Search results

Search for "multicomponent reaction" in Full Text gives 138 result(s) in Beilstein Journal of Organic Chemistry.

Recent advances in the syntheses of anthracene derivatives

- Giovanni S. Baviera and

- Paulo M. Donate

Beilstein J. Org. Chem. 2021, 17, 2028–2050, doi:10.3762/bjoc.17.131

- synthesize tetrahydrobenzo[a]xanthene-11-ones 184 and diazabenzo[a]anthracene-9,11-dione derivatives 185 in good yields via a multicomponent reaction (Scheme 42) [76]. This methodology was based on the cyclocondensation of aromatic aldehydes 180, β-naphthol (181), and cyclic 1,3-dicarbonyl compounds 182 or

- -workers [77] provided better results. In a related approach, Estévez-Braun and co-workers synthesized dibenzo[a,h]anthracene-12,13-diones 188 from 2-hydroxy-1,4-naphthoquinone (186), β-naphthol (181), and aromatic aldehydes 187 through a multicomponent reaction that used InCl3 as catalyst under solvent

Graphical Abstract

Figure 1: Examples of anthracene derivatives and their applications.

Scheme 1: Rhodium-catalyzed oxidative coupling reactions of arylboronic acids with internal alkynes.

Scheme 2: Rhodium-catalyzed oxidative benzannulation reactions of 1-adamantoyl-1-naphthylamines with internal...

Scheme 3: Gold/bismuth-catalyzed cyclization of o-alkynyldiarylmethanes.

Scheme 4: [2 + 2 + 2] Cyclotrimerization reactions with alkynes/nitriles in the presence of nickel and cobalt...

Scheme 5: Cobalt-catalyzed [2 + 2 + 2] cyclotrimerization reactions with bis(trimethylsilyl)acetylene (23).

Scheme 6: [2 + 2 + 2] Alkyne-cyclotrimerization reactions catalyzed by a CoCl2·6H2O/Zn reagent.

Scheme 7: Pd(II)-catalyzed sp3 C–H alkenylation of diphenyl carboxylic acids with acrylates.

Scheme 8: Pd(II)-catalyzed sp3 C–H arylation with o-tolualdehydes and aryl iodides.

Scheme 9: Alkylation of arenes with aromatic aldehydes in the presence of acetyl bromide and ZnBr2/SiO2.

Scheme 10: BF3·H2O-catalyzed hydroxyalkylation of arenes with aromatic dialdehyde 44.

Scheme 11: Bi(OTf)3-promoted Friedel–Crafts alkylation of triarylmethanes and aromatic acylals and of arenes a...

Scheme 12: Reduction of anthraquinones by using Zn/pyridine or Zn/NaOH reductive methods.

Scheme 13: Two-step route to novel substituted Indenoanthracenes.

Scheme 14: Synthesis of 1,8-diarylanthracenes through Suzuki–Miyaura coupling reaction in the presence of Pd-P...

Scheme 15: Synthesis of five new substituted anthracenes by using LAH as reducing agent.

Scheme 16: One-pot procedure to synthesize substituted 9,10-dicyanoanthracenes.

Scheme 17: Reduction of bromoanthraquinones with NaBH4 in alkaline medium.

Scheme 18: In(III)-catalyzed reductive-dehydration intramolecular cycloaromatization of 2-benzylic aromatic al...

Scheme 19: Acid-catalyzed cyclization of new O-protected ortho-acetal diarylmethanols.

Scheme 20: Lewis acid-mediated regioselective cyclization of asymmetric diarylmethine dipivalates and diarylme...

Scheme 21: BF3·OEt2/CF3SO3H-mediated cyclodehydration reactions of 2-(arylmethyl)benzaldehydes and 2-(arylmeth...

Scheme 22: Synthesis of 2,3,6,7-anthracenetetracarbonitrile (90) by double Wittig reaction followed by deprote...

Scheme 23: Homo-elongation protocol for the synthesis of substituted acene diesters/dinitriles.

Scheme 24: Synthesis of two new parental BN anthracenes via borylative cyclization.

Scheme 25: Synthesis of substituted anthracenes from a bifunctional organomagnesium alkoxide.

Scheme 26: Palladium-catalyzed tandem C–H activation/bis-cyclization of propargylic carbonates.

Scheme 27: Ruthenium-catalyzed C–H arylation of acetophenone derivatives with arenediboronates.

Scheme 28: Pd-catalyzed intramolecular cyclization of (Z,Z)-p-styrylstilbene derivatives.

Scheme 29: AuCl-catalyzed double cyclization of diiodoethynylterphenyl compounds.

Scheme 30: Iodonium-induced electrophilic cyclization of terphenyl derivatives.

Scheme 31: Oxidative photocyclization of 1,3-distyrylbenzene derivatives.

Scheme 32: Oxidative cyclization of 2,3-diphenylnaphthalenes.

Scheme 33: Suzuki-Miyaura/isomerization/ring closing metathesis strategy to synthesize benz[a]anthracenes.

Scheme 34: Green synthesis of oxa-aza-benzo[a]anthracene and oxa-aza-phenanthrene derivatives.

Scheme 35: Triple benzannulation of substituted naphtalene via a 1,3,6-naphthotriyne synthetic equivalent.

Scheme 36: Zinc iodide-catalyzed Diels–Alder reactions with 1,3-dienes and aroyl propiolates followed by intra...

Scheme 37: H3PO4-promoted intramolecular cyclization of substituted benzoic acids.

Scheme 38: Palladium-catalyzed intermolecular direct acylation of aromatic aldehydes and o-iodoesters.

Scheme 39: Cycloaddition/oxidative aromatization of quinone and β-enamino esters.

Scheme 40: ʟ-Proline-catalyzed [4 + 2] cycloaddition reaction of naphthoquinones and α,β-unsaturated aldehydes....

Scheme 41: Iridium-catalyzed [2 + 2 + 2] cycloaddition of a 1,2-bis(propiolyl)benzene derivative with alkynes.

Scheme 42: Synthesis of several anthraquinone derivatives by using InCl3 and molecular iodine.

Scheme 43: Indium-catalyzed multicomponent reactions employing 2-hydroxy-1,4-naphthoquinone (186), β-naphthol (...

Scheme 44: Synthesis of substituted anthraquinones catalyzed by an AlCl3/MeSO3H system.

Scheme 45: Palladium(II)-catalyzed/visible light-mediated synthesis of anthraquinones.

Scheme 46: [4 + 2] Anionic annulation reaction for the synthesis of substituted anthraquinones.

Correction: One-pot multicomponent green Hantzsch synthesis of 1,2-dihydropyridine derivatives with antiproliferative activity

- Giovanna Bosica,

- Kaylie Demanuele,

- José M. Padrón and

- Adrián Puerta

Beilstein J. Org. Chem. 2021, 17, 2026–2027, doi:10.3762/bjoc.17.130

- 10.3762/bjoc.17.130 Keywords: antiproliferative activity; 1,2-dihydropyridines; green Hantzsch synthesis; heterogeneous catalysis; one-pot multicomponent reaction; The authors noticed that the E-factor (E) was calculated using a wrong Equation 2 in the original publication: The correct Equation 2 should

Asymmetric organocatalyzed synthesis of coumarin derivatives

- Natália M. Moreira,

- Lorena S. R. Martelli and

- Arlene G. Corrêa

Beilstein J. Org. Chem. 2021, 17, 1952–1980, doi:10.3762/bjoc.17.128

- multicomponent reaction (IMCR) [31]. The enantioenriched hemiacetals 5 were obtained using the Jørgensen catalyst 7 as previously described by Rueping et al. [32]. This approach enables the rapid assembly of complex natural product hybrids 6 including up to four different molecular fragments, such as

Graphical Abstract

Figure 1: Coumarin-derived commercially available drugs.

Figure 2: Inhibition of acetylcholinesterase by coumarin derivatives.

Scheme 1: Michael addition of 4-hydroxycoumarins 1 to α,β‐unsaturated enones 2.

Scheme 2: Organocatalytic conjugate addition of 4-hydroxycoumarin 1 to α,β-unsaturated aldehydes 2 followed b...

Scheme 3: Synthesis of 3,4-dihydrocoumarin derivatives 10 through decarboxylative and dearomatizative cascade...

Scheme 4: Total synthesis of (+)-smyrindiol (17).

Scheme 5: Michael addition of 4-hydroxycoumarin (1) to enones 2 through a bifunctional modified binaphthyl or...

Scheme 6: Michael addition of ketones 20 to 3-aroylcoumarins 19 using a cinchona alkaloid-derived primary ami...

Scheme 7: Enantioselective reaction of cyclopent-2-enone-derived MBH alcohols 24 with 4-hydroxycoumarins 1.

Scheme 8: Sequential Michael addition/hydroalkoxylation one-pot approach to annulated coumarins 28 and 30.

Scheme 9: Michael addition of 4-hydroxycoumarins 1 to enones 2 using a binaphthyl diamine catalyst 31.

Scheme 10: Asymmetric Michael addition of 4-hydroxycoumarin 1 with α,β-unsaturated ketones 2 catalyzed by a ch...

Scheme 11: Catalytic asymmetric β-C–H functionalization of ketones via enamine oxidation.

Scheme 12: Enantioselective synthesis of polycyclic coumarin derivatives 37 catalyzed by an primary amine-imin...

Scheme 13: Allylic alkylation reaction between 3-cyano-4-methylcoumarins 39 and MBH carbonates 40.

Scheme 14: Enantioselective synthesis of cyclopropa[c]coumarins 45.

Scheme 15: NHC-catalyzed lactonization of 2-bromoenals 46 with 4-hydroxycoumarin (1).

Scheme 16: NHC-catalyzed enantioselective synthesis of dihydrocoumarins 51.

Scheme 17: Domino reaction of enals 2 with hydroxylated malonate 53 catalyzed by NHC 55.

Scheme 18: Oxidative [4 + 2] cycloaddition of enals 57 to coumarins 56 catalyzed by NHC 59.

Scheme 19: Asymmetric [3 + 2] cycloaddition of coumarins 43 to azomethine ylides 60 organocatalyzed by quinidi...

Scheme 20: Synthesis of α-benzylaminocoumarins 64 through Mannich reaction between 4-hydroxycoumarins (1) and ...

Scheme 21: Asymmetric addition of malonic acid half-thioesters 67 to coumarins 66 using the sulphonamide organ...

Scheme 22: Enantioselective 1,4-addition of azadienes 71 to 3-homoacyl coumarins 70.

Scheme 23: Michael addition/intramolecular cyclization of 3-acylcoumarins 43 to 3-halooxindoles 74.

Scheme 24: Enantioselective synthesis of 3,4-dihydrocoumarins 78 catalyzed by squaramide 73.

