Search results

Search for "annealing" in Full Text gives 460 result(s) in Beilstein Journal of Nanotechnology. Showing first 200.

Imaging the surface potential at the steps on the rutile TiO2(110) surface by Kelvin probe force microscopy

Beilstein J. Nanotechnol. 2019, 10, 1228–1236, doi:10.3762/bjnano.10.122

- (1 keV, 6.7 × 10−7 mbar, 5 min) and annealing (600 K, less than 2.7 × 10−10 mbar, 20 min) to remove the native oxide layer and other contaminants. A clean rutile TiO2(110) crystal (provided by Furuuchi Chemical Corporation) was prepared by dozens of cycles of Ar+ sputtering (1 keV, 1.3 × 10−6 mbar

- , 10 min) and annealing (993 K, less than 2.7 × 10−10 mbar, 30 min). After the surface preparation, the color of the surface became the dark-blue, which implies that TiO2 is in a highly reduced state [2]. After cooling to room temperature, the sample was exposed to O2 (300 K, less than 2.7 × 10−9 mbar

Pure and mixed ordered monolayers of tetracyano-2,6-naphthoquinodimethane and hexathiapentacene on the Ag(100) surface

Beilstein J. Nanotechnol. 2019, 10, 1188–1199, doi:10.3762/bjnano.10.118

- Metrology, Denmark). The correction was done such that the unit cell of the periodic structures fitted to the unit cell determined by LEED. All experiments were performed on the same Ag(100) single crystal, which was prepared by cycles of Ar+ ion sputtering at 800 eV for 30 min and annealing at 800–900 K

- the intermolecular interactions in the multilayers, too. Mixed HTPEN/TNAP monolayer When about equal amounts of both molecules were deposited, we immediately observed a LEED pattern that differs from the two LEED patterns of the pure layers (Figure 6a). No additional annealing step was required, and

Quantitative analysis of annealing-induced instabilities of photo-leakage current and negative-bias-illumination-stress in a-InGaZnO thin-film transistors

Beilstein J. Nanotechnol. 2019, 10, 1125–1130, doi:10.3762/bjnano.10.112

- , China School of Environmental Science and Engineering, Kochi University of Technology, Kami, Kochi 782-8502, Japan Center for Nanotechnology in Research Institute, Kochi University of Technology, Kami, Kochi 782-8502, Japan 10.3762/bjnano.10.112 Abstract This study examines the effect of the annealing

- bulk, whereas high-temperature annealing causes a quality degradation of the adjacent interfaces. Light of short wavelengths below 460 nm induces defect generation in the forward measurement and the leakage current increases in the reverse measurement, especially for the low-temperature-annealed device

- irrespective of treatment temperature. NBIS-induced critical instability occurs in the high-temperature-annealed TFT. Keywords: metal oxide; photo-induced instabilities; photon energy; thermal annealing; thin-film transistor (TFT) device; Introduction The rapid process of industrialization and

Synthesis and characterization of quaternary La(Sr)S–TaS2 misfit-layered nanotubes

Beilstein J. Nanotechnol. 2019, 10, 1112–1124, doi:10.3762/bjnano.10.111

- (Sigma-Aldrich Chemicals 99.99%). The mixtures were mechanically ground under inert atmosphere in a glove box and charged into quartz ampoules. The ampoules were evacuated and sealed under a vacuum on the order of 1 × 10−5 Torr and placed in a preheated two-zone vertical furnace. The annealing was

Structural and optical properties of penicillamine-protected gold nanocluster fractions separated by sequential size-selective fractionation

Beilstein J. Nanotechnol. 2019, 10, 955–966, doi:10.3762/bjnano.10.96

- of the AuNCs can be improved to some extent by changing the ratio of the initial reactants (Au and ligand) and the synthesis conditions, or by other means such as heating [9], etching [10], and annealing [11], these methods are difficult to precisely control the size of the products. In addition, for

Comparing a porphyrin- and a coumarin-based dye adsorbed on NiO(001)

Beilstein J. Nanotechnol. 2019, 10, 874–881, doi:10.3762/bjnano.10.88

- cleavage and annealing. The surface shows extended terraces separated by monoatomic steps that are 210 pm in height. Additionally, some line-shaped defects are observed all over the terraces. These defects, thought to be due to segregation of bulk impurities, were not further investigated in the present

