Search results

Search for "environmentally friendly" in Full Text gives 204 result(s) in Beilstein Journal of Organic Chemistry. Showing first 200.

A recent overview on the synthesis of 1,4,5-trisubstituted 1,2,3-triazoles

- Pezhman Shiri,

- Ali Mohammad Amani and

- Thomas Mayer-Gall

Beilstein J. Org. Chem. 2021, 17, 1600–1628, doi:10.3762/bjoc.17.114

- enaminones 18 with tosyl azide. A wide range of desired 5-thiolated 1,2,3-triazoles 19 has been prepared in good to high yield in H2O as solvent using TMEDA as a weak base, thus providing an environmentally friendly procedure that was demonstrated to be practicable also on a gram scale. A wide range of β

Graphical Abstract

Figure 1: Some significant triazole derivatives [8,23-27].

Scheme 1: A general comparison between synthetic routes for disubstituted 1,2,3-triazole derivatives and full...

Scheme 2: Synthesis of formyltriazoles 3 from the treatment of α-bromoacroleins 1 with azides 2.

Scheme 3: A probable mechanism for the synthesis of formyltriazoles 5 from the treatment of α-bromoacroleins 1...

Scheme 4: Synthesis of 1,4,5-trisubstituted 1,2,3-triazoles 8 from the reaction of aryl azides 7 with enamino...

Scheme 5: Proposed mechanism for the synthesis of 1,4,5-trisubstituted 1,2,3-triazoles from the reaction of a...

Scheme 6: Synthesis of 1,4,5-trisubstituted 1,2,3-triazoles 11 from the reaction of primary amines 10 with 1,...

Scheme 7: The proposed mechanism for the synthesis of 1,4,5-trisubstituted 1,2,3-triazoles 11 from the reacti...

Scheme 8: Synthesis of fully decorated 1,2,3-triazoles 19 containing a sulfur-based side chain.

Scheme 9: Mechanism for the formation of fully decorated 1,2,3-triazoles 19 containing a sulfur-based side ch...

Scheme 10: Synthesis of fully decorated 1,2,3-triazole compounds 25 through the regioselective addition and cy...

Scheme 11: A reasonable mechanism for the synthesis of fully decorated 1,2,3-triazole compounds 25 through the...

Scheme 12: Synthesis of 1,4,5-trisubstituted glycosyl-containing 1,2,3-triazole derivatives 30 from the reacti...

Scheme 13: Synthesis of 1,4,5-trisubstituted 1,2,3-triazoles 34 via intramolecular cyclization reaction of ket...

Scheme 14: Synthesis of fully decorated 1,2,3-triazoles 38 from the reaction of aldehydes 35, amines 36, and α...

Scheme 15: A reasonable mechanism for the synthesis of fully decorated 1,2,3-triazoles 38 from the reaction of...

Scheme 16: Synthesis of functionally rich double C- and N-vinylated 1,2,3-triazoles 45 and 47.

Scheme 17: Synthesis of disubstituted 4-chloro-, 4-bromo-, and 4-iodo-1,2,3-triazoles 50.

Scheme 18: a) A general route for SPAAC in polymer chemistry and b) synthesis of a novel pH-sensitive polymeri...

Scheme 19: Synthesis of 5-allenyl-1,2,3-triazoles 60 by the treatment of alkynes 57, azides 58, and propargyli...

Scheme 20: A reasonable mechanism for the synthesis of 5-allenyl-1,2,3-triazoles 60 by the treatment of alkyne...

Scheme 21: Synthesis of 5‐alkynyl-1,2,3-triazoles 69.

Scheme 22: A reasonable mechanism for the synthesis of 5‐alkynyl-1,2,3-triazoles 69.

Scheme 23: Synthesis of sulfur-cycle-fused 1,2,3-triazoles 75 and 77.

Scheme 24: A reasonable mechanism for the synthesis of sulfur-cycle-fused 1,2,3‐triazoles 75 and 77.

Scheme 25: Synthesis of 5-selanyltriazoles 85 from the reaction of ethynylstibanes 82, organic azides 83, and ...

Scheme 26: A mechanism for the synthesis of 5-selanyltriazoles 85 from the reaction of ethynylstibanes 82, org...

Scheme 27: Synthesis of trisubstituted triazoles containing an Sb substituent at position C5 in 93 and 5-unsub...

Scheme 28: Synthesis of asymmetric triazole disulfides 98 from disulfide-containing tert-butyltosyl disulfide 97...

Scheme 29: A mechanism for the synthesis of asymmetric triazole disulfides 98 from disulfide-containing tert-bu...

Scheme 30: Synthesis of triazole-fused sultams 104.

Scheme 31: Synthesis of 1,2,3-triazole-fused tricyclic heterocycles 106.

Scheme 32: A reasonable mechanism for the synthesis of 1,2,3-triazole-fused tricyclic heterocycles 106.

Scheme 33: Synthesis of 5-aryl-substituted 1,2,3-triazole derivatives 112.

Scheme 34: A reasonable mechanism for the synthesis of 5-aryl-substituted 1,2,3-triazole derivatives 112.

Scheme 35: Synthesis of 1,4,5-trisubstituted 1,2,3-triazole-5-carboxamides 119.

Scheme 36: A probable mechanism for the synthesis of 1,4,5-trisubstituted 1,2,3-triazole-5-carboxamides 119.

Scheme 37: Synthesis of fully decorated triazoles 125 via the Pd/C-catalyzed arylation of disubstituted triazo...

Scheme 38: Synthesis of triazolo[1,5-a]indolones 131.

Scheme 39: Synthesis of unsymmetrically substituted triazole-fused enediyne systems 135 and 5-aryl-4-ethynyltr...

Scheme 40: Synthesis of Pd/Cu-BNP 139 and application of 139 in the synthesis of polycyclic triazoles 142.

Scheme 41: A probable mechanism for the synthesis of polycyclic triazoles 142.

Scheme 42: Synthesis of highly functionalized 1,2,3-triazole-fused 5-, 6-, and 7-membered rings 152–154.

Scheme 43: A probable mechanism for the synthesis of highly functionalized 1,2,3-triazole-fused 5-, 6-, and 7-...

Scheme 44: Synthesis of fully functionalized 1,2,3-triazolo-fused chromenes 162, 164, and 166 via the intramol...

Scheme 45: Ru-catalyzed synthesis of fully decorated triazoles 172.

Scheme 46: Synthesis of 4-cyano-1,2,3-triazoles 175.

Scheme 47: Synthesis of functionalized triazoles from the reaction of 1-alkyltriazenes 176 and azides 177 and ...

Scheme 48: Mechanism for the synthesis of functionalized triazoles from the reaction of 1-alkyltriazenes 176 a...

A comprehensive review of flow chemistry techniques tailored to the flavours and fragrances industries

- Guido Gambacorta,

- James S. Sharley and

- Ian R. Baxendale

Beilstein J. Org. Chem. 2021, 17, 1181–1312, doi:10.3762/bjoc.17.90

- striving to deliver cheaper and more environmentally friendly processes. All commercially available products comprised of fragrance ingredients on the market can be traced back to the innovation of fragrance companies as their manufactured products (both of natural and synthetic origin) are sold on to

Graphical Abstract

Figure 1: Representative shares of the global F&F market (2018) segmented on their applications [1].

Figure 2: General structure of an international fragrance company [2].

Figure 3: The Michael Edwards fragrance wheel.

Figure 4: Examples of oriental (1–3), woody (4–7), fresh (8–10), and floral (11 and 12) notes.

Figure 5: A basic depiction of batch vs flow.

Scheme 1: Examples of reactions for which flow processing outperforms batch.

Scheme 2: Some industrially important aldol-based transformations.

Scheme 3: Biphasic continuous aldol reactions of acetone and various aldehydes.

Scheme 4: Aldol synthesis of 43 in flow using LiHMDS as the base.

Scheme 5: A semi-continuous synthesis of doravirine (49) involving a key aldol reaction.

Scheme 6: Enantioselective aldol reaction using 5-(pyrrolidin-2-yl)tetrazole (51) as catalyst in a microreact...

Scheme 7: Gröger's example of asymmetric aldol reaction in aqueous media.

Figure 6: Immobilised reagent column reactor types.

Scheme 8: Photoinduced thiol–ene coupling preparation of silica-supported 5-(pyrrolidin-2-yl)tetrazole 63 and...

Scheme 9: Continuous-flow approach for enantioselective aldol reactions using the supported catalyst 67.

Scheme 10: Ötvös’ employment of a solid-supported peptide aldol catalyst in flow.

Scheme 11: The use of proline tetrazole packed in a column for aldol reaction between cyclohexanone (65) and 2...

Scheme 12: Schematic diagram of an aminosilane-grafted Si-Zr-Ti/PAI-HF reactor for continuous-flow aldol and n...

Scheme 13: Continuous-flow condensation for the synthesis of the intermediate 76 to nabumetone (77) and Microi...

Scheme 14: Synthesis of ψ-Ionone (80) in continuous-flow via aldol condensation between citral (79) and aceton...

Scheme 15: Synthesis of β-methyl-ionones (83) from citral (79) in flow. The steps are separately described, an...

Scheme 16: Continuous-flow synthesis of 85 from 84 described by Gavriilidis et al.

Scheme 17: Continuous-flow scCO2 apparatus for the synthesis of 2-methylpentanal (87) and the self-condensed u...

Scheme 18: Chen’s two-step flow synthesis of coumarin (90).

Scheme 19: Pechmann condensation for the synthesis of 7-hydroxyxcoumarin (93) in flow. The setup extended to c...

Scheme 20: Synthesis of the dihydrojasmonate 35 exploiting nitro derivative proposed by Ballini et al.

Scheme 21: Silica-supported amines as heterogeneous catalyst for nitroaldol condensation in flow.

Scheme 22: Flow apparatus for the nitroaldol condensation of p-hydroxybenzaldehyde (102) to nitrostyrene 103 a...

Scheme 23: Nitroaldol reaction of 64 to 105 employing a quaternary ammonium functionalised PANF.

Scheme 24: Enantioselective nitroaldol condensation for the synthesis of 108 under flow conditions.

Scheme 25: Enatioselective synthesis of 1,2-aminoalcohol 110 via a copper-catalysed nitroaldol condensation.

