Search results

Search for "renewable" in Full Text gives 106 result(s) in Beilstein Journal of Organic Chemistry.

One-pot synthesis of ethylmaltol from maltol

- Immanuel Plangger,

- Marcel Jenny,

- Gregor Plangger and

- Thomas Magauer

Beilstein J. Org. Chem. 2025, 21, 2755–2760, doi:10.3762/bjoc.21.212

- synthesis of ethylmaltol from a renewable precursor. Keywords: ethylmaltol; flavor enhancer; maltol; methylation; 4-pyrones; Introduction In 1969, a Pfizer patent first disclosed ethylmaltol (1) as a powerful, purely synthetic flavor and aroma enhancer (Scheme 1a) [1]. It has been found to have a 6-times

Graphical Abstract

Scheme 1: Importance and synthetic approaches to ethylmaltol (1). (a) Ethylmaltol (1) is widely used as a fla...

Scheme 2: Optimized one-pot procedure to access ethylmaltol (1) via a transient protecting group strategy.

The high potential of methyl laurate as a recyclable competitor to conventional toxic solvents in [3 + 2] cycloaddition reactions

- Ayhan Yıldırım and

- Mustafa Göker

Beilstein J. Org. Chem. 2025, 21, 2389–2415, doi:10.3762/bjoc.21.184

- against other solvents. Keywords: cycloaddition; fused isoxazolidines; renewable solvent; reusable solvent; trans-diastereoselectivity; Introduction It is an established fact that a significant number of conventional organic solvents, which are widely utilized in both industrial and academic contexts

- overlooked [69]. However, these methods are accompanied by the inevitability of long reaction times or the use of toxic organic solvents. Such negative aspects encountered during the synthesis of these compounds prompted us to seek alternative, environmentally benign, renewable, and reusable solvents [70

- all of the above criteria. For example, it can be synthesized easily and with high efficiency through the biodiesel production process, it can be reused, it is stable under storage conditions, it can be obtained from renewable resources, it is biodegradable, non-flammable etc. It is widely

Graphical Abstract

Figure 1: Versatile compounds via cycloaddition reactions.

Scheme 1: Molecular structures of parent compounds 1a–f, 2a–d and cycloadducts 3a–u.

Figure 2: a) Radar view of the physical properties of methyl laurate. b) Oral toxicity values of methyl laura...

Figure 3: The oral toxicity values of all the solvents utilized in the present study obtained with ProTox 3.0....

Figure 4: Ecological, environmental risk assessments, pesticide similarity and biodegradability assessments o...

Figure 5: Ecological, environmental risk assessments, pesticide similarity and biodegradability assessments o...

Figure 6: Ecological, environmental risk assessments, pesticide similarity and biodegradability assessments o...

Figure 7: Various toxicity parameters of methyl laurate and a series of other solvents calculated by ADMETLab...

Figure 8: a) Visualization of the localization of conventional organic and bio-based solvents in the Hansen s...

Figure 9: Vapour pressures of the solvents used (values retrieved from the Chemeo molecular database).

Scheme 2: Endo and exo stereoisomeric approaches of nitrone 1a and maleimide 2a in [3 + 2] cycloaddition reac...

Figure 10: Signals of protons used in the calculation of the diastereomeric ratios (cis/trans) of cycloadditio...

Figure 11: Results of studies on the recovery of solvents used in the reaction.

Figure 12: Simplified scheme describing the reaction monitoring and solvent recovery.

Figure 13: a) The superimposed spectra of C,N-diphenylnitrone and N-phenylmaleimide. b) The spectrum of methyl...

Electrochemical cyclization of alkynes to construct five-membered nitrogen-heterocyclic rings

- Lifen Peng,

- Ting Wang,

- Zhiwen Yuan,

- Bin Li,

- Zilong Tang,

- Xirong Liu,

- Hui Li,

- Guofang Jiang,

- Chunling Zeng,

- Henry N. C. Wong and

- Xiao-Shui Peng

Beilstein J. Org. Chem. 2025, 21, 2173–2201, doi:10.3762/bjoc.21.166

- ][94]. Electrochemical transformations used renewable and clean electricity as a source of electrons and electron holes to generate radical species, showing several superiorities such as safety, economy, high selectivity, scalability, mild reaction conditions, powerful efficiency, environment-friendly

Graphical Abstract

Figure 1: Natural products and functional molecules possessing five-membered rings.

Scheme 1: Electrochemical intramolecular coupling of ureas to form indoles.

Scheme 2: Electrochemical dehydrogenative annulation of alkynes with anilines.

Scheme 3: Electrochemical annulations of o-arylalkynylanilines.

Scheme 4: Electrochemical cyclization of 2-ethynylanilines.

Scheme 5: Electrochemical selenocyclization of diselenides and 2-ethynylanilines.

Scheme 6: Electrochemical cascade approach towards 3-selenylindoles.

Scheme 7: Electrochemical C–H indolization.

Scheme 8: Electrochemical annulation of benzamides and terminal alkynes.

Scheme 9: Electrochemical synthesis of isoindolinone by 5-exo-dig aza-cyclization.

Scheme 10: Electrochemical reductive cascade annulation of o-alkynylbenzamide.

Scheme 11: Electrochemical intramolecular 1,2-amino oxygenation of alkyne.

Scheme 12: Electrochemical multicomponent reaction of nitrile, (thio)xanthene, terminal alkyne and water.

Scheme 13: Electrochemical aminotrifluoromethylation/cyclization of alkynes.

Scheme 14: Electrochemical cyclization of o-nitrophenylacetylene.

Scheme 15: Electrochemical annulation of alkynyl enaminones.

Scheme 16: Electrochemical annulation of alkyne and enamide.

Scheme 17: Electrochemical tandem Michael addition/azidation/cyclization.

Scheme 18: Electrochemical [3 + 2] cyclization of heteroarylamines.

Scheme 19: Electrochemical CuAAC to access 1,2,3-triazole.

C2 to C6 biobased carbonyl platforms for fine chemistry

- Jingjing Jiang,

- Muhammad Noman Haider Tariq,

- Florence Popowycz,

- Yanlong Gu and

- Yves Queneau

Beilstein J. Org. Chem. 2025, 21, 2103–2172, doi:10.3762/bjoc.21.165

- impact while maintaining the efficiency of the chemical processes [1]. Green Chemistry principles outlined by Anastas and Warner in their work “Green Chemistry: Theory and Practice (2000)” [2] notably highlight atom economy, waste minimization and the use of renewable feedstock as pillars of sustainable

- biomass shows how renewable carbon sources can replace non-renewable chemicals in important industrial processes [18][19][20]. Many, if not most, biobased platform molecules contain carbonyl groups. Carbonyl compounds have unique electrophilic and nucleophilic reactivity which make them central players in

- –Crafts alkylation products were then converted into an intermediate tryptaldehyde that underwent intramolecular olefination to form the targeted product [34]. Glycolic acid (GA) The growing impact of fossil fuel consumption has heightened the need for advancing renewable energy technologies. One

Graphical Abstract

Figure 1: C2–C6 biobased carbonyl building blocks.

Scheme 1: Proposed (2 + 2) route to glycolaldehyde and glycolic acid from erythritol by Cu/AC catalyst (AC = ...

Scheme 2: Reductive amination of GCA.

Scheme 3: N-Formylation of secondary amines by reaction with GCA.

Scheme 4: Synthesis and conversion of hydroxy acetals to cyclic acetals.

Scheme 5: Synthesis of 3-(indol-3-yl)-2,3-dihydrofurans via three-component reaction of glycolaldehyde, indol...

Scheme 6: BiCl3-catalyzed synthesis of benzo[a]carbazoles from 2-arylindoles and α-bromoacetaldehyde ethylene...

Scheme 7: Cu/NCNSs-based conversion of glycerol to glycolic acid and other short biobased acids.

Scheme 8: E. coli-based biotransformation of C1 source molecules (CH4, CO2 and CO) towards C2 glycolic acid.

Scheme 9: N-Formylation of amines with C2 (a) or C3 (b) biomass-based feedstocks.

Scheme 10: Methods for the formation of propanoic acid (PA) from lactic acid (LA).

Scheme 11: Co-polymerization of biobased lactic acid and glycolic acid via a bicatalytic process.

Scheme 12: Oxidation of α-hydroxy acids by tetrachloroaurate(III) in acetic acid–sodium acetate buffer medium.

Figure 2: Selective catalytic pathways for the conversion of lactic acid (LA).

Scheme 13: Synthesis of 1,3-PDO via cross-aldol reaction between formaldehyde and acetaldehyde to 3-hydroxypro...

Scheme 14: Hydrothermal conversion of 1,3-dihydroxy-2-propane and 2,3-dihydroxypropanal to methylglyoxal.

Scheme 15: FLS-catalyzed formose reaction to synthesize GA and DHA.

Scheme 16: GCA and DHA oxidation products of glycerol and isomerization of GCA to DHA under flow conditions us...

Scheme 17: Acid-catalyzed reactions of DHA with alcohols.

Scheme 18: Synthesis of dihydroxyacetone phosphate from dihydroxyacetone.

Scheme 19: Bifunctional acid–base catalyst DHA conversion into lactic acid via pyruvaldehyde or fructose forma...

Scheme 20: Catalytic one-pot synthesis of GA and co-synthesis of formamides and formates from DHA.

Scheme 21: (a) Synthesis of furan derivatives and (b) synthesis of thiophene derivative by cascade [3 + 2] ann...

Scheme 22: Brønsted acidic ionic liquid catalyzed synthesis of benzo[a]carbazole from renewable acetol and 2-p...

Scheme 23: Asymmetric hydrogenation of α-hydroxy ketones to 1,2-diols.

Scheme 24: Synthesis of novel 6-(substituted benzylidene)-2-methylthiazolo [2,3-b]oxazol-5(6H)-one from 1-hydr...

Scheme 25: ʟ-Proline-catalyzed synthesis of anti-diols from hydroxyacetone and aldehydes.

Scheme 26: C–C-bond-formation reactions of a biomass-based feedstock aromatic aldehyde (C5) and hydroxyacetone...

Scheme 27: Ethanol upgrading to C4 bulk chemicals via the thiamine (VB1)-catalyzed acetoin condensation.

Scheme 28: One-pot sequential chemoenzymatic synthesis of 2-aminobutane-1,4-diol and 1,2,4-butanetriol via 1,4...

