Abstract

Over the last decade isoindigo derivatives have attracted much attention due to their high potential in pharmacy and in the chemistry of materials. In addition, isoindigo derivatives can be modified to form supramolecular structures with tunable morphologies for the use in drug delivery. Amphiphilic long-chain dialkylated isoindigos have the ability to form stable solid nanoparticles via a simple nanoprecipitation technique. Their self-assembly was investigated using tensiometry, dynamic light scattering, spectrophotometry, and fluorometry. The critical association concentrations and aggregate sizes were measured. The hydrophilic–lipophilic balance of alkylated isoindigo derivatives strongly influences aggregate morphology. In the case of short-chain dialkylated isoindigo derivatives, supramolecular polymers of 200 to 700 nm were formed. For long-chain dialkylated isoindigo derivatives, micellar aggregates of 100 to 200 nm were observed. Using micellar surfactant water-soluble forms of monosubstituted 1-hexadecylisoindigo as well as 1,1′-dimethylisoindigo were prepared for the first time. The formation of mixed micellar structures of different types in micellar anionic surfactant solutions (sodium dodecyl sulfate) was determined. These findings are of practical importance and are of potential interest for the design of drug delivery systems and new nanomaterials.

Introduction

Studies of amphiphilic isoindigo derivatives have revealed perspectives and high potential in several fields: (i) Supramolecular assemblies of amphiphilic conjugated π-systems can potentially be useful structures with improved tunable optical and electrical properties [1-5]. This makes possible to develop new technologies for biodiagnostics, biomedical applications, including photothermal therapy [6-8], study of biomembranes [9] and dynamically probing cells [10,11]. (ii) These heterocyclic compounds found applications in various pharmaceutical and synthetic protocols [12-21]. It is known that isatin and isoindigo derivatives possess antibacterial [12,22], antifungal [23,24], and antiviral activity [25,26]; they are promising platforms for the design of anti-HIV agents [27] and they are also used in the treatment of leukaemia [28-32]. (iii) Another advantage of isatin and isoindigo derivatives is that they display binding properties of biomacromolecules (DNA, proteins and enzymes). It is noteworthy that isatin derivatives interact with DNA via an intercalating mechanism [12,13,33]. This may be of potential interest in biomedicine for the delivery of drugs or genetic material into cells [34,35].

The development of effective therapeutic drugs based on isoindigo derivatives focuses on improving their bioavailability because of their weak solubility in water. To this end an isoindigo scaffold was functionalized with carbohydrate substituents [36,37]. Over the last three decades, extensive research in nanomedicine led to several strategies to improve drug biocompatibility and drug delivery efficacy (e.g., synthesis of polymer–drug conjugates, such as polyethylene glycol, hyaluronic acid, and heparin, also amphiphilic prodrugs, and supramolecular hydrogels) [38-40]. One of the main strategies deals with the creation of self-assembled supramolecular structures with tunable morphologies (e.g., nanospheres, rods, nanofibers or nanotubes) adapted to the administration route. Drug nanostructures thus obtained are single-component systems unlike traditional colloidal drug carriers. The design of building blocks allows for the control of physical and chemical properties of self-assembled systems. Self-assembly [41] and nanoprecipitation [42] are the most common approaches to create nanostructures [43]. Unlike traditional low-molecular surfactants, e.g., π-functional amphiphiles, the self-assembly of amphiphilic drugs bearing a chromophoric moiety can produce more robust self-assemblies [44,45]. Different approaches can be used to produce various supramolecular systems [46-48]. These strong interactions are critical for the biological function of drugs [49]. In our previous work we described the ability of an amphiphilic isoindigo derivative bearing octadecyl substituents to form self-assembled structures of micellar type in water/DMF solution [50]. In the present work, we focused on the fabrication of nanoscale isoindigo carriers using two approaches: self-assembly and nanoprecipitation. The study aimed to demonstrate the possibility to modulate drug delivery of amphiphilic isoindigo derivatives by tuning hydrophilic–lipophilic balance, π–π stacking interaction and hydrogen bonding.

Another strategy is the use of soft matter (micelles, emulsions, dendrimers, nanospheres, solid lipid nanoparticles or liposomes) as the delivery vehicle. These studies have been encouraged by the possibility to prevent side effects, to increase drug bioavailability, to decrease toxicity as well as to minimize drug degradation and to provide a controllable drug release [51-53]. The modification of nanostructures with conjugated π–π fragments leads to the absorption of anticancer drugs via π–π stacking interaction and increases the drug-loading capacity of nanoscale soft materials [54]. The latter feature is essential for designing novel antitumor drugs.

The second stage of the work was devoted to solubilize amphiphilic isoindigo derivatives using surfactants that are widely used in pharmaceutical industry. The aim of the present work was to investigate the ability of surfactants to bind isoindigo derivatives. For this purpose were used three different surfactants and amphiphilic isoindigo compounds with different lengths of the alkyl substituent at the endocyclic nitrogen atom (Figure 1).

Figure 1: Structures of isatin (1a–h), isoindigo derivatives 2a–h, 3 and anionic (sodium dodecyl sulfate, SDS), cationic (cetyltrimethylammonium bromide, CTAB) and nonionic (Tween 80) surfactants.

Figure 1: Structures of isatin (1a–h), isoindigo derivatives 2a–h, 3 and anionic (sodium dodecyl sulfate, SDS...

Results and Discussion

Nanoscale isoindigo carriers: self-assembly and solid nanoparticles

For the preparation of solid isoindigo nanoparticles (SIPs), the method of nanoprecipitation was used. Precipitation is a commonly used technique in pharmaceutical technology [42,55,56]. This method is documented for protein encapsulation [57], hydrophobic drugs [58], and also for targeting cancer cells [59]. The factors controlling the formation of nanoparticles have been determined [42,57]. Nanoprecipitation is ideal, when the compound must dissolve in one component (the solvent), but must not in the second one (the non-solvent). This one-step manufacturing process commonly available to prepare nanoparticles from polymers that was already reviewed [57,60,61]. In recent years, amphiphilic cyclodextrins [62], calix[n]arenes and calix[n]resorcinarenes [63] were used in the formation of nanoparticles via a simple nanoprecipitation technique. The influence of the hydrophobicity of the drug (paclitaxel) on the therapeutic efficacy was also shown [64].

As seen in Figure 2a, the size of SIPs of 2h is ca. 300 nm, which is comparable with that determined by DLS (Figure 2c). The morphology of aggregates resembles branched elongated structures consisting of small particles of 2–3 nm (Figure 2b). The sizes of SIPs of 2b, 2d, 2e, 2f, 2h are given in Table S1 (Supporting Information File 1). The long-chain homologues 2g and 2h have smaller sizes of 150 to 300 nm and a low polydispersity index (0.15 ± 0.02). They are rather stable, i.e., the size and polydispersity index change only little over time at room temperature (for more than 80 days). The zeta potentials of SIPs from 2d, 2e, 2f, 2h are about −34, −28, −30, −39 mV, respectively (Table S1, Figure S1, Supporting Information File 1). To characterize the colloidal stability of the compounds under study in the presence of electrolytes, the stability of these fabricated SIPs was evaluated under in vitro conditions. After 3 h dialysis in phosphate buffer (pH 7.4) at 37 °C the size of 2d SIPs was shown to increase, with the polydispersity index reaching values greater than 0.4 (Figure S2, Supporting Information File 1). Homologues 2b and 2e form large aggregates of 500 to 700 nm in size. We failed to prepare nanoparticles for high homologues 1g and 3 through the nanoprecipitation technique. It is known that size and morphology of aggregates in aqueous solutions are markedly determined by hydrophilic-lipophilic balance. This is probably due to the packing parameter [65] of compounds 2. Unlike derivatives 1g and 3, a series of compounds 2 tends to form layered self-assembled structures, as described further.

![[2190-4286-8-34-2]](/bjnano/content/figures/2190-4286-8-34-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: Transmission electron micrographs (TEM) (a,b); histogram of the particle size distribution (c) of 2h solid isoindigo nanoparticles (SIPs).

Figure 2: Transmission electron micrographs (TEM) (a,b); histogram of the particle size distribution (c) of 2h...

Size and morphology of isoindigo supramolecular structures

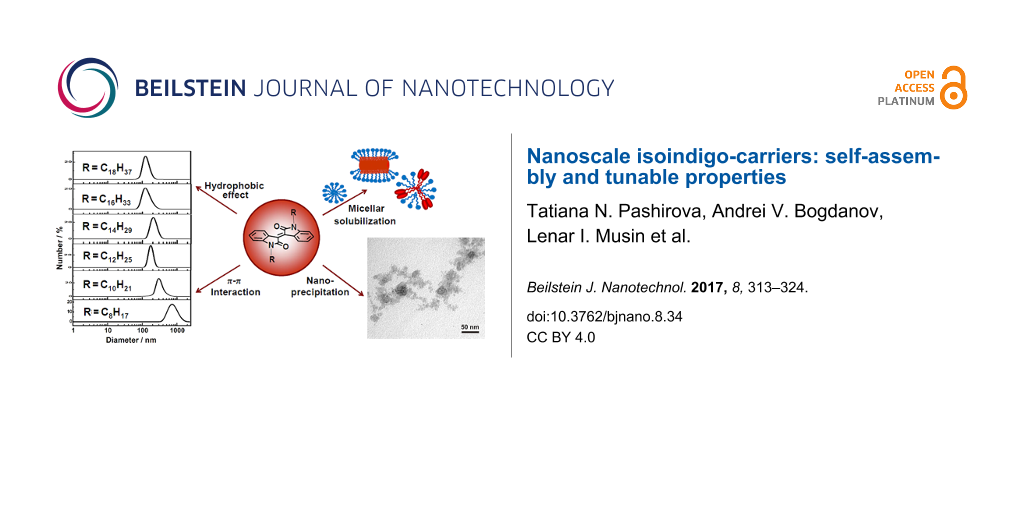

The DLS study of isoindigo derivatives demonstrated the ability to self-assemble in solution. In Figure 3 and Table S2 (Supporting Information File 1), aggregate sizes and polydispersity index at various isoindigo concentrations are given.