Scheme 26: Examples of Knoevenagel condensations applied for fragrance components.

Scheme 27: Flow apparatus for Knoevenagel condensation described in 1989 by Venturello et al.

Scheme 28: Knoevenagel reaction using a coated multichannel membrane microreactor.

Scheme 29: Continuous-flow apparatus for Knoevenagel condensation employing sugar cane bagasse as support deve...

Scheme 30: Knoevenagel reaction for the synthesis of 131–135 in flow using an amine-functionalised silica gel. ...

Scheme 31: Continuous-flow synthesis of compound 137, a key intermediate for the synthesis of pregabalin (138)...

Scheme 32: Continuous solvent-free apparatus applied for the synthesis of compounds 140–143 using a TSE. Throu...

Scheme 33: Lewis et al. developed a spinning disc reactor for Darzens condensation of 144 and a ketone to furn...

Scheme 34: Some key industrial applications of conjugate additions in the F&F industry.

Scheme 35: Continuous-flow synthesis of 4-(2-hydroxyethyl)thiomorpholine 1,1-dioxide (156) via double conjugat...

Scheme 36: Continuous-flow system for Michael addition using CsF on alumina as the catalyst.

Scheme 37: Calcium chloride-catalysed asymmetric Michael addition using an immobilised chiral ligand.

Scheme 38: Continuous multistep synthesis for the preparation of (R)-rolipram (173). Si-NH2: primary amine-fun...

Scheme 39: Continuous-flow Michael addition using ion exchange resin Amberlyst® A26.

Scheme 40: Preparation of the heterogeneous catalyst 181 developed by Paixão et al. exploiting Ugi multicompon...

Scheme 41: Continuous-flow system developed by the Paixão’s group for the preparation of Michael asymmetric ad...

Scheme 42: Continuous-flow synthesis of nitroaldols catalysed by supported catalyst 184 developed by Wennemers...

Scheme 43: Heterogenous polystyrene-supported catalysts developed by Pericàs and co-workers.

Scheme 44: PANF-supported pyrrolidine catalyst for the conjugate addition of cyclohexanone (65) and trans-β-ni...

Scheme 45: Synthesis of (−)-paroxetine precursor 195 developed by Ötvös, Pericàs, and Kappe.

Scheme 46: Continuous-flow approach for the 5-step synthesis of (−)-oseltamivir (201) as devised by Hayashi an...

Scheme 47: Continuous-flow enzyme-catalysed Michael addition.

Scheme 48: Continuous-flow copper-catalysed 1,4 conjugate addition of Grignard reagents to enones. Reprinted w...

Scheme 49: A collection of commonly encountered hydrogenation reactions.

Figure 7: The ThalesNano H-Cube® continuous-flow hydrogenator.

Scheme 50: Chemoselective reduction of an α,β-unsaturated ketone using the H-Cube® reactor.

Scheme 51: Incorporation of Lindlar’s catalyst into the H-Cube® reactor for the reduction of an alkyne.

Scheme 52: Continuous-flow semi-hydrogenation of alkyne 208 to 209 using SACs with H-Cube® system.

Figure 8: The standard setups for tube-in-tube gas–liquid reactor units.

Scheme 53: Homogeneous hydrogenation of olefins using a tube-in-tube reactor setup.

Scheme 54: Recyclable heterogeneous flow hydrogenation system.

Scheme 55: Leadbeater’s reverse tube-in-tube hydrogenation system for olefin reductions.

Scheme 56: a) Hydrogenation using a Pd-immobilised microchannel reactor (MCR) and b) a representation of the i...

Scheme 57: Hydrogenation of alkyne 238 exploiting segmented flow in a Pd-immobilised capillary reactor.

Scheme 58: Continuous hydrogenation system for the preparation of cyrene (241) from (−)-levoglucosenone (240).

Scheme 59: Continuous hydrogenation system based on CSMs developed by Hornung et al.

Scheme 60: Chemoselective reduction of carbonyls (ketones over aldehydes) in flow.

Scheme 61: Continuous system for the semi-hydrogenation of 256 and 258, developed by Galarneau et al.

Scheme 62: Continuous synthesis of biodiesel fuel 261 from lignin-derived furfural acetone (260).

Scheme 63: Continuous synthesis of γ-valerolacetone (263) via CTH developed by Pineda et al.

Scheme 64: Continuous hydrogenation of lignin-derived biomass (products 265, 266, and 267) using a sustainable...

Scheme 65: Ru/C or Rh/C-catalysed hydrogenation of arene in flow as developed by Sajiki et al.

Scheme 66: Polysilane-immobilized Rh–Pt-catalysed hydrogenation of arenes in flow by Kobayashi et al.

Scheme 67: High-pressure in-line mixing of H2 for the asymmetric reduction of 278 at pilot scale with a 73 L p...

Figure 9: Picture of the PFR employed at Eli Lilly & Co. for the continuous hydrogenation of 278 [287]. Reprinted ...

Scheme 68: Continuous-flow asymmetric hydrogenation using Oppolzer's sultam 280 as chiral auxiliary.

Scheme 69: Some examples of industrially important oxidation reactions in the F&F industry. CFL: compact fluor...

Scheme 70: Gold-catalysed heterogeneous oxidation of alcohols in flow.

Scheme 71: Uozumi’s ARP-Pt flow oxidation protocol.

Scheme 72: High-throughput screening of aldehyde oxidation in flow using an in-line GC.

Scheme 73: Permanganate-mediated Nef oxidation of nitroalkanes in flow with the use of in-line sonication to p...

Scheme 74: Continuous-flow aerobic anti-Markovnikov Wacker oxidation.

Scheme 75: Continuous-flow oxidation of 2-benzylpyridine (312) using air as the oxidant.

Scheme 76: Continuous-flow photo-oxygenation of monoterpenes.

Scheme 77: A tubular reactor design for flow photo-oxygenation.

Scheme 78: Glucose oxidase (GOx)-mediated continuous oxidation of glucose using compressed air and the FFMR re...

Scheme 79: Schematic continuous-flow sodium hypochlorite/TEMPO oxidation of alcohols.

Scheme 80: Oxidation using immobilised TEMPO (344) was developed by McQuade et al.

Scheme 81: General protocol for the bleach/catalytic TBAB oxidation of aldehydes and alcohols.

Scheme 82: Continuous-flow PTC-assisted oxidation using hydrogen peroxide. The process was easily scaled up by...

Scheme 83: Continuous-flow epoxidation of cyclohexene (348) and in situ preparation of m-CPBA.

Scheme 84: Continuous-flow epoxidation using DMDO as oxidant.

Scheme 85: Mukayama aerobic epoxidation optimised in flow mode by the Favre-Réguillon group.

Scheme 86: Continuous-flow asymmetric epoxidation of derivatives of 359 exploiting a biomimetic iron catalyst.

Scheme 87: Continuous-flow enzymatic epoxidation of alkenes developed by Watts et al.

Scheme 88: Engineered multichannel microreactor for continuous-flow ozonolysis of 366.

Scheme 89: Continuous-flow synthesis of the vitamin D precursor 368 using multichannel microreactors. MFC: mas...

Scheme 90: Continuous ozonolysis setup used by Kappe et al. for the synthesis of various substrates employing ...

Scheme 91: Continuous-flow apparatus for ozonolysis as developed by Ley et al.

Scheme 92: Continuous-flow ozonolysis for synthesis of vanillin (2) using a film-shear flow reactor.

Scheme 93: Examples of preparative methods for ajoene (386) and allicin (388).

Scheme 94: Continuous-flow oxidation of thioanisole (389) using styrene-based polymer-supported peroxytungstat...

Scheme 95: Continuous oxidation of thiosulfinates using Oxone®-packed reactor.

Scheme 96: Continuous-flow electrochemical oxidation of thioethers.

Scheme 97: Continuous-flow oxidation of 400 to cinnamophenone (235).

Scheme 98: Continuous-flow synthesis of dehydrated material 401 via oxidation of methyl dihydrojasmonate (33).

Scheme 99: Some industrially important transformations involving Grignard reagents.

Scheme 100: Grachev et al. apparatus for continuous preparation of Grignard reagents.

Scheme 101: Example of fluidized Mg bed reactor with NMR spectrometer as on-line monitoring system.

Scheme 102: Continuous-flow synthesis of Grignard reagents and subsequent quenching reaction.

Figure 10: Membrane-based, liquid–liquid separator with integrated pressure control [52]. Adapted with permission ...

Scheme 103: Continuous-flow synthesis of 458, an intermediate to fluconazole (459).

Scheme 104: Continuous-flow synthesis of ketones starting from benzoyl chlorides.

Scheme 105: A Grignard alkylation combining CSTR and PFR technologies with in-line infrared reaction monitoring....

Scheme 106: Continuous-flow preparation of 469 from Grignard addition of methylmagnesium bromide.

Scheme 107: Continuous-flow synthesis of Grignard reagents 471.

Scheme 108: Preparation of the Grignard reagent 471 using CSTR and the continuous process for synthesis of the ...

Scheme 109: Continuous process for carboxylation of Grignard reagents in flow using tube-in-tube technology.

Scheme 110: Continuous synthesis of propargylic alcohols via ethynyl-Grignard reagent.

Scheme 111: Silica-supported catalysed enantioselective arylation of aldehydes using Grignard reagents in flow ...

Scheme 112: Acid-catalysed rearrangement of citral and dehydrolinalool derivatives.

Scheme 113: Continuous stilbene isomerisation with continuous recycling of photoredox catalyst.

Scheme 114: Continuous-flow synthesis of compound 494 as developed by Ley et al.

Scheme 115: Selected industrial applications of DA reaction.

Scheme 116: Multistep flow synthesis of the spirocyclic structure 505 via employing DA cycloaddition.

Scheme 117: Continuous-flow DA reaction developed in a plater flow reactor for the preparation of the adduct 508...

Scheme 118: Continuous-flow DA reaction using a silica-supported imidazolidinone organocatalyst.

Scheme 119: Batch vs flow for the DA reaction of (cyclohexa-1,5-dien-1-yloxy)trimethylsilane (513) with acrylon...

Scheme 120: Continuous-flow DA reaction between 510 and 515 using a shell-core droplet system.

