Search results

Search for "delamination" in Full Text gives 44 result(s) in Beilstein Journal of Nanotechnology.

Beyond the bilayer: multilayered hygroscopic actuation in pine cone scales

Beilstein J. Nanotechnol. 2025, 16, 1695–1710, doi:10.3762/bjnano.16.119

- delamination or cracking [18][19]. Additionally, research concerning the initial cone opening [20] and scale opening orchestration [21] has been conducted, highlighting the functional robustness and resilience [22] of pine cones. A better understanding of the pine cone scale and how its tissue properties and

Bioinspired polypropylene-based functionally graded materials and metamaterials modeling the mistletoe–host interface

Beilstein J. Nanotechnol. 2025, 16, 1592–1606, doi:10.3762/bjnano.16.113

- ], as well as graded porosities [16][46][47], but are mostly not capable of achieving a continuous material gradient. Such a continuous gradient affects the global and local mechanical properties of the sample and prevents the risk of delamination along the interface compared to abrupt material

Synthesis and antibacterial properties of nanosilver-modified cellulose triacetate membranes for seawater desalination

Beilstein J. Nanotechnol. 2025, 16, 1380–1391, doi:10.3762/bjnano.16.100

- reveal delamination, partial loss of PDA microspheres, and Ag nanoparticles, as well as the presence NaCl within the coating (Figure 4g). These observations are attributed to the prolonged exposure to saline water, which causes chemical degradation of the PDA layer. Also, the high ionic strength and

Influence of ion beam current on the structural, optical, and mechanical properties of TiO2 coatings: ion beam-assisted vs conventional electron beam evaporation

Beilstein J. Nanotechnol. 2025, 16, 1097–1112, doi:10.3762/bjnano.16.81

- substrates during deposition. In fact, this contributes to the increased density of the thin films. This increases the resistance to material removal and improves adhesion, which prevents delamination during abrasion. Moreover, the increased energy of ions during deposition led to the formation of a finer

Bioinspired nanofilament coatings for scale reduction on steel

Beilstein J. Nanotechnol. 2025, 16, 25–34, doi:10.3762/bjnano.16.3

- the original value to 146 ± 3°, still at the limit to super-hydrophobicity. To further test the coating stability, we also performed an explosion/decompression test after NACE TM0185, a standardized industry test of coating delamination. Here, the samples are pressurized in the autoclave and the

- pressure is quickly released after 24 hours at 100 °C and 100 bar. The pressure is reduced to 50 bar over a period of five minutes and afterwards the pressure is reduced to ambient pressure over a period of ten minutes. Any blisters or cracks in the coating indicate delamination or mechanical failure. As

- the shear stress test. The coating is still water repelling. (A,B) Photos of the samples before and after the explosion/decompression test. The samples are still intact after the test, no delamination is visible on the samples. (C) SEM image of an SNF surface coating after the decompression/explosion

Beyond biomimicry – next generation applications of bioinspired adhesives from microfluidics to composites

Beilstein J. Nanotechnol. 2024, 15, 965–976, doi:10.3762/bjnano.15.79

- ) simplified modeling of effective bending stiffness as either two parallel non-adhesive sheets or as iii) a bonded sandwich composite structure. (b) Small scale tests show substantial bending stiffness increase as anticipated, but the large hysteresis indicates that internal delamination and plastic behavior

Liquid phase exfoliation of talc: effect of the medium on flake size and shape

Beilstein J. Nanotechnol. 2023, 14, 68–78, doi:10.3762/bjnano.14.8

- materials in an appropriate liquid medium. To exfoliate a material of interest, it must be reduced to a fine powder and mixed with a liquid that serves as an exfoliation medium. The solution is exposed to a mechanical energy source that leads to the delamination of the material, resulting in a suspension of

- leads to delamination of its layers. After exfoliation, the sample is centrifuged to separate non-exfoliated flakes from nanometer-sized flakes, and the supernatant is collected for further analysis. Atomic force microscopy images of the samples produced employing the four different media under