![[2190-4286-8-34-3]](/bjnano/content/figures/2190-4286-8-34-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: Analysis of the size distribution of 2c (a), 2d (b), 2e (c), 2f (d), 2g (e), 2h (f) particles in water/DMF (50% v/v) solutions using the number parameter, c = 1 mM, 25 °C.

Figure 3: Analysis of the size distribution of 2c (a), 2d (b), 2e (c), 2f (d), 2g (e), 2h (f) particles in wa...

As seen, aggregate size depends on the length of hydrocarbon fragments of isoindigo with the particle sizes of compounds 2с–f varying within the range of 200 to 700 nm. The long-chain homologues 2g and 2h form particles of 100 to 200 nm. The sizes tend to increase with the increase in concentration of isoindigo derivatives (Figure S3 and Figure S4, Supporting Information File 1). The polydispersity index is rather low (0.2) and changes only little with increasing concentration (Table S2, Supporting Information File 1). The zeta potential of 2h particles is about −30 ± 1 mV (Figure S5, Supporting Information File 1). The increase in temperature up to 50 °С is shown to result in the breaking of the particles of the short-chain derivative 2c. This behaviour may be caused by the effect of temperature on hydrogen bonds and/or π-stacking interaction of aggregated 2с. In the case of the long-chain homologue 2h, the increase in temperature exerted little effect on aggregation (Figure S6, Supporting Information File 1). The size of the 2h aggregates increased when using phosphate buffer instead of water during preparation of the colloidal aggregates (Figure S7, Supporting Information File 1).

To predict the morphology of aggregates, the packing parameter P [65] was calculated for all compounds by using Equation 1:

The dimensionless quantity P is the ratio between the volume of the hydrophobic fragment, v0 and the polar head surface area, a, multiplied by the chain length of the hydrophobic fragment, l. For the cone-like amphiphilic molecules, the value of P of which is below 1/3, the formation of spherical aggregates may be expected. This is observed in the case of typical surfactants bearing relative large polar fragment and single alkyl chain. If 1/2 < P ≤ 1, the formation of bilayers is predicted, including closed structures, i.e., vesicles.

The polar head surface area was calculated as the sum of the area of hexagons and pentagons based on the XRD data for isoindigo derivatives available in the Cambridge Structural Database. As seen in Figure S8 (Supporting Information File 1), the surface of the oxindole fragment of isoindigo derivatives, for which the crystal structure is currently known is in the range of 0.84–0.87 nm2. The dimensions of the oxindole fragment for compounds 1g, 2c, and 2d are 0.86, 0.86 and 0.85 nm2, respectively, (Table S3; Supporting Information File 1). All of these values are very close. The values of v0 and l for alkyl groups can be calculated using the relationships in Equation 2 and Equation 3 [66]:

Data in Table S3 (Supporting Information File 1) show that packing parameters (P) are 0.25 and 0.12 for compounds 1g and 3, respectively, which makes it plausible to assume the occurrence of spherical normal micelles. For derivatives 2a–h P values are close to 0.5, which indicates the formation of aggregates with lower surface curvatures, e.g., layered structures.

CAC and other aggregation parameters

The structure of the long-chain homologues of isatin (1g) and isoindigo (2e, 2g, 2h and 3) contains hydrocarbon fragments and is similar to that of typical surfactants. The self-assembly of amphiphilic molecules bearing a chromophoric moiety is somewhat different from that of classical surfactants. For example, π-functional amphiphiles can yield a more robust self-assembly [44,45]. Nevertheless, we tried to determine the critical association concentration (CAC) and other aggregation parameters. Initially we studied the ability of compounds to localize at the air–solvent interface. A water/DMF (50% v/v) mixture was used as solvent. Unfortunately, we failed to prepare stable solutions of 1g and 3. Tensiometry experiments allowed us to determine that the amphiphilic isoindigo derivatives 2e, 2g, 2h do not decrease the surface tension of the solvent (52 mN/m). They are surface-inactive compounds (Figure S9, Supporting Information File 1).

The study of the entrapment of hydrophobic probes is a generally accepted assay for the potential of soft materials to be used as nanocontainers for hydropohobic solutes including drugs. Furthermore, the solubilization of organic hydrophobic dyes makes it possible to detect the formation of micelles in solution [67]. In Figure 4a, the dependence of the absorbance of hydrophobic dye (Sudan I) on the concentration of isoindigo derivatives 2g and 2h is shown. The samples based on compounds 2a–f were not used in this experiment due to their low stability in the presence of Sudan I. In these cases, gradual agglomeration and precipitation were observed in the systems.

![[2190-4286-8-34-4]](/bjnano/content/figures/2190-4286-8-34-4.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 4: (a) Absorbance of the dye (Sudan I) at 495 nm as a function of the concentration of 2g and 2h in water/DMF (50% v/v) solution, 25 °C; optical length 0.1 cm. (b) Fluorescence of pyrene (cpyrene = 1 × 10−6 M) in 2a (a), 2d (b), 2e (c), 2f (d), and 2g (e) in water/DMF (50% v/v) solution, 25 °C, c2a (mM): 0 (1)–0.257 (7); c2d (mM): 0 (1)–0.2 (9); c2e (mM): 0 (1)–0.5 (9); c2f (mM): 0 (1)–0.5 (9); c2g (mM): 0.0097 (1)–0.255 (7). (c) Dependence of the intensity ratio (I1/I3) of the first and third peaks of pyrene on the 2a, 2d–g concentrations, cpyrene = 1 × 10−6 M, 25 °C.

Figure 4: (a) Absorbance of the dye (Sudan I) at 495 nm as a function of the concentration of 2g and 2h in wa...

As seen in Figure 4a an increase in absorbance occurs at concentrations above 0.2 mМ (for 2g) and 0.1 mМ (for 2h). Thus, experimental data prove the formation of self-assembled structures of 2g and 2h with a hydrophobic field that can dissolve nonpolar probes. The critical association concentrations for 2g and 2h are 0.2 and 0.1 mМ, respectively. Calculated values of the solubilization capacity of 2g and 2h micellar aggregates are given in Table S4 (Supporting Information File 1). As can be seen, the solubilization capacity value grows with the increasing length of the alkyl chain. According to Table S4 (Supporting Information File 1), the solubilization ability of 2g and 2h is, respectively, two times and 20 times higher than that of the classical surfactants, CTAB and SDS.

Fluorescence studies showed that significant changes occur in the pyrene spectrum of the isoindigo derivatives in solution for all the compounds under study, regardless the length of the alkyl chain (Figure 4b). The change in pyrene fluorescence intensity is likely due to the decrease in the polarity of the pyrene microenvironment. Based on these spectra, the CAC of amphiphilic compounds was calculated from the I1/I3 values in the pyrene fluorescence spectrum as a function of the concentration of amphiphilic compounds [68,69]. Most probably, pyrene is incorporated into the hydrophobic region of the colloidal aggregates. Usually, the CMC values of surfactants determined by different methods are very similar [70]. But an additional binding of the fluorescent probe (pyrene) to the heterocyclic core of the isoindigo compounds cannot be excluded. Therefore, we recognize that some perturbation of micelles can occur. On the other hand, the latter can be neglected because of the very low pyrene concentration used. In our case, according to data given in Figure 4c, the CAC of compound 2g is 0.3 mM, which is comparable with that determined spectrophotometrically (Figure 4a). Compounds 2e and 2f aggregate at higher concentrations (CAC ≈ 0.6 mМ). Importantly, this rather low aggregation number may result from the quenching effect of isoindigo derivatives [50]. Figure 4b and Figure S10 (Supporting Information File 1) (Stern–Volmer dependences) show that the most effective quenching occurs for compounds 2a, 2d and 2g. The short-chain isoindigo derivatives 2a–d presumably form supramolecular polymers or layered particles, which can effectively quench the pyrene fluorescence. These structures can be formed through intermolecular π-stacking interactions and/or the formation of hydrogen bonds. The literature data provide information that some isoindigo derivatives and other chromophores tend to form J-aggregates in solid state [71].

One can assume that short-chain isoindigo derivatives form layered supramolecular aggregates largely through π–π stacking interactions, while the aggregation of the long-chain homologues is mainly guided by hydrophobic effects (Scheme 1).

![[2190-4286-8-34-i1]](/bjnano/content/inline/2190-4286-8-34-i1.png?scale=2.0&max-width=1024&background=FFFFFF)

Scheme 1: Supramolecular assemblies of isoindigo derivatives 2a–h.

Scheme 1: Supramolecular assemblies of isoindigo derivatives 2a–h.