Scheme 25: Organocatalyzed [4 + 2] cycloaddition between 2,4-dienals 79 and 3-coumarincarboxylates 43.

Scheme 26: Enantioselective one-pot Michael addition/intramolecular cyclization for the synthesis of spiro[dih...

Scheme 27: Michael/hemiketalization addition enantioselective of hydroxycoumarins (1) to: (a) enones 2 and (b)...

Scheme 28: Synthesis of 2,3-dihydrofurocoumarins 89 through Michael addition of 4-hydroxycoumarins 1 to β-nitr...

Scheme 29: Synthesis of pyrano[3,2-c]chromene derivatives 93 via domino reaction between 4-hydroxycoumarins (1...

Scheme 30: Conjugated addition of 4-hydroxycoumarins 1 to nitroolefins 95.

Scheme 31: Michael addition of 4-hydroxycoumarin 1 to α,β-unsaturated ketones 2 promoted by primary amine thio...

Scheme 32: Enantioselective synthesis of functionalized pyranocoumarins 99.

Scheme 33: 3-Homoacylcoumarin 70 as 1,3-dipole for enantioselective concerted [3 + 2] cycloaddition.

Scheme 34: Synthesis of warfarin derivatives 107 through addition of 4-hydroxycoumarins 1 to β,γ-unsaturated α...

Scheme 35: Asymmetric multicatalytic reaction sequence of 2-hydroxycinnamaldehydes 109 with 4-hydroxycoumarins ...

Scheme 36: Mannich asymmetric addition of cyanocoumarins 39 to isatin imines 112 catalyzed by the amide-phosph...

Scheme 37: Enantioselective total synthesis of (+)-scuteflorin A (119).

A comprehensive review of flow chemistry techniques tailored to the flavours and fragrances industries

- Guido Gambacorta,

- James S. Sharley and

- Ian R. Baxendale

Beilstein J. Org. Chem. 2021, 17, 1181–1312, doi:10.3762/bjoc.17.90

Graphical Abstract

Figure 1: Representative shares of the global F&F market (2018) segmented on their applications [1].

Figure 2: General structure of an international fragrance company [2].

Figure 3: The Michael Edwards fragrance wheel.

Figure 4: Examples of oriental (1–3), woody (4–7), fresh (8–10), and floral (11 and 12) notes.

Figure 5: A basic depiction of batch vs flow.

Scheme 1: Examples of reactions for which flow processing outperforms batch.

Scheme 2: Some industrially important aldol-based transformations.

Scheme 3: Biphasic continuous aldol reactions of acetone and various aldehydes.

Scheme 4: Aldol synthesis of 43 in flow using LiHMDS as the base.

Scheme 5: A semi-continuous synthesis of doravirine (49) involving a key aldol reaction.

Scheme 6: Enantioselective aldol reaction using 5-(pyrrolidin-2-yl)tetrazole (51) as catalyst in a microreact...

Scheme 7: Gröger's example of asymmetric aldol reaction in aqueous media.

Figure 6: Immobilised reagent column reactor types.

Scheme 8: Photoinduced thiol–ene coupling preparation of silica-supported 5-(pyrrolidin-2-yl)tetrazole 63 and...

Scheme 9: Continuous-flow approach for enantioselective aldol reactions using the supported catalyst 67.

Scheme 10: Ötvös’ employment of a solid-supported peptide aldol catalyst in flow.

Scheme 11: The use of proline tetrazole packed in a column for aldol reaction between cyclohexanone (65) and 2...

Scheme 12: Schematic diagram of an aminosilane-grafted Si-Zr-Ti/PAI-HF reactor for continuous-flow aldol and n...

Scheme 13: Continuous-flow condensation for the synthesis of the intermediate 76 to nabumetone (77) and Microi...

Scheme 14: Synthesis of ψ-Ionone (80) in continuous-flow via aldol condensation between citral (79) and aceton...

Scheme 15: Synthesis of β-methyl-ionones (83) from citral (79) in flow. The steps are separately described, an...

Scheme 16: Continuous-flow synthesis of 85 from 84 described by Gavriilidis et al.

Scheme 17: Continuous-flow scCO2 apparatus for the synthesis of 2-methylpentanal (87) and the self-condensed u...

Scheme 18: Chen’s two-step flow synthesis of coumarin (90).

Scheme 19: Pechmann condensation for the synthesis of 7-hydroxyxcoumarin (93) in flow. The setup extended to c...

Scheme 20: Synthesis of the dihydrojasmonate 35 exploiting nitro derivative proposed by Ballini et al.

Scheme 21: Silica-supported amines as heterogeneous catalyst for nitroaldol condensation in flow.

Scheme 22: Flow apparatus for the nitroaldol condensation of p-hydroxybenzaldehyde (102) to nitrostyrene 103 a...

Scheme 23: Nitroaldol reaction of 64 to 105 employing a quaternary ammonium functionalised PANF.

Scheme 24: Enantioselective nitroaldol condensation for the synthesis of 108 under flow conditions.

Scheme 25: Enatioselective synthesis of 1,2-aminoalcohol 110 via a copper-catalysed nitroaldol condensation.

Scheme 26: Examples of Knoevenagel condensations applied for fragrance components.

Scheme 27: Flow apparatus for Knoevenagel condensation described in 1989 by Venturello et al.

Scheme 28: Knoevenagel reaction using a coated multichannel membrane microreactor.

Scheme 29: Continuous-flow apparatus for Knoevenagel condensation employing sugar cane bagasse as support deve...

Scheme 30: Knoevenagel reaction for the synthesis of 131–135 in flow using an amine-functionalised silica gel. ...

Scheme 31: Continuous-flow synthesis of compound 137, a key intermediate for the synthesis of pregabalin (138)...

Scheme 32: Continuous solvent-free apparatus applied for the synthesis of compounds 140–143 using a TSE. Throu...

Scheme 33: Lewis et al. developed a spinning disc reactor for Darzens condensation of 144 and a ketone to furn...

Scheme 34: Some key industrial applications of conjugate additions in the F&F industry.

Scheme 35: Continuous-flow synthesis of 4-(2-hydroxyethyl)thiomorpholine 1,1-dioxide (156) via double conjugat...

Scheme 36: Continuous-flow system for Michael addition using CsF on alumina as the catalyst.

Scheme 37: Calcium chloride-catalysed asymmetric Michael addition using an immobilised chiral ligand.

Scheme 38: Continuous multistep synthesis for the preparation of (R)-rolipram (173). Si-NH2: primary amine-fun...

Scheme 39: Continuous-flow Michael addition using ion exchange resin Amberlyst® A26.

Scheme 40: Preparation of the heterogeneous catalyst 181 developed by Paixão et al. exploiting Ugi multicompon...

Scheme 41: Continuous-flow system developed by the Paixão’s group for the preparation of Michael asymmetric ad...

Scheme 42: Continuous-flow synthesis of nitroaldols catalysed by supported catalyst 184 developed by Wennemers...

Scheme 43: Heterogenous polystyrene-supported catalysts developed by Pericàs and co-workers.

Scheme 44: PANF-supported pyrrolidine catalyst for the conjugate addition of cyclohexanone (65) and trans-β-ni...

Scheme 45: Synthesis of (−)-paroxetine precursor 195 developed by Ötvös, Pericàs, and Kappe.

Scheme 46: Continuous-flow approach for the 5-step synthesis of (−)-oseltamivir (201) as devised by Hayashi an...

Scheme 47: Continuous-flow enzyme-catalysed Michael addition.

Scheme 48: Continuous-flow copper-catalysed 1,4 conjugate addition of Grignard reagents to enones. Reprinted w...

Scheme 49: A collection of commonly encountered hydrogenation reactions.

Figure 7: The ThalesNano H-Cube® continuous-flow hydrogenator.

Scheme 50: Chemoselective reduction of an α,β-unsaturated ketone using the H-Cube® reactor.

Scheme 51: Incorporation of Lindlar’s catalyst into the H-Cube® reactor for the reduction of an alkyne.

Scheme 52: Continuous-flow semi-hydrogenation of alkyne 208 to 209 using SACs with H-Cube® system.

Figure 8: The standard setups for tube-in-tube gas–liquid reactor units.

Scheme 53: Homogeneous hydrogenation of olefins using a tube-in-tube reactor setup.

Scheme 54: Recyclable heterogeneous flow hydrogenation system.

Scheme 55: Leadbeater’s reverse tube-in-tube hydrogenation system for olefin reductions.

Scheme 56: a) Hydrogenation using a Pd-immobilised microchannel reactor (MCR) and b) a representation of the i...

Scheme 57: Hydrogenation of alkyne 238 exploiting segmented flow in a Pd-immobilised capillary reactor.

Scheme 58: Continuous hydrogenation system for the preparation of cyrene (241) from (−)-levoglucosenone (240).

Scheme 59: Continuous hydrogenation system based on CSMs developed by Hornung et al.

Scheme 60: Chemoselective reduction of carbonyls (ketones over aldehydes) in flow.

Scheme 61: Continuous system for the semi-hydrogenation of 256 and 258, developed by Galarneau et al.

Scheme 62: Continuous synthesis of biodiesel fuel 261 from lignin-derived furfural acetone (260).

Scheme 63: Continuous synthesis of γ-valerolacetone (263) via CTH developed by Pineda et al.

Scheme 64: Continuous hydrogenation of lignin-derived biomass (products 265, 266, and 267) using a sustainable...

Scheme 65: Ru/C or Rh/C-catalysed hydrogenation of arene in flow as developed by Sajiki et al.

Scheme 66: Polysilane-immobilized Rh–Pt-catalysed hydrogenation of arenes in flow by Kobayashi et al.

Scheme 67: High-pressure in-line mixing of H2 for the asymmetric reduction of 278 at pilot scale with a 73 L p...

Figure 9: Picture of the PFR employed at Eli Lilly & Co. for the continuous hydrogenation of 278 [287]. Reprinted ...

Scheme 68: Continuous-flow asymmetric hydrogenation using Oppolzer's sultam 280 as chiral auxiliary.

Scheme 69: Some examples of industrially important oxidation reactions in the F&F industry. CFL: compact fluor...

Scheme 70: Gold-catalysed heterogeneous oxidation of alcohols in flow.

Scheme 71: Uozumi’s ARP-Pt flow oxidation protocol.

Scheme 72: High-throughput screening of aldehyde oxidation in flow using an in-line GC.

Scheme 73: Permanganate-mediated Nef oxidation of nitroalkanes in flow with the use of in-line sonication to p...

Scheme 74: Continuous-flow aerobic anti-Markovnikov Wacker oxidation.

Scheme 75: Continuous-flow oxidation of 2-benzylpyridine (312) using air as the oxidant.

Scheme 76: Continuous-flow photo-oxygenation of monoterpenes.

