Search results

Search for "homogeneous catalysis" in Full Text gives 60 result(s) in Beilstein Journal of Organic Chemistry.

C2 to C6 biobased carbonyl platforms for fine chemistry

- Jingjing Jiang,

- Muhammad Noman Haider Tariq,

- Florence Popowycz,

- Yanlong Gu and

- Yves Queneau

Beilstein J. Org. Chem. 2025, 21, 2103–2172, doi:10.3762/bjoc.21.165

- from homogeneous catalysts such as mineral acids, organic acids, metal salts (with high availability and low costs) to heterogeneous ones such as zeolites, metal oxides, sulfonated polymers, carbon-based solid acids. The latter allow to overcome the problems of separation encountered with homogeneous

- catalysis. The mechanism first involves the isomerization of xylose into xylulose under Lewis acid-type catalysis, and the subsequent dehydration of xylulose into furfural under Brønsted acid-type catalysis (Scheme 47). Humins are naturally formed in all processes involving the acid-catalyzed degradation of

Graphical Abstract

Figure 1: C2–C6 biobased carbonyl building blocks.

Scheme 1: Proposed (2 + 2) route to glycolaldehyde and glycolic acid from erythritol by Cu/AC catalyst (AC = ...

Scheme 2: Reductive amination of GCA.

Scheme 3: N-Formylation of secondary amines by reaction with GCA.

Scheme 4: Synthesis and conversion of hydroxy acetals to cyclic acetals.

Scheme 5: Synthesis of 3-(indol-3-yl)-2,3-dihydrofurans via three-component reaction of glycolaldehyde, indol...

Scheme 6: BiCl3-catalyzed synthesis of benzo[a]carbazoles from 2-arylindoles and α-bromoacetaldehyde ethylene...

Scheme 7: Cu/NCNSs-based conversion of glycerol to glycolic acid and other short biobased acids.

Scheme 8: E. coli-based biotransformation of C1 source molecules (CH4, CO2 and CO) towards C2 glycolic acid.

Scheme 9: N-Formylation of amines with C2 (a) or C3 (b) biomass-based feedstocks.

Scheme 10: Methods for the formation of propanoic acid (PA) from lactic acid (LA).

Scheme 11: Co-polymerization of biobased lactic acid and glycolic acid via a bicatalytic process.

Scheme 12: Oxidation of α-hydroxy acids by tetrachloroaurate(III) in acetic acid–sodium acetate buffer medium.

Figure 2: Selective catalytic pathways for the conversion of lactic acid (LA).

Scheme 13: Synthesis of 1,3-PDO via cross-aldol reaction between formaldehyde and acetaldehyde to 3-hydroxypro...

Scheme 14: Hydrothermal conversion of 1,3-dihydroxy-2-propane and 2,3-dihydroxypropanal to methylglyoxal.

Scheme 15: FLS-catalyzed formose reaction to synthesize GA and DHA.

Scheme 16: GCA and DHA oxidation products of glycerol and isomerization of GCA to DHA under flow conditions us...

Scheme 17: Acid-catalyzed reactions of DHA with alcohols.

Scheme 18: Synthesis of dihydroxyacetone phosphate from dihydroxyacetone.

Scheme 19: Bifunctional acid–base catalyst DHA conversion into lactic acid via pyruvaldehyde or fructose forma...

Scheme 20: Catalytic one-pot synthesis of GA and co-synthesis of formamides and formates from DHA.

Scheme 21: (a) Synthesis of furan derivatives and (b) synthesis of thiophene derivative by cascade [3 + 2] ann...

Scheme 22: Brønsted acidic ionic liquid catalyzed synthesis of benzo[a]carbazole from renewable acetol and 2-p...

Scheme 23: Asymmetric hydrogenation of α-hydroxy ketones to 1,2-diols.

Scheme 24: Synthesis of novel 6-(substituted benzylidene)-2-methylthiazolo [2,3-b]oxazol-5(6H)-one from 1-hydr...

Scheme 25: ʟ-Proline-catalyzed synthesis of anti-diols from hydroxyacetone and aldehydes.

Scheme 26: C–C-bond-formation reactions of a biomass-based feedstock aromatic aldehyde (C5) and hydroxyacetone...

Scheme 27: Ethanol upgrading to C4 bulk chemicals via the thiamine (VB1)-catalyzed acetoin condensation.

Scheme 28: One-pot sequential chemoenzymatic synthesis of 2-aminobutane-1,4-diol and 1,2,4-butanetriol via 1,4...

Scheme 29: Synthesis of 1,4-dihydroxybutan-2-one by microbial transformation.

Scheme 30: Conversion of polyols by [neocuproine)Pd(OAc)]2(OTf)2] to α-hydroxy ketones.

Scheme 31: Chemoselective oxidation of alcohols with chiral palladium-based catalyst 2.

Scheme 32: Electrochemical transformation of furfural to 5-hydroxy-2(5H)-furanone (HFO).

Scheme 33: Selective hydrodeoxygenation of HFO and oxidation to γ-butyrolactone (GBL).

Scheme 34: Photosensitized oxygenation of furan towards HFO via ozonide intermediates.

Scheme 35: Conversion of furfural to HFO and MAN by using mesoporous carbon nitride (SGCN) as photocatalyst.

Scheme 36: Synthesis of HFO from furan derivatives.

Scheme 37: Photooxidation of furfural to 5-hydroxy-2(5H)-furanone (HFO).

Scheme 38: Synthesis of Friedel–Crafts indole adduct from HFO.

Scheme 39: Conversion of HFO to α,γ-substituted chiral γ-lactones.

Scheme 40: Tautomeric transformation of HFO to formylacrylic acid.

Scheme 41: Hydrolysis of HFO to succinic acid in aqueous solution.

Scheme 42: Substitution and condensation reactions of 5-hydroxy-2(5H)-furanone (HFO).

Scheme 43: (a) Conversion of HFO towards valuable C4 chemicals and (b) anodic oxidation of 5-hydroxy-2(5H)-fur...

Figure 3: Conversion of HFO towards other natural and synthetic substances.

Scheme 44: Conversion of furfural to maleic anhydride (reaction a: VOx/Al2O3; reaction b: VPO).

Scheme 45: Conversion of furfural into succinic acid.

Scheme 46: Electro‑, photo‑, and biocatalysis for one-pot selective conversions of furfural into C4 chemicals.

Scheme 47: Production route of furfural from hemicellulose.

Scheme 48: Mechanism for xylose dehydration to furfural through a choline xyloside intermediate.

Scheme 49: Conversion of furfural to furfuryl alcohol and its derivatives.

Scheme 50: Conversion of furfural to furfuryl alcohol and 3-(2-furyl)acrolein.

Scheme 51: The aerobic oxidative condensation of biomass-derived furfural and linear alcohols.

Scheme 52: The single-step synthesis of 2-pentanone from furfural.

Scheme 53: Electrocatalytic coupling reaction of furfural and levulinic acid.

Scheme 54: Conversion of furfural to m-xylylenediamine.

Scheme 55: Conversion of furfural to tetrahydrofuran-derived amines.

Scheme 56: Formation of trans-4,5-diamino-cyclopent-2-enones from furfural.

Scheme 57: Production of pyrrole and proline from furfural.

Scheme 58: Synthesis of 1‑(trifluoromethyl)-8-oxabicyclo[3.2.1]oct-3-en-2-ones from furfural.

Scheme 59: Conversion of furfural to furfural-derived diacids.

Scheme 60: A telescope protocol derived from furfural and glycerol.

Scheme 61: A tandem cyclization of furfural and 5,5-dimethyl-1,3-cyclohexanedione.

Scheme 62: A Ugi four-component reaction to construct furfural-based polyamides.

Scheme 63: One-pot synthesis of γ-acyloxy-Cy7 from furfural.

Scheme 64: Dimerization–Piancatelli sequence toward humins precursors from furfural.

Scheme 65: Conversion of furfural to CPN.

Scheme 66: Synthesis of jet fuels range cycloalkanes from CPN and lignin-derived vanillin.

Scheme 67: Solar-energy-driven synthesis of high-density biofuels from CPN.

Scheme 68: Reductive amination of CPN to cyclopentylamine.

Scheme 69: Asymmetric hydrogenation of C=O bonds of exocyclic α,β-unsaturated cyclopentanones.

Scheme 70: Preparation of levulinic acid via the C5 route (route a) or C6 route (routes b1 and b2).

Scheme 71: Mechanism of the rehydration of HMF to levulinic acid and formic acid.

Scheme 72: Important levulinic acid-derived chemicals.

Scheme 73: Direct conversion of levulinic acid to pentanoic acid.

Scheme 74: Catalytic aerobic oxidation of levulinic acid to citramalic acid.

Scheme 75: Conversion of levulinic acid to 1,4-pentanediol (a) see ref. [236]; b) see ref. [237]; c) see ref. [238]; d) see r...

Scheme 76: Selective production of 2-butanol through hydrogenolysis of levulinic acid.

Scheme 77: General reaction pathways proposed for the formation of 5MPs from levulinic acid.

Scheme 78: Selective reductive amination of levulinic acid to N-substituted pyrroles.

Scheme 79: Reductive amination of levulinic acid to chiral pyrrolidinone.

Scheme 80: Reductive amination of levulinic acid to non-natural chiral γ-amino acid.

Scheme 81: Nitrogen-containing chemicals derived from levulinic acid.

Scheme 82: Preparation of GVL from levulinic acid by dehydration and hydrogenation.

Scheme 83: Ruthenium-catalyzed levulinic acid to chiral γ-valerolactone.

Scheme 84: Catalytic asymmetric hydrogenation of levulinic acid to chiral GVL.

Scheme 85: Three steps synthesis of ε-caprolactam from GVL.

Scheme 86: Multistep synthesis of nylon 6,6 from GVL.

Scheme 87: Preparation of MeGVL by α-alkylation of GVL.

Scheme 88: Ring-opening polymerization of five-membered lactones.

Scheme 89: Synthesis of GVL-based ionic liquids.

Scheme 90: Preparation of butene isomers from GVL under Lewis acid conditions.

Scheme 91: Construction of C5–C12 fuels from GVL over nano-HZSM-5 catalysts.

Scheme 92: Preparation of alkyl valerate from GVL via ring opening/reduction/esterification sequence.

Scheme 93: Construction of 4-acyloxypentanoic acids from GVL.

Scheme 94: Synthesis of 1,4-pentanediol (PDO) from GVL.

Scheme 95: Construction of novel cyclic hemiketal platforms via self-Claisen condensation of GVL.

Scheme 96: Copper-catalyzed lactamization of GVL.

Figure 4: Main scaffolds obtained from HMF.

Scheme 97: Biginelli reactions towards HMF-containing dihydropyrimidinones.

