi:10.1002/mas.21607

Return to citation in text: [1] -

Cortese, M.; Gigliobianco, M. R.; Magnoni, F.; Censi, R.; Di Martino, P. Molecules 2020, 25, 3047. doi:10.3390/molecules25133047

Return to citation in text: [1] -

Gottlieb, H. E.; Kotlyar, V.; Nudelman, A. J. Org. Chem. 1997, 62, 7512–7515. doi:10.1021/jo971176v

Return to citation in text: [1] -

Derosa, J.; Kleinmans, R.; Tran, V. T.; Karunananda, M. K.; Wisniewski, S. R.; Eastgate, M. D.; Engle, K. M. J. Am. Chem. Soc. 2018, 140, 17878–17883. doi:10.1021/jacs.8b11942

Return to citation in text: [1] -

Said, M. S.; Navale, G. R.; Gajbhiye, J. M.; Shinde, S. S. RSC Adv. 2019, 9, 28258–28261. doi:10.1039/c9ra00163h

Return to citation in text: [1] [2]

| 20. | Sandholm, J.; Lehtimäki, J.; Ishizu, T.; Velu, S. E.; Clark, J.; Härkönen, P.; Jukkola-Vuorinen, A.; Schrey, A.; Harris, K. W.; Tuomela, J. M.; Selander, K. S. Oncotarget 2016, 7, 87373–87389. doi:10.18632/oncotarget.13570 |

| 21. | Puljula, E.; Turhanen, P. A. J. Chromatogr., B 2017, 1063, 180–182. doi:10.1016/j.jchromb.2017.08.038 |

| 20. | Sandholm, J.; Lehtimäki, J.; Ishizu, T.; Velu, S. E.; Clark, J.; Härkönen, P.; Jukkola-Vuorinen, A.; Schrey, A.; Harris, K. W.; Tuomela, J. M.; Selander, K. S. Oncotarget 2016, 7, 87373–87389. doi:10.18632/oncotarget.13570 |

| 1. | Rodriguez, J. B.; Gallo-Rodriguez, C. ChemMedChem 2019, 14, 190–216. doi:10.1002/cmdc.201800693 |

| 2. | Turhanen, P. A:. J. Biomed. Res. Environ. Sci. 2022, 3, 195–197. doi:10.37871/jbres1421 |

| 3. | Turhanen, P. A.; Demadis, K. D.; Kafarski, P. Front. Chem. (Lausanne, Switz.) 2021, 9, 10.3389/fchem.2021.695128. doi:10.3389/fchem.2021.695128 |

| 4. | Krečmerová, M.; Majer, P.; Rais, R.; Slusher, B. S. Front. Chem. (Lausanne, Switz.) 2022, 10, 10.3389/fchem.2022.889737. doi:10.3389/fchem.2022.889737 |

| 10. | Martin, M. B.; Arnold, W.; Heath, H. T., III; Urbina, J. A.; Oldfield, E. Biochem. Biophys. Res. Commun. 1999, 263, 754–758. doi:10.1006/bbrc.1999.1404 |

| 11. | van Beek, E.; Pieterman, E.; Cohen, L.; Löwik, C.; Papapoulos, S. Biochem. Biophys. Res. Commun. 1999, 264, 108–111. doi:10.1006/bbrc.1999.1499 |

| 12. | Lehenkari, P. P.; Kellinsalmi, M.; Näpänkangas, J. P.; Ylitalo, K. V.; Mönkkönen, J.; Rogers, M. J.; Azhayev, A.; Väänänen, H. K.; Hassinen, I. E. Mol. Pharmacol. 2002, 61, 1255–1262. doi:10.1124/mol.61.5.1255 |

| 13. | Rogers, M. J.; Mönkkönen, J.; Munoz, M. A. Bone 2020, 139, 115493. doi:10.1016/j.bone.2020.115493 |

| 26. | Gottlieb, H. E.; Kotlyar, V.; Nudelman, A. J. Org. Chem. 1997, 62, 7512–7515. doi:10.1021/jo971176v |

| 9. | Popov, K.; Oshchepkov, M.; Tkachenko, S.; Sergienko, V.; Oshchepkov, A. J. Mol. Liq. 2022, 351, 118619. doi:10.1016/j.molliq.2022.118619 |

| 21. | Puljula, E.; Turhanen, P. A. J. Chromatogr., B 2017, 1063, 180–182. doi:10.1016/j.jchromb.2017.08.038 |

| 7. | Russell, R. G. G. Bone 2011, 49, 2–19. doi:10.1016/j.bone.2011.04.022 |

| 8. | Ebetino, F. H.; Hogan, A.-M. L.; Sun, S.; Tsoumpra, M. K.; Duan, X.; Triffitt, J. T.; Kwaasi, A. A.; Dunford, J. E.; Barnett, B. L.; Oppermann, U.; Lundy, M. W.; Boyde, A.; Kashemirov, B. A.; McKenna, C. E.; Russell, R. G. G. Bone 2011, 49, 20–33. doi:10.1016/j.bone.2011.03.774 |

| 21. | Puljula, E.; Turhanen, P. A. J. Chromatogr., B 2017, 1063, 180–182. doi:10.1016/j.jchromb.2017.08.038 |

| 2. | Turhanen, P. A:. J. Biomed. Res. Environ. Sci. 2022, 3, 195–197. doi:10.37871/jbres1421 |