Scheme 121: Continuous-flow synthesis of bicyclic systems from benzyne precursors.

Scheme 122: Continuous-flow synthesis of bicyclic scaffolds 527 and 528 for further development of potential ph...

Scheme 123: Continuous-flow inverse-electron hetero-DA reaction to pyridine derivatives such as 531.

Scheme 124: Comparison between batch and flow for the synthesis of pyrimidinones 532–536 via retro-DA reaction ...

Scheme 125: Continuous-flow coupled with ultrasonic system for preparation of ʟ-ascorbic acid derivatives 539 d...

Scheme 126: Two-step continuous-flow synthesis of triazole 543.

Scheme 127: Continuous-flow preparation of triazoles via CuAAC employing 546-based heterogeneous catalyst.

Scheme 128: Continuous-flow synthesis of compounds 558 through A3-coupling and 560 via AgAAC both employing the...

Scheme 129: Continuous-flow photoinduced [2 + 2] cycloaddition for the preparation of bicyclic derivatives of 5...

Scheme 130: Continuous-flow [2 + 2] and [5 + 2] cycloaddition on large scale employing a flow reactor developed...

Scheme 131: Continuous-flow preparation of the tricyclic structures 573 and 574 starting from pyrrole 570 via [...

Scheme 132: Continuous-flow [2 + 2] photocyclization of cinnamates.

Scheme 133: Continuous-flow preparation of cyclobutane 580 on a 5-plates photoreactor.

Scheme 134: Continuous-flow [2 + 2] photocycloaddition under white LED lamp using heterogeneous PCN as photocat...

Figure 11: Picture of the parallel tube flow reactor (PTFR) "The Firefly" developed by Booker-Milburn et al. a...

Scheme 135: Continuous-flow acid-catalysed [2 + 2] cycloaddition between silyl enol ethers and acrylic esters.

Scheme 136: Continuous synthesis of lactam 602 using glass column reactors.

Scheme 137: In situ generation of ketenes for the Staudinger lactam synthesis developed by Ley and Hafner.

Scheme 138: Application of [2 + 2 + 2] cycloadditions in flow employed by Ley et al.

Scheme 139: Examples of FC reactions applied in F&F industry.

Scheme 140: Continuous-flow synthesis of ibuprofen developed by McQuade et al.

Scheme 141: The FC acylation step of Jamison’s three-step ibuprofen synthesis.

Scheme 142: Synthesis of naphthalene derivative 629 via FC acylation in microreactors.

Scheme 143: Flow system for rapid screening of catalysts and reaction conditions developed by Weber et al.

Scheme 144: Continuous-flow system developed by Buorne, Muller et al. for DSD optimisation of the FC acylation ...

Scheme 145: Continuous-flow FC acylation of alkynes to yield β-chlorovinyl ketones such as 638.

Scheme 146: Continuous-flow synthesis of tonalide (619) developed by Wang et al.

Scheme 147: Continuous-flow preparation of acylated arene such as 290 employing Zr4+-β-zeolite developed by Kob...

Scheme 148: Flow system applied on an Aza-FC reaction catalysed by the thiourea catalyst 648.

Scheme 149: Continuous hydroformylation in scCO2.

Scheme 150: Two-step flow synthesis of aldehyde 655 through a sequential Heck reaction and subsequent hydroform...

Scheme 151: Single-droplet (above) and continuous (below) flow reactors developed by Abolhasani et al. for the ...

Scheme 152: Continuous hydroformylation of 1-dodecene (655) using a PFR-CSTR system developed by Sundmacher et ...

Scheme 153: Continuous-flow synthesis of the aldehyde 660 developed by Eli Lilly & Co. [32]. Adapted with permissio...

Scheme 154: Continuous asymmetric hydroformylation employing heterogenous catalst supported on carbon-based sup...

Scheme 155: Examples of acetylation in F&F industry: synthesis of bornyl (S,R,S-664) and isobornyl (S,S,S-664) ...

Scheme 156: Continuous-flow preparation of bornyl acetate (S,R,S-664) employing the oscillating flow reactor.

Scheme 157: Continuous-flow synthesis of geranyl acetate (666) from acetylation of geraniol (343) developed by ...

Scheme 158: 12-Ttungstosilicic acid-supported silica monolith-catalysed acetylation in flow.

Scheme 159: Continuous-flow preparation of cyclopentenone 676.

Scheme 160: Two-stage synthesis of coumarin (90) via acetylation of salicylaldehyde (88).

Scheme 161: Intensification process for acetylation of 5-methoxytryptamine (677) to melatonin (678) developed b...

Scheme 162: Examples of macrocyclic musky odorants both natural (679–681) and synthetic (682 and 683).

Scheme 163: Flow setup combined with microwave for the synthesis of macrocycle 686 via RCM.

Scheme 164: Continuous synthesis of 2,5-dihydro-1H-pyrroles via ring-closing metathesis.

Scheme 165: Continuous-flow metathesis of 485 developed by Leadbeater et al.

Figure 12: Comparison between RCM performed using different routes for the preparation of 696. On the left the...

Scheme 166: Continuous-flow RCM of 697 employed the solid-supported catalyst 698 developed by Grela, Kirschning...

Scheme 167: Continuous-flow RORCM of cyclooctene employing the silica-absorbed catalyst 700.

Scheme 168: Continuous-flow self-metathesis of methyl oleate (703) employing SILP catalyst 704.

Scheme 169: Flow apparatus for the RCM of 697 using a nanofiltration membrane for the recovery and reuse of the...

Scheme 170: Comparison of loadings between RCMs performed with different routes for the synthesis of 709.

Heterogeneous photocatalytic cyanomethylarylation of alkenes with acetonitrile: synthesis of diverse nitrogenous heterocyclic compounds

- Guanglong Pan,

- Qian Yang,

- Wentao Wang,

- Yurong Tang and

- Yunfei Cai

Beilstein J. Org. Chem. 2021, 17, 1171–1180, doi:10.3762/bjoc.17.89

- reaction mixture and reused several times, illustrating the practicability of this heterogeneous photocatalysis protocol. Further applying this sustainable and environmentally friendly CN-K heterogeneous photocatalyst to realize other synthetic useful transformations is undergoing. Evaluation of catalyst

Graphical Abstract

Scheme 1: CN-K-Catalyzed cyanomethylarylation of alkenes to access diverse heterocyclic compounds.

Scheme 2: CN-K-catalyzed cyanomethylarylation of N-arylallylamines for the synthesis of indolines. Reaction c...

Scheme 3: CN-K-catalyzed cyanomethylarylation of N-benzoylallylamines for the synthesis of isoquinolinones. R...

Scheme 4: CN-K-catalyzed cyanomethylarylation of N-aryl acrylamides for the synthesis of oxindoles. Reaction ...

Scheme 5: CN-K-catalyzed cyanomethylarylation of N-benzoyl acrylamides for the synthesis of isoquinolinedione...

Figure 1: Evaluation of catalyst recycling. Reaction conditions: 1a (0.1 mmol, 1 equiv), 2d (0.2 mmol, 2 equi...

Scheme 6: Further survey of reaction scope and derivatization studies of 8a.

Scheme 7: Experiments for the mechanistic study.

Scheme 8: Plausible mechanism of the CN-K-catalyzed cyanomethylarylation of alkenes.

Metal-free glycosylation with glycosyl fluorides in liquid SO2

- Krista Gulbe,

- Jevgeņija Lugiņina,

- Edijs Jansons,

- Artis Kinens and

- Māris Turks

Beilstein J. Org. Chem. 2021, 17, 964–976, doi:10.3762/bjoc.17.78

- and promoter have been developed. Due to the absence of any external additive, the presented method is considered to be an atom efficient and environmentally friendly synthetic approach. The glycosylation conditions in liquid SO2 have been optimized for both disarmed and armed mannose- and glucose

Graphical Abstract

Scheme 1: Scope of glycosyl acceptors for glycosylation with pivaloyl-protected mannosyl fluoride α-1a in liq...

Scheme 2: Glycosylation of binucleophiles 7a,b in liquid SO2.

Scheme 3: Pivaloyl-protected glucosyl fluoride β-9 as a glycosyl donor in liquid SO2.

Scheme 4: Benzyl protected manno- and glucopyranosyl fluorides α-15 and 16 as glycosyl donors in liquid SO2. ...

Scheme 5: 2-Deoxy glycosyl fluoride α-19 as a glycosyl donor in liquid SO2.

Figure 1: Detection of the FSO2− species by 19F NMR (471 MHz, D2O).

Figure 2: Computational study of reaction mechanism α-11 + MeOH → α-13c in the presence of and in absence of ...

[2 + 1] Cycloaddition reactions of fullerene C60 based on diazo compounds

- Yuliya N. Biglova

Beilstein J. Org. Chem. 2021, 17, 630–670, doi:10.3762/bjoc.17.55

- solar cells [49][50]. In view of the globalization of energy problems, the issues of switching to alternative energy sources are becoming increasingly relevant. Solar energy, like the majority of renewable energy sources, is environmentally friendly and has almost no negative impact on the environment

- is environmentally friendly (Scheme 14). Researchers obtained various nitrofullerene derivatives, viz, nitrophenylfullerenes 48 and 50, reduction of which gave the corresponding aminophenylfullerenes 49 and 51 (Scheme 15) [98][99]. C60 adducts were doped with tetrakis(dimethylamino)ethylene (TDAE

Valorisation of plastic waste via metal-catalysed depolymerisation

- Francesca Liguori,

- Carmen Moreno-Marrodán and

- Pierluigi Barbaro

Beilstein J. Org. Chem. 2021, 17, 589–621, doi:10.3762/bjoc.17.53

- selective depolymerisation methods of plastics. Achievements are broken down according to the plastic material, namely polyolefins, polyesters, polycarbonates and polyamides. The focus is on recent advancements targeting sustainable and environmentally friendly processes. Biocatalytic or unselective

- alkali bases and chlorinated solvents [176][177], which makes them neither economically competitive nor environmentally friendly [178][179]. A survey of patents related to the chemical recycling of PET up to 2005 can be found in the literature [180]. Hydrogenolysis. In the recent years, hydrogenolysis

Graphical Abstract

Figure 1: Potential classification of plastic recycling processes. The area covered by the present review is ...