Scheme 98: Hantzsch dihydropyridine synthesis involving HMF.

Scheme 99: The Kabachnik–Fields reaction involving HMF.

Scheme 100: Construction of oxazolidinone from HMF.

Scheme 101: Construction of rhodamine-furan hybrids from HMF.

Scheme 102: A Groebke–Blackburn–Bienaymé reaction involving HMF.

Scheme 103: HMF-containing benzodiazepines by [4 + 2 + 1] cycloadditions.

Scheme 104: Synthesis of fluorinated analogues of α-aryl ketones.

Scheme 105: Synthesis of HMF derived disubstituted γ-butyrolactone.

Scheme 106: Functionalized aromatics from furfural and HMF.

Scheme 107: Diels–Alder adducts from HMF or furfural with N-methylmaleimide.

Scheme 108: Pathway of the one-pot conversion of HMF into phthalic anhydride.

Scheme 109: Photocatalyzed preparation of humins (L-H) from HMF mixed with spoiled HMF residues (LMW-H) and fur...

Scheme 110: Asymmetric dipolar cycloadditions on HMF.

Scheme 111: Dipolar cycloadditions of HMF based nitrones to 3,4- and 3,5-substituted isoxazolidines.

Scheme 112: Production of δ-lactone-fused cyclopenten-2-ones from HMF.

Scheme 113: Aza-Piancatelli access to aza-spirocycles from HMF-derived intermediates.

Scheme 114: Cross-condensation of furfural, acetone and HMF into C13, C14 and C15 products.

Scheme 115: Base-catalyzed aldol condensation/dehydration sequences from HMF.

Scheme 116: Condensation of HMF and active methylene nitrile.

Scheme 117: MBH reactions involving HMF.

Scheme 118: Synthesis of HMF-derived ionic liquids.

Scheme 119: Reductive amination/enzymatic acylation sequence towards HMF-based surfactants.

Scheme 120: The formation of 5-chloromethylfurfural (CMF).

Scheme 121: Conversion of CMF to HMF, levulinic acid, and alkyl levulinates.

Scheme 122: Conversion of CMF to CMFCC and FDCC.

Scheme 123: Conversion of CMF to BHMF.

Scheme 124: Conversion of CMF to DMF.

Scheme 125: CMF chlorine atom substitutions toward HMF ethers and esters.

Scheme 126: Introduction of carbon nucleophiles in CMF.

Scheme 127: NHC-catalyzed remote enantioselective Mannich-type reactions of CMF.

Scheme 128: Conversion of CMF to promising biomass-derived dyes.

Scheme 129: Radical transformation of CMF with styrenes.

Scheme 130: Synthesis of natural herbicide δ-aminolevulinic acid from CMF.

Scheme 131: Four step synthesis of the drug ranitidine from CMF.

Scheme 132: Pd/CO2 cooperative catalysis for the production of HHD and HXD.

Scheme 133: Different ruthenium (Ru) catalysts for the ring-opening of 5-HMF to HHD.

Scheme 134: Proposed pathways for preparing HXD from HMF.

Scheme 135: MCP formation and uses.

Scheme 136: Cu(I)-catalyzed highly selective oxidation of HHD to 2,5-dioxohexanal.

Scheme 137: Synthesis of N‑substituted 3‑hydroxypyridinium salts from 2,5-dioxohexanal.

Scheme 138: Ru catalyzed hydrogenations of HHD to 1,2,5-hexanetriol (a) see ref. [396]; b) see ref. [397]).

Scheme 139: Aviation fuel range quadricyclanes produced by HXD.

Scheme 140: Synthesis of HDGK from HXD and glycerol as a chain extender.

Scheme 141: Synthesis of serinol pyrrole from HXD and serinol.

Scheme 142: Synthesis of pyrroles from HXD and nitroarenes.

Scheme 143: Two-step production of PX from cellulose via HXD.

Scheme 144: Preparation of HCPN from HMF via hydrogenation and ring rearrangement.

Scheme 145: Suggested pathways from HMF to HCPN.

Scheme 146: α-Alkylation of HCPN with ethylene gas.

Scheme 147: Synthesis of 3-(hydroxymethyl)cyclopentylamine from HMF via reductive amination of HCPN.

Scheme 148: Production of LGO and Cyrene® from biomass.

Scheme 149: Synthesis of HBO from LGO and other applications.

Scheme 150: Construction of m-Cyrene® homopolymer.

Scheme 151: Conversion of Cyrene® to THFDM and 1,6-hexanediol.

Scheme 152: RAFT co-polymerization of LGO and butadienes.

Scheme 153: Polycondensation of HO-LGOL and diols with dimethyl adipate.

Scheme 154: Self-condensation of Cyrene® and Claisen–Schmidt reactions.

Scheme 155: Synthesis of 5-amino-2-(hydroxymethyl)tetrahydropyran from Cyrene®.

Microwave-enhanced additive-free C–H amination of benzoxazoles catalysed by supported copper

- Andrei Paraschiv,

- Valentina Maruzzo,

- Filippo Pettazzi,

- Stefano Magliocco,

- Paolo Inaudi,

- Daria Brambilla,

- Gloria Berlier,

- Giancarlo Cravotto and

- Katia Martina

Beilstein J. Org. Chem. 2025, 21, 1462–1476, doi:10.3762/bjoc.21.108

- , to the best of our knowledge, this study represents one of the few examples of a heterogeneous catalysed copper-mediated C–H amination of benzoxazole. The pursuit for greener methodologies in organic synthesis and transitioning from traditional homogeneous catalysis to the use of heterogeneous

- catalysts for direct C–H amination processes could be a significant breakthrough in optimising these reactions. Despite recent progress in site-selective C–H functionalisation [49], most reactions have remained reliant on homogeneous catalysis due to its molecularly defined nature. By contrast, the

- characterised. When undergoing regeneration, 200 mg of the exhausted Si-MonoAm-Cu(I) and 8 mg of CuCl were dispersed in 4 mL of THF. The reaction mixture was treated as described for the preparation of the fresh catalyst. General procedure for synthesis of derivative 2a by means of homogeneous catalysis

Graphical Abstract

Scheme 1: Representative synthetic routes for the C–H amination of benzoxazole using supported copper catalys...

Figure 1: Reaction of benzimidazole with piperidine. a) Reaction scheme including intermaidates and b) conver...

Figure 2: Reaction rate comparison between conventional (oil bath) and MW heating. Reaction conditions: benzo...

Scheme 2: Graphical representation of Si-MonoAm-Cu(I) and Si-DiAm-Cu(I) preparation.

Figure 3: TGA profiles of SIPERNAT silica and Si-MonoAm and Si-DiAm.

Scheme 3: Scope of the MW-promoted C2-amination of benzoxazole catalysed by Si-MonoAm-Cu(I). Reaction conditi...

Scheme 4: C2-Amination of substituted benzoxazoles. Reaction conditions: benzoxazole (1.0 mmol), piperidine (...

Figure 4: Hot filtration test for the Si-MonoAm-Cu(I)-catalysed C2-amination of benzoxazole with piperidine i...

Figure 5: FTIR spectra of samples on the left 3800–2400 cm−1 wavenumber on the right 1750–1350 cm−1 wavenumbe...

Figure 6: Si-MonoAm-Cu(I) catalyst reuse.

Figure 7: FESEM images of sample a) Si-MonoAm-Cu(I) 5 wt % and c) Si-MonoAm-Cu(I) 5 wt % used.

Figure 8: EDS maps of a) Si-MonoAm-Cu(I) and b) Si-MonoAm-Cu(I) used.

Catalysing (organo-)catalysis: Trends in the application of machine learning to enantioselective organocatalysis

- Stefan P. Schmid,

- Leon Schlosser,

- Frank Glorius and

- Kjell Jorner

Beilstein J. Org. Chem. 2024, 20, 2280–2304, doi:10.3762/bjoc.20.196

- Research (NCCR) Catalysis, ETH Zurich, Zurich CH-8093, Switzerland 10.3762/bjoc.20.196 Abstract Organocatalysis has established itself as a third pillar of homogeneous catalysis, besides transition metal catalysis and biocatalysis, as its use for enantioselective reactions has gathered significant

Graphical Abstract

Figure 1: Schematic depiction of available data sources for predictive modelling, each with its advantages an...

Figure 2: Schematic depiction of different kinds of molecular representations for fluoronitroethane. Among th...

Figure 3: Depiction of the energy diagram of a generic enantioselective reaction. In the centre, catalyst and...

Figure 4: Hammett parameters are derived from the equilibrium constant of substituted benzoic acids (example ...

Figure 5: Selected examples of popular descriptors applied to model organocatalytic reactions. Descriptors en...

Figure 6: Example bromocyclization reaction from Toste and co-workers using a DABCOnium catalyst system and C...

Figure 7: Example from Neel et al. using a chiral ion pair catalyst for the selective fluorination of allylic...

Figure 8: Data set created by Denmark and co-workers for the CPA-catalysed thiol addition to N-acylimines [67]. T...

Figure 9: Selected examples of ML developments that used the dataset from Denmark and co-workers [67]. (A) Varnek...

Figure 10: Study from Reid and Sigman developing statistical models for CPA-catalysed nucleophilic addition re...

Figure 11: Selected examples of studies where mechanistic transferability was exploited to model multiple reac...

Figure 12: Generality approach by Denmark and co-workers [132] for the iodination of arylpyridines. From the releva...

Figure 13: Betinol et al. [133] clustered the relevant chemical space and then evaluated the average ee for every c...

Figure 14: Corminboeuf and co-workers [134] chose a representative subset of the reaction space (indicated by dark ...

Figure 15: Example for data-driven modelling to improve substrate and catalyst design. (A) C–N coupling cataly...

Figure 16: Example for utilising a genetic algorithm for catalyst design. (A) Morita–Baylis–Hillman reaction s...

Figure 17: Organocatalysed synthesis of spirooxindole analogues by Kondo et al. [171] (A) Reaction scheme of dienon...

Figure 18: Schematic depiction of required developments in order to overcome current limitations of ML for org...

Factors influencing the performance of organocatalysts immobilised on solid supports: A review

- Zsuzsanna Fehér,

- Dóra Richter,

- Gyula Dargó and

- József Kupai

Beilstein J. Org. Chem. 2024, 20, 2129–2142, doi:10.3762/bjoc.20.183

- and an environmental perspective. An efficient catalytic process is characterised by the fact that the catalyst can be easily and, if possible, completely separated from the reaction mixture. Catalysts can be classified into homogeneous and heterogeneous catalysts. In homogeneous catalysis, the

- reaction components and the catalyst are in the same phase. Active catalytic sites are readily accessible to the reactants and therefore generally result in higher catalytic activity and selectivity [8]. As a result, homogeneous catalysis is generally preferred to heterogeneous catalysis, especially in the

Graphical Abstract

Scheme 1: Esterification of oleic acid (1) with propylsulfonic acid (Pr-SO3H)-functionalised mesoporous silic...