| 5. | Kraszewski, A.; Sobkowski, M.; Stawinski, J. Front. Chem. (Lausanne, Switz.) 2020, 8, 10.3389/fchem.2020.595738. doi:10.3389/fchem.2020.595738 |

| 6. | Kusy, D.; Marchwicka, A.; Małolepsza, J.; Justyna, K.; Gendaszewska-Darmach, E.; Błażewska, K. M. Front. Chem. (Lausanne, Switz.) 2021, 8, 10.3389/fchem.2020.596162. doi:10.3389/fchem.2020.596162 |

| 17. | Malwal, S. R.; O’Dowd, B.; Feng, X.; Turhanen, P.; Shin, C.; Yao, J.; Kim, B. K.; Baig, N.; Zhou, T.; Bansal, S.; Khade, R. L.; Zhang, Y.; Oldfield, E. J. Am. Chem. Soc. 2018, 140, 7568–7578. doi:10.1021/jacs.8b02363 |

| 18. | Ishchenko, Y.; Shakirzyanova, A.; Giniatullina, R.; Skorinkin, A.; Bart, G.; Turhanen, P.; Määttä, J. A.; Mönkkönen, J.; Giniatullin, R. J. Pharmacol. Exp. Ther. 2017, 361, 472–481. doi:10.1124/jpet.116.238840 |

| 23. | Häkkinen, M. R.; Keinänen, T. A.; Khomutov, A. R.; Auriola, S.; Weisell, J.; Alhonen, L.; Jänne, J.; Vepsäläinen, J. Tetrahedron 2009, 65, 547–562. doi:10.1016/j.tet.2008.10.071 |

| 24. | Khamis, M. M.; Adamko, D. J.; El‐Aneed, A. Mass Spectrom. Rev. 2021, 40, 31–52. doi:10.1002/mas.21607 |

| 25. | Cortese, M.; Gigliobianco, M. R.; Magnoni, F.; Censi, R.; Di Martino, P. Molecules 2020, 25, 3047. doi:10.3390/molecules25133047 |

| 28. | Said, M. S.; Navale, G. R.; Gajbhiye, J. M.; Shinde, S. S. RSC Adv. 2019, 9, 28258–28261. doi:10.1039/c9ra00163h |

| 16. | Suomen lääketilasto 2020 (in finnish), page 187, Julkari shared open repository for the publications of the Ministry of Social Affairs and Health’s administrative branch organizations;. https://www.julkari.fi/handle/10024/143550 |

| 21. | Puljula, E.; Turhanen, P. A. J. Chromatogr., B 2017, 1063, 180–182. doi:10.1016/j.jchromb.2017.08.038 |

| 28. | Said, M. S.; Navale, G. R.; Gajbhiye, J. M.; Shinde, S. S. RSC Adv. 2019, 9, 28258–28261. doi:10.1039/c9ra00163h |

| 15. | Santini, D.; Stumbo, L.; Spoto, C.; D’Onofrio, L.; Pantano, F.; Iuliani, M.; fioramonti, M.; Zoccoli, A.; Ribelli, G.; Virzì, V.; Vincenzi, B.; Tonini, G. Breast Cancer Res. 2015, 17, 121. doi:10.1186/s13058-015-0634-8 |

| 19. | Weisell, J.; Vepsäläinen, J.; Turhanen, P. A. Beilstein J. Org. Chem. 2015, 11, 2189–2193. doi:10.3762/bjoc.11.237 |

| 21. | Puljula, E.; Turhanen, P. A. J. Chromatogr., B 2017, 1063, 180–182. doi:10.1016/j.jchromb.2017.08.038 |

| 14. | Mönkkönen, H.; Auriola, S.; Lehenkari, P.; Kellinsalmi, M.; Hassinen, I. E.; Vepsäläinen, J.; Mönkkönen, J. Br. J. Pharmacol. 2006, 147, 437–445. doi:10.1038/sj.bjp.0706628 |

| 19. | Weisell, J.; Vepsäläinen, J.; Turhanen, P. A. Beilstein J. Org. Chem. 2015, 11, 2189–2193. doi:10.3762/bjoc.11.237 |

| 20. | Sandholm, J.; Lehtimäki, J.; Ishizu, T.; Velu, S. E.; Clark, J.; Härkönen, P.; Jukkola-Vuorinen, A.; Schrey, A.; Harris, K. W.; Tuomela, J. M.; Selander, K. S. Oncotarget 2016, 7, 87373–87389. doi:10.18632/oncotarget.13570 |

| 21. | Puljula, E.; Turhanen, P. A. J. Chromatogr., B 2017, 1063, 180–182. doi:10.1016/j.jchromb.2017.08.038 |

| 22. | Turhanen, P. A. ACS Omega 2017, 2, 2835–2838. doi:10.1021/acsomega.7b00531 |

| 27. | Derosa, J.; Kleinmans, R.; Tran, V. T.; Karunananda, M. K.; Wisniewski, S. R.; Eastgate, M. D.; Engle, K. M. J. Am. Chem. Soc. 2018, 140, 17878–17883. doi:10.1021/jacs.8b11942 |

© 2022 Turhanen; licensee Beilstein-Institut.

This is an open access article licensed under the terms of the Beilstein-Institut Open Access License Agreement (https://www.beilstein-journals.org/bjoc/terms), which is identical to the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0). The reuse of material under this license requires that the author(s), source and license are credited. Third-party material in this article could be subject to other licenses (typically indicated in the credit line), and in this case, users are required to obtain permission from the license holder to reuse the material.