Micellar solutions of isoindigo derivatives and their spectroscopic properties

One way to improve the bioavailability of isoindigo derivatives is the formation of mixed supramolecular assemblies with various types of surfactants. Micellar solubilization is one approach for the improvement of solubility of hydrophobic drugs [72]. It is known that the incorporation of poorly water-soluble drugs in the nonpolar core of micelles may increase solubility, stability, and bioavailability [73-75]. Importantly, amphiphilic molecules and drugs can form mixed assemblies that would result in changing in the micellization process [66]. In addition, the amphiphilic nature of surfactant micelles can serve as a tentative model of biomembranes [74,76]. Thus, the study of interactions with various surfactants may provide a deeper insight into the transport and binding of isatin and isoindigo derivatives at the molecular level. We have studied the effect of the structure of isatin and isoindigo derivatives on the solubilizing properties of commercially available classical anionic (SDS), cationic (CTAB) and nonionic (Tween 80) surfactants.

Because isatin and isoindigo derivatives are new dyes, their extinction coefficients were determined for the first time. UV–vis absorption spectra of 2a–h and 3 in chloroform are presented in Figures S11–S18 (Supporting Information File 1). The absorption spectra of 1g in different solvents (CHCl3, EtOH and DMF, Figures S19–S21, Supporting Information File 1) were also recorded. The maximum absorption wavelength of 1g (λmax = 300 nm) does not vary significantly with the type of solvent. The extinction coefficients of the studied compounds are presented in Table S5 (Supporting Information File 1). In Figure 5, the dependence of the absorbance of isatin and isoindigo derivatives in aqueous SDS solution on the SDS concentration is given.

![[2190-4286-8-34-5]](/bjnano/content/figures/2190-4286-8-34-5.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 5: Absorbance of 2a, 2b, 2d–g at λmax ≈ 395 nm and 1g, 3 at λmax = 300 nm in aqueous micellar SDS solution; 25 °C, optical path 1 cm and solubility profile solution of SDS in the presence of 2a on concentration of SDS, cSDS= 2–80 mM, 25 °C.

Figure 5: Absorbance of 2a, 2b, 2d–g at λmax ≈ 395 nm and 1g, 3 at λmax = 300 nm in aqueous micellar SDS solu...

The data show that the isoindigo derivatives 2a and 3 are most effectively solubilized in SDS micelles. For isoindigo derivatives with two alkyl tails, the highest solubilization occurs for compound 2a, i.e. for isoindigo with two methyl groups. It is important to note that unlike the other tested compounds, 2a has the highest extinction coefficient of ε = 13447 M−1·cm−1 (λmax = 395 nm, Table S5, Supporting Information File 1). Although compound 2e has a similar value of ε = 13156 M−1·cm−1 (λmax = 395 nm), it is less effectively solubilized in SDS micelles. In the case of compound 1g, solubilizing capacity cannot be estimated because its extinction coefficient is only about one sixth of that of isoindigo 2a. The solubilization of compound 3 is observed in micellar solutions of CTAB and Tween 80 (Figure S23 and Figure S24, Supporting Information File 1).

It is noteworthy that apart from the solubilization mechanism by typical interaction between surfactants and dyes, mixed aggregates can be formed. The surface tension of SDS solutions admixed with 2а and 3 are given in Figure 6. The formation of mixed structures of SDS and isoindigo derivative 2a is observed in a lower concentration range compared to single SDS micelles. This is supported by the left-shift in the surface tension isotherms of SDS with 2a additives (Figure 6a) and the decrease of the slope, indicating a lower surface activity. This is presumably related to the formation of structures with various aggregation numbers. Measurement of the size of 2а particles in SDS solution showed the presence of particles of about 1 and about 200 nm in diameter (Figure 6b). The former most likely correspond to SDS micelles, while the latter represent mixed structures of SDS and the isoindigo derivative. In the SDS–2a system an increase in zeta potential is observed (Figure 6c).

![[2190-4286-8-34-6]](/bjnano/content/figures/2190-4286-8-34-6.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 6: (a) Surface tension isotherms of SDS in the absence and presence of 2a and 3 in water, (b) Analysis of the size distribution and (c) zeta potential of 2a particles in water–SDS solutions, cSDS (mM): 60 (1), 80 (2), 25 °C.

Figure 6: (a) Surface tension isotherms of SDS in the absence and presence of 2a and 3 in water, (b) Analysis...

According to our results and literature data [77,78], the zeta potential of SDS micelles is about −70 mV, while the mixed aggregates of SDS and 2a have a zeta potential of about −110 mV. In the case of compound 3, there is a decrease in the zeta potential of SDS micelles by ca. 20 mV. Most probably, 2a molecules are incorporated and dissolved in the nonpolar core of the SDS micelles. This may lead to a change in the packing parameter of SDS molecules, an increase in the aggregation numbers of surfactant micelles and/or the formation of non-spherical structures, and, consequently, in an increase in the zeta potential of the system. For the amphiphilic derivative 3, the probability of the formation of micelle-like aggregates of SDS and 3 increases. This may result in a loosening of the SDS micelles, a decrease in the aggregation numbers and, hence, in a decrease in the zeta potential of the system. A schematic representation of mixed structures of SDS and isoindigo derivatives is shown in Scheme 2.

![[2190-4286-8-34-i2]](/bjnano/content/inline/2190-4286-8-34-i2.png?scale=2.0&max-width=1024&background=FFFFFF)

Scheme 2: Solubilization of 2a and 3 in SDS.

Scheme 2: Solubilization of 2a and 3 in SDS.

Conclusion

Solid nanoparticles and self-assembled structures of dialkylated isoindigo derivatives were obtained. Size, morphology, and stability of supramolecular associates and solid nanoparticles of dialkylated isoindigo derivatives depend on the length of the alkyl-chain moiety. Stable solid nanoparticles were obtained for dialkylated isoindigo derivatives with C16H33, and C18H37, their size ranged between 150 and 300 nm. The size of self-assembled structures of dialkylated isoindigo derivatives was equal to 200–700 nm in the case of R = C8H17, C10H21, C12H25, C14H29; and 100–200 nm in the case of R = C16H33 and C18H37. The polydispersity index of the particles is below 0.2. The critical association concentration for dialkylated isoindigo derivatives with R = C12H25, C14H29, C16H33, and C18H37 decreases with the increase in hydrocarbon chain length and corresponds to 0.6, 0.2, and 0.1 mМ, respectively. Effective pyrene quenching is observed for all dialkylated isoindigo derivatives. This is mostly related to the formation of supramolecular polymers or layered aggregates driven by π–π interaction in the case of short-chain isoindigo derivatives and micelle-like aggregates in the case of long-chain isoindigo derivatives. The alkylated isatin and isoindigo derivatives were employed for the first time as probe dyes for various types of surfactants (cationic, anionic, and nonionic). It was spectrophotometrically determined that at surfactant (SDS, CTAB, Tween 80) concentrations above the CMC, an increase in absorption occurs for the compounds 2a and 3. Likely, the dissolution of short-chain dialkylated isoindigo derivative 2a and monoalkylated isoindigo derivative 3 in micellar surfactant solutions is due to the formation of different types of mixed surfactant–isoindigo derivative assemblies. The data obtained are expected to contribute to the development of nanodevices with interesting optical properties and pharmacological applications as drug delivery systems.

Experimental

Materials

1-Phenylazo-2-naphthol (Sudan I, Acros Organics, New Jersey, USA), pyrene for fluorescence (Sigma, Switzerland, 99%), cetyltrimethylammonium bromide (CTAB) (Acros Organics, New Jersey, USA, 99%), sodium dodecyl sulfate (SDS) (Acros Organics, New Jersey, USA, 99%), Tween 80 (Acros Organics, New Jersey, USA, BioXtra) were used. Unless otherwise mentioned, other chemicals and solvents were of analytical grade from commercial sources. Dimethylformamide (DMF) and tetrahydrofuran (THF) were purified according to conventional procedures [79]. Compounds 1a–h, 2a–h were obtained as reported earlier [50].

Synthesis of 1-hexadecyl-(3,3′-biindolinylidene)-2,2′-dione 3

A mixture of 1-hexadecylisatin 1g (3.0 g, 8.1 mmol) and indolin-2-one (1.08 g, 8.1 mmol) in acetic acid (15 mL) was heated at 80 °C in the presence of a catalytic amount of HCl (conc) for 4 h. After cooling to room temperature the precipitate was filtered off, washed thoroughly with H2O (50 mL) and air-dried, affording 3 as dark-red crystalline powder. Yield: 97% (3.8 g), mp 135–137 °С; IR (KBr): 3419, 2915, 2848, 1698, 1662, 1619, 1464, 1364, 1334, 1102, 745 cm−1; 1H NMR (500 MHz, CDCl3/DMSO-d6 (9:1)) δH 0.74 (t, J = 7.0 Hz, 3H, CH3), 1.30–1.05 (m, 26H, 13CH2), 1.57 (q, J = 7.3 Hz, 2H, NCH2CH2), 3.63 (t, J = 7.3 Hz, 2H, NCH2), 6.66 (d, J = 7.6 Hz, 1H, H7), 6.70 (d, J = 7.6 Hz, 1H, H7’), 6.84 (ddd, J = 7.9 Hz, J = 7.8 Hz, J = 0.9 Hz, 1H, H5’), 6.88 (ddd, J = 7.9 Hz, J = 7.8 Hz, J = 0.9 Hz, 1H, H5), 7.14 (ddd, J = 7.8 Hz, J = 7.6 Hz, J = 0.9 Hz, 1H, H6’), 7.21 (ddd, J = 7.8 Hz, J = 7.6 Hz, J = 0.9 Hz, 1H, H6), 8.99 (d, J = 7.9 Hz, 1H, H4’), 9.02 (d, J = 7.9 Hz, 1H, H4), 9.81 (s, 1H, H1’); 13C{1H} NMR (125.7 MHz, CDCl3/DMSO-d6 (9:1)) δC 13.73 (CH3), 22.25 (C(15)H2), 26.63 (C(3)H2), 27.08 (NCH2CH2), 28.91 (C(4)H2+C(13)H2), 29.34–29.00 (C(5)H2–C(12)H2), 31.49 (C(14)H2), 39.66 (NCH2), 107.50 (C7), 109.30 (C7’), 121.30 (C5’), 121.32 (C3a), 121.64 (C5), 121.99 (C3a’), 129.30 (C4), 129.47 (C4’), 131.76 (C6), 132.12 (C6’), 132.62 (C3), 134.11 (C3’), 143.67 (C7a’), 144.22 (C7a), 167.50 (C2), 169.34 (C2’); 15N NMR (50.6 MHz, CDCl3/DMSO-d6 (9:1)) δN 136.2 (N1’), 142.5 (N1); Anal. calcd for C32H42N2O2: С, 78.97; Н, 8.70; N, 5.76; found: С, 78.85; Н, 8.57; N, 5.63.