Scheme 77: A tubular reactor design for flow photo-oxygenation.

Scheme 78: Glucose oxidase (GOx)-mediated continuous oxidation of glucose using compressed air and the FFMR re...

Scheme 79: Schematic continuous-flow sodium hypochlorite/TEMPO oxidation of alcohols.

Scheme 80: Oxidation using immobilised TEMPO (344) was developed by McQuade et al.

Scheme 81: General protocol for the bleach/catalytic TBAB oxidation of aldehydes and alcohols.

Scheme 82: Continuous-flow PTC-assisted oxidation using hydrogen peroxide. The process was easily scaled up by...

Scheme 83: Continuous-flow epoxidation of cyclohexene (348) and in situ preparation of m-CPBA.

Scheme 84: Continuous-flow epoxidation using DMDO as oxidant.

Scheme 85: Mukayama aerobic epoxidation optimised in flow mode by the Favre-Réguillon group.

Scheme 86: Continuous-flow asymmetric epoxidation of derivatives of 359 exploiting a biomimetic iron catalyst.

Scheme 87: Continuous-flow enzymatic epoxidation of alkenes developed by Watts et al.

Scheme 88: Engineered multichannel microreactor for continuous-flow ozonolysis of 366.

Scheme 89: Continuous-flow synthesis of the vitamin D precursor 368 using multichannel microreactors. MFC: mas...

Scheme 90: Continuous ozonolysis setup used by Kappe et al. for the synthesis of various substrates employing ...

Scheme 91: Continuous-flow apparatus for ozonolysis as developed by Ley et al.

Scheme 92: Continuous-flow ozonolysis for synthesis of vanillin (2) using a film-shear flow reactor.

Scheme 93: Examples of preparative methods for ajoene (386) and allicin (388).

Scheme 94: Continuous-flow oxidation of thioanisole (389) using styrene-based polymer-supported peroxytungstat...

Scheme 95: Continuous oxidation of thiosulfinates using Oxone®-packed reactor.

Scheme 96: Continuous-flow electrochemical oxidation of thioethers.

Scheme 97: Continuous-flow oxidation of 400 to cinnamophenone (235).

Scheme 98: Continuous-flow synthesis of dehydrated material 401 via oxidation of methyl dihydrojasmonate (33).

Scheme 99: Some industrially important transformations involving Grignard reagents.

Scheme 100: Grachev et al. apparatus for continuous preparation of Grignard reagents.

Scheme 101: Example of fluidized Mg bed reactor with NMR spectrometer as on-line monitoring system.

Scheme 102: Continuous-flow synthesis of Grignard reagents and subsequent quenching reaction.

Figure 10: Membrane-based, liquid–liquid separator with integrated pressure control [52]. Adapted with permission ...

Scheme 103: Continuous-flow synthesis of 458, an intermediate to fluconazole (459).

Scheme 104: Continuous-flow synthesis of ketones starting from benzoyl chlorides.

Scheme 105: A Grignard alkylation combining CSTR and PFR technologies with in-line infrared reaction monitoring....

Scheme 106: Continuous-flow preparation of 469 from Grignard addition of methylmagnesium bromide.

Scheme 107: Continuous-flow synthesis of Grignard reagents 471.

Scheme 108: Preparation of the Grignard reagent 471 using CSTR and the continuous process for synthesis of the ...

Scheme 109: Continuous process for carboxylation of Grignard reagents in flow using tube-in-tube technology.

Scheme 110: Continuous synthesis of propargylic alcohols via ethynyl-Grignard reagent.

Scheme 111: Silica-supported catalysed enantioselective arylation of aldehydes using Grignard reagents in flow ...

Scheme 112: Acid-catalysed rearrangement of citral and dehydrolinalool derivatives.

Scheme 113: Continuous stilbene isomerisation with continuous recycling of photoredox catalyst.

Scheme 114: Continuous-flow synthesis of compound 494 as developed by Ley et al.

Scheme 115: Selected industrial applications of DA reaction.

Scheme 116: Multistep flow synthesis of the spirocyclic structure 505 via employing DA cycloaddition.

Scheme 117: Continuous-flow DA reaction developed in a plater flow reactor for the preparation of the adduct 508...

Scheme 118: Continuous-flow DA reaction using a silica-supported imidazolidinone organocatalyst.

Scheme 119: Batch vs flow for the DA reaction of (cyclohexa-1,5-dien-1-yloxy)trimethylsilane (513) with acrylon...

Scheme 120: Continuous-flow DA reaction between 510 and 515 using a shell-core droplet system.

Scheme 121: Continuous-flow synthesis of bicyclic systems from benzyne precursors.

Scheme 122: Continuous-flow synthesis of bicyclic scaffolds 527 and 528 for further development of potential ph...

Scheme 123: Continuous-flow inverse-electron hetero-DA reaction to pyridine derivatives such as 531.

Scheme 124: Comparison between batch and flow for the synthesis of pyrimidinones 532–536 via retro-DA reaction ...

Scheme 125: Continuous-flow coupled with ultrasonic system for preparation of ʟ-ascorbic acid derivatives 539 d...

Scheme 126: Two-step continuous-flow synthesis of triazole 543.

Scheme 127: Continuous-flow preparation of triazoles via CuAAC employing 546-based heterogeneous catalyst.

Scheme 128: Continuous-flow synthesis of compounds 558 through A3-coupling and 560 via AgAAC both employing the...

Scheme 129: Continuous-flow photoinduced [2 + 2] cycloaddition for the preparation of bicyclic derivatives of 5...

Scheme 130: Continuous-flow [2 + 2] and [5 + 2] cycloaddition on large scale employing a flow reactor developed...

Scheme 131: Continuous-flow preparation of the tricyclic structures 573 and 574 starting from pyrrole 570 via [...

Scheme 132: Continuous-flow [2 + 2] photocyclization of cinnamates.

Scheme 133: Continuous-flow preparation of cyclobutane 580 on a 5-plates photoreactor.

Scheme 134: Continuous-flow [2 + 2] photocycloaddition under white LED lamp using heterogeneous PCN as photocat...

Figure 11: Picture of the parallel tube flow reactor (PTFR) "The Firefly" developed by Booker-Milburn et al. a...

Scheme 135: Continuous-flow acid-catalysed [2 + 2] cycloaddition between silyl enol ethers and acrylic esters.

Scheme 136: Continuous synthesis of lactam 602 using glass column reactors.

Scheme 137: In situ generation of ketenes for the Staudinger lactam synthesis developed by Ley and Hafner.

Scheme 138: Application of [2 + 2 + 2] cycloadditions in flow employed by Ley et al.

Scheme 139: Examples of FC reactions applied in F&F industry.

Scheme 140: Continuous-flow synthesis of ibuprofen developed by McQuade et al.

Scheme 141: The FC acylation step of Jamison’s three-step ibuprofen synthesis.

Scheme 142: Synthesis of naphthalene derivative 629 via FC acylation in microreactors.

Scheme 143: Flow system for rapid screening of catalysts and reaction conditions developed by Weber et al.

Scheme 144: Continuous-flow system developed by Buorne, Muller et al. for DSD optimisation of the FC acylation ...

Scheme 145: Continuous-flow FC acylation of alkynes to yield β-chlorovinyl ketones such as 638.

Scheme 146: Continuous-flow synthesis of tonalide (619) developed by Wang et al.

Scheme 147: Continuous-flow preparation of acylated arene such as 290 employing Zr4+-β-zeolite developed by Kob...

Scheme 148: Flow system applied on an Aza-FC reaction catalysed by the thiourea catalyst 648.

Scheme 149: Continuous hydroformylation in scCO2.

Scheme 150: Two-step flow synthesis of aldehyde 655 through a sequential Heck reaction and subsequent hydroform...

Scheme 151: Single-droplet (above) and continuous (below) flow reactors developed by Abolhasani et al. for the ...

Scheme 152: Continuous hydroformylation of 1-dodecene (655) using a PFR-CSTR system developed by Sundmacher et ...

Scheme 153: Continuous-flow synthesis of the aldehyde 660 developed by Eli Lilly & Co. [32]. Adapted with permissio...

Scheme 154: Continuous asymmetric hydroformylation employing heterogenous catalst supported on carbon-based sup...

Scheme 155: Examples of acetylation in F&F industry: synthesis of bornyl (S,R,S-664) and isobornyl (S,S,S-664) ...

Scheme 156: Continuous-flow preparation of bornyl acetate (S,R,S-664) employing the oscillating flow reactor.

Scheme 157: Continuous-flow synthesis of geranyl acetate (666) from acetylation of geraniol (343) developed by ...

Scheme 158: 12-Ttungstosilicic acid-supported silica monolith-catalysed acetylation in flow.

Scheme 159: Continuous-flow preparation of cyclopentenone 676.

Scheme 160: Two-stage synthesis of coumarin (90) via acetylation of salicylaldehyde (88).

Scheme 161: Intensification process for acetylation of 5-methoxytryptamine (677) to melatonin (678) developed b...

Scheme 162: Examples of macrocyclic musky odorants both natural (679–681) and synthetic (682 and 683).

Scheme 163: Flow setup combined with microwave for the synthesis of macrocycle 686 via RCM.

Scheme 164: Continuous synthesis of 2,5-dihydro-1H-pyrroles via ring-closing metathesis.

Scheme 165: Continuous-flow metathesis of 485 developed by Leadbeater et al.

Figure 12: Comparison between RCM performed using different routes for the preparation of 696. On the left the...

Scheme 166: Continuous-flow RCM of 697 employed the solid-supported catalyst 698 developed by Grela, Kirschning...

Scheme 167: Continuous-flow RORCM of cyclooctene employing the silica-absorbed catalyst 700.

Scheme 168: Continuous-flow self-metathesis of methyl oleate (703) employing SILP catalyst 704.

Scheme 169: Flow apparatus for the RCM of 697 using a nanofiltration membrane for the recovery and reuse of the...

Scheme 170: Comparison of loadings between RCMs performed with different routes for the synthesis of 709.

Microwave-assisted multicomponent reactions in heterocyclic chemistry and mechanistic aspects

- Shivani Gulati,

- Stephy Elza John and

- Nagula Shankaraiah

Beilstein J. Org. Chem. 2021, 17, 819–865, doi:10.3762/bjoc.17.71

- economic perspective due to increased amounts of waste generation, toxic solvents, and no real-time control of pollution generated, etc. [4]. Therefore, in this connection, the multicomponent reaction (MCR) is one such approach where three or more reactants combine to form a single product retaining the

- majority of the atoms of the starting materials. The ability of forming multiple bonds in one-pot via a multicomponent reaction provides a novel and sustainable method in drug discovery [4]. In the recent years, these reactions have emerged as a promising strategy following green chemistry principles such

- ] tailored a microwave-assisted multicomponent reaction for fast and efficient generation of diastereoselective dibenzo[c,e]azepinones. The protocol utilized substituted 2'-formylbiphenyl-2-carboxylic acid 19, benzylamines 20, and isocyanides 21 in TFE and Na2SO4 as drying agent for the construction of

Graphical Abstract

Figure 1: Marketed drugs with acridine moiety.

