Abstract

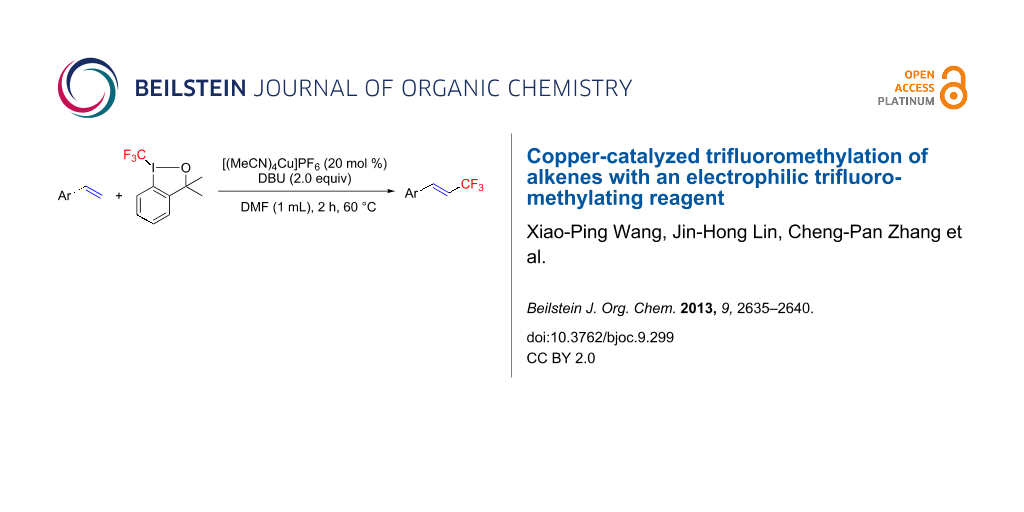

An efficient method for the copper-catalyzed trifluoromethylation of terminal alkenes with an electrophilic trifluoromethylating reagent has been developed. The reactions proceeded smoothly to give trifluoromethylated alkenes in good to excellent yields. The results provided a versatile approach for the construction of Cvinyl–CF3 bonds without using prefunctionalized substrates.

Graphical Abstract

Introduction

The incorporation of a trifluoromethyl group into pharmaceutically and agrochemically relevant molecules usually enhances their chemical and metabolic stability, lipophilicity and binding selectivity [1-7]. As a result, considerable effort has been directed towards the development of efficient and versatile trifluoromethylation methods [8-16]. The past few years has witnessed the rapid advances in transition metal-promoted trifluoromethylation for the construction of Caryl–CF3 bonds [17-31]. In contrast, transition metal-mediated trifluoromethylation to form Cvinyl–CF3 bonds has been much less explored. As illustrated in Scheme 1, the strategies developed recently usually require the use of prefunctionalized alkenes, which could be classified into the following: vinylboronic acids, vinyl borates, vinyl halides, vinyl sulfonates and vinyl carboxylic acids (Scheme 1, reaction 1) [32-38]. Cho and co-workers reported a radical process for the trifluoromethylation of terminal alkenes without using prefunctionalized substrates, but a volatile reagent was used (Scheme 1, reaction 1) [39]. Szabó described trifluoromethyl-benzoyloxylation of alkynes to construct Cvinyl–CF3 bonds (Scheme 2, reaction 2) [40]. As part of our continuing interest in trifluoromethylation reactions [25,41-45], we investigated the copper-catalyzed trifluoromethylation of terminal alkenes with electrophilic trifluoromethylating reagents (Scheme 1, reaction 3).

Scheme 1: Construction of the Cvinyl–CF3 bond.

Scheme 1: Construction of the Cvinyl–CF3 bond.

Transition metal-catalyzed trifluoromethylation of terminal alkenes has been reported by several groups. However, these methods focused on the formation of Csp3–CF3 bonds [46-56]. In copper-catalyzed reactions with electrophilic trifluoromethylating reagents, it was proposed that the transformation might proceed via a radical, electrophilic or Heck-type process (Scheme 2) [47-50]. We reasoned that even if the reaction involved the radical process (path A, Scheme 2), the radical intermediate could still be oxidized to a cation because electrophilic trifluoromethylation reagents can be considered as an oxidant. In the presence of base, both of the cation and Heck-type intermediates should be able to undergo hydrogen elimination to form a Cvinyl–CF3 bond. On the basis of these reports and our hypothesis, we commenced to examine the reaction of aromatic alkenes with electrophilic trifluoromethylation reagents in the presence of copper and base.

Scheme 2: Proposed reaction paths for the trifluoromethylation of alkenes.

Scheme 2: Proposed reaction paths for the trifluoromethylation of alkenes.

