Search results

Search for "melting" in Full Text gives 206 result(s) in Beilstein Journal of Nanotechnology. Showing first 200.

Design and facile synthesis of defect-rich C-MoS2/rGO nanosheets for enhanced lithium–sulfur battery performance

Beilstein J. Nanotechnol. 2019, 10, 2251–2260, doi:10.3762/bjnano.10.217

- verifies the ultrathin nanosheet morphology, as shown in Figure 2b. Due to the addition of amorphous carbon and rGO, the size of C-MoS2/rGO nanosheets obviously becomes smaller, as shown in Figure 2c,d. After melting with elemental sulfur, the MoS2 nanosheets keep the sheet-like morphology as shown in

Nontoxic pyrite iron sulfide nanocrystals as second electron acceptor in PTB7:PC71BM-based organic photovoltaic cells

Beilstein J. Nanotechnol. 2019, 10, 2238–2250, doi:10.3762/bjnano.10.216

- an alternative top electrode, which we attached by free vacuum deposition. The FM is composed of 32.5% Bi, 51% In and 16.5% Sn and is characterized by a melting point of around 62 °C. It was deposited on the active layer/PFN by drop casting (or doctor blade) at low temperature (≈95 °C) and

- . The active area (0.07 cm2) was delimited with Scotch tape. The FM top electrode was deposited (after melting it at 95 °C in a hot plate) on top of the PFN layer by drop casting, using the previously reported procedure [34]. The final device structure is as follows: glass (1.1 mm)/ITO (≈165 nm

Nonlinear absorption and scattering of a single plasmonic nanostructure characterized by x-scan technique

Beilstein J. Nanotechnol. 2019, 10, 2182–2191, doi:10.3762/bjnano.10.211

- signals increases faster than the excitation intensity. This means that the power dependency in this region (slope of output versus input) exceeds linearity. Moreover, we did not observe any melting of the nanoparticles in the measurement range, thus, the x-scan measurement is fully reversible and

BergaCare SmartLipids: commercial lipophilic active concentrates for improved performance of dermal products

Beilstein J. Nanotechnol. 2019, 10, 2152–2162, doi:10.3762/bjnano.10.208

- is very easy by measuring the melting enthalpy using differential scanning calorimetry (DSC). The melting enthalpy of a SmartLipids suspension can be determined before addition to the product, after addition to a gel or a cream and after storage. In case the particles dissolve, e.g., in an oil of a

- cream, the melting enthalpy will decrease. Thus, the physical stability of SmartLipids is easy to analyze and to prove. Chemical stabilization of active agents Classical fluid carriers such as nanoemulsion and liposomes have a limited ability to protect labile lipophilic active agents. Due to the

- melting point of the highest melting lipid, then the active agent is dissolved in the lipid melt and the melt containing the active agent is dispersed in a hot aqueous stabilizer solution (surfactant, polymer) of identical temperature by high-speed stirring to form a coarse emulsion. This pre-emulsion is

Oblique angle deposition of nickel thin films by high-power impulse magnetron sputtering

Beilstein J. Nanotechnol. 2019, 10, 1914–1921, doi:10.3762/bjnano.10.186

- ) conditions analogous with electron beam and thermal evaporation methods. However, at our working gas pressure the mean free path is around 11 mm which is remarkably shorter than target to substrate distance (250 mm). Besides, Elofsson et al. [55] show that the melting point of the deposited materials impacts

- the inclined growth of columns by affecting their surface diffusion. Thus, a variation in β is expected for depositing materials with different melting point. The less tilted grains and the higher thickness uniformity of HiPIMS-deposited films can be explained by a different distribution angle of

Synthesis of nickel/gallium nanoalloys using a dual-source approach in 1-alkyl-3-methylimidazole ionic liquids

Beilstein J. Nanotechnol. 2019, 10, 1754–1767, doi:10.3762/bjnano.10.171

- Ga3+ as well as the low melting point of Ga metal leading to coagulation. During the synthesis of NiGa [42] or PdGa [27] nanoparticles from Ni2+ or Pd2+ precursors, using aminoborane as reducing agent, the formation of a transition-metal hydride was reported as a first step. These hydrides can then

- distribution of 6 ± 1 nm can be assigned to be NiGa nanoparticles. Moreover, the large particles with a size distribution of 90 ± 20 nm can be assigned to be Ga-rich nanoparticles. We suggest that they cannot be pure Ga nanoparticles, because the low melting point of Ga metal of 30 °C, would yield liquid Ga