Scheme 29: Synthesis of 1,4-dihydroxybutan-2-one by microbial transformation.

Scheme 30: Conversion of polyols by [neocuproine)Pd(OAc)]2(OTf)2] to α-hydroxy ketones.

Scheme 31: Chemoselective oxidation of alcohols with chiral palladium-based catalyst 2.

Scheme 32: Electrochemical transformation of furfural to 5-hydroxy-2(5H)-furanone (HFO).

Scheme 33: Selective hydrodeoxygenation of HFO and oxidation to γ-butyrolactone (GBL).

Scheme 34: Photosensitized oxygenation of furan towards HFO via ozonide intermediates.

Scheme 35: Conversion of furfural to HFO and MAN by using mesoporous carbon nitride (SGCN) as photocatalyst.

Scheme 36: Synthesis of HFO from furan derivatives.

Scheme 37: Photooxidation of furfural to 5-hydroxy-2(5H)-furanone (HFO).

Scheme 38: Synthesis of Friedel–Crafts indole adduct from HFO.

Scheme 39: Conversion of HFO to α,γ-substituted chiral γ-lactones.

Scheme 40: Tautomeric transformation of HFO to formylacrylic acid.

Scheme 41: Hydrolysis of HFO to succinic acid in aqueous solution.

Scheme 42: Substitution and condensation reactions of 5-hydroxy-2(5H)-furanone (HFO).

Scheme 43: (a) Conversion of HFO towards valuable C4 chemicals and (b) anodic oxidation of 5-hydroxy-2(5H)-fur...

Figure 3: Conversion of HFO towards other natural and synthetic substances.

Scheme 44: Conversion of furfural to maleic anhydride (reaction a: VOx/Al2O3; reaction b: VPO).

Scheme 45: Conversion of furfural into succinic acid.

Scheme 46: Electro‑, photo‑, and biocatalysis for one-pot selective conversions of furfural into C4 chemicals.

Scheme 47: Production route of furfural from hemicellulose.

Scheme 48: Mechanism for xylose dehydration to furfural through a choline xyloside intermediate.

Scheme 49: Conversion of furfural to furfuryl alcohol and its derivatives.

Scheme 50: Conversion of furfural to furfuryl alcohol and 3-(2-furyl)acrolein.

Scheme 51: The aerobic oxidative condensation of biomass-derived furfural and linear alcohols.

Scheme 52: The single-step synthesis of 2-pentanone from furfural.

Scheme 53: Electrocatalytic coupling reaction of furfural and levulinic acid.

Scheme 54: Conversion of furfural to m-xylylenediamine.

Scheme 55: Conversion of furfural to tetrahydrofuran-derived amines.

Scheme 56: Formation of trans-4,5-diamino-cyclopent-2-enones from furfural.

Scheme 57: Production of pyrrole and proline from furfural.

Scheme 58: Synthesis of 1‑(trifluoromethyl)-8-oxabicyclo[3.2.1]oct-3-en-2-ones from furfural.

Scheme 59: Conversion of furfural to furfural-derived diacids.

Scheme 60: A telescope protocol derived from furfural and glycerol.

Scheme 61: A tandem cyclization of furfural and 5,5-dimethyl-1,3-cyclohexanedione.

Scheme 62: A Ugi four-component reaction to construct furfural-based polyamides.

Scheme 63: One-pot synthesis of γ-acyloxy-Cy7 from furfural.

Scheme 64: Dimerization–Piancatelli sequence toward humins precursors from furfural.

Scheme 65: Conversion of furfural to CPN.

Scheme 66: Synthesis of jet fuels range cycloalkanes from CPN and lignin-derived vanillin.

Scheme 67: Solar-energy-driven synthesis of high-density biofuels from CPN.

Scheme 68: Reductive amination of CPN to cyclopentylamine.

Scheme 69: Asymmetric hydrogenation of C=O bonds of exocyclic α,β-unsaturated cyclopentanones.

Scheme 70: Preparation of levulinic acid via the C5 route (route a) or C6 route (routes b1 and b2).

Scheme 71: Mechanism of the rehydration of HMF to levulinic acid and formic acid.

Scheme 72: Important levulinic acid-derived chemicals.

Scheme 73: Direct conversion of levulinic acid to pentanoic acid.

Scheme 74: Catalytic aerobic oxidation of levulinic acid to citramalic acid.

Scheme 75: Conversion of levulinic acid to 1,4-pentanediol (a) see ref. [236]; b) see ref. [237]; c) see ref. [238]; d) see r...

Scheme 76: Selective production of 2-butanol through hydrogenolysis of levulinic acid.

Scheme 77: General reaction pathways proposed for the formation of 5MPs from levulinic acid.

Scheme 78: Selective reductive amination of levulinic acid to N-substituted pyrroles.

Scheme 79: Reductive amination of levulinic acid to chiral pyrrolidinone.

Scheme 80: Reductive amination of levulinic acid to non-natural chiral γ-amino acid.

Scheme 81: Nitrogen-containing chemicals derived from levulinic acid.

Scheme 82: Preparation of GVL from levulinic acid by dehydration and hydrogenation.

Scheme 83: Ruthenium-catalyzed levulinic acid to chiral γ-valerolactone.

Scheme 84: Catalytic asymmetric hydrogenation of levulinic acid to chiral GVL.

Scheme 85: Three steps synthesis of ε-caprolactam from GVL.

Scheme 86: Multistep synthesis of nylon 6,6 from GVL.

Scheme 87: Preparation of MeGVL by α-alkylation of GVL.

Scheme 88: Ring-opening polymerization of five-membered lactones.

Scheme 89: Synthesis of GVL-based ionic liquids.

Scheme 90: Preparation of butene isomers from GVL under Lewis acid conditions.

Scheme 91: Construction of C5–C12 fuels from GVL over nano-HZSM-5 catalysts.

Scheme 92: Preparation of alkyl valerate from GVL via ring opening/reduction/esterification sequence.

Scheme 93: Construction of 4-acyloxypentanoic acids from GVL.

Scheme 94: Synthesis of 1,4-pentanediol (PDO) from GVL.

Scheme 95: Construction of novel cyclic hemiketal platforms via self-Claisen condensation of GVL.

Scheme 96: Copper-catalyzed lactamization of GVL.

Figure 4: Main scaffolds obtained from HMF.

Scheme 97: Biginelli reactions towards HMF-containing dihydropyrimidinones.

Scheme 98: Hantzsch dihydropyridine synthesis involving HMF.

Scheme 99: The Kabachnik–Fields reaction involving HMF.

Scheme 100: Construction of oxazolidinone from HMF.

Scheme 101: Construction of rhodamine-furan hybrids from HMF.

Scheme 102: A Groebke–Blackburn–Bienaymé reaction involving HMF.

Scheme 103: HMF-containing benzodiazepines by [4 + 2 + 1] cycloadditions.

Scheme 104: Synthesis of fluorinated analogues of α-aryl ketones.

Scheme 105: Synthesis of HMF derived disubstituted γ-butyrolactone.

Scheme 106: Functionalized aromatics from furfural and HMF.

Scheme 107: Diels–Alder adducts from HMF or furfural with N-methylmaleimide.

Scheme 108: Pathway of the one-pot conversion of HMF into phthalic anhydride.

Scheme 109: Photocatalyzed preparation of humins (L-H) from HMF mixed with spoiled HMF residues (LMW-H) and fur...

Scheme 110: Asymmetric dipolar cycloadditions on HMF.

Scheme 111: Dipolar cycloadditions of HMF based nitrones to 3,4- and 3,5-substituted isoxazolidines.

Scheme 112: Production of δ-lactone-fused cyclopenten-2-ones from HMF.

Scheme 113: Aza-Piancatelli access to aza-spirocycles from HMF-derived intermediates.

Scheme 114: Cross-condensation of furfural, acetone and HMF into C13, C14 and C15 products.

Scheme 115: Base-catalyzed aldol condensation/dehydration sequences from HMF.

Scheme 116: Condensation of HMF and active methylene nitrile.

Scheme 117: MBH reactions involving HMF.

Scheme 118: Synthesis of HMF-derived ionic liquids.

Scheme 119: Reductive amination/enzymatic acylation sequence towards HMF-based surfactants.

Scheme 120: The formation of 5-chloromethylfurfural (CMF).

Scheme 121: Conversion of CMF to HMF, levulinic acid, and alkyl levulinates.

Scheme 122: Conversion of CMF to CMFCC and FDCC.

Scheme 123: Conversion of CMF to BHMF.

Scheme 124: Conversion of CMF to DMF.

Scheme 125: CMF chlorine atom substitutions toward HMF ethers and esters.

Scheme 126: Introduction of carbon nucleophiles in CMF.

Scheme 127: NHC-catalyzed remote enantioselective Mannich-type reactions of CMF.

Scheme 128: Conversion of CMF to promising biomass-derived dyes.

Scheme 129: Radical transformation of CMF with styrenes.

Scheme 130: Synthesis of natural herbicide δ-aminolevulinic acid from CMF.

Scheme 131: Four step synthesis of the drug ranitidine from CMF.

Scheme 132: Pd/CO2 cooperative catalysis for the production of HHD and HXD.

Scheme 133: Different ruthenium (Ru) catalysts for the ring-opening of 5-HMF to HHD.

Scheme 134: Proposed pathways for preparing HXD from HMF.

Scheme 135: MCP formation and uses.

Scheme 136: Cu(I)-catalyzed highly selective oxidation of HHD to 2,5-dioxohexanal.

Scheme 137: Synthesis of N‑substituted 3‑hydroxypyridinium salts from 2,5-dioxohexanal.

Scheme 138: Ru catalyzed hydrogenations of HHD to 1,2,5-hexanetriol (a) see ref. [396]; b) see ref. [397]).

Scheme 139: Aviation fuel range quadricyclanes produced by HXD.

Scheme 140: Synthesis of HDGK from HXD and glycerol as a chain extender.

Scheme 141: Synthesis of serinol pyrrole from HXD and serinol.

Scheme 142: Synthesis of pyrroles from HXD and nitroarenes.

Scheme 143: Two-step production of PX from cellulose via HXD.

Scheme 144: Preparation of HCPN from HMF via hydrogenation and ring rearrangement.

Scheme 145: Suggested pathways from HMF to HCPN.