- (001) surface was prepared by in situ cleavage with prior and subsequent annealing (at 600 °C and 500 °C, respectively) resulting in an atomically clean surface. Molecules were then thermally evaporated, from commercially available molecular powders, at RT and under UHV conditions (p < 1 × 10−10 mbar

Novel reversibly switchable wettability of superhydrophobic–superhydrophilic surfaces induced by charge injection and heating

Beilstein J. Nanotechnol. 2019, 10, 840–847, doi:10.3762/bjnano.10.84

- angle of 0°), and the reverse process took only 30 s. Esmeryan et al. [12] revealed collapsed superhydrophobicity and conversion to superhydrophilicity upon thermal annealing of the coating at temperatures above 300 °C. Lai et al. [13] prepared a uniform and stable TiO2-based nanoband film by

On the transformation of “zincone”-like into porous ZnO thin films from sub-saturated plasma enhanced atomic layer deposition

Beilstein J. Nanotechnol. 2019, 10, 746–759, doi:10.3762/bjnano.10.74

- /bjnano.10.74 Abstract The synthesis of nanoporous ZnO thin films is achieved through annealing of zinc-alkoxide (“zincone”-like) layers obtained by plasma-enhanced atomic layer deposition (PE-ALD). The zincone-like layers are deposited through sub-saturated PE-ALD adopting diethylzinc and O2 plasma with

- , development of controlled porosity, and formation and growth of ZnO crystallites. The layers developed controlled nanoporosity in the range of 1–5%, with pore sizes between 0.27 and 2.00 nm as measured with ellipsometric porosimetry (EP), as a function of the plasma dose and post-annealing temperature

- content of mesopores were found to decrease with the post-deposition annealing temperature, which was attributed to clogging of the pores upon growth of ZnO crystals at relatively low temperatures. Thermogravimetric analyses were performed on the layers as a function of the post-deposition treatment up to

Features and advantages of flexible silicon nanowires for SERS applications

Beilstein J. Nanotechnol. 2019, 10, 725–734, doi:10.3762/bjnano.10.72

- ]. In short, Si wafers (<100> orientation, 5–10 Ω·cm resistivity, p-type) were cleaned following the standard RCA (Radio Corporation of America) cleaning processes [24], followed by Au sputtering in a Polaron E5000 sputter coater at ca. 5·10−4 mbar work pressure. Prior to VLS synthesis, annealing in

- vacuum for one hour at temperatures from 480–560 °C was performed. In the VLS process, 26% SiH4 diluted in Ar with 270 sccm flow rate was deposited for 1 h. In each experiment, the annealing temperature was the same as the VLS process temperature. The Ag nanoparticle decoration of the horizontal SiNWs

- signal significantly increases after washing with water. The first observation can be clearly explained as follows: The temperature during annealing prior to VLS synthesis influences the size and distribution of the Au seeds on the Si wafer, while the VLS process temperature determines growth rate and

Enhancement in thermoelectric properties due to Ag nanoparticles incorporated in Bi2Te3 matrix

Beilstein J. Nanotechnol. 2019, 10, 634–643, doi:10.3762/bjnano.10.63

- how different annealing temperatures lead to the different sizes and shapes of nanoparticles with different influence on thermoelectric properties. We have used different amounts of Ag microparticles (0, 2. 5, 10, 15 and 20 wt %) uniformly mixed with commercially purchased Bi2Te3, which was annealed

- powder mixtures were well grinded and pressed to pellets. These pellets were then annealed at 573 or 773 K for 1 h under Ar atmosphere. Annealing temperatures were chosen to be below the melting point of Bi2Te3 (586 °C) and above the melting points of Bi (271 °C) and Te (449 °C). These samples were

- ) planes, respectively (JCPDS 38-0420). At Ag concentrations of 5% and 20% in Bi2Te3 after 773 K annealing, all peaks are at the same positions. In samples with 5 and 20% Ag, annealed at 573 K, two peaks at 2θ = 37.98° and 44.58° matching the (1 1 1) and (2 0 0) planes of cubic with Ag (JCPDS-04-0783