Results and Discussion

Previously, we reported that copper powder or cuprous iodide could promote trifluoromethylation of heteroaromatics, arylboronic acids or terminal alkynes with trifluoromethyl sulfonium salt I [25,44,45,57,58]. But the same trifluoromethylation reagent (2 equiv) failed to convert 4-vinylbiphenyl to the expected alkene in reasonable yields in acetonitrile with B1 (DBU) as the base, even though cuprous iodide gave better results (Table 1, entries 1 and 2). In the presence of cuprous iodide, Umemoto’s reagent (II) and Togni’s reagent (III) were found to be more efficient in this transformation (Table 1, entries 3 and 4). 19F NMR measurements showed that the reaction system turned to be complex and low yield of the desired product was determined when another Togni’s reagent (IV) was used (Table 1, entry 5). Other cuprous complexes were also studied with the use of Togni’s reagent (III) (Table 1, entries 6–10). Better result obtained with [(MeCN)4Cu]PF6 prompted us to continue to use this copper source (Table 1, entry 10). When B2 was used instead of B1, almost no desired product was observed (Table 1, entry 11). That might be because B2 not only acted as base, but also acted as strongly coordinating ligand, which poisoned the catalyst and shut down the reaction. Other bases (Table 1, entries 12–15), including an inorganic base (Table 1, entry 15), failed to accelerate the desired conversion either. The examination of the solvent effect showed that the solvent is quite important for the reaction (Table 1, entries 16–20). When the reaction was carried out in DMF, the expected product 2a was obtained in excellent yield (Table 1, entry 16). The yield was decreased dramatically in DMSO (Table 1, entry 17). Almost no reaction took place in polar protic solvent (Table 1, entry 18) and moderate results were achieved in less polar solvents (Table 1, entries 19 and 20). With increasing the amount of Togni’s reagent (III) in the suitable solvent, DMF, the product was obtained almost in quantitative yield with excellent stereoselectivity (dr >98:2) determined by 19F NMR (Table 1, entry 21). Decreasing the amount of this reagent resulted in a lower yield (Table 1, entry 22). The absence of catalyst or base led to no reaction or incredibly low yield, which means both of them are crucial for the reaction (Table 1, entries 23–25).

Table 1: Trifluoromethylation of 4-vinylbiphenyl by electrophilic trifluoromethylation reagents.

|

|

|||||

| Entry | Cat. | Base | Solvent | “CF3+” | Yield (%)a |

|---|---|---|---|---|---|

| 1 | Cu | B1 | CH3CN | I | trace |

| 2 | CuI | B1 | CH3CN | I | 30 |

| 3 | CuI | B1 | CH3CN | II | 56 |

| 4 | CuI | B1 | CH3CN | III | 60 |

| 5 | CuI | B1 | CH3CN | IV | 30 |

| 6 | CuBr | B1 | CH3CN | III | 46 |

| 7 | CuCl | B1 | CH3CN | III | 36 |

| 8 | CuTc | B1 | CH3CN | III | 54 |

| 9 | CuOAc | B1 | CH3CN | III | 41 |

| 10 | [(MeCN)4Cu]PF6 | B1 | CH3CN | III | 75 |

| 11 | [(MeCN)4Cu]PF6 | B2 | CH3CN | III | trace |

| 12 | [(MeCN)4Cu]PF6 | B3 | CH3CN | III | 10 |

| 13 | [(MeCN)4Cu]PF6 | B4 | CH3CN | III | trace |

| 14 | [(MeCN)4Cu]PF6 | B5 | CH3CN | III | 10 |

| 15 | [(MeCN)4Cu]PF6 | B6 | CH3CN | III | 7 |

| 16 | [(MeCN)4Cu]PF6 | B1 | DMF | III | 90 |

| 17 | [(MeCN)4Cu]PF6 | B1 | DMSO | III | 57 |

| 18 | [(MeCN)4Cu]PF6 | B1 | CH3OH | III | trace |

| 19 | [(MeCN)4Cu]PF6 | B1 | THF | III | 67 |

| 20 | [(MeCN)4Cu]PF6 | B1 | CHCl3 | III | 75 |

| 21b | [(MeCN)4Cu]PF6 | B1 | DMF | III | 98 |

| 22c | [(MeCN)4Cu]PF6 | B1 | DMF | III | 58 |

| 23 | – | – | DMF | III | 0 |

| 24 | – | B1 | DMF | III | 0 |

| 25 | [(MeCN)4Cu]PF6 | – | DMF | III | 10 |

aYields determined by 19 F NMR spectroscopy. b2.5 equiv of III was used. c1.5 equiv of III was used.

With the optimized reaction conditions in hand (Table 1, entry 21), we then explored the substrate scope of the Cu(I)-catalyzed trifluoromethylation of terminal alkenes with Togni’s reagent. As shown in Figure 1, the reaction could tolerate various functional groups. It is worth mentioning that all of the products were obtained with excellent stereoselectivity (E/Z >97/3), determined by 19F NMR. Substrates with an electron-donating group were converted smoothly into the desired products in excellent yields (2a–2f). Irrespective of the position of the bromine substituent on the aryl ring, the reaction proceeded very well to afford the desired products in excellent yields (2g–2i). Stronger electron-withdrawing groups showed some negative effect on the reaction, as exemplified by the poor results of substrates with other halides, carbonyl or nitro groups on the benzene ring (2j–2m). Heteroaromatic alkenes were also investigated (2n and 2o). As previously seen, alkene 1n endowed with an electron-rich heteroaromatic group led to a good result (2n) and an electron-deficient substrate resulted in low yield (2o).