The structure of 3 was established unambiguously by different of NMR correlation methods [80,81]. First, nOe's from NH1' and H1-Alk let us to reveal H7' and H7, respectively (Supporting Information File 1). Then, structures of these moieties were determined by combination of 1H,1H COSY, 1H,13C HSQC/HMBC and 1H,15N HSQC/HMBC correlations. Almost perfect correlation between calculated [82] for a simplified model of 3 (with Alk = C6H13 instead of C16H33) and experimental 13C CS's (R2 = 0.998, Supporting Information File 1) strongly supports this structural hypothesis.

Preparation of solid isoindigo nanoparticles

The nanoprecipitation technique was used for preparation of nanoparticles based on amphiphilic isoindigo derivatives. The relevant derivative in different quantities was dissolved in DMF or THF (1 mL) at 60 °C, and the hot solution (0.5 mL) was added in 1 min to deionized water (25 mL) or phosphate buffer (25 mL) at 60 °C and stirred at 750 rpm. Nanoparticles were formed spontaneously. Solvent (THF) and part of water were removed under reduced pressure and the total volume was adjusted to 25 mL with deionized water.

Methods

NMR spectroscopy

NMR experiments were performed with a 500 MHz (500 MHz for 1H NMR; 125 MHz for 13C NMR; 50.7 MHz for 15N NMR, respectively) spectrometer equipped with a 5 mm diameter gradient direct broad band probehead and a pulsed gradient unit capable of producing magnetic field pulse gradients in the z-direction of 53.5 G·cm-1. NMR experiments, carried out at 303 K. DPFGNOE [80], were obtained using a Hermite-shaped pulse for selective excitation. Chemical shifts (δ in ppm) are referenced to the solvent CDCl3 (δ = 7.27 ppm for 1H and 77.0 ppm for 13C NMR), to external CD3NO2 (380.2 ppm) for 15N NMR spectra (conversion factor to NH3: −380.2 ppm).

The quantum chemical calculations

The quantum chemical calculations were performed using Gaussian 03 software package [83]. Full geometry optimizations were carried out within the framework of DFT (B3LYP) method using 6-31G(d) basis sets. Chemical shifts (CSs) were calculated by the GIAO method at the same level of theory. All data were referred to TMS (13C) and NH3 (15N) chemical shifts, which were calculated under the same conditions.

Surface tension

Surface tension measurements were performed using the du Nouy ring detachment method (Kruss K6 Tensiometer, Hamburg, Germany). The experimental details are described elsewhere [84]. Briefly, the planar and spherical ring was placed parallel to the air–solvent interface. Between the surface tension analyses, the ring was cleaned by rinsing it with double-distilled water, followed by soaking it in nitric acid for 5–7 min, rinsing again with double-distilled water, and finally flame-drying. All glassware was soaked in nitric acid to avoid any contaminants, thoroughly rinsed with double-distilled water, and then steamed before use. Temperature was kept at 25 ± 0.2 °C during all experiments.

Solubilization study

The solubilization studies of the dye (Sudan I) were performed by adding an excess of crystalline Sudan I to the isoindigo derivatives solutions. These solutions were allowed to equilibrate for about 48 h at room temperature, followed by filtration, and the absorbance measured at 495 nm using the spectrophotometer Specord 250 Plus (Analytik Jena AG, Germany). Quartz cuvettes containing sample were used, with a 0.1 cm cell path.

For the solubilization studies of compounds 1–3, saturated solutions were prepared in glass vessels by mixing of the excess of powdered compounds 1–3 with surfactants solutions with different concentrations. These solutions were allowed to equilibrate for about 48 h at room temperature, followed by filtration, and the absorbance of compounds 1–3 at appropriate wavelengths using the spectrophotometer Specord 250 Plus (Analytik Jena AG, Germany). Quartz cuvettes with a 1 cm cell path were used.

Dynamic light scattering

Dynamic light scattering (DLS) measurements were performed using the Malvern Instrument Zetasizer Nano (Worcestershire, UK). The measured autocorrelation functions were analysed by Malvern DTS software, applying the second-order cumulant expansion methods. The effective hydrodynamic radius (RH) was calculated according to the Einstein–Stokes equation: D = kBT/6πηRH, in which D is the diffusion coefficient, kB is the Boltzmann constant, T is the absolute temperature, and η is the viscosity. The diffusion coefficient was measured at least in triplicate for each sample. The average error in these experiments was approximately 4%. The solutions were filtered with Millipore filters to remove dust particles from the scattering volume.

Fluorescence

Fluorescence spectra of pyrene (1 × 10−6 M) in water/DMF (50% v/v) solutions of 2a–h were recorded at 25 °C on a Varian Cary Eclipse spectrofluorimeter (Varian, Inc., California, USA) with an excitation wavelength for pyrene at 335 nm using 1 cm path length quartz cuvettes. Emission spectra were recorded in the range of 350–500 nm.

Transmission electron microscopy (TEM)

Transmission electron microscopy (TEM) images were obtained using a microscope Hitachi HT7700, Japan. The images were acquired at an accelerating voltage of 110 kV. Samples were dispersed on 300 mesh copper grids with continuous carbon-formvar support films.

In vitro stability of SIPs

The SIP sample (5 mL) was poured into a dialysis bag that was immersed in 200 mL of phosphate buffer (pH 7.4) and incubated at 37 °C and 100 rpm. Bags with a pore size of 12 Da (Sigma-Aldrich) were used for this study. They were soaked in Milli-Q water for 12 h before use. After dialysis (3 h), a SIP sample (1 mL) of the fluid inside dialysis bag was withdrawn and assayed by determining the size and zeta potential using the Malvern Instrument Zetasizer Nano (Worcestershire, UK).

Supporting Information

| Supporting Information File 1: Additional experimental data. | ||

| Format: PDF | Size: 1.5 MB | Download |

References

-

Kar, H.; Gehrig, D. W.; Laquai, F.; Ghosh, S. Nanoscale 2015, 7, 6729–6736. doi:10.1039/C5NR00483G

Return to citation in text: [1] -

Squillaci, M. A.; Ferlauto, L.; Zagranyarski, Y.; Milita, S.; Müllen, K.; Samorì, P. Adv. Mater. 2015, 27, 3170–3174. doi:10.1002/adma.201500940

Return to citation in text: [1] -

Jung, E. H.; Bae, S.; Yoo, T. W.; Jo, W. H. Polym. Chem. 2014, 5, 6545–6550. doi:10.1039/C4PY00791C

Return to citation in text: [1] -

Yan, Q.; Luo, Z.; Cai, K.; Ma, Y.; Zhao, D. Chem. Soc. Rev. 2014, 43, 4199–4221. doi:10.1039/c3cs60375j

Return to citation in text: [1] -

Ho, C.-C.; Chen, C.-A.; Chang, C.-Y.; Darling, S. B.; Su, W.-F. J. Mater. Chem. A 2014, 2, 8026–8032. doi:10.1039/C4TA01083C

Return to citation in text: [1] -

Jang, B.; Kwon, H.; Katila, P.; Lee, S. J.; Lee, H. Adv. Drug Delivery Rev. 2016, 98, 113–133. doi:10.1016/j.addr.2015.10.023

Return to citation in text: [1] -

Khemthongcharoen, N.; Jolivot, R.; Rattanavarin, S.; Piyawattanametha, W. Adv. Drug Delivery Rev. 2014, 74, 53–74. doi:10.1016/j.addr.2013.09.012

Return to citation in text: [1] -

Walia, S.; Acharya, A. Beilstein J. Nanotechnol. 2015, 6, 546–558. doi:10.3762/bjnano.6.57

Return to citation in text: [1] -

Viseu, M. I.; Tatikolov, A. S.; Correia, R. F.; Costa, S. M. B. J. Photochem. Photobiol., A 2014, 280, 54–62. doi:10.1016/j.jphotochem.2014.02.007

Return to citation in text: [1] -

Brinkmann, J.; Cavatorta, E.; Sankaran, S.; Schmidt, B.; van Weerd, J.; Jonkheijm, P. Chem. Soc. Rev. 2014, 43, 4449–4469. doi:10.1039/C4CS00034J

Return to citation in text: [1] -

Xia, Y.; Peng, L. Chem. Rev. 2013, 113, 7880–7929. doi:10.1021/cr300419p

Return to citation in text: [1] -

Pakravan, P.; Kashanian, S.; Khodaei, M. M.; Harding, F. J. Pharmacol. Rep. 2013, 65, 313–335. doi:10.1016/S1734-1140(13)71007-7