Figure 2: EG produced during glycolytic depolymerisation of PET using DEG + DPG as solvent and titanium(IV) n...

Scheme 1: Simplified representation of the conversion of 1,4-PBD to C16–C44 macrocycles using Ru metathesis c...

Figure 3: Main added-value monomers obtainable by catalytic depolymerisation of PET via chemolytic methods.

Scheme 2: Hydrogenolytic depolymerisation of PET by ruthenium complexes.

Scheme 3: Depolymerisation of PET via catalytic hydrosilylation by Ir(III) pincer complex.

Scheme 4: Catalytic hydrolysis (top) and methanolysis (bottom) reactions of PET.

Scheme 5: Depolymerisation of PET by glycolysis with ethylene glycol.

Figure 4: Glycolysis of PET: evolution of BHET yield over time, with and without zinc acetate catalyst (196 °...

Scheme 6: Potential activated complex for the glycolysis reaction of PET catalysed by metallated ILs and evol...

Scheme 7: One-pot, two-step process for PET repurposing via chemical recycling.

Scheme 8: Synthetic routes to PLA.

Scheme 9: Structures of the zinc molecular catalysts used for PLA-methanolysis in various works. a) See [265], b) ...

Scheme 10: Depolymerisation of PLLA by Zn–N-heterocyclic carbene complex.

Scheme 11: Salalen ligands.

Scheme 12: Catalytic hydrogenolysis of PLA.

Scheme 13: Catalytic hydrosilylation of PLA.

Scheme 14: Hydrogenative depolymerisation of PBT and PCL by molecular Ru catalysts.

Scheme 15: Glycolysis reaction of PCT by diethylene glycol.

Scheme 16: Polymerisation–depolymerisation cycle of 3,4-T6GBL.

Scheme 17: Polymerisation–depolymerisation cycle of 2,3-HDB.

Scheme 18: Hydrogenative depolymerisation of PBPAC by molecular Ru catalysts.

Scheme 19: Catalytic hydrolysis (top), alcoholysis (middle) and aminolysis (bottom) reactions of PBPAC.

Scheme 20: Hydrogenative depolymerisation of PPC (top) and PEC (bottom) by molecular Ru catalysts.

Scheme 21: Polymerisation-depolymerisation cycle of BEP.

Scheme 22: Hydrogenolysis of polyamides using soluble Ru catalysts.

Scheme 23: Catalytic depolymerisation of epoxy resin/carbon fibres composite.

Scheme 24: Depolymerisation of polyethers with metal salt catalysts and acyl chlorides.

Scheme 25: Proposed mechanism for the iron-catalysed depolymerisation reaction of polyethers. Adapted with per...

Mesoionic tetrazolium-5-aminides: Synthesis, molecular and crystal structures, UV–vis spectra, and DFT calculations

- Vladislav A. Budevich,

- Sergei V. Voitekhovich,

- Alexander V. Zuraev,

- Vadim E. Matulis,

- Vitaly E. Matulis,

- Alexander S. Lyakhov,

- Ludmila S. Ivashkevich and

- Oleg A. Ivashkevich

Beilstein J. Org. Chem. 2021, 17, 385–395, doi:10.3762/bjoc.17.34

- attractive as environmentally friendly pyrotechnics [4], insensitive high-energy materials [5][6][7], and promising energetic ionic liquids [8][9][10]. The most interesting and less examined 5-aminotetrazole derivatives are tetrazolium-5-aminides, which can be depicted as 4 by analogy with other mesoionic

Graphical Abstract

Figure 1: 5-Aminotetrazole derivatives.

Scheme 1: Synthesis of tetrazolium-5-aminides.

Scheme 2: N-Functionalizations of 1,3-disubstituted tetrazolium-5-aminides 8a,b.

Figure 2: Molecules of compounds 8a, 10, 11a, and the bistetrazolium cation 9, with displacement ellipsoids d...

Scheme 3: Possible Lewis structures for the molecule of 8a, with non-Lewis occupancies as % of the total elec...

Figure 3: Experimental (a) and TD-tHCTHhyb/6-311+G(2d,p) calculated (b) UV–vis spectra of compound 8a in diff...

Figure 4: Model structures of 8a used for the calculations of the UV–vis spectra: a) In n-hexane and THF, b) ...

Figure 5: NPA charges (left) and MESP contour map (right) for the molecule of 8a.

Figure 6: The calculated plots in n-hexane of a) HOMO, b) LUMO, c) electron density difference between the S1...

Figure 7: The calculated plots in water of a) HOMO, b) LUMO, c) electron density difference between the S1 an...

Ultrasound-assisted Strecker synthesis of novel 2-(hetero)aryl-2-(arylamino)acetonitrile derivatives

- Emese Gal,

- Luiza Gaina,

- Hermina Petkes,

- Alexandra Pop,

- Castelia Cristea,

- Gabriel Barta,

- Dan Cristian Vodnar and

- Luminiţa Silaghi-Dumitrescu

Beilstein J. Org. Chem. 2020, 16, 2929–2936, doi:10.3762/bjoc.16.242

- contributor to green chemistry mainly due to the ability of minimizing the energy consumption required by chemical transformations and allowing the development of environmentally friendly chemical procedures which may be eventually scaled up for industrial applications [1]. For the synthesis of organic

- -(amino)cyanocyclopropane derivatives not contaminated by intermediates or ring-opening byproducts [21], whereas the asymmetric Strecker synthesis induced by chiral amines was successfully conducted by sonication in the presence of silica gel [22]. Pursuing our interest in developing environmentally

- friendly procedures for the synthesis of new phenothiazine and ferrocene derivatives [23][24][25][26][27] and perceiving the importance of α-aminoacetonitrile derivatives as pharmaceutical and agrochemical intermediates with a great number of α-aminonitrile derivatives which were proved to have remarkable

Graphical Abstract

Scheme 1: Synthesis of α-amino-acetonitrile derivatives. Reaction conditions: Aldimine (1 equiv), TMSCN (1 eq...

Figure 1: Crystal structure of 2-phenothiazinyl-2-(p-tolylamino)acetonitrile 2a. a) ORTEP plot and b) crystal...

Figure 2: SEM images recorded at 200× for the raw reaction product 2b obtained through a) ultrasound-assisted...

Figure 3: SEM image recorded at 200× for the raw reaction product 2c obtained through a) ultrasound-assisted ...

One-pot multicomponent green Hantzsch synthesis of 1,2-dihydropyridine derivatives with antiproliferative activity

- Giovanna Bosica,

- Kaylie Demanuele,

- José M. Padrón and

- Adrián Puerta

Beilstein J. Org. Chem. 2020, 16, 2862–2869, doi:10.3762/bjoc.16.235

- reaction; Introduction A multicomponent approach towards the synthesis of the desired product offers a number of advantages over a stepwise method. Such advantages include the development of a design that is: cheaper, simpler, economical, and environmentally friendly [1][2]. Multicomponent reactions are

- libraries and then shifted to obtaining products that are in high demand on an industrial scale at a cheaper and more benign way [4]. Recently, negative human impacts have been greatly witnessed as a result of population growth, so environmentally friendly design has become one of the most important

- addition, further developments were made to the methodology in order to enhance the reaction yield and also to reduce the reaction time. Other recent developments involve reducing the energy and waste that is produced in the reaction for a more environmentally friendly synthesis [13][14][15][16]. The

Graphical Abstract

Scheme 1: The classical Hantzsch synthesis between benzaldehyde (1a), ethyl acetoacetate (2), and ammonium ac...

Figure 1: Optimization trials with the selected solid catalysts.

Figure 2: Graphical representation of the results obtained in the reusability test.

Dirhamnolipid ester – formation of reverse wormlike micelles in a binary (primerless) system

- David Liese,

- Hans Henning Wenk,

- Xin Lu,

- Jochen Kleinen and

- Gebhard Haberhauer

Beilstein J. Org. Chem. 2020, 16, 2820–2830, doi:10.3762/bjoc.16.232

- environmentally friendly biosurfactants because they are 100% biodegradable and are more compatible with water organisms than traditional surfactants. In solution, surfactants self-assemble into micelles with different shapes (spherical, cylindrical, double layer, etc.). In aqueous solution, the surfactant

Graphical Abstract

Figure 1: Chemical structure of dirhamnolipid 1.

Scheme 1: Synthesis of the dirhamnolipid esters and the chemical structure of 7.

Figure 2: Solubility of the dirhamnolipid esters in various solvents (+ = soluble, − = insoluble, G = gel).

Figure 3: Phase transition temperature for the dirhamnolipid esters in toluene while heating (TGS, blue) and ...

Figure 4: Amplitude sweep: double logarithmic plot of the dynamic moduli against the amplitude (deformation) ...

Figure 5: Frequency sweep: double logarithmic plot of the dynamic moduli against the frequency for the dirham...

Figure 6: Double logarithmic plot of (a) the plateau modulus G0 and (b) the relaxation time τR against the co...

Figure 7: Semilogarithmic plot of (a) G0/G''min, (b) η0, and (c) τR against the inverse absolute temperature ...

Figure 8: Polarized optical microscopy (POM) images of the 2/toluene system (5 wt %) with crossed polarizers ...

Figure 9: Schematic representation of the formation of RWLM by dirhamnolipid esters.

Conformational preferences of fluorine-containing agrochemicals and their implications for lipophilicity prediction

- Daniela Rodrigues Silva,

- Joyce K. Daré and

- Matheus P. Freitas

Beilstein J. Org. Chem. 2020, 16, 2469–2476, doi:10.3762/bjoc.16.200

- other variables, recent events have shown signs of recovery [1]. Currently, the agrochemical industry focuses on introducing new efficient and more environmentally friendly products, that attend the new regulation requirements, for replacing those agrochemicals that were banned due to either their

Graphical Abstract

Figure 1: Chemical structure of penoxsulam (I) and the main staggered conformations along the two F–C–C–O tor...

Figure 2: Optimized structures of conformers Igg (left), Iag (middle), and Iga (right), along with the relati...

Figure 3: Energy profile for the rotation around the C–C(F) bond and NBO analysis project onto the φO–C–C–H t...

Figure 4: Chemical structure of the agrochemicals I–VII analyzed herein.