Figure 1: Cu(I)-catalyzed trifluoromethylation of terminal alkenes with Togni’s reagent. Isolated yield are recorded.

Figure 1: Cu(I)-catalyzed trifluoromethylation of terminal alkenes with Togni’s reagent. Isolated yield are r...

With regard to the reaction mechanism, it is reasonable to conceive a pathway involving radical species according to previous reports [47-50]. To gain more insight into the mechanism, further evidence was collected. 2,2,6,6-Tetramethyl-1-piperidinyloxy (TEMPO), a well-known radical scavenger, was added to the reaction of 4-vinylbiphenyl with Togni’s reagent (III) in the presence of [(MeCN)4Cu]PF6. It was found that the desired trifluoromethylation was completely suppressed, which suggested that the transformation involved a radical process. Based on the above results, we proposed the mechanism as outlined in Scheme 3. Initially, the activation of III by Cu(I) led to the formation of radical intermediate A. Decomposition of this intermediate produces ((2-(2-iodophenyl)propan-2-yl)oxy)copper(II) (C) and a CF3 radical, which is trapped by alkenes to form the trifluoromethylated radical intermediate B. Subsequently, the radical intermediate B is oxidized by Cu(II) (C) to the cation intermediate D with simultaneous release of catalyst Cu(I). In the presence of base, intermediate D readily undergoes hydrogen elimination to give the final product.

Scheme 3: Proposed mechanism for the trifluoromethylation of terminal alkenes.

Scheme 3: Proposed mechanism for the trifluoromethylation of terminal alkenes.

Conclusion

In conclusion, we have described the copper-catalyzed trifluoromethylation of alkenes with Togni’s reagent under mild conditions. The results presented here provided a versatile approach for the construction of Cvinyl–CF3 bonds without using prefunctionalized substrates. Investigations on the application of the trifluoromethylation method to the synthesis of pharmaceuticals and agrochemicals are currently underway.

Supporting Information

| Supporting Information File 1: Full experimental details, analytical data and spectra of the target compounds. | ||

| Format: PDF | Size: 1.8 MB | Download |

References

-

Kirsch, P. Modern Fluoroorganic Chemistry Synthesis, Reactivity, Applications; Wiley-VCH: Weinheim, 2004. doi:10.1002/352760393X

Return to citation in text: [1] -

Bégué, J.-P.; Bonnet-Delpon, D. Bioorganic and Medicinal Chemistry of Fluorine; John Wiley & Sons: Hoboken, 2008. doi:10.1002/9780470281895

Return to citation in text: [1] -

Schlosser, M. Angew. Chem., Int. Ed. 2006, 45, 5432–5446. doi:10.1002/anie.200600449

Return to citation in text: [1] -

Müller, K.; Faeh, C.; Diederich, F. Science 2007, 317, 1881–1886. doi:10.1126/science.1131943

Return to citation in text: [1] -

Hagmann, W. K. J. Med. Chem. 2008, 51, 4359–4369. doi:10.1021/jm800219f

Return to citation in text: [1] -

Purser, S.; Moore, P. R.; Swallow, S.; Gouverneur, V. Chem. Soc. Rev. 2008, 37, 320–330. doi:10.1039/b610213c

Return to citation in text: [1] -

Furuya, T.; Kamlet, A. S.; Ritter, T. Nature 2011, 473, 470–477. doi:10.1038/nature10108

Return to citation in text: [1] -

Zheng, Y.; Ma, J.-A. Adv. Synth. Catal. 2010, 352, 2745–2750. doi:10.1002/adsc.201000545

Return to citation in text: [1] -

Nie, J.; Guo, H.-C.; Cahard, D.; Ma, J.-A. Chem. Rev. 2010, 111, 455–529. doi:10.1021/cr100166a

Return to citation in text: [1] -

Parsons, A. T.; Buchwald, S. L. Nature 2011, 480, 184–185. doi:10.1038/480184a

Return to citation in text: [1] -

Studer, A. Angew. Chem., Int. Ed. 2012, 51, 8950–8958. doi:10.1002/anie.201202624

Return to citation in text: [1] -

Nagib, D. A.; MacMillan, D. W. C. Nature 2011, 480, 224–228. doi:10.1038/nature10647

Return to citation in text: [1] -

Pham, P. V.; Nagib, D. A.; MacMillan, D. W. C. Angew. Chem., Int. Ed. 2011, 50, 6119–6122. doi:10.1002/anie.201101861

Return to citation in text: [1] -

Prakash, G. K. S.; Jog, P. V.; Batamack, P. T. D.; Olah, G. A. Science 2012, 338, 1324–1327. doi:10.1126/science.1227859