Scheme 2: Using confinement of organocatalytic units for improving the enantioselectivity of silica-supported...

Scheme 3: Michael addition catalysed by cinchona thiourea immobilised on magnetic nanoparticles (13).

Scheme 4: Michael addition catalysed by cinchona thiourea in the presence of magnetic nanoparticles.

Scheme 5: Benzoin condensation catalysed by N-benzylthiazolium salt attached to mesoporous material.

Scheme 6: Photoinduced RAFT polymerisation of n-butyl acrylate (19) catalysed by silica nanoparticle-supporte...

Scheme 7: Pressure and temperature dependence of the 1,4-addition of propanal to trans-β-nitrostyrene under c...

Scheme 8: α-Amination of ethyl 2-oxocyclopentanecarboxylate catalysed by PS-THU which could be recycled over ...

Scheme 9: Preparation of supported catalysts C29–C31 from cinchona squaramides 29–31 modified with a primary ...

Scheme 10: Application of PGMA-supported organocatalysts C29–C31 in the asymmetric Michael addition of pentane...

Scheme 11: Alcoholytic desymmetrisation of a cyclic anhydride 34 catalysed by polyamide-supported cinchona sul...

Aldiminium and 1,2,3-triazolium dithiocarboxylate zwitterions derived from cyclic (alkyl)(amino) and mesoionic carbenes

- Nedra Touj,

- François Mazars,

- Guillermo Zaragoza and

- Lionel Delaude

Beilstein J. Org. Chem. 2023, 19, 1947–1956, doi:10.3762/bjoc.19.145

- just three decades (Figure 1) [2]. In particular, cyclic diaminocarbenes based on the imidazoline, benzimidazole, or imidazole ring system (A–C) have led to a myriad of applications in organometallic chemistry, homogeneous catalysis, and materials science, to name just a few [3][4][5]. Due to their

Graphical Abstract

Figure 1: Various types of stable singlet carbenes and their acronyms.

Figure 2: Various types of NHC·CS2 zwitterions and their coordination modes.

Scheme 1: Synthesis of CAAC·CS2 zwitterion 2 from its free carbene parent 1.

Scheme 2: Synthesis of CAAC·CS2 zwitterions 4a–c with KN(SiMe3)2.

Scheme 3: Synthesis of 1,2,3-triazolium iodides 5a–f.

Scheme 4: Synthesis of MIC·CS2 zwitterions 6a and 6b with KN(SiMe3)2.

Scheme 5: Synthesis of MIC·CS2 zwitterions 6c–f with NaOt-Bu.

Figure 3: ORTEP representations of zwitterions 4a (CAAC-Mes-Cy·CS2, top) and 4c (CAAC-Die-MePh·CS2, bottom) w...

Figure 4: ORTEP representations of zwitterions 6b (MIC-Dip-Ph-Me·CS2, top) and 6e (MIC-Mes-Bu-Me·CS2, bottom)...

A novel recyclable organocatalyst for the gram-scale enantioselective synthesis of (S)-baclofen

- Gyula Dargó,

- Dóra Erdélyi,

- Balázs Molnár,

- Péter Kisszékelyi,

- Zsófia Garádi and

- József Kupai

Beilstein J. Org. Chem. 2023, 19, 1811–1824, doi:10.3762/bjoc.19.133

- stereoselective Michael addition reactions. Homogeneous catalysis was carried out in non-polar solvents (i.e., toluene), which allows the high performance of the lipophilic organocatalyst in terms of yield and stereoselectivity. To facilitate the pharmaceutical use of the lipophilic organocatalyst, we

Graphical Abstract

Figure 1: Application of cinchona squaramide 1 and recyclable, lipophilic cinchona squaramide organocatalysts ...

Scheme 1: Synthesis of demethylated cinchona squaramide organocatalyst and the incorporation of the flexible ...

Scheme 2: Synthesis of the lipophilic tag from methyl gallate (8) and attachment to the cinchona squaramide.

Figure 2: Classification of the tested non-polar solvents according to the GSK’s solvent sustainability guide ...

Figure 3: Recycling of the lipophilic organocatalyst in the stereoselective Michael addition by replacing the...

Scheme 3: A new, stereoselective synthetic route for baclofen.

Scheme 4: Gram-scale synthesis of (S)-baclofen hydrochloride.

Application of N-heterocyclic carbene–Cu(I) complexes as catalysts in organic synthesis: a review

- Nosheen Beig,

- Varsha Goyal and

- Raj K. Bansal

Beilstein J. Org. Chem. 2023, 19, 1408–1442, doi:10.3762/bjoc.19.102

- . A number of excellent reviews on different aspects of NHC chemistry has been published during this period [12][13][14]. NHCs have been widely employed in homogeneous catalysis [12] and as ligands for the preparation of coordination compounds of different metals [13]. The M–NHC bond is relatively

- for more acidic alkyne substrates. In contrast to the reaction under homogeneous catalysis conditions by a saturated solution of Cu(OAc), the reaction in the presence of catalyst 136 was 4.5 times (in the absence of HOAc) and 7.5 times (with HOAc) faster. Recently in 2022, Pérez-Torrente and co

Graphical Abstract

Scheme 1: In situ generation of imidazolylidene carbene.

Scheme 2: Hg(II) complex of NHC.

Scheme 3: Isolable and bottlable carbene reported by Arduengo [3].

Scheme 4: First air-stable carbene synthesized by Arduengo in 1992 [5].

Figure 1: General structure of an NHC.

Figure 2: Stabilization of an NHC by donation of the lone pair electrons into the vacant p-orbital (LUMO) at ...

Figure 3: Abnormal NHC reported by Bertrand [8,9].

Figure 4: Cu(d) orbital to σ*C-N(NHC) interactions in NHC–CuX complexes computed at the B3LYP/def2-SVP level ...

Figure 5: Molecular orbital contributions to the NHC–metal bond.

Scheme 5: Synthesis of NHC–Cu(I) complexes by deprotonation of NHC precursors with a base.

Scheme 6: Synthesis of [NHC–CuX] complexes.

Scheme 7: Synthesis of [(ICy)CuX] and [(It-Bu)CuX] complexes.

Scheme 8: Synthesis of iodido-bridged copper–NHC complexes by deprotonation of benzimidazolium salts reported...

Scheme 9: Synthesis of copper complexes by deprotonation of triazolium salts.

Scheme 10: Synthesis of thiazolylidene–Cu(I) complex by deprotonation with KOt-Bu.

Scheme 11: Preparation of NHC–Cu(I) complexes.

Scheme 12: Synthesis of methylmalonic acid-derived anionic [(26a,b)CuCl]Li(THF)2 and zwitterionic (28) heterol...

Scheme 13: Synthesis of diaminocarbene and diamidocarbene (DAC)–Cu(I) complexes.

Scheme 14: Synthesis of the cationic (NHC)2Cu(I) complex 39 from benzimidazolium salts 38 with tetrakis(aceton...

Scheme 15: Synthesis of NHC and ADC (acyclic diamino carbenes) Cu(I) hexamethyldisilazide complexes reported b...

Scheme 16: Synthesis of NHC–copper(I) complexes using an acetylacetonate-functionalized imidazolium zwitterion...

Scheme 17: Synthesis of NHC–Cu(I) complexes through deprotonation of azolium salts with Cu2O.

Scheme 18: Synthesis of NHC–CuBr complex through deprotonation with Cu2O reported by Kolychev [31].

Scheme 19: Synthesis of chiral NHC–CuBr complexes from phenoxyimine-imidazolium salts reported by Douthwaite a...

Scheme 20: Preparation of linear neutral NHC–CuCl complexes through the use of Cu2O. For abbreviations, please...

Scheme 21: Synthesis of abnormal-NHC–copper(I) complexes by Bertrand, Cazin and co-workers [35].

Scheme 22: Microwave-assisted synthesis of thiazolylidene/benzothiazolylidene–CuBr complexes by Bansal and co-...

Scheme 23: Synthesis of NHC–CuX complexes through transmetallation.

Scheme 24: Preparation of six- or seven-membered NHC–Cu(I) complexes through transmetalation from Ag(I) comple...

Scheme 25: Synthesis of 1,2,3-triazolylidene–CuCl complexes through transmetallation of Ag(I) complexes genera...

Scheme 26: Synthesis of NHC–copper complexes having both Cu(I) and Cu(II) units through transmetalation report...

Scheme 27: Synthesis of new [(IPr(CH2)3Si(OiPr)3)CuX] complexes and anchoring on MCM-41.

Scheme 28: Synthesis of bis(trimethylsilyl)phosphide–Cu(I)–NHC complexes through ligand displacement.

Scheme 29: Synthesis of silyl- and stannyl [(NHC)Cu−ER3] complexes.

Scheme 30: Synthesis of amido-, phenolato-, thiophenolato–Cu(NHC) complexes.

Scheme 31: Synthesis of first isolable NHC–Cu–difluoromethyl complexes reported by Sanford et al. [44].

Scheme 32: Synthesis of NHC–Cu(I)–bifluoride complexes reported by Riant, Leyssens and co-workers [45].

Scheme 33: Conjugate addition of Et2Zn to enones catalyzed by an NHC–Cu(I) complex reported by Woodward in 200...

Scheme 34: Hydrosilylation of a carbonyl group.

Scheme 35: NHC–Cu(I)-catalyzed hydrosilylation of ketones reported by Nolan et al. [48,49].

Scheme 36: Application of chiral NHC–CuCl complex 104 for the enantioselective hydrosilylation of ketones.

Scheme 37: Hydrosilylation reactions catalyzed by NHC–Cu(Ot-Bu) complexes.

Scheme 38: NHC–CuCl catalyzed carbonylative silylation of alkyl halides.

Scheme 39: Nucleophilic conjugate addition to an activated C=C bond.

Figure 6: Molecular electrostatic potential maps (MESP) of two NHC–CuX complexes computed at the B3LYP/def2-S...

Scheme 40: Conjugate addition of Grignard reagents to 3-alkyl-substituted cyclohexenones catalyzed by a chiral...

Scheme 41: NHC–copper complex-catalyzed conjugate addition of Grignard reagent to 3-substituted hexenone repor...

Scheme 42: Conjugate addition or organoaluminum reagents to β-substituted cyclic enones.

Scheme 43: Conjugate addition of boronates to acyclic α,β-unsaturated carboxylic esters, ketones, and thioeste...

Scheme 44: NHC–Cu(I)-catalyzed hydroboration of an allene reported by Hoveyda [63].