Scheme 146: α-Alkylation of HCPN with ethylene gas.

Scheme 147: Synthesis of 3-(hydroxymethyl)cyclopentylamine from HMF via reductive amination of HCPN.

Scheme 148: Production of LGO and Cyrene® from biomass.

Scheme 149: Synthesis of HBO from LGO and other applications.

Scheme 150: Construction of m-Cyrene® homopolymer.

Scheme 151: Conversion of Cyrene® to THFDM and 1,6-hexanediol.

Scheme 152: RAFT co-polymerization of LGO and butadienes.

Scheme 153: Polycondensation of HO-LGOL and diols with dimethyl adipate.

Scheme 154: Self-condensation of Cyrene® and Claisen–Schmidt reactions.

Scheme 155: Synthesis of 5-amino-2-(hydroxymethyl)tetrahydropyran from Cyrene®.

Solar thermal fuels: azobenzene as a cyclic photon–heat transduction platform

- Jie Yan,

- Shaodong Sun,

- Minghao Wang and

- Si Wu

Beilstein J. Org. Chem. 2025, 21, 2036–2047, doi:10.3762/bjoc.21.159

- pivotal position among renewable energy sources. To date, solar energy conversion and storage technologies have experienced considerable progress, including artificial photosynthesis [1], solar thermal collectors [2], photovoltaic cells [3], and solar thermal fuels [4][5]. Among these innovations, solar

Graphical Abstract

Figure 1: Schematic diagram of molecular solar thermal energy storage system.

Figure 2: Photoisomerization of different types of molecular optical switches. Figure 2 was redrawn from [8].

Figure 3: Nanocarbon-based azobenzene polymer solar thermal fuels: (a) SWCNT templating. Figure 3a is from [43] (T. J. Kuc...

Figure 4: Conjugated azobenzene polymer solar thermal fuels: (a) Photoisomerization and thermally induced rev...

Figure 5: Linear azobenzene polymer solar thermal fuels: (a) Schematic illustration of the trans-to-cis isome...

Figure 6: Representative examples of azobenzene small-molecule derivative solar thermal fuels. (a) Polarized ...

Figure 7: (a) Deicing test of charged solar thermal fuels under green light irradiation (550 nm). Figure 7a was reprin...

Optimized synthesis of aroyl-S,N-ketene acetals by omission of solubilizing alcohol cosolvents

- Julius Krenzer and

- Thomas J. J. Müller

Beilstein J. Org. Chem. 2025, 21, 1201–1206, doi:10.3762/bjoc.21.97

- . This can be obtained from renewable biomass and is therefore considered to be a "green" solvent. In 2-MeTHF (conditions (C)), product 1f was isolated with a yield of 95% and derivative 1h with a yield of 91%. This shows that the sustainable solvent is a potent alternative to 1,4-dioxane. With the new

Graphical Abstract

Scheme 1: Retrosynthetic analysis of aroyl-S,N-ketene acetals 1 and tentative mechanistic scenario of the add...

Scheme 2: Standard protocol for the synthesis of (hetero)aroyl-S,N-ketene acetals 8 in binary dioxane/ethanol...

Scheme 3: Modified protocol for the synthesis of aroyl-S,N-ketene acetals 1 in dioxane at room temperature.

Recent advances in synthetic approaches for bioactive cinnamic acid derivatives

- Betty A. Kustiana,

- Galuh Widiyarti and

- Teni Ernawati

Beilstein J. Org. Chem. 2025, 21, 1031–1086, doi:10.3762/bjoc.21.85

- cinnamic acid (7) to give amide 12 in excellent yield via Ti(IV)–O=C complex 102 (Scheme 31C) [69]. 2.1.3 Photocatalysis: Photoredox catalysis has gained much attention as a sustainable alternative approach to performing O/N-acylation by utilizing light as a renewable source. For example, Li and co-workers

Graphical Abstract

Figure 1: Biologically active cinnamic acid derivatives.

Scheme 1: General synthetic strategies for cinnamic acid derivatizations.

Scheme 2: Cinnamic acid coupling via isobutyl anhydride formation.

Scheme 3: Amidation reaction via O/N-pivaloyl activation.

Scheme 4: Cinnamic acid amidation using TCCA/PPh3 reagent.

Scheme 5: Cinnamic acid amidation using triazine-based reagents.

Scheme 6: Cinnamic acid amidation using continuous flow mechanochemistry.

Scheme 7: Cinnamic acid amidation using COMU as coupling reagent.

Scheme 8: Cinnamic acid amidation using allenone coupling reagent.

Scheme 9: Cinnamic acid amidation using 4-acetamidophenyl triflimide as reagent.

Scheme 10: Cinnamic acid amidation using methyltrimethoxysilane (MTM).

Scheme 11: Cinnamic acid amidation utilizing amine–borane reagent.

Scheme 12: Cinnamic acid amidation using TCCA/PPh3 reagent.

Scheme 13: Cinnamic acid amidation using PPh3/I2 reagent.

Scheme 14: Cinnamic acid amidation using PCl3 reagent.

Scheme 15: Cinnamic acid amidation utilizing pentafluoropyridine (PFP) as reagent.

Scheme 16: Cinnamic acid amidation using hypervalent iodine(III).

Scheme 17: Mechanochemical amidation using 1,1,2,2-tetrafluoroethyl-N,N-dimethylamine (TFEDMA) reagent.

Scheme 18: Methyl ester preparation using tris(2,4,6-trimethoxyphenyl)phosphine (TMPP).

Scheme 19: N-Trifluoromethyl amide preparation using isothiocyanate and AgF.

Scheme 20: POCl3-mediated amide coupling of carboxylic acid and DMF.

Scheme 21: O-Alkylation of cinnamic acid using alkylating agents.

Scheme 22: Glycoside preparation via Mitsunobu reaction.

Scheme 23: O/N-Acylation via rearrangement reactions.

Scheme 24: Amidation reactions using sulfur-based alkylating agents.

Scheme 25: Amidation reaction catalyzed by Pd0 via C–N cleavage.

Scheme 26: Amidation reaction catalyzed by CuCl/PPh3.

Scheme 27: Cu(II) triflate-catalyzed N-difluoroethylimide synthesis.

Scheme 28: Cu/Selectfluor-catalyzed transamidation reaction.

Scheme 29: CuO–CaCO3-catalyzed amidation reaction.

Scheme 30: Ni-catalyzed reductive amidation.

Scheme 31: Lewis acidic transition-metal-catalyzed O/N-acylations.

Scheme 32: Visible-light-promoted amidation of cinnamic acid.

Scheme 33: Sunlight/LED-promoted amidation of cinnamic acid.

Scheme 34: Organophotocatalyst-promoted N–O cleavage of Weinreb amides to synthesize primary amides.

Scheme 35: Cinnamamide synthesis through [Ir] photocatalyst-promoted C–N-bond cleavage of tertiary amines.

Scheme 36: Blue LED-promoted FeCl3-catalyzed reductive transamidation.

Scheme 37: FPyr/TCT-catalyzed amidation of cinnamic acid derivative 121.

Scheme 38: Cs2CO3/DMAP-mediated esterification.

Scheme 39: HBTM organocatalyzed atroposelective N-acylation.

Scheme 40: BH3-catalyzed N-acylation reactions.

Scheme 41: Borane-catalyzed N-acylation reactions.

Scheme 42: Catalytic N-acylation reactions via H/F bonding activation.

Scheme 43: Brønsted base-catalyzed synthesis of cinnamic acid esters.

Scheme 44: DABCO/Fe3O4-catalyzed N-methyl amidation of cinnamic acid 122.

Scheme 45: Catalytic oxidation reactions of acylating agents.

Scheme 46: Preparation of cinnamamide-substituted benzocyclooctene using I(I)/I(III) catalysis.

Scheme 47: Pd-colloids-catalyzed oxidative esterification of cinnamyl alcohol.

Scheme 48: Graphene-supported Pd/Au alloy-catalyzed oxidative esterification via hemiacetal intermediate.

Scheme 49: Au-supported on A) carbon nanotubes (CNT) and B) on porous boron nitride (pBN) as catalyst for the ...

Scheme 50: Cr-based catalyzed oxidative esterification of cinnamyl alcohols with H2O2 as the oxidant.

Scheme 51: Co-based catalysts used for oxidative esterification of cinnamyl alcohol.

Scheme 52: Iron (A) and copper (B)-catalyzed oxidative esterification of cinnamaldehyde.

Scheme 53: NiHPMA-catalyzed oxidative esterification of cinnamaldehyde.

Scheme 54: Synthesis of cinammic acid esters through NHC-catalyzed oxidative esterification via intermolecular...

Scheme 55: Redox-active NHC-catalyzed esterification via intramolecular oxidation.

Scheme 56: Electrochemical conversion of cinnamaldehyde to methyl cinnamate.

Scheme 57: Bu4NI/TBHP-catalyzed synthesis of bisamides from cinnamalaldehyde N-tosylhydrazone.

Scheme 58: Zn/NC-950-catalyzed oxidative esterification of ketone 182.

Scheme 59: Ru-catalyzed oxidative carboxylation of terminal alkenes.

Scheme 60: Direct carboxylation of alkenes using CO2.

Scheme 61: Carboxylation of alkenylboronic acid/ester.

Scheme 62: Carboxylation of gem-difluoroalkenes with CO2.

Scheme 63: Photoredox-catalyzed carboxylation of difluoroalkenes.

Scheme 64: Ru-catalyzed carboxylation of alkenyl halide.

Scheme 65: Carboxylation of alkenyl halides under flow conditions.

Scheme 66: Cinnamic acid ester syntheses through carboxylation of alkenyl sulfides/sulfones.

Scheme 67: Cinnamic acid derivatives synthesis through a Ag-catalyzed decarboxylative cross-coupling proceedin...

Scheme 68: Pd-catalyzed alkyne hydrocarbonylation.

Scheme 69: Fe-catalyzed alkyne hydrocarbonylation.

Scheme 70: Alkyne hydrocarboxylation using CO2.

Scheme 71: Alkyne hydrocarboxylation using HCO2H as CO surrogate.

Scheme 72: Co/AlMe3-catalyzed alkyne hydrocarboxylation using DMF.

Scheme 73: Au-catalyzed oxidation of Au–allenylidenes.

Scheme 74: Pd-catalyzed C–C-bond activation of cyclopropenones to synthesize unsaturated esters and amides.