Upcycling of polyurethane waste by mechanochemistry: synthesis of N-doped porous carbon materials for supercapacitor applications

Beilstein J. Nanotechnol. 2019, 10, 1618–1627, doi:10.3762/bjnano.10.157

- ][4][5]. So far, different recycling techniques have been devised to counteract environmental pollution through accumulation of plastic waste. Especially, the recovery of PE and PP, as well as depolymerization processes for PET and the reprocessing of PVC by crushing and melting in conversion systems

Energy distribution in an ensemble of nanoparticles and its consequences

Beilstein J. Nanotechnol. 2019, 10, 1452–1457, doi:10.3762/bjnano.10.143

- . Therefore, the description of fluctuations has to be expanded. This necessary extension is demonstrated using as an example of melting gold particles at different particle sizes. Figure 1 displays the free enthalpy of the solid and the liquid phase of a 2 nm gold particle in the vicinity of the melting

- . Probability for the transformation of (a) 2 nm and (b) 5 nm diameter gold particles in the vicinity of the melting point. Experimental data for the magnetic noise power of cobalt measured at a frequency of 100 Hz according to Woods et al. [5]. The approximation using Equation 7 was made assuming one normal

Kelvin probe force microscopy of the nanoscale electrical surface potential barrier of metal/semiconductor interfaces in ambient atmosphere

Beilstein J. Nanotechnol. 2019, 10, 1401–1411, doi:10.3762/bjnano.10.138

- optimization of the efficiency of TE materials. Our efforts to prepare separated Mo NPs on the Bi2Se3 surface was not successful. Because Mo has significantly higher melting/boiling points (bulk Mo 2623/4639 °C, bulk Au 1064/2856 °C [47]) dc sputtering yielded homogeneous layers of Mo instead of separated NPs

- ). In the case of Mo the situation is more complex. We were not able to prepare separated Mo 1D particles due to the higher melting temperature of Mo compared to the Au. The thinnest Mo layer led to the highest contrast in the surface contact potential of the NIs (see Figure 7) due to the formation of a

Enhanced inhibition of influenza virus infection by peptide–noble-metal nanoparticle conjugates

Beilstein J. Nanotechnol. 2019, 10, 1038–1047, doi:10.3762/bjnano.10.104

- agarose overlay was prepared by mixing equal volumes of 2% (w/v) of pre-warmed (55 °C) low-melting agarose (Melford Laboratories Ltd, Blideston Road, Ipswich, UK) and the overlay solution (14 mL 10× MEM, 3.7 mL 7.5% (w/v) bovine serum albumin (fraction V, Sigma-Aldrich, UK), 1.4 mL L-glutamine, 2.6 mL 7.5

Outstanding chain-extension effect and high UV resistance of polybutylene succinate containing amino-acid-modified layered double hydroxides

Beilstein J. Nanotechnol. 2019, 10, 684–695, doi:10.3762/bjnano.10.68

- was deleted and a second scan profile was performed by heating from −60 °C to 150 °C at 10 °C min−1. The glass transition temperature (Tg), the melting temperature (Tm) and the enthalpy of fusion (∆Hm) were measured from the second scan. Tg was taken as the midpoint of the heat capacity increment

- layers. The calculated residual masses correspond with the filler loading. The addition of LDHs does not affect the melting temperature Tm which is quite constant at 115–114 °C. A slight decrease can be observed in the crystallization temperature Tc for nanocomposites with LDH/amino acids, from 85 °C

Enhancement in thermoelectric properties due to Ag nanoparticles incorporated in Bi2Te3 matrix

Beilstein J. Nanotechnol. 2019, 10, 634–643, doi:10.3762/bjnano.10.63

- powder mixtures were well grinded and pressed to pellets. These pellets were then annealed at 573 or 773 K for 1 h under Ar atmosphere. Annealing temperatures were chosen to be below the melting point of Bi2Te3 (586 °C) and above the melting points of Bi (271 °C) and Te (449 °C). These samples were

Topochemical engineering of composite hybrid fibers using layered double hydroxides and abietic acid

Beilstein J. Nanotechnol. 2019, 10, 589–605, doi:10.3762/bjnano.10.60

- high melting temperature. These properties can yield improved hydrophobicity and mechanical strength to the fibers. Layered double hydroxides are hydroxylated mixed metal salts (clay minerals) that have unique fascinating three-dimensional structures in which positively and negatively charged ions are