Scheme 45: Conjugate addition of Et2Zn to cyclohexenone catalyzed by NHC–Cu(I) complex derived from benzimidaz...

Scheme 46: Asymmetric conjugate addition of diethylzinc to 3-nonen-2-one catalyzed by NHC–Cu complexes derived...

Scheme 47: General scheme of a [3 + 2] cycloaddition reaction.

Scheme 48: [3 + 2] Cycloaddition of azides with alkynes catalyzed by NHC–Cu(I) complexes reported by Diez-Gonz...

Scheme 49: Application of NHC–CuCl/N-donor combination to catalyze the [3 + 2] cycloaddition of benzyl azide w...

Scheme 50: [3 + 2] Cycloaddition of azides with acetylenes catalyzed by bis(NHC)–Cu complex 131 and mixed NHC–...

Figure 7: NHC–CuCl complex 133 as catalyst for the [3 + 2] cycloaddition of alkynes with azides at room tempe...

Scheme 51: [3 + 2] Cycloaddition of a bulky azide with an alkynylpyridine using [(NHC)Cu(μ-I)2Cu(NHC)] copper ...

Scheme 52: [3 + 2] Cycloaddition of benzyl azide with phenylacetylene under homogeneous and heterogeneous cata...

Scheme 53: [3 + 2] Cycloaddition of benzyl azide with acetylenes catalyzed by bisthiazolylidene dicopper(I) co...

Figure 8: Copper (I)–NHC linear coordination polymer 137 and its conversion into tetranuclear (138) and dinuc...

Scheme 54: An A3 reaction.

Scheme 55: Synthesis of SiO2-immobilized NHC–Cu(I) catalyst 141 and its application in the A3-coupling reactio...

Scheme 56: Preparation of dual-purpose Ru@SiO2–[(NHC)CuCl] catalyst system 142 developed by Bordet, Leitner an...

Scheme 57: Application of the catalyst system Ru@SiO2–[Cu(NHC)] 142 to the one-pot tandem A3 reaction and hydr...

Scheme 58: A3 reaction of phenylacetylene with secondary amines and aldehydes catalyzed by benzothiazolylidene...

Figure 9: Kohn–Sham HOMOs of phenylacetylene and NHC–Cu(I)–phenylacetylene complex computed at the B3LYP/def2...

Figure 10: Energies of the FMOs of phenylacetylene, iminium ion, and NHC–Cu(I)–phenylacetylene complex compute...

Scheme 59: NHC–Cu(I) catalyzed diboration of ketones 147 by reacting with bis(pinacolato)diboron (148) reporte...

Scheme 60: Protoboration of terminal allenes catalyzed by NHC–Cu(I) complexes reported by Hoveyda and co-worke...

Scheme 61: NHC–CuCl-catalyzed borylation of α-alkoxyallenes to give 2-boryl-1,3-butadienes.

Scheme 62: Regioselective hydroborylation of propargylic alcohols and ethers catalyzed by NHC–CuCl complexes 1...

Scheme 63: NHC–CuOt-Bu-catalyzed semihydrogenation and hydroborylation of alkynes.

Scheme 64: Enantioselective NHC–Cu(I)-catalyzed hydroborations of 1,1-disubstituted aryl olefins reported by H...

Scheme 65: Enantioselective NHC–Cu(I)-catalyzed hydroboration of exocyclic 1,1-disubstituted alkenes reported ...

Scheme 66: Markovnikov-selective NHC–CuOH-catalyzed hydroboration of alkenes and alkynes reported by Jones et ...

Scheme 67: Dehydrogenative borylation and silylation of styrenes catalyzed by NHC–CuOt-Bu complexes developed ...

Scheme 68: N–H/C(sp2)–H carboxylation catalyzed by NHC–CuOH complexes.

Scheme 69: C–H Carboxylation of benzoxazole and benzothiazole derivatives with CO2 using a 1,2,3-triazol-5-yli...

Scheme 70: Use of Cu(I) complex derived from diethylene glycol-functionalized imidazo[1,5,a] pyridin-3-ylidene...

Scheme 71: Allylation and alkenylation of polyfluoroarenes and heteroarenes catalyzed by NHC–Cu(I) complexes r...

Scheme 72: Enantioselective C(sp2)–H allylation of (benz)oxazoles and benzothiazoles with γ,γ-disubstituted pr...

Scheme 73: C(sp2)–H arylation of arenes catalyzed by dual NHC–Cu/NHC–Pd catalytic system.

Scheme 74: C(sp2)–H Amidation of (hetero)arenes with N-chlorocarbamates/N-chloro-N-sodiocarbamates catalyzed b...

Scheme 75: NHC–CuI catalyzed thiolation of benzothiazoles and benzoxazoles.

C3-Alkylation of furfural derivatives by continuous flow homogeneous catalysis

- Grédy Kiala Kinkutu,

- Catherine Louis,

- Myriam Roy,

- Juliette Blanchard and

- Julie Oble

Beilstein J. Org. Chem. 2023, 19, 582–592, doi:10.3762/bjoc.19.43

- formation of the imine directing group and the C3-functionalization with some vinylsilanes and norbonene. Keywords: biomass; C–H activation; flow; furfural; homogeneous catalysis; Introduction The conversion of biomass derivatives into value-added products is one of the key branches of green chemistry and

Graphical Abstract

Scheme 1: C3-Functionalization of furfural derivatives by C–H activation, a) in batch: previous works, and b)...

Scheme 2: C3-alkylation of bidentate imine 1 performed in batch.

Scheme 3: Optimization of the heating for the alkylation reaction on the homemade pulsed-flow setup.

Scheme 4: Proposed reaction mechanism for the alkylation reaction with formation of ruthenium aggregates and ...

Scheme 5: A) Isolation test of a reaction intermediate; B) XPS and TEM (in ethanol) of the recovered solid ph...

Scheme 6: Ruthenium aggregate-catalyzed alkylation reaction.

Scheme 7: Scope of continuous flow furfural derivative alkylation reaction.

Scheme 8: Scaling up comparison: batch and continuous flow conditions.

Transition-metal-catalyzed C–H bond activation as a sustainable strategy for the synthesis of fluorinated molecules: an overview

- Louis Monsigny,

- Floriane Doche and

- Tatiana Besset

Beilstein J. Org. Chem. 2023, 19, 448–473, doi:10.3762/bjoc.19.35

- functionalization of C(sp2) and C(sp3) centers with SCF3, SeCF3, or OCH2CF3 groups among others, by C–H bond activation. The scope and limitations of these transformations are discussed in this review. Keywords: C–H bond activation; emergent fluorinated groups; homogeneous catalysis; organofluorine chemistry

Graphical Abstract

Scheme 1: Transition-metal-catalyzed C–XRF bond formation by C–H bond activation: an overview.

Scheme 2: Cu(OAc)2-promoted mono- and ditrifluoromethylthiolation of benzamide derivatives derived from 8-ami...

Scheme 3: Trifluoromethylthiolation of azacalix[1]arene[3]pyridines using copper salts and a nucleophilic SCF3...

Scheme 4: Working hypothesis for the palladium-catalyzed C–H trifluoromethylthiolation reaction.

Scheme 5: Trifluoromethylthiolation of 2-arylpyridine derivatives and analogs by means of palladium-catalyzed...

Scheme 6: C(sp2)–SCF3 bond formation by Pd-catalyzed C–H bond activation using AgSCF3 and Selectfluor® as rep...

Scheme 7: Palladium-catalyzed ortho-trifluoromethylthiolation of 2-arylpyridine derivatives reported by the g...

Scheme 8: Palladium-catalyzed ortho-trifluoromethylthiolation of 2-arylpyridine and analogs reported by Anbar...

Scheme 9: Mono- and ditrifluoromethylthiolation of benzamide derivatives derived from 8-aminoquinoline using ...

Scheme 10: Regioselective Cp*Rh(III)-catalyzed directed trifluoromethylthiolation reported by the group of Li [123]...

Scheme 11: Cp*Co(III)-catalyzed ortho-trifluoromethylthiolation of 2-phenylpyridine and 2-phenylpyrimidine der...

Scheme 12: Cp*Co(III)-catalyzed ortho-trifluoromethylthiolation of 2-phenylpyridine and 6-phenylpurine derivat...

Scheme 13: Diastereoselective trifluoromethylthiolation of acrylamide derivatives derived from 8-aminoquinolin...

Scheme 14: C(sp3)–SCF3 bond formation on aliphatic amide derivatives derived from 8-aminoquinoline by palladiu...

Scheme 15: Regio- and diastereoselective difluoromethylthiolation of acrylamides under palladium catalysis rep...

Scheme 16: Palladium-catalyzed (ethoxycarbonyl)difluoromethylthiolation reaction of 2-(hetero)aryl and 2-(α-ar...

Scheme 17: Pd(II)-catalyzed trifluoromethylselenolation of benzamides derived from 5-methoxy-8-aminoquinoline ...

Scheme 18: Pd(II)-catalyzed trifluoromethylselenolation of acrylamide derivatives derived from 5-methoxy-8-ami...

Scheme 19: Transition-metal-catalyzed dehydrogenative 2,2,2-trifluoroethoxylation of (hetero)aromatic derivati...

Scheme 20: Pd(II)-catalyzed ortho-2,2,2-trifluoroethoxylation of N-sulfonylbenzamides reported by the group of...

Scheme 21: Pd(II)-catalyzed selective 2,2,2-trifluoroethoxylation and other fluoroalkoxylations of naphthalene...

Scheme 22: Pd(II)-catalyzed selective ortho-2,2,2-trifluoroethoxylation of benzaldehyde derivatives by means o...

Scheme 23: Pd(II)-catalyzed selective ortho-2,2,2-trifluoroethoxylation (and other fluoroalkoxylations) of ben...

Scheme 24: Pd(II)-catalyzed selective 2,2,2-trifluoroethoxylation of aliphatic amides using a bidentate direct...

Friedel–Crafts acylation of benzene derivatives in tunable aryl alkyl ionic liquids (TAAILs)

- Swantje Lerch,

- Stefan Fritsch and

- Thomas Strassner

Beilstein J. Org. Chem. 2023, 19, 212–216, doi:10.3762/bjoc.19.20

- acylation; homogeneous catalysis; ionic liquids; iron catalysis; TAAILs; Introduction The Friedel–Crafts acylation is one of the oldest metal-catalyzed reactions in organic chemistry [1] and allows for the synthesis of a broad range of diverse compounds [2][3][4][5]. Starting from electron-rich aromatic

Graphical Abstract

Scheme 1: Synthesis of TAAILs. i) 1 equiv glyoxal, 2.1 equiv formaldehyde, 2 equiv NH4Cl, MeOH, 65 °C, ii) 1....

Scheme 2: Model reaction for the Friedel–Crafts acylation.