Scheme 75: Ag-catalyzed C–C-bond activation of diphenylcyclopropenone.

Scheme 76: Cu-catalyzed C–C bond activation of diphenylcyclopropenone.

Scheme 77: PPh3-catalyzed C–C-bond activation of diphenylcyclopropenone.

Scheme 78: Catalyst-free C–C-bond activation of diphenylcyclopropenone.

Scheme 79: Cu-catalyzed dioxolane cleavage.

Scheme 80: Multicomponent coupling reactions.

Scheme 81: Pd-catalyzed partial hydrogenation of electrophilic alkynes.

Scheme 82: Nickel and cobalt as earth-abundant transition metals used as catalysts for the partial hydrogenati...

Scheme 83: Metal-free-catalyzed partial hydrogenation of conjugated alkynes.

Scheme 84: Horner–Wadsworth–Emmons reaction between triethyl 2-fluoro-2-phosphonoacetate and aldehydes with ei...

Scheme 85: Preparation of E/Z-cinnamates using thiouronium ylides.

Scheme 86: Transition-metal-catalyzed ylide reactions.

Scheme 87: Redox-driven ylide reactions.

Scheme 88: Noble transition-metal-catalyzed olefination via carbenoid species.

Scheme 89: TrBF4-catalyzed olefination via carbene species.

Scheme 90: Grubbs catalyst (cat 7)/photocatalyst-mediated metathesis reactions.

Scheme 91: Elemental I2-catalyzed carbonyl-olefin metathesis.

Scheme 92: Cu-photocatalyzed E-to-Z isomerization of cinnamic acid derivatives.

Scheme 93: Ni-catalyzed E-to-Z isomerization.

Scheme 94: Dehydration of β-hydroxy esters via an E1cB mechanism to access (E)-cinnamic acid esters.

Scheme 95: Domino ring-opening reaction induced by a base.

Scheme 96: Dehydroamination of α-aminoester derivatives.

Scheme 97: Accessing methyl cinnamate (44) via metal-free deamination or decarboxylation.

Scheme 98: The core–shell magnetic nanosupport-catalyzed condensation reaction.

Scheme 99: Accessing cinnamic acid derivatives from acetic acid esters/amides through α-olefination.

Scheme 100: Accessing cinnamic acid derivatives via acceptorless α,β-dehydrogenation.

Scheme 101: Cu-catalyzed formal [3 + 2] cycloaddition.

Scheme 102: Pd-catalyzed C–C bond formation via 1,4-Pd-shift.

Scheme 103: NHC-catalyzed Rauhut–Currier reactions.

Scheme 104: Heck-type reaction for Cα arylation.

Scheme 105: Cu-catalyzed trifluoromethylation of cinnamamide.

Scheme 106: Ru-catalyzed alkenylation of arenes using directing groups.

Scheme 107: Earth-abundant transition-metal-catalyzed hydroarylation of α,β-alkynyl ester 374.

Scheme 108: Precious transition-metal-catalyzed β-arylation of cinnamic acid amide/ester.

Scheme 109: Pd-catalyzed β-amination of cinnamamide.

Scheme 110: S8-mediated β-amination of methyl cinnamate (44).

Scheme 111: Pd-catalyzed cross-coupling reaction of alkynyl esters with phenylsilanes.

Scheme 112: Pd-catalyzed β-cyanation of alkynyl amide/ester.

Scheme 113: Au-catalyzed β-amination of alkynyl ester 374.

Scheme 114: Metal-free-catalyzed Cβ-functionalizations of alkynyl esters.

Scheme 115: Heck-type reactions.

Scheme 116: Mizoroki–Heck coupling reactions using unconventional functionalized arenes.

Scheme 117: Functional group-directed Mizoroki–Heck coupling reactions.

Scheme 118: Pd nanoparticles-catalyzed Mizoroki–Heck coupling reactions.

Scheme 119: Catellani-type reactions to access methyl cinnamate with multifunctionalized arene.

Scheme 120: Multicomponent coupling reactions.

Scheme 121: Single atom Pt-catalyzed Heck coupling reaction.

Scheme 122: Earth-abundant transition metal-catalyzed Heck coupling reactions.

Scheme 123: Polymer-coated earth-abundant transition metals-catalyzed Heck coupling reactions.

Scheme 124: Earth-abundant transition-metal-based nanoparticles as catalysts for Heck coupling reactions.

Scheme 125: CN- and Si-based directing groups to access o-selective cinnamic acid derivatives.

Scheme 126: Amide-based directing group to access o-selective cinnamic acid derivatives.

Scheme 127: Carbonyl-based directing group to access o-selective cinnamic acid derivatives.

Scheme 128: Stereoselective preparation of atropisomers via o-selective C(sp2)–H functionalization.

Scheme 129: meta-Selective C(sp2)–H functionalization using directing group-tethered arenes.

Scheme 130: para-Selective C(sp2)–H functionalization using directing group-tethered arenes.

Scheme 131: Non-directed C(sp2)–H functionalization via electrooxidative Fujiwara–Moritani reaction.

Scheme 132: Interconversion of functional groups attached to cinnamic acid.

Scheme 133: meta-Selective C(sp2)–H functionalization of cinnamate ester.

Scheme 134: C(sp2)–F arylation using Grignard reagents.

Scheme 135: Truce–Smiles rearrangement of N-aryl metacrylamides.

Scheme 136: Phosphine-catalyzed cyclization of γ-vinyl allenoate with enamino esters.

Synthesis and photoinduced switching properties of C7-heteroatom containing push–pull norbornadiene derivatives

- Daniel Krappmann and

- Andreas Hirsch

Beilstein J. Org. Chem. 2025, 21, 807–816, doi:10.3762/bjoc.21.64

- catalytic back-conversion studies. Keywords: heterocycles; molecular solar thermal systems; norbornadiene; photochemistry; quadricyclane; Introduction In recent decades, the demand for renewable energy has increased tremendously [1]. A promising alternative to fossil fuels is the utilization of so-called

Graphical Abstract

Figure 1: Basic principle of the NBD to QC conversion and vice versa. The bridge-atom at position 7 was varie...

Scheme 1: Synthetic procedure towards new X-NBD derivatives C-NBD1, O-NBD1 and N-NBD1. 1-((Bromoethynyl)sulfo...

Figure 2: Conversion of O-NBD1 to O-QC1 using a 275 nm LED. The UV–vis spectrum was recorded in MeCN; b) the ...

Figure 3: Rearrangement of O-NBD2 to O-QC2 using a 385 nm LED. The UV–vis measurement in the middle were cond...

Figure 4: Rearrangement of N-NBD2 using a 385 nm LED. The UV–vis measurement in the middle were conducted in ...

The effect of neighbouring group participation and possible long range remote group participation in O-glycosylation

- Rituparna Das and

- Balaram Mukhopadhyay

Beilstein J. Org. Chem. 2025, 21, 369–406, doi:10.3762/bjoc.21.27

- ], cosmetics, and detergents. Carbohydrates are the most abundant and versatile renewable sources of energy on earth. However, extraction of naturally occurring complex glycans from natural sources is a laborious and cumbersome task. Moreover, the isolated samples provide a low-yield heterogenous mixture of

Graphical Abstract

Scheme 1: Continuum in the mechanistic pathway of glycosylation [32] reactions ranging between SN2 and SN1.

Scheme 2: Formation of 1,2-trans glycosides by neighbouring group participation with acyl protection in C-2 p...

Scheme 3: Solvent-free activation [92] of disarmed per-acetylated (15) and per-benzoylated (18) glycosyl donors.

Scheme 4: Synthesis of donor 2-(2,2,2-trichloroethoxy)glucopyrano-[2,1-d]-2-oxazoline 22 [94] and regioselective ...

Scheme 5: The use of levulinoyl protection for an orthogonal glycosylation reaction.

Figure 1: The derivatives 32–36 of the pivaloyl group.

Scheme 6: Benzyl and cyanopivalolyl ester-protected hexarhamnoside derivative 37 and its global deprotection ...

Scheme 7: Orthogonal chloroacetyl group deprotection in oligosaccharide synthesis [113].

Figure 2: The derivatives of the chloroacetyl group: CAMB protection (41) [123], CAEB protection (42) [124], POMB prote...

Scheme 8: Use of the (2-nitrophenyl)acetyl protecting group [126] as the neighbouring group protecting group at th...

Scheme 9: Neighbouring group participation protocol by the BnPAc protecting group [128] in the C-2 position.

Scheme 10: Glycosylation reaction with O-PhCar (54) and O-Poc (55) donors showing high β-selectivity [133].

Scheme 11: Neighbouring group participation rendered by an N-benzylcarbamoyl (BnCar) group [137] at the C-2 positio...

Scheme 12: Stereoselectivity obtained from glycosylation [138] with 2-O-(o-trifluoromethylbenzenesulfonyl)-protecte...

Scheme 13: (a) Plausible mechanistic pathway for glycosylation with C-2 DMTM protection [139] and (b) example of a ...

Scheme 14: Glycosylation reactions employing MOM 78, BOM 81, and NAPOM 83-protected thioglycoside donors. Reag...

Scheme 15: Plausible mechanistic pathway for alkoxymethyl-protected glycosyl donors. Path A. Expected product ...

Scheme 16: Plausible mechanistic pathway for alkoxymethyl-protected glycosyl donors [147].

Scheme 17: A. Formation of α-glycosides and B formation of β-glycosides by using chiral auxiliary neighbouring...

Scheme 18: Bimodal participation of 2-O-(o-tosylamido)benzyl (TAB) protecting group to form both α and β-isome...

Scheme 19: (a) 1,2-trans-Directing nature using C-2 cyanomethyl protection and (b) the effect of acceptors and...

Scheme 20: 1,3-Remote assistance by C-3-ester protection for gluco- and galactopyranosides to form 1,2-cis gly...

Scheme 21: 1,6-Remote assistance by C-6-ester protection for gluco- and galactopyranosides to form 1,2-cis gly...

Scheme 22: 1,4-Remote assistance by C-4-ester protection for galactopyranosides to form 1,2-cis glycosidic pro...

Scheme 23: Different products obtained on activation of axial 3-O and equatorial 3-O ester protected glycoside...

Scheme 24: The role of 3-O-protection on the stereochemistry of the produced glycoside [191].