Return to citation in text: [1] [2] [3] -

Ray, D.; Paul, B. K.; Guchhait, N. J. Photochem. Photobiol., B 2013, 127, 18–27. doi:10.1016/j.jphotobiol.2013.06.016

Return to citation in text: [1] [2] -

Prakash, C.; Raja, S. Mini-Rev. Med. Chem. 2012, 12, 98–119. doi:10.2174/138955712798995039

Return to citation in text: [1] -

Wee, X. K.; Yang, T.; Go, M. L. ChemMedChem 2012, 7, 777–791. doi:10.1002/cmdc.201200018

Return to citation in text: [1] -

Marko, D.; Schätzle, S.; Friedel, A.; Genzlinger, A.; Zankl, H.; Meijer, L.; Eisenbrand, G. Br. J. Cancer 2001, 84, 283–289. doi:10.1054/bjoc.2000.1546

Return to citation in text: [1] -

Moon, M. J.; Lee, S. K.; Lee, J.-W.; Song, W. K.; Kim, S. W.; Kim, J. I.; Cho, C.; Choi, S. J.; Kim, Y.-C. Bioorg. Med. Chem. 2006, 14, 237–246. doi:10.1016/j.bmc.2005.08.008

Return to citation in text: [1] -

Damiens, E.; Baratte, B.; Marie, D.; Eisenbrand, G.; Meijer, L. Oncogene 2001, 20, 3786–3797. doi:10.1038/sj.onc.1204503

Return to citation in text: [1] -

Myrianthopoulos, V.; Magiatis, P.; Ferandin, Y.; Skaltsounis, A.-L.; Meijer, L.; Mikros, E. J. Med. Chem. 2007, 50, 4027–4037. doi:10.1021/jm070077z

Return to citation in text: [1] -

Klein, L. L.; Petukhova, V.; Wan, B.; Wang, Y.; Santasiero, B. D.; Lankin, D. C.; Pauli, G. F.; Franzblau, S. G. Bioorg. Med. Chem. Lett. 2014, 24, 268–270. doi:10.1016/j.bmcl.2013.11.024

Return to citation in text: [1] -

Bogdanov, A. V.; Musin, L. I.; Mironov, V. F. ARKIVOC 2015, vi, 362–392. doi:10.3998/ark.5550190.p009.090

Return to citation in text: [1] -

Farag, A. A. Drug Res. (Stuttgart, Ger.) 2015, 65, 373–379. doi:10.1055/s-0034-1384609

Return to citation in text: [1] -

Thanh, N. D.; Giang, N. T. K.; Quyen, T. H.; Huong, D. T.; Toan, V. N. Eur. J. Med. Chem. 2016, 123, 532–543. doi:10.1016/j.ejmech.2016.07.074

Return to citation in text: [1] -

Chohan, Z. H.; Pervez, H.; Rauf, A.; Khan, K. M.; Supuran, C. T. J. Enzyme Inhib. Med. Chem. 2004, 19, 417–423. doi:10.1080/14756360410001710383

Return to citation in text: [1] -

Rane, R. A.; Karunanidhi, S.; Jain, K.; Shaikh, M.; Hampannavar, G.; Karpoormath, R. Curr. Top. Med. Chem. 2016, 16, 1262–1289. doi:10.2174/1568026615666150915112334

Return to citation in text: [1] -

Medvedev, A.; Buneeva, O.; Glover, V. Biol.: Targets Ther. 2007, 1, 151–162.

Return to citation in text: [1] -

Sriram, D.; Yogeeswari, P.; Meena, K. Pharmazie 2006, 61, 274–277.

Return to citation in text: [1] -

Saleh, A. M.; Al-As'ad, R. M.; El-Abadelah, M. M.; Sabri, S. S.; Zahra, J. A.; Alaskar, A. S.; Aljada, A. Molecules 2014, 19, 13076–13092. doi:10.3390/molecules190913076

Return to citation in text: [1] -

Saleh, A. M.; El-Abadelah, M. M.; Aziz, M. A.; Taha, M. O.; Nasr, A.; Rizvi, S. A. A. Cancer Lett. 2015, 361, 251–261. doi:10.1016/j.canlet.2015.03.013

Return to citation in text: [1] -

Xiao, Z.; Hao, Y.; Liu, B.; Qian, L. Leuk. Lymphoma 2002, 43, 1763–1768. doi:10.1080/1042819021000006295

Return to citation in text: [1] -

Xiao, Z.; Qian, L.; Liu, B.; Hao, Y. Br. J. Haematol. 2000, 111, 711–712. doi:10.1046/j.1365-2141.2000.02357.x

Return to citation in text: [1] -

Chen, F.; Li, L.; Ma, D.; Yan, S.; Sun, J.; Zhang, M.; Ji, C.; Hou, M. Leuk. Res. 2010, 34, e75–e77. doi:10.1016/j.leukres.2009.09.001

Return to citation in text: [1] -

Kashanian, S.; Khodaei, M. M.; Pakravan, P.; Adibi, H. Mol. Biol. Rep. 2012, 39, 3853–3861. doi:10.1007/s11033-011-1164-9

Return to citation in text: [1] -

Kashanian, S.; Khodaei, M. M.; Pakravan, P. DNA Cell Biol. 2010, 29, 639–646. doi:10.1089/dna.2010.1054

Return to citation in text: [1] -

Gusakov, A. V.; Sinitsyn, A. P.; Markov, A. V.; Sinitsyna, O. A.; Ankudimova, N. V.; Berlin, A. G. J. Biotechnol. 2001, 87, 83–90. doi:10.1016/S0168-1656(01)00234-6

Return to citation in text: [1] -

Kleeblatt, D.; Siyo, B.; Hein, M.; Iaroshenko, V. O.; Iqbal, J.; Villinger, A.; Langer, P. Org. Biomol. Chem. 2013, 11, 886–895. doi:10.1039/c2ob25866h

Return to citation in text: [1] -

Sassatelli, M.; Bouchikhi, F.; Messaoudi, S.; Anizon, F.; Debiton, E.; Barthomeuf, C.; Prudhomme, M.; Moreau, P. Eur. J. Med. Chem. 2006, 41, 88–100. doi:10.1016/j.ejmech.2005.10.004

Return to citation in text: [1] -

Ma, W.; Cheetham, A. G.; Cui, H. Nano Today 2016, 11, 13–30. doi:10.1016/j.nantod.2015.11.003

Return to citation in text: [1] -

Fumagalli, G.; Marucci, C.; Christodoulou, M. S.; Stella, B.; Dosio, F.; Passarella, D. Drug Discovery Today 2016, 21, 1321–1329. doi:10.1016/j.drudis.2016.06.018

Return to citation in text: [1] -

Luo, C.; Sun, J.; Sun, B.; He, Z. Trends Pharmacol. Sci. 2014, 35, 556–566. doi:10.1016/j.tips.2014.09.008

Return to citation in text: [1] -

Lin, R.; Cui, H. Curr. Opin. Chem. Eng. 2015, 7, 75–83. doi:10.1016/j.coche.2014.11.005

Return to citation in text: [1] -

Saad, W. S.; Prud’homme, R. K. Nano Today 2016, 11, 212–227. doi:10.1016/j.nantod.2016.04.006

Return to citation in text: [1] [2] [3] -

Su, H.; Koo, J. M.; Cui, H. J. Controlled Release 2015, 219, 383–395. doi:10.1016/j.jconrel.2015.09.056

Return to citation in text: [1] -

Molla, M. R.; Ghosh, S. Phys. Chem. Chem. Phys. 2014, 16, 26672–26683. doi:10.1039/C4CP03791J

Return to citation in text: [1] [2] -

Hill, J. P.; Shrestha, L. K.; Ishihara, S.; Ji, Q.; Ariga, K. Molecules 2014, 19, 8589–8609. doi:10.3390/molecules19068589

Return to citation in text: [1] [2] -

Das, A.; Ghosh, S. Chem. Commun. 2016, 52, 6860–6872. doi:10.1039/C6CC01983H

Return to citation in text: [1] -

Sikder, A.; Das, A.; Ghosh, S. Angew. Chem., Int. Ed. 2015, 54, 6755–6760. doi:10.1002/anie.201500971

Return to citation in text: [1] -

Shankar, B. H.; Jayaram, D. T.; Ramaiah, D. Chem. – Eur. J. 2015, 21, 17657–17663. doi:10.1002/chem.201502955

Return to citation in text: [1] -

Lock, L. L.; LaComb, M.; Schwarz, K.; Cheetham, A. G.; Lin, Y.-a.; Zhang, P.; Cui, H. Faraday Discuss. 2013, 166, 285–301. doi:10.1039/c3fd00099k

Return to citation in text: [1] -

Bogdanov, A. V.; Pashirova, T. N.; Musin, L. I.; Krivolapov, D. B.; Zakharova, L. Y.; Mironov, V. F.; Konovalov, A. I. Chem. Phys. Lett. 2014, 594, 69–73. doi:10.1016/j.cplett.2014.01.026

Return to citation in text: [1] [2] [3] -

Soussan, E.; Cassel, S.; Blanzat, M.; Rico-Lattes, I. Angew. Chem., Int. Ed. 2009, 48, 274–288. doi:10.1002/anie.200802453

Return to citation in text: [1] -

Kumar, A.; Chen, F.; Mozhi, A.; Zhang, X.; Zhao, Y.; Xue, X.; Hao, Y.; Zhang, X.; Wang, P. C.; Liang, X.-J. Nanoscale 2013, 5, 8307–8325. doi:10.1039/c3nr01525d