Figure 1: Time-dependent analysis of the reaction using varying amounts of anhydride. Reaction conditions: 1 ...

Scheme 3: Scope of the Friedel–Crafts acylation. Reaction conditions: 1 mmol benzene derivative, 2 equiv anhy...

Heterogeneous metallaphotoredox catalysis in a continuous-flow packed-bed reactor

- Wei-Hsin Hsu,

- Susanne Reischauer,

- Peter H. Seeberger,

- Bartholomäus Pieber and

- Dario Cambié

Beilstein J. Org. Chem. 2022, 18, 1123–1130, doi:10.3762/bjoc.18.115

- development of several strategies to immobilize transition-metal photocatalysts [22]. In the case of flow-metallaphotoredox catalysis packed-bed reactors were not applied to date. This is likely because these reactions are mainly carried out using homogeneous catalysis. Several studies have shown that the

Graphical Abstract

Figure 1: Different approaches to heterogeneous photochemistry in flow. a) Serial micro-batch reactors (SMBR)...

Figure 2: Light-mediated carbon–heteroatom cross-couplings. The yields reported are the NMR yields obtained i...

Figure 3: Flow diagram of the experimental setup loaded in an injection loop with the reaction mixture.

Figure 4: Flow diagram of the experimental setup adopted and time necessary to obtain steady-state conditions...

Figure 5: The production campaign of 1 for a seven day experiment.

Figure 6: Photo of the packed column with a helical static mixer (polished SS316, 10 cm length, 15 mixing ele...

Scheme 1: C–O coupling between 4-iodobenzotrifluoride and N-(Boc)-proline.

Diametric calix[6]arene-based phosphine gold(I) cavitands

- Gabriele Giovanardi,

- Andrea Secchi,

- Arturo Arduini and

- Gianpiero Cera

Beilstein J. Org. Chem. 2022, 18, 190–196, doi:10.3762/bjoc.18.21

- ][2][3]. In this context, phosphines represent the most exploited class of ligands in homogeneous catalysis [4]. Noteworthy, reason of their wide applicability is the possibility of controlling the steric and electronic properties by proper functionalizations, hence tuning the catalytic properties of

Graphical Abstract

Figure 1: Selected examples of: a) calix[4]arene-; b) resorcin[4]arene-; c) calix[6]arene-gold(I) macrocyclic...

Scheme 1: i) NH2NH2∙H2O, Pd/C in EtOH, 80 °C (quant.); ii) diphenylphosphinobenzoic acid, EDC∙HCl, DMAP (cat....

Figure 2: Stacked-plot, mid-field expanded region of the 1H NMR spectrum (400 MHz, 298 K) of A(AuCl)2, B(AuCl)...

Figure 3: Stacked plot 1H NMR (tetrachloroethane-d2) of A(AuCl)2 at variable temperature.

Scheme 2: Synthesis of the monomeric gold catalyst analogues A’,B’,C’(AuCl). Conditions: i) diphenylphosphino...

Earth-abundant 3d transition metals on the rise in catalysis

- Nikolaos Kaplaneris and

- Lutz Ackermann

Beilstein J. Org. Chem. 2022, 18, 86–88, doi:10.3762/bjoc.18.8

- , notable advances have been accomplished with environmentally benign, Earth-abundant 3d transition metals [6][7]. The articles in this thematic issue dedicated to advances in Earth-abundant 3d metal catalysis highlight the unique power of 3d transition metals with a topical focus on homogeneous catalysis

A comprehensive review of flow chemistry techniques tailored to the flavours and fragrances industries

- Guido Gambacorta,

- James S. Sharley and

- Ian R. Baxendale

Beilstein J. Org. Chem. 2021, 17, 1181–1312, doi:10.3762/bjoc.17.90

Graphical Abstract

Figure 1: Representative shares of the global F&F market (2018) segmented on their applications [1].

Figure 2: General structure of an international fragrance company [2].

Figure 3: The Michael Edwards fragrance wheel.

Figure 4: Examples of oriental (1–3), woody (4–7), fresh (8–10), and floral (11 and 12) notes.

Figure 5: A basic depiction of batch vs flow.

Scheme 1: Examples of reactions for which flow processing outperforms batch.

Scheme 2: Some industrially important aldol-based transformations.

Scheme 3: Biphasic continuous aldol reactions of acetone and various aldehydes.

Scheme 4: Aldol synthesis of 43 in flow using LiHMDS as the base.

Scheme 5: A semi-continuous synthesis of doravirine (49) involving a key aldol reaction.

Scheme 6: Enantioselective aldol reaction using 5-(pyrrolidin-2-yl)tetrazole (51) as catalyst in a microreact...

Scheme 7: Gröger's example of asymmetric aldol reaction in aqueous media.

Figure 6: Immobilised reagent column reactor types.

Scheme 8: Photoinduced thiol–ene coupling preparation of silica-supported 5-(pyrrolidin-2-yl)tetrazole 63 and...

Scheme 9: Continuous-flow approach for enantioselective aldol reactions using the supported catalyst 67.

Scheme 10: Ötvös’ employment of a solid-supported peptide aldol catalyst in flow.

Scheme 11: The use of proline tetrazole packed in a column for aldol reaction between cyclohexanone (65) and 2...

Scheme 12: Schematic diagram of an aminosilane-grafted Si-Zr-Ti/PAI-HF reactor for continuous-flow aldol and n...

Scheme 13: Continuous-flow condensation for the synthesis of the intermediate 76 to nabumetone (77) and Microi...

Scheme 14: Synthesis of ψ-Ionone (80) in continuous-flow via aldol condensation between citral (79) and aceton...

Scheme 15: Synthesis of β-methyl-ionones (83) from citral (79) in flow. The steps are separately described, an...

Scheme 16: Continuous-flow synthesis of 85 from 84 described by Gavriilidis et al.

Scheme 17: Continuous-flow scCO2 apparatus for the synthesis of 2-methylpentanal (87) and the self-condensed u...

Scheme 18: Chen’s two-step flow synthesis of coumarin (90).

Scheme 19: Pechmann condensation for the synthesis of 7-hydroxyxcoumarin (93) in flow. The setup extended to c...

Scheme 20: Synthesis of the dihydrojasmonate 35 exploiting nitro derivative proposed by Ballini et al.

Scheme 21: Silica-supported amines as heterogeneous catalyst for nitroaldol condensation in flow.

Scheme 22: Flow apparatus for the nitroaldol condensation of p-hydroxybenzaldehyde (102) to nitrostyrene 103 a...

Scheme 23: Nitroaldol reaction of 64 to 105 employing a quaternary ammonium functionalised PANF.

Scheme 24: Enantioselective nitroaldol condensation for the synthesis of 108 under flow conditions.

Scheme 25: Enatioselective synthesis of 1,2-aminoalcohol 110 via a copper-catalysed nitroaldol condensation.

Scheme 26: Examples of Knoevenagel condensations applied for fragrance components.

Scheme 27: Flow apparatus for Knoevenagel condensation described in 1989 by Venturello et al.

Scheme 28: Knoevenagel reaction using a coated multichannel membrane microreactor.

Scheme 29: Continuous-flow apparatus for Knoevenagel condensation employing sugar cane bagasse as support deve...

Scheme 30: Knoevenagel reaction for the synthesis of 131–135 in flow using an amine-functionalised silica gel. ...

Scheme 31: Continuous-flow synthesis of compound 137, a key intermediate for the synthesis of pregabalin (138)...

Scheme 32: Continuous solvent-free apparatus applied for the synthesis of compounds 140–143 using a TSE. Throu...

Scheme 33: Lewis et al. developed a spinning disc reactor for Darzens condensation of 144 and a ketone to furn...

Scheme 34: Some key industrial applications of conjugate additions in the F&F industry.

Scheme 35: Continuous-flow synthesis of 4-(2-hydroxyethyl)thiomorpholine 1,1-dioxide (156) via double conjugat...

Scheme 36: Continuous-flow system for Michael addition using CsF on alumina as the catalyst.

Scheme 37: Calcium chloride-catalysed asymmetric Michael addition using an immobilised chiral ligand.

Scheme 38: Continuous multistep synthesis for the preparation of (R)-rolipram (173). Si-NH2: primary amine-fun...

Scheme 39: Continuous-flow Michael addition using ion exchange resin Amberlyst® A26.

Scheme 40: Preparation of the heterogeneous catalyst 181 developed by Paixão et al. exploiting Ugi multicompon...

Scheme 41: Continuous-flow system developed by the Paixão’s group for the preparation of Michael asymmetric ad...

Scheme 42: Continuous-flow synthesis of nitroaldols catalysed by supported catalyst 184 developed by Wennemers...

Scheme 43: Heterogenous polystyrene-supported catalysts developed by Pericàs and co-workers.

Scheme 44: PANF-supported pyrrolidine catalyst for the conjugate addition of cyclohexanone (65) and trans-β-ni...

Scheme 45: Synthesis of (−)-paroxetine precursor 195 developed by Ötvös, Pericàs, and Kappe.

Scheme 46: Continuous-flow approach for the 5-step synthesis of (−)-oseltamivir (201) as devised by Hayashi an...

Scheme 47: Continuous-flow enzyme-catalysed Michael addition.

Scheme 48: Continuous-flow copper-catalysed 1,4 conjugate addition of Grignard reagents to enones. Reprinted w...

Scheme 49: A collection of commonly encountered hydrogenation reactions.

Figure 7: The ThalesNano H-Cube® continuous-flow hydrogenator.

Scheme 50: Chemoselective reduction of an α,β-unsaturated ketone using the H-Cube® reactor.

Scheme 51: Incorporation of Lindlar’s catalyst into the H-Cube® reactor for the reduction of an alkyne.

Scheme 52: Continuous-flow semi-hydrogenation of alkyne 208 to 209 using SACs with H-Cube® system.

Figure 8: The standard setups for tube-in-tube gas–liquid reactor units.

Scheme 53: Homogeneous hydrogenation of olefins using a tube-in-tube reactor setup.

Scheme 54: Recyclable heterogeneous flow hydrogenation system.

Scheme 55: Leadbeater’s reverse tube-in-tube hydrogenation system for olefin reductions.

Scheme 56: a) Hydrogenation using a Pd-immobilised microchannel reactor (MCR) and b) a representation of the i...

Scheme 57: Hydrogenation of alkyne 238 exploiting segmented flow in a Pd-immobilised capillary reactor.

Scheme 58: Continuous hydrogenation system for the preparation of cyrene (241) from (−)-levoglucosenone (240).

Scheme 59: Continuous hydrogenation system based on CSMs developed by Hornung et al.

Scheme 60: Chemoselective reduction of carbonyls (ketones over aldehydes) in flow.