Scheme 25: The role of 4-O-protection on the stereochemistry of the produced glycosides.

Scheme 26: Formation and subsequent stability of the bicyclic oxocarbenium intermediate formed due to remote p...

Scheme 27: The role a C-6 p-nitrobenzoyl group on the stereochemistry of the glycosylated product [196].

Scheme 28: Difference in stereoselectivity obtained in glycosylation reactions by replacing non-participating ...

Scheme 29: The role of electron-withdrawing and electron-donating substituents on the C-4 acetyl group in glyc...

Scheme 30: Effect of the introduction of a methyl group in the C-4 position on the glycosylation with more rea...

Figure 3: Remote group participation effect exhibited by the 2,2-dimethyl-2-(o-nitrophenyl)acetyl (DMNPA) pro...

Scheme 31: The different stereoselectivities obtained by Pic and Pico donors on being activated by DMTST.

Figure 4: Hydrogen bond-mediated aglycon delivery (HAD) in glycosylation reactions for 1,2-cis 198a and 1,2-t...

Scheme 32: The role of different acceptor with 6-O-Pic-protected glycosyl donors.

Scheme 33: The role of the remote C-3 protection on various 4,6-O-benzylidene-protected mannosyl donors affect...

Scheme 34: The dual contribution of the DTBS group in glycosylation reactions [246,247].

Heteroannulations of cyanoacetamide-based MCR scaffolds utilizing formamide

- Marios Zingiridis,

- Danae Papachristodoulou,

- Despoina Menegaki,

- Konstantinos G. Froudas and

- Constantinos G. Neochoritis

Beilstein J. Org. Chem. 2025, 21, 217–225, doi:10.3762/bjoc.21.13

- Goals (SDGs), wherein the 7th goal focuses on ensuring access to affordable, renewable and clean energy [1]. Moreover, the European Union has committed to ambitious environmental targets as part of the European Green Deal [2]. Advancements in C1 chemistry are pivotal to achieving this equilibrium. As

Graphical Abstract

Figure 1: Heteroannulated pyrimidones in drug discovery: blockbuster drugs that are based on the privileged p...

Scheme 1: Strategies towards targeted adducts: A) Niementowski quinazoline synthesis utilizing anthranilic ac...

Scheme 2: Access to the key building blocks 2–4 by employing three different nonisocyanide-based MCRs. Divers...

Scheme 3: Synthesis of N-substituted thienopyrimidones 5a–e by a Gewald three-component reaction employing 2-...

Scheme 4: Synthesis of N-substituted quinolinopyrimidones 6a–e from 2-aminoindoles 3a–e and formamide as C1 s...

Scheme 5: Synthesis of N-substituted indolopyrimidones 7a–e from 2-aminoindoles 4a–e and formamide as C1 sour...

Figure 2: Representative fluorescence spectrum of compounds 5b (λex = 330 nm) and 6e (λex = 430 nm) at 0.2 M ...

Figure 3: Molecular geometry observed within the crystal structure of compound 7b (CCDC 2376493).

Advances in the use of metal-free tetrapyrrolic macrocycles as catalysts

- Mandeep K. Chahal

Beilstein J. Org. Chem. 2024, 20, 3085–3112, doi:10.3762/bjoc.20.257

- macrocycles as electrocatalysts Development of efficient renewable technologies is a driving force in the efforts to achieve sustainability with the same or even increasing demands for energy worldwide. In this context, transition-metal complexes of tetraazamacrocycles (N4-macrocycle) such as porphyrins

Graphical Abstract

Figure 1: Chemical structures of the main tetrapyrrolic macrocycles studied in this review for their role as ...

Figure 2: Calix[4]pyrroles 3 and 4 and an their acyclic analogue 5 used for the transformation of Danishefsky...

Figure 3: Calixpyrrole-based organocatalysts 11 and 12 for the diastereoselective addition reaction of TMSOF ...

Figure 4: (a) Chemical structures of macrocyclic organocatalysts used for the synthesis of cyclic carbonates ...

Figure 5: Cuprous chloride-catalyzed aziridination of styrene (22) by chloramine-T (23) providing 1-tosyl-2-p...

Figure 6: Chemical structures of the various porphyrin macrocycles (18, 25–41) screened as potential catalyst...

Figure 7: Organocatalytic activity of distorted porphyrins explored by Senge and co-workers. Planar macrocycl...

Figure 8: Chemical structures of H2EtxTPP (x = 0, 2, 4, 6, 8) compounds with incrementally increasing nonplan...

Figure 9: Chemical structures of OxP macrocycles tested as potential organocatalysts for the conjugate additi...

Figure 10: a) Fundamental structure of the J-aggregates of diprotonated TPPS3 53 and b) its use as a catalyst ...

Figure 11: Chemical structures of amphiphilic porphyrin macrocycles used as pH-switchable catalysts based on i...

Figure 12: a) Chemical structures of porphyrin macrocycles for the cycloaddition of CO2 to N-alkyl/arylaziridi...

Figure 13: Electron and energy-transfer processes typical for excited porphyrin molecules (Por = porphyrin mac...

Figure 14: Proposed mechanism for the light-induced α-alkylation of aldehydes with EDA in the presence of H2TP...

Figure 15: a) Chemical structures of porphyrins screened as photoredox catalysts, b) model reaction of furan (...

Figure 16: Porphyrin macrocycles H2TPP (18) and PPIX 78 as photoreductants for the red light-induced C–H aryla...

Figure 17: Porphyrin macrocycles H2TPP (18) and PPIX 78 as photoredox catalyst for (a) α-alkylation of an alde...

Figure 18: Corrole macrocycles 98–100 as photoredox catalysts for C–H arylation and borylation reactions. Adap...

Figure 19: Proposed catalytic cycle of electrocatalytic generation of H2 evolution using tetrapyrrolic macrocy...

Figure 20: a) Chemical structures of tetrapyrrolic macrocycles 109, 73, and 110 used for oxygen reductions in ...

Figure 21: a) Absorption spectra (left) of the air-saturated DCE solutions containing: 5 × 10−5 M H2TPP (black...

Figure 22: Chemical structures of N,N’-dimethylated saddle-distorted porphyrin isomers, syn-Me2P 111 and anti-...

Figure 23: Reaction mechanisms for the two-electron reduction of O2 by a) syn-Me2Iph 113 and b) anti-Me2Iph 114...

Figure 24: O2/H2O2 interconversion using methylated saddle-distorted porphyrin and isophlorin (reduced porphyr...

Figure 25: Chemical structures of distorted dodecaphenylporphyrin macrocycle 117 and its diprotonated form 118...

Copper-catalyzed yne-allylic substitutions: concept and recent developments

- Shuang Yang and

- Xinqiang Fang

Beilstein J. Org. Chem. 2024, 20, 2739–2775, doi:10.3762/bjoc.20.232

- stereoselective aromatization serves as a pivotal step in the transfer of central chirality to axial chirality (Scheme 52). To harness the full potential of CO2 as a renewable and abundant carbon source, He et al. [82] proposed an innovative strategy that married asymmetric yne-allylic substitution with CO2

Graphical Abstract

Scheme 1: Copper-catalyzed allylic and yne-allylic substitution.

Scheme 2: Challenges in achieving highly selective yne-allylic substitution.

Scheme 3: Yne-allylic substitutions using indoles and pyroles.

Scheme 4: Yne-allylic substitutions using amines.

Scheme 5: Yne-allylic substitution using 1,3-dicarbonyls.

Scheme 6: Postulated mechanism via copper acetylide-bonded allylic cation.

Scheme 7: Amine-participated asymmetric yne-allylic substitution.

Scheme 8: Asymmetric decarboxylative yne-allylic substitution.

Scheme 9: Asymmetric yne-allylic alkoxylation and alkylation.

Scheme 10: Proposed mechanism for Cu(I) system.

Scheme 11: Asymmetric yne-allylic dialkylamination.

Scheme 12: Proposed mechanism of yne-allylic dialkylamination.

Scheme 13: Asymmetric yne-allylic sulfonylation.

Scheme 14: Proposed mechanism of yne-allylic sulfonylation.

Scheme 15: Aymmetric yne-allylic substitutions using indoles and indolizines.

Scheme 16: Double yne-allylic substitutions using pyrrole.

Scheme 17: Proposed mechanism of yne-allylic substitution using electron-rich arenes.

Scheme 18: Aymmetric yne-allylic monofluoroalkylations.

Scheme 19: Proposed mechanism.

Scheme 20: Aymmetric yne-allylic substitution of yne-allylic esters with anthrones.

Scheme 21: Aymmetric yne-allylic substitution of yne-allylic esters with coumarins.

Scheme 22: Aymmetric yne-allylic substitution of with coumarins by Lin.

Scheme 23: Proposed mechanism.

Scheme 24: Amination by alkynylcopper driven dearomatization and rearomatization.

Scheme 25: Arylation by alkynylcopper driven dearomatization and rearomatization.

Scheme 26: Remote substitution/cyclization/1,5-H shift process.

Scheme 27: Proposed mechanism.

Scheme 28: Arylation or amination by alkynylcopper driven dearomatization and rearomatization.

Scheme 29: Remote nucleophilic substitution of 5-ethynylthiophene esters.

Scheme 30: Proposed mechanism.

Scheme 31: [4 + 1] annulation of yne-allylic esters and cyclic 1,3-dicarbonyls.

Scheme 32: Asymmetric [4 + 1] annulation of yne-allylic esters.

Scheme 33: Proposed mechanism.

Scheme 34: Asymmetric [3 + 2] annulation of yne-allylic esters.

Scheme 35: Postulated annulation step.

Scheme 36: [4 + 1] Annulations of vinyl ethynylethylene carbonates and 1,3-dicarbonyls.

Scheme 37: Proposed mechanism.

Scheme 38: Formal [4 + 1] annulations with amines.

Scheme 39: Formal [4 + 2] annulations with hydrazines.

Scheme 40: Proposed mechanism.

Scheme 41: Dearomative annulation of 1-naphthols and yne-allylic esters.

Scheme 42: Dearomative annulation of phenols or 2-naphthols and yne-allylic esters.

Scheme 43: Postulated annulation mechanism.

Scheme 44: Dearomative annulation of phenols or 2-naphthols.

Scheme 45: Dearomative annulation of indoles.

Scheme 46: Postulated annulation step.