Mechanical and thermodynamic properties of Aβ42, Aβ40, and α-synuclein fibrils: a coarse-grained method to complement experimental studies

Beilstein J. Nanotechnol. 2019, 10, 500–513, doi:10.3762/bjnano.10.51

- preparation of samples with well-ordered Aβ40 or Aβ42 fibrils. In this regard, our CG simulation is an ideal protocol as it enables the calculation of the melting temperatures for well-ordered Aβ fibrils. To assess the thermal stability of the fibril, we compute the probability of finding the protein in the

A Ni(OH)2 nanopetals network for high-performance supercapacitors synthesized by immersing Ni nanofoam in water

Beilstein J. Nanotechnol. 2019, 10, 281–293, doi:10.3762/bjnano.10.27

- 20–30 µm thick) are fabricated by arc melting of the pure metals (99.99 wt %) followed by melt spinning [27][28]. Subsequently the dealloying process, as reported in our previous work [29][30], is carried out in 0.05 M HF solution for 4 h open to air at 298 K to form a Ni nanofoam layer on the MG

Study of silica-based intrinsically emitting nanoparticles produced by an excimer laser

Beilstein J. Nanotechnol. 2019, 10, 211–221, doi:10.3762/bjnano.10.19

- avalanche ionization [14][20]. The feasibility of ablating pure silica has been demonstrated using lasers of different wavelengths and pulse durations ranging from tens of nanoseconds down to hundreds of femtoseconds [15]. It was also proposed that the damage is related to melting, boiling or fracture of

- absorption can induce melting of part of the sample, the quenching is sufficiently fast to avoid the formation of large crystalline regions. The obtained nanoparticles differ in size and are in general larger than a few tens of nanometers. Such dimensions do not represent a relevant issue for some

New micro/mesoporous nanocomposite material from low-cost sources for the efficient removal of aromatic and pathogenic pollutants from water

Beilstein J. Nanotechnol. 2019, 10, 119–131, doi:10.3762/bjnano.10.11

- the form of water, rather than as hydrocarbons or as oxygenated organic compounds [29]. The hydrogen loss could have led to aromatization of the carbon skeleton, and the formation of pores. Some authors suggest that ZnCl2 is very mobile above its melting point (283 °C) which inhibits the formation of

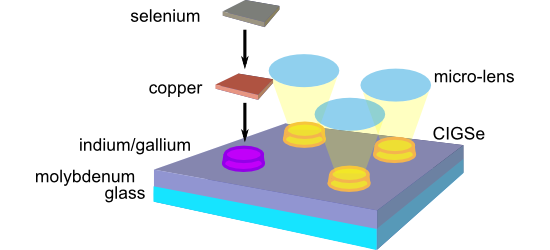

Femtosecond laser-assisted fabrication of chalcopyrite micro-concentrator photovoltaics

Beilstein J. Nanotechnol. 2018, 9, 3025–3038, doi:10.3762/bjnano.9.281

- -induced periodic surface structures (LIPSS [19]) and round melting features form on the glass surface (Figure 5b). The LIPSS with periods in the sub-micrometer range are generated via intra-pulse scattering and interference of the fs-laser radiation at the roughened glass surface, leading to the spatially

- modulated deposition of energy in a shallow near-surface layer and, finally, to periodic material removal [20]. The micrometer-sized melting features supposedly arise from heterogeneities of the glass composition affecting the local optical and thermo-physical properties during the multi-pulse irradiation

- set to 150 µm. Single layers of copper (10–100 nm thickness) or indium (150–1000 nm thickness) as well as combined copper–indium layer stacks (210–1010 nm) were used as donor materials. Copper was first applied by PVD in all layer stacks because it has a significantly higher melting point than indium

Hydrogen-induced plasticity in nanoporous palladium

Beilstein J. Nanotechnol. 2018, 9, 3013–3024, doi:10.3762/bjnano.9.280

- vs Ag/AgCl in 1 M KOH) was determined. Experimental Alloy fabrication A Co75Pd25 master alloy was prepared from Pd granules (AlfaAesar, 99.95%) and Co slug (AlfaAesar, 99.95%) via electron-beam melting. The sample was melted multiple times to ensure complete intermixing in the liquid state and

Co-intercalated layered double hydroxides as thermal and photo-oxidation stabilizers for polypropylene