Scheme 1: Synthesis of 4-arylacridinediones.

Scheme 2: Proposed mechanism for acridinedione synthesis.

Scheme 3: Synthesis of tetrahydrodibenzoacridinones.

Scheme 4: Synthesis of naphthoacridines.

Scheme 5: Plausible mechanism for naphthoacridines.

Figure 2: Benzoazepines based potent molecules.

Scheme 6: Synthesis of azepinone.

Scheme 7: Proposed mechanism for azepinone formation.

Scheme 8: Synthesis of benzoazulenen-1-one derivatives.

Scheme 9: Proposed mechanism for benzoazulene-1-one synthesis.

Figure 3: Indole-containing pharmacologically active molecules.

Scheme 10: Synthesis of functionalized indoles.

Scheme 11: Plausible mechanism for the synthesis of functionalized indoles.

Scheme 12: Synthesis of spirooxindoles.

Scheme 13: Synthesis of substituted spirooxindoles.

Scheme 14: Plausible mechanism for the synthesis of substituted spirooxindoles.

Scheme 15: Synthesis of pyrrolidinyl spirooxindoles.

Scheme 16: Proposed mechanism for pyrrolidinyl spirooxindoles.

Figure 4: Pyran-containing biologically active molecules.

Scheme 17: Synthesis of functionalized benzopyrans.

Scheme 18: Plausible mechanism for synthesis of benzopyran.

Scheme 19: Synthesis of indoline-spiro-fused pyran derivatives.

Scheme 20: Proposed mechanism for indoline-spiro-fused pyran.

Scheme 21: Synthesis of substituted naphthopyrans.

Figure 5: Marketed drugs with pyrrole ring.

Scheme 22: Synthesis of tetra-substituted pyrroles.

Scheme 23: Mechanism for silica-supported PPA-SiO2-catalyzed pyrrole synthesis.

Scheme 24: Synthesis of pyrrolo[1,10]-phenanthrolines.

Scheme 25: Proposed mechanism for pyrrolo[1,10]-phenanthrolines.

Figure 6: Marketed drugs and molecules containing pyrimidine and pyrimidinones skeletons.

Scheme 26: MWA-MCR pyrimidinone synthesis.

Scheme 27: Two proposed mechanisms for pyrimidinone synthesis.

Scheme 28: MWA multicomponent synthesis of dihydropyrimidinones.

Scheme 29: Proposed mechanism for dihydropyrimidinones.

Figure 7: Biologically active fused pyrimidines.

Scheme 30: MWA- MCR for the synthesis of pyrrolo[2,3-d]pyrimidines.

Scheme 31: Proposed mechanism for pyrrolo[2,3-d]pyrimidines.

Scheme 32: Synthesis of substituted pyrrolo[2,3-d]pyrimidine-2,4-diones.

Scheme 33: Probable pathway for pyrrolo[2,3-d]pyrimidine-2,4-diones.

Scheme 34: Synthesis of pyridopyrimidines.

Scheme 35: Plausible mechanism for the synthesis of pyridopyrimidines.

Scheme 36: Synthesis of dihydropyridopyrimidine and dihydropyrazolopyridine.

Scheme 37: Proposed mechanism for the formation of dihydropyridopyrimidine.

Scheme 38: Synthesis of thiopyrano[4,3-d]pyrimidines.

Scheme 39: Plausible mechanism for the synthesis of thiopyrano[4,3-d]pyrimidines.

Scheme 40: Synthesis of decorated imidazopyrimidines.

Scheme 41: Proposed mechanism for imidazopyrimidine synthesis.

Figure 8: Pharmacologically active molecules containing purine bases.

Scheme 42: Synthesis of aza-adenines.

Scheme 43: Synthesis of 5-aza-7-deazapurines.

Scheme 44: Proposed mechanism for deazapurines synthesis.

Figure 9: Biologically active molecules containing pyridine moiety.

Scheme 45: Synthesis of steroidal pyridines.

Scheme 46: Proposed mechanism for steroidal pyridine.

Scheme 47: Synthesis of N-alkylated 2-pyridones.

Scheme 48: Two possible mechanisms for pyridone synthesis.

Scheme 49: Synthesis of pyridone derivatives.

Scheme 50: Postulated mechanism for synthesis of pyridone.

Figure 10: Biologically active fused pyridines.

Scheme 51: Benzimidazole-imidazo[1,2-a]pyridines synthesis.

Scheme 52: Mechanism for the synthesis of benzimidazole-imidazo[1,2-a]pyridines.

Scheme 53: Synthesis of pyrazolo[3,4-b]pyridine-5-spirocycloalkanedione derivatives.

Scheme 54: Proposed mechanism for spiro-pyridines.

Scheme 55: Functionalized macrocyclane-fused pyrazolo[3,4-b]pyridine derivatives.

Scheme 56: Mechanism postulated for macrocyclane-fused pyrazolo[3,4-b]pyridine.

Scheme 57: Generation of pyrazolo[3,4-b]pyridines.

Scheme 58: Proposed mechanism for the synthesis of pyrazolo[3,4-b]pyridines.

Scheme 59: Proposed mechanism for the synthesis of azepinoindole.

Figure 11: Pharmaceutically important molecules with quinoline moiety.

Scheme 60: Povarov-mediated quinoline synthesis.

Scheme 61: Proposed mechanism for Povarov reaction.

Scheme 62: Synthesis of pyrazoloquinoline.

Scheme 63: Plausible mechanism for pyrazoloquinoline synthesis.

Figure 12: Quinazolinones as pharmacologically significant scaffolds.

Scheme 64: Four-component reaction for dihydroquinazolinone.

Scheme 65: Proposed mechanism for dihydroquinazolinones.

Scheme 66: Synthesis purine quinazolinone and PI3K-δ inhibitor.

Scheme 67: Synthesis of fused benzothiazolo/benzoimidazoloquinazolinones.

Scheme 68: Proposed mechanism for fused benzothiazolo/benzoimidazoloquinazolinones.

Scheme 69: On-water reaction for synthesis of thiazoloquinazolinone.

Scheme 70: Proposed mechanism for the thiazoloquinazolinone synthesis.

Scheme 71: β-Cyclodextrin-mediated synthesis of indoloquinazolinediones.

Scheme 72: Proposed mechanism for synthesis of indoloquinazolinediones.

Figure 13: Triazoles-containing marketted drugs and pharmacologically active molecules.

Scheme 73: Cu(I) DAPTA-catalyzed 1,2,3-triazole formation.

Scheme 74: Mechanism for Cu(I) DAPTA-catalyzed triazole formation.

Scheme 75: Synthesis of β-hydroxy-1,2,3-triazole.

Scheme 76: Proposed mechanism for synthesis of β-hydroxy-1,2,3-triazoles.

Scheme 77: Synthesis of bis-1,2,4-triazoles.

Scheme 78: Proposed mechanism for bis-1,2,4-triazoles synthesis.

Figure 14: Thiazole containing drugs.

Scheme 79: Synthesis of a substituted thiazole ring.

Scheme 80: Synthesis of pyrazolothiazoles.

Figure 15: Chromene containing drugs.

Scheme 81: Magnetic nanocatalyst-mediated aminochromene synthesis.

Scheme 82: Proposed mechanism for the synthesis of chromenes.

Synthetic reactions driven by electron-donor–acceptor (EDA) complexes

- Zhonglie Yang,

- Yutong Liu,

- Kun Cao,

- Xiaobin Zhang,

- Hezhong Jiang and

- Jiahong Li

Beilstein J. Org. Chem. 2021, 17, 771–799, doi:10.3762/bjoc.17.67

- 22 can be afforded easily (Scheme 7). This procedure offers a novel cyclization method with bifunctionalization, causing a multicomponent reaction of vinylaniline, halide, and sulfonylate to give corresponding indole derivatives. Furthermore, a wide variety of applicable substrates and good

- successfully applied to the gram scale, providing a step towards assorted aryl sulfide structural units with medicinal value. In 2019, Yang and colleagues [52] developed a method for preparing S-aryl dithiocarbamates 135 by a multicomponent reaction of an EDA complex under visible-light irradiation (Scheme 47

Graphical Abstract

Scheme 1: The electron transfer process in EDA complexes.

Scheme 2: Synthesis of benzo[b]phosphorus oxide 3 initiated by an EDA complex.

Scheme 3: Mechanism of the synthesis of quinoxaline derivative 7.

Scheme 4: Synthesis of imidazole derivative 10 initiated by an EDA complex.

Scheme 5: Synthesis of sulfamoylation product 12 initiated by an EDA complex.

Scheme 6: Mechanism of the synthesis of sulfamoylation product 12.

Scheme 7: Synthesis of indole derivative 22 initiated by an EDA complex.

Scheme 8: Synthesis of perfluoroalkylated pyrimidines 26 initiated by an EDA complex.

Scheme 9: Synthesis of phenanthridine derivative 29 initiated by an EDA complex.

Scheme 10: Synthesis of cis-tetrahydroquinoline derivative 32 initiated by an EDA complex.

Scheme 11: Mechanism of the synthesis of cis-tetrahydroquinoline derivative 32.

Scheme 12: Synthesis of phenanthridine derivative 38 initiated by an EDA complex.

Scheme 13: Synthesis of spiropyrroline derivative 40 initiated by an EDA complex.

Scheme 14: Synthesis of benzothiazole derivative 43 initiated by an EDA complex.

Scheme 15: Synthesis of perfluoroalkyl-s-triazine derivative 45 initiated by an EDA complex.

Scheme 16: Synthesis of indoline derivative 47 initiated by an EDA complex.

Scheme 17: Mechanism of the synthesis of spirocyclic indoline derivative 47.

Scheme 18: Synthesis of cyclobutane product 50 initiated by an EDA complex.

Scheme 19: Mechanism of the synthesis of spirocyclic indoline derivative 50.

Scheme 20: Synthesis of 1,3-oxazolidine compound 59 initiated by an EDA complex.

Scheme 21: Synthesis of trifluoromethylated product 61 initiated by an EDA complex.

Scheme 22: Synthesis of indole alkylation product 64 initiated by an EDA complex.

Scheme 23: Synthesis of perfluoroalkylation product 67 initiated by an EDA complex.

Scheme 24: Synthesis of hydrotrifluoromethylated product 70 initiated by an EDA complex.

Scheme 25: Synthesis of β-trifluoromethylated alkyne product 71 initiated by an EDA complex.