Scheme 47: Asymmetric [4 + 1] cyclization of yne-allylic esters with pyrazolones.

Scheme 48: Proposed mechanism.

Scheme 49: Construction of C–C axially chiral arylpyrroles.

Scheme 50: Construction of C–N axially chiral arylpyrroles.

Scheme 51: Construction of chiral arylpyrroles with 1,2-di-axial chirality.

Scheme 52: Proposed mechanism.

Scheme 53: CO2 shuttling in yne-allylic substitution.

Scheme 54: CO2 fixing in yne-allylic substitution.

Scheme 55: Proposed mechanism.

The Groebke–Blackburn–Bienaymé reaction in its maturity: innovation and improvements since its 21st birthday (2019–2023)

- Cristina Martini,

- Muhammad Idham Darussalam Mardjan and

- Andrea Basso

Beilstein J. Org. Chem. 2024, 20, 1839–1879, doi:10.3762/bjoc.20.162

- adducts. An intriguing study is reported by Porcal et al. [35] in which they evaluate the use of 5-hydroxymethylfurfural (5-HMF, 23). Nowadays, the need to move towards more sustainable protocols is impending and the emphasis on green chemistry and on the use of renewable carbon sources is huge. Indeed

- , the use of 5-HMF (23) [36], a renewable carbon source derived from biomass, responds to these requirements. This aldehyde displays additional functionalities useful for further modifications of the GBB adducts, but some optimization was necessary due to its intolerance to high temperatures and

Graphical Abstract

Scheme 1: Mechanism of the GBB reaction.

Scheme 2: Comparison of the performance of Sc(OTf)3 with some RE(OTf)3 in a model GBB reaction. Conditions: a...

Scheme 3: Comparison of the performance of various Brønsted acid catalysts in the synthesis of GBB adduct 6. ...

Scheme 4: Synthesis of Brønsted acidic ionic liquid catalyst 7. Conditions: a) neat, 60 °C, 24 h; b) TfOH, DC...

Scheme 5: Aryliodonium derivatives as organic catalysts in the GBB reaction. In the box the proposed binding ...

Scheme 6: DNA-encoded GBB reaction in micelles made of amphiphilic polymer 13. Conditions: a) 13 (50 equiv), ...

Scheme 7: GBB reaction catalyzed by cyclodextrin derivative 14. Conditions: a) 14 (1 mol %), water, 100 °C, 4...

Scheme 8: Proposed mode of activation of CALB. a) activation of the substrates; b) activation of the imine; c...

Scheme 9: One-pot GBB reaction–Suzuki coupling with a bifunctional hybrid biocatalyst. Conditions: a) Pd(0)-C...

Scheme 10: GBB reaction employing 5-HMF (23) as carbonyl component. Conditions: a) TFA (20 mol %), EtOH, 60 °C...

Scheme 11: GBB reaction with β-C-glucopyranosyl aldehyde 26. Conditions: a) InCl3 (20 mol %), MeOH, 70 °C, 2–3...

Scheme 12: GBB reaction with diacetylated 5-formyldeoxyuridine 29, followed by deacetylation of GBB adduct 30....

Scheme 13: GBB reaction with glycal aldehydes 32. Conditions: a) HFIP, 25 °C, 2–4 h.

Scheme 14: Vilsmeier–Haack formylation of 6-β-acetoxyvouacapane (34) and subsequent GBB reaction. Conditions: ...

Scheme 15: GBB reaction of 4-formlyl-PCP 37. Conditions: a) HOAc or HClO4, MeOH/DCM (2:3), rt, 3 d.

Scheme 16: GBB reaction with HexT-aldehyde 39. Conditions: a) 39 (20 nmol) and amidine (20 μmol), MeOH, rt, 6 ...

Scheme 17: GBB reaction of 2,4-diaminopirimidine 41. Conditions: a) Sc(OTf)3 (20 mol %), MeCN, 120 °C (MW), 1 ...

Scheme 18: Synthesis of N-edited guanine derivatives from 3,6-diamine-1,2,4-triazin-5-one 44. Conditions: a) S...

Scheme 19: Synthesis of 2-aminoimidazoles 49 by a Mannich-3CR followed by a one-pot intramolecular oxidative a...

Scheme 20: On DNA Suzuki–Miyaura reaction followed by GBB reaction. Conditions: a) CsOH, sSPhos-Pd-G2; b) AcOH...

Scheme 21: One-pot cascade synthesis of 5-iminoimidazoles. Conditions: a) Na2SO4, DMF, 220 °C (MW).

Scheme 22: GBB reaction of 5-amino-1H-imidazole-4-carbonile 57. Conditions: a) HClO4 (5 mol %), MeOH, rt, 24 h....

Scheme 23: One-pot cascade synthesis of indole-imidazo[1,2,a]pyridine hybrids. In blue the structural motif in...

Scheme 24: One-pot cascade synthesis of fused polycyclic indoles 67 or 69 from indole-3-carbaldehyde. Conditio...

Scheme 25: One-pot cascade synthesis of linked- and bridged polycyclic indoles from indole-2-carbaldehyde (70)...

Scheme 26: One-pot cascade synthesis of pentacyclic dihydroisoquinolines (X = N or CH). In blue the structural...

Scheme 27: One-pot stepwise synthesis of imidazopyridine-fused benzodiazepines 85. Conditions: a) p-TsOH (20 m...

Scheme 28: One-pot stepwise synthesis of benzoxazepinium-fused imidazothiazoles 89. Conditions: a) Yb(OTf)3 (2...

Scheme 29: One-pot stepwise synthesis of fused imidazo[4,5,b]pyridines 95. Conditions: a) HClO4, MeOH, rt, ove...

Scheme 30: Synthesis of heterocyclic polymers via the GBB reaction. Conditions: a) p-TsOH, EtOH, 70 °C, 24 h.

Scheme 31: One-pot multicomponent reaction towards the synthesis of covalent organic frameworks via the GBB re...

Scheme 32: One-pot multicomponent reaction towards the synthesis of covalent organic frameworks via the GBB re...

Scheme 33: GBB-like multicomponent reaction towards the synthesis of benzothiazolpyrroles (X = S) and benzoxaz...

Scheme 34: GBB-like multicomponent reaction towards the formation of imidazo[1,2,a]pyridines. Conditions: a) I2...

Scheme 35: Post-functionalization of GBB products via Ugi reaction. Conditions a) HClO4, DMF, rt, 24 h; b) MeO...

Scheme 36: Post-functionalization of GBB products via Click reaction. Conditions: a) solvent-free, 150 °C, 24 ...

Scheme 37: Post-functionalization of GBB products via cascade alkyne–allene isomerization–intramolecular nucle...

Scheme 38: Post-functionalization of GBB products via metal-catalyzed intramolecular N-arylation. In red and b...

Scheme 39: Post-functionalization of GBB products via isocyanide insertion (X = N or CH). Conditions: a) HClO4...

Scheme 40: Post-functionalization of GBB products via intramolecular nucleophilic addition to nitriles. Condit...

Scheme 41: Post-functionalization of GBB products via Pictet–Spengler cyclization. Conditions: a) 4 N HCl/diox...

Scheme 42: Post-functionalization of GBB products via O-alkylation. Conditions: a) TFA (20 mol %), EtOH, 120 °...

Scheme 43: Post-functionalization of GBB products via macrocyclization (X = -CH2CH2O-, -CH2-, -(CH2)4-). Condi...

Figure 1: Antibacterial activity of GBB-Ugi adducts 113 on both Gram-negative and Gram-positive strains.

Scheme 44: GBB multicomponent reaction using trimethoprim as the precursor. Conditions: a) Yb(OTf)3 or Y(OTf)3...

Figure 2: Antibacterial activity of GBB adducts 152 against MRSA and VRE; NA = not available.

Figure 3: Antibacterial activity of GBB adduct 153 against Leishmania amazonensis promastigotes and amastigot...

Figure 4: Antiviral and anticancer evaluation of the GBB adducts 154a and 154b. In vitro antiproliferative ac...

Figure 5: Anticancer activity of the GBB-furoxan hybrids 145b, 145c and 145d determined through antiprolifera...

Scheme 45: Synthesis and anticancer activity of the GBB-gossypol conjugates. Conditions: a) Sc(OTf)3 (10 mol %...

Figure 6: Anticancer activity of polyheterocycles 133a and 136a against human neuroblastoma. Clonogenic assay...

Figure 7: Development of GBB-adducts 158a and 158b as PD-L1 antagonists. HTRF assays were carried out against...

Figure 8: Development of imidazo[1,2-a]pyridines and imidazo[1,2-a]pyrazines as TDP1 inhibitors. The SMM meth...

Figure 9: GBB adducts 164a–c as anticancer through in vitro HDACs inhibition assays. Additional cytotoxic ass...

Figure 10: GBB adducts 165, 166a and 166b as anti-inflammatory agents through HDAC6 inhibition; NA = not avail...

Scheme 46: GBB reaction of triphenylamine 167. Conditions: a) NH4Cl (10 mol %), MeOH, 80 °C (MW), 1 h.

Scheme 47: 1) Modified GBB-3CR. Conditions: a) TMSCN (1.0 equiv), Sc(OTf)3 (0.2 equiv), MeOH, 140 °C (MW), 20 ...

Scheme 48: GBB reaction to assemble imidazo-fused heterocycle dimers 172. Conditions: a) Sc(OTf)3 (20 mol %), ...

Figure 11: Model compounds 173 and 174, used to study the acid/base-triggered reversible fluorescence response...

New triazinephosphonate dopants for Nafion proton exchange membranes (PEM)

- Fátima C. Teixeira,

- António P. S. Teixeira and

- C. M. Rangel

Beilstein J. Org. Chem. 2024, 20, 1623–1634, doi:10.3762/bjoc.20.145

- , renewable, and environmental-friendly technological processes are being considered using electrochemical devices which convert chemical to electric energy and/or vice versa that, when associated to renewable energy sources, can promote sustainable energy systems [1][2][3][4]. Among them are included proton

Graphical Abstract

Figure 1: General synthesis of triazinephosphonate compounds.

Scheme 1: Synthesis of diethyl phenylphosphonates 2, 4 and 6.

Scheme 2: Synthesis of (4-hydroxyphenyl)methylphosphonate 7 starting from [4-(benzyloxy)phenyl]methanol (8).