Widening of the electroactivity potential range by composite formation – capacitive properties of TiO2/BiVO4/PEDOT:PSS electrodes in contact with an aqueous electrolyte

Beilstein J. Nanotechnol. 2019, 10, 483–493, doi:10.3762/bjnano.10.49

- annealing) or titanium foil. The bismuth vanadate films were deposited for 20 min and the PLD process was carried out using a Nd:YAG laser equipped with a fourth harmonic generation (FHG) module, generating 266 nm 6 ns pulses with 4 Hz repetition. Assuming that the obtained layer is flat and continuous, its

Temperature-dependent Raman spectroscopy and sensor applications of PtSe2 nanosheets synthesized by wet chemistry

Beilstein J. Nanotechnol. 2019, 10, 467–474, doi:10.3762/bjnano.10.46

- method used to grow PtSe2 nanosheets followed by thermal annealing. The SEM and TEM analysis confirms the formation of PtSe2 nanosheets. Furthermore, XRD, Raman, XPS and SAED patterns were used to analyze the crystal structure and to confirm the formation of the PtSe2 phase. The temperature-dependent

- chemical method [25] at 90 °C using chloroplatinic acid (H2PtCl6) and Se powder as precursors followed by thermal annealing at 500 °C. Temperature-dependent Raman spectroscopic characterization was carried out on the materials. Materials and Methods All the chemicals such as chloroplatinic acid, Se powder

- , hexamethylenetetramine, and NaBH4 were purchased from Sigma-Aldrich for the synthesis of PtSe2 nanosheets. Synthesis method The PtSe2 nanosheets were synthesized using a solvothermal method followed by annealing at 500 °C using a previously described method for PtSe2 synthesis [25]. The PtSe2 material was prepared in

Improving control of carbide-derived carbon microstructure by immobilization of a transition-metal catalyst within the shell of carbide/carbon core–shell structures

Beilstein J. Nanotechnol. 2019, 10, 419–427, doi:10.3762/bjnano.10.41

- carbide (chlorination) and subsequent carbon surface annealing. Nickel chloride hexahydrate (99.95% purity, Alfa Aesar) was used as precursor of the Ni catalyst. Synthesis of carbon shell/carbide core starting material The synthesis of hybrid particles where carbide cores are covered with a porous carbon

- , 1 mol·m−3 chlorine and 3 h reaction time. To remove residual chlorine, an annealing treatment using hydrogen (0.5 mol·m−3) again was carried out after the extractive reaction. The nomenclature of the final carbon material obtained is “CDC” followed by “Ni” and catalyst loading. For instance, CDC

Integration of LaMnO3+δ films on platinized silicon substrates for resistive switching applications by PI-MOCVD

Beilstein J. Nanotechnol. 2019, 10, 389–398, doi:10.3762/bjnano.10.38

- deposition time (controlled number of pulses). Several deposition temperatures in the range of 650–700 °C were tested. (II) Single-step strategy with annealing: The heating and deposition procedure was the same as described in strategy I, but adjusting the deposition temperature between 660 and 680 °C. Once

- the injection was completed, an additional thermal treatment at 500 °C was performed. The samples were let to cool down to the post-deposition annealing temperature at a rate of 10 °C/min. At this temperature the environment was modified (i.e., annealing in oxygen) and the temperature was held for 1 h

- higher δ values in the LMO film by adding a post-deposition annealing step. LMO films were grown following strategy II (represented in Figure 2 by blue triangles) respecting the same critical limits established from strategy I. It was proved that despite the addition of a thermal annealing at 500 °C for

Effects of post-lithography cleaning on the yield and performance of CVD graphene-based devices

Beilstein J. Nanotechnol. 2019, 10, 349–355, doi:10.3762/bjnano.10.34

- a NMP bath. In the second cleaning method (C2), we used N,N-dimethylformamide (DMF) to clean the graphene devices. Finally, a third method (C3) consisted of graphene cleaning by H2/Ar (1:1) annealing at 300 °C for 2 h [17][18]. Nonetheless, we have observed that both cleaning methods C1 and C2

- and cleaned with NMP (Figure 3d) and DMF (Figure 3e) present the same features associated to the PMGI polymer. Regarding the H2/Ar annealing, Figure 3f shows that this process did not remove the residual PMGI polymer completely from the graphene surface, because some Raman bands associated with the