Scheme 26: Mechanism of the synthesis of 2-phenylthiophene derivative 74.

Scheme 27: Synthesis of allylated product 80 initiated by an EDA complex.

Scheme 28: Synthesis of trifluoromethyl-substituted alkynyl product 84 initiated by an EDA complex.

Scheme 29: Synthesis of dearomatized fluoroalkylation product 86 initiated by an EDA complex.

Scheme 30: Mechanism of the synthesis of dearomatized fluoroalkylation product 86.

Scheme 31: Synthesis of C(sp3)–H allylation product 91 initiated by an EDA complex.

Scheme 32: Synthesis of perfluoroalkylation product 93 initiated by an EDA complex.

Scheme 33: Synthesis of spirocyclic indolene derivative 95 initiated by an EDA complex.

Scheme 34: Synthesis of perfluoroalkylation product 97 initiated by an EDA complex.

Scheme 35: Synthesis of alkylated indole derivative 100 initiated by an EDA complex.

Scheme 36: Mechanism of the synthesis of alkylated indole derivative 100.

Scheme 37: Synthesis of arylated oxidized indole derivative 108 initiated by an EDA complex.

Scheme 38: Synthesis of 4-ketoaldehyde derivative 111 initiated by an EDA complex.

Scheme 39: Mechanism of the synthesis of 4-ketoaldehyde derivative 111.

Scheme 40: Synthesis of perfluoroalkylated olefin 118 initiated by an EDA complex.

Scheme 41: Synthesis of alkylation product 121 initiated by an EDA complex.

Scheme 42: Synthesis of acylation product 123 initiated by an EDA complex.

Scheme 43: Mechanism of the synthesis of acylation product 123.

Scheme 44: Synthesis of trifluoromethylation product 126 initiated by an EDA complex.

Scheme 45: Synthesis of unnatural α-amino acid 129 initiated by an EDA complex.

Scheme 46: Synthesis of thioether derivative 132 initiated by an EDA complex.

Scheme 47: Synthesis of S-aryl dithiocarbamate product 135 initiated by an EDA complex.

Scheme 48: Mechanism of the synthesis of S-aryl dithiocarbamate product 135.

Scheme 49: Synthesis of thioether product 141 initiated by an EDA complex.

Scheme 50: Mechanism of the synthesis of borate product 144.

Scheme 51: Synthesis of boronation product 148 initiated by an EDA complex.

Scheme 52: Synthesis of boration product 151 initiated by an EDA complex.

Scheme 53: Synthesis of boronic acid ester derivative 154 initiated by an EDA complex.

Scheme 54: Synthesis of β-azide product 157 initiated by an EDA complex.

Scheme 55: Decarboxylation reaction initiated by an EDA complex.

Scheme 56: Synthesis of amidated product 162 initiated by an EDA complex.

Scheme 57: Synthesis of diethyl phenylphosphonate 165 initiated by an EDA complex.

Scheme 58: Mechanism of the synthesis of diethyl phenylphosphonate derivative 165.

Scheme 59: Synthesis of (Z)-2-iodovinyl phenyl ether 168 initiated by an EDA complex.

Scheme 60: Mechanism of the synthesis of (Z)-2-iodovinyl phenyl ether derivative 168.

Scheme 61: Dehalogenation reaction initiated by an EDA complex.

Direct synthesis of anomeric tetrazolyl iminosugars from sugar-derived lactams

- Michał M. Więcław and

- Bartłomiej Furman

Beilstein J. Org. Chem. 2021, 17, 115–123, doi:10.3762/bjoc.17.12

- Schwartz’s reagent-mediated reductive amide functionalization followed by a variant of the Ugi–azide multicomponent reaction. The anomeric configurations of two products were unambiguously confirmed by X-ray analysis. This work also describes examples of interesting further transformations of the title

- one-pot Mannich/Michael sequence leading to oligocyclic compounds [24], and employment in subsequent Joulié–Ugi multicomponent reactions [25]. This work is an extension of these efforts and seeks to investigate the possibility of incorporating the Ugi–azide multicomponent reaction in this workflow. A

- first example of using Schwartz’s reagent-mediated partial reduction of lactams and the Ugi–azide multicomponent reaction in a tandem process. Yields of the described products are moderate to good, a satisfying result for such a multistep process. We have shown that such a reaction does not necessarily

Graphical Abstract

Scheme 1: Our previous efforts in the field of functionalization of sugar-derived lactams.

Figure 1: Key concepts behind the goal of this work [34].

Scheme 2: Preliminary experiment in search of a procedure for the synthesis of 2-(1H-tetrazol-5-yl)-iminosuga...

Scheme 3: Synthesis of a new class of alkaloid scaffold using the presented methodology.

Scheme 4: Synthesis of a new, chiral 2-(tetrazol-5-yl)-iminosugar based potential organocatalyst.

Scheme 5: Principle behind Woerpel’s model for prediction of the direction of nucleophile addition to oxocarb...

Scheme 6: Difference in conformational stability of glucose- and galactose-derived iminium cations and the maj...

Figure 2: ORTEP structures of compounds 3a and 3e obtained by X-ray analysis. Hydrogen atoms and benzyl group...

Figure 3: Proposed structures of compounds 5a and 2-epi-5a with 1H-1H couplings and NOE effects shown.

Scheme 7: Proposed reaction mechanism for the described Ugi–azide reaction variant.

Scheme 8: Possible pathway for spontaneous imine formation. Values reported are in kcal·mol−1.

Scheme 9: A possible path for tetrazole formation in the described conditions. Values reported are in kcal·mol...

Regioselective synthesis of heterocyclic N-sulfonyl amidines from heteroaromatic thioamides and sulfonyl azides

- Vladimir Ilkin,

- Vera Berseneva,

- Tetyana Beryozkina,

- Tatiana Glukhareva,

- Lidia Dianova,

- Wim Dehaen,

- Eugenia Seliverstova and

- Vasiliy Bakulev

Beilstein J. Org. Chem. 2020, 16, 2937–2947, doi:10.3762/bjoc.16.243

- commonly used methods to prepare these compounds include the Cu-catalyzed multicomponent reaction of alkynes, sulfonyl azides and amines [23][24][25][26][27][28][29][30][31], the reaction of thioacetamide derivatives and cyclic thioamides with sulfonyl azides [22][32][33], the chlorophosphite-mediated

Graphical Abstract

Figure 1: Examples of biological activity and interesting chemical reactivity of N-sulfonyl amidines.

Figure 2: Data on the synthesis of N′-sulfonylazole-4-carboximidamides.

Scheme 1: Synthesis of 1-alkyl-N-phenyl-N'-(sulfonyl)-1H-1,2,3-triazole-4-carboximidamides 3.

Figure 3: Starting compounds.

Scheme 2: Scope for the reaction of 1-alkyl-1,2,3-triazole-4-carbothioamides 1a–d with azides 2a–f.

Scheme 3: Scope of the reaction of 5-arylamino-1,2,3-triazole-4-carbothioamides 1i–l with azides 2a,c–f.

Scheme 4: Synthesis of 2-aminothiazole-4-N-sulfonyl amidines.

Scheme 5: Synthesis of N-sulfonyl amidines of isoxazolylcarboxylic acid.

Scheme 6: Synthesis of bis(sulfonyl amidines) 3aj–an.

Scheme 7: Plausible mechanism for the reaction of heterocyclic thioamides with sulfonyl azides.

Three-component reactions of aromatic amines, 1,3-dicarbonyl compounds, and α-bromoacetaldehyde acetal to access N-(hetero)aryl-4,5-unsubstituted pyrroles

- Wenbo Huang,

- Kaimei Wang,

- Ping Liu,

- Minghao Li,

- Shaoyong Ke and

- Yanlong Gu

Beilstein J. Org. Chem. 2020, 16, 2920–2928, doi:10.3762/bjoc.16.241

- reactivity of aliphatic aldehydes, the reaction in Scheme 6 should be a wise choice for the synthesis of products similar in type to 5a. This point deserves further investigation. Conclusion In summary, an efficient and practical one-pot multicomponent reaction of (hetero)arylamines with α-bromoacetaldehyde

Graphical Abstract

Figure 1: Representative biologically active N-(hetero)aryl-4,5-unsubstituted pyrrole scaffolds.

Scheme 1: Typical routes to N-(heteroaryl)-4,5-unsubstituted pyrroles.

Scheme 2: Substrate scope of the pyrrole synthesis.

Scheme 3: Synthesis of N-heterocyclic pyrroles.

Scheme 4: Direct synthesis of pyrrole-3-carboxamide derivatives.

Scheme 5: Plausible mechanism of the three-component reaction.

Scheme 6: Synthesis of polysubstituted pyrazolo[3,4-b]pyridine derivatives.

One-pot multicomponent green Hantzsch synthesis of 1,2-dihydropyridine derivatives with antiproliferative activity

- Giovanna Bosica,

- Kaylie Demanuele,

- José M. Padrón and

- Adrián Puerta

Beilstein J. Org. Chem. 2020, 16, 2862–2869, doi:10.3762/bjoc.16.235

- oxidizing agents [7][17][18]. One of the greatest limitations of this synthesis is however the fact that the dihydropyridines that are obtained are usually the 1,4-symmetrical ones. This multicomponent reaction has been thought to have one of the most complex mechanisms since various routes might take place

- find a green catalyst that could provide a wide substrate scope for the Hantzsch synthesis of 1,2-dihydropyridines in a short reaction time. In order to achieve a green method, apart from utilizing a multicomponent reaction as a route providing a high atom economy, heterogeneous catalysis should be

- preliminary study of the antiproliferative activity against human solid tumor cells demonstrated that 1,2-DHPs could inhibit cancer cell growth in the low micromolar range. Keywords: antiproliferative activity; 1,2-dihydropyridines; green Hantzsch synthesis; heterogeneous catalysis; one-pot multicomponent

Graphical Abstract

Scheme 1: The classical Hantzsch synthesis between benzaldehyde (1a), ethyl acetoacetate (2), and ammonium ac...

Figure 1: Optimization trials with the selected solid catalysts.

Figure 2: Graphical representation of the results obtained in the reusability test.