Hydroxyapatite–bioglass nanocomposites: Structural, mechanical, and biological aspects

Beilstein J. Nanotechnol. 2022, 13, 1490–1504, doi:10.3762/bjnano.13.123

- . For composites with plastic-fragile and fragile behavior, the ISE is caused by involving and developing delamination and cracking with increasing load (Figure 6), which leads to the relaxation of stress in the deformation zone and, as a result, to the decrease of hardness. SBF testing and bioactivity

A nonenzymatic reduced graphene oxide-based nanosensor for parathion

Beilstein J. Nanotechnol. 2022, 13, 730–744, doi:10.3762/bjnano.13.65

- transparency due to the exfoliation of stacking layers of GO. This suggests an increased surface area due to delamination of graphene layers (thickness of about one to a few layers) by electrochemical reduction. The high-resolution TEM of ERGO shows a d-spacing of 0.413 nm (Figure 3E), indicating a reduced

Fabrication and testing of polymer microneedles for transdermal drug delivery

Beilstein J. Nanotechnol. 2022, 13, 629–640, doi:10.3762/bjnano.13.55

- power of 100 mW were selected after process optimization to reduce MN fabrication time and delamination from the substrate. GWL files are then imported to NanoWrite software (Nanoscribe GmbH, Karlsruhe, Germany), which is synced with NanoScribe to initiate the polymerization. The IP-S negative-tone

A review of defect engineering, ion implantation, and nanofabrication using the helium ion microscope

Beilstein J. Nanotechnol. 2021, 12, 633–664, doi:10.3762/bjnano.12.52

- irradiation-induced defects and implanted ions [79][80][82][83][86][87], and at higher doses, the subsurface swelling that results in blistering and delamination [84] (Figure 3d), which for deployment of a material in a reactor needs to be avoided [80][82][83][84][85]. Returning to silicon, the nanomechanical

ZnO and MXenes as electrode materials for supercapacitor devices

Beilstein J. Nanotechnol. 2021, 12, 49–57, doi:10.3762/bjnano.12.4

- . synthesized large-scale 2D Mo2CTx from Mo2Ga2C powder by etching gallium (Ga) selectively with the aid of two etchants, hydrogen fluoride (HF) and lithium fluoride (LiF)/HCl, with subsequent delamination. The morphology of the developed flakes differed with the used etchant. After using LiF/HCl as etchant

- stability [36]. Xu et al. developed an rGO/Ti3C2Tx MXene-based supercapacitor. The rGO/Ti3C2Tx films were synthesized using vacuum-assisted filtration of rGO/Ti3C2Tx. The supercapacitor showed specific capacitance values up to 405 F·g−1. The approach used here eliminated the requirement of a delamination of

Atomic layer deposited films of Al2O3 on fluorine-doped tin oxide electrodes: stability and barrier properties

Beilstein J. Nanotechnol. 2021, 12, 24–34, doi:10.3762/bjnano.12.2

- that of pure FTO is higher than three. This means that there are B-type defects in the barrier film. These defects cause not only the delamination of the Al2O3 film from the FTO substrate, but also a slowdown of the charge-transfer kinetics (accompanied by a strong increase in ΔEpp). The Table 1 shows

Out-of-plane surface patterning by subsurface processing of polymer substrates with focused ion beams

Beilstein J. Nanotechnol. 2020, 11, 1693–1703, doi:10.3762/bjnano.11.151

- -plane features, at the nanoscale, of the pre-deposited films. Ion irradiation of the Au-coated samples results in delamination, bulging, and perforation of the Au film, which is attributed to the accumulation of gases from radiolysis at the film–substrate interface. The irradiation with Ne+ and Ga+ ions

- [4], the results shown in this work demonstrate that for samples coated with 5 nm Pt60Pd40 films, extensive delamination and bulging of the Au film from the substrate surface are observed in the irradiated cells and in the regions surrounding the cells. This is seen as changes in the color contrast