Return to citation in text: [1] -

Pair, E.; Monteiro, N.; Bouyssi, D.; Baudoin, O. Angew. Chem., Int. Ed. 2013, 52, 5346–5349. doi:10.1002/anie.201300782

Return to citation in text: [1] -

Wang, X.; Xu, Y.; Mo, F.; Ji, G.; Qiu, D.; Feng, J.; Ye, Y.; Zhang, S.; Zhang, Y.; Wang, J. J. Am. Chem. Soc. 2013, 135, 10330–10333. doi:10.1021/ja4056239

Return to citation in text: [1] -

Lundgren, R. J.; Stradiotto, M. Angew. Chem., Int. Ed. 2010, 49, 9322–9324. doi:10.1002/anie.201004051

Return to citation in text: [1] -

Tomashenko, O. A.; Grushin, V. V. Chem. Rev. 2011, 111, 4475–4521. doi:10.1021/cr1004293

Return to citation in text: [1] -

Besset, T.; Schneider, C.; Cahard, D. Angew. Chem., Int. Ed. 2012, 51, 5048–5050. doi:10.1002/anie.201201012

Return to citation in text: [1] -

Wu, X.-F.; Neumann, H.; Beller, M. Chem.–Asian J. 2012, 7, 1744–1754. doi:10.1002/asia.201200211

Return to citation in text: [1] -

Oishi, M.; Kondo, H.; Amii, H. Chem. Commun. 2009, 1909–1911. doi:10.1039/b823249k

Return to citation in text: [1] -

Cho, E. J.; Senecal, T. D.; Kinzel, T.; Zhang, Y.; Watson, D. A.; Buchwald, S. L. Science 2010, 328, 1679–1681. doi:10.1126/science.1190524

Return to citation in text: [1] -

Wang, X.; Truesdale, L.; Yu, J.-Q. J. Am. Chem. Soc. 2010, 132, 3648–3649. doi:10.1021/ja909522s

Return to citation in text: [1] -

Chu, L.; Qing, F.-L. J. Am. Chem. Soc. 2012, 134, 1298–1304. doi:10.1021/ja209992w

Return to citation in text: [1] -

Zhang, C.-P.; Wang, Z.-L.; Chen, Q.-Y.; Zhang, C.-T.; Gu, Y.-C.; Xiao, J.-C. Angew. Chem., Int. Ed. 2011, 50, 1896–1900. doi:10.1002/anie.201006823

Return to citation in text: [1] [2] [3] -

Zhang, X.-G.; Dai, H.-X.; Wasa, M.; Yu, J.-Q. J. Am. Chem. Soc. 2012, 134, 11948–11951. doi:10.1021/ja305259n

Return to citation in text: [1] -

Herrmann, A. T.; Smith, L. L.; Zakarian, A. J. Am. Chem. Soc. 2012, 134, 6976–6979. doi:10.1021/ja302552e

Return to citation in text: [1] -

Liu, T.; Shao, X.; Wu, Y.; Shen, Q. Angew. Chem., Int. Ed. 2012, 51, 540–543. doi:10.1002/anie.201106673

Return to citation in text: [1] -

Ye, Y.; Sanford, M. S. J. Am. Chem. Soc. 2012, 134, 9034–9037. doi:10.1021/ja301553c

Return to citation in text: [1] -

Zeng, Y.; Zhang, L.; Zhao, Y.; Ni, C.; Zhao, J.; Hu, J. J. Am. Chem. Soc. 2013, 135, 2955–2958. doi:10.1021/ja312711c

Return to citation in text: [1] -

Dai, J.-J.; Fang, C.; Xiao, B.; Yi, J.; Xu, J.; Liu, Z.-J.; Lu, X.; Liu, L.; Fu, Y. J. Am. Chem. Soc. 2013, 135, 8436–8439. doi:10.1021/ja404217t

Return to citation in text: [1] -

Cho, E. J.; Buchwald, S. L. Org. Lett. 2011, 13, 6552–6555. doi:10.1021/ol202885w

Return to citation in text: [1] -

Hafner, A.; Bräse, S. Adv. Synth. Catal. 2011, 353, 3044–3048. doi:10.1002/adsc.201100528

Return to citation in text: [1] -

Parsons, A. T.; Senecal, T. D.; Buchwald, S. L. Angew. Chem., Int. Ed. 2012, 51, 2947–2950. doi:10.1002/anie.201108267

Return to citation in text: [1] -

He, Z.; Luo, T.; Hu, M.; Cao, Y.; Hu, J. Angew. Chem., Int. Ed. 2012, 51, 3944–3947. doi:10.1002/anie.201200140

Return to citation in text: [1] -

Yasu, Y.; Koike, T.; Akita, M. Chem. Commun. 2013, 49, 2037–2039. doi:10.1039/c3cc39235j