One-pot synthesis of oxazolidinones and five-membered cyclic carbonates from epoxides and chlorosulfonyl isocyanate: theoretical evidence for an asynchronous concerted pathway

- Esra Demir,

- Ozlem Sari,

- Yasin Çetinkaya,

- Ufuk Atmaca,

- Safiye Sağ Erdem and

- Murat Çelik

Beilstein J. Org. Chem. 2020, 16, 1805–1819, doi:10.3762/bjoc.16.148

- multicomponent reaction of rare-earth metal amides [28], the reaction of CO2 with propargylamines or aziridines [29][30] and the cycloaddition reaction of epoxides with isocyanates [31][32]. On the other hand, for the synthesis of five-membered cyclic carbonates, the cycloaddition of CO2 to epoxides, the

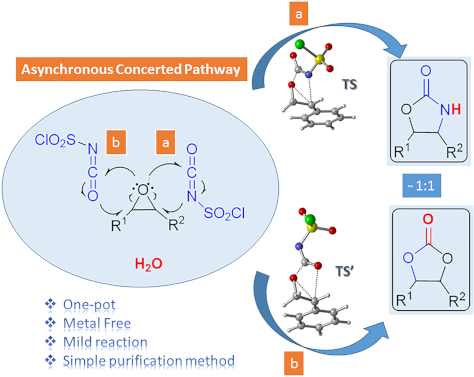

Graphical Abstract

Scheme 1: Oxazolidinone (1), five-membered cyclic carbonate (2) and some important compounds containing an ox...

Scheme 2: Proposed mechanisms by Keshava Murthy and Dhar [41] and De Meijere and co-workers [42].

Figure 1: Possible pathways for the formation of oxazolidinone intermediates 10 and 11. Optimized transition ...

Figure 2: Potential energy profile related to the formation of oxazolidinone intermediates 10 and 11 at the P...

Figure 3: IRC calculated for the formation of (a) 10 and (b) 11 at M06-2X/6-31+G(d,p) level. I-1, I-15, I-35, ...

Figure 4: Optimized geometries for the stationary points for the formation of 10 at PCM(DCM)/M06-2X/6-31+G(d,...

Scheme 3: Proposed mechanisms for the formation of oxazolidinone 9f.

Figure 5: Potential energy profiles for paths 1a (blue), 1b (red), 2 (green) and relative Gibbs free energies...

Figure 6: Optimized geometries for the stationary points of path 1b at PCM(DCM)/M06-2X/6-31+G(d,p)//M06-2X/6-...

Scheme 4: Proposed mechanism for the formation of five-membered cyclic carbonate 8f.

Figure 7: Potential energy profile and relative Gibbs free energies (kcal/mol) in DCM related to the formatio...

Figure 8: Optimized geometries for the stationary points of step 1 for the formation of 16 at PCM(DCM)/M06-2X...

Figure 9: Optimized geometries for the stationary points of step 2 for the formation of 17 at PCM(DCM)/M06-2X...

Figure 10: Optimized geometries for the stationary points of step 3 for the formation of PC8 at PCM(DCM)/M06-2...

One-pot synthesis of 1,3,5-triazine-2,4-dithione derivatives via three-component reactions

- Gui-Feng Kang and

- Gang Zhang

Beilstein J. Org. Chem. 2020, 16, 1447–1455, doi:10.3762/bjoc.16.120

- thiocarbonyl group source in the multicomponent reaction with aldehydes and other reactive intermediates for the preparation of various triazinethione derivatives by independently varying the individual components thus represents a significant extension in this area. On the other hand, trialkyl orthoformates

- generality of this multicomponent reaction with a wide range of aldehydes 1 together with thiourea (2) and trimethyl orthoformate (3a) (Scheme 2). The reaction carried out with 4-methylbenzaldehyde delivered the expected 6-(methylthio)-4-(p-tolyl)-3,4-dihydro-1,3,5-triazine-2(1H)-thione (6ba) in 92% yield

- alkylation, and/or due to the instability of the imines formed. In order to further explore the substrate scope of this multicomponent reaction, next we wanted to use other orthoformates. Interestingly, under the similar reaction conditions triethyl orthoformate (3b), tripropyl orthoformate (3c), and

Graphical Abstract

Figure 1: Selected examples of triazinethione-containing bioactive compounds.

Scheme 1: Strategies for the synthesis of triazinethiones.

Scheme 2: Aldehyde substrate scope of three-component reaction of aldehydes, thiourea and trimethyl orthoform...

Scheme 3: Orthoformate substrate scope of the three component reaction of benzaldehyde, thiourea, and orthofo...

Scheme 4: Gram-scale synthesis of 6aa.

Figure 2: X-ray structure of 6-(methylthio)-4-phenyl-3,4-dihydro-1,3,5-triazine-2(1H)-thione (6aa) with therm...

Scheme 5: Control experiments for investigation of the mechanism.

Scheme 6: Plausible mechanism.

Synthesis of pyrrolidinedione-fused hexahydropyrrolo[2,1-a]isoquinolines via three-component [3 + 2] cycloaddition followed by one-pot N-allylation and intramolecular Heck reactions

- Xiaoming Ma,

- Suzhi Meng,

- Xiaofeng Zhang,

- Qiang Zhang,

- Shenghu Yan,

- Yue Zhang and

- Wei Zhang

Beilstein J. Org. Chem. 2020, 16, 1225–1233, doi:10.3762/bjoc.16.106

- ]isoquinolines. The multicomponent reaction was combined with one-pot reactions to make a synthetic method with good pot, atom and step economy. MeCN was used as a preferable green solvent for the reactions. Keywords: [3 + 2] cycloaddition; Heck reaction; hexahydropyrrolo[2,1-a]isoquinoline; one-pot reactions

- via sequential 1,3-dipolar cycloaddition, N-allylation, and intramolecular Heck cyclization reactions [50][51][52][53][54] (Scheme 2, K). Both stabilized and non-stabilized azomethine ylides could be used for the initial [3 + 2] cycloaddition. A multicomponent reaction was combined with one-pot

Graphical Abstract

Figure 1: Bioactive pyrrolo[2,1-a]isoquinolines and hexahydropyrrolo[2,1-a]isoquinolines.

Scheme 1: [3 + 2] Cycloaddition with amino esters or amino acids.

Scheme 2: Scaffolds derived from the initial [3 + 2] adducts.

Scheme 3: [3 + 2] Cycloaddition with amino esters or amino acids. Conditions: 1:3:4 (1.2:1:1.1), Et3N (1.5 eq...

Scheme 4: Synthesis of pyrrolo[2,1-a]isoquinolines 9. Reaction conditions: 5 (0.5 mmol, 1 equiv), 7 (3 equiv)...

Scheme 5: Synthesis of pyrrolo[2,1-a]isoquinolines 11. Reaction conditions: 6 (0.5 mmol, 1 equiv), 7 (3 equiv...

Scheme 6: Synthesis of pyrrolo[2,1-a]isoquinolines 12. Reaction conditions: 5 or 6 (0.5 mmol, 1 equiv), cinna...

Scheme 7: Plausible mechanism for the synthesis of 9a.

Fluorinated phenylalanines: synthesis and pharmaceutical applications

- Laila F. Awad and

- Mohammed Salah Ayoup

Beilstein J. Org. Chem. 2020, 16, 1022–1050, doi:10.3762/bjoc.16.91

- 53a–h [48]. The free amino acid 53i was prepared by the same protocol [49] (Scheme 12). 2,5-Difluorophenylalanines with either R or S configuration were synthesized also via the Erlenmeyer azalactone method. The synthesis started with the multicomponent reaction of aldehyde 55, acetylglycine 51a and

Graphical Abstract

Figure 1: Categories I–V of fluorinated phenylalanines.

Scheme 1: Synthesis of fluorinated phenylalanines via Jackson’s method.

Scheme 2: Synthesis of all-cis-tetrafluorocyclohexylphenylalanines.

Scheme 3: Synthesis of ʟ-4-[sulfono(difluoromethyl)]phenylalanine (nPt: neopentyl, TCE: trichloroethyl).

Scheme 4: Synthesis of ʟ-4-[sulfono(difluoromethyl)]phenylalanine derivatives 17.

Scheme 5: Synthesis of fluorinated Phe analogues from Cbz-protected aminomalonates.

Scheme 6: Synthesis of tetrafluorophenylalanine analogues via the 3-methyl-4-imidazolidinone auxiliary 25.

Scheme 7: Synthesis of tetrafluoro-Phe derivatives via chiral auxiliary 31.

Scheme 8: Synthesis of 2,5-difluoro-Phe and 2,4,5-trifluoro-Phe via Schöllkopf reagent 34.

Scheme 9: Synthesis of 2-fluoro- and 2,6-difluoro Fmoc-Phe derivatives starting from chiral auxiliary 39.

Scheme 10: Synthesis of 2-[18F]FPhe via chiral auxiliary 43.

Scheme 11: Synthesis of FPhe 49a via photooxidative cyanation.

Scheme 12: Synthesis of FPhe derivatives via Erlenmeyer azalactone synthesis.

Scheme 13: Synthesis of (R)- and (S)-2,5-difluoro Phe via the azalactone method.

Scheme 14: Synthesis of 3-bromo-4-fluoro-(S)-Phe (65).

Scheme 15: Synthesis of [18F]FPhe via radiofluorination of phenylalanine with [18F]F2 or [18F]AcOF.

Scheme 16: Synthesis of 4-borono-2-[18F]FPhe.

Scheme 17: Synthesis of protected 4-[18F]FPhe via arylstannane derivatives.

Scheme 18: Synthesis of FPhe derivatives via intermediate imine formation.

Scheme 19: Synthesis of FPhe derivatives via Knoevenagel condensation.

Scheme 20: Synthesis of FPhe derivatives 88a,b from aspartic acid derivatives.

Scheme 21: Synthesis of 2-(2-fluoroethyl)phenylalanine derivatives 93 and 95.

Scheme 22: Synthesis of FPhe derivatives via Zn2+ complexes.

Scheme 23: Synthesis of FPhe derivatives via Ni2+ complexes.

Scheme 24: Synthesis of 3,4,5-trifluorophenylalanine hydrochloride (109).

Scheme 25: Synthesis of FPhe derivatives via phenylalanine aminomutase (PAM).

Scheme 26: Synthesis of (R)-2,5-difluorophenylalanine 115.

Scheme 27: Synthesis of β-fluorophenylalanine via 2-amino-1,3-diol derivatives.

Scheme 28: Synthesis of β-fluorophenylalanine derivatives via the oxazolidinone chiral auxiliary 122.

Scheme 29: Synthesis of β-fluorophenylalanine from pyruvate hemiketal 130.

Scheme 30: Synthesis of β-fluorophenylalanine (136) via fluorination of β-hydroxyphenylalanine (137).

Scheme 31: Synthesis of β-fluorophenylalanine from aziridine derivatives.

Scheme 32: Synthesis of β-fluorophenylalanine 136 via direct fluorination of pyruvate esters.

Scheme 33: Synthesis of β-fluorophenylalanine via fluorination of ethyl 3-phenylpyruvate enol using DAST.

Scheme 34: Synthesis of β-fluorophenylalanine derivatives using photosensitizer TCB.

Scheme 35: Synthesis of β-fluorophenylalanine derivatives using Selectflour and dibenzosuberenone.