- features. The irradiation of the Au-coated samples results in delamination of the Au thin film followed by its bulging and perforation, which points to the important role of available pathways for the desorption of gases resulting from radiolysis. The irradiation with Ne+ or Ga+ ion beams destroys the

Wafer-level integration of self-aligned high aspect ratio silicon 3D structures using the MACE method with Au, Pd, Pt, Cu, and Ir

Beilstein J. Nanotechnol. 2020, 11, 1439–1449, doi:10.3762/bjnano.11.128

- created nanoporous sponge-like structures, which consist of various pinholes with a diameter below 1 nm. This shows that the etching was dominated by the second etching mechanism where n = 2. Higher H2O2 concentrations lead to significant structural destruction, including the delamination of wide areas

- . The etching process with Pd yields bundles of nanoscopic sponge structures. They are separated by larger free spaces formed by agglomerated Pd particles (Figure 7b). The mean etching depth was approx. 600 nm at the wafer centre. The wafer edge showed significant structure delamination. In contrast to

Fabrication of phase masks from amorphous carbon thin films for electron-beam shaping

Beilstein J. Nanotechnol. 2019, 10, 1290–1302, doi:10.3762/bjnano.10.128

- considerably smoother compared to the technique described first (cf. Figure 3a,b). However, we observed delamination of the aC film from the Pt layer. This effect was more pronounced for thicker aC films, e.g., an 80 nm thick film was detached from the Pt layer when it came in contact with another surface

- alternative material to commonly used SixNy for beam-shaping phase masks (PMs). The most challenging aspect is the fabrication of smooth aC thin films in combination with an aperture. Floated aC thin films from mica yielded best results, although possible delamination of the film makes these PMs in general

- ) Delamination of floated aC films is visible in the bottom half of the SEM image. FIB scanning over relatively large areas flattens the film, which is visible in the top part. The straight edges of the FIB scanning windows are clearly visible. SEM images after structuring the pattern according to Equation 3

Photoactive nanoarchitectures based on clays incorporating TiO2 and ZnO nanoparticles

Beilstein J. Nanotechnol. 2019, 10, 1140–1156, doi:10.3762/bjnano.10.114

- NPs already synthesized or formed in situ by incorporation of the corresponding precursors (alkoxides, salts in alkaline medium and metal complexes) as schematized in Figure 3. Of particular relevance is the irreversible delamination of the 2:1 charged layered silicates, e.g., smectite clay minerals

- TiO2@clay and ZnO@clay materials. Following this approach, micro- and mesoporous clay–semiconductor nanoarchitectures with high pore volume and increased specific surface area due to clay delamination have been obtained. In some of these materials, the TiO2 and ZnO NPs generated from the corresponding

- for the removal of ammonia from wastewater (Table 1) [161]. Also, TiO2–ZnO@clay nanoarchitectures derived from a smectite (Cloisite®30B) have been also prepared by sol–gel reactions involving the delamination of the silicate. The resulting materials show good photocatalytic activity for the

Outstanding chain-extension effect and high UV resistance of polybutylene succinate containing amino-acid-modified layered double hydroxides

Beilstein J. Nanotechnol. 2019, 10, 684–695, doi:10.3762/bjnano.10.68

- towards lower wavelengths, at about 300 nm, which is characteristic for pristine amino acid. A similar phenomenon was observed for the PBS composite with Zn2Al/TYR LDH and is described in the literature [15]. It can be explained by the delamination of the LDH platelets and the presence of LDH filler in a

Effects of post-lithography cleaning on the yield and performance of CVD graphene-based devices

Beilstein J. Nanotechnol. 2019, 10, 349–355, doi:10.3762/bjnano.10.34

- solubility of graphene in NMP, which tends to promote the delamination of the graphene layer from the substrate. Since procedure P1 is quite destructive, its yield of high-quality GFETs was 10% in a total of 60 devices. In order to improve the efficiency of device production, we removed the photoresist and