Return to citation in text: [1] -

Li, Z.; Cui, Z.; Liu, Z.-Q. Org. Lett. 2013, 15, 406–409. doi:10.1021/ol3034059

Return to citation in text: [1] -

Li, Y.; Wu, L.; Neumann, H.; Beller, M. Chem. Commun. 2013, 49, 2628–2630. doi:10.1039/c2cc36554e

Return to citation in text: [1] -

Iqbal, N.; Choi, S.; Kim, E.; Cho, E. J. J. Org. Chem. 2012, 77, 11383–11387. doi:10.1021/jo3022346

Return to citation in text: [1] -

Janson, P. G.; Ghoneim, I.; Ilchenko, N. O.; Szabó, K. J. Org. Lett. 2012, 14, 2882–2885. doi:10.1021/ol3011419

Return to citation in text: [1] -

Lin, J.-H.; Xiao, J.-C. Eur. J. Org. Chem. 2011, 4536–4539. doi:10.1002/ejoc.201100683

Return to citation in text: [1] -

Lin, J.-H.; Zong, G.; Du, R.-B.; Xiao, J.-C.; Liu, S. Chem. Commun. 2012, 48, 7738–7740. doi:10.1039/c2cc18064b

Return to citation in text: [1] -

Zhang, C.-P.; Wang, Z.-L.; Chen, Q.-Y.; Zhang, C.-T.; Gu, Y.-C.; Xiao, J.-C. Chem. Commun. 2011, 47, 6632–6634. doi:10.1039/c1cc11765c

Return to citation in text: [1] -

Zhang, C.-P.; Cai, J.; Zhou, C.-B.; Wang, X.-P.; Zheng, X.; Gu, Y.-C.; Xiao, J.-C. Chem. Commun. 2011, 47, 9516–9518. doi:10.1039/c1cc13460d

Return to citation in text: [1] [2] -

Wang, X.; Lin, J.; Zhang, C.; Xiao, J.; Zheng, X. Chin. J. Chem. 2013, 31, 915–920. doi:10.1002/cjoc.201300393

Return to citation in text: [1] [2] -

Mu, X.; Wu, T.; Wang, H.-Y.; Guo, Y.-L.; Liu, G. J. Am. Chem. Soc. 2012, 134, 878–881. doi:10.1021/ja210614y

Return to citation in text: [1] -

Parsons, A. T.; Buchwald, S. L. Angew. Chem., Int. Ed. 2011, 50, 9120–9123. doi:10.1002/anie.201104053

Return to citation in text: [1] [2] [3] -

Wang, X.; Ye, Y.; Zhang, S.; Feng, J.; Xu, Y.; Zhang, Y.; Wang, J. J. Am. Chem. Soc. 2011, 133, 16410–16413. doi:10.1021/ja207775a

Return to citation in text: [1] [2] [3] -

Xu, J.; Fu, Y.; Luo, D.-F.; Jiang, Y.-Y.; Xiao, B.; Liu, Z.-J.; Gong, T.-J.; Liu, L. J. Am. Chem. Soc. 2011, 133, 15300–15303. doi:10.1021/ja206330m

Return to citation in text: [1] [2] [3] -

Zhu, R.; Buchwald, S. L. J. Am. Chem. Soc. 2012, 134, 12462–12465. doi:10.1021/ja305840g

Return to citation in text: [1] [2] [3] -

Miyake, Y.; Ota, S.-I.; Nishibayashi, Y. Chem.–Eur. J. 2012, 18, 13255–13258. doi:10.1002/chem.201202853

Return to citation in text: [1] -

Yasu, Y.; Koike, T.; Akita, M. Angew. Chem., Int. Ed. 2012, 51, 9567–9571. doi:10.1002/anie.201205071

Return to citation in text: [1] -

Egami, H.; Shimizu, R.; Kawamura, S.; Sodeoka, M. Angew. Chem., Int. Ed. 2013, 52, 4000–4003. doi:10.1002/anie.201210250

Return to citation in text: [1] -

Liu, X.; Xiong, F.; Huang, X.; Xu, L.; Li, P.; Wu, X. Angew. Chem., Int. Ed. 2013, 52, 6962–6966. doi:10.1002/anie.201302673

Return to citation in text: [1] -

Wu, X.; Chu, L.; Qing, F.-L. Angew. Chem., Int. Ed. 2013, 52, 2198–2202. doi:10.1002/anie.201208971

Return to citation in text: [1] -

Mizuta, S.; Verhoog, S.; Engle, K. M.; Khotavivattana, T.; O’Duill, M.; Wheelhouse, K.; Rassias, G.; Médebielle, M.; Gouverneur, V. J. Am. Chem. Soc. 2013, 135, 2505–2508. doi:10.1021/ja401022x

Return to citation in text: [1] -

Yang, J.-J.; Kirchmeier, R. L.; Shreeve, J. M. J. Org. Chem. 1998, 63, 2656–2660. doi:10.1021/jo972213l

See for some references on S-tifluoromethyl sulfonium salt.