Scheme 36: Synthesis of protected β-fluorophenylalanine via aziridinium intermediate 150.

Scheme 37: Synthesis of β-fluorophenylalanine derivatives via fluorination of α-hydroxy-β-aminophenylalanine d...

Scheme 38: Synthesis of β-fluorophenylalanine derivatives from α- or β-hydroxy esters 152a and 155.

Scheme 39: Synthesis of a series of β-fluoro-Phe derivatives via Pd-catalyzed direct fluorination of β-methyle...

Scheme 40: Synthesis of series of β-fluorinated Phe derivatives using quinoline-based ligand 162 in the Pd-cat...

Scheme 41: Synthesis of β,β-difluorophenylalanine derivatives from 2,2-difluoroacetaldehyde derivatives 164a,b....

Scheme 42: Synthesis of β,β-difluorophenylalanine derivatives via an imine chiral auxiliary.

Scheme 43: Synthesis of α-fluorophenylalanine derivatives via direct fluorination of protected Phe 174.

Figure 2: Structures of PET radiotracers of 18FPhe derivatives.

Figure 3: Structures of melfufen (179) and melphalan (180) anticancer drugs.

Figure 4: Structure of gastrazole (JB95008, 181), a CCK2 receptor antagonist.

Figure 5: Dual CCK1/CCK2 antagonist 182.

Figure 6: Structure of sitagliptin (183), an antidiabetic drug.

Figure 7: Structure of retaglpitin (184) and antidiabetic drug.

Figure 8: Structure of evogliptin (185), an antidiabetic drug.

Figure 9: Structure of LY2497282 (186) a DPP-4 inhibitor for the treatment of type II diabetes.

Figure 10: Structure of ulimorelin (187).

Figure 11: Structure of GLP1R (188).

Figure 12: Structures of Nav1.7 blockers 189 and 190.

Asymmetric synthesis of CF2-functionalized aziridines by combined strong Brønsted acid catalysis

- Xing-Fa Tan,

- Fa-Guang Zhang and

- Jun-An Ma

Beilstein J. Org. Chem. 2020, 16, 638–644, doi:10.3762/bjoc.16.60

- Tianjin University, Fuzhou 350207, China 10.3762/bjoc.16.60 Abstract A diastereo- and enantioselective approach to access chiral CF2-functionalized aziridines from difluorodiazoethyl phenyl sulfone (PhSO2CF2CHN2) and in situ-formed aldimines is described. This multicomponent reaction is enabled by a

Graphical Abstract

Scheme 1: Preparation of chiral aziridines from fluorinated diazo reagents.

Scheme 2: Substrate scope of chiral CF2-substituted aziridines from PhSO2CF2CHN2. General reaction conditions...

Scheme 3: Scale-up experiment to 4a and further synthetic transformations.

A systematic review on silica-, carbon-, and magnetic materials-supported copper species as efficient heterogeneous nanocatalysts in “click” reactions

- Pezhman Shiri and

- Jasem Aboonajmi

Beilstein J. Org. Chem. 2020, 16, 551–586, doi:10.3762/bjoc.16.52

Graphical Abstract

Scheme 1: Chemical structure of the catalysts 1a and 1b and their catalytic application in CuAAC reactions.

Scheme 2: Synthetic route to the catalyst 11 and its catalytic application in CuAAC reactions.

Scheme 3: Synthetic route of dendrons, illustrated using G2-AMP 23.

Scheme 4: The catalytic application of CuYAu–Gx-AAA–SBA-15 in a CuAAC reaction.

Scheme 5: Synthetic route to the catalyst 36.

Scheme 6: Application of the catalyst 36 in CuAAC reactions.

Scheme 7: The synthetic route to the catalyst 45 and catalytic application of 45 in “click” reactions.

Scheme 8: Synthetic route to the catalyst 48 and catalytic application of 48 in “click” reactions.

Scheme 9: Synthetic route to the catalyst 58 and catalytic application of 58 in “click” reactions.

Scheme 10: Synthetic route to the catalyst 64 and catalytic application of 64 in “click” reactions.

Scheme 11: Chemical structure of the catalyst 68 and catalytic application of 68 in “click” reactions.

Scheme 12: Chemical structure of the catalyst 69 and catalytic application of 69 in “click” reactions.

Scheme 13: Synthetic route to, and chemical structure of the catalyst 74.

Scheme 14: Application of the cayalyst 74 in “click” reactions.

Scheme 15: Synthetic route to, and chemical structure of the catalyst 78 and catalytic application of 78 in “c...

Scheme 16: Synthetic route to the catalyst 85.

Scheme 17: Application of the catalyst 85 in “click” reactions.

Scheme 18: Synthetic route to the catalyst 87 and catalytic application of 87 in “click” reactions.

Scheme 19: Chemical structure of the catalyst 88 and catalytic application of 88 in “click” reactions.

Scheme 20: Synthetic route to the catalyst 90 and catalytic application of 90 in “click” reactions.

Scheme 21: Synthetic route to the catalyst 96 and catalytic application of 96 in “click” reactions.

Scheme 22: Synthetic route to the catalyst 100 and catalytic application of 100 in “click” reactions.

Scheme 23: Synthetic route to the catalyst 102 and catalytic application of 23 in “click” reactions.

Scheme 24: Synthetic route to the catalysts 108–111.

Scheme 25: Catalytic application of 108–111 in “click” reactions.

Scheme 26: Synthetic route to the catalyst 121 and catalytic application of 121 in “click” reactions.

Scheme 27: Synthetic route to 125 and application of 125 in “click” reactions.

Scheme 28: Synthetic route to the catalyst 131 and catalytic application of 131 in “click” reactions.

Scheme 29: Synthetic route to the catalyst 136.

Scheme 30: Application of the catalyst 136 in “click” reactions.

Scheme 31: Synthetic route to the catalyst 141 and catalytic application of 141 in “click” reactions.

Scheme 32: Synthetic route to the catalyst 144 and catalytic application of 144 in “click” reactions.

Scheme 33: Synthetic route to the catalyst 149 and catalytic application of 149 in “click” reactions.

Scheme 34: Synthetic route to the catalyst 153 and catalytic application of 153 in “click” reactions.

Scheme 35: Synthetic route to the catalyst 155 and catalytic application of 155 in “click” reactions.

Scheme 36: Synthetic route to the catalyst 157 and catalytic application of 157 in “click” reactions.

Scheme 37: Synthetic route to the catalyst 162.

Scheme 38: Application of the catalyst 162 in “click” reactions.

Scheme 39: Synthetic route to the catalyst 167 and catalytic application of 167 in “click” reactions.

Scheme 40: Synthetic route to the catalyst 169 and catalytic application of 169 in “click” reactions.

Scheme 41: Synthetic route to the catalyst 172.

Scheme 42: Application of the catalyst 172 in “click” reactions.

Ultrasonic-assisted unusual four-component synthesis of 7-azolylamino-4,5,6,7-tetrahydroazolo[1,5-a]pyrimidines

- Yana I. Sakhno,

- Maryna V. Murlykina,

- Oleksandr I. Zbruyev,

- Anton V. Kozyryev,

- Svetlana V. Shishkina,

- Dmytro Sysoiev,

- Vladimir I. Musatov,

- Sergey M. Desenko and

- Valentyn A. Chebanov

Beilstein J. Org. Chem. 2020, 16, 281–289, doi:10.3762/bjoc.16.27

- 7-azolylaminotetrahydroazolo[1,5-a]pyrimidines. Keywords: 5-amino-1H-pyrazole-4-carbonitrile; 3-amino-1,2,4-triazole; 7-azolylaminotetrahydroazolo[1,5-a]pyrimidines; heterocycle; multicomponent reaction; ultrasonication; Introduction Tetrahydropyrimidines are heterocycles of high pharmacological

- (Figure 3). Conclusion In this study we disclosed a new direction for the multicomponent reaction of 5-aminopyrazole-4-carbonitriles or 3-amino-1,2,4-triazole with pyruvic acid or ethyl pyruvate and aromatic aldehydes under ultrasonication, leading to 7-azolylamino-4,5,6,7-tetrahydroazolo[1,5-a

Graphical Abstract

Scheme 1: Synthesis of tetrahydroazolopyrimidine derivatives.

Scheme 2: Various multicomponent reactions involving pyruvic acids (pyruvates) and different α-aminoazoles.

Scheme 3: Synthesis of 4-arylamino-substituted tetrahydroquinolines.

Scheme 4: Ultrasound-assisted multicomponent reactions of 3-amino-1,2,4-triazole or 5-amino-1H-pyrazole-4-car...

Scheme 5: Synthesis of 3-cyano-7-(4-methoxyphenyl)-4,7-dihydropyrazolo[1,5-a]pyrimidine-5-carboxylic acid (7)....

Scheme 6: Proposed reaction mechanism.

Figure 1: Alternative structures A and B for the tetrahydroazolopyrimidines 4.

Figure 2: Molecular structure of ethyl 5-(4-bromophenyl)-3-cyano-7-((4-cyano-1H-pyrazol-5-yl)amino)-4,5,6,7-t...

Figure 3: Chains of 4g molecules in the crystal phase.

Combining the Ugi-azide multicomponent reaction and rhodium(III)-catalyzed annulation for the synthesis of tetrazole-isoquinolone/pyridone hybrids

- Gerardo M. Ojeda,

- Prabhat Ranjan,

- Pavel Fedoseev,

- Lisandra Amable,

- Upendra K. Sharma,

- Daniel G. Rivera and

- Erik V. Van der Eycken

Beilstein J. Org. Chem. 2019, 15, 2447–2457, doi:10.3762/bjoc.15.237

- . Keywords: C–H activation; cyclization; isoquinolone; multicomponent reaction; tetrazole; Introduction Pyridones and isoquinolones are relevant heterocyclic scaffolds present in numerous bioactive compounds and natural products [1][2][3][4]. Similarly, molecules containing a tetrazole ring exhibit a wide

Graphical Abstract

Figure 1: Bioactive molecules containing a tetrazole, pyridone or isoquinolone ring.

Scheme 1: Approaches for the synthesis of tetrazoles and isoquinolones and their interplay as designed in thi...

Scheme 2: Scope of the Ugi-azide-4CR/deprotection/acylation sequence. Ugi-azide-4CR conducted at the 2.0 mmol...

Scheme 3: Influence of substituents R and R2 on the reaction outcome. For compounds 4k–m the overall yield in...

Scheme 4: Influence of the alkyne and R1 substituent on the reaction outcome.

Scheme 5: Scope of acrylic, heterocyclic and ring-fused N-acylaminomethyl tetrazole substrates.

Scheme 6: Proposed reaction mechanism using substrates 1a and 3a.