Return to citation in text: [1] -

Verma, G.; Hassan, P. A. Phys. Chem. Chem. Phys. 2013, 15, 17016–17028. doi:10.1039/c3cp51207j

Return to citation in text: [1] -

Liang, Y.; Deng, X.; Zhang, L.; Peng, X.; Gao, W.; Cao, J.; Gu, Z.; He, B. Biomaterials 2015, 71, 1–10. doi:10.1016/j.biomaterials.2015.08.032

Return to citation in text: [1] -

Karnik, R.; Gu, F.; Basto, P.; Cannizzaro, C.; Dean, L.; Kyei-Manu, W.; Langer, R.; Farokhzad, O. C. Nano Lett. 2008, 8, 2906–2912. doi:10.1021/nl801736q

Return to citation in text: [1] -

Mora-Huertas, C. E.; Fessi, H.; Elaissari, A. Int. J. Pharm. 2010, 385, 113–142. doi:10.1016/j.ijpharm.2009.10.018

Return to citation in text: [1] -

Bilati, U.; Allémann, E.; Doelker, E. Eur. J. Pharm. Sci. 2005, 24, 67–75. doi:10.1016/j.ejps.2004.09.011

Return to citation in text: [1] [2] [3] -

Zhu, Z. Biomaterials 2013, 34, 10238–10248. doi:10.1016/j.biomaterials.2013.09.015

Return to citation in text: [1] -

Tong, R.; Yala, L.; Fan, T. M.; Cheng, J. Biomaterials 2010, 31, 3043–3053. doi:10.1016/j.biomaterials.2010.01.009

Return to citation in text: [1] -

Fessi, H.; Puisieux, F.; Devissaguet, J. P.; Ammoury, N.; Benita, S. Int. J. Pharm. 1989, 55, R1–R4. doi:10.1016/0378-5173(89)90281-0

Return to citation in text: [1] -

Quintanar-Guerrero, D.; Allémann, E.; Fessi, H.; Doelker, E. Drug Dev. Ind. Pharm. 1998, 24, 1113–1128. doi:10.3109/03639049809108571

Return to citation in text: [1] -

Lakkakula, J. R.; Maçedo Krause, R. W. Nanomedicine (London, U. K.) 2014, 9, 877–894. doi:10.2217/nnm.14.41

Return to citation in text: [1] -

Montasser, I.; Shahgaldian, P.; Perret, F.; Coleman, A. W. Int. J. Mol. Sci. 2013, 14, 21899–21942. doi:10.3390/ijms141121899

Return to citation in text: [1] -

Ansell, S. M.; Johnstone, S. A.; Tardi, P. G.; Lo, L.; Xie, S.; Shu, Y.; Harasym, T. O.; Harasym, N. L.; Williams, L.; Bermudes, D.; Liboiron, B. D.; Saad, W.; Prud'homme, R. K.; Mayer, L. D. J. Med. Chem. 2008, 51, 3288–3296. doi:10.1021/jm800002y

Return to citation in text: [1] -

Geng, Y.; Romsted, L. S.; Menger, F. J. Am. Chem. Soc. 2006, 128, 492–501. doi:10.1021/ja056807e

Return to citation in text: [1] [2] -

Tanford, C. J. Phys. Chem. 1972, 76, 3020–3024. doi:10.1021/j100665a018

Return to citation in text: [1] [2] -

Tehrani-Bagha, A. R.; Holmberg, K. Materials 2013, 6, 580–608. doi:10.3390/ma6020580

Return to citation in text: [1] -

Aguiar, J.; Carpena, P.; Molina-Bolívar, J. A.; Ruiz, C. C. J. Colloid Interface Sci. 2003, 258, 116–122. doi:10.1016/S0021-9797(02)00082-6

Return to citation in text: [1] -

Yan, M.; Li, B.; Zhao, X. Food Chem. 2010, 122, 1333–1337. doi:10.1016/j.foodchem.2010.03.102

Return to citation in text: [1] -

Gabdrakhmanov, D. R.; Valeeva, F. G.; Syakaev, V. V.; Lukashenko, S. S.; Zakharov, S. V.; Kuryashov, D. A.; Bashkirtseva, N. Y.; Zakharova, L. Y.; Latypov, S. K.; Sinyashin, O. G. Mendeleev Commun. 2015, 25, 174–176. doi:10.1016/j.mencom.2015.05.004

Return to citation in text: [1] -

Ren, Y.; Hiszpanski, A. M.; Whittaker-Brooks, L.; Loo, Y.-L. ACS Appl. Mater. Interfaces 2014, 6, 14533–14542. doi:10.1021/am503812f

Return to citation in text: [1] -

Williams, H. D.; Trevaskis, N. L.; Charman, S. A.; Shanker, R. M.; Charman, W. N.; Pouton, C. W.; Porter, C. J. H. Pharmacol. Rev. 2013, 65, 315–499. doi:10.1124/pr.112.005660

Return to citation in text: [1] -

Reddy, L. H.; Bazile, D. Adv. Drug Delivery Rev. 2014, 71, 34–57. doi:10.1016/j.addr.2013.10.007

Return to citation in text: [1] -

Mahajan, S.; Mahajan, R. K. Adv. Colloid Interface Sci. 2013, 199–200, 1–14. doi:10.1016/j.cis.2013.06.008

Return to citation in text: [1] [2] -

Noori, S.; Naqvi, A. Z.; Ansari, W. H.; Kabir-ud-Din. Colloids Surf., B 2014, 115, 71–78. doi:10.1016/j.colsurfb.2013.11.023

Return to citation in text: [1] -

Bhattacharya, S.; Biswas, J. Langmuir 2010, 26, 4642–4654. doi:10.1021/la9011718

Return to citation in text: [1] -

Sun, Z.; Nicolosi, V.; Rickard, D.; Bergin, S. D.; Aherne, D.; Coleman, J. N. J. Phys. Chem. C 2008, 112, 10692–10699. doi:10.1021/jp8021634

Return to citation in text: [1] -

Gharibi, H.; Moosavi-Movahedi, Z.; Javadian, S.; Nazari, K.; Moosavi-Movahedi, A. A. J. Phys. Chem. B 2011, 115, 4671–4679. doi:10.1021/jp112051t

Return to citation in text: [1] -

Gordon, A.; Ford, R. The Chemist’s Companion. A Handbook of Practical Data, Techniques, and Reference; J. Wiley & Sons, 1972.

Return to citation in text: [1] -

Derome, A. E. Modern NMR Techniques for Chemistry Research; Pergamon, 1988.

Return to citation in text: [1] [2] -

Stott, K.; Stonehouse, J.; Keeler, J.; Hwang, T.-L.; Shaka, A. J. J. Am. Chem. Soc. 1995, 117, 4199–4200. doi:10.1021/ja00119a048

Return to citation in text: [1] -

Latypov, S.; Balandina, A.; Boccalini, M.; Matteucci, A.; Usachev, K.; Chimichi, S. Eur. J. Org. Chem. 2008, 4640–4646. doi:10.1002/ejoc.200800550

Return to citation in text: [1] -

Gaussian 03, Revision A.6; Gaussian Inc: Pittsburgh, PA, 2003.

Return to citation in text: [1] -

Pashirova, T. N.; Lukashenko, S. S.; Zakharov, S. V.; Voloshina, A. D.; Zhiltsova, E. P.; Zobov, V. V.; Souto, E. B.; Zakharova, L. Y. Colloids Surf., B 2015, 127, 266–273. doi:10.1016/j.colsurfb.2015.01.044

Return to citation in text: [1]

| 42. | Saad, W. S.; Prud’homme, R. K. Nano Today 2016, 11, 212–227. doi:10.1016/j.nantod.2016.04.006 |

| 57. | Bilati, U.; Allémann, E.; Doelker, E. Eur. J. Pharm. Sci. 2005, 24, 67–75. doi:10.1016/j.ejps.2004.09.011 |

| 57. | Bilati, U.; Allémann, E.; Doelker, E. Eur. J. Pharm. Sci. 2005, 24, 67–75. doi:10.1016/j.ejps.2004.09.011 |

| 60. | Fessi, H.; Puisieux, F.; Devissaguet, J. P.; Ammoury, N.; Benita, S. Int. J. Pharm. 1989, 55, R1–R4. doi:10.1016/0378-5173(89)90281-0 |

| 61. | Quintanar-Guerrero, D.; Allémann, E.; Fessi, H.; Doelker, E. Drug Dev. Ind. Pharm. 1998, 24, 1113–1128. doi:10.3109/03639049809108571 |

| 62. | Lakkakula, J. R.; Maçedo Krause, R. W. Nanomedicine (London, U. K.) 2014, 9, 877–894. doi:10.2217/nnm.14.41 |

| 67. | Tehrani-Bagha, A. R.; Holmberg, K. Materials 2013, 6, 580–608. doi:10.3390/ma6020580 |

| 68. | Aguiar, J.; Carpena, P.; Molina-Bolívar, J. A.; Ruiz, C. C. J. Colloid Interface Sci. 2003, 258, 116–122. doi:10.1016/S0021-9797(02)00082-6 |

| 69. | Yan, M.; Li, B.; Zhao, X. Food Chem. 2010, 122, 1333–1337. doi:10.1016/j.foodchem.2010.03.102 |