- mobility of the C1 graphene devices. Finally, Raman characterization shows that DMF (Figure 4e) and H2/Ar annealing (Figure 4f) are not efficient in removing PMGI molecules from the graphene surface. Otherwise, these cleaning methods introduce lattice defects in graphene, which increase the value of nd

Intuitive human interface to a scanning tunnelling microscope: observation of parity oscillations for a single atomic chain

Beilstein J. Nanotechnol. 2019, 10, 337–348, doi:10.3762/bjnano.10.33

- refer to as point contact pushing (PCP) technique. Keywords: adatom imaging; mechanical annealing; scanning tunnelling microscopy (STM); STM tip; tip apex; Introduction It is of fundamental interest both for chemists and physicists to study the electronic transport through single atoms and molecules

- annealing cycles to obtain an atomically flat Au(111) facet showing herringbone surface reconstruction. We further prepare the surface at low temperature by creating a localized stress pattern [11][12][13][14] on the surface using gentle indentation of the STM tip at a spot on the surface remote from the

- preparing a crystalline tip apex up to the second atomic layer from the apex atom. In this method mechanical annealing cycles are used to achieve a more regular atomic packing. Furthermore, by imaging an adatom placed above a smooth Au surface the structure of the tip apex is imaged, and a smooth and

Development of an anti-pollution coating process technology for the application of an on-site PV module

Beilstein J. Nanotechnol. 2019, 10, 332–336, doi:10.3762/bjnano.10.32

- Engineering and Biotechnology, Hanbat National University, Daejeon 34158, Republic of Korea 10.3762/bjnano.10.32 Abstract This study aimed to apply annealing processes during the coating of photovoltaic (PV) module glasses to PV modules already installed through an easy and simple procedure. Three types of

- annealing treatments were applied to PV module glasses, i.e., furnace, rapid thermal annealing (RTA) and torch. Among these, torch annealing, which can be easily carried out at PV module installation sites, was applied to PV module glasses using different numbers of repetition. Light transmittance, contact

- angle, anti-pollution characteristics, adhesion and hardness of the functional coating films after using different annealing treatment times and methods were measured, and it was confirmed that these characteristics varied depending on the annealing treatment times and methods. Through this, it was

Geometrical optimisation of core–shell nanowire arrays for enhanced absorption in thin crystalline silicon heterojunction solar cells

Beilstein J. Nanotechnol. 2019, 10, 322–331, doi:10.3762/bjnano.10.31

- 20 keV. Oxidation and annealing were carried out in dry ambient at 850 °C for 90 min, resulting in a sheet resistance RSH of 60 Ω/square. Before depositing the coating layers, the silicon wafer with nanowires on top was treated with diluted hydrofluoric acid, to remove the thin native oxide layer

Nitrous oxide as an effective AFM tip functionalization: a comparative study

Beilstein J. Nanotechnol. 2019, 10, 315–321, doi:10.3762/bjnano.10.30

- ) was cleaned by repeated cycles of sputtering (1 keV) and subsequent annealing to 600 °C. FePc molecules (Sigma Aldrich, evaporation temperature ca. 250 °C) were directly evaporated onto a clean Au(111) surface at room temperature. N2O was adsorbed onto the Au(111) surface at temperatures below 12 K

Raman study of flash-lamp annealed aqueous Cu2ZnSnS4 nanocrystals

Beilstein J. Nanotechnol. 2019, 10, 222–227, doi:10.3762/bjnano.10.20

- University of Technology, 09107 Chemnitz, Germany L. V. Pysarzhevsky Institute of Physical Chemistry, National Academy of Sciences of Ukraine, Kyiv, 03028, Ukraine 10.3762/bjnano.10.20 Abstract The effect of flash-lamp annealing (FLA) on the re-crystallization of thin films made of colloidal Cu2ZnSnS4

- importance. The technologies of rapid annealing by thermal heating or intensive pulsed light radiation turned out to be very promising [14][15][16]. The effectiveness of the method of flash-lamp annealing (FLA) was demonstrated for various compounds, including quaternary metal chalcogenides [17][18]. The