Graphene–graphite hybrid epoxy composites with controllable workability for thermal management

Beilstein J. Nanotechnol. 2019, 10, 95–104, doi:10.3762/bjnano.10.9

- a result of the cycling between high and low working temperatures that is typical in electronic devices [2]. In solid TIMs, delamination, which can occur due to differences in thermal expansion between the substrate and the TIM, will introduce thermally insulating air voids into the interface. In

Layered calcium phenylphosphonate: a hybrid material for a new generation of nanofillers

Beilstein J. Nanotechnol. 2018, 9, 2906–2915, doi:10.3762/bjnano.9.269

- used to obtain nanostructures [12][13]. As was mentioned in the Introduction, calcium phenylphosphonate, by its layered nature, should be a good candidate for the delamination. As previously described by several research groups, solvent compatibility with exfoliated material is one of the key

- parameters for successful delamination [13][14]. If the solvent–material interaction is not favorable, delamination could likely be observed within a short time; however, the dispersion of the resulting nanosheets will not be stable enough for further application. There is the possibility to extend the

Nanocellulose: Recent advances and its prospects in environmental remediation

Beilstein J. Nanotechnol. 2018, 9, 2479–2498, doi:10.3762/bjnano.9.232

- post-treatment and purification steps for CNC production [33]. Mechanical disintegration is commonly used to break cellulose pulp into smaller particles. However, efficient mechanical disintegration of cellulosic fibre normally requires elementary fibril delamination of cellulosic fibre instead of

- merely fibre shredding [32]. The occurrence of fibre shredding during mechanical disintegration of dry cellulose pulp tends to produce nanocellulose with poor mechanical properties. For improved delamination of nanofibrils, an aqueous medium is employed during mechanical disintegration to loosen

- interfibrillar hydrogen bonding and avoid reverse coalescence or fibril aggregation [32]. Several examples of commonly used techniques for efficient delamination of cellulosic fibre include homogenization [63], grinding [64][65], and refining [66]. Unlike finely structured or short rod-like nanocelluloses

Formation mechanisms of boron oxide films fabricated by large-area electron beam-induced deposition of trimethyl borate

Beilstein J. Nanotechnol. 2018, 9, 1282–1287, doi:10.3762/bjnano.9.120

- instabilities produced during the thermally induced fabrication process. Exposure to high temperatures is incompatible with many substrate materials and leads to the development of undesirable stress, which often results in film cracking and delamination [1]. A rapidly developing technique that has been

Semi-automatic spray pyrolysis deposition of thin, transparent, titania films as blocking layers for dye-sensitized and perovskite solar cells

Beilstein J. Nanotechnol. 2018, 9, 1135–1145, doi:10.3762/bjnano.9.105

- the defect causes not only the delamination of the titania film from FTO, but also the slowdown of charge transfer kinetics (accompanied by a strong increase in ΔEpp). The barrier properties after post calcination were fairly good for the 0.05 M TAA precursor and the largest layer thickness (200 SCs

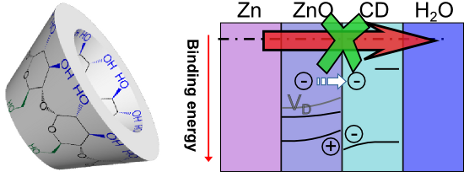

Cyclodextrin inhibits zinc corrosion by destabilizing point defect formation in the oxide layer

Beilstein J. Nanotechnol. 2018, 9, 936–944, doi:10.3762/bjnano.9.86

- result that the coating delamination rate reduced also in the presence of pure β-CD [8]. This observation served as a motivation to investigate whether β-CD acts as corrosion inhibitor on its own. β-CD consists of seven α-D-1,4-linked glucosepyranose subunits, and is produced from starch by enzymatic