Figure 5: Correlation between the experimental log P of agrochemicals I–VII and a) dipole moment (for I, μ is...

Figure 6: Chemical structure of the compounds 1–11 analyzed herein.

Figure 7: Correlation between the experimental log P of compounds 1–11 and a) dipole moment (for 7, 9, and 10...

Photosensitized direct C–H fluorination and trifluoromethylation in organic synthesis

- Shahboz Yakubov and

- Joshua P. Barham

Beilstein J. Org. Chem. 2020, 16, 2151–2192, doi:10.3762/bjoc.16.183

- , light is inexpensive, nontoxic, noncontaminating, ample (or “limitless” in the case of sunlight) and a renewable source of energy for environmentally-friendly and “green” chemical synthesis. As a consequence of comprehending the detrimental impact of human industry on the environment, new methods to

Graphical Abstract

Figure 1: Fluorine-containing drugs.

Figure 2: Fluorinated agrochemicals.

Scheme 1: Selectivity of fluorination reactions.

Scheme 2: Different mechanisms of photocatalytic activation. Sub = substrate.

Figure 3: Jablonski diagram showing visible-light-induced energy transfer pathways: a) absorption, b) IC, c) ...

Figure 4: Schematic illustration of TTET.

Figure 5: Organic triplet PSCats.

Figure 6: Additional organic triplet PSCats.

Figure 7: A) Further organic triplet PSCats and B) transition metal triplet PSCats.

Figure 8: Different fluorination reagents grouped by generation.

Scheme 3: Synthesis of Selectfluor®.

Scheme 4: General mechanism of PS TTET C(sp3)–H fluorination.

Scheme 5: Selective benzylic mono- and difluorination using 9-fluorenone and xanthone PSCats, respectively.

Scheme 6: Chen’s photosensitized monofluorination: reaction scope.

Scheme 7: Chen’s photosensitized benzylic difluorination reaction scope.

Scheme 8: Photosensitized monofluorination of ethylbenzene on a gram scale.

Scheme 9: Substrate scope of Tan’s AQN-photosensitized C(sp3)–H fluorination.

Scheme 10: AQN-photosensitized C–H fluorination reaction on a gram scale.

Scheme 11: Reaction mechanism of the AQN-assisted fluorination.

Figure 9: 3D structures of the singlet ground and triplet excited states of Selectfluor®.

Scheme 12: Associated transitions for the activation of acetophenone by violet light.

Scheme 13: Ethylbenzene C–H fluorination with various PSCats and conditions.

Scheme 14: Effect of different PSCats on the C(sp3)–H fluorination of cyclohexane (39).

Scheme 15: Reaction scope of Chen’s acetophenone-photosensitized C(sp3)–H fluorination reaction.

Figure 10: a) Site-selectivity of Chen’s acetophenone-photosensitized C–H fluorination reaction [201]. b) Site-sele...

Scheme 16: Formation of the AQN–Selectfluor® exciplex Int1.

Scheme 17: Generation of the C3 2° pentane radical and the Selectfluor® N-radical cation from the exciplex.

Scheme 18: Hydrogen atom abstraction by the Selectfluor® N-radical cation from pentane to give the C3 2° penta...

Scheme 19: Fluorine atom transfer from Selectfluor® to the C3 2° pentane radical to yield 3-fluoropentane and ...

Scheme 20: Barrierless fluorine atom transfer from Int1 to the C3 2° pentane radical to yield 3-fluoropentane,...

Scheme 21: Ketone-directed C(sp3)–H fluorination.

Scheme 22: Ketone-directed fluorination through a 5- and a 6-membered transition state, respectively.

Scheme 23: Effect of different PSCats on the photosensitized C(sp3)–H fluorination of 47.

Scheme 24: Substrate scope of benzil-photoassisted C(sp3)–H fluorinations.

Scheme 25: A) Benzil-photoassisted enone-directed C(sp3)–H fluorination. B) Classification of the reaction mod...

Scheme 26: A) Xanthone-photoassisted ketal-directed C(sp3)–H fluorination. B) Substrate scope. C) C–H fluorina...

Scheme 27: Rationale for the selective HAT at the C2 C–H bond of galactose acetonide.

Scheme 28: Photosensitized C(sp3)–H benzylic fluorination of a peptide using different PSCats.

Scheme 29: Peptide scope of 5-benzosuberenone-photoassisted C(sp3)–H fluorinations.

Scheme 30: Continuous flow PS TTET monofluorination of 72.

Scheme 31: Photosensitized C–H fluorination of N-butylphthalimide as a PSX.

Scheme 32: Substrate scope and limitations of the PSX C(sp3)–H monofluorination.

Scheme 33: Substrate crossover monofluorination experiment.

Scheme 34: PS TTET mechanism proposed by Hamashima and co-workers.

Scheme 35: Photosensitized TFM of 78 to afford α-trifluoromethylated ketone 80.

Scheme 36: Substrate scope for photosensitized styrene TFM to give α-trifluoromethylated ketones.

Scheme 37: Control reactions for photosensitized TFM of styrenes.

Scheme 38: Reaction mechanism for photosensitized TFM of styrenes to afford α-trifluoromethylated ketones.

Scheme 39: Reaction conditions for TFMs to yield the cis- and the trans-product, respectively.

Scheme 40: Substrate scope of trifluoromethylated (E)-styrenes.

Scheme 41: Strategies toward trifluoromethylated (Z)-styrenes.

Scheme 42: Substrate scope of trifluoromethylated (Z)-styrenes.

Scheme 43: Reaction mechanism for photosensitized TFM of styrenes to afford E- or Z-products.

When metal-catalyzed C–H functionalization meets visible-light photocatalysis

- Lucas Guillemard and

- Joanna Wencel-Delord

Beilstein J. Org. Chem. 2020, 16, 1754–1804, doi:10.3762/bjoc.16.147

- rapidly expanding domain of organic synthesis [1][2][3][4][5][6][7][8][9][10][11][12][13][14]. Indeed, this approach tends in rendering the classical metal-catalyzed cross-coupling more environmentally friendly, as simple, non-prefunctionalized substrates could be used in the presence of a metallic

Graphical Abstract

Figure 1: Concept of dual synergistic catalysis.

Figure 2: Classification of catalytic systems involving two catalysts.

Figure 3: General mechanism for the dual nickel/photoredox catalytic system.

Figure 4: General mechanisms for C–H activation catalysis involving different reoxidation strategies.

Figure 5: Indole synthesis via dual C–H activation/photoredox catalysis.

Figure 6: Proposed mechanism for the indole synthesis via dual catalysis.

Figure 7: Oxidative Heck reaction on arenes via the dual catalysis.

Figure 8: Proposed mechanism for the Heck reaction on arenes via dual catalysis.

Figure 9: Oxidative Heck reaction on phenols via the dual catalysis.

Figure 10: Proposed mechanism for the Heck reaction on phenols via dual catalysis.

Figure 11: Carbazole synthesis via dual C–H activation/photoredox catalysis.

Figure 12: Proposed mechanism for the carbazole synthesis via dual catalysis.

Figure 13: Carbonylation of enamides via the dual C–H activation/photoredox catalysis.

Figure 14: Proposed mechanism for carbonylation of enamides via dual catalysis.

Figure 15: Annulation of benzamides via the dual C–H activation/photoredox catalysis.

Figure 16: Proposed mechanism for the annulation of benzamides via dual catalysis.

Figure 17: Synthesis of indoles via the dual C–H activation/photoredox catalysis.

Figure 18: Proposed mechanism for the indole synthesis via dual catalysis.

Figure 19: General concept of dual catalysis merging C–H activation and photoredox catalysis.

Figure 20: The first example of dual catalysis merging C–H activation and photoredox catalysis.

Figure 21: Proposed mechanism for the C–H arylation with diazonium salts via dual catalysis.

Figure 22: Dual catalysis merging C–H activation/photoredox using diaryliodonium salts.

Figure 23: Direct arylation via the dual catalytic system reported by Xu.

Figure 24: Direct arylation via dual catalytic system reported by Balaraman.

Figure 25: Direct arylation via dual catalytic system reported by Guo.

Figure 26: C(sp3)–H bond arylation via the dual Pd/photoredox catalytic system.

Figure 27: Acetanilide derivatives acylation via the dual C–H activation/photoredox catalysis.

Figure 28: Proposed mechanism for the C–H acylation with α-ketoacids via dual catalysis.

Figure 29: Acylation of azobenzenes via the dual catalysis C–H activation/photoredox.

Figure 30: C2-acylation of indoles via the dual C–H activation/photoredox catalysis.

Figure 31: Proposed mechanism for the C2-acylation of indoles with aldehydes via dual catalysis.

Figure 32: C2-acylation of indoles via the dual C–H activation/photoredox catalysis.

Figure 33: Perfluoroalkylation of arenes via the dual C–H activation/photoredox catalysis.

Figure 34: Proposed mechanism for perfluoroalkylation of arenes via dual catalysis.

Figure 35: Sulfonylation of 1-naphthylamides via the dual C–H activation/photoredox catalysis.

Figure 36: Proposed mechanism for sulfonylation of 1-naphthylamides via dual catalysis.

Figure 37: meta-C–H Alkylation of arenes via visible-light metallaphotocatalysis.

Figure 38: Alternative procedure for meta-C–H alkylation of arenes via metallaphotocatalysis.

Figure 39: Proposed mechanism for meta-C–H alkylation of arenes via metallaphotocatalysis.

Figure 40: C–H borylation of arenes via visible-light metallaphotocatalysis.

Figure 41: Proposed mechanism for C–H borylation of arenes via visible-light metallaphotocatalysis.

Figure 42: Undirected C–H aryl–aryl cross coupling via dual gold/photoredox catalysis.

Figure 43: Proposed mechanism for the undirected C–H aryl–aryl cross-coupling via dual catalysis.

Figure 44: Undirected C–H arylation of (hetero)arenes via dual manganese/photoredox catalysis.

Figure 45: Proposed mechanism for the undirected arylation of (hetero)arenes via dual catalysis.

Figure 46: Photoinduced C–H arylation of azoles via copper catalysis.

Figure 47: Photo-induced C–H chalcogenation of azoles via copper catalysis.