- size of 35 nm. The effect of annealing was investigated only up to an energy density of 11.6 J/cm2 and possible influences of NC film thickness and ambient atmosphere were not considered. In this work, we investigated the effect of FLA on CZTS NCs synthesized under mild conditions, namely at 80 °C in

Uniform Sb2S3 optical coatings by chemical spray method

Beilstein J. Nanotechnol. 2019, 10, 198–210, doi:10.3762/bjnano.10.18

- pyrolysis in air by tuning of the deposition temperature, the Sb/S precursor molar ratio in the spray solution, and the post-deposition treatment temperature. Keywords: antimony sulfide; thin films; ultrasonic spray; vacuum annealing; Volmer–Weber growth; Introduction Antimony sulfide (Sb2S3) is an

- /S 1:3 Sb2S3 layers, as the crystallite size increases after vacuum annealing at 170 °C from 19 ± 8 nm to 100 ± 23 nm by raising TD from 200 to 220 °C. The crystallite size in Sb/S 1:6 Sb2S3 layers (42 ± 15 nm) does not change significantly with TD or vacuum treatment. Furthermore, vacuum treatment

Zn/F-doped tin oxide nanoparticles synthesized by laser pyrolysis: structural and optical properties

Beilstein J. Nanotechnol. 2019, 10, 9–21, doi:10.3762/bjnano.10.2

- .) antimony by spray pyrolysis [9] or by sol–gel methods followed by spin-coating and annealing in different environments [10], ii.) manganese by long-time annealing of Mn/SnO2 bilayers in air at 200 °C [11] or by co-precipitation [12], iii.) aluminum, copper or indium all by spray pyrolysis from ethanolic

- solutions [13] and iv.) iron by laser pyrolysis [14][15] or by electron beam evaporation [16]. Cobalt-doped tin oxide has also been reported, and the resulting polycrystalline films were prepared by spin-coating and annealing from chloride ethanolic solutions resulted in lower bandgap values than pure SnO2

- bandgap values were shown to increase with the vacuum annealing treatment temperature (from 3.41 eV at 300 °C to 3.60 eV at 600 °C), where the amorphous to crystalline conversion was observed only at 600 °C, accompanied by an almost complete fluorine loss [33]. Results and Discussion Structural properties

Characterization and influence of hydroxyapatite nanopowders on living cells

Beilstein J. Nanotechnol. 2018, 9, 3079–3094, doi:10.3762/bjnano.9.286

- ; the particle size associated with the controlled reaction time and the annealing of the material at 375 °C slightly negatively influenced the interaction with cells, but no toxic effect was observed. Most of the materials induced cell growth at low concentration levels. The overdose effect is best

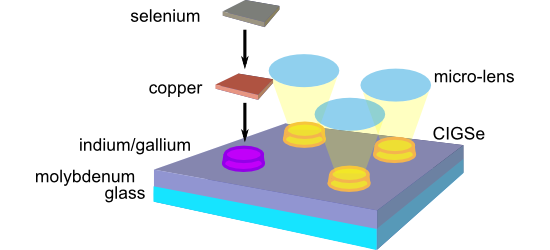

Femtosecond laser-assisted fabrication of chalcopyrite micro-concentrator photovoltaics

Beilstein J. Nanotechnol. 2018, 9, 3025–3038, doi:10.3762/bjnano.9.281

- pressure for CISe samples from the nucleation approach and all samples from the LIFT approach, or in an ultrahigh-vacuum chamber with a directed selenium beam for CIGSe samples from the nucleation approach. In both cases, the temperature protocol comprised an annealing step at around 200–250 °C followed by

Hydrogen-induced plasticity in nanoporous palladium

Beilstein J. Nanotechnol. 2018, 9, 3013–3024, doi:10.3762/bjnano.9.280

- consequently a homogeneous single-phase alloy. The produced alloy drop was thinned to a platelet (4–5 mm in height) using a screw press. Homogeneity of the alloy was confirmed by XRD-measurements. Further processing consisted of several consecutive rolling and annealing steps until a thickness of 270 μm was

- reached. The annealing steps were conducted in a vacuum furnace at 700 °C and 10−5 mbar for 1 h. The resulting foil was cut into squares of 5 × 5 mm2. Dealloying The setup used for in situ dilatometry during electrochemical characterisation was similar to that described in an earlier work of our group [17