| 44. | Molla, M. R.; Ghosh, S. Phys. Chem. Chem. Phys. 2014, 16, 26672–26683. doi:10.1039/C4CP03791J |

| 45. | Hill, J. P.; Shrestha, L. K.; Ishihara, S.; Ji, Q.; Ariga, K. Molecules 2014, 19, 8589–8609. doi:10.3390/molecules19068589 |

| 65. | Geng, Y.; Romsted, L. S.; Menger, F. J. Am. Chem. Soc. 2006, 128, 492–501. doi:10.1021/ja056807e |

| 65. | Geng, Y.; Romsted, L. S.; Menger, F. J. Am. Chem. Soc. 2006, 128, 492–501. doi:10.1021/ja056807e |

| 63. | Montasser, I.; Shahgaldian, P.; Perret, F.; Coleman, A. W. Int. J. Mol. Sci. 2013, 14, 21899–21942. doi:10.3390/ijms141121899 |

| 64. | Ansell, S. M.; Johnstone, S. A.; Tardi, P. G.; Lo, L.; Xie, S.; Shu, Y.; Harasym, T. O.; Harasym, N. L.; Williams, L.; Bermudes, D.; Liboiron, B. D.; Saad, W.; Prud'homme, R. K.; Mayer, L. D. J. Med. Chem. 2008, 51, 3288–3296. doi:10.1021/jm800002y |

| 70. | Gabdrakhmanov, D. R.; Valeeva, F. G.; Syakaev, V. V.; Lukashenko, S. S.; Zakharov, S. V.; Kuryashov, D. A.; Bashkirtseva, N. Y.; Zakharova, L. Y.; Latypov, S. K.; Sinyashin, O. G. Mendeleev Commun. 2015, 25, 174–176. doi:10.1016/j.mencom.2015.05.004 |

| 50. | Bogdanov, A. V.; Pashirova, T. N.; Musin, L. I.; Krivolapov, D. B.; Zakharova, L. Y.; Mironov, V. F.; Konovalov, A. I. Chem. Phys. Lett. 2014, 594, 69–73. doi:10.1016/j.cplett.2014.01.026 |

| 71. | Ren, Y.; Hiszpanski, A. M.; Whittaker-Brooks, L.; Loo, Y.-L. ACS Appl. Mater. Interfaces 2014, 6, 14533–14542. doi:10.1021/am503812f |

| 50. | Bogdanov, A. V.; Pashirova, T. N.; Musin, L. I.; Krivolapov, D. B.; Zakharova, L. Y.; Mironov, V. F.; Konovalov, A. I. Chem. Phys. Lett. 2014, 594, 69–73. doi:10.1016/j.cplett.2014.01.026 |

| 80. | Derome, A. E. Modern NMR Techniques for Chemistry Research; Pergamon, 1988. |

| 81. | Stott, K.; Stonehouse, J.; Keeler, J.; Hwang, T.-L.; Shaka, A. J. J. Am. Chem. Soc. 1995, 117, 4199–4200. doi:10.1021/ja00119a048 |

| 77. | Sun, Z.; Nicolosi, V.; Rickard, D.; Bergin, S. D.; Aherne, D.; Coleman, J. N. J. Phys. Chem. C 2008, 112, 10692–10699. doi:10.1021/jp8021634 |

| 78. | Gharibi, H.; Moosavi-Movahedi, Z.; Javadian, S.; Nazari, K.; Moosavi-Movahedi, A. A. J. Phys. Chem. B 2011, 115, 4671–4679. doi:10.1021/jp112051t |

| 79. | Gordon, A.; Ford, R. The Chemist’s Companion. A Handbook of Practical Data, Techniques, and Reference; J. Wiley & Sons, 1972. |

| 74. | Mahajan, S.; Mahajan, R. K. Adv. Colloid Interface Sci. 2013, 199–200, 1–14. doi:10.1016/j.cis.2013.06.008 |

| 76. | Bhattacharya, S.; Biswas, J. Langmuir 2010, 26, 4642–4654. doi:10.1021/la9011718 |

| 72. | Williams, H. D.; Trevaskis, N. L.; Charman, S. A.; Shanker, R. M.; Charman, W. N.; Pouton, C. W.; Porter, C. J. H. Pharmacol. Rev. 2013, 65, 315–499. doi:10.1124/pr.112.005660 |

| 73. | Reddy, L. H.; Bazile, D. Adv. Drug Delivery Rev. 2014, 71, 34–57. doi:10.1016/j.addr.2013.10.007 |

| 74. | Mahajan, S.; Mahajan, R. K. Adv. Colloid Interface Sci. 2013, 199–200, 1–14. doi:10.1016/j.cis.2013.06.008 |

| 75. | Noori, S.; Naqvi, A. Z.; Ansari, W. H.; Kabir-ud-Din. Colloids Surf., B 2014, 115, 71–78. doi:10.1016/j.colsurfb.2013.11.023 |

| 82. | Latypov, S.; Balandina, A.; Boccalini, M.; Matteucci, A.; Usachev, K.; Chimichi, S. Eur. J. Org. Chem. 2008, 4640–4646. doi:10.1002/ejoc.200800550 |

| 1. | Kar, H.; Gehrig, D. W.; Laquai, F.; Ghosh, S. Nanoscale 2015, 7, 6729–6736. doi:10.1039/C5NR00483G |

| 2. | Squillaci, M. A.; Ferlauto, L.; Zagranyarski, Y.; Milita, S.; Müllen, K.; Samorì, P. Adv. Mater. 2015, 27, 3170–3174. doi:10.1002/adma.201500940 |

| 3. | Jung, E. H.; Bae, S.; Yoo, T. W.; Jo, W. H. Polym. Chem. 2014, 5, 6545–6550. doi:10.1039/C4PY00791C |

| 4. | Yan, Q.; Luo, Z.; Cai, K.; Ma, Y.; Zhao, D. Chem. Soc. Rev. 2014, 43, 4199–4221. doi:10.1039/c3cs60375j |

| 5. | Ho, C.-C.; Chen, C.-A.; Chang, C.-Y.; Darling, S. B.; Su, W.-F. J. Mater. Chem. A 2014, 2, 8026–8032. doi:10.1039/C4TA01083C |

| 12. | Pakravan, P.; Kashanian, S.; Khodaei, M. M.; Harding, F. J. Pharmacol. Rep. 2013, 65, 313–335. doi:10.1016/S1734-1140(13)71007-7 |

| 13. | Ray, D.; Paul, B. K.; Guchhait, N. J. Photochem. Photobiol., B 2013, 127, 18–27. doi:10.1016/j.jphotobiol.2013.06.016 |

| 14. | Prakash, C.; Raja, S. Mini-Rev. Med. Chem. 2012, 12, 98–119. doi:10.2174/138955712798995039 |

| 15. | Wee, X. K.; Yang, T.; Go, M. L. ChemMedChem 2012, 7, 777–791. doi:10.1002/cmdc.201200018 |

| 16. | Marko, D.; Schätzle, S.; Friedel, A.; Genzlinger, A.; Zankl, H.; Meijer, L.; Eisenbrand, G. Br. J. Cancer 2001, 84, 283–289. doi:10.1054/bjoc.2000.1546 |

| 17. | Moon, M. J.; Lee, S. K.; Lee, J.-W.; Song, W. K.; Kim, S. W.; Kim, J. I.; Cho, C.; Choi, S. J.; Kim, Y.-C. Bioorg. Med. Chem. 2006, 14, 237–246. doi:10.1016/j.bmc.2005.08.008 |

| 18. | Damiens, E.; Baratte, B.; Marie, D.; Eisenbrand, G.; Meijer, L. Oncogene 2001, 20, 3786–3797. doi:10.1038/sj.onc.1204503 |

| 19. | Myrianthopoulos, V.; Magiatis, P.; Ferandin, Y.; Skaltsounis, A.-L.; Meijer, L.; Mikros, E. J. Med. Chem. 2007, 50, 4027–4037. doi:10.1021/jm070077z |

| 20. | Klein, L. L.; Petukhova, V.; Wan, B.; Wang, Y.; Santasiero, B. D.; Lankin, D. C.; Pauli, G. F.; Franzblau, S. G. Bioorg. Med. Chem. Lett. 2014, 24, 268–270. doi:10.1016/j.bmcl.2013.11.024 |

| 21. | Bogdanov, A. V.; Musin, L. I.; Mironov, V. F. ARKIVOC 2015, vi, 362–392. doi:10.3998/ark.5550190.p009.090 |

| 41. | Lin, R.; Cui, H. Curr. Opin. Chem. Eng. 2015, 7, 75–83. doi:10.1016/j.coche.2014.11.005 |

| 10. | Brinkmann, J.; Cavatorta, E.; Sankaran, S.; Schmidt, B.; van Weerd, J.; Jonkheijm, P. Chem. Soc. Rev. 2014, 43, 4449–4469. doi:10.1039/C4CS00034J |

| 11. | Xia, Y.; Peng, L. Chem. Rev. 2013, 113, 7880–7929. doi:10.1021/cr300419p |

| 42. | Saad, W. S.; Prud’homme, R. K. Nano Today 2016, 11, 212–227. doi:10.1016/j.nantod.2016.04.006 |

| 9. | Viseu, M. I.; Tatikolov, A. S.; Correia, R. F.; Costa, S. M. B. J. Photochem. Photobiol., A 2014, 280, 54–62. doi:10.1016/j.jphotochem.2014.02.007 |

| 36. | Kleeblatt, D.; Siyo, B.; Hein, M.; Iaroshenko, V. O.; Iqbal, J.; Villinger, A.; Langer, P. Org. Biomol. Chem. 2013, 11, 886–895. doi:10.1039/c2ob25866h |