Scheme 61: Continuous system for the semi-hydrogenation of 256 and 258, developed by Galarneau et al.

Scheme 62: Continuous synthesis of biodiesel fuel 261 from lignin-derived furfural acetone (260).

Scheme 63: Continuous synthesis of γ-valerolacetone (263) via CTH developed by Pineda et al.

Scheme 64: Continuous hydrogenation of lignin-derived biomass (products 265, 266, and 267) using a sustainable...

Scheme 65: Ru/C or Rh/C-catalysed hydrogenation of arene in flow as developed by Sajiki et al.

Scheme 66: Polysilane-immobilized Rh–Pt-catalysed hydrogenation of arenes in flow by Kobayashi et al.

Scheme 67: High-pressure in-line mixing of H2 for the asymmetric reduction of 278 at pilot scale with a 73 L p...

Figure 9: Picture of the PFR employed at Eli Lilly & Co. for the continuous hydrogenation of 278 [287]. Reprinted ...

Scheme 68: Continuous-flow asymmetric hydrogenation using Oppolzer's sultam 280 as chiral auxiliary.

Scheme 69: Some examples of industrially important oxidation reactions in the F&F industry. CFL: compact fluor...

Scheme 70: Gold-catalysed heterogeneous oxidation of alcohols in flow.

Scheme 71: Uozumi’s ARP-Pt flow oxidation protocol.

Scheme 72: High-throughput screening of aldehyde oxidation in flow using an in-line GC.

Scheme 73: Permanganate-mediated Nef oxidation of nitroalkanes in flow with the use of in-line sonication to p...

Scheme 74: Continuous-flow aerobic anti-Markovnikov Wacker oxidation.

Scheme 75: Continuous-flow oxidation of 2-benzylpyridine (312) using air as the oxidant.

Scheme 76: Continuous-flow photo-oxygenation of monoterpenes.

Scheme 77: A tubular reactor design for flow photo-oxygenation.

Scheme 78: Glucose oxidase (GOx)-mediated continuous oxidation of glucose using compressed air and the FFMR re...

Scheme 79: Schematic continuous-flow sodium hypochlorite/TEMPO oxidation of alcohols.

Scheme 80: Oxidation using immobilised TEMPO (344) was developed by McQuade et al.

Scheme 81: General protocol for the bleach/catalytic TBAB oxidation of aldehydes and alcohols.

Scheme 82: Continuous-flow PTC-assisted oxidation using hydrogen peroxide. The process was easily scaled up by...

Scheme 83: Continuous-flow epoxidation of cyclohexene (348) and in situ preparation of m-CPBA.

Scheme 84: Continuous-flow epoxidation using DMDO as oxidant.

Scheme 85: Mukayama aerobic epoxidation optimised in flow mode by the Favre-Réguillon group.

Scheme 86: Continuous-flow asymmetric epoxidation of derivatives of 359 exploiting a biomimetic iron catalyst.

Scheme 87: Continuous-flow enzymatic epoxidation of alkenes developed by Watts et al.

Scheme 88: Engineered multichannel microreactor for continuous-flow ozonolysis of 366.

Scheme 89: Continuous-flow synthesis of the vitamin D precursor 368 using multichannel microreactors. MFC: mas...

Scheme 90: Continuous ozonolysis setup used by Kappe et al. for the synthesis of various substrates employing ...

Scheme 91: Continuous-flow apparatus for ozonolysis as developed by Ley et al.

Scheme 92: Continuous-flow ozonolysis for synthesis of vanillin (2) using a film-shear flow reactor.

Scheme 93: Examples of preparative methods for ajoene (386) and allicin (388).

Scheme 94: Continuous-flow oxidation of thioanisole (389) using styrene-based polymer-supported peroxytungstat...

Scheme 95: Continuous oxidation of thiosulfinates using Oxone®-packed reactor.

Scheme 96: Continuous-flow electrochemical oxidation of thioethers.

Scheme 97: Continuous-flow oxidation of 400 to cinnamophenone (235).

Scheme 98: Continuous-flow synthesis of dehydrated material 401 via oxidation of methyl dihydrojasmonate (33).

Scheme 99: Some industrially important transformations involving Grignard reagents.

Scheme 100: Grachev et al. apparatus for continuous preparation of Grignard reagents.

Scheme 101: Example of fluidized Mg bed reactor with NMR spectrometer as on-line monitoring system.

Scheme 102: Continuous-flow synthesis of Grignard reagents and subsequent quenching reaction.

Figure 10: Membrane-based, liquid–liquid separator with integrated pressure control [52]. Adapted with permission ...

Scheme 103: Continuous-flow synthesis of 458, an intermediate to fluconazole (459).

Scheme 104: Continuous-flow synthesis of ketones starting from benzoyl chlorides.

Scheme 105: A Grignard alkylation combining CSTR and PFR technologies with in-line infrared reaction monitoring....

Scheme 106: Continuous-flow preparation of 469 from Grignard addition of methylmagnesium bromide.

Scheme 107: Continuous-flow synthesis of Grignard reagents 471.

Scheme 108: Preparation of the Grignard reagent 471 using CSTR and the continuous process for synthesis of the ...

Scheme 109: Continuous process for carboxylation of Grignard reagents in flow using tube-in-tube technology.

Scheme 110: Continuous synthesis of propargylic alcohols via ethynyl-Grignard reagent.

Scheme 111: Silica-supported catalysed enantioselective arylation of aldehydes using Grignard reagents in flow ...

Scheme 112: Acid-catalysed rearrangement of citral and dehydrolinalool derivatives.

Scheme 113: Continuous stilbene isomerisation with continuous recycling of photoredox catalyst.

Scheme 114: Continuous-flow synthesis of compound 494 as developed by Ley et al.

Scheme 115: Selected industrial applications of DA reaction.

Scheme 116: Multistep flow synthesis of the spirocyclic structure 505 via employing DA cycloaddition.

Scheme 117: Continuous-flow DA reaction developed in a plater flow reactor for the preparation of the adduct 508...

Scheme 118: Continuous-flow DA reaction using a silica-supported imidazolidinone organocatalyst.

Scheme 119: Batch vs flow for the DA reaction of (cyclohexa-1,5-dien-1-yloxy)trimethylsilane (513) with acrylon...

Scheme 120: Continuous-flow DA reaction between 510 and 515 using a shell-core droplet system.

Scheme 121: Continuous-flow synthesis of bicyclic systems from benzyne precursors.

Scheme 122: Continuous-flow synthesis of bicyclic scaffolds 527 and 528 for further development of potential ph...

Scheme 123: Continuous-flow inverse-electron hetero-DA reaction to pyridine derivatives such as 531.

Scheme 124: Comparison between batch and flow for the synthesis of pyrimidinones 532–536 via retro-DA reaction ...

Scheme 125: Continuous-flow coupled with ultrasonic system for preparation of ʟ-ascorbic acid derivatives 539 d...

Scheme 126: Two-step continuous-flow synthesis of triazole 543.

Scheme 127: Continuous-flow preparation of triazoles via CuAAC employing 546-based heterogeneous catalyst.

Scheme 128: Continuous-flow synthesis of compounds 558 through A3-coupling and 560 via AgAAC both employing the...

Scheme 129: Continuous-flow photoinduced [2 + 2] cycloaddition for the preparation of bicyclic derivatives of 5...

Scheme 130: Continuous-flow [2 + 2] and [5 + 2] cycloaddition on large scale employing a flow reactor developed...

Scheme 131: Continuous-flow preparation of the tricyclic structures 573 and 574 starting from pyrrole 570 via [...

Scheme 132: Continuous-flow [2 + 2] photocyclization of cinnamates.

Scheme 133: Continuous-flow preparation of cyclobutane 580 on a 5-plates photoreactor.

Scheme 134: Continuous-flow [2 + 2] photocycloaddition under white LED lamp using heterogeneous PCN as photocat...

Figure 11: Picture of the parallel tube flow reactor (PTFR) "The Firefly" developed by Booker-Milburn et al. a...

Scheme 135: Continuous-flow acid-catalysed [2 + 2] cycloaddition between silyl enol ethers and acrylic esters.

Scheme 136: Continuous synthesis of lactam 602 using glass column reactors.

Scheme 137: In situ generation of ketenes for the Staudinger lactam synthesis developed by Ley and Hafner.

Scheme 138: Application of [2 + 2 + 2] cycloadditions in flow employed by Ley et al.

Scheme 139: Examples of FC reactions applied in F&F industry.

Scheme 140: Continuous-flow synthesis of ibuprofen developed by McQuade et al.

Scheme 141: The FC acylation step of Jamison’s three-step ibuprofen synthesis.

Scheme 142: Synthesis of naphthalene derivative 629 via FC acylation in microreactors.

Scheme 143: Flow system for rapid screening of catalysts and reaction conditions developed by Weber et al.

Scheme 144: Continuous-flow system developed by Buorne, Muller et al. for DSD optimisation of the FC acylation ...

Scheme 145: Continuous-flow FC acylation of alkynes to yield β-chlorovinyl ketones such as 638.

Scheme 146: Continuous-flow synthesis of tonalide (619) developed by Wang et al.

Scheme 147: Continuous-flow preparation of acylated arene such as 290 employing Zr4+-β-zeolite developed by Kob...

Scheme 148: Flow system applied on an Aza-FC reaction catalysed by the thiourea catalyst 648.

Scheme 149: Continuous hydroformylation in scCO2.

Scheme 150: Two-step flow synthesis of aldehyde 655 through a sequential Heck reaction and subsequent hydroform...

Scheme 151: Single-droplet (above) and continuous (below) flow reactors developed by Abolhasani et al. for the ...

Scheme 152: Continuous hydroformylation of 1-dodecene (655) using a PFR-CSTR system developed by Sundmacher et ...

Scheme 153: Continuous-flow synthesis of the aldehyde 660 developed by Eli Lilly & Co. [32]. Adapted with permissio...

Scheme 154: Continuous asymmetric hydroformylation employing heterogenous catalst supported on carbon-based sup...

Scheme 155: Examples of acetylation in F&F industry: synthesis of bornyl (S,R,S-664) and isobornyl (S,S,S-664) ...

Scheme 156: Continuous-flow preparation of bornyl acetate (S,R,S-664) employing the oscillating flow reactor.

Scheme 157: Continuous-flow synthesis of geranyl acetate (666) from acetylation of geraniol (343) developed by ...

Scheme 158: 12-Ttungstosilicic acid-supported silica monolith-catalysed acetylation in flow.

Scheme 159: Continuous-flow preparation of cyclopentenone 676.

Scheme 160: Two-stage synthesis of coumarin (90) via acetylation of salicylaldehyde (88).

Scheme 161: Intensification process for acetylation of 5-methoxytryptamine (677) to melatonin (678) developed b...