Vicinal difunctionalization of alkenes by four-component radical cascade reaction of xanthogenates, alkenes, CO, and sulfonyl oxime ethers

- Shuhei Sumino,

- Takahide Fukuyama,

- Mika Sasano,

- Ilhyong Ryu,

- Antoine Jacquet,

- Frédéric Robert and

- Yannick Landais

Beilstein J. Org. Chem. 2019, 15, 1822–1828, doi:10.3762/bjoc.15.176

- functionalities, have the potential for further elaboration. Keywords: CO; multicomponent reaction; radicals; sulfonyl oxime ethers; xanthogenates; Introduction Multicomponent reactions constitute a powerful and highly efficient tool in organic synthesis to build up intricate compounds from simple molecules in

- /acceptor type C1 synthons [6][7][8][9][10][11][12][13][14][15]. In this context, sulfonyl oxime ethers are powerful acceptors of type C1 synthon [8][16][17], which terminates the multicomponent reaction by a β-scission of RSO2 radicals [18][19][20]. Recently, one of us reported on a three-component radical

Graphical Abstract

Scheme 1: Concept: Alkene difuctionalization by four-component radical reaction using xanthates, alkenes, CO ...

Figure 1: Vicinal difunctionalization of alkenes by four-component radical cascade reaction using xanthogenat...

Figure 2: Proposed radical chain mechanism.

A novel three-component reaction between isocyanides, alcohols or thiols and elemental sulfur: a mild, catalyst-free approach towards O-thiocarbamates and dithiocarbamates

- András György Németh,

- György Miklós Keserű and

- Péter Ábrányi-Balogh

Beilstein J. Org. Chem. 2019, 15, 1523–1533, doi:10.3762/bjoc.15.155

- Andras Gyorgy Nemeth Gyorgy Miklos Keseru Peter Abranyi-Balogh Hungarian Academy of Sciences, Research Centre for Natural Sciences, Institute of Organic Chemistry, Medicinal Chemistry Research Group, 1519 Budapest, POB 286, Hungary 10.3762/bjoc.15.155 Abstract A new multicomponent reaction has

- ; multicomponent reaction; one-pot; thiocarbamate; Introduction O-Thiocarbamates belong to a class of important biologically active molecules, used mainly as fungicides [1][2][3] in agricultural and pharmaceutical fields. In particular, recently antitumor [4], anesthetic [5] and enzyme inhibitory effects were

- the work-up, no chromatography was necessary and the crude product was purified by recrystallization from hexane/ethyl acetate. The three collected crops of crystals provided the thiocarbamate 3a in a total of 74% yield. We have envisaged that our multicomponent reaction could be compatible with

Graphical Abstract

Scheme 1: Synthetic routes to O-thiocarbamates and dithiocarbamates.

Scheme 2: Substrate scope of isocyanides. aReaction conditions: 1 (1 mmol), S8 (2 mmol), 2a (2mmol), NaH (2 m...

Scheme 3: Substrate scope of alcohols. Reaction conditions: 1a (1 mmol), S8 (2 mmol), 2 (2mmol), NaH (2 mmol)...

Scheme 4: Substrate scope of thiols. Reaction conditions: 1a (1 mmol), S8 (1.2 mmol), 4 (2 mmol), NaOH (2 mmo...

Scheme 5: Scaled-up synthesis for 3a.

Scheme 6: Multicomponent domino synthesis of quinazolinone 7.

Scheme 7: Control experiments.

Scheme 8: Proposed mechanism.

A heteroditopic macrocycle as organocatalytic nanoreactor for pyrroloacridinone synthesis in water

- Piyali Sarkar,

- Sayan Sarkar and

- Pradyut Ghosh

Beilstein J. Org. Chem. 2019, 15, 1505–1514, doi:10.3762/bjoc.15.152

- nanoreactor which is a single molecule as catalyst in the earliest steps of the mechanistic pathway (Figure 6). This multicomponent reaction is expected to comprise a series of condensations and subsequent ring-closure cascade reactions (Scheme 3). To demonstrate the mechanistic pathway, dimedone (2), isatin

Graphical Abstract

Figure 1: Bis-amido-tris-amine macrocycle BATA-MC.

Figure 2: (a) Number distribution plot with particle size in DLS, (b) SEM image and (c) TEM image showing the...

Figure 3: Dependence of the yield of compound 4a on the reaction time using BATA-MC.

Figure 4: Yields of product 4a at different catalyst loading.

Scheme 1: BATA-MC-catalyzed synthesis of 4,5-dihydropyrrolo[2,3,4-kl]acridinones.

Scheme 2: BATA-MC-catalyzed synthesis of pyrrolo[2,3,4-kl]acridinone derivatives.

Figure 5: X-ray single crystal structure of 4d (CCDC 1898008).

Scheme 3: Probable mechanism illustrated for the synthesis of 4a using BATA-MC. For the sake of simplicity, w...

Figure 6: Representation of BATA-MC nanoreactor.

Figure 7: The reusability of the nanoreactor for the synthesis of 4a.

Efficiency Effsyn of complex syntheses as multicomponent reactions, its algorithm and calculations based on concrete criteria

- Heiner Eckert

Beilstein J. Org. Chem. 2019, 15, 1425–1433, doi:10.3762/bjoc.15.142

- synthesis steps yn (Equation 1). An extreme example for the impact of the overall yield is the tropinone synthesis by Willstätter (yoa = 0.75%) [7][8] compared to the Robinson–Schöpf synthesis (yoa = 90%) [9][10]) using a double Mannich reaction, a multicomponent reaction (MCR) [11][12][13]. The Mannich-3CR

Graphical Abstract

Scheme 1: Case study of a complex synthesis, parallel reactions. 10 possible synthesis STMs in green, other 1...

Scheme 2: Ordered reactions of the above complex synthesis to a main reaction set and connected parallel reac...

Scheme 3: Section A–J case study of Scheme 2 with operations of yoa calculation.

Scheme 4: Sequential synthesis and fragment linking of a decapeptide with comparison of results in Equations ...

Scheme 5: U-4CR with 17 precursors in the total synthesis of Et-743 (1) [14].

Scheme 6: Synthesis of 4 as key step of (+)-20S-camptothecin (3) total synthesis.

Doebner-type pyrazolopyridine carboxylic acids in an Ugi four-component reaction

- Maryna V. Murlykina,

- Oleksandr V. Kolomiets,

- Maryna M. Kornet,

- Yana I. Sakhno,

- Sergey M. Desenko,

- Victoriya V. Dyakonenko,

- Svetlana V. Shishkina,

- Oleksandr A. Brazhko,

- Vladimir I. Musatov,

- Alexander V. Tsygankov,

- Erik V. Van der Eycken and

- Valentyn A. Chebanov

Beilstein J. Org. Chem. 2019, 15, 1281–1288, doi:10.3762/bjoc.15.126

- , Kharkiv, Ukraine Peoples' Friendship University of Russia, Miklukho-Maklya str., 6, 117198, Moscow, Russia 10.3762/bjoc.15.126 Abstract Substituted 1H-pyrazolo[3,4-b]pyridine-4- and 1H-pyrazolo[3,4-b]pyridine-6-carboxamides have been synthetized through a Doebner–Ugi multicomponent reaction sequence in a

Graphical Abstract

Scheme 1: An overview of heterocyclic acids used in the Ugi reaction.

Scheme 2: Synthesis of pyrazolopyridine carboxylic acids 4 [45] and 7 [45] in Doebner-type reaction.

Figure 1: Molecular structure of N-(2-(tert-butylamino)-1-(4-chlorophenyl)-2-oxoethyl)-6-(4-methoxyphenyl)-3-...

Multicomponent reactions (MCRs): a useful access to the synthesis of benzo-fused γ-lactams

- Edorta Martínez de Marigorta,

- Jesús M. de Los Santos,

- Ana M. Ochoa de Retana,

- Javier Vicario and

- Francisco Palacios

Beilstein J. Org. Chem. 2019, 15, 1065–1085, doi:10.3762/bjoc.15.104

- dialkyl ones (Scheme 26, path A) [104]. When cyclopropyl ketones 91 were used as substrates, a ring expansion and a new quaternary centre formation happened through the multicomponent reaction to produce pentacyclic derivatives 92 (Scheme 26, path B) [105]. These reactions, either with arenes 86 or

- . Another aromatic aldehyde, in this case derived from a quinoline, can also be used as substrate for a multicomponent reaction, appropriate for the preparation of 3-aminoisoindolinone analogues 98 (Scheme 28) [106]. Indeed, the reaction of chloroquinolinecarbaldehydes 97 with isocyanides 42 and aromatic

- -(2-iodoaryl)acrylamides 113, DABCO·(SO2)2 (69) and hydrazines 114. Proposed mechanism for the preparation of oxindoles 115. Three-component reaction of acrylamide 113, CO (23) and 1,4-benzodiazepine 121. Multicomponent reaction of sulfonylacrylamides 123, aryldiazonium tetrafluoroborates 68 and DABCO

Graphical Abstract

Figure 1: γ-Lactam-derived structures considered in this review.

Figure 2: Alkaloids containing an isoindolinone moiety.

Figure 3: Alkaloids containing the 2-oxindole ring system.

Figure 4: Drugs and biological active compounds containing an isoindolinone moiety.

Figure 5: Drugs and biologically active compounds bearing a 2-oxindole skeleton.

Scheme 1: Three-component reaction of benzoic acid 1, amides 2 and DMSO (3).

Scheme 2: Copper-catalysed three-component reaction of 2-iodobenzoic acids 10, alkynylcarboxylic acids 11 and...

Scheme 3: Proposed mechanism for the formation of methylene isoindolinones 13.

Scheme 4: Copper-catalysed three-component reaction of 2-iodobenzamide 17, terminal alkyne 18 and pyrrole or ...

Scheme 5: Palladium-catalysed three-component reaction of ethynylbenzamides 21, secondary amines 22 and CO (23...

Scheme 6: Proposed mechanism for the formation of methyleneisoindolinones 24.

Scheme 7: Copper-catalysed three-component reaction of formyl benzoate 29, amines 2 and alkynes 18.

Scheme 8: Copper-catalysed three-component reaction of formylbenzoate 29, amines 2 and ketones 31.

Scheme 9: Non-catalysed (A) and phase-transfer catalysed (B) three-component reactions of formylbenzoic acids ...

Scheme 10: Proposed mechanism for the formation of isoindolinones 36.

Scheme 11: Three-component reaction of formylbenzoic acid 33, amines 2 and fluorinated silyl ethers 39.

Scheme 12: Three-component Ugi reaction of 2-formylbenzoic acid (33), diamines 41 and isocyanides 42.

Scheme 13: Non-catalysed (A, B) and chiral phosphoric acid promoted (C) three-component Ugi reactions of formy...

Scheme 14: Proposed mechanism for the enantioselective formation of isoindolinones 46.