Figure 48: Decarboxylative C–H adamantylation of azoles via dual cobalt/photoredox catalysis.

Figure 49: Proposed mechanism for the C–H adamantylation of azoles via dual catalysis.

Figure 50: General mechanisms for the “classical” (left) and Cu-free variant (right) Sonogoshira reaction.

Figure 51: First example of a dual palladium/photoredox catalysis for Sonogashira-type couplings.

Figure 52: Arylation of terminal alkynes with diazonium salts via dual gold/photoredox catalysis.

Figure 53: Proposed mechanism for the arylation of terminal alkynes via dual catalysis.

Figure 54: C–H Alkylation of alcohols promoted by H-atom transfer (HAT).

Figure 55: Proposed mechanism for the C–H alkylation of alcohols promoted by HAT.

Figure 56: C(sp3)–H arylation of latent nucleophiles promoted by H-atom transfer.

Figure 57: Proposed mechanism for the C(sp3)–H arylation of latent nucleophiles promoted by HAT.

Figure 58: Direct α-arylation of alcohols promoted by H-atom transfer.

Figure 59: Proposed mechanism for the direct α-arylation of alcohols promoted by HAT.

Figure 60: C–H arylation of amines via dual Ni/photoredox catalysis.

Figure 61: Proposed mechanism for the C–H arylation of amines via dual Ni/photoredox catalysis.

Figure 62: C–H functionalization of nucleophiles via excited ketone/nickel dual catalysis.

Figure 63: Proposed mechanism for the C–H functionalization enabled by excited ketones.

Figure 64: Selective sp3–sp3 cross-coupling promoted by H-atom transfer.

Figure 65: Proposed mechanism for the selective sp3–sp3 cross-coupling promoted by HAT.

Figure 66: Direct C(sp3)–H acylation of amines via dual Ni/photoredox catalysis.

Figure 67: Proposed mechanism for the C–H acylation of amines via dual Ni/photoredox catalysis.

Figure 68: C–H hydroalkylation of internal alkynes via dual Ni/photoredox catalysis.

Figure 69: Proposed mechanism for the C–H hydroalkylation of internal alkynes.

Figure 70: Alternative procedure for the C–H hydroalkylation of ynones, ynoates, and ynamides.

Figure 71: Allylic C(sp3)–H activation via dual Ni/photoredox catalysis.

Figure 72: Proposed mechanism for the allylic C(sp3)–H activation via dual Ni/photoredox catalysis.

Figure 73: Asymmetric allylation of aldehydes via dual Cr/photoredox catalysis.

Figure 74: Proposed mechanism for the asymmetric allylation of aldehydes via dual catalysis.

Figure 75: Aldehyde C–H functionalization promoted by H-atom transfer.

Figure 76: Proposed mechanism for the C–H functionalization of aldehydes promoted by HAT.

Figure 77: Direct C–H arylation of strong aliphatic bonds promoted by HAT.

Figure 78: Proposed mechanism for the C–H arylation of strong aliphatic bonds promoted by HAT.

Figure 79: Direct C–H trifluoromethylation of strong aliphatic bonds promoted by HAT.

Figure 80: Proposed mechanism for the C–H trifluoromethylation of strong aliphatic bonds.

In silico rationalisation of selectivity and reactivity in Pd-catalysed C–H activation reactions

- Liwei Cao,

- Mikhail Kabeshov,

- Steven V. Ley and

- Alexei A. Lapkin

Beilstein J. Org. Chem. 2020, 16, 1465–1475, doi:10.3762/bjoc.16.122

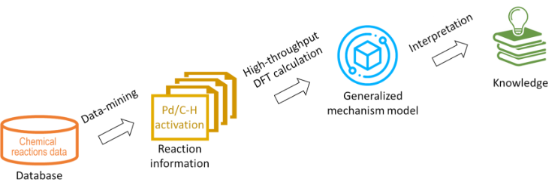

- developing machine learning models for predicting reaction outcomes. C–H activation reactions allow conversion of relatively inexpensive and abundant hydrocarbons into the more sophisticated value-added molecules [11]. With the notion of step-economical and environmentally friendly synthesis, direct

Graphical Abstract

Figure 1: An approximate energy map for the electrophilic aromatic substitution mechanism.

Scheme 1: Schematic representation of the two mechanisms of Pd-catalysed C–H activation reaction considered i...

An overview on disulfide-catalyzed and -cocatalyzed photoreactions

- Yeersen Patehebieke

Beilstein J. Org. Chem. 2020, 16, 1418–1435, doi:10.3762/bjoc.16.118

- gained some interest from researchers, their full potential has not been discovered and released yet. They are environmentally friendly and efficient catalyst that deserve more attention. [3 + 2] cyclization catalyzed by diaryl disulfide. [3 + 2] cycloaddition catalyzed by disulfide. Disulfide-bridged

Graphical Abstract

Scheme 1: [3 + 2] cyclization catalyzed by diaryl disulfide.

Scheme 2: [3 + 2] cycloaddition catalyzed by disulfide.

Scheme 3: Disulfide-bridged peptide-catalyzed enantioselective cycloaddition.

Scheme 4: Disulfide-catalyzed [3 + 2] methylenecyclopentane annulations.

Scheme 5: Disulfide as a HAT cocatalyst in the [4 + 2] cycloaddition reaction.

Scheme 6: Proposed mechanism of the [4 + 2] cycloaddition reaction using disulfide as a HAT cocatalyst.

Scheme 7: Disulfide-catalyzed ring expansion of vinyl spiro epoxides.

Scheme 8: Disulfide-catalyzed aerobic oxidation of diarylacetylene.

Scheme 9: Disulfide-catalyzed aerobic photooxidative cleavage of olefins.

Scheme 10: Disulfide-catalyzed aerobic oxidation of 1,3-dicarbonyl compounds.

Scheme 11: Proposed mechanism of the disulfide-catalyzed aerobic oxidation of 1,3-dicarbonyl compounds.

Scheme 12: Disulfide-catalyzed oxidation of allyl alcohols.

Scheme 13: Disulfide-catalyzed diboration of alkynes.

Scheme 14: Dehalogenative radical cyclization catalyzed by disulfide.

Scheme 15: Hydrodifluoroacetamidation of alkenes catalyzed by disulfide.

Scheme 16: Plausible mechanism of the hydrodifluoroacetamidation of alkenes catalyzed by disulfide.

Scheme 17: Disulfide-cocatalyzed anti-Markovnikov olefin hydration reactions.

Scheme 18: Disulfide-catalyzed decarboxylation of carboxylic acids.

Scheme 19: Proposed mechanism of the disulfide-catalyzed decarboxylation of carboxylic acids.

Scheme 20: Disulfide-catalyzed decarboxylation of carboxylic acids.

Scheme 21: Disulfide-catalyzed conversion of maleate esters to fumarates and 5H-furanones.

Scheme 22: Disulfide-catalyzed isomerization of difluorotriethylsilylethylene.

Scheme 23: Disulfide-catalyzed isomerization of allyl alcohols to carbonyl compounds.

Scheme 24: Proposed mechanism for the disulfide-catalyzed isomerization of allyl alcohols to carbonyl compound...

Scheme 25: Diphenyl disulfide-catalyzed enantioselective synthesis of ophirin B.

Scheme 26: Disulfide-catalyzed isomerization in the total synthesis of (+)-hitachimycin.

Scheme 27: Disulfide-catalyzed isomerization in the synthesis of (−)-gloeosporone.

Palladium-catalyzed regio- and stereoselective synthesis of aryl and 3-indolyl-substituted 4-methylene-3,4-dihydroisoquinolin-1(2H)-ones

- Valeria Nori,

- Antonio Arcadi,

- Armando Carlone,

- Fabio Marinelli and

- Marco Chiarini

Beilstein J. Org. Chem. 2020, 16, 1084–1091, doi:10.3762/bjoc.16.95

- -dioxane/H2O as the reaction medium (Table 1, entry 5). While MeCN, DMF, THF and DMSO as solvents gave worse results (Table 1, entries 6–9), the environmentally friendly EtOH proved to be the most efficient reaction medium (Table 1, entry 10). Further attempts to increase the yield of 4aa by tuning the

- presence of a catalytic amount of the ligand-free PdCl2 in environmentally friendly ethanol, achieve an efficient regio- and stereoselective synthesis of 4-methylene-3,4-dihydroisoquinolin-1(2H)-ones 4. It is worth noting that, during the preparation of this paper, a related article focused on the

Graphical Abstract

Scheme 1: Planned approach to tetrasubstituted-4-methylene-3,4-dihydroisoquinolin-1(2H)-ones 4 and 6.

Scheme 2: Preparation of the starting N-propargyl-2-iodobenzamides 2.

Scheme 3: Substrate scope of the reaction of N-propargyl-2-iodobenzamide 2a with arylboronic acids 3b–i.

Scheme 4: Substrate scope of the reaction of N-propargyl-2-iodobenzamides 2c–f with arylboronic acids 3a–c/j.

Scheme 5: Reaction of N-propargyl-2-iodobenzamides 2b,f with the 2-alkynyltrifluoroacetanilides 5a–c.

Aldehydes as powerful initiators for photochemical transformations

- Maria A. Theodoropoulou,

- Nikolaos F. Nikitas and

- Christoforos G. Kokotos

Beilstein J. Org. Chem. 2020, 16, 833–857, doi:10.3762/bjoc.16.76

- support through the programme “EPISTHMONIKES MELETES 2015” (PhotoOrganocatalysis: Development of new environmentally-friendly methods for the synthesis of compounds for the

Graphical Abstract

Scheme 1: Norrish type I and II dissociations.

Scheme 2: Proposed radical pair formation after the photolysis of benzaldehyde (8).

Scheme 3: Aldehydes in the Paterno–Büchi reaction.

Scheme 4: 2,3-Diazabicyclo[2.2.1]hept-2-ene (DBH).

Scheme 5: Dissociation pathways of benzaldehyde.

Scheme 6: Reactions that lead to polarized products detectable by CIDNP.

Scheme 7: MMA (26), DEABP (27), and Michler’s ketone (28).

Scheme 8: Radical intermediates of DEABP.

Scheme 9: Photoinitiated polymerization of monomeric MMA (26) using the quinoxalines 32 and benzaldehyde (8).