Return to citation in text: [1] -

Magnier, E.; Blazejewski, J.-C.; Tordeux, M.; Wakselman, C. Angew. Chem., Int. Ed. 2006, 45, 1279–1282. doi:10.1002/anie.200503776

See for some references on S-tifluoromethyl sulfonium salt.

Return to citation in text: [1]

| 1. | Kirsch, P. Modern Fluoroorganic Chemistry Synthesis, Reactivity, Applications; Wiley-VCH: Weinheim, 2004. doi:10.1002/352760393X |

| 2. | Bégué, J.-P.; Bonnet-Delpon, D. Bioorganic and Medicinal Chemistry of Fluorine; John Wiley & Sons: Hoboken, 2008. doi:10.1002/9780470281895 |

| 3. | Schlosser, M. Angew. Chem., Int. Ed. 2006, 45, 5432–5446. doi:10.1002/anie.200600449 |

| 4. | Müller, K.; Faeh, C.; Diederich, F. Science 2007, 317, 1881–1886. doi:10.1126/science.1131943 |

| 5. | Hagmann, W. K. J. Med. Chem. 2008, 51, 4359–4369. doi:10.1021/jm800219f |

| 6. | Purser, S.; Moore, P. R.; Swallow, S.; Gouverneur, V. Chem. Soc. Rev. 2008, 37, 320–330. doi:10.1039/b610213c |

| 7. | Furuya, T.; Kamlet, A. S.; Ritter, T. Nature 2011, 473, 470–477. doi:10.1038/nature10108 |

| 39. | Iqbal, N.; Choi, S.; Kim, E.; Cho, E. J. J. Org. Chem. 2012, 77, 11383–11387. doi:10.1021/jo3022346 |

| 32. | Cho, E. J.; Buchwald, S. L. Org. Lett. 2011, 13, 6552–6555. doi:10.1021/ol202885w |

| 33. | Hafner, A.; Bräse, S. Adv. Synth. Catal. 2011, 353, 3044–3048. doi:10.1002/adsc.201100528 |

| 34. | Parsons, A. T.; Senecal, T. D.; Buchwald, S. L. Angew. Chem., Int. Ed. 2012, 51, 2947–2950. doi:10.1002/anie.201108267 |

| 35. | He, Z.; Luo, T.; Hu, M.; Cao, Y.; Hu, J. Angew. Chem., Int. Ed. 2012, 51, 3944–3947. doi:10.1002/anie.201200140 |

| 36. | Yasu, Y.; Koike, T.; Akita, M. Chem. Commun. 2013, 49, 2037–2039. doi:10.1039/c3cc39235j |

| 37. | Li, Z.; Cui, Z.; Liu, Z.-Q. Org. Lett. 2013, 15, 406–409. doi:10.1021/ol3034059 |

| 38. | Li, Y.; Wu, L.; Neumann, H.; Beller, M. Chem. Commun. 2013, 49, 2628–2630. doi:10.1039/c2cc36554e |

| 17. | Lundgren, R. J.; Stradiotto, M. Angew. Chem., Int. Ed. 2010, 49, 9322–9324. doi:10.1002/anie.201004051 |

| 18. | Tomashenko, O. A.; Grushin, V. V. Chem. Rev. 2011, 111, 4475–4521. doi:10.1021/cr1004293 |

| 19. | Besset, T.; Schneider, C.; Cahard, D. Angew. Chem., Int. Ed. 2012, 51, 5048–5050. doi:10.1002/anie.201201012 |

| 20. | Wu, X.-F.; Neumann, H.; Beller, M. Chem.–Asian J. 2012, 7, 1744–1754. doi:10.1002/asia.201200211 |

| 21. | Oishi, M.; Kondo, H.; Amii, H. Chem. Commun. 2009, 1909–1911. doi:10.1039/b823249k |

| 22. | Cho, E. J.; Senecal, T. D.; Kinzel, T.; Zhang, Y.; Watson, D. A.; Buchwald, S. L. Science 2010, 328, 1679–1681. doi:10.1126/science.1190524 |

| 23. | Wang, X.; Truesdale, L.; Yu, J.-Q. J. Am. Chem. Soc. 2010, 132, 3648–3649. doi:10.1021/ja909522s |

| 24. | Chu, L.; Qing, F.-L. J. Am. Chem. Soc. 2012, 134, 1298–1304. doi:10.1021/ja209992w |

| 25. | Zhang, C.-P.; Wang, Z.-L.; Chen, Q.-Y.; Zhang, C.-T.; Gu, Y.-C.; Xiao, J.-C. Angew. Chem., Int. Ed. 2011, 50, 1896–1900. doi:10.1002/anie.201006823 |

| 26. | Zhang, X.-G.; Dai, H.-X.; Wasa, M.; Yu, J.-Q. J. Am. Chem. Soc. 2012, 134, 11948–11951. doi:10.1021/ja305259n |

| 27. | Herrmann, A. T.; Smith, L. L.; Zakarian, A. J. Am. Chem. Soc. 2012, 134, 6976–6979. doi:10.1021/ja302552e |