Scheme 162: Examples of macrocyclic musky odorants both natural (679–681) and synthetic (682 and 683).

Scheme 163: Flow setup combined with microwave for the synthesis of macrocycle 686 via RCM.

Scheme 164: Continuous synthesis of 2,5-dihydro-1H-pyrroles via ring-closing metathesis.

Scheme 165: Continuous-flow metathesis of 485 developed by Leadbeater et al.

Figure 12: Comparison between RCM performed using different routes for the preparation of 696. On the left the...

Scheme 166: Continuous-flow RCM of 697 employed the solid-supported catalyst 698 developed by Grela, Kirschning...

Scheme 167: Continuous-flow RORCM of cyclooctene employing the silica-absorbed catalyst 700.

Scheme 168: Continuous-flow self-metathesis of methyl oleate (703) employing SILP catalyst 704.

Scheme 169: Flow apparatus for the RCM of 697 using a nanofiltration membrane for the recovery and reuse of the...

Scheme 170: Comparison of loadings between RCMs performed with different routes for the synthesis of 709.

One-pot multicomponent green Hantzsch synthesis of 1,2-dihydropyridine derivatives with antiproliferative activity

- Giovanna Bosica,

- Kaylie Demanuele,

- José M. Padrón and

- Adrián Puerta

Beilstein J. Org. Chem. 2020, 16, 2862–2869, doi:10.3762/bjoc.16.235

- used since it offers a greener alternative to homogeneous catalysis and ideally a solvent-free design to reduce the amount of solvent waste [21][22]. These two factors will reduce the amount of hazardous chemicals by reducing the amount of solvent in the reactor and during the workup of the product. A

Graphical Abstract

Scheme 1: The classical Hantzsch synthesis between benzaldehyde (1a), ethyl acetoacetate (2), and ammonium ac...

Figure 1: Optimization trials with the selected solid catalysts.

Figure 2: Graphical representation of the results obtained in the reusability test.

Efficient [(NHC)Au(NTf2)]-catalyzed hydrohydrazidation of terminal and internal alkynes

- Maximillian Heidrich and

- Herbert Plenio

Beilstein J. Org. Chem. 2020, 16, 2080–2086, doi:10.3762/bjoc.16.175

- alkynes (7a–j, 10 examples, 0.2–0.5 mol % [(NHC)Au(NTf2)], T = 60–80 °C) utilizing a complex with a sterically demanding bispentiptycenyl-substituted NHC ligand and the benign reaction solvent anisole, is reported. Keywords: alkyne; gold; homogeneous catalysis; hydrohydrazidation; NHC ligand

Graphical Abstract

Scheme 1: Simplified mechanism of the hydrohydrazidation (NuH= ArCONHNH2) of alkynes.

Scheme 2: [(NHC)Au(NTf2)] complexes tested in hydrohydrazidation reactions of phenylacetylene.

Scheme 3: Hydrohydrazidation of terminal alkynes in chlorobenzene and anisole using complex 1 (first line sol...

Scheme 4: Hydrohydrazidation of internal alkynes in chlorobenzene and anisole using complex 1. Reaction tempe...

In silico rationalisation of selectivity and reactivity in Pd-catalysed C–H activation reactions

- Liwei Cao,

- Mikhail Kabeshov,

- Steven V. Ley and

- Alexei A. Lapkin

Beilstein J. Org. Chem. 2020, 16, 1465–1475, doi:10.3762/bjoc.16.122

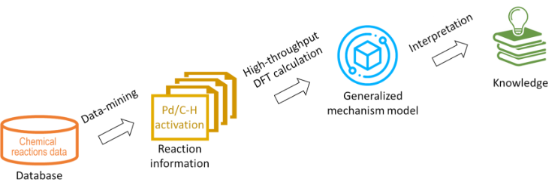

- functionalization of C–H bonds is a powerful strategy for the synthesis and derivatization of organic molecules [12]. Homogeneous catalysis employing transition metal complexes has been widely accepted as one of the most efficient ways to perform C–H activation-based synthesis with high selectivity under relatively

Graphical Abstract

Figure 1: An approximate energy map for the electrophilic aromatic substitution mechanism.

Scheme 1: Schematic representation of the two mechanisms of Pd-catalysed C–H activation reaction considered i...

The charge-assisted hydrogen-bonded organic framework (CAHOF) self-assembled from the conjugated acid of tetrakis(4-aminophenyl)methane and 2,6-naphthalenedisulfonate as a new class of recyclable Brønsted acid catalysts

- Svetlana A. Kuznetsova,

- Alexander S. Gak,

- Yulia V. Nelyubina,

- Vladimir A. Larionov,

- Han Li,

- Michael North,

- Vladimir P. Zhereb,

- Alexander F. Smol'yakov,

- Artem O. Dmitrienko,

- Michael G. Medvedev,

- Igor S. Gerasimov,

- Ashot S. Saghyan and

- Yuri N. Belokon

Beilstein J. Org. Chem. 2020, 16, 1124–1134, doi:10.3762/bjoc.16.99

- , providing some dissolved F-1 as the real catalyst. In all cases, the catalyst could easily be recovered and recycled. Keywords: Brønsted acid catalyst; charge-assisted hydrogen-bonded framework; Diels–Alder; epoxide ring opening; heterogeneous catalyst; Introduction Tremendous successes in homogeneous

- catalysis are well-known and documented [1][2][3]. However, problems associated with catalyst recovery limit the application of homogeneous catalysts in industry and sometimes make their heterogenization necessary. Unfortunately, the immobilization of a homogeneous catalyst onto supports, such as

Graphical Abstract

Scheme 1: The synthesis of F-1.

Figure 1: View of the crystal structure of F-1 (F-1a phase), with representation of atoms by thermal ellipsoi...

Figure 2: View of the crystal structure of F-1 (F-1a’ phase), with representation of the atoms via thermal el...

Figure 3: SEM image of F-1.

Figure 4: SEM image of F-1 with an F-1a phase.

Figure 5: TGA-DSC analysis of a sample of F-1. The TGA plot is shown in green, the DSC curve is shown in blue...

Scheme 2: Uncrystallized F-1 or F-1 with an F-1a phase promoted the two- and three-phase reactions of styrene...

Scheme 3: CAHOF F-1-promoted reactions of cyclohexene oxide (5) with alcohols and water.

Scheme 4: F-1-promoted Diels–Alder reaction.

Copper catalysis with redox-active ligands

- Agnideep Das,

- Yufeng Ren,

- Cheriehan Hessin and

- Marine Desage-El Murr

Beilstein J. Org. Chem. 2020, 16, 858–870, doi:10.3762/bjoc.16.77

- [2][3]. Inspired by the broad chemical repertoire of radical-ligand containing metalloenzymes, chemists have developed redox-active ligands as surrogates for the biologically occurring redox cofactors and this has translated into active developments in homogeneous catalysis [4]. The unique electronic

Graphical Abstract

Scheme 1: Copper complexes with amidophenolate type benzoxazole ligands for alcohol oxidations.

Scheme 2: Copper-catalyzed aerobic oxidation of alcohols and representative substrate scope.

Scheme 3: Introduction of H-bonding network in the ligand coordination sphere.

Scheme 4: Well-defined isatin copper complexes.

Scheme 5: Catalyst control in the biomimetic phenol ortho-oxidation.

Scheme 6: Structural diversity accessible by direct functionalization.

Scheme 7: Copper-catalyzed trifluoromethylation of heteroaromatics with redox-active iminosemiquinone ligands....

Scheme 8: Reversal of helical chirality upon redox stimuli and enantioselective Michael addition with a redox...

Scheme 9: Interaction of guanidine-copper catalyst with oxygen and representative coupling products. a4 mol %...

Scheme 10: Access to 1,2-oxy-aminoarenes by copper-catalyzed phenol–amine coupling.

Scheme 11: Copper-catalyzed aziridination through molecular spin catalysis with redox-active iminosemiquinone ...

Scheme 12: Nitrogen-group and carbon-group transfer in copper-catalyzed aziridination and cyclopropanation thr...

Rhodium-catalyzed reductive carbonylation of aryl iodides to arylaldehydes with syngas

- Zhenghui Liu,

- Peng Wang,

- Zhenzhong Yan,

- Suqing Chen,

- Dongkun Yu,

- Xinhui Zhao and

- Tiancheng Mu

Beilstein J. Org. Chem. 2020, 16, 645–656, doi:10.3762/bjoc.16.61

- homogeneous catalysis, and substantial value-added bulk and fine chemicals are available through this technology [13]. In spite of the existing plentiful progress in this conversion, the exploitation of advanced and more effective catalytic systems to the activity and to widen the range of substrates is

Graphical Abstract

Figure 1: Rhodium-catalyzed reductive carbonylation of iodobenzene with CO and H2 to afford benzaldehyde. a) ...

Scheme 1: Scaled-up experiment of the reductive carbonylation of iodobenzene to benzaldehyde under the optimi...

Scheme 2: Catalytic species participating in the catalytic process.

Scheme 3: Substrate scope for the Rh-catalyzed reductive carbonylation of aryl iodides using CO and H2. React...

Scheme 4: Isotope-labeling experiments.

Scheme 5: Proposed reaction mechanism for the Rh-catalyzed reductive carbonylation of aryl iodides using CO a...

Architecture and synthesis of P,N-heterocyclic phosphine ligands

- Wisdom A. Munzeiwa,

- Bernard Omondi and

- Vincent O. Nyamori

Beilstein J. Org. Chem. 2020, 16, 362–383, doi:10.3762/bjoc.16.35

- applicability of the catalysts in two-phase homogeneous catalysis because it allows easy recycling [85] and separation from the reaction mixture [8]. Carbon–halogen bonds are more activated than carbon–hydrogen bonds and hence the halogen is more labile and preferentially displaced. Brill et al. [86] took

Graphical Abstract

Scheme 1: Synthesis of pyridylphosphine ligands.

Figure 1: Pyridylphosphine ligands.

Scheme 2: Synthesis of piperidyl- and oxazinylphosphine ligands.

Scheme 3: Synthesis of linear multi-chelate pyridylphosphine ligands.

Scheme 4: Synthesis of chiral acetal pyridylphosphine ligands.

Scheme 5: Synthesis of diphenylphosphine-substituted triazine ligands.

Scheme 6: Synthesis of (pyridine-2-ylmethyl)phosphine ligands.

Scheme 7: Synthesis of diphosphine pyrrole ligands.

Scheme 8: Synthesis of 4,5-diazafluorenylphosphine ligands.

Scheme 9: Synthesis of thioether-containing pyridyldiphosphine ligands starting from ethylene sulfide and dip...

Scheme 10: Synthesis of monoterpene-derived phosphine pyridine ligands.