Scheme 10: Acetone (4) and formaldehyde (35) as photografting initiators.

Scheme 11: Photografting by employing acetaldehyde (36) as the photoinitiator.

Scheme 12: Proposed photolysis mechanism for aliphatic ketones 44 and formaldehyde (35).

Scheme 13: Initiator 50, reductant 51, and benzaldehyde derivatives 52–54 for the polymerization of the methac...

Scheme 14: Proposed mechanism of the photomediated atom transfer radical polymerization employing the benzalde...

Scheme 15: cis/trans isomerization employing triplet states of photosensitizers.

Scheme 16: Salicylaldehyde (68) forms an internal hydrogen bond.

Scheme 17: Olefin isomerization via energy transfer from a carbonyl compound.

Scheme 18: Mechanistic pathways for the Paterno–Büchi reaction.

Scheme 19: Isomeric oxetanes formed after photochemical addition of aryl aldehydes to 2-butenes.

Scheme 20: Rotation of the C3–C4 bond of the biradical intermediate may lead to all four conformations.

Scheme 21: Photolysis products of benzaldehyde (8) in different solvents. a) In benzene or ethanol. b) In hex-...

Scheme 22: N-tert-Butylbenzamide formation proceeds via a benzoyl radical.

Scheme 23: Photochemical pinacol coupling.

Scheme 24: Photochemical ATRA catalyzed by 4-anisaldehyde (52).

Scheme 25: Proposed triplet sensitization mechanism of the ATRA reaction in the presence of 4-anisaldehyde (52...

Scheme 26: Benzaldehyde-mediated photoredox CDC reaction: compatible amides and ethers.

Scheme 27: Photoredox cross-dehydrogenative coupling (CDC) conditions and proposed reaction mechanism.

Scheme 28: Optimized conditions for the photoredox merger reaction.

Scheme 29: Proposed mechanism for the C(sp3)–H alkylation/arylation of ethers.

Scheme 30: Substrate scope for the photochemical alkylation of ethers.

Scheme 31: C(sp3)–H Functionalization of N-containing molecules.

Scheme 32: Substrate scope for the photochemical alkylation of N-containing molecules.

Scheme 33: Additional products yielded by the photochemical alkylation reaction of N-containing molecules.

Scheme 34: C(sp3)–H functionalization of thioethers.

Scheme 35: Proposed mechanism for the C(sp3)–H alkylation/arylation of N-containing molecules and thioethers.

Scheme 36: Hydroacylation using 4-cyanobenzaldehyde (53) as the photoinitiator.

Scheme 37: Selectivity for the formation of the α,α-disubstituted aldehydes.

Scheme 38: Substrate scope for the photochemical addition of aldehydes to Michael acceptors.

Scheme 39: Proposed mechanism for the hydroacylation of Michael acceptors using 4-cyanobenzaldehyde (53) as th...

Scheme 40: Catalytic arylation of aromatic aldehydes by aryl bromides in which the reaction product acts as th...

Scheme 41: Proposed mechanism for the catalytic arylation of benzaldehydes by aryl bromides in which the react...

Scheme 42: Functionalization of the chiral cyclobutanes 180.

Scheme 43: Optimized reaction conditions and proposed mechanism for the sulfonylcyanation of cyclobutenes.

Rhodium-catalyzed reductive carbonylation of aryl iodides to arylaldehydes with syngas

- Zhenghui Liu,

- Peng Wang,

- Zhenzhong Yan,

- Suqing Chen,

- Dongkun Yu,

- Xinhui Zhao and

- Tiancheng Mu

Beilstein J. Org. Chem. 2020, 16, 645–656, doi:10.3762/bjoc.16.61

- environmentally friendly than other frequently used hydrogen sources like hydrosilanes [17], tributyltin hydride (Bu3SnH) (often used in natural product syntheses) [18][19][20] and hydroboranes [21][22][23], since the only byproduct is water. The production, storage and use of H2 received much attention and

- pressure, cheap ligand and low metal dosage could significantly improve the practicability in both chemical researches and industrial applications. Keywords: cost-effective ligand; industrial catalysis; reductive carbonylation; rhodium catalyst; syngas; Introduction The exploration of environmentally

- friendly and highly effective synthetic methods has been a significant goal of research [1][2][3][4][5]. In this aspect, effective catalytic systems and organometallic chemistry are suitable technologies to accomplish these goals. Carbonylation processes are important transformations in the refinement and

Graphical Abstract

Figure 1: Rhodium-catalyzed reductive carbonylation of iodobenzene with CO and H2 to afford benzaldehyde. a) ...

Scheme 1: Scaled-up experiment of the reductive carbonylation of iodobenzene to benzaldehyde under the optimi...

Scheme 2: Catalytic species participating in the catalytic process.

Scheme 3: Substrate scope for the Rh-catalyzed reductive carbonylation of aryl iodides using CO and H2. React...

Scheme 4: Isotope-labeling experiments.

Scheme 5: Proposed reaction mechanism for the Rh-catalyzed reductive carbonylation of aryl iodides using CO a...

A systematic review on silica-, carbon-, and magnetic materials-supported copper species as efficient heterogeneous nanocatalysts in “click” reactions

- Pezhman Shiri and

- Jasem Aboonajmi

Beilstein J. Org. Chem. 2020, 16, 551–586, doi:10.3762/bjoc.16.52

- methodologies. These inorganic supported nanocatalysts have been found to be efficient, environmentally friendly, recyclable, and durable. In addition, one of the vital issues for expanding new, stable, and reusable catalysts is the discovery of unique catalysts. The basis and foundation of this review article

Graphical Abstract

Scheme 1: Chemical structure of the catalysts 1a and 1b and their catalytic application in CuAAC reactions.

Scheme 2: Synthetic route to the catalyst 11 and its catalytic application in CuAAC reactions.

Scheme 3: Synthetic route of dendrons, illustrated using G2-AMP 23.

Scheme 4: The catalytic application of CuYAu–Gx-AAA–SBA-15 in a CuAAC reaction.

Scheme 5: Synthetic route to the catalyst 36.

Scheme 6: Application of the catalyst 36 in CuAAC reactions.

Scheme 7: The synthetic route to the catalyst 45 and catalytic application of 45 in “click” reactions.

Scheme 8: Synthetic route to the catalyst 48 and catalytic application of 48 in “click” reactions.

Scheme 9: Synthetic route to the catalyst 58 and catalytic application of 58 in “click” reactions.

Scheme 10: Synthetic route to the catalyst 64 and catalytic application of 64 in “click” reactions.

Scheme 11: Chemical structure of the catalyst 68 and catalytic application of 68 in “click” reactions.

Scheme 12: Chemical structure of the catalyst 69 and catalytic application of 69 in “click” reactions.

Scheme 13: Synthetic route to, and chemical structure of the catalyst 74.

Scheme 14: Application of the cayalyst 74 in “click” reactions.

Scheme 15: Synthetic route to, and chemical structure of the catalyst 78 and catalytic application of 78 in “c...

Scheme 16: Synthetic route to the catalyst 85.

Scheme 17: Application of the catalyst 85 in “click” reactions.

Scheme 18: Synthetic route to the catalyst 87 and catalytic application of 87 in “click” reactions.

Scheme 19: Chemical structure of the catalyst 88 and catalytic application of 88 in “click” reactions.

Scheme 20: Synthetic route to the catalyst 90 and catalytic application of 90 in “click” reactions.

Scheme 21: Synthetic route to the catalyst 96 and catalytic application of 96 in “click” reactions.

Scheme 22: Synthetic route to the catalyst 100 and catalytic application of 100 in “click” reactions.

Scheme 23: Synthetic route to the catalyst 102 and catalytic application of 23 in “click” reactions.

Scheme 24: Synthetic route to the catalysts 108–111.

Scheme 25: Catalytic application of 108–111 in “click” reactions.

Scheme 26: Synthetic route to the catalyst 121 and catalytic application of 121 in “click” reactions.

Scheme 27: Synthetic route to 125 and application of 125 in “click” reactions.

Scheme 28: Synthetic route to the catalyst 131 and catalytic application of 131 in “click” reactions.

Scheme 29: Synthetic route to the catalyst 136.

Scheme 30: Application of the catalyst 136 in “click” reactions.

Scheme 31: Synthetic route to the catalyst 141 and catalytic application of 141 in “click” reactions.

Scheme 32: Synthetic route to the catalyst 144 and catalytic application of 144 in “click” reactions.

Scheme 33: Synthetic route to the catalyst 149 and catalytic application of 149 in “click” reactions.

Scheme 34: Synthetic route to the catalyst 153 and catalytic application of 153 in “click” reactions.

Scheme 35: Synthetic route to the catalyst 155 and catalytic application of 155 in “click” reactions.

Scheme 36: Synthetic route to the catalyst 157 and catalytic application of 157 in “click” reactions.

Scheme 37: Synthetic route to the catalyst 162.

Scheme 38: Application of the catalyst 162 in “click” reactions.

Scheme 39: Synthetic route to the catalyst 167 and catalytic application of 167 in “click” reactions.

Scheme 40: Synthetic route to the catalyst 169 and catalytic application of 169 in “click” reactions.

Scheme 41: Synthetic route to the catalyst 172.

Scheme 42: Application of the catalyst 172 in “click” reactions.

Regio- and stereoselective synthesis of new ensembles of diversely functionalized 1,3-thiaselenol-2-ylmethyl selenides by a double rearrangement reaction

- Svetlana V. Amosova,

- Andrey A. Filippov,

- Nataliya A. Makhaeva,

- Alexander I. Albanov and

- Vladimir A. Potapov

Beilstein J. Org. Chem. 2020, 16, 515–523, doi:10.3762/bjoc.16.47

- activity based on affordable and environmentally friendly materials is another important trend in organoselenium chemistry [17]. Reviews on the biological activity of organoselenium compounds reported examples exhibiting high antitumor, antiviral, antimicrobial, and neuroprotective activities [12][18][19

Graphical Abstract

Scheme 1: Possible formation of reaction products starting from 1 via seleniranium 2 or thiiranium cations 3.

Scheme 2: Unusual regio- and stereoselective nucleophilic reactions of thiaselenole 1 at two centers of the s...