| 28. | Liu, T.; Shao, X.; Wu, Y.; Shen, Q. Angew. Chem., Int. Ed. 2012, 51, 540–543. doi:10.1002/anie.201106673 |

| 29. | Ye, Y.; Sanford, M. S. J. Am. Chem. Soc. 2012, 134, 9034–9037. doi:10.1021/ja301553c |

| 30. | Zeng, Y.; Zhang, L.; Zhao, Y.; Ni, C.; Zhao, J.; Hu, J. J. Am. Chem. Soc. 2013, 135, 2955–2958. doi:10.1021/ja312711c |

| 31. | Dai, J.-J.; Fang, C.; Xiao, B.; Yi, J.; Xu, J.; Liu, Z.-J.; Lu, X.; Liu, L.; Fu, Y. J. Am. Chem. Soc. 2013, 135, 8436–8439. doi:10.1021/ja404217t |

| 8. | Zheng, Y.; Ma, J.-A. Adv. Synth. Catal. 2010, 352, 2745–2750. doi:10.1002/adsc.201000545 |

| 9. | Nie, J.; Guo, H.-C.; Cahard, D.; Ma, J.-A. Chem. Rev. 2010, 111, 455–529. doi:10.1021/cr100166a |

| 10. | Parsons, A. T.; Buchwald, S. L. Nature 2011, 480, 184–185. doi:10.1038/480184a |

| 11. | Studer, A. Angew. Chem., Int. Ed. 2012, 51, 8950–8958. doi:10.1002/anie.201202624 |

| 12. | Nagib, D. A.; MacMillan, D. W. C. Nature 2011, 480, 224–228. doi:10.1038/nature10647 |

| 13. | Pham, P. V.; Nagib, D. A.; MacMillan, D. W. C. Angew. Chem., Int. Ed. 2011, 50, 6119–6122. doi:10.1002/anie.201101861 |

| 14. | Prakash, G. K. S.; Jog, P. V.; Batamack, P. T. D.; Olah, G. A. Science 2012, 338, 1324–1327. doi:10.1126/science.1227859 |

| 15. | Pair, E.; Monteiro, N.; Bouyssi, D.; Baudoin, O. Angew. Chem., Int. Ed. 2013, 52, 5346–5349. doi:10.1002/anie.201300782 |

| 16. | Wang, X.; Xu, Y.; Mo, F.; Ji, G.; Qiu, D.; Feng, J.; Ye, Y.; Zhang, S.; Zhang, Y.; Wang, J. J. Am. Chem. Soc. 2013, 135, 10330–10333. doi:10.1021/ja4056239 |

| 47. | Parsons, A. T.; Buchwald, S. L. Angew. Chem., Int. Ed. 2011, 50, 9120–9123. doi:10.1002/anie.201104053 |

| 48. | Wang, X.; Ye, Y.; Zhang, S.; Feng, J.; Xu, Y.; Zhang, Y.; Wang, J. J. Am. Chem. Soc. 2011, 133, 16410–16413. doi:10.1021/ja207775a |

| 49. | Xu, J.; Fu, Y.; Luo, D.-F.; Jiang, Y.-Y.; Xiao, B.; Liu, Z.-J.; Gong, T.-J.; Liu, L. J. Am. Chem. Soc. 2011, 133, 15300–15303. doi:10.1021/ja206330m |

| 50. | Zhu, R.; Buchwald, S. L. J. Am. Chem. Soc. 2012, 134, 12462–12465. doi:10.1021/ja305840g |

| 47. | Parsons, A. T.; Buchwald, S. L. Angew. Chem., Int. Ed. 2011, 50, 9120–9123. doi:10.1002/anie.201104053 |

| 48. | Wang, X.; Ye, Y.; Zhang, S.; Feng, J.; Xu, Y.; Zhang, Y.; Wang, J. J. Am. Chem. Soc. 2011, 133, 16410–16413. doi:10.1021/ja207775a |

| 49. | Xu, J.; Fu, Y.; Luo, D.-F.; Jiang, Y.-Y.; Xiao, B.; Liu, Z.-J.; Gong, T.-J.; Liu, L. J. Am. Chem. Soc. 2011, 133, 15300–15303. doi:10.1021/ja206330m |

| 50. | Zhu, R.; Buchwald, S. L. J. Am. Chem. Soc. 2012, 134, 12462–12465. doi:10.1021/ja305840g |

| 46. | Mu, X.; Wu, T.; Wang, H.-Y.; Guo, Y.-L.; Liu, G. J. Am. Chem. Soc. 2012, 134, 878–881. doi:10.1021/ja210614y |

| 47. | Parsons, A. T.; Buchwald, S. L. Angew. Chem., Int. Ed. 2011, 50, 9120–9123. doi:10.1002/anie.201104053 |