Scheme 3: Synthesis of diethyl [hydroxy(4-hydroxyphenyl)methyl]phosphonate (11) and tetraethyl [(4-hydroxyphe...

Scheme 4: Synthesis of diethyl phenylphosphonates 16 and 14.

Scheme 5: Synthesis of 4-aminophenyltriazinephosphonate derivatives TP1–TP3.

Figure 2: Partial view of 1H and 31P NMR spectra of 4-aminophenyltriazinephosphonate derivatives TP1–TP3.

Scheme 6: Synthesis of (4-hydroxyphenyl)triazinephosphonate derivatives TP4–TP6.

Figure 3: Partial view of 1H and 31P NMR spectra of (4-hydroxyphenyl)triazinephosphonate derivatives TP4–TP6.

Scheme 7: Attempted synthesis of triazinephosphonate TP7.

Figure 4: Preparation of the new doped membranes.

Figure 5: Comparison of in-plane proton conductivity vs RH of Nafion doped membranes, at 60 °C.

Generation of alkyl and acyl radicals by visible-light photoredox catalysis: direct activation of C–O bonds in organic transformations

- Mithu Roy,

- Bitan Sardar,

- Itu Mallick and

- Dipankar Srimani

Beilstein J. Org. Chem. 2024, 20, 1348–1375, doi:10.3762/bjoc.20.119

- heightened by the current energy crisis and the adverse impacts of industrialization. The development of green and energy-efficient methods in organic chemistry that use renewable sources of starting materials is considered highly sustainable [1][2][3]. Radical reactions have profound applications in organic

- is highly expected that many groups will explore many new useful synthetic transformations based on renewable feedstocks, such as alcohols and acids, which will likely lead to even more exciting opportunities in the near future. Generation of alkyl and acyl radicals via C–O bond breaking. General

Graphical Abstract

Figure 1: Generation of alkyl and acyl radicals via C–O bond breaking.

Figure 2: General photocatalytic mechanism.

Scheme 1: Photoredox-catalyzed hydroacylation of olefins with aliphatic carboxylic acids.

Scheme 2: Acylation–aromatization of p-quinone methides using carboxylic acids.

Scheme 3: Visible-light-induced deoxygenation–defluorination for the synthesis of γ,γ-difluoroallylic ketones....

Scheme 4: Photochemical hydroacylation of azobenzenes with carboxylic acids.

Scheme 5: Photoredox-catalyzed synthesis of flavonoids.

Scheme 6: Synthesis of O-thiocarbamates and photocatalytic reduction of O-thiocarbamates.

Scheme 7: Deoxygenative borylation of alcohols.

Scheme 8: Trifluoromethylation of O-alkyl thiocarbonyl substrates.

Scheme 9: Redox-neutral radical coupling reactions of alkyl oxalates and Michael acceptors.

Scheme 10: Visible-light-catalyzed and Ni-mediated syn-alkylarylation of alkynes.

Scheme 11: 1,2-Alkylarylation of alkenes with aryl halides and alkyl oxalates.

Scheme 12: Deoxygenative borylation of oxalates.

Scheme 13: Coupling of N-phthalimidoyl oxalates with various acceptors.

Scheme 14: Cross-coupling of O-alkyl xanthates with aryl halides via dual photoredox and nickel catalysis.

Scheme 15: Deoxygenative borylation of secondary alcohol.

Scheme 16: Deoxygenative alkyl radical generation from alcohols under visible-light photoredox conditions.

Scheme 17: Deoxygenative alkylation via alkoxy radicals against hydrogenation or β-fragmentation.

Scheme 18: Direct C–O bond activation of benzyl alcohols.

Scheme 19: Deoxygenative arylation of alcohols using NHC to activate alcohols.

Scheme 20: Deoxygenative conjugate addition of alcohol using NHC as alcohol activator.

Scheme 21: Synthesis of polysubstituted aldehydes.

Sustainable tandem acylation/Diels–Alder reaction toward versatile tricyclic epoxyisoindole-7-carboxylic acids in renewable green solvents

- Ayhan Yıldırım

Beilstein J. Org. Chem. 2024, 20, 1308–1319, doi:10.3762/bjoc.20.114

- prediction that their resources will run out in the near future has led 'green chemists' to explore solvents that can be derived from renewable resources and used effectively in various organic transformations. In this context, we have shown for the first time that the 100% atom-economical tandem Diels–Alder

- bisepoxyisoindole-7-carboxylic acids were obtained in good yields after a practical isolation procedure. The results obtained in this study demonstrate the potential of vegetable oils and their renewable materials to provide a reaction medium that is more sustainable than conventional organic solvents in cascade

- among the main sources of serious environmental problems [2]. However, the risk of depletion of these resources in the near future has led researchers to research and develop safer, environmentally friendly and renewable resources [3][4][5]. Biomass is an important and more economical renewable source

Graphical Abstract

Figure 1: Reaction yields after seven uses of SSO and average recovery of the oil.

Scheme 1: Synthesis of epoxyisoindole-7-carboxylic acids 2a–m and 2n–p.

Scheme 2: Possible side reactions of unsaturated fatty acids with maleic anhydride.

Figure 2: Coupling constants of selected protons in compound 2a and its optimized geometric structure.

Scheme 3: Equilibrium of 2n–p with maleamic acid precursors.

Figure 3: Possible mechanism for the IMDAF reaction.

Figure 4: IRC calculations of a) endo-, b) exo-transition structures and products for compound 2a (semi-empir...

Optimizing reaction conditions for the light-driven hydrogen evolution in a loop photoreactor

- Pengcheng Li,

- Daniel Kowalczyk,

- Johannes Liessem,

- Mohamed M. Elnagar,

- Dariusz Mitoraj,

- Radim Beranek and

- Dirk Ziegenbalg

Beilstein J. Org. Chem. 2024, 20, 74–91, doi:10.3762/bjoc.20.9

- years to come to be [7], they are considered limited resources and nonrenewable compared to the current consumption rate [8]. Therefore, a pressing need exists to transition towards renewable energy sources to ensure sustainable energy development and environmental preservation. Solar energy stands out

- as the most compelling renewable energy source, holding the potential to fully satisfy the energy requirements of humanity [9]. The reliance on geographic locations and seasonal changes, however, makes it difficult to maintain a constant supply of solar energy year-round [10]. To harness solar energy

Graphical Abstract

Scheme 1: Photocatalytic hydrogen evolution with Pt-loaded polymeric carbon nitride.

Figure 1: SEM images of the Pt-PCN photocatalyst at different magnifications.

Figure 2: SEM-EDX elemental mapping images of C, N, and Pt on a particle.

Figure 3: Exemplary results of the mixing experiments using methylene blue to visualize and quantify fluid fl...

Figure 4: Red channel values of ROIs with different stirring speeds: (a) left space between reactor and draft...

Figure 5: Quantified mixing time using different stirring speeds.

Figure 6: Chemical actinometry results: (a) actinometer conversion at different irradiation time, (b) photon ...

Figure 7: Photon flux in the loop reactor with respect to the LED electrical current.

Figure 8: Absorbance as function of photocatalyst loading for different optical path lengths.

Figure 9: Long-term operation of the loop photoreactor.

Figure 10: Visualization of the response surfaces of the modified DOE model for the four parameters: (a) photo...

Figure 11: Parity plot of the measured photocatalytic hydrogen generation rate versus the values predicted by ...

Figure 12: Effect of photon flux on hydrogen generation rate: (a) hydrogen generation rate as function of the ...

Figure 13: Effect of inert gas flow rate on hydrogen generation rate: (a) hydrogen generation rate as a functi...

Figure 14: Effect of photocatalyst loading on the hydrogen generation rate: (a) hydrogen generation rate as fu...

Figure 15: Effect of stirring speed on hydrogen generation rate: (a) hydrogen generation rate as function of i...

Figure 16: 3D plot of AQE for different studied parameters: (a) AQE for different photon fluxes and inert gas ...

Figure 17: Reactor design: (a) CAD drawing of the loop reactor, (b) picture of the manufactured loop reactor.

Figure 18: Assembled reactor and 3D printed parts: (a) the whole reactor setup, (b) 3D printed propellers.

Figure 19: Photocatalytic reaction setup: (a) reaction setup flow diagram, (b) reaction setup in lab. 1 argon ...

Beyond n-dopants for organic semiconductors: use of bibenzo[d]imidazoles in UV-promoted dehalogenation reactions of organic halides

- Kan Tang,

- Megan R. Brown,

- Chad Risko,

- Melissa K. Gish,

- Garry Rumbles,

- Phuc H. Pham,

- Oana R. Luca,

- Stephen Barlow and

- Seth R. Marder

Beilstein J. Org. Chem. 2023, 19, 1912–1922, doi:10.3762/bjoc.19.142

- Kan Tang Megan R. Brown Chad Risko Melissa K. Gish Garry Rumbles Phuc H. Pham Oana R. Luca Stephen Barlow Seth R. Marder Renewable and Sustainable Energy Institute (RASEI), University of Colorado Boulder, Boulder, Colorado 80309, United States Department of Chemistry & Center for Applied Energy

- Research (CAER), University of Kentucky, Lexington, Kentucky, 40506, United States National Renewable Energy Laboratory, Chemistry and Nanoscience Center, Golden, Colorado, 80401, United States Department of Chemical and Biological Engineering, University of Colorado Boulder, Boulder, Colorado 80309

- , additional TD-DFT results, and NMR spectra of compounds. Funding This work was authored in part by the National Renewable Energy Laboratory (NREL), operated by Alliance for Sustainable Energy, LLC, for the U.S. Department of Energy (DOE) under Contract No. DE-AC36-08GO28308. This work was primarily

Graphical Abstract

Figure 1: (a, b) Schematics of previous approaches to dehalogenation-based reactions using molecular reductan...

Scheme 1: Selective deiodination of 2-iodobenzyl chloride.

Scheme 2: Reaction mechanisms for the reactions of dimeric reductants (D2) such as (Y-DMBI)2 derivatives with...

Figure 2: (a) A representative temporal evolution of % conversion (blue squares), % toluene yield (red diamon...

Figure 3: Top: UV–vis absorption spectra for the two dimeric reductants in THF emphasizing (a) the different ...

Figure 4: Transient absorption spectra of (a) (N-DMBI)2 in MeCN, (b) (N-DMBI)2 in toluene, and (c) (Cyc-DMBI)2...