Scheme 3: Reactions of thiaselenole 1 with С- and S-centered nucleophiles affording new families of linear un...

Scheme 4: The reactions of thiaselenole 1 with the formation of polyfunctionalized 2,3-dihydro-1,4-thiaseleni...

Scheme 5: The synthesis of new 1,3-thiaselenole ensembles by reactions of thiaselenole 1 with mercapto benzaz...

Scheme 6: The formation of product 4 via compound 5 by the reaction of thiaselenole 1 with potassium selenocy...

Figure 1: Monitoring the reaction of thiaselenole 1 with KSeCN by 1H NMR spectroscopy (in accordance with the...

Scheme 7: The reaction pathway for the formation of compounds 4 and 5.

Scheme 8: Synthesis of new ensembles of 1,3-thiaselenol-2-ylmethyl selenides 6a–l (77Se NMR data are included...

Scheme 9: The synthesis of vinyl selenides 7a,b through nucleophilic addition of 1,3-thiaselenol-2-ylmethylse...

Scheme 10: One-pot synthesis of diselenide 8 from thiaselenole 1 (77Se NMR data are included).

Scheme 11: Synthesis of compounds 6a–j from diselenide 8.

Recent developments in photoredox-catalyzed remote ortho and para C–H bond functionalizations

- Rafia Siddiqui and

- Rashid Ali

Beilstein J. Org. Chem. 2020, 16, 248–280, doi:10.3762/bjoc.16.26

- groundbreaking advancements were accomplished in this wonderful area of research, transforming a specific C–H bond effectively and selectively under favorable conditions (viz, room temperature, without external oxidant, cost-effective, sustainable, and environmentally friendly) still remains a highly challenging

- observed a number of interesting facts, viz: (i) the reaction proceeded with environmentally friendly molecular oxygen as oxidant, (ii) water was the only byproduct of the reaction, (iii) no reaction occurred without the involvement of a photocatalyst, (iv) high yields were obtained with electron-donating

- reported the synthesis of coumarin derivatives using photoredox catalyst 12 and CF3SO2Cl as a potent radical source [111]. In comparison to other reported methods, the reaction was carried out under mild as well as environmentally friendly conditions, and the reaction remarkably showed much tolerance for

Graphical Abstract

Figure 1: List of photoredox catalysts used for C–H bond functionalizations.

Figure 2: List of metal-based photoredox catalysts used in this review article.

Figure 3: Jablonski diagram.

Figure 4: Photoredox catalysis via reductive or oxidative pathways. D = donor, A = acceptor, S = substrate, P...

Figure 5: Schematic representation of the combination of photoredox catalysis and transition metal catalysis.

Scheme 1: Weinreb amide C–H olefination.

Figure 6: Mechanism for the formation of 21 from 19 using photoredox catalyst 11.

Scheme 2: C–H olefination of phenolic ethers.

Scheme 3: Decarboxylative acylation of acetanilides.

Figure 7: Mechanism for the formation of 30 from acetanilide derivatives.

Scheme 4: Synthesis of fluorenone derivatives by intramolecular deoxygenative acylation of biaryl carboxylic ...

Figure 8: Mechanism for the photoredox-catalyzed synthesis of fluorenone derivatives.

Scheme 5: Synthesis of benzothiazoles via aerobic C–H thiolation.

Figure 9: Plausible mechanism for the construction of benzothiazoles from benzothioamides.

Scheme 6: Synthesis of benzothiazoles via oxidant-free C–H thiolation.

Figure 10: Mechanism involved in the synthesis of benzothiazoles via oxidant-free C–H thiolation.

Scheme 7: Synthesis of indoles via C–H cyclization of anilides with alkynes.

Scheme 8: Preparation of 3-trifluoromethylcoumarins via C–H cyclization of arylpropiolate esters.

Figure 11: Mechanistic pathway for the synthesis of coumarin derivatives via C–H cyclization.

Scheme 9: Monobenzoyloxylation without chelation assistance.

Figure 12: Plausible mechanism for the formation of 71 from 70.

Scheme 10: Aryl-substituted arenes prepared by inorganic photoredox catalysis using 12a.

Figure 13: Proposed mechanism for C–H arylations in the presence of 12a and a Pd catalyst.

Scheme 11: Arylation of purines via dual photoredox catalysis.

Scheme 12: Arylation of substituted arenes with an organic photoredox catalyst.

Scheme 13: C–H trifluoromethylation.

Figure 14: Proposed mechanism for the trifluoromethylation of 88.

Scheme 14: Synthesis of benzo-3,4-coumarin derivatives.

Figure 15: Plausible mechanism for the synthesis of substituted coumarins.

Scheme 15: Oxidant-free oxidative phosphonylation.

Figure 16: Mechanism proposed for the phosphonylation reaction of 100.

Scheme 16: Nitration of anilines.

Figure 17: Plausible mechanism for the nitration of aniline derivatives via photoredox catalysis.

Scheme 17: Synthesis of carbazoles via intramolecular amination.

Figure 18: Proposed mechanism for the formation of carbazoles from biaryl derivatives.

Scheme 18: Synthesis of substituted phenols using QuCN.

Figure 19: Mechanism for the synthesis of phenol derivatives with photoredox catalyst 8.

Scheme 19: Synthesis of substituted phenols with DDQ (5).

Figure 20: Possible mechanism for the generation of phenols with the aid of photoredox catalyst 5.

Scheme 20: Aerobic bromination of arenes using an acridinium-based photocatalyst.

Scheme 21: Aerobic bromination of arenes with anthraquinone.

Figure 21: Proposed mechanism for the synthesis of monobrominated compounds.

Scheme 22: Chlorination of benzene derivatives with Mes-Acr-MeClO4 (2).

Figure 22: Mechanism for the synthesis of 131 from 132.

Scheme 23: Chlorination of arenes with 4CzIPN (5a).

Figure 23: Plausible mechanism for the oxidative photocatalytic monochlorination using 5a.

Scheme 24: Monofluorination using QuCN-ClO4 (8).

Scheme 25: Fluorination with fluorine-18.

Scheme 26: Aerobic amination with acridinium catalyst 3a.

Figure 24: Plausible mechanism for the aerobic amination using acridinium catalyst 3a.

Scheme 27: Aerobic aminations with semiconductor photoredox catalyst 18.

Scheme 28: Perfluoroalkylation of arenes.

Scheme 29: Synthesis of benzonitriles in the presence of 3a.

Figure 25: Plausible mechanism for the synthesis of substituted benzonitrile derivatives in the presence of 3a....

A green, economical synthesis of β-ketonitriles and trifunctionalized building blocks from esters and lactones

- Daniel P. Pienaar,

- Kamogelo R. Butsi,

- Amanda L. Rousseau and

- Dean Brady

Beilstein J. Org. Chem. 2019, 15, 2930–2935, doi:10.3762/bjoc.15.287

- hydroxy ester 4 followed by reaction with acetonitrile (CH3CN), a multistep approach would be less economical in industry (Scheme 1). Results and Discussion To date, the most economically appealing conditions from an environmentally friendly perspective entail relatively mild base-promoted (potassium tert

- ether resulted in recovery complications for some of the other compounds (e.g., when this methodology was applied to δ-valerolactone and γ-butyrolactone) and may therefore not be universally beneficial. Conclusion In conclusion, mild, environmentally friendly procedures were developed for the

Graphical Abstract

Scheme 1: Proposed retrosynthesis of the free diol 1.

Scheme 2: Preparation of O-unprotected, trifunctionalized synthons from lactones.

α-Photooxygenation of chiral aldehydes with singlet oxygen

- Dominika J. Walaszek,

- Magdalena Jawiczuk,

- Jakub Durka,

- Olga Drapała and

- Dorota Gryko

Beilstein J. Org. Chem. 2019, 15, 2076–2084, doi:10.3762/bjoc.15.205

- ], TEMPO [4], or benzoyl peroxide [5][6][7][8]. Therefore, the use of environmentally friendly reagents instead is highly desirable. Along this line, singlet oxygen by being easily photochemically generated from triplet oxygen in the presence of organic dyes seems promising. Despite its high reactivity and

Graphical Abstract

Scheme 1: Asymmetric α-photooxygenation of chiral aldehydes.

Scheme 2: α-Photooxygenation of β-substituted aldehydes.

Scheme 3: Synthesis and α-photooxygenation of 3,4-diphenylbutanal (1).

Scheme 4: Stereoselective α-photooxygenation of 3,4-diphenylbutanal (1) with 1O2.

Scheme 5: Schematic representation of the in situ methodology and preferred conformation of diols with Mo2 co...

Figure 1: ECD spectra of diols syn-6 and anti’-6 recorded a) with 19 in DMSO and b) in acetonitrile compared ...

Scheme 6: Asymmetric synthesis of 3,4-diphenylbutane-1,2-diol.

Molecular basis for the plasticity of aromatic prenyltransferases in hapalindole biosynthesis

- Takayoshi Awakawa and

- Ikuro Abe

Beilstein J. Org. Chem. 2019, 15, 1545–1551, doi:10.3762/bjoc.15.157

- useful catalysts that control the regiospecificity in an environmentally friendly manner. The information from their X-ray structures will contribute to future engineering of PTases. Furthermore, the structure of AmbP1 can serve as a model to alter the reaction through creating a metal binding site

Graphical Abstract

Figure 1: The reactions of aromatic PTases.

Figure 2: The reactions catalyzed by AmbP1 (A) and AmbP3 (B).

Figure 3: The overall structure of apo-AmbP1 (A), the Mg2+-free structure (B), and the Mg2+-bound structure (...

Figure 4: The active site structure of AmbP1. 1 and GSPP were bound in the active site without Mg2+ (A, Mg2+-...

Figure 5: The active site structure of AmbP3 with substrates. The AmbP3 structure in complex with hapalindole...

Figure 6: Multiple amino acid sequence alignment of AmbP1, AmbP3, and other ABBA PTases, visualized by ESPrip...

Understanding the unexpected effect of frequency on the kinetics of a covalent reaction under ball-milling conditions

- Ana M. Belenguer,

- Adam A. L. Michalchuk,

- Giulio I. Lampronti and

- Jeremy K. M. Sanders

Beilstein J. Org. Chem. 2019, 15, 1226–1235, doi:10.3762/bjoc.15.120