| 37. | Sassatelli, M.; Bouchikhi, F.; Messaoudi, S.; Anizon, F.; Debiton, E.; Barthomeuf, C.; Prudhomme, M.; Moreau, P. Eur. J. Med. Chem. 2006, 41, 88–100. doi:10.1016/j.ejmech.2005.10.004 |

| 6. | Jang, B.; Kwon, H.; Katila, P.; Lee, S. J.; Lee, H. Adv. Drug Delivery Rev. 2016, 98, 113–133. doi:10.1016/j.addr.2015.10.023 |

| 7. | Khemthongcharoen, N.; Jolivot, R.; Rattanavarin, S.; Piyawattanametha, W. Adv. Drug Delivery Rev. 2014, 74, 53–74. doi:10.1016/j.addr.2013.09.012 |

| 8. | Walia, S.; Acharya, A. Beilstein J. Nanotechnol. 2015, 6, 546–558. doi:10.3762/bjnano.6.57 |

| 38. | Ma, W.; Cheetham, A. G.; Cui, H. Nano Today 2016, 11, 13–30. doi:10.1016/j.nantod.2015.11.003 |

| 39. | Fumagalli, G.; Marucci, C.; Christodoulou, M. S.; Stella, B.; Dosio, F.; Passarella, D. Drug Discovery Today 2016, 21, 1321–1329. doi:10.1016/j.drudis.2016.06.018 |

| 40. | Luo, C.; Sun, J.; Sun, B.; He, Z. Trends Pharmacol. Sci. 2014, 35, 556–566. doi:10.1016/j.tips.2014.09.008 |

| 12. | Pakravan, P.; Kashanian, S.; Khodaei, M. M.; Harding, F. J. Pharmacol. Rep. 2013, 65, 313–335. doi:10.1016/S1734-1140(13)71007-7 |

| 13. | Ray, D.; Paul, B. K.; Guchhait, N. J. Photochem. Photobiol., B 2013, 127, 18–27. doi:10.1016/j.jphotobiol.2013.06.016 |

| 33. | Kashanian, S.; Khodaei, M. M.; Pakravan, P.; Adibi, H. Mol. Biol. Rep. 2012, 39, 3853–3861. doi:10.1007/s11033-011-1164-9 |

| 25. | Rane, R. A.; Karunanidhi, S.; Jain, K.; Shaikh, M.; Hampannavar, G.; Karpoormath, R. Curr. Top. Med. Chem. 2016, 16, 1262–1289. doi:10.2174/1568026615666150915112334 |

| 26. | Medvedev, A.; Buneeva, O.; Glover, V. Biol.: Targets Ther. 2007, 1, 151–162. |

| 34. | Kashanian, S.; Khodaei, M. M.; Pakravan, P. DNA Cell Biol. 2010, 29, 639–646. doi:10.1089/dna.2010.1054 |

| 35. | Gusakov, A. V.; Sinitsyn, A. P.; Markov, A. V.; Sinitsyna, O. A.; Ankudimova, N. V.; Berlin, A. G. J. Biotechnol. 2001, 87, 83–90. doi:10.1016/S0168-1656(01)00234-6 |

| 23. | Thanh, N. D.; Giang, N. T. K.; Quyen, T. H.; Huong, D. T.; Toan, V. N. Eur. J. Med. Chem. 2016, 123, 532–543. doi:10.1016/j.ejmech.2016.07.074 |

| 24. | Chohan, Z. H.; Pervez, H.; Rauf, A.; Khan, K. M.; Supuran, C. T. J. Enzyme Inhib. Med. Chem. 2004, 19, 417–423. doi:10.1080/14756360410001710383 |

| 84. | Pashirova, T. N.; Lukashenko, S. S.; Zakharov, S. V.; Voloshina, A. D.; Zhiltsova, E. P.; Zobov, V. V.; Souto, E. B.; Zakharova, L. Y. Colloids Surf., B 2015, 127, 266–273. doi:10.1016/j.colsurfb.2015.01.044 |

| 12. | Pakravan, P.; Kashanian, S.; Khodaei, M. M.; Harding, F. J. Pharmacol. Rep. 2013, 65, 313–335. doi:10.1016/S1734-1140(13)71007-7 |

| 22. | Farag, A. A. Drug Res. (Stuttgart, Ger.) 2015, 65, 373–379. doi:10.1055/s-0034-1384609 |

| 28. | Saleh, A. M.; Al-As'ad, R. M.; El-Abadelah, M. M.; Sabri, S. S.; Zahra, J. A.; Alaskar, A. S.; Aljada, A. Molecules 2014, 19, 13076–13092. doi:10.3390/molecules190913076 |

| 29. | Saleh, A. M.; El-Abadelah, M. M.; Aziz, M. A.; Taha, M. O.; Nasr, A.; Rizvi, S. A. A. Cancer Lett. 2015, 361, 251–261. doi:10.1016/j.canlet.2015.03.013 |

| 30. | Xiao, Z.; Hao, Y.; Liu, B.; Qian, L. Leuk. Lymphoma 2002, 43, 1763–1768. doi:10.1080/1042819021000006295 |

| 31. | Xiao, Z.; Qian, L.; Liu, B.; Hao, Y. Br. J. Haematol. 2000, 111, 711–712. doi:10.1046/j.1365-2141.2000.02357.x |

| 32. | Chen, F.; Li, L.; Ma, D.; Yan, S.; Sun, J.; Zhang, M.; Ji, C.; Hou, M. Leuk. Res. 2010, 34, e75–e77. doi:10.1016/j.leukres.2009.09.001 |

| 46. | Das, A.; Ghosh, S. Chem. Commun. 2016, 52, 6860–6872. doi:10.1039/C6CC01983H |

| 47. | Sikder, A.; Das, A.; Ghosh, S. Angew. Chem., Int. Ed. 2015, 54, 6755–6760. doi:10.1002/anie.201500971 |

| 48. | Shankar, B. H.; Jayaram, D. T.; Ramaiah, D. Chem. – Eur. J. 2015, 21, 17657–17663. doi:10.1002/chem.201502955 |

| 43. | Su, H.; Koo, J. M.; Cui, H. J. Controlled Release 2015, 219, 383–395. doi:10.1016/j.jconrel.2015.09.056 |

| 44. | Molla, M. R.; Ghosh, S. Phys. Chem. Chem. Phys. 2014, 16, 26672–26683. doi:10.1039/C4CP03791J |

| 45. | Hill, J. P.; Shrestha, L. K.; Ishihara, S.; Ji, Q.; Ariga, K. Molecules 2014, 19, 8589–8609. doi:10.3390/molecules19068589 |

| 58. | Zhu, Z. Biomaterials 2013, 34, 10238–10248. doi:10.1016/j.biomaterials.2013.09.015 |

| 59. | Tong, R.; Yala, L.; Fan, T. M.; Cheng, J. Biomaterials 2010, 31, 3043–3053. doi:10.1016/j.biomaterials.2010.01.009 |

| 42. | Saad, W. S.; Prud’homme, R. K. Nano Today 2016, 11, 212–227. doi:10.1016/j.nantod.2016.04.006 |

| 55. | Karnik, R.; Gu, F.; Basto, P.; Cannizzaro, C.; Dean, L.; Kyei-Manu, W.; Langer, R.; Farokhzad, O. C. Nano Lett. 2008, 8, 2906–2912. doi:10.1021/nl801736q |

| 56. | Mora-Huertas, C. E.; Fessi, H.; Elaissari, A. Int. J. Pharm. 2010, 385, 113–142. doi:10.1016/j.ijpharm.2009.10.018 |

| 57. | Bilati, U.; Allémann, E.; Doelker, E. Eur. J. Pharm. Sci. 2005, 24, 67–75. doi:10.1016/j.ejps.2004.09.011 |

| 51. | Soussan, E.; Cassel, S.; Blanzat, M.; Rico-Lattes, I. Angew. Chem., Int. Ed. 2009, 48, 274–288. doi:10.1002/anie.200802453 |

| 52. | Kumar, A.; Chen, F.; Mozhi, A.; Zhang, X.; Zhao, Y.; Xue, X.; Hao, Y.; Zhang, X.; Wang, P. C.; Liang, X.-J. Nanoscale 2013, 5, 8307–8325. doi:10.1039/c3nr01525d |

| 53. | Verma, G.; Hassan, P. A. Phys. Chem. Chem. Phys. 2013, 15, 17016–17028. doi:10.1039/c3cp51207j |

| 54. | Liang, Y.; Deng, X.; Zhang, L.; Peng, X.; Gao, W.; Cao, J.; Gu, Z.; He, B. Biomaterials 2015, 71, 1–10. doi:10.1016/j.biomaterials.2015.08.032 |

| 49. | Lock, L. L.; LaComb, M.; Schwarz, K.; Cheetham, A. G.; Lin, Y.-a.; Zhang, P.; Cui, H. Faraday Discuss. 2013, 166, 285–301. doi:10.1039/c3fd00099k |

| 50. | Bogdanov, A. V.; Pashirova, T. N.; Musin, L. I.; Krivolapov, D. B.; Zakharova, L. Y.; Mironov, V. F.; Konovalov, A. I. Chem. Phys. Lett. 2014, 594, 69–73. doi:10.1016/j.cplett.2014.01.026 |

© 2017 Pashirova et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Nanotechnology terms and conditions: (http://www.beilstein-journals.org/bjnano)