Scheme 11: Synthesis of N-phenylphosphine-substituted imidazole ligands.

Scheme 12: Synthesis of triazol-4-ylphosphine ligands.

Scheme 13: Synthesis of phosphanyltriazolopyridines and product selectivity depending on the substituents’ eff...

Scheme 14: Synthesis of PTA-phosphine ligands.

Scheme 15: Synthesis of isomeric phosphine dipyrazole ligands by varying the reaction temperature.

Scheme 16: Synthesis of N-tethered phosphine imidazolium ligands (route A) and diphosphine imidazolium ligands...

Scheme 17: Synthesis of {1-[2-(pyridin-2-yl)- (R = CH) and {1-[2-(pyrazin-2-yl)quinazolin-4-yl]naphthalen-2-yl...

Scheme 18: Synthesis of oxazolylindolylphosphine ligands 102.

Scheme 19: Synthesis of pyrrolylphosphine ligands.

Scheme 20: Synthesis of phosphine guanidinium ligands.

Scheme 21: Synthesis of a polydentate aminophosphine ligand.

Scheme 22: Synthesis of quinolylphosphine ligands.

Scheme 23: Synthesis of N-(triazolylmethyl)phosphanamine ligands.

Figure 2: Triazolylphosphanamine ligands synthesized by Wassenaar’s method [22].

Scheme 24: Synthesis of oxazaphosphorines.

Scheme 25: Synthesis of paracyclophane pyridylphosphine ligands.

Scheme 26: Synthesis of triazolylphosphine ligands.

Figure 3: Click-phosphine ligands.

Scheme 27: Ferrocenyl pyridylphosphine imine ligands.

Scheme 28: Synthesis of phosphinooxazolines (PHOX).

Scheme 29: Synthesis of ferrocenylphosphine oxazoles.

Synthesis of 3-alkenylindoles through regioselective C–H alkenylation of indoles by a ruthenium nanocatalyst

- Abhijit Paul,

- Debnath Chatterjee,

- Srirupa Banerjee and

- Somnath Yadav

Beilstein J. Org. Chem. 2020, 16, 140–148, doi:10.3762/bjoc.16.16

- anchored indole derivative under homogeneous catalysis with RuCl3⋅3H2O. Probable catalytic mechanism for the transformation of 1a by the RuNC. Control experiments and optimisation of the conditions for the alkenylation of indole (1a). Robustness screen of the synthesis of 3-alkenylindole 3b.a Supporting

Graphical Abstract

Figure 1: Biologically and medicinally important 3-alkenylindoles.

Scheme 1: a) Previous and b) present work related to the synthesis of 3-alkenylindoles.

Scheme 2: Substrate scope for the C–H alkenylation of the indoles 1. Reaction conditions: 1 (1 mmol), 2 (2 mm...

Scheme 3: a) Three-phase test to determine a homogeneous or heterogeneous catalytic mechanism of action for t...

Scheme 4: Probable catalytic mechanism for the transformation of 1a by the RuNC.

Formation of alkyne-bridged ferrocenophanes using ring-closing alkyne metathesis on 1,1’-diacetylenic ferrocenes

- Celine Bittner,

- Dirk Bockfeld and

- Matthias Tamm

Beilstein J. Org. Chem. 2019, 15, 2534–2543, doi:10.3762/bjoc.15.246

- isolated from THF solution. Keywords: alkyne metathesis; ferrocene; homogeneous catalysis; molybdenum; terminal alkynes; Introduction Alkyne metathesis, the reversible making and breaking of carbon–carbon triple bonds, is clearly gaining more attention. Not only could a great number of active catalysts

Graphical Abstract

Figure 1: Well-defined catalysts for alkyne metathesis.

Figure 2: Examples for a ferrrocenic thiacrown ether complexing palladium (IV), and a dicationic ferrocenopha...

Scheme 1: Synthesis of substrates 1 (a n = 2; b n = 3) via esterification of 3 and following RCAM with cataly...

Figure 3: ORTEP diagram of 1a with thermal displacement parameters drawn at 50% probability; hydrogen atoms a...

Figure 4: ORTEP diagram of 1b with thermal displacement parameters drawn at 50% probability; hydrogen atoms a...

Figure 5: ORTEP diagram of 2a with thermal displacement parameters drawn at 50% probability; hydrogen atoms a...

Figure 6: ORTEP diagram of 2b (one of two molecules of the asymmetric unit) with thermal displacement paramet...

Figure 7: Cyclic voltammogram of 2a in DCM, 0.2 M n-Bu4NPF6, 1 V s−1 scan rate, referenced vs FcH/FcH +.

Scheme 2: Top: Oxidation of ferrocenophane 2a to the corresponding ferrocenium cation 4 with Ag(SbF6) in DCM ...

Figure 8: ORTEP diagram of 4 with thermal displacement drawn at 50% probability; hydrogen atoms are omitted f...

Figure 9: 1H NMR (200.1 MHz, 298 K) spectrum of top: 2a in CDCl3; bottom: 5 in THF-d8 – signals for solvate T...

Figure 10: ORTEP diagram of 5(thf) with thermal displacement drawn at 50% probability; hydrogens atoms, [SbF6]−...

Self-assembled coordination thioether silver(I) macrocyclic complexes for homogeneous catalysis

- Zhen Cao,

- Aline Lacoudre,

- Cybille Rossy and

- Brigitte Bibal

Beilstein J. Org. Chem. 2019, 15, 2465–2472, doi:10.3762/bjoc.15.239

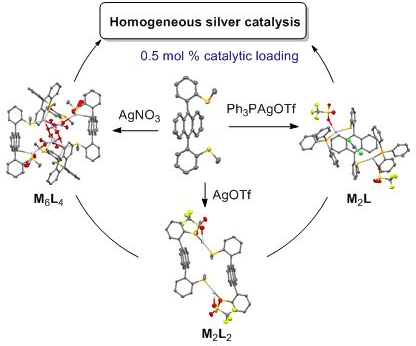

- ; homogeneous catalysis; prochiral; silver complex; thioether ligand; Introduction Since the early advances in the late eighties [1][2][3][4][5][6][7][8][9][10], silver(I) catalysis has been widely exploited based on the versatile redox and soft Lewis acid properties of this coinage metal cation. Silver

- candidates for directional metal coordination. Herein, a new syn-atropisomer of 9,10-DPA ortho-substituted by two thioethers is exploited as a ligand for silver(I) salts. The impact of this bis-thioether ligand on silver(I) homogeneous catalysis is evaluated in two tandem addition/cycloisomerization

Graphical Abstract

Scheme 1: Synthesis of ligand 1, as its syn-atropisomer.

Figure 1: X-ray structures of complex 1a, as two diastereoisomeric macrocycles (R,S-1)2·(AgOTf)2 with ligands...

Figure 2: X-ray structure of complex 1c, as a (R,S-1)4·(AgNO3)6 cage with three nitrate anions as coordinatin...

Figure 3: X-ray structure of complex 1d, as a racemic mixture of (R,R)- and (S,S)-(syn-1)·(PPh3AgOTf)2.

Figure 4: Variable temperature 1H NMR of complex 1a in CDCl3 (7 mM) from −30 °C to 60 °C.

Recent advances on the transition-metal-catalyzed synthesis of imidazopyridines: an updated coverage

- Gagandeep Kour Reen,

- Ashok Kumar and

- Pratibha Sharma

Beilstein J. Org. Chem. 2019, 15, 1612–1704, doi:10.3762/bjoc.15.165

- ][42][43][44]. Various copper salts have been used as Lewis acid in homogeneous catalysis. CuO nanoparticles (NPs) were used for C–N, C–S, C–O cross-coupling reactions and C-arylation. Recently, exploiting the cross-coupling tendency of CuO NPs, Reddy et al. have reported their use as a heterogeneous

Graphical Abstract

Figure 1: Various drugs having IP nucleus.

Figure 2: Participation percentage of various TMs for the syntheses of IPs.

Scheme 1: CuI–NaHSO4·SiO2-catalyzed synthesis of imidazo[1,2-a]pyridines.

Scheme 2: Experimental examination of reaction conditions.

Scheme 3: One-pot tandem reaction for the synthesis of 2-haloimidazopyridines.

Scheme 4: Mechanistic scheme for the synthesis of 2-haloimidazopyridine.

Scheme 5: Copper-MOF-catalyzed three-component reaction (3-CR) for imidazo[1,2-a]pyridines.

Scheme 6: Mechanism for copper-MOF-driven synthesis.

Scheme 7: Heterogeneous synthesis via titania-supported CuCl2.

Scheme 8: Mechanism involving oxidative C–H functionalization.

Scheme 9: Heterogeneous synthesis of IPs.

Scheme 10: One-pot regiospecific synthesis of imidazo[1,2-a]pyridines.

Scheme 11: Vinyl azide as an unprecedented substrate for imidazo[1,2-a]pyridines.

Scheme 12: Radical pathway.

Scheme 13: Cu(I)-catalyzed transannulation approach for imidazo[1,5-a]pyridines.

Scheme 14: Plausible radical pathway for the synthesis of imidazo[1,5-a]pyridines.

Scheme 15: A solvent-free domino reaction for imidazo[1,2-a]pyridines.

Scheme 16: Cu-NPs-mediated synthesis of imidazo[1,2-a]pyridines.

Scheme 17: CuI-catalyzed synthesis of isoxazolylimidazo[1,2-a]pyridines.

Scheme 18: Functionalization of 4-bromo derivative via Sonogashira coupling reaction.

Scheme 19: A plausible reaction pathway.

Scheme 20: Cu(I)-catalyzed intramolecular oxidative C–H amidation reaction.

Scheme 21: One-pot synthetic reaction for imidazo[1,2-a]pyridine.

Scheme 22: Plausible reaction mechanism.

Scheme 23: Cu(OAc)2-promoted synthesis of imidazo[1,2-a]pyridines.

Scheme 24: Mechanism for aminomethylation/cycloisomerization of propiolates with imines.

Scheme 25: Three-component synthesis of imidazo[1,2-a]pyridines.

Figure 3: Scope of pyridin-2(1H)-ones and acetophenones.

Scheme 26: CuO NPS-promoted A3 coupling reaction.

Scheme 27: Cu(II)-catalyzed C–N bond formation reaction.

Scheme 28: Mechanism involving Chan–Lam/Ullmann coupling.

Scheme 29: Synthesis of formyl-substituted imidazo[1,2-a]pyridines.

Scheme 30: A tandem sp3 C–H amination reaction.

Scheme 31: Probable mechanistic approach.

Scheme 32: Dual catalytic system for imidazo[1,2-a]pyridines.

Scheme 33: Tentative mechanism.

Scheme 34: CuO/CuAl2O4/ᴅ-glucose-promoted 3-CCR.