GlAIcomics: a deep neural network classifier for spectroscopy-augmented mass spectrometric glycans data

- Thomas Barillot,

- Baptiste Schindler,

- Baptiste Moge,

- Elisa Fadda,

- Franck Lépine and

- Isabelle Compagnon

Beilstein J. Org. Chem. 2023, 19, 1825–1831, doi:10.3762/bjoc.19.134

- dedicated analytical tools (glycomics) is clearly identified as a critical bottleneck, impeding the full development of glycosciences despite their relevance for various strategic fields such as pharmaceutical and food industry; bio-based materials and renewable energy, and their considerable potential

Graphical Abstract

Figure 1: (a) Fingerprint of an unknown monosaccharide. (b) Labelled reference spectra of monosaccharide stan...

Figure 2: Typical experimental MS–IR spectra of the four categories of monosaccharides included in the first ...

Figure 3: Synthetic IRMPD spectrum (grey trace) generated on the basis of a high resolution endogeneous exper...

Figure 4: Model accuracy dependance with experimental conditions, represented by the dataset augmentation par...

Figure 5: DNN Prediction results for third endogenous dataset (5 hexosamine samples and 7 other molecules). T...

Selectivity control towards CO versus H2 for photo-driven CO2 reduction with a novel Co(II) catalyst

- Lisa-Lou Gracia,

- Philip Henkel,

- Olaf Fuhr and

- Claudia Bizzarri

Beilstein J. Org. Chem. 2023, 19, 1766–1775, doi:10.3762/bjoc.19.129

- ) complex; earth-abundant; hexafluoropropanol; photocatalytic CO2 reduction; Introduction Solar energy conversion into chemical energy addresses the issues of energy shortage with the exploitation of renewable sources [1]. Photoinduced CO2 reduction is included in the vast research field of artificial

Graphical Abstract

Figure 1: Chemical structures of the molecular components used in this work: Co(II) complex 1 as the novel ca...

Figure 2: ORTEP drawing of crystal polymorph 1a (left) and 1b (right), shown at the 50% probability level. Hy...

Figure 3: UV–vis absorbance of complex 1 in DMA. Inset: zoom-in of the 500–800 nm range to visualize the low-...

Figure 4: Cyclic voltammetry of complex 1 in 0.1 M TBAPF6 solution of (a) DMA and (b) DMA/TEOA 5:1 (v/v). Bla...

Figure 5: Time evolution of CO (blue squares) and H2 (red triangles) with the power functional fitting (blue ...

Scheme 1: Proposed mechanism for the photoinduced reduction of carbon dioxide with the system presented in th...

Quinoxaline derivatives as attractive electron-transporting materials

- Zeeshan Abid,

- Liaqat Ali,

- Sughra Gulzar,

- Faiza Wahad,

- Raja Shahid Ashraf and

- Christian B. Nielsen

Beilstein J. Org. Chem. 2023, 19, 1694–1712, doi:10.3762/bjoc.19.124

- , their potential in renewable energy applications aligns with the objectives of clean energy generation and reducing dependence on fossil fuels. As research progresses, we anticipate significant advancements and breakthroughs that will pave the way for a future where quinoxaline-based materials play a

- vital role in shaping the next generation of electronic devices and renewable energy systems. Structures of some of the most versatile Qx scaffolds; dashed lines indicate the substitution sites for core expansion. Qx-derived polymer acceptors. Qx-derived small molecule NFAs. Qx-derived small molecule

Graphical Abstract

Figure 1: Structures of some of the most versatile Qx scaffolds; dashed lines indicate the substitution sites...

Figure 2: Qx-derived polymer acceptors.

Figure 3: Qx-derived small molecule NFAs.

Figure 4: Qx-derived small molecule NFAs.

Figure 5: Dyes and sensitizers based on Qx auxiliary acceptors or bridging units.

Figure 6: Qx-derived n-type transistor materials.

Figure 7: Qx-derived ETM and TADF emitters.

Figure 8: Qx-derived chromophores.

Benzoimidazolium-derived dimeric and hydride n-dopants for organic electron-transport materials: impact of substitution on structures, electrochemistry, and reactivity

- Swagat K. Mohapatra,

- Khaled Al Kurdi,

- Samik Jhulki,

- Georgii Bogdanov,

- John Bacsa,

- Maxwell Conte,

- Tatiana V. Timofeeva,

- Seth R. Marder and

- Stephen Barlow

Beilstein J. Org. Chem. 2023, 19, 1651–1663, doi:10.3762/bjoc.19.121

- , Atlanta, Georgia 30322, United States Renewable and Sustainable Energy Institute (RASEI), University of Colorado Boulder, Boulder, Colorado 80309, United States Department of Chemical and Biological Engineering and Department of Chemistry, University of Colorado Boulder, Boulder, Colorado 80309, United

- States National Renewable Energy Laboratory, Chemistry and Nanoscience Center, Golden, Colorado, 80401, United States 10.3762/bjoc.19.121 Abstract 1,3-Dimethyl-2,3-dihydrobenzo[d]imidazoles, 1H, and 1,1',3,3'-tetramethyl-2,2',3,3'-tetrahydro-2,2'-bibenzo[d]imidazoles, 12, are of interest as n-dopants

- Fellowship from the United States-India Educational Foundation and Institute of International Education for (grant no. 2266/FNPDR/2017). This work was also authored in part by the National Renewable Energy Laboratory (NREL), operated by Alliance for Sustainable Energy, LLC, for the U.S. Department of Energy

Graphical Abstract

Figure 1: DMBI+, DMBI-H, and (DMBI)2 derivatives discussed in this work (new compounds in red).

Scheme 1: Synthesis of DMBI-H and (DMBI)2 derivatives and structures of side products.

Figure 2: Crystallographically characterized molecules related to DMBI dimers.

Figure 3: Molecular structures from the single crystal structures of 1b2 (two crystallographically inequivale...

Figure 4: Molecular structures from the single crystal structures of 1bH (upper left), 1gH (upper right), 1hH...

Figure 5: Structures of the cations from the single crystal structures of 1g+I− (left), 1h+PF6− (center), and ...

Figure 6: Cyclic voltammograms (50 mV s−1, THF, 0.1 M Bu4NPF6) of 1g+PF6–, 1gH, and 1g2, in each case contain...

Figure 7: Acceptors used to examine reactivity of DMBI-H and (DMBI)2 derivatives.

Figure 8: a) Temporal evolution of the absorbance at 1030 nm, corresponding to an absorption maximum of VI•–,...

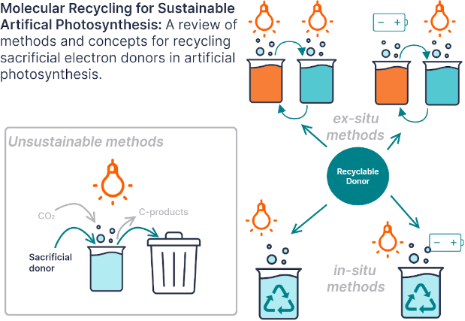

Enabling artificial photosynthesis systems with molecular recycling: A review of photo- and electrochemical methods for regenerating organic sacrificial electron donors

- Grace A. Lowe

Beilstein J. Org. Chem. 2023, 19, 1198–1215, doi:10.3762/bjoc.19.88

- small organic molecules that can be used as sacrificial donors in photochemical carbon dioxide reduction. A large scale decoupled, or macro, model of photosynthesis is electrochemical carbon dioxide reduction powered by renewable energy sources. Electrochemical carbon dioxide reduction has been

- national electricity grid. In countries like the UK, the competition to install new batteries and renewable energy sources appears to have created an increase in demand and waiting times for installing grid connections [11][12]. This is potentially a large barrier to fast adoption and scaling of purely

- photochemical recycling in-situ. However, electrochemical in-situ recycling could be achieved in 2 ways: 1. The driving force for recycling an oxidized donor at an electrode could be supplied by a photosensitizer. 2. The driving force for donor re-reduction could be an applied voltage from renewable energy

Graphical Abstract

Figure 1: Diagram comparing the two reaction pathways for sacrificial electron donors (SD) in photocatalyzed ...

Figure 2: Diagram showing water-splitting systems developed by Girault, Scanlon, and co-workers that employ i...

Figure 3: Diagram illustrating the transfer of electrons in a photocatalytic particulate suspensions Z-scheme...

Figure 4: A. Structures of the molecules represented in part B. The numbers in brackets correspond to the com...

Figure 5: A. Structures of the molecules represented in part B. The numbers in brackets correspond to the com...

Cyclodextrins as building blocks for new materials

- Miriana Kfoury and

- Sophie Fourmentin

Beilstein J. Org. Chem. 2023, 19, 889–891, doi:10.3762/bjoc.19.66

- use of CDs and further stimulate their market. The exploration of the potential of inclusion complexation is not limited to the biomedical field. CDs are renewable and biodegradable materials that enable green and environmental biotechnologies for all applications [11]. The ability of CDs to act as

C3-Alkylation of furfural derivatives by continuous flow homogeneous catalysis

- Grédy Kiala Kinkutu,

- Catherine Louis,

- Myriam Roy,

- Juliette Blanchard and

- Julie Oble

Beilstein J. Org. Chem. 2023, 19, 582–592, doi:10.3762/bjoc.19.43

- of the development of a sustainable chemical industry [1][2][3][4]. Furfurals, which are versatile platform molecules derived from renewable lignocellulose present in agricultural wastes [5][6][7][8], have proven to be of great importance for the preparation of value-added chemicals, biofuels, as

Graphical Abstract

Scheme 1: C3-Functionalization of furfural derivatives by C–H activation, a) in batch: previous works, and b)...

Scheme 2: C3-alkylation of bidentate imine 1 performed in batch.

Scheme 3: Optimization of the heating for the alkylation reaction on the homemade pulsed-flow setup.

Scheme 4: Proposed reaction mechanism for the alkylation reaction with formation of ruthenium aggregates and ...

Scheme 5: A) Isolation test of a reaction intermediate; B) XPS and TEM (in ethanol) of the recovered solid ph...

Scheme 6: Ruthenium aggregate-catalyzed alkylation reaction.

Scheme 7: Scope of continuous flow furfural derivative alkylation reaction.

Scheme 8: Scaling up comparison: batch and continuous flow conditions.