Beilstein J. Nanotechnol. 2018, 9, 2980–2988, doi:10.3762/bjnano.9.277

- , NaOH, C2H5OH, CH3COCH3, xylene and hexane were directly used as received from Beijing Chemical Co. Limited. Deionized water was employed in all experiments. Polypropylene (PP1300, melting index: 1.5 g/10 min; melting point: 164–170 °C; density: 0.91 g·cm−3), and Irganox 1425 were supplied from Beijing

Variation of the photoluminescence spectrum of InAs/GaAs heterostructures grown by ion-beam deposition

Beilstein J. Nanotechnol. 2018, 9, 2794–2801, doi:10.3762/bjnano.9.261

- container with the batch was carried out by a resistive heater to a temperature above the melting point of GaAs (1250 °C), which is the highest-melting compound. The melt was kept for 10 min under such conditions, then rapid shutdown of the heating elements was followed by crystallization of the initial

Au–Si plasmonic platforms: synthesis, structure and FDTD simulations

Beilstein J. Nanotechnol. 2018, 9, 2599–2608, doi:10.3762/bjnano.9.241

- grow, depending on the phase equilibrium system. The formation of various geometries during eutectic solidification is also possible. In addition, the existence of a eutectic between the substrate, to which a metal in the form of a thin layer is applied, and the metal, significantly reduces the melting

- point of the metal. This is clearly visible in the case of the Au–Si eutectic, which has a melting temperature of ca. 363 °C [1][2][3][4]. It seems that in the case of directional solidification of eutectics as a method of manufacturing of nanostructures, the platforms are homogeneous. Unfortunately, as

- thin films are most often metastable and can dewet or agglomerate with increase of temperature. During annealing of thin films, small fluctuations of the film thickness appear leading to the creation of voids in the film and their subsequent growth. This can happen well below melting temperature of the

Non-agglomerated silicon–organic nanoparticles and their nanocomplexes with oligonucleotides: synthesis and properties

Beilstein J. Nanotechnol. 2018, 9, 2516–2525, doi:10.3762/bjnano.9.234

- size. The melting temperature values for the ODN(2)/ODN(3) duplex in the melting buffer (PBS) in the absence and in the presence of Si–NH2 nanoparticles (Tm = 57.5 ± 0.1 °C and 57.5 ± 0.3 °C, respectively) are equal, i.e., the presence of the nanoparticles does not prevent the duplex formation. At the

- spectrophotometer equipped with a TMSPC-8 instrument (Shimadzu, Japan) for analyzing the melting temperature of the samples. The mixtures of ODN(2) and ODN(3) (10 μL, 30 μM, each) in a PBS buffer (80 μL), pH 7.4, or in water (80 μL) was annealed and gradually heated from 5 °C up to 90 °C and cooled from 90 °C to 5

Surface energy of nanoparticles – influence of particle size and structure

Beilstein J. Nanotechnol. 2018, 9, 2265–2276, doi:10.3762/bjnano.9.211

- glass phase with very different properties. A typical example is demonstrated in Figure 1, which depicts the course of the melting temperature of gold particles on the inverse particle size [11]. Besides the well-known inverse linear dependence according to Pawlow [12] (Range I), Tmelt–bulk − Tmelt–nano

- γ/d, a range where the melting temperature is independent of the particle size (Range II) can also be observed. The experimental error bar also covers the results of other authors. In this range, the particles are glassy, indicating a structure more stable than a crystalline one [13][14]. The

- Fermi–Dirac statistics (e.g., melting, ferromagnetism, diffusion, etc.) and s = 1 for properties related to quasi-particles following the Bose–Einstein statistics (e.g., superconductivity or vibration) [30][31][32]. Karasevskii [33] started with a different approach based on size dependent quantization

Filling nanopipettes with apertures smaller than 50 nm: dynamic microdistillation

Beilstein J. Nanotechnol. 2018, 9, 2181–2187, doi:10.3762/bjnano.9.204

- nanopipette reliably usable in any experimental application. Experimental Nanopipette fabrication The capillaries used are pure silica tubes (quartz tubes) from Sutter (HERAEUS HSQ300) with 1 mm outer diameter and inner diameters of 300, 500 or 700 µm. Due to their high melting temperature, they are pulled

- large-field optical microscope. The filament of 250 µm tantalum wire is 5 mm long and its loop diameter is also about 5 mm. Tantalum was chosen because of its high melting point and its resistance to oxidation. The filament is heated by using the Joule effect at V = 3 V, which means at roughly I = 3.5 A