| 48. | Wang, X.; Ye, Y.; Zhang, S.; Feng, J.; Xu, Y.; Zhang, Y.; Wang, J. J. Am. Chem. Soc. 2011, 133, 16410–16413. doi:10.1021/ja207775a |

| 49. | Xu, J.; Fu, Y.; Luo, D.-F.; Jiang, Y.-Y.; Xiao, B.; Liu, Z.-J.; Gong, T.-J.; Liu, L. J. Am. Chem. Soc. 2011, 133, 15300–15303. doi:10.1021/ja206330m |

| 50. | Zhu, R.; Buchwald, S. L. J. Am. Chem. Soc. 2012, 134, 12462–12465. doi:10.1021/ja305840g |

| 51. | Miyake, Y.; Ota, S.-I.; Nishibayashi, Y. Chem.–Eur. J. 2012, 18, 13255–13258. doi:10.1002/chem.201202853 |

| 52. | Yasu, Y.; Koike, T.; Akita, M. Angew. Chem., Int. Ed. 2012, 51, 9567–9571. doi:10.1002/anie.201205071 |

| 53. | Egami, H.; Shimizu, R.; Kawamura, S.; Sodeoka, M. Angew. Chem., Int. Ed. 2013, 52, 4000–4003. doi:10.1002/anie.201210250 |

| 54. | Liu, X.; Xiong, F.; Huang, X.; Xu, L.; Li, P.; Wu, X. Angew. Chem., Int. Ed. 2013, 52, 6962–6966. doi:10.1002/anie.201302673 |

| 55. | Wu, X.; Chu, L.; Qing, F.-L. Angew. Chem., Int. Ed. 2013, 52, 2198–2202. doi:10.1002/anie.201208971 |

| 56. | Mizuta, S.; Verhoog, S.; Engle, K. M.; Khotavivattana, T.; O’Duill, M.; Wheelhouse, K.; Rassias, G.; Médebielle, M.; Gouverneur, V. J. Am. Chem. Soc. 2013, 135, 2505–2508. doi:10.1021/ja401022x |

| 25. | Zhang, C.-P.; Wang, Z.-L.; Chen, Q.-Y.; Zhang, C.-T.; Gu, Y.-C.; Xiao, J.-C. Angew. Chem., Int. Ed. 2011, 50, 1896–1900. doi:10.1002/anie.201006823 |

| 41. | Lin, J.-H.; Xiao, J.-C. Eur. J. Org. Chem. 2011, 4536–4539. doi:10.1002/ejoc.201100683 |

| 42. | Lin, J.-H.; Zong, G.; Du, R.-B.; Xiao, J.-C.; Liu, S. Chem. Commun. 2012, 48, 7738–7740. doi:10.1039/c2cc18064b |

| 43. | Zhang, C.-P.; Wang, Z.-L.; Chen, Q.-Y.; Zhang, C.-T.; Gu, Y.-C.; Xiao, J.-C. Chem. Commun. 2011, 47, 6632–6634. doi:10.1039/c1cc11765c |

| 44. | Zhang, C.-P.; Cai, J.; Zhou, C.-B.; Wang, X.-P.; Zheng, X.; Gu, Y.-C.; Xiao, J.-C. Chem. Commun. 2011, 47, 9516–9518. doi:10.1039/c1cc13460d |

| 45. | Wang, X.; Lin, J.; Zhang, C.; Xiao, J.; Zheng, X. Chin. J. Chem. 2013, 31, 915–920. doi:10.1002/cjoc.201300393 |

| 40. | Janson, P. G.; Ghoneim, I.; Ilchenko, N. O.; Szabó, K. J. Org. Lett. 2012, 14, 2882–2885. doi:10.1021/ol3011419 |

| 25. | Zhang, C.-P.; Wang, Z.-L.; Chen, Q.-Y.; Zhang, C.-T.; Gu, Y.-C.; Xiao, J.-C. Angew. Chem., Int. Ed. 2011, 50, 1896–1900. doi:10.1002/anie.201006823 |

| 44. | Zhang, C.-P.; Cai, J.; Zhou, C.-B.; Wang, X.-P.; Zheng, X.; Gu, Y.-C.; Xiao, J.-C. Chem. Commun. 2011, 47, 9516–9518. doi:10.1039/c1cc13460d |

| 45. | Wang, X.; Lin, J.; Zhang, C.; Xiao, J.; Zheng, X. Chin. J. Chem. 2013, 31, 915–920. doi:10.1002/cjoc.201300393 |

| 57. |

Yang, J.-J.; Kirchmeier, R. L.; Shreeve, J. M. J. Org. Chem. 1998, 63, 2656–2660. doi:10.1021/jo972213l

See for some references on S-tifluoromethyl sulfonium salt. |

| 58. |

Magnier, E.; Blazejewski, J.-C.; Tordeux, M.; Wakselman, C. Angew. Chem., Int. Ed. 2006, 45, 1279–1282. doi:10.1002/anie.200503776

See for some references on S-tifluoromethyl sulfonium salt. |

© 2013